Abstract

Silks are fibrous proteins with remarkable mechanical properties produced in fiber form by silkworms and spiders. Silk fibers in the form of sutures have been used for centuries. Recently regenerated silk solutions have been used to form a variety of biomaterials, such as gels, sponges and films, for medical applications. Silks can be chemically modified through amino acid side chains to alter surface properties or to immobilize cellular growth factors. Molecular engineering of silk sequences has been used to modify silks with specific features, such as cell recognition or mineralization. The degradability of silk biomaterials can be related to the mode of processing and the corresponding content of beta sheet crystallinity. Several primary cells and cell lines have been successfully grown on different silk biomaterials to demonstrate a range of biological outcomes. Silk biomaterials are biocompatible when studied in vitro and in vivo. Silk scaffolds have been successfully used in wound healing and in tissue engineering of bone, cartilage, tendon and ligament tissues.

Keywords: Silk, Fibroin, Spidroin, Scaffold, Tissue Engineering, Biomaterial

1. Introduction

Silk, popularly known in the textile industry for its luster and mechanical properties, is produced by cultured silkworms. Silks are produced by members of the class Arachnida (over 30,000 species of spiders) and by several worms of the order Lepidoptera, which includes mites, butterflies and moths. Silk are fibrous proteins synthesized in specialized epithelial cells that line glands in these organisms [1].

Silk fibroin polymers consist of repetitive protein sequences and provide structural roles in cocoon formation, nest building, traps, web formation, safety lines and egg protection [1, 2]. Silks are generally composted of β-sheet structures due to the dominance of hydrophobic domains consisting of short side chain amino acids in the primary sequence. These structures permit tight packing of stacked sheets of hydrogen bonded anti-parallel chains of the protein. Large hydrophobic domains interspaced with smaller hydrophilic domains foster the assembly of silk and the strength and resiliency of silk fibers [3].

Silks from silkworms (e.g., Bombyx mori) and orb-weaving spiders (e.g., Nephila clavipes) have been explored to understand the processing mechanisms and to exploit the properties of these proteins for use as biomaterials. Silks from silkworms and orb-weaving spiders have impressive mechanical properties (Table 1), in addition to environmental stability, biocompatibility, controlled proteolytic biodegradability, morphologic flexibility, and the ability for amino acid side change modification to immobilize growth factors [2, 4–15].

Table 1.

Mechanical properties of biodegradable polymeric materials (modified from [4]).

| Source of Biomaterial | Modulus (GPa) |

UTS (MPa) |

Strain (%) at break | Reference |

|---|---|---|---|---|

|

B. mori silk (with sericin) |

5–12 | 500 | 19 | [110] |

| B. mori silk (without sericin) | 15–17 | 610–690 | 4–16 | [110] |

| B. mori silk | 10 | 740 | 20 | [111] |

| N. clavipes silk | 11–13 | 875–972 | 17–18 | [111] |

| Collagen | 0.0018–0.046 | 0.9–7.4 | 24–68 | [112] |

| Crosslinked collagen | 0.4–0.8 | 47–72 | 12–16 | [112] |

| Polylactic acid | 1.2–3.0 | 28–50 | 2–6 | [113] |

Biomaterial design is an important element of tissue engineering, incorporating physical, chemical, and biological cues to guide cells into functional tissues via cell migration, adhesion, and differentiation. Many biomaterials need to degrade at a rate commensurate with new tissue formation to allow cells to deposit new extracellular matrix (ECM) and regenerate functional tissue. In addition, biomaterials may need to include provisions for mechanical support appropriate to the level of functional tissue development. In general, biomaterials must be biocompatible and elicit little to no host immune response.

Thus, silks have been investigated as biomaterials due to the successful use of silk fibers from B. mori as suture material for centuries [16]. Functional differences among silks of different species and within a species are a result of structural differences due to differences in primary amino acid sequence, processing, and the impact of environmental factors [17]. Silks represent a unique family of structural proteins that are biocompatible, degradable, mechanically superior, offer a wide range of properties, are amenable to aqueous or organic solvent processing, and can be chemically modified to suit a wide range of biomedical applications.

2. Silkworm (Bombyx mori) Silk

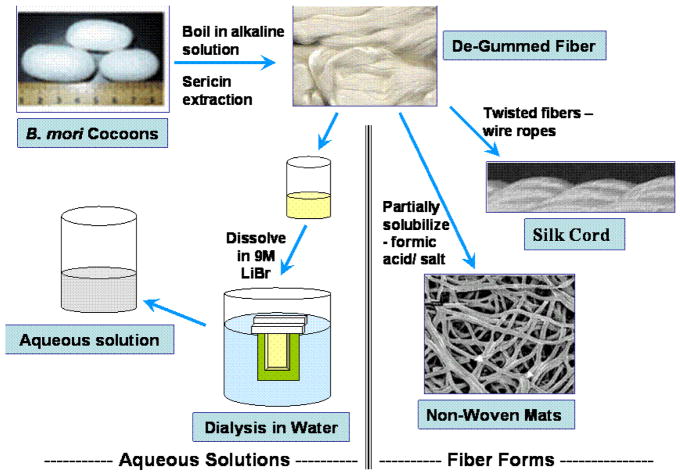

The domesticated silkworm (B. mori) silk fibroin fibers are about 10–.25 μm in diameter and consist of two proteins: a light chain (~26 kDa) and heavy chain (~390 kDa) which are present in a 1:1 ratio and linked by a single disulfide bond [18]. These proteins are coated with a family of hydrophilic proteins called sericins (20–310 kDa) [1, 18–20]. The disulfide linkage between the Cys-c20 (twentieth residue from the carboxyl terminus) of the heavy chain and Cys-172 of the light chain holds the fibroin together and a 25 kDa glycoprotein, named P25, is non-covalently linked to these proteins [21]. Silk fibroin is purified from sericins by boiling silk cocoons in an alkaline solution (Figure 1A). Twenty-five to thirty percent of the silk cocoon mass is sericin, which is removed during the de-gumming process.

Fig. 1.

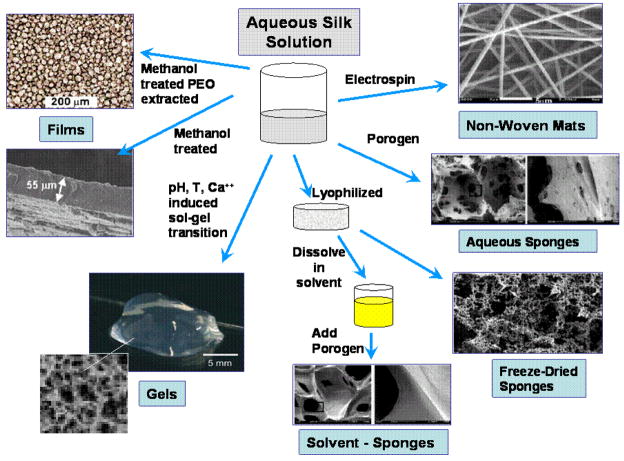

Fig. 1A: Silk fibroin is purified from sericins via boiling in an alkaline solution. The de-gummed or purified silk fibers can be processed into silk cords by twisting [4]; non-woven silk mats by partial solubilization [32]; or dissolved in lithium bromide, dialyzed and formed into aqueous silk fibroin solution [67] for preparation of other material morphologies (See figure 1B).

Fig. 1B: Processing of silk morphologies from aqueous silk fibroin solution into non-woven silk fibers [11]; aqueous and solvent based porous sponges [67, 69]; hydrogels [108]; and films [46].

2.1 B. mori silk fibroin structure

The amino acid composition of silk fibroin from B. mori consists primarily of glycine (Gly) (43%), alanine (Ala) (30%) and serine (Ser) (12%) [1]. The heavy chain consists of 12 domains that form the crystalline regions in silk fibers, which are interspersed with primary sequence that is non-repetitive and thus forms fewer organized domains in the fibers. The crystalline domains in the fibers consist of Gly-X repeats, with X being Ala, Ser, Threonine (Thr) and Valine (Val) [22]. The crystalline forming domains consist of an average of 381 residues (596 in size in the seventh domain to 36 in the twelfth domain). Each domain consists of sub-domain hexapeptides including: GAGAGS, GAGAGY, GAGAGA or GAGYGA where G is Glycine, A is Alanine, S is Serine and Y is Tyrosine. These sub domains end with tetrapeptides such as GAAS or GAGS [18, 22, 23]. The less crystalline forming regions of the fibroin heavy chain, also known as linkers, are between 42–44 amino acid residues in length. All the linkers have an identical 25 amino acid residue (non-repetitive sequence) which is composed of charged amino acids not found in the crystalline regions [22]. The primary sequence results in a hydrophobic protein with a natural co-block polymer design. Efficient secretion of fibroin is believed to be due in part to the formation of a disulfide bond between the heavy and light fibroin chains. A naked pupa mutation in B. mori has been mapped to the same locus as of the light chain on the 14th chromosome. The resulting fibroin light chain does not have a disulfide bond with the fibroin heavy chain and the cocoon has less than 0.3% fibroin protein content [24].

A number of silk polymorphs have been reported, including the glandular state prior to crystallization (silk I), the spun silk state which consists of the β-sheet secondary structure (silk II), and an air/water assembled interfacial silk (silk III, with a helical structure) [1, 25, 26]. The silk I structure is the water-soluble state and upon exposure to heat or physical spinning easily converts to a silk II structure. The silk I structure is observed in vitro in aqueous conditions and converts to a β-sheet structure when exposed to methanol or potassium chloride [27]. The β-sheet structures are asymmetrical with one side occupied with hydrogen side chains from glycine and the other occupied with the methyl side chains from the alanines that populate the hydrophobic domains. The β-sheets are arranged so that the methyl groups and hydrogen groups of opposing sheets interact to form the inter-sheet stacking in the crystals. Strong hydrogen bonds and van der Waals forces generate a structure that is thermodynamically stable [1]. The inter- and intra-chain hydrogen bonds form between amino acids perpendicular to the axis of the chains and the fiber [1]. The silk II structure excludes water and is insoluble in several solvents including mild acid and alkaline conditions, and several chaotropes.

2.2. Control of morphology of silk biomaterials

Due to the well-established sericulture process, 400,000 tons of dry silkworm cocoons are available worldwide per annum for the textile industry [28] and thus for biomaterials applications. Several different material morphologies can be formed from aqueous or solvent formulations of the natural fiber form of silk for utilization in biomaterials for biomedical applications (Figure 1B and Table 2). The fibers must first be dissolved in aqueous systems, followed by reprocessing into desired material formats.

Table 2.

Cell and tissue applications of silk fibroin scaffolds.

| Application | Morphologic form | References |

|---|---|---|

| Wound dressings | Film | [49] |

| Sponge | [78] | |

| Bone tissue engineering | Sponge | [70–72, 114–117] |

| Film | [9, 50, 118] | |

| Hydrogel | [13, 63] | |

| Non-woven | [11, 41] | |

| Cartilage Tissue engineering | Porous sponge | [73, 74, 76, 77, 117] |

| Hydrogel | [75] | |

| Ligament tissue engineering | Fiber | [30, 31, 119] |

| Tendon tissue engineering | Fibers | [29] |

| Hepatic tissue engineering | Films | [8] |

| Connective tissue | Non-woven mats | [32] |

| Endothelial and blood vessel | Non-woven mats | [6, 34] |

| Antithrombogenesis | Films | [54] |

2.2.1 Silk fibers

Silk fibers can be obtained by reeling from cocoons [1]. Sutures braided from silk fibers have been used for centuries in gummed (virgin) and de-gummed (black braided silk) forms as sutures for surgical options [4]. A thorough review of the utilization of virgin and black braided silk (coated with silicone or wax to prevent fraying) and associated immune responses has been previously described [4]. Silk sutures have been used for tendon tissue engineering [29]. Sutures modified with immobilized Arg-Gly-Asp (RGD) peptide to increase cell attachment, were cultured with human tenocytes and supported increased adhesion after 3 days when compared with unmodified silk fiber and tissue cultured plastic [29]. An increase in collagen type I and decorin transcript levels was observed on the RGD-modified sutures compared with unmodified silk and tissue culture plastic at six weeks [29]. Textile engineering techniques with silk fibers were used to generate biomaterial replacements for ligaments. A wire rope design was studied to generate silk protein devices with mechanical strength equivalent to the human anterior cruciate ligament (ACL). Human bone marrow stromal cells (hMSCs) and fibroblasts obtained from ligaments seeded on these silk fibroin wire ropes attached and proliferated [30]. Cells cultured with mechanical stimulation expressed collagen types I and III and tenascin C characteristic of human ligaments [4, 31].

2.2.1 Non-woven silk fibroin mats

Non-woven mats are of interest as biomaterials due to the increased surface area and rougher topography for cell attachment. Silk fibroin has been used to generate non-woven silk mats from reprocessed native silk fibers or by electrospinning. Non-woven silk fibroin mats were prepared by partial solubilization of native silk fibers, usually in formic acid and small amounts of calcium chloride. The mats were washed and planted subcutaneously in rats, where they demonstrated good biocompatibility. Histology, mRNA transcript levels, and immunohistochemistry all suggest that the silk fibroin non-woven mat guided the formation of vascularized reticular connective tissue [32].

Silk fibers can also be treated by homogenization to achieve similar outcomes [33]. Silk fibroin mats 10–30 μm in diameter and pores of about 300 μm in diameter? were obtained. These non-woven mats were studied with a variety of cells, including keratinocytes, fibroblasts, osteoblasts, and cell lines from epithelial lung, colon, and cervical carcinomas for up to 7 weeks. No degradation of the silk fibers was observed during culture [33], possibly due to low infiltration of the cells within the matrix. Endothelial cells (both primary and transformed), when cultured on the silk fibroin mats, attached and proliferated. This outcome improved with a coating of collagen type I or fibronectin, most likely due to the presence of RGD sequences available for cell binding. Endothelial cells cultured for a week formed microvessel-like structures on the nonwoven mats [34].

Electrospun fibers can be produced in a wide range of diameters, ranging from a few nanometers to a few microns depending on mode of processing [35]. Electrospinning from aqueous silk fibroin solution mixed with poly(ethylene oxide) (PEO) was established and fiber morphology based on scanning electron microscopy (SEM) analysis showed uniform fibers less than 0.8 μm in diameter [36]. hMSC’s cultured on these mats showed attachment and spreading [37]. Atomic force microscopy nano-indentation was used to analyze the mechanical properties of the fibers. Electrospun silk fibers prepared from silk fibroin and poly(ethylene oxide) (PEO) had a lateral modulus of 8 GPa, compared with 13.6 GPa for native silk fibers [38]. Silk fibroin mats prepared from formic acid with fiber diameters averaging 100 nm showed a Young’s modulus of 515 MPa, ultimate tensile strength (UTS) of 7.25 MPa and strain of 3% [39].

Electrospun non-woven meshes can be prepared as predominately random coil structure from which β-sheet structures can be formed via methanol treatment [40]. The porosity changed from 76 to 68% due to dehydration after methanol treatment of these non-woven meshes [40]. Silk fibroin non-woven mats prepared using formic acid contained? 30–120 nm diameter fibers. Fibroblasts were cultured on the non-woven meshes and attached on silk and silk fibers coated with collagen type I, fibronectin, and laminin [40].

Blends of silk fibroin-PEO have been electrospun into nanoscale diameter fibers for the delivery of cell morphogens like bone morphogenetic protein-2 (BMP-2) [11]. BMP-2 is a morphogen which induces osteogenesis from mesenchymal stem cells. Nanoparticles of hydroxyapaptite were added with or without BMP-2 and the mats were seeded with hMSCs and grown under osteogenic conditions. Differentiation was evaluated by calcium deposition and transcript levels of osteogenic markers. The silk fibroin mats supported the differentiation of the hMSCs to bone-like cells, and the mats formed with hydroxyapaptite and BMP-2 showed the most calcium deposition and upregulation of osteogenic markers. This difference was attributed to the availability and release of BMP-2. Electrospun mats with hydroxyapatite also induced significant osteogenesis and the upregulation of BMP-2 transcript [11]. Silk fibroin non-woven mats electrospun from a 98% silk formic acid solution were implanted in calvarial defects of rabbits for bone regeneration and resulted in complete healing with new bone at 12 weeks [41].

Aside from biologically generated bone as above, options to control hydroxyapatite mineralization on silk biomaterial matrices have also been reported [42]. In nature, the organic/inorganic interface gives rise to unique material properties. Silk fibroin, when blended with added poly(L-aspartate), was successfully used as a template for the growth of apatite crystals [42].

2.2.2 Silk fibroin films

Silk fibroin films have been cast from aqueous or organic solvent systems, as well as after blending with other polymers. Silk films prepared from aqueous silk fibroin solution had oxygen and water vapor permeability dependent on the content of silk I and silk II structures [43, 44]. Alteration of silk structure was induced by treatment with 50% methanol for varying times. Changes in silk structure resulted in differing mechanical and degradability properties of the films [44]. Nanoscale silk fibroin films can also be formed from aqueous solution using a layer-by-layer technique (Wang et al., 2005). These ultrathin films were stable due to hydrophobic interactions and predictable film thickness could be obtained based on control of solution conditions. The films supported hMSC adhesion and proliferation [45].

Microstructures in films, which are advantageous for increasing surface roughness for cell attachment, were formed via blending of silk with poly(ethylene oxide) (PEO) [46]. The rough surfaces were exposed by extracting the PEO with water, after locking in the beta sheet crystallinity with methanol [46]. The roughness was directly related to the content of PEO used in the process.

Fibroblast attachment to silk films has been shown to be as high as for collagen films [12, 47]. Other mammalian and insect cells also showed good attachment on silk fibroin films when compared with collagen films [48]. Silk films, employed for healing full thickness skin wounds in rats, healed in seven days faster with a lower inflammatory response than traditional porcine based wound dressings [49]. Silk films have also been used for improved cell attachment and bone formation, particularly when chemically modified with RGD cell binding domains [50]. Silk fibroin films coupled with BMP-2 showed increased bone formation compared with the same silk fibroin films without the BMP-2 [9].

Transparent films cast from a blend of silk and cellulose showed increased mechanical strength compared with silk films alone [51]. Films cast from blends of silk fibroin and recombinant human-like collagen were seeded with hepatocytes and showed higher cell viability than silk fibroin films alone [8]. Silk fibroin solution, when coated on polyurethane and poly(carbonate) urethane films and scaffolds, increased the adhesion and proliferation of human fibroblasts [52, 53]. Films cast from silk fibroin and S-carboxymethyl kerateine (SCMK) showed decreased blood coagulation compared with silk fibroin or SCMK films alone [54].

2.2.4 Silk fibroin hydrogels

Hydrogels are three-dimensional polymer networks which are physically durable to swelling in aqueous solutions but do not dissolve in these solutions. Hydrogel biomaterials provide important options for the delivery of cells and cytokines. Silk fibroin hydrogels have been prepared from aqueous silk fibroin solution and are formed from? β-sheet structures [55, 56]. The pH of the silk fibroin solution impacted the rate of solution gelation. Gelation of a 3% solution was obtained in two days at pH 3–4, compared with eight days as required from a solution with pH 5–12 [56]. Other factors important in gelation included silk polymer concentration and Ca++ [55]. An increase in silk fibroin concentration, increase in temperature, decrease in pH, and an increase in Ca++ concentration decreased the time of silk fibroin gelation. Hydrogel pore size was controllable based on silk fibroin concentration and temperature [55].

Supplementation of silk solutions with poloxamer 407 (a nonionic surfactant) induced gelation; however, additional poloxamer reversed the sol-gel transition [57]. Semi-interpenetrating polymer networks (SIPNs) formed by mixing poloxamer 407 and silk fibroin solution increased the mechanical properties of the hydrogel [58]. A hydrogel blend of silk fibroin and gelatin showed a temperature dependent helix coil transition of the gelatin that impacted the rheological and mechanical properties of the gel. Composition and temperature dependent properties of gelatin-silk fibroin hydrogels were examined for drug delivery purposes [59, 60]. The release of benfotiamide for oral delivery was dependent upon the concentration of fibroin in silk fibroin-glycerol hydrogels [61]. The hydrolysis of trichlormethiazide in silk fibroin hydrogels prepared in various monosaccharides (ribose, fructose, glucose, and mannose) was dependent upon the number of hydroxyl groups on the various monosaccharide molecules [62].

Osteoblasts-like cells that attached when cultured on 2% (w/v) silk fibroin hydrogels showed adherence and biocompatibility [13]. Addition of 30% glycerol to the hydrogel increased the proliferation of the cells [13]. Silk fibroin hydrogels injected in critical-sized femur defects in rabbits resulted in greater trabecular bone volume and thickness, significantly higher mineral and rate of bone formation when compared to poly(D,L lactide-glycolide) [63].

Hydrogels combining the properties of silk and elastin were formed to generate biomaterials called silk-elastin-like protein polymers (SELPs). The water content in SELP hydrogels could be managed by time of gelation and concentration of polymer, while the properties were not affected by pH, ionic strength, or temperature [64, 65]. SELP hydrogels have been employed for the release of small molecules like theophylline, vitamin B12, and cytochrome c [65]. SELP hydrogels were also used for the controlled release of DNA. Size, conformation, and concentration of DNA determined release rates of DNA from SELP hydrogels. The transfection efficiency was 1–3 orders higher than DNA delivered without hydrogel [66].

2.2.5 Silk fibroin porous sponges

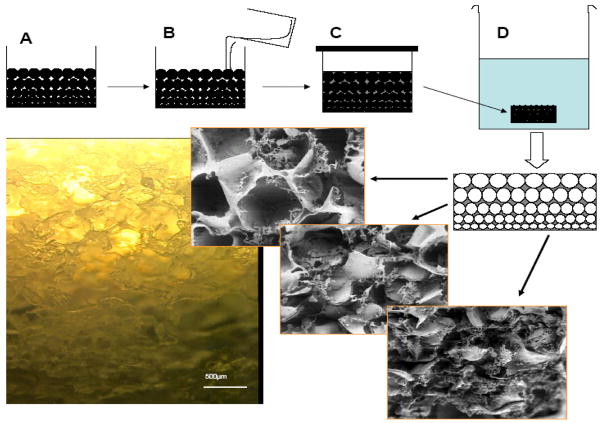

Porous sponge scaffolds are important for tissue engineering applications for cell attachment, proliferation, and migration, as well as for nutrient and waste transport. Regenerated silk fibroin solutions, both aqueous and solvent, have been utilized in the preparation of porous sponges. Sponges have been formed using porogens, gas foaming, and lyophilization [67]. Solvent-based sponges were prepared using salt (e.g., sodium chloride) or sugar as porogen. Solvents such as 1,1 3,3 hexafluropropanol (HFIP) do not solubilize salt or sugar; therefore, pores sizes in the sponges reflect the size of the porogen used in the process [67]. A gradient of pore sizes can be generated by stacking porogens of different sizes (Figure 2). Sponges with varying porosity can be controlled by stacking variations of salt/HFIP-silk solutions. Solvent-based porous sponges can also be prepared by addition of a small amount of solvent (ethanol, methanol, DMSO) into aqueous silk fibroin solution before pouring into a mold and freezing [68].

Fig. 2.

Porous gradient silk sponges prepared by stacking a water soluble porogen from smallest to largest (A). Solvent based silk solution is added and allowed to diffuse through the salt crystals (B & C). The porogen is dissolved in water leaving the sponge with pore gradient (D) [109].

Aqueous based porous silk sponges can be prepared using variable size salt crystals as porogen, with control of pore sizes from 490 to 940 μm, by manipulating the percent silk solution and size of salt crystals. Pore sizes are 80–90% smaller than the size of salt crystals due to the limited solubilization of the surface of the crystals during supersaturation of the silk solution prior to solidification [10]. Aqueous-based sponges have rougher surface morphology, based on SEM, than solvent-based sponges due to this partial solubilization. Aqueous silk fibroin sponges demonstrated improved cell attachment than the solvent-based porous sponges, likely due to these rougher surfaces. Sponges with high porosity and better mechanical strength were obtained with aqueous-based processing. Stiffness, compressive strength, and modulus were elevated with an increase in percent silk fibroin solution utilized in the process (Table 3) [10]. Enzymatic degradation of aqueous based sponges was more rapid than the solvent-based sponges [10].

Table 3.

Comparison of compressive strength and modulus of degradable polymeric porous sponge scaffolds (modified from [10, 67].

| Porous sponge material | Compression strength (KPa) |

Compression modulus (KPa) |

Reference |

|---|---|---|---|

| Silk fibroin (aqueous) | 11–320 | 70–3330 | [10] |

| Silk fibroin (solvent) | 30–250 | 100–1000 | [67] |

| Collagen | 15 | 150 | [120] |

| Fibroin/collagen composite | 20–354 | 430–30000 | [121] |

| Chitosan | 45 | 750 | [120] |

| Crosslinked Collagen/Chitosan | 30 | 500 | [120] |

| crosslinked Hyaluronan | 0.6 | [122] | |

| Poly(D,L-lactide) | 227–301 | [123] | |

| Poly(lactic acid) | 66–242 | [124] | |

| Poly(lactic acid)/poly(glycolic acid) | 1.0– 20 | [125] | |

| Polyurethane | 40–400 | [126] | |

| Poly(ε-caprolactone) | 44–90 | [123] | |

| Poly(ε-caprolactone/D, L-lactide) | 190–900 | [127] | |

| Poly(1,8-octanediol citrate) | 3.7 | [128] | |

| Poly(propylene fumarate) | 290,000 | [129] |

A phase diagram for the processing of aqueous- and solvent-based porous sponges has been developed. The concentration of silk fibroin solution and size of sodium chloride crystals (porogen) can be related to stable sponge formation with predictable morphological and structural features [69].

Porous three-dimensional silk sponges have been utilized in a number of studies with cells to generate various connective tissues. RGD coupled silk sponges seeded with hMSCs that have been cultured in osteogenic media resulted in differentiation of the cells, deposition of hydroxyapaptite, and upregulation of bone markers in vitro [70]. Tissue engineered silk sponges were useful for healing critical size femur defects in rats [71]. Aqueous porous sponge sponges with large pore sizes (900 μm) were used for bone tissue engineering. Structures similar to trabecular bone were observed after 28 days of hMSC differentiation in osteogenic media [72]. Solvent-based silk sponges were cultured with hMSCs in chondrogenic media and collagen type II and glycosaminglycan transcripts were upregulated to a higher degree than sponges composed of collagen or cross-linked collagen [73]. The structural integrity of silk sponges compared with rapidly degrading collagen-based sponges was in part responsible for these differences [73]. Aqueous-based silk fibroin sponges seeded with chondrocytes also supported cartilage tissue engineering [74]. Chondrocytes originating from New Zealand white rabbits were cultured in silk fibroin sponges and proliferated faster in the silk fibroin sponges and generated a higher content of glycosaminoglycan compared with collagen sponges [75]. Porous silk fibroin scaffold sponges seeded with rabbit chondrocytes [76], cultured in chondrogenic media, yielded a frictional coefficient similar to that of native cartilage after 28 days of culture [77]. Sponges formed from a blend of poly(vinyl alcohol) (PVA), chitosan, and silk fibroin showed the best healing of the epidermis and dermis of rats when compared to the paired and single polymers [78].

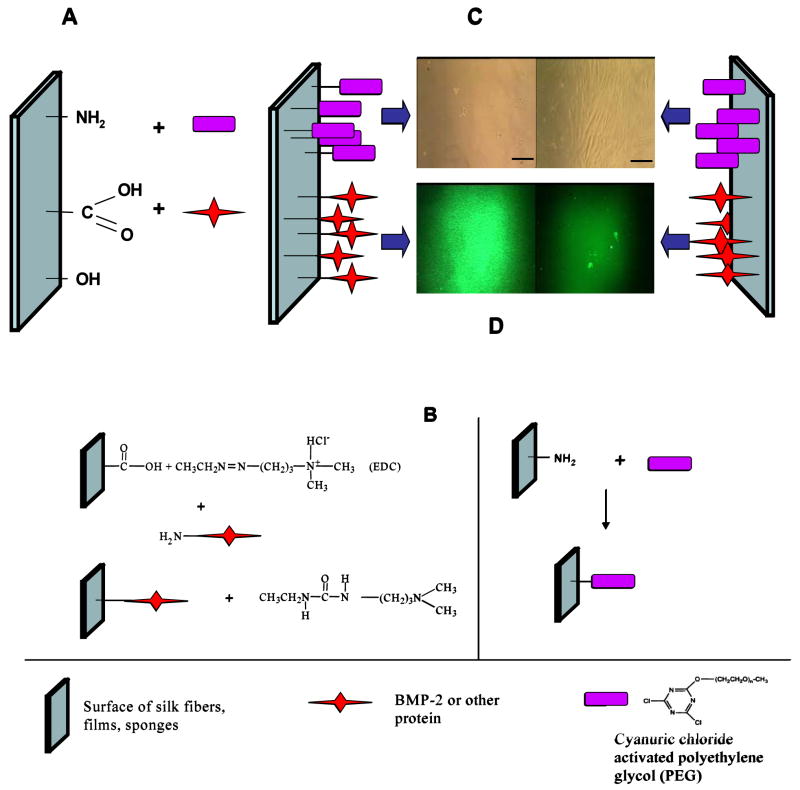

2.3 Surface modification

Surface modification can be used to alter cell attachment and impact cell proliferation. Surface modification with the integrin recognition sequence RGDS can increase cell attachment [79]. Modification of silk fibroin with poly(ethylene glycol) (PEG) showed decreased attachment of fibroblasts [80]. Silk fibroin surfaces coupled with PEG also showed contact angle, protein adsorption, and hMSC attachment related to the amount of PEG on the surface of the fibroin [81]. Surface modification includes physical adsorption or chemical immobilization of a protein or ligand. Silk surfaces are hydrophobic, and attract and repel proteins depending upon the pI and hydrophobicity of the protein and pH of the solution. Differential adsorption of horseradish peroxidase (HRP) to silk fibroin porous sponges depended on the pH of the solution; HRP precipitated on the surface when the pI and solution pH were similar [14]. Chemical immobilization of HRP increased the amount of HRP available on the silk fibroin surface [14].

Silk fibroin can be functionalized using the amino acid side chain chemistry. The limitation to using silk fibroin for chemical modification is the limited total content of modifiable amino acid side chain groups: 3.3% of the amino acids contain carboxyl side groups [1] compared with 9.5% found in bovine collagen [82]. Carbodiimide chemistry, which uses amine or carboxyl groups on silk for modification, has been used to modify the surface of silk fibroin biomaterials or to react in solution followed by biomaterials formation. Glucose-oxidase was immobilized on silk fibroin films for use as a glucose sensor [83]. Arginine residues of silk fibroin were modified by 1,2-cyclohexanedione, altering cell attachment and proliferation [84]. Silk fibers modified with RGD (covalently coupled) resulted in improved cell attachment and proliferation and subsequently increased collagen type I production by hMSCs and ligament fibroblast cells [30]. Covalent attachment of RGD to silk fibroin films increased the number of mineral modules formed by Saos-2 cells in osteogenic media [50]. Interestingly, some wild type silkworms like Antheraea pernyi have RGD, an integrin recognition sequence, in their silk fibroin sequence, which improves cell adhesion [47]. BMP-2 immobilized vs. adsorbed on silk fibroin films showed increased inducement of bone markers from hMSCs, including alkaline phosphatase, calcium deposition, and transcripts for collagen type I, bone sialoprotein, osteopontin, and BMP-2 [9].

Tissue development occurs in response to gradients of morphogens during embryogenesis and is recapitulated during adult tissue regeneration [85]. These signaling cues required by cells to develop into tissues would be useful to incorporate into biomaterial designs. Silk fibroin sponges were used to form immobilized gradients of morphogens [14]. Covalently coupled and adsorbed BMP-2 gradients within three-dimensional silk fibroin sponges were studied with hMSCs and a gradient response of calcium deposition was observed (Vepari et al., unpublished results). Immobilized gradients provide new options for biomaterial scaffolds for the generation of more complex cell and tissue outcomes in vitro and in vivo.

Organic-inorganic composites can also be generated through covalent linkage. Nanoscale particles of hydroxyapatite, less than 200 nm in diameter, were chemically bonded to silk fibroin [86]. Vinyl groups were introduced on silk fibroin by treatment with 2-methacryloxyethyl isocyanate. Subsequently, the modified silk fibroin surface was grafted with poly γ-methacryloxypropyl trimethoxysilane (polyMPTS). Hydroxyapatite particles were reacted with alkoxysilyl group of MPTS to form a siloxane bond. The crystallinity of silk fibroin remained constant during the coupling procedure and resulted in a silk-hydroxyapatite composite with properties of both components [86].

2.4 Degradation

The degradation of biomaterials is important in terms of restoring full tissue structure and function in vivo. Control over the rate of degradation is an important feature of functional tissue design, such that the rate of scaffold degradation matches the rate of tissue growth [87]. Silk fibroin fibers retain more than 50% of their mechanical properties after two months of implantation in vivo; thus, they are defined as a non-degradable biomaterial by the United States Pharmacopeia [7]. Other polymers like poly (lactic acid) (PLA), poly (glycolic acid) (PGA), and PLGA have degradation rates related to hydrolysis based on the polyester composition, purity, and processing conditions. The degradation of these polymers is usually controlled by varying ratios of polymers with different degradation rates or by altering molecular weight of the polymer [88]. These polymers only exhibit limited degradation by enzymes, such as metalloproteinases (MMPs). Furthermore, the degradation products of synthetic polymers like PLA decrease local pH and result in inflammation [89].

Natural polymers like collagen and silks degrade via the action of proteases. Typically, the rate of collagen degradation is altered by cross-linking in order to reduce enzymatic degradation. Cross-linking of collagen may also reduce immunogenicity [90]. The degradation byproducts of collagen are peptides and amino acids. The rate of silk fibroin degradation depends upon the structure, morphology, and mechanical and biological conditions at the location of implantation. Degradation of silk fibroin films and fibers has been explored using several types of proteases, including α-chymotrypsin and collagenases [5, 7]. Interestingly, a 6 kDa trypsin inhibitor isolated from the water extract from silkworm cocoons, termed cocoon shell associated trypsin inhibitor (CSTI), protected the light chain of silk fibroin against tryptic degradation [91]. This inhibitor may be a useful tool in biomaterials design for spatial restriction of the degradation process.

A correlation between in vitro and in vivo rates of degradation of silk fibroin fibers has also been established (Horan et al. unpublished). Arai et al. [5] compared degradation of silk fibers with silk films when exposed to different amounts and types of enzymes. Exposure to similar enzymes resulted in faster film degradation than the fibers based on weight loss. The weight loss was accompanied by a change in average molecular weight of silk from 120 kDa for control silk films to 53 kDa for silk films degraded with α-chymotrypsin for 17 days. An increase in the crystallinity of the silk was observed with degradation. Tensile properties of silk fibers decreased without a large change in molecular weight of the silk fibers [5].

Silk fibroin porous sponges from regenerated B. mori fibers degraded differently with different processing conditions [10]. Aqueous processed 3D sponges, with similar pore sizes, degraded more slowly upon exposure to proteases with an increased percent silk present during the processing. Solvent-processed sponges degraded more slowly than the aqueous-processed systems with similar pore sizes: 65% mass remained after 21 days as compared to aqueous-based sponges, which degraded completely in 4 days. The difference in degradation was due to increased surface roughness or differences in content or distribution of crystallinity [10].

Silk fibroin degradation could be regulated by changing crystallinity [44], pore size, porosity, and molecular weight distribution (MWD) of the silk fibroin. A change in MWD can be achieved by treating silk fibroin under alkaline conditions and heat. A decrease in MWD may disrupt ordered structures and reduce cross-links, potentially resulting in faster degradation. It will be useful to understand the mechanism and correlation of silk fibroin degradation with mechanical properties. Poly(D,L-lactic acid) surfaces coated with silk fibroin of different MWD resulted in differential attachment of osteoblasts. The adhesion of osteoblasts could have been a result of differences in surface hydrophilicity [92].

2.5 Immunological responses

Immunological reactions to biomaterials are an important consideration. Sutures made from virgin silk compared with sutures from de-gummed silk showed differences in hypersensitivity [4]. The inflammatory response of de-gummed silk fibroin in vitro compared with polystyrene and poly(2-hydroxyethyl methacrylate) showed less adhesion of immuno-competent cells [93]. Silk films implanted in vivo induced a lower inflammatory response than collagen films and PLA films [94]. Silk fibroin non-woven mats implanted subcutaneously in rats induced a weak foreign body response and no occurrence of fibrosis. There was little upregulation of inflammatory pathways at the implantation site and no invasion by lymphocytes after six months in vivo [32].

Sericins, which have been known to cause hypersensitivity [4], have been used to increase cell proliferation and attachment. Sericin M, a 400 kDa protein, supported cell attachment of skin fibroblasts to collagen [95]. Sericin-S (5–100 kDa) have been used to increase proliferation of mammalian cells like T-lymphocytes and hybridomas [96]. Fibroblast cells cultured on sericin matrices showed non-elongated morphology, unlike the normal spindle shaped morphology observed on silk fibroin and collagen matrices [12]. Biomaterials like tricalcium phosphate have also been coated with sericin to improve biocompatibility [97].

2.6 Sterilizability

An important feature of silk as a biomaterial, compared with other fibrous proteins such as collagen, is the versatility of options for sterilization [49]. Sterilization of silk fibroin scaffolds by autoclaving does not change morphology [73] or β-sheet structure when heated to 120°C [86]. Comparatively, collagen denatures at these temperatures [98]. Silk fibroin scaffolds can also be sterilized using ethylene oxide [4], γ-radiation, or 70% ethanol [9, 11].

3. Spider (Nephilia clavipes) silk

Spider silk from N. clavipes has been studied extensively and is characterized by its remarkable mechanical strength and thermal stability in fiber form [2]. The different types of silks formed by spiders serve various functions. The mechanical properties of the different silks are due to structural differences derived from different amino acid compositions and sequences. Dragline silk for safety and web construction is one the strongest natural materials and is composed of two proteins: major ampullate spidroins protein 1 and 2 (MaSp1 and (MaSp2). A putative molecular weight of 275 kDa based on gel electrophoresis of MaSp1 [1] and 740 kDa based on the major ampullate gland silk by size exclusion chromatography [99] this sentence sounds a little strange, but I’m not sure why, so I left it alone. The molecular weight of minor ampullate gland silk was determined to be 290 kDa, as measured by size exclusion chromatography [99]. Unlike silkworms, spider silks characterized to date do not indicate the presence of sericin proteins. The dragline silks from different species of spiders have different mechanical properties [100] (Table 4).

Table 4.

Mechanical properties of dragline silk from different species (abridged from [100].

| Species | Young’s modulus (GPa) |

Toughness (MJ/m3) |

|---|---|---|

| Nephila clavipes | 7.38–22 | 80–111.2 |

| Araneus diadematus | 4.0–10 | 131–160 |

| Argiope trifasciata | 6.9–11 | 90–116.3 |

| Latrodectus hesperus | 6–10.2 | 180.9 |

| Leucauge verusta | 10.6 | 151 |

| Plectreurys tristis | 16.1 | 112.1 |

| Kukulcania hibernalis | 22.2 | 132.2 |

The superior mechanical properties of dragline spider silks can be used as a template for developing specific structures for various biomaterial needs. Spider silks have not been commercialized in a similar fashion as has been done with silkworm silk due to the lack of domestication and lower productivity of spiders. However, genetic engineering provides the opportunity to produce spider silks, both native and hybrids, for biomaterial applications.

3.1 Structure of Dragline silk

The amino acid composition of dragline silk, MaSp1 from N. clavipes, consists mainly of the amino acids glycine and alanine, like silkworm silk, while glutamic acid, proline, and arginine are also significant in content [1]. This silk consists of repetitive blocks of peptides which give rise to the unique structural properties. The crystalline domains, which contribute to the tensile strength, contain repeats of alanine or glycine-alanine in MaSp1 and MaSp2. Another motif consisting of GPGXX (where X is most likely Glutamine and P is Proline) found only in MaSp2 is responsible for β-turn spiral and results in the elasticity of silk. Flagelliform silk from N. clavipes is rich in this motif and is highly elastic to serve its function in prey capture. Another motif, GGX, a glycine helix found in MaSp1, is responsible for the less crystalline regions of the silk structure. These domains also give rise to elasticity of dragline silk. At the carboxy- and amino- termini of the protein, non-repetitive sequences are found which have been proposed to have a role in assembly of the protein [101].

3.2 Large scale production of spider silk

MaSp1 from N. clavipes was expressed in E. coli; however, gene stability and complications in processing long repetitive sequences were encountered [102]. Therefore, alternative host systems have been explored for the cloning and expression of MASp1- and MaSp2-like proteins, such as transgenic tobacco [103]. Spider dragline-like protein with yields of 1 g/L were expressed in the yeast, Pichia pastoris [104]. MaSp1 and MaSp2/ADF-3 were cloned and expressed in baby hamster kidney cells and bovine mammary epithelial alveolar cells [105]. Proteins of 60–140 kDa were produced and spun into fibers with reasonable mechanical properties [105]. Genes encoding spider silk have also been expressed in mouse milk [106]. Despite the above efforts, no substantial effort at commercialization of spider silk via genetic engineering has been successful to date, a required step to realize biomaterials applications from spider silks.

3.3 Morphology of recombinant spider silk

Environmental factors such as pH, water content, concentration of protein, salt, and charge impact the processing and assembly of spider silk in vivo and in vitro. For example, interchain interactions increased with enhanced calcium concentration and low water content [107]. Films cast from dragline silk proteins of Araneus diadematus in HFIP exhibited α-helical structure which dissolved in aqueous solution. Insoluble films were prepared by treatment with methanol and resulted in β-sheet structures. These films could be chemically coupled with fluorescein and β-galactosidase, which showed higher activity in chemically coupled than adsorbed forms [27]. A higher percentage of aspartic acid and glutamic acid found in MaSp1 (11.7%) than fibroin (3.3) [1] provides enhanced options for the chemical modification or coupling of factors to MaSp silk when compared to silk fibroin from silkworm. Hydrogels have also been prepared from recombinant spider silk and were found to be stable for several weeks and demonstrated high elastic modulus [108].

4. Conclusion

Silks are a unique group of fibrous proteins with unusually high mechanical strength in fiber form. The clinical success of silk sutures and availability of silkworm silk have encouraged a recent expansion of new biomaterials generated from the original suture-based protein harvested and processed from silkworms. Native silk fibers can be processed into wire ropes and non-woven silk mats. The same fibers can be solubilized and regenerated in aqueous solution, then further processed into sponges, films, hydrogels, and nanoscale electrospun non-woven mats. Surface modification of silk fibroin biomaterials can be used to alter cell responses. Cell culture on silk-based biomaterials has resulted in the formation of a variety of tissues including bone, cartilage, and ligament, both in vitro and in vivo. The degradability of silk fibroin can be altered by processing conditions. Molecular biology has been used to generate spider silks, although reasonable quantities are still not available. These genetically engineered spider silk proteins which have been formed into films can be chemically modified [27]. The unique structure of silk, versatility in processing, biocompatibility, availability of different biomaterial morphologies, options for genetic engineering of variations of silks, the ease of sterilization, thermal stability, surface chemistry for facile chemical modifications, and controllable degradation features make silks promising biomaterials for many clinical functions. Since the exploration of biomaterial applications for silks, aside from sutures, is only a relatively recent advance, the future for this family of structural proteins to impact clinical needs appears promising.

Fig. 3.

Covalent coupling versus adsorption of proteins on silk surfaces. A: Modifiable amino acid side chains; presence of amine, carboxyl and hydroxyl groups. B: Carboxyl side groups activated by 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) for 10–15 minutes. A protein like BMP-2 can be introduced via amine groups reacting with the activated silk to form amide bonds. Cyanuric activated polyethylene glycol (PEG) reacts with amine and hydroxyl groups on silk fibroin surface. C: Coupling of PEG on silk fibroin films generates a more hydrophilic surface and reduced attachment of human mesenchymal stem cells (hMSCs) [81]. D: Coupling BMP-2 to silk fibroin films via carbodiimide coupling results in increased calcium deposition (increased calcein labeling) by differentiated hMSCs [9].

Acknowledgments

We thank our many colleagues inside and outside of Tufts University for their contributions to the studies on silk over the years. We also thank various funding agencies for support of different aspects of our studies on silks, including the NIH, the NSF, and the DoD.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Kaplan DL, Mello SM, Arcidiacono S, Fossey S, Senecal KWM. In: Protein based materials. McGrath KKD, editor. Boston: Birkhauser; 1998. pp. 103–131. [Google Scholar]

- 2.Wong Po Foo C, Kaplan DL. Genetic engineering of fibrous proteins: spider dragline silk and collagen. Adv Drug Deliv Rev. 2002;54(8):1131–1143. doi: 10.1016/s0169-409x(02)00061-3. [DOI] [PubMed] [Google Scholar]

- 3.Bini E, Knight DP, Kaplan DL. Mapping domain structures in silks from insects and spiders related to protein assembly. J Mol Biol. 2004;335(1):27–40. doi: 10.1016/j.jmb.2003.10.043. [DOI] [PubMed] [Google Scholar]

- 4.Altman GH, Diaz F, Jakuba C, Calabro T, Horan RL, Chen J, Lu H, Richmond J, Kaplan DL. Silk-based biomaterials. Biomaterials. 2003;24(3):401–416. doi: 10.1016/s0142-9612(02)00353-8. [DOI] [PubMed] [Google Scholar]

- 5.Arai T, Freddi G, Innocenti R, Tsukada M. Biodegradation of Bombyx mori Silk Fibroin Fibers and Films. J Appl Polym Sci. 2004;91:2383–2390. [Google Scholar]

- 6.Fuchs S, Motta A, Migliaresi C, Kirkpatrick CJ. Outgrowth endothelial cells isolated and expanded from human peripheral blood progenitor cells as a potential source of autologous cells for endothelialization of silk fibroin biomaterials. Biomaterials. 2006;27(31):5399–5408. doi: 10.1016/j.biomaterials.2006.06.015. [DOI] [PubMed] [Google Scholar]

- 7.Horan RL, Antle K, Collette AL, Wang Y, Huang J, Moreau JE, Volloch V, Kaplan DL, Altman GH. In vitro degradation of silk fibroin. Biomaterials. 2005;26(17):3385–3393. doi: 10.1016/j.biomaterials.2004.09.020. [DOI] [PubMed] [Google Scholar]

- 8.Hu K, Lv Q, Cui F, Feng Q, Kong X, Wang H, Huang L, Li T. Biocompatible fibroin blended films with recombinant human-like collagen for hepatic tissue engineering. J Bioact Compat Polym. 2006;21(1):23–37. [Google Scholar]

- 9.Karageorgiou V, Meinel L, Hofmann S, Malhotra A, Volloch V, Kaplan D. Bone morphogenetic protein-2 decorated silk fibroin films induce osteogenic differentiation of human bone marrow stromal cells. J Biomed Mater Res A. 2004;71(3):528–537. doi: 10.1002/jbm.a.30186. [DOI] [PubMed] [Google Scholar]

- 10.Kim UJ, Park J, Kim HJ, Wada M, Kaplan DL. Three-dimensional aqueous-derived biomaterial scaffolds from silk fibroin. Biomaterials. 2005;26(15):2775–2785. doi: 10.1016/j.biomaterials.2004.07.044. [DOI] [PubMed] [Google Scholar]

- 11.Li C, Vepari C, Jin HJ, Kim HJ, Kaplan DL. Electrospun silk-BMP-2 scaffolds for bone tissue engineering. Biomaterials. 2006;27(16):3115–3124. doi: 10.1016/j.biomaterials.2006.01.022. [DOI] [PubMed] [Google Scholar]

- 12.Minoura N, Aiba S, Gotoh Y, Tsukada M, Imai Y. Attachment and growth of cultured fibroblast cells on silk protein matrices. J Biomed Mater Res. 1995;29(10):1215–1221. doi: 10.1002/jbm.820291008. [DOI] [PubMed] [Google Scholar]

- 13.Motta A, Migliaresi C, Faccioni F, Torricelli P, Fini M, Giardino R. Fibroin hydrogels for biomedical applications: preparation, characterization and in vitro cell culture studies. J Biomater Sci Polym Ed. 2004;15(7):851–864. doi: 10.1163/1568562041271075. [DOI] [PubMed] [Google Scholar]

- 14.Vepari CP, Kaplan DL. Covalently immobilized enzyme gradients within three-dimensional porous scaffolds. Biotechnol Bioeng. 2006;93(6):1130–1137. doi: 10.1002/bit.20833. [DOI] [PubMed] [Google Scholar]

- 15.Arai T, Freddi G, Colonna GM, Scotti E, Boschi A, Murakami R, Tsukada M. Absorption of Metal Cations by Modified B. mori Silk and Preparation of Fabrics with Antimicrobial Activity. J Appl Polym Sci. 2001:80297–303. [Google Scholar]

- 16.Moy RL, Lee A, Zalka A. Commonly used suture materials in skin surgery. Am Fam Physician. 1991;44(6):2123–2128. [PubMed] [Google Scholar]

- 17.Vollrath F, Knight DP. Liquid crystalline spinning of spider silk. Nature. 2001;410(6828):541–548. doi: 10.1038/35069000. [DOI] [PubMed] [Google Scholar]

- 18.Zhou CZ, Confalonieri F, Medina N, Zivanovic Y, Esnault C, Yang T, Jacquet M, Janin J, Duguet M, Perasso R, Li ZG. Fine organization of Bombyx mori fibroin heavy chain gene. Nucleic Acids Res. 2000;28(12):2413–2419. doi: 10.1093/nar/28.12.2413. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Yamaguchi K, Kikuchi Y, Takagi T, Kikuchi A, Oyama F, Shimura K, Mizuno S. Primary structure of the silk fibroin light chain determined by cDNA sequencing and peptide analysis. J Mol Biol. 1989;210(1):127–139. doi: 10.1016/0022-2836(89)90295-7. [DOI] [PubMed] [Google Scholar]

- 20.Inoue S, Tanaka K, Arisaka F, Kimura S, Ohtomo K, Mizuno S. Silk fibroin of Bombyx mori is secreted, assembling a high molecular mass elementary unit consisting of H-chain, L-chain, and P25, with a 6:6:1 molar ratio. J Biol Chem. 2000;275(51):40517–40528. doi: 10.1074/jbc.M006897200. [DOI] [PubMed] [Google Scholar]

- 21.Tanaka K, Inoue S, Mizuno S. Hydrophobic interaction of P25, containing Asn-linked oligosaccharide chains, with the H-L complex of silk fibroin produced by Bombyx mori. Insect Biochem Mol Biol. 1999;29(3):269–276. doi: 10.1016/s0965-1748(98)00135-0. [DOI] [PubMed] [Google Scholar]

- 22.Zhou CZ, Confalonieri F, Jacquet M, Perasso R, Li ZG, Janin J. Silk fibroin: structural implications of a remarkable amino acid sequence. Proteins. 2001;44(2):119–122. doi: 10.1002/prot.1078. [DOI] [PubMed] [Google Scholar]

- 23.Gage LP, Manning RF. Internal structure of the silk fibroin gene of Bombyx mori. I The fibroin gene consists of a homogeneous alternating array of repetitious crystalline and amorphous coding sequences. J Biol Chem. 1980;255(19):9444–9450. [PubMed] [Google Scholar]

- 24.Mori K, Tanaka K, Kikuchi Y, Waga M, Waga S, Mizuno S. Production of a chimeric fibroin light-chain polypeptide in a fibroin secretion-deficient naked pupa mutant of the silkworm Bombyx mori. J Mol Biol. 1995;251(2):217–228. doi: 10.1006/jmbi.1995.0429. [DOI] [PubMed] [Google Scholar]

- 25.Jin HJ, Kaplan DL. Mechanism of silk processing in insects and spiders. Nature. 2003;424(6952):1057–1061. doi: 10.1038/nature01809. [DOI] [PubMed] [Google Scholar]

- 26.Motta A, Fambri L, Migliaresi C. Regenerated silk fibroin films: Thermal and dynamic mechanical analysis. Macromolecular Chemistry and Physics. 2002;203(10–11):1658–1665. [Google Scholar]

- 27.Huemmerich D, Slotta U, Scheibel T. Processing and modification of films made from recombinant spider silk proteins. Appl Phys A. 2006;82:219–222. [Google Scholar]

- 28.Zhang YQ. Applications of natural silk protein sericin in biomaterials. Biotechnol Adv. 2002;20(2):91–100. doi: 10.1016/s0734-9750(02)00003-4. [DOI] [PubMed] [Google Scholar]

- 29.Kardestuncer T, McCarthy MB, Karageorgiou V, Kaplan D, Gronowicz G. RGD-tethered silk substrate stimulates the differentiation of human tendon cells. Clin Orthop Relat Res. 2006:448234–239. doi: 10.1097/01.blo.0000205879.50834.fe. [DOI] [PubMed] [Google Scholar]

- 30.Chen J, Altman GH, Karageorgiou V, Horan R, Collette A, Volloch V, Colabro T, Kaplan DL. Human bone marrow stromal cell and ligament fibroblast responses on RGD-modified silk fibers. J Biomed Mater Res A. 2003;67(2):559–570. doi: 10.1002/jbm.a.10120. [DOI] [PubMed] [Google Scholar]

- 31.Altman GH, Horan RL, Lu HH, Moreau J, Martin I, Richmond JC, Kaplan DL. Silk matrix for tissue engineered anterior cruciate ligaments. Biomaterials. 2002;23(20):4131–4141. doi: 10.1016/s0142-9612(02)00156-4. [DOI] [PubMed] [Google Scholar]

- 32.Dal Pra I, Freddi G, Minic J, Chiarini A, Armato U. De novo engineering of reticular connective tissue in vivo by silk fibroin nonwoven materials. Biomaterials. 2005;26(14):1987–1999. doi: 10.1016/j.biomaterials.2004.06.036. [DOI] [PubMed] [Google Scholar]

- 33.Unger RE, Wolf M, Peters K, Motta A, Migliaresi C, James Kirkpatrick C. Growth of human cells on a non-woven silk fibroin net: a potential for use in tissue engineering. Biomaterials. 2004;25(6):1069–1075. doi: 10.1016/s0142-9612(03)00619-7. [DOI] [PubMed] [Google Scholar]

- 34.Unger RE, Peters K, Wolf M, Motta A, Migliaresi C, Kirkpatrick CJ. Endothelialization of a non-woven silk fibroin net for use in tissue engineering: growth and gene regulation of human endothelial cells. Biomaterials. 2004;25(21):5137–5146. doi: 10.1016/j.biomaterials.2003.12.040. [DOI] [PubMed] [Google Scholar]

- 35.Reneker D, Chun I. Nanometer diameter fibers of polymer, produced by electrospinning. Nanotechnology. 1996;7(3):216–223. [Google Scholar]

- 36.Jin HJ, Fridrikh SV, Rutledge GC, Kaplan DL. Electrospinning Bombyx mori silk with poly(ethylene oxide) Biomacromolecules. 2002;3(6):1233–1239. doi: 10.1021/bm025581u. [DOI] [PubMed] [Google Scholar]

- 37.Jin HJ, Chen J, Karageorgiou V, Altman GH, Kaplan DL. Human bone marrow stromal cell responses on electrospun silk fibroin mats. Biomaterials. 2004;25(6):1039–1047. doi: 10.1016/s0142-9612(03)00609-4. [DOI] [PubMed] [Google Scholar]

- 38.Wang M, Jin HJ, Kaplan DL, Rutledge GC. Mechanical properties of electrospun silk fibers. Macromolecules. 2004;37(18):6856–6864. [Google Scholar]

- 39.Ayutsede J, Gandhi M, Sukigara S, Micklus M, Chen HE, Ko F. Regeneration of Bombyx mori silk by electrospinning, Part 3: characterization of electrospun nonwoven mat. Polymer. 2005;46(5):1625–1634. [Google Scholar]

- 40.Min BM, Lee G, Kim SH, Nam YS, Lee TS, Park WH. Electrospinning of silk fibroin nanofibers and its effect on the adhesion and spreading of normal human keratinocytes and fibroblasts in vitro. Biomaterials. 2004;25(7–8):1289–1297. doi: 10.1016/j.biomaterials.2003.08.045. [DOI] [PubMed] [Google Scholar]

- 41.Kim KH, Jeong L, Park HN, Shin SY, Park WH, Lee SC, Kim TI, Park YJ, Seol YJ, Lee YM, Ku Y, Rhyu IC, Han SB, Chung CP. Biological efficacy of silk fibroin nanofiber membranes for guided bone regeneration. J Biotechnol. 2005;120(3):327–339. doi: 10.1016/j.jbiotec.2005.06.033. [DOI] [PubMed] [Google Scholar]

- 42.Li C, Jin H, Botsaris G, Kaplan D. Silk apatite composites from electrospun fibers. Journal of Materials Research. 2005;20(12):3374–3384. [Google Scholar]

- 43.Minoura N, Tsukada M, Nagura M. Fine structure and oxygen permeability of silk fibroin membrane treated with methanol. Polymer. 1990;31(2):265–269. [Google Scholar]

- 44.Minoura N, Tsukada M, Nagura M. Physico-chemical properties of silk fibroin membrane as a biomaterial. Biomaterials. 1990;11(6):430–434. doi: 10.1016/0142-9612(90)90100-5. [DOI] [PubMed] [Google Scholar]

- 45.Wang X, Kim HJ, Xu P, Matsumoto A, Kaplan DL. Biomaterial coatings by stepwise deposition of silk fibroin. Langmuir. 2005;21(24):11335–11341. doi: 10.1021/la051862m. [DOI] [PubMed] [Google Scholar]

- 46.Jin HJ, Park J, Valluzzi R, Cebe P, Kaplan DL. Biomaterial films of Bombyx mori silk fibroin with poly(ethylene oxide) Biomacromolecules. 2004;5(3):711–717. doi: 10.1021/bm0343287. [DOI] [PubMed] [Google Scholar]

- 47.Minoura N, Aiba S, Higuchi M, Gotoh Y, Tsukada M, Imai Y. Attachment and growth of fibroblast cells on silk fibroin. Biochem Biophys Res Commun. 1995;208(2):511–516. doi: 10.1006/bbrc.1995.1368. [DOI] [PubMed] [Google Scholar]

- 48.Inouye K, Kurokawa M, Nishikawa S, Tsukada M. Use of Bombyx mori silk fibroin as a substratum for cultivation of animal cells. J Biochem Biophys Methods. 1998;37(3):159–164. doi: 10.1016/s0165-022x(98)00024-4. [DOI] [PubMed] [Google Scholar]

- 49.Sugihara A, Sugiura K, Morita H, Ninagawa T, Tubouchi K, Tobe R, Izumiya M, Horio T, Abraham NG, Ikehara S. Promotive effects of a silk film on epidermal recovery from full-thickness skin wounds. Proc Soc Exp Biol Med. 2000;225(1):58–64. doi: 10.1046/j.1525-1373.2000.22507.x. [DOI] [PubMed] [Google Scholar]

- 50.Sofia S, McCarthy MB, Gronowicz G, Kaplan DL. Functionalized silk-based biomaterials for bone formation. J Biomed Mater Res. 2001;54(1):139–148. doi: 10.1002/1097-4636(200101)54:1<139::aid-jbm17>3.0.co;2-7. [DOI] [PubMed] [Google Scholar]

- 51.Freddi G, Romano M, Massafra M, Tsukada M. Silk fibroin/cellulose blend films—preparation, structure, and physical-properties. J Appl Polym Science. 1995;56(12):1537–1545. [Google Scholar]

- 52.Petrini P, Parolari C, Tanzi MC. Silk fibroin-polyurethane scaffolds for tissue engineering. J Mater Sci Mater Med. 2001;12(10–12):849–853. doi: 10.1023/a:1012847301850. [DOI] [PubMed] [Google Scholar]

- 53.Chiarini A, Petrini P, Bozzini S, Pra I, Armato U. Silk fibroin/poly(carbonate)-urethane as a substrate for cell growth: in vitro interactions with human cells. Biomaterials. 2003;24(5):789–799. doi: 10.1016/s0142-9612(02)00417-9. [DOI] [PubMed] [Google Scholar]

- 54.Lee K, Kong S, Park W, Ha W, Kwon I. Effect of surface properties on the antithrombogenicity of silk fibroin/S-carboxymethyl kerateine blend films. J Biomater Sci—Polym Ed. 1998;9(9):905–914. doi: 10.1163/156856298x00235. [DOI] [PubMed] [Google Scholar]

- 55.Kim UJ, Park J, Li C, Jin HJ, Valluzzi R, Kaplan DL. Structure and properties of silk hydrogels. Biomacromolecules. 2004;5(3):786–792. doi: 10.1021/bm0345460. [DOI] [PubMed] [Google Scholar]

- 56.Ayub Z, Arai M, Hirabayashi K. Mechanism of the gelation of fibroin solution. Biosci Biotechnol Biochem. 1993;57(11):1910–1912. [Google Scholar]

- 57.Kang G-D, Nahm J-H, Park J-S, Moon J-Y, Cho C-S, Yeo J-H. Effects of Poloxamer on the gelation of silk fibroin. Macromolecular Rapid Communications. 2000;21(11):788–791. [Google Scholar]

- 58.Yoo MK, Kweon HY, Lee KG, Lee HC, Cho CS. Preparation of semi-interpenetrating polymer networks composed of silk fibroin and poloxamer macromer. Int J Biol Macromol. 2004;34(4):263–270. doi: 10.1016/j.ijbiomac.2004.06.002. [DOI] [PubMed] [Google Scholar]

- 59.Gil ES, Spontak RJ, Hudson SM. Effect of beta-sheet crystals on the thermal and rheological behavior of protein-based hydrogels derived from gelatin and silk fibroin. Macromol Biosci. 2005;5(8):702–709. doi: 10.1002/mabi.200500076. [DOI] [PubMed] [Google Scholar]

- 60.Gil ES, Frankowski DJ, Spontak RJ, Hudson SM. Swelling behavior and morphological evolution of mixed gelatin/silk fibroin hydrogels. Biomacromolecules. 2005;6(6):3079–3087. doi: 10.1021/bm050396c. [DOI] [PubMed] [Google Scholar]

- 61.Hanawa T, Watanabe A, Tsuchiya T, Ikoma R, Hidaka M, Sugihara M. New oral dosage form for elderly patients, II: release behavior of benfotiamine from silk fibroin gel. Chem Pharm Bull. 1995;43(5):872–876. doi: 10.1248/cpb.43.872. [DOI] [PubMed] [Google Scholar]

- 62.Hanawa T, Maeda R, Muramatsu E, Suzuki M, Sugihara M, Nakajima S. New oral dosage form for elderly patients. III. Stability of trichlormethiazide in silk fibroin gel and various sugar solutions. Drug Dev Ind Pharm. 2000;26(10):1091–1097. doi: 10.1081/ddc-100100273. [DOI] [PubMed] [Google Scholar]

- 63.Fini M, Motta A, Torricelli P, Giavaresi G, Nicoli Aldini N, Tschon M, Giardino R, Migliaresi C. The healing of confined critical size cancellous defects in the presence of silk fibroin hydrogel. Biomaterials. 2005;26(17):3527–3536. doi: 10.1016/j.biomaterials.2004.09.040. [DOI] [PubMed] [Google Scholar]

- 64.Dinerman AA, Cappello J, Ghandehari H, Hoag SW. Swelling behavior of a genetically engineered silk-elastinlike protein polymer hydrogel. Biomaterials. 2002;23(21):4203–4210. doi: 10.1016/s0142-9612(02)00164-3. [DOI] [PubMed] [Google Scholar]

- 65.Dinerman AA, Cappello J, Ghandehari H, Hoag SW. Solute diffusion in genetically engineered silk-elastinlike protein polymer hydrogels. J Control Release. 2002;82(2–3):277–287. doi: 10.1016/s0168-3659(02)00134-7. [DOI] [PubMed] [Google Scholar]

- 66.Megeed Z, Haider M, Li D, O’Malley BW, Jr, Cappello J, Ghandehari H. In vitro and in vivo evaluation of recombinant silk-elastinlike hydrogels for cancer gene therapy. J Control Release. 2004;94(2–3):433–445. doi: 10.1016/j.jconrel.2003.10.027. [DOI] [PubMed] [Google Scholar]

- 67.Nazarov R, Jin HJ, Kaplan DL. Porous 3-D scaffolds from regenerated silk fibroin. Biomacromolecules. 2004;5(3):718–726. doi: 10.1021/bm034327e. [DOI] [PubMed] [Google Scholar]

- 68.Tamada Y. New process to form a silk fibroin porous 3-D structure. Biomacromolecules. 2005;6(6):3100–3106. doi: 10.1021/bm050431f. [DOI] [PubMed] [Google Scholar]

- 69.Kim H, Kim H, Matsumoto A, Chin I, Jin H, Kaplan D. Processing windows for forming silk fibroin biomaterials into a 3D porous matrix. Aust J Chem. 2005:58716–720. [Google Scholar]

- 70.Meinel L, Karageorgiou V, Fajardo R, Snyder B, Shinde-Patil V, Zichner L, Kaplan D, Langer R, Vunjak-Novakovic G. Bone tissue engineering using human mesenchymal stem cells: effects of scaffold material and medium flow. Ann Biomed Eng. 2004;32(1):112–122. doi: 10.1023/b:abme.0000007796.48329.b4. [DOI] [PubMed] [Google Scholar]

- 71.Meinel L, Fajardo R, Hofmann S, Langer R, Chen J, Snyder B, Vunjak-Novakovic G, Kaplan D. Silk implants for the healing of critical size bone defects. Bone. 2005;37(5):688–698. doi: 10.1016/j.bone.2005.06.010. [DOI] [PubMed] [Google Scholar]

- 72.Kim HJ, Kim UJ, Vunjak-Novakovic G, Min BH, Kaplan DL. Influence of macroporous protein scaffolds on bone tissue engineering from bone marrow stem cells. Biomaterials. 2005;26(21):4442–4452. doi: 10.1016/j.biomaterials.2004.11.013. [DOI] [PubMed] [Google Scholar]

- 73.Meinel L, Hofmann S, Karageorgiou V, Zichner L, Langer R, Kaplan D, Vunjak-Novakovic G. Engineering cartilage-like tissue using human mesenchymal stem cells and silk protein scaffolds. Biotechnol Bioeng. 2004;88(3):379–391. doi: 10.1002/bit.20252. [DOI] [PubMed] [Google Scholar]

- 74.Wang Y, Blasioli DJ, Kim HJ, Kim HS, Kaplan DL. Cartilage tissue engineering with silk scaffolds and human articular chondrocytes. Biomaterials. 2006;27(25):4434–4442. doi: 10.1016/j.biomaterials.2006.03.050. [DOI] [PubMed] [Google Scholar]

- 75.Aoki H, Tomita N, Morita Y, Hattori K, Harada Y, Sonobe M, Wakitani S, Tamada Y. Culture of chondrocytes in fibroin-hydrogel sponge. Biomed Mater Eng. 2003;13(4):309–316. [PubMed] [Google Scholar]

- 76.Morita Y, Tomita N, Aoki H, Wakitani S, Tamada Y, Suguro T, Ikeuchi K. Visco-elastic properties of cartilage tissue regenerated with fibroin sponge. Biomed Mater Eng. 2002;12(3):291–298. [PubMed] [Google Scholar]

- 77.Morita Y, Tomita N, Aoki H, Sonobe M, Wakitani S, Tamada Y, Suguro T, Ikeuchi K. Frictional properties of regenerated cartilage in vitro. J Biomech. 2006;39(1):103–109. doi: 10.1016/j.jbiomech.2004.10.031. [DOI] [PubMed] [Google Scholar]

- 78.Yeo JH, Lee KG, Kim HC, Oh HYL, Kim AJ, Kim SY. The effects of Pva/chitosan/fibroin (PCF)-blended spongy sheets on wound healing in rats. Biol Pharm Bull. 2000;23(10):1220–1223. doi: 10.1248/bpb.23.1220. [DOI] [PubMed] [Google Scholar]

- 79.Pierschbacher MD, Ruoslahti E. Cell attachment activity of fibronectin can be duplicated by small synthetic fragments of the molecule. Nature. 1984;309(5963):30–33. doi: 10.1038/309030a0. [DOI] [PubMed] [Google Scholar]

- 80.Gotoh Y, Tsukada M, Minoura N, Imai Y. Synthesis of poly(ethylene glycol)-silk fibroin conjugates and surface interaction between L-929 cells and the conjugates. Biomaterials. 1997;18(3):267–271. doi: 10.1016/s0142-9612(96)00137-8. [DOI] [PubMed] [Google Scholar]

- 81.Vepari C, Matheson D, Naik R, Kaplan DL. Regulation of mesenchymal stem cell behavior on silk fibroin surfaces modified with polyethylene glycol - in preparation [Google Scholar]

- 82.Bowes JH, Elliott RG, Moss JA. The composition of collagen and acid-soluble collagen of bovine skin. Biochem J. 1955;61(1):143–150. doi: 10.1042/bj0610143. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 83.Demura M, Asakura T. Porous membrane of Bombyx mori silk fibroin—structure characterization, physical-properties and application to glucose-oxidase immobilization. J Membr Sci. 1991;59(1):39–52. [Google Scholar]

- 84.Gotoh Y, Tsukada M, Minoura N. Effect of the chemical modification of the arginyl residue in Bombyx mori silk fibroin on the attachment and growth of fibroblast cells. J Biomed Mater Res. 1998;39(3):351–357. doi: 10.1002/(sici)1097-4636(19980305)39:3<351::aid-jbm2>3.0.co;2-i. [DOI] [PubMed] [Google Scholar]

- 85.Teixeira J, Urist M. Bone morphogenetic protein induced repair of compartmentalized segmental diaphyseal defects. Arch Orthop Trauma Surg. 1998;117(1–2):27–34. doi: 10.1007/BF00703435. [DOI] [PubMed] [Google Scholar]

- 86.Furuzono T, Kishida A, Tanaka J. Nano-scaled hydroxyapatite/polymer composite I. Coating of sintered hydroxyapatite particles on poly(gamma-methacryloxypropyl trimethoxysilane)grafted silk fibroin fibers through chemical bonding. J Mater Sci Mater Med. 2004;15(1):19–23. doi: 10.1023/b:jmsm.0000010093.39298.5a. [DOI] [PubMed] [Google Scholar]

- 87.Lanza R, Langer R, Vacanti J. Principles of Tissue Engineering. San Diego, CA: Academic Press; 2000. [Google Scholar]

- 88.Oh JE, Nam YS, Lee KH, Park TG. Conjugation of drug to poly(D,L-lactic-co-glycolic acid) for controlled release from biodegradable microspheres. J Control Release. 1999;57(3):269–280. doi: 10.1016/s0168-3659(98)00123-0. [DOI] [PubMed] [Google Scholar]

- 89.Solheim E, Sudmann B, Bang G, Sudmann E. Biocompatibility and effect on osteogenesis of poly(ortho ester) compared to poly(DL-lactic acid) J Biomed Mater Res. 2000;49(2):257–263. doi: 10.1002/(sici)1097-4636(200002)49:2<257::aid-jbm15>3.0.co;2-5. [DOI] [PubMed] [Google Scholar]

- 90.Basu S, Cunningham LP, Pins GD, Bush KA, Taboada R, Howell AR, Wang J, Campagnola PJ. Multiphoton excited fabrication of collagen matrixes cross-linked by a modified benzophenone dimer: bioactivity and enzymatic degradation. Biomacromolecules. 2005;6(3):1465–1474. doi: 10.1021/bm049258y. [DOI] [PubMed] [Google Scholar]

- 91.Kurioka A, Yamazaki M, Hirano H. Primary structure and possible functions of a trypsin inhibitor of Bombyx mori. Eur J Biochem. 1999;259(1–2):120–126. doi: 10.1046/j.1432-1327.1999.00030.x. [DOI] [PubMed] [Google Scholar]

- 92.Cai K, Yao K, Lin S, Yang Z, Li X, Xie H, Qing T, Gao L. Poly(D,L-lactic acid) surfaces modified by silk fibroin: effects on the culture of osteoblast in vitro. Biomaterials. 2002;23(4):1153–1160. doi: 10.1016/s0142-9612(01)00230-7. [DOI] [PubMed] [Google Scholar]

- 93.Santin M, Motta A, Freddi G, Cannas M. In vitro evaluation of the inflammatory potential of the silk fibroin. J Biomed Mater Res. 1999;46(3):382–389. doi: 10.1002/(sici)1097-4636(19990905)46:3<382::aid-jbm11>3.0.co;2-r. [DOI] [PubMed] [Google Scholar]

- 94.Meinel L, Hofmann S, Karageorgiou V, Kirker-Head C, McCool J, Gronowicz G, Zichner L, Langer R, Vunjak-Novakovic G, Kaplan DL. The inflammatory responses to silk films in vitro and in vivo. Biomaterials. 2005;26(2):147–155. doi: 10.1016/j.biomaterials.2004.02.047. [DOI] [PubMed] [Google Scholar]

- 95.Tsubouchi K, Igarashi Y, Takasu Y, Yamada H. Sericin enhances attachment of cultured human skin fibroblasts. Biosci Biotechnol Biochem. 2005;69(2):403–405. doi: 10.1271/bbb.69.403. [DOI] [PubMed] [Google Scholar]

- 96.Terada S, Sasaki M, Yanagihara K, Yamada H. Preparation of silk protein sericin as mitogenic factor for better mammalian cell culture. J Biosci Bioeng. 2005:6667–671. doi: 10.1263/jbb.100.667. [DOI] [PubMed] [Google Scholar]

- 97.Takeuchi A, Ohtsuki C, Kamitakahara M, Ogata S, Tanihara M, Miyazaki T, Yamazaki M, Furutani Y, Kinoshita H. Biodegradation of porous alpha-tricalcium phosphate coated with silk sericin. Key Engineering Materials. 2005:284–286. 329–332. [Google Scholar]

- 98.McClain PE, Wiley ER. Differential scanning calorimeter studies of the thermal transitions of collagen. Implications on structure and stability. J Biol Chem. 1972;247(3):692–697. [PubMed] [Google Scholar]

- 99.Jackson C, O’Brien J. Molecular weight distribution of Nephila clavipes dragline silk. Macromolecules. 1995:285975–5977. [Google Scholar]

- 100.Swanson BO, Blackledge TA, Beltran J, Hayashi CY. Variation in the material properties of spider dragline silk across species. Appl Phys. 2006:A 82213–218. [Google Scholar]

- 101.Scheibel T. Spider silks: recombinant synthesis, assembly, spinning, and engineering of synthetic proteins. Microb Cell Fact. 2004;3(1):14. doi: 10.1186/1475-2859-3-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 102.Arcidiacono S, Mello C, Kaplan D, Cheley S, Bayley H. Purification and characterization of recombinant spider silk expressed in Escherichia coli. Appl Microbiol Biotechnol. 1998;49(1):31–38. doi: 10.1007/s002530051133. [DOI] [PubMed] [Google Scholar]

- 103.Menassa R, Zhu H, Karatzas C, Lazaris A, Richman A, Brandle J. Spider dragline silk proteins in transgenic tobacco leaves: accumulation and field production. Plant Biotechnology Journal. 2004;2(5):431–438. doi: 10.1111/j.1467-7652.2004.00087.x. [DOI] [PubMed] [Google Scholar]

- 104.Fahnestock SR, Bedzyk LA. Production of synthetic spider dragline silk protein in Pichia pastoris. Appl Microbiol Biotechnol. 1997;47(1):33–39. doi: 10.1007/s002530050884. [DOI] [PubMed] [Google Scholar]

- 105.Lazaris A, Arcidiacono S, Huang Y, Zhou JF, Duguay F, Chretien N, Welsh EA, Soares JW, Karatzas CN. Spider silk fibers spun from soluble recombinant silk produced in mammalian cells. Science. 2002;295(5554):472–476. doi: 10.1126/science.1065780. [DOI] [PubMed] [Google Scholar]

- 106.Karatzas CN, Chretien N, Duguay F, Bellemare A, Zhou JF, Rodenhiser A, Islam SA, Turcotte C, Huang Y, Lazaris A. High-toughness spider silk fibers spun from soluble recombinant silk produced in mammalian cells. Biopolymers. 2003:897–117. [Google Scholar]

- 107.Wong Po Foo C, Bini E, hensman J, Knight DP, Lewis RV, Kaplan DL. Role of pH and charge on silk protein assembly in insects and spiders. Appl Phys A. 2006:82223–233. [Google Scholar]

- 108.Rammensee S, Huemmerich D, Hermanson KD, Scheibel T, Bausch AR. Rheological characterization of hydrogels formed by recombinantly produced spider silk. Appl Phys A. 2006:82261–264. [Google Scholar]

- 109.Wang X, Kim HJ, Wong C, Vepari C, Matsumoto A, Kaplan DL. Fibrous Proteins - Role in Biomaterials and Tissue Engineering. Materials Today. In press. [Google Scholar]

- 110.Perez-Rigueiro J, Viney C, Llorca J, Elices M. Mechanical properties of single-brin silkworm silk. J Appl Polym Sci. 2000:751270–1277. [Google Scholar]

- 111.Cunniff P, Fossey S, Auerbach M, Song J, Kaplan D, Adams WW, Eby R, Mahoney D, Vezie D. Mechanical and thermal properties of dragline silk from the spider Nephila clavipes. Polymers for Advanced Technologies. 1994;5(8):401–410. [Google Scholar]

- 112.Pins G, Christianse D, Patel R, Silver F. Self-assembly of collagen fibers: influence of fibrillar alignment and decorin on mechanical properties. Biophys J. 1997:732164–2172. doi: 10.1016/S0006-3495(97)78247-X. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 113.Engelberg I, Kohn J. Physicomechanical properties of degradable polymers used in medical applications: a comparative study. Biomaterials. 1991:12292–304. doi: 10.1016/0142-9612(91)90037-b. [DOI] [PubMed] [Google Scholar]

- 114.Meinel L, Betz O, Fajardo R, Hofmann S, Nazarian A, Cory E, Hilbe M, McCool J, Langer R, Vunjak-Novakovic G, Merkle HP, Rechenberg B, Kaplan DL, Kirker-Head C. Silk based biomaterials to heal critical sized femur defects. Bone. 2006 doi: 10.1016/j.bone.2006.04.019. [DOI] [PubMed] [Google Scholar]

- 115.Meinel L, Hofmann S, Betz O, Fajardo R, Merkle HP, Langer R, Evans CH, Vunjak-Novakovic G, Kaplan DL. Osteogenesis by human mesenchymal stem cells cultured on silk biomaterials: comparison of adenovirus mediated gene transfer and protein delivery of BMP-2. Biomaterials. 2006;27(28):4993–5002. doi: 10.1016/j.biomaterials.2006.05.021. [DOI] [PubMed] [Google Scholar]

- 116.Karageorgiou V, Tomkins M, Fajardo R, Meinel L, Snyder B, Wade K, Chen J, Vunjak-Novakovic G, Kaplan DL. Porous silk fibroin 3-D scaffolds for delivery of bone morphogenetic protein-2 in vitro and in vivo. J Biomed Mater Res A. 2006;78(2):324–334. doi: 10.1002/jbm.a.30728. [DOI] [PubMed] [Google Scholar]

- 117.Marolt D, Augst A, Freed LE, Vepari C, Fajardo R, Patel N, Gray M, Farley M, Kaplan D, Vunjak-Novakovic G. Bone and cartilage tissue constructs grown using human bone marrow stromal cells, silk scaffolds and rotating bioreactors. Biomaterials. 2006 doi: 10.1016/j.biomaterials.2006.07.015. [DOI] [PubMed] [Google Scholar]

- 118.Kino R, Ikoma T, Monkawa A, Yunoki S, Munekata M, Tanaka J, Asakura T. Deposition of bone-like apatite on modified silk fibroin films from simulated body fluid. Journal of Applied Polymer Science. 2006;99(5):2822–2830. [Google Scholar]

- 119.Moreau JE, Chen J, Horan RL, Kaplan DL, Altman GH. Sequential growth factor application in bone marrow stromal cell ligament engineering. Tissue Eng. 2005;11(11–12):1887–1897. doi: 10.1089/ten.2005.11.1887. [DOI] [PubMed] [Google Scholar]

- 120.Kim S, Cho Y, Kang E, Kwon I, Lee E, Kim J, Chung H, Jeong S. Three-dimensional porous collagen/chitosan complex sponge for tissue engineering. Fibers and Polymers. 2001;2(2):64–70. [Google Scholar]

- 121.Lv Q, Feng Q, Hu K, Cui F. Three-dimensional fibroin/collagen scaffolds derived from aqueous solution and the use for HepG2 culture. Polymer. 2005;46(26):12662–12669. [Google Scholar]

- 122.Nettles DL, Vail TP, Morgan MT, Grinstaff MW, Setton LA. Photocrosslinkable hyaluronan as a scaffold for articular cartilage repair. Ann Biomed Eng. 2004;32(3):391–397. doi: 10.1023/b:abme.0000017552.65260.94. [DOI] [PubMed] [Google Scholar]

- 123.Hou Q, Grijpma DW, Feijen J. Preparation of interconnected highly porous polymeric structures by a replication and freeze-drying process. J Biomed Mater Res B Appl Biomater. 2003;67(2):732–740. doi: 10.1002/jbm.b.10066. [DOI] [PubMed] [Google Scholar]

- 124.Nam YS, Yoon JJ, Park TG. A novel fabrication method of macroporous biodegradable polymer scaffolds using gas foaming salt as a porogen additive. J Biomed Mater Res. 2000;53(1):1–7. doi: 10.1002/(sici)1097-4636(2000)53:1<1::aid-jbm1>3.0.co;2-r. [DOI] [PubMed] [Google Scholar]

- 125.Moran JM, Pazzano D, Bonassar LJ. Characterization of polylactic acid-polyglycolic acid composites for cartilage tissue engineering. Tissue Eng. 2003;9(1):63–70. doi: 10.1089/107632703762687546. [DOI] [PubMed] [Google Scholar]

- 126.Heijkants R, Van Tienen T, De Groot J, Pennings A, Buma P, Veth R, Schouten A. Preparation of a polyurethane scaffold for tissue engineering made by a combination of salt leaching and freeze-drying of dioxane. Journal of Materials Science. 2006;41(8):2423–2428. [Google Scholar]

- 127.Meretoja VV, Helminen AO, Korventausta JJ, Haapa-aho V, Seppala JV, Narhi TO. Crosslinked poly(epsilon-caprolactone/D,L-lactide)/bioactive glass composite scaffolds for bone tissue engineering. J Biomed Mater Res A. 2006;77(2):261–268. doi: 10.1002/jbm.a.30630. [DOI] [PubMed] [Google Scholar]

- 128.Kang Y, Yang J, Khan S, Anissian L, Ameer GA. A new biodegradable polyester elastomer for cartilage tissue engineering. J Biomed Mater Res A. 2006;77(2):331–339. doi: 10.1002/jbm.a.30607. [DOI] [PubMed] [Google Scholar]

- 129.Fisher JP, Holland TA, Dean D, Mikos AG. Photoinitiated cross-linking of the biodegradable polyester poly(propylene fumarate). Part II. In vitro degradation. Biomacromolecules. 2003;4(5):1335–1342. doi: 10.1021/bm0300296. [DOI] [PubMed] [Google Scholar]