Electronics of the future will be soft and rubbery. Devices based on this new technology will be stretchable, twistable, and deformable into curvilinear shapes, thereby enabling applications that would be impossible to achieve by using the hard, rigid electronics of today. Examples range from ultrathin, conformable health-monitoring tapes that seamlessly mount on the skin, “electronic skin,” to advanced imaging devices that use hemispherical detector layouts, “electronic eyeball cameras.” In these and other systems, mechanical design will be as important as circuit design. Vella et al. (1) in this issue of PNAS introduce simple schemes to measure the mechanical properties of structures for stretchable electronics and they describe powerful analytical approaches that capture the underlying physics.

Historically, progress in electronics has been dominated by a development path first noted by Gordon Moore in 1965 (2): the number of transistors in silicon microprocessors tends to double every 18–24 months, mainly through reductions in the sizes of the transistors. This trend, known as Moore's Law, is now so well established that it is self-fulfilling, via roadmaps that guide the efforts of the entire industry. Modern processors incorporate more than a billion transistors each with critical dimensions of tens of nanometers. Continued downscaling represents an important future for electronics, but not the only one. In the early 1990s, a completely different class of electronics emerged to meet a need that was impossible to address with silicon wafer technology: active matrix circuits for switching pixels in liquid crystal displays. Progress in this kind of electronics is most definitely not dictated by Moore's Law. Here, the primary scaling metric is overall size: bigger is better, because large area coverage means large video screens. The total number of transistors, beyond a few million, and their sizes are both comparatively unimportant. The most advanced fabrication facilities produce circuits that cover areas of nearly 10 m2, with total outputs that exceed a thousand acres of electronics per year. This “macroelectronics” (3) technology began its growth nearly 40 years after the birth of modern microelectronics, yet it captures a rapidly growing market that now represents a sizable fraction of the entire broader industry.

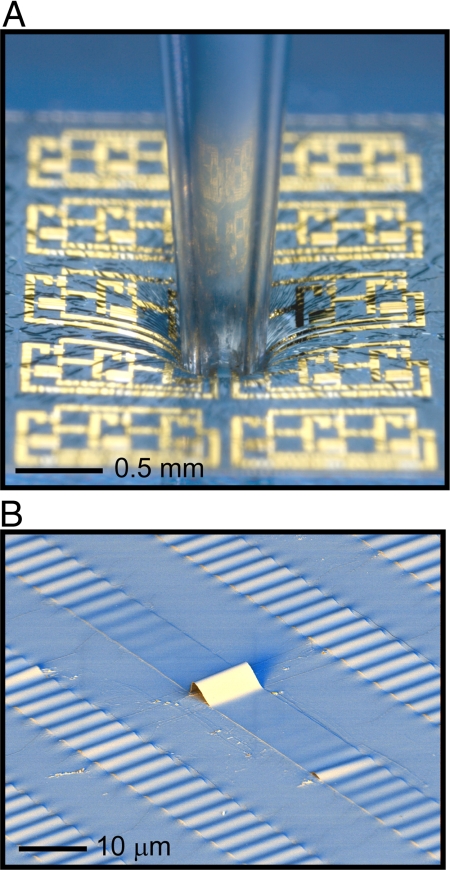

Many believe that the “next big thing” in electronics is with systems that avoid the rigid, brittle, and planar nature of micro/macroelectronics, to enable new modes of use. Research in this direction began ≈15 years ago (4), initially driven by interest in flexible, paperlike displays (5, 6). More recently, the scope has expanded to include more compelling, and more technically challenging, opportunities in biomedical devices that intimately integrate with the human body and in product designs that exploit curvilinear, ergonomic, or biologically inspired layouts. One approach to such technology relies on the development of new electronic materials, e.g., organic semiconductors that can flex (4) and composite elastomer conductors that can stretch (7). Different strategies use optimized structural configurations (8) of established inorganic materials for stretchable interconnects (8–13) and/or active devices (8, 14–16). The concepts that enable stretchy properties from these brittle materials are simple. For example, ultrathin sheets of silicon are flexible, for the same reason that any material in thin film form is flexible: bending strains are inversely proportional to thickness. Such sheets, formed in buckled “wavy” shapes and integrated with rubber substrates, yield composite systems that provide fully elastic responses to applied strains, with an underlying physics similar to that of an accordion bellows. These and related ideas provide routes to high-performance electronics with the mechanical properties of a rubber band. Fig. 1A shows a wavy silicon integrated circuit that has these characteristics (14). In parallel with fundamental research on the materials and mechanics, advanced development work is increasing in areas of biomedicine such as intracardial and neural monitoring. As applied to digital imaging, this technology enables hemispherical electronic eyeball cameras that provide enhanced operating characteristics compared with devices with conventional planar layouts (17).

Fig. 1.

Buckled ultrathin silicon circuit sheets bonded to elastomeric substrates represent a form of electronics that responds elastically to applied strains. (A) Optical image of a silicon CMOS (complementary metal–oxide semiconductor) integrated circuit of this type, pressed downward in the central region with a glass rod. The wavelengths and amplitudes of the buckled structures, visible here as color and contrast variations, change to accommodate the deformation. This physics provides a useful degree of circuit-level stretchability that avoids any significant strains in the electronic materials themselves. (B) Scanning electron micrograph of buckled nanoribbons of single crystalline silicon bonded to an elastomer substrate. This composite system provides an elastic response to applied strains, with a physics that is conceptually similar to that of an accordion bellows. The ribbon in the center of this image had a defect that caused it to delaminate locally from the substrate to form an isolated bridge structure, further highlighting certain aspects of the mechanics. This stretchable form of silicon embodies, in a simple system, the key physics associated with the full integrated circuit shown in A.

Mechanical design plays a critically important role in this type of stretchable electronics technology. Experimental work involves characterizing the microscopic behavior of the material structures, the devices, circuits, and systems, where the length scales for the relevant deformations range from millimeters to nanometers (8, 10, 12, 14–16). Fig. 1B presents a scanning electron micrograph of an array of wavy silicon nonoribbons on an elastomer substrate (16). Analytical and computational modeling can quantitatively capture the physics (18) of this basic subunit of stretchable integrated circuits (Fig. 1A). Although such studies of the mechanics are critically important, they require sophisticated capabilities in device fabrication and test. Vella et al. (1) show that the essential physics can be explored by using macroscopic analogs, consisting of plastic sheets on rubber supports, manipulated with clamps and translation stages. This approach greatly simplifies the experiments, thereby opening up the field to researchers who do not have access to cleanroom fabrication facilities or advanced microscope systems. Vella et al. exploit their setups to study the nonlinear processes that lead to buckled structures. Their mathematical treatment uses established methods of energy minimization (16, 18, 19), but with a unique linking of the release of total system energy to the interfacial fracture toughness. The result provides a useful way to determine not only the onset but also the evolution of buckling with applied strain. They use macroscopically measurable interfacial toughness to determine microscopic parameters such as buckling and wavelength and amplitude. One outcome of this analysis is the recognition of a critical film thickness needed to avoid damage or plastic deformation, thereby providing an important design rule for devices. Explicitly accounting for the loading and geometry dependence of the interfacial fracture toughness in the theory will further improve the accuracy of the results.

Vella et al. exploit their setups to study the nonlinear processes that lead to buckled structures.

This and other recent research in stretchable electronics indicate that progress requires multidisciplinary programs, incorporating nearly every field of traditional study, from chemistry, materials science, mathematics, and physics to mechanical and electrical engineering. Successful efforts will transform the way that we think about electronics, from rigid semiconductor chips for consumer electronics to soft biocompatible sheets for devices that address important problems in human health. The rich range of scientific aspects together with the strong potential for societal benefits creates an exciting future for this field.

Footnotes

The authors declare no conflict of interest.

See companion article on page 10901.

References

- 1.Vella D, Bicoa J, Boudaoudb A, Romana B, Reis PM. The macroscopic delamination of thin films from elastic substrates. Proc Natl Acad Sci USA. 2009;106:10901–10906. doi: 10.1073/pnas.0902160106. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Moore GE. Cramming more components onto integrated circuits. Electronics. 1965;38:114–117. [Google Scholar]

- 3.Reuss R, et al. Macroelectronics: Perspectives on technology and applications. Proc IEEE. 2005;93:1239–1256. [Google Scholar]

- 4.Garnier F, Hajlaoui R, Yassar A, Srivastava P. All-polymer field-effect transistor realized by printing techniques. Science. 1994;265:1684–1686. doi: 10.1126/science.265.5179.1684. [DOI] [PubMed] [Google Scholar]

- 5.Rogers JA. Toward paperlike displays. Science. 2001;291:1502–1503. doi: 10.1126/science.291.5508.1502. [DOI] [PubMed] [Google Scholar]

- 6.Rogers JA, et al. Paper-like electronic displays: Large-area, rubber-stamped plastic sheets of electronics and electrophoretic inks. Proc Natl Acad Sci USA. 2001;98:4835–4840. doi: 10.1073/pnas.091588098. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Sekitani T, et al. A rubberlike stretchable active matrix using elastic conductors. Science. 2008;321:1468–1472. doi: 10.1126/science.1160309. [DOI] [PubMed] [Google Scholar]

- 8.Kim D.-H, Rogers JA. Stretchable electronics: Materials strategies and devices. Adv Mater. 2008;20:4887–4892. [Google Scholar]

- 9.Lacour SP, Jones J, Wagner S, Li T, Suo Z. Stretchable interconnects for elastic electronic surfaces. Proc IEEE. 2005;93:1459–1467. [Google Scholar]

- 10.Kim D-H, et al. Materials and noncoplanar mesh designs for integrated circuits with linear elastic responses to extreme mechanical deformations. Proc Natl Acad Sci USA. 2008;105:18675–18680. doi: 10.1073/pnas.0807476105. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Someya T, et al. Conformable, flexible, large-area networks of pressure and thermal sensors with organic transistor active matrixes. Proc Natl Acad Sci USA. 2005;102:12321–12325. doi: 10.1073/pnas.0502392102. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Kim DH, et al. Complementary metal oxide silicon integrated circuits incorporating monolithically integrated stretchable wavy interconnects. Appl Phys Lett. 2008;93 044102. [Google Scholar]

- 13.Brosteaux D, Axisa F, Gonzalez M, Vanfleteren J. Design and fabrication of elastic interconnections for stretchable electronic circuits. IEEE Electron Device Lett. 2007;28:552–554. [Google Scholar]

- 14.Kim D-H, et al. Stretchable and foldable silicon integrated circuits. Science. 2008;320:507–511. doi: 10.1126/science.1154367. [DOI] [PubMed] [Google Scholar]

- 15.Sun Y, Jiang H, Huang YY, Sun Y, Rogers JA. Controlled buckling of semiconductor nanoribbons for stretchable electronics. Nat Nanotechnol. 2006;1:201–207. doi: 10.1038/nnano.2006.131. [DOI] [PubMed] [Google Scholar]

- 16.Khang DY, Jiang H, Huang Y, Rogers JA. A stretchable form of single-crystal silicon for high-performance electronics on rubber substrates. Science. 2006;311:208–212. doi: 10.1126/science.1121401. [DOI] [PubMed] [Google Scholar]

- 17.Ko HC, et al. A hemispherical electronic eye camera based on compressible silicon optoelectronics. Nature. 2008;454:748–753. doi: 10.1038/nature07113. [DOI] [PubMed] [Google Scholar]

- 18.Jiang H, et al. Finite deformation mechanics in buckled thin films on compliant supports. Proc Natl Acad Sci USA. 2007;104:15607–15612. doi: 10.1073/pnas.0702927104. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Huang ZY, Hong W, Suo Z. Nonlinear analyses of wrinkles in a film bonded to a compliant substrate. J Mech Phys Solids. 2005;53:2101–2118. [Google Scholar]