Abstract

The synthesis of the novel Small Cell Lung Cancer (SCLC) Fucosyl GM1-based vaccine construct, featuring insertion of the HLA-DR binding 15 amino acid sequence derived from Plasmodium Falciparum, is described. The resultant glycopeptide has been synthesized in an efficient manner. Finally, successful conjugation of the glycopeptide to the Keyhole Limpet Hemocyanin (KLH) carrier protein completed the preparation of the vaccine.

Introduction

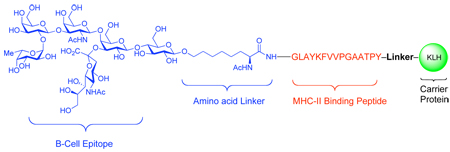

Among the large number of emerging anticancer strategies, the prospect of mobilizing the immune system against the disease is especially attractive. One can imagine employing a vaccine– based therapeutic approach against a number of different primary tumors, as well as against metastatic cells, in an adjuvant mode.1 Along these lines, we are pursuing the idea of targeting as immune system markers complex carbohydrate epitopes, which are overexpressed on cancer cell surfaces. Though this concept has occurred to others, our group has made a particularly strong commitment to accessing these structures by total synthesis.2 A typical carbohydrate-based anticancer vaccine would consist of a complex carbohydrate hapten, overexpressed on the cancer cell, a carrier protein, and a linker attaching the carbohydrate to the protein (Figure 1). Beside being a potent immunogen, the carrier protein is known to provide the MHC-II binding peptides bound to the epitope, thus helping to present the carbohydrate to the T-cells for T-cell activation and initiation of the cellular response.3,4 Consequently, one could imagine that the immunogenicity of a vaccine might well be enhanced by providing MHC-II binding peptides in the environs of the epitope, thereby serving to increase the number of epitopes presented to the CD4+ T cell. In a sense, this rationale is related to the idea of conjugating epitopes to carrier protein to create vaccines. However, this approach of placing an MHC-II binding sequence in a fixed relation to the antigen has been pursued mostly for vaccines unconjugated to carrier protein. We hope to explore the possibility that introduction of an MHC-II binding sequence could also improve the immunogenicity of vaccines incorporating standard carriers such as Keyhole Limpet Hemocyanin (KLH).

Figure 1.

New Generation Bidomainal Fucosyl GM1-Based Vaccine for the Treatment of SCLC

To test the notion of upgrading the immunogenicity of a candidate carbohydrate based vaccine in this way, we pursued the synthesis of the construct illustrated in Figure 1. Fucosyl GM1 is a carbohydrate epitope that is expressed on the surface of Small-Cell Lung Cancer (SCLC) cells.6 This carbohydrate has been previously synthesized by our group as well as by others7 and it was selected based on the promising results demonstrated by its KLH conjugate in our recent clinical trials.8 A fifteen amino acid peptide sequence derived from Plasmodium Falciparum and illustrated in Figure 1 was chosen as the T-cell epitope. This sequence has been shown to be general for binding up to 9 different alleles of human HLA-DR with binding capacity prevalently in the nanomolar range.9

The appendage of the fucosyl GM1 epitope to the peptide portion could be accomplished using the norleucine linker developed by our group.10 The long aliphatic chain of this linker would be optimal in preventing potentially adverse interactions between the epitope and the peptide backbone. The amino acid functionality makes this linker a powerful handle for conjugation.

The synthesis of glycoprotein conjugates still presents a challenge for numerous reasons. One of the issues is compatibility and “collegiality” of the protecting groups required for peptidic and carbohydrate assemblies. Thus, a complex glycan is often unstable under the highly acidic conditions that are required to remove peptide protecting groups. Correspondingly, peptides maybe unstable under the basic conditions that are required for the deprotection and retrieval of the oligosaccharide ensembles.11 However, since the protecting groups of the selected peptide would be limited to t-butylcarboxy for lysine and t-butyl for tyrosines and threonine, there is, hopefully, no requirement for prolonged treatment with acid in the deprotection phase. Thus, the glycoside linkages of peracetylated fucose and sialic acid moieties could be stable under the deprotection conditions. Of course, the cleavage of a methyl ester and seventeen acetate groups could prove to be a challenging task that might well require careful selection of hydrolysis conditions.

Results and Discussion

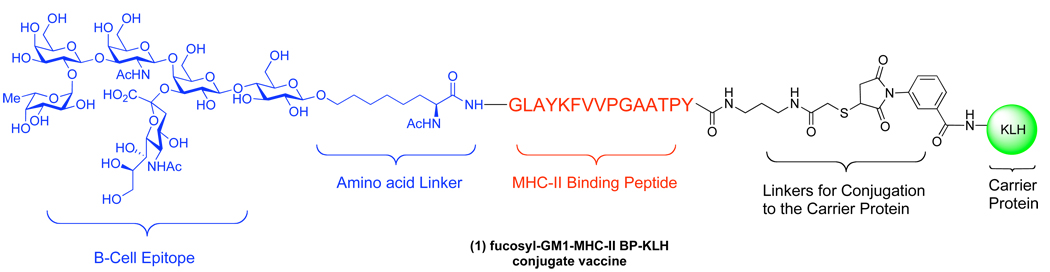

The construction of the vaccine began from the known Fuc-GM1 hexasaccharide 2, obtained through a previously disclosed sequence.7a After deprotection of the triisopropylsilyl groups with TBAF/acetic acid, and subsequent cleavage of acetates, carbonate and sialic acid methyl ester, the resultant product was debenzylated under Birch conditions.12 The obtained acid 3, was exhaustively peracetylated to provide a corresponding lactone that was subsequently opened with methanol and DMAP. Acylation afforded 4 (56%, 7 steps). Glycoside 4 was treated with Fmoc-L-allylglycine benzyl ester (A) and Hoveyda-Grubbs catalyst (B) under the previously developed conditions and the resultant olefin cross-metathesis product was subjected to catalytic hydrogenation.10ab,13 The side-chain olefinic linkage was reduced with concomitant selective removal of the benzyl protecting group in the presence of Fmoc-protected amine to afford the cassette 5 (49%, 2 steps) ready for coupling (Scheme 1).

Scheme 1a.

aKey: (a) TBAF, AcOH, THF; (b) NaOMe, MeOH; (c) NaOH, THF; (d) Na, NH3, THF; (e) Ac2O, DMAP, Py; (f) DMAP, NaOMe; (g) Ac2O, DMAP, Py; 56% (7 steps); (h) A, B, CH2Cl2, rt; (i) H2, Pt/C, MeOH-H2O; 49%, 2 steps.

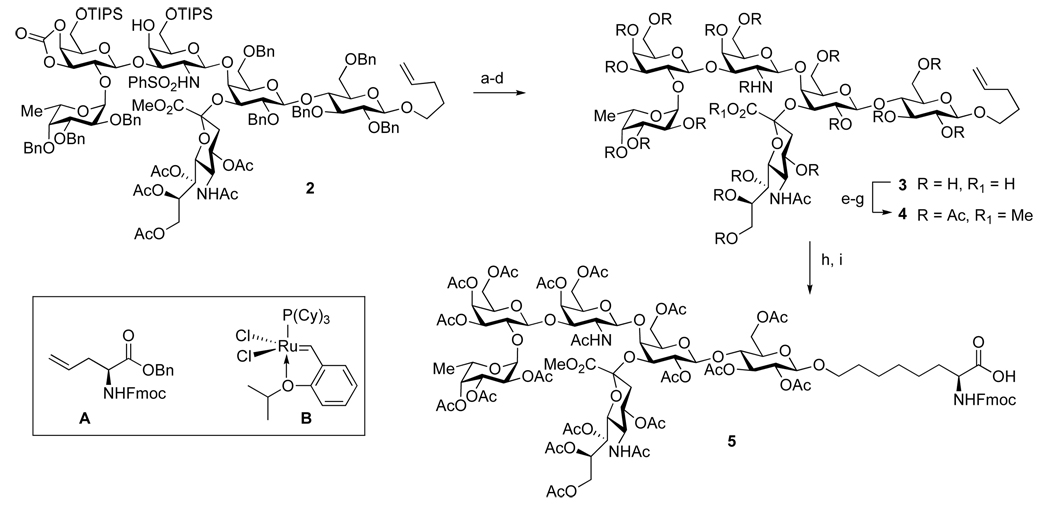

The synthesis of peptide 7 was accomplished by standard Fmoc solid phase peptide synthesis (SPPS), starting from the protected tyrosine, 6, preloaded on TGT-Nova Syn resin. Peptide 7 was obtained in 95% yield after cleavage from the resin, in more than 95% purity, as judged by LC/MS and 1H NMR analysis. The elaboration of 7 to peptide 8 was executed by first conjugating 7 to the linker C14 using the standard EDCI/HOBt protocol.10c The Fmoc protecting group was next removed by treatment with piperidine, providing fragment 8 in 71% yield (2 steps). The attachment of 8 to carbohydrate epitope 5 proceeded in 81% yield, thereby providing glycopeptide 9 (see Scheme 2).

Scheme 2a.

aKey: (a) SPPS, then AcOH:CF3CH2OH:CH2Cl2 (1:1:8), 95%; (b) C, EDC, HOOBt, CHCl3:CF3CH2OH (3:1); (c) Piperidine, DMF; 71%, 2 steps; (d) 5, EDCI, HOBt, DMF: CH2Cl2 (1:1), 81%.

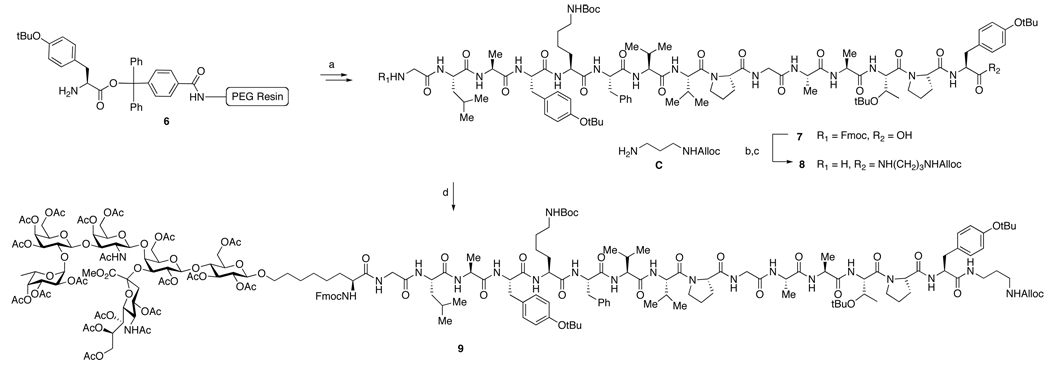

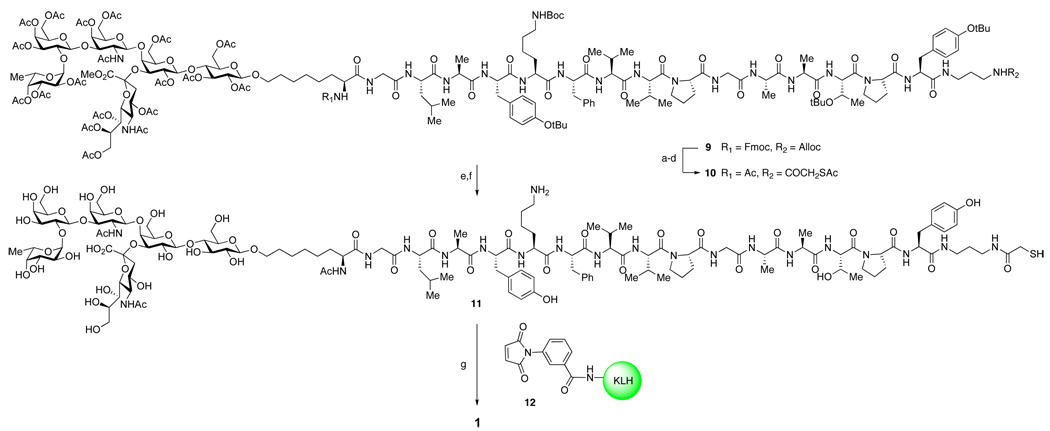

Compound 9 was treated sequentially with piperidine/DMF and Ac2O/Py. The allylcarboxy protecting group was exchanged to the acetate-protected 2-sulfhydrylacetate linker by reduction with Pd(PPh3)4/PhSiH3 followed by acylation with SAMA-OPbf.10c Finally, three tert-butyl and one tert-butylcarboxy groups were removed by treating 10 with TFA/PhOH/H2O/TIPS providing the corresponding deprotected product in 71% yield (5 steps) from 9 following purification by HPLC. This compound was treated with a degassed solution of NaOH in MeOH/H2O (pH = 10.5), providing the desired deprotected product 11 in 19% yield following HPLC purification.15 Minor amounts of a dehydration side product (ca. 5% yield after HPLC) were also isolated.

Next, the conjugation of construct 11 to maleimide activated KLH 12 was examined (Scheme 3). Thus, 11 was pretreated with TCEP gel for 2h and then treated with freshly prepared 12 at pH = 7.2. The efficiency of the coupling was estimated by a combination of Bradford protein assay16 and neuraminic acid determination according to Svennerholm17 to be 210 epitopes per molecule of KLH (MW = 8 MDa).

Scheme 3.

aKey: (a) Piperidine, DMF; (b) Ac2O, Py; (c) Pd(PPh3)4, PhSiH3, CH2Cl2/DMF (1:1); (d) SAMA-OPbf, TEA, Py; (e) TFA/PhOH/H2O/TIPS, (71% from 9, 5 steps); (f) NaOH in MeOH/H2O, pH = 10.5, 19%; (g) i) TCEP gel; ii) PBS buffer, pH = 7.2, 0.9 M NaCl, 0.1 M EDTA.

Conclusion

In summary, a new kind of Fucosyl GM1 epitope-based vaccine has been efficiently prepared, through the coupling of the Fucosyl GM1 cassette with a promiscuous HLA-DR binding peptide. The resultant construct was further functionalized and deprotected to provide the glycopeptide, which was next conjugated to the carrier protein (KLH). The results of immunological evaluations of the vaccine will be forthcoming. This synthetic accomplishment is in keeping with an important theme in our laboratory, to the effect that there have emerged exciting opportunities for chemistry in the fashioning of structure types previously perceived as strictly “biologics”. It goes without saying that chemistry offers vast opportunities (and challenges) in de novo design, thus offering far greater flexibility than is available though strictly biology-driven routes to biologics.

Experimental Section

Synthesis of acetylated glycoside 4 (steps (a)-(c), Scheme 1)

To a solution of the hexasaccharide 27a (335 mg, 0.131 mmol) in THF (6.0 mL) was added glacial AcOH (0.12 mL) and TBAF (1.0 M in THF, 1.31 mL). The reaction mixture was stirred at rt for 2 days, poured into ice-water (25 mL), and extracted with EtOAc. The organic extracts were dried over MgSO4 and concentrated. The resulting triol was dissolved in anhydrous MeOH (6 mL) and sodium methoxide was added (25% solution in MeOH, 0.6 mL). The contents were stirred at rt for 3 days, and then water (6.0 mL) and THF (6.0 mL) were added. Stirring at rt for an additional 2 days was followed by neutralization with Dowex-H+, filtration with MeOH washing, and concentration. The crude material was allowed to dry under high vacuum for 1 day.

Synthesis of acetylated glycoside 4 (steps (d)-(g), Scheme 1)

To a blue solution of sodium (160 mg) in liquid NH3 (50 mL) was added a solution of the white solid from above in THF (5.0 mL), and the resulting mixture was stirred at −78 °C for 2 h. The reaction was quenched by the addition of anhydrous MeOH (20 mL), warmed to rt, and concentrated with a stream of dry argon. The residue was diluted with MeOH (70 mL) and treated with Dowex 50wX8-400 until pH was nearly 5–6. The mixture was filtered and concentrated to provide a solid. This solid was dissolved in a mixture of pyridine (12.0 mL) and Ac2O (6.0 mL) at rt. To the solution of tetrasaccharide was added DMAP (10 mg) and the mixture was stirred for an additional 2 days. The reaction mixture was cooled to 0 °C and treated with MeOH (24 mL). To this solution was added DMAP (15 mg) and the resultant mixture was stirred at rt for an additional 4 days. The reaction mixture was then concentrated and co-evaporated with toluene (4×100 mL). The residue was dissolved in pyridine (5.0 mL) and Ac2O (1.0 mL) at rt. The mixture was stirred for 1 day and then concentrated. The resultant oil was dissolved in MeOAc (10.0 mL) and MeI (0.2 mL). To the solution cesium carbonate (33 mg) was added, and the mixture was stirred for 1 h, and then diluted with methyl acetate (250 mL). The organic phase was washed with brine/NH4Cl(sat) (1:1, 100 mL), NaHCO3(sat.) (100 mL), brine (100 mL), and dried over MgSO4. Concentration followed by flash chromatography (silica, 5% methanol/dichloromethane) provided the acetylated glycoside 4 (142 mg, 56% from 2). [α]24D = −40.4 (c 1.00, CHCl3); IR (film CHCl3) 2969, 1746, 1689, 1530, 1371, 1231, 1131, 1058 cm1; 1H NMR (CDCl3, 600 MHz) δ 7.22 (d, J = 5.9 Hz, 1H), 5.76-5.69 (m, 1H), 5.61-5.58 (m, 1H), 5.43 (d, J = 3.5 Hz, 1H), 5.34-5.30 (m, 4H), 5.21-5.10 (m, 5H), 5.00 (d, J = 8.2 Hz, 1H), 4.97-4.89 (m, 4H), 4.82 (t, J = 8.8 Hz, 1H), 4.74 (td, J = 11.4, 3.6 Hz, 1H), 4.65 (d, J = 7.7 Hz, 1H), 4.52 (d, J = 7.8 Hz, 1H), 4.49-4.45 (m, 1H), 4.39-4.33 (m, 3H), 4.21-4.17 (m, 2H), 4.14-4.02 (m, 6H), 4.00-3.89 (m, 3H), 3.85-3.70 (m, 9H), 3.58-3.56 (m, 2H), 3.45-3.40 (m, 2H), 3.01 (dt, J = 12.7, 5.6 Hz, 1H), 2.81 (dd, J = 12.9, 4.1 Hz, 1H), 2.19 (s, 3H), 2.12 (s, 3H), 2.10 (s, 3H), 2.09 (s, 3H), 2.03-1.97 (m, 33H), 1.95 (s, 3H), 1.94 (s, 3H), 1.93 (s, 3H), 1.80 (s, 3H), 1.70 (t, J = 12.8 Hz, 1H), 1.64-1.57 (m, 2H), 1.22-1.20 (m, 2H), 1.11 (d, J = 6.4 Hz, 3H); 13C NMR (CDCl3, 150 MHz) δ 173.6, 171.0, 170.9, 170.9, 170.4, 170.4, 170.4, 170.3, 170.3, 170.3, 170.3, 170.3, 170.2, 170.2, 170.0, 169.7, 169.6, 169.5, 169.4, 169.2, 168.2, 137.7, 114.9, 102.0, 100.4, 98.7, 97.3, 94.4, 75.6, 73.7, 73.5, 73.3, 73.2, 72.8, 72.5, 72.0, 71.8, 71.7, 71.3, 70.9, 70.3, 70.2, 69.8, 69.4, 69.2, 69.1, 68.7, 68.1, 67.7, 67.4, 67.2, 67.0, 65.0, 63.3, 62.4, 62.4, 62.4, 60.6, 60.3, 55.5, 53.7, 52.5, 49.3, 37.1, 31.6, 29.7, 29.2, 28.5, 23.5, 23.0, 21.3, 20.9, 20.8, 20.7, 20.7, 20.7, 20.7, 20.6, 20.6, 20.5, 20.4, 20.4, 15.9, 14.1; ESI/MS: Exact mass calcd for C83H116N2O50 [M+Na]+: 1963.7; [M+Cl]−: 1975.6. Found: 1963.9, 1977.0.

Synthesis of amino acid 5 (step (h), Scheme 1)

The first generation Hoveyda-Grubbs catalyst (B, 9.6 mg, 0.016 mmol) was added to a solution of acetylated glycoside 4 (124 mg, 0.064 mmol) and allylglycine A (273 mg, 0.640 mmol) in CH2Cl2 (1 mL) at rt. The reaction mixture was stirred for 12 h and exposed to air for 3 h. The mixture was concentrated and the resultant residue was purified by flash chromatography (100% ethyl acetate) to provide the coupled product.

Synthesis of amino acid 5 (step (i), Scheme 1)

Pt/C (10% w/w, 15 mg) was added to a solution of the metathesis adduct from above in MeOH (3 mL) and H2O (0.2 mL) and the hydrogen atmosphere was established. The reaction mixture was stirred for 4 days at rt, filtered through a short pad of silicagel, and concentrated. The residue was purified by flash chromatography (10% MeOH in CH2Cl2) to give the amino acid 5 (70 mg, 49% over two steps). [α]24 D =-30.2° (c 1.00, CHCl3); IR (film CHCl3) 3470, 2928, 2854, 1746, 1429, 1370, 1232, 1057 cm−1; 1H NMR (CDCl3, 600 MHz) δ 8.16 (d, 1H, J = 6.4 Hz), 7.79 (d, 2H, J = 7.4 Hz), 7.67-7.65 (m, 2H), 7.39-7.37 (m, 2H), 7.30 (br.s, 2H), 5.62-5.60 (m, 1H), 5.48- 5.47 (m, 2H), 5.39 (d, 1H, J = 10 Hz), 5.25-5.23 (m, 3H), 5.14-5.05 (m, 3H), 4.98-4.78 (m, 6H), 4.68 (d, 1H, J = 7.5 Hz), 4.64 (d, 1H, J = 7.8 Hz), 4.54-4.53 (m, 2H), 4.47 (d, 1H, J = 11.2 Hz), 4.40-4.32 (m, 3H), 4.29-4.10 (m, 7H), 4.07-3.76 (m, 15H), 3.72-3.65 (m, 3H), 3.57 (s, 1H), 3.48-3.44 (m, 1H), 3.25-3.17 (m, 1H), 2.86 (dd, 1H, J = 3.9 and 12.5 Hz), 2.27 (s, 3H), 2.16 (s, 3H), 2.14 (s, 3H), 2.12 (s, 6H), 2.11 (s, 3H), 2.08 (s, 3H), 2.06 (s, 6H), 2.03 (s, 6H), 2.02 (s, 6H), 2.00 (s, 3H), 1.98 (s, 6H), 1.95 (s, 6H), 1.82 (s, 3H), 1.61 (t, 2H, 12.5 Hz), 1.52 (br.s, 2H), 1.37-1.25 (m, 7H), 1.18 (d, 3H, J = 6.2 Hz); 13C NMR (CDCl3, 150 MHz) δ 180.2, 175.4, 173.6, 172.4, 172.4, 172.4, 172.3, 172.2, 172.2, 172.1, 171.8, 171.7, 171.7, 171.5, 171.4, 171.1, 169.7, 158.2, 145.5, 145.4, 142.6, 128.8, 128.2, 126.3, 126.3, 121.0, 102.6, 102.3, 101.7, 101.1, 98.7, 97.3, 77.6, 75.2, 75.0, 74.8, 74.4, 74.3, 74.2, 73.8, 73.3, 73.2, 73.0, 72.7, 72.4, 72.2, 71.9, 71.3, 71.0, 70.6, 69.7, 69.2, 68.9, 68.4, 67.7, 66.2, 65.0, 63.8, 63.6, 63.5, 62.6, 57.6, 55.8, 53.8, 50.0, 49.6, 48.6, 38.7, 34.1, 30.6, 30.2, 27.0, 26.8, 24.2, 22.8, 21.7, 21.7, 21.3, 21.0, 21.0, 20.9, 20.9, 20.8, 20.8, 20.8, 20.7, 20.6, 20.6, 20.6, 16.3; ESI/MS: Exact mass calcd for C101H133N3O54 [M+Na]+: 2275.8; [M+2Na]2+: 1149.4. Found: 2275.5, 1149.3.

Synthesis of peptide 7 (step (a), Scheme 2)

NovaSyn TGT resin (purchased from NovaBiochem) was chlorinated, then esterified with Fmoc-Tyr(tBu)-OH for 3 hours, and then immediately Fmoc-deprotected according to the literature procedure.17 0.21 g (ca. 0.05 mmol) of this resin was subjected to continuous flow automated peptide synthesis. For coupling steps, resin was treated with a 4-fold excess of HATU and Fmoc amino acids in 1M DIEA/DMF, and for deblocking, a solution of 2% piperidine / 2% DBU in DMF was used. The amino acids used were, in order of synthesis: Fmoc-Pro-OH, Fmoc-Thr(tBu)-OH, Fmoc-Ala-OH, Fmoc-Ala-OH, Fmoc-Gly-OH, Fmoc-Pro-OH, Fmoc-Val-OH, Fmoc-Val-OH, Fmoc-Phe-OH, Fmoc-Lys(Boc)-OH, Fmoc-Tyr(tBu)-OH, Fmoc-Ala-OH, Fmoc-Leu-OH, Fmoc-Gly-OH. The resin was then transferred to a manual peptide synthesis vessel and treated with a cleavage solution of 5 mL of 1:1:8 trifluoroethanol/acetic acid/dichloromethane for 1.5 h. The beads were filtered, rinsed with another 10 mL of cleavage solution, filtered again, and then treated for another 1 h with 10 mL of the cleavage solution. This process was repeated for a total of three 2-hour cleavage cycles, and the combined organic phase was concentrated in vacuo to afford 97 mg of peptide after cleavage (ca. 95% yield). This material was found to be >95% pure as judged by reverse-phase LC/ESI (C4 column) MS and 1H NMR analysis: 1H-NMR (500MHz, DMF-d7)19 δ 8.44 (t, J = 5.5Hz, NH), 8.34 (br, NH), 8.27 (br, NH), 8.13 (t, J = 8.6 Hz, NH), 8.00 (m, NH), 7.94 (d, J = 7.6 Hz, 2H), 7.89 (d, J = 6.5 Hz, NH), 7.86 (d, J = 7.1 Hz, NH), 7.79 (br, NH), 7.73 (t, J = 8.4 Hz, 2H, NH), 7.62 (d, J = 7.9 Hz, NH), 7.60 (d, J = 7.4 Hz, NH), 7.55 (d, J = 6.0 Hz, NH), 7.45 (t, J = 7.4 Hz, 2H), 7.34 (t, J = 7.6 Hz, 2H), 7.31 (d, J = 7.6 Hz, 2H), 7.25 (m, 2H), 7.22-7.17 (m, 5H), 6.93 (t, J = 8.3 Hz, 2H), 6.88 (d, J = 8.2 Hz, 2H), 6.63 (m, NH), 5.12 (t, J = 4.7 Hz, NH), 4.71-4.67 (m, 2H), 4.66-4.59 (m, 1H), 4.54-4.47 (m, 3H), 4.46-4.41 (m, 2H), 4.41-4.37 (m, 2H), 4.30 (m, 2H), 4.29-4.23 (m, 2H), 4.00-3.85 (m, 4H), 3,77 (d, J = 16.7 Hz, 1H), 3.70 (m, 2H), 3.52 (br t, J = 8.8 Hz, 2H), 3.40 (q, J = 8.5 Hz, 1H), 3.23 (d, J = 10.6 Hz, 1H), 3.19-3.08 (m, 3H), 3.08-2.96 (m, 3H), 2.96 (s, 2H), 2.79 (s, 2H), 2.18-2.05 (m, 4H), 2.02-1.93 (m, 1H), 1.92-1.83 (m, 3H), 1.77-1.72 (m, 1H), 1.71-1.66 (m, 2H), 1.63 (m, 2H), 1.54 (m, 1H), 1.40 (s, 9H), 1.42-1.33 (m, 6H), 1.31 (s, 9H), 1.30 (s, 9H), 1.26 (s, 9H), 1.3-1.23 (m, 2H), 1.23 (s, 6H), 1.19 (s, 3H), 1.12 (d, J = 6.2 Hz, 6H), 1.05 (d, J = 6.2 Hz, 3H), 0.99 (d, J = 6.8 Hz, 3H), 0.97 (d, J = 6.6 Hz, 3H), 0.92 (d, J = 6.2 Hz, 6H), 0.90 (d, J = 5.2 Hz, 6H); LC/MS (ESI): Rf = 16.6 min (C4 column, 50–95% MeCN in H2O, 30 m); Exact mass calcd for C108H154N16O23 [M+H]+: 2045.2; [M+Na]+: 2067.1; [M+2H]2+ : 1023.1. Found: 2044.7, 2066.6, 1022.9.

Synthesis of compound 8 (step (b), Scheme 2)

To compound 7 (30 mg, 0.0147 mmol), linker C (5.6 mg, 0.0352 mmol), HOOBt (5.7 mg, 0.0352 mmol) in 1:3 trifluoroethanol/CHCl3, EDC (6.2 mL, 0.0352 µmol) was added. After 2h, LC/MS indicated completion of the reaction. The mixture was concentrated under reduced pressure and purified via flash chromatography (silica, 2% → 10% MeOH/ CH2Cl2) and the appropriate fractions were concentrated (Rf0.5, 10% MeOH/ CH2Cl2) to afford 30 mg of product in 94% yield. This material was found to be >95% pure as judged by reverse-phase LC/ESI (C4 column). MS: Exact mass calcd for C115H166N18O24 [M+H : 2185.2; [M+Na]+ : 2207.2; [M+2H]2+ : 1093.1. Found: 2184.8, 2206.8, 1093.2.

Synthesis of compound 8 (step (c), Scheme 2)

The product from above (26.8 mg, 0.0123 mmol) was dissolved in 1.0 mL of DMF, and to this solution piperidine (0.25 mL) was added. After 1h, LC/MS analysis indicated the completion of the reaction. The mixture was concentrated under reduced pressure and purified via flash chromatography (silica, 10% → 12% MeOH/ CH2Cl2) and the appropriate fractions were concentrated (Rf0.15, 10% MeOH/ CH2Cl2) to afford 18 mg of product 8 in 75% yield. This material was found to be >95% pure as judged by reverse-phase LC/ESI analysis: Rf = 15.7 (C4 column, 40–85% MeCN in H2O, 30 min); Exact mass calcd for C100H156N18O22 [M+H]+ : 1963.2; [M+Na]+ : 1985.2; [M+2H]+ : 982.1. Found: 1962.9, 1984.9, 982.1.

Synthesis of compound 9 (step (d), Scheme 2)

Amine 8 (9.5 mg, 0.048 mmol) was combined with acid 5 (6.6 mg, 0.029 mmol), EDCI (1.8 mg, 0.093 mmol), and HOBt (1.3 mg, 0.0093 mmol) and this mixture was dissolved in 0.30 mL of 1:1 DMF/ CH2Cl2. After 3 h of stirring under argon, the solvents were removed under high vacuum, and the resultant oil was purified via flash chromatography (silica, 5% → 10% MeOH/ CH2Cl2) and the appropriate fractions concentrated (Rf0.5, 10% MeOH/ CH2Cl2) to afford 10 mg of product 9 in 81% yield. This material was found to be >90% pure as judged by reverse-phase LC/ESI MS (C4 column) and 1H NMR analysis: 1H-NMR (500MHz, CD3OD)19 Selected peaks: δ 8.12 (d, 1H), 7.95 (m, 1H), 7.80 (d, J = 9.1 Hz, 2H), 7.74 (d, J = 7.6 Hz, 2H), 7.72 (m, 1H), 7.67 (d, J = 8.2 Hz, 2H), 7.66 (m, 1H), 7.62 (d, J = 7.4 Hz, 1H), 7.57 (d, J = 7.5 Hz, 1H), 7.56 (m, 1H), 7.45 (t, J = 7.2 Hz, 1H), 7.39 (t, J = 7.7 Hz, 1H), 7.33 (t, J = 7.4 Hz, 1H), 7.24 (dt, J = 7.3, 4.1 Hz, 1H), 7.18 (d, J = 7.3 Hz, 1H), 7.14 (t, J = 7.6 Hz, 1H), 7.08 (d, J = 5.5 Hz, 4H), 6.97 (m, NH), 6.93 (m, NH), 6.85 (d, J = 7.9 Hz, 2H), 6.80 (d, J = 8.0 Hz, 4H), 5.85 (ddd, J = 16.2, 10.5, 5.5 Hz, 1H), 5.55 (dt, J = 9.5, 4.1 Hz, 1H), 5.42 (dd, J = 9.5, 2.8 Hz, 2H), 5.32 (dd, J = 9.6, 2.1 Hz, 1H), 5.19 (m, 4H), 5.07 (m, 4H), 4.97 (m, 2H), 4.75 (m, 1H), 4.60 (d, J = 7.5 Hz, 3H), 4.49 (dt, J = 16.3, 8.1 Hz, 1H), 4.47-4.37 (m, 8H), 4.33-4.24 (m, 8H), 4.20-4.08 (m, 7H), 4.06 (dd, J = 11.2, 6.0 Hz, 2H), 4.05 (dt, J = 9.1, 4.0 Hz, 2H), 3.95 (m, 2H), 3.94-3.81 (m, 8H), 3.83 (s, 3H), 3.80 (m, 3H), 3.75 (m, 1H), 3.71 (m, 1H), 3.68 (m, 1H), 3.64 (m, 3H), 3,58 (m, 1H), 3.50 (s, 1H), 3,42 (m, 1H), 3.15 (dd, J = 13.3, 6.2 Hz, 2H), 3.12 (m, 1H), 3.11-3.03 (m, 4H), 2.97 (t, J = 6.2 Hz, 2H), 2.93-2.83 (m, 4H), 2.80 (dd, J = 12.7, 4.4 Hz, 1H), 2.21 (s, 3H), 2.20-2.13 (m, 2H), 2.11 (s, 3H), 2.09 (s, 3H), 2.06 (s, 9H), 2.01 (s, 3H), 2.00 (s, 3H), 1.99 (s, 3H), 1.97 (s, 6H), 1.96 (s, 6H), 1.94 (s, 3H), 1.92 (s, 3H), 1.91 (s, 3H), 1.89 (s, 3H), 1.89 (s, 3H), 2.13-1.77 (m, 13H), 1.75 (s, 3H), 1.58-1.48 (m, 12H), 1.36 (s, 3H), 1.36 (s, 3H), 1.34-1.24 (m, 8H), 1.23 (s, 18H), 1.21 (s, 9H), 1.15 (s, 6H), 1.15-1.09 (m, 6H), 1.05 (d, J = 6.2 Hz, 3H), 0.91 (d, J = 6.7 Hz, 3H), 0.89 (d, J = 8.6 Hz, 6H), 0.87 (d, J = 7.0 Hz, 6H), 0.85 (d, J = 6.6 Hz, 3H), 0.75 (m, 3H): Rf = 22.5 (C4 column, 50–95% MeCN in H2O, 30 min); Exact mass calcd for C201H287N21O75 [M+2H]2+: 2099.5, [M+2Na]2+: 2121.5, [M+3H]3+: 1400.0. Found: 2099.4, 2121.6, 1400.2.

Synthesis of compound 10 (step (a), Scheme 3)

Compound 9 (10.5 mg, 0.00250 mmol) was dissolved in 1.0 mL of DMF, and piperidine (0.25 mL) was added. After 1h, LC/MS analysis indicated the completion of the reaction: Rf = 15.3 (C4 column, 50–95% MeCN in H2O, 30 min); Exact mass calcd for C186H277N21O71 [M+2H]2+: 1988.4; [M+Na+H]2+: 1999.4; [M+2Na]2+: 2010.4, [M+3Na]3+: 1326.0. Found: 1988.4, 1999.37, 2010.45, 1326.1.

Synthesis of compound 10 (step (b), Scheme 3)

The mixture from above was concentrated under reduced pressure, re-dissolved in pyridine (1.0 mL) and treated with acetic anhydride (0.5 mL). After 4 h, the reaction mixture was concentrated and purified via flash chromatography (silica, 10% MeOH/CH2Cl2) and the appropriate fractions were concentrated (Rf0.2, 10% MeOH/CH2Cl2) to afford 10 mg (quantitative yield) of product 9a. This material was found to be >85% pure as judged by reverse-phase LC/ESI analysis: Rf = 17.8 (C4 column, 50–95% MeCN in H2O, 30 min); Exact mass calcd for C188H279N21O74 [M+2H]2+: 2009.5; [M+2Na]2+: 2031.4; [M+3H]3+: 1340.0. Found: 2009.4, 2032.0, 1340.0.

Synthesis of compound 10 (step (c), Scheme 3)

A solution of Pd(PPh3)4 (14 mg, 0.0125 mmol) and phenylsilane (46 µL, 0.373 mmol) in 3.5 mL of CH2Cl2 was prepared, and 0.35 mL of this solution was added to the solution of compound 9a (10 mg, 0.00249 mmol) in DMF (0.35 mL). After 30 min, LC/MS analysis indicated the completion of the reaction. Pyridine (0.1 mL) was added, and the resultant mixture was concentrated under vacuum to provide crude product: Rf = 16.4 (C4 column, 50–95% MeCN in H2O, 30 min); Exact mass calcd for C184H275N21O72 [M+2H]2+: 1966.9; [M+Na+H]2+: 1977.9; [M+2Na]2+: 1988.9, [M+3Na]3+: 1311.6. Found: 1967.5, 1978.6, 1989.7, 1312.6.

Synthesis of compound 10 (step (d), Scheme 3)

The residue was re-dissolved in pyridine (0.35 mL) and triethylamine (0.15 mL), and SAMAOPbf (11.2 mg, 0.0373 mmol) was added to this solution. The reaction mixture was stirred for 3 h, concentrated and purified by flash chromatography (silica, 5% → 10% MeOH/CH2Cl2) and the appropriate fractions were concentrated (Rf0.3, 10% MeOH/CH2Cl2) to afford product 10 contaminated with SAMAOPbf decomposition products (70% purity as judged by LC/MS): Rf = 16.5 (C4 column, 50–95% MeCN in H2O, 30 min); Exact mass calcd for C188H279N21O74S [M+2Na]2+ : 2026.4; [M+3Na]3+ : 1351.3. Found: 2026.0, 1350.8. This product was advanced to the next step without further purification.

Synthesis of compound 11 (step (e), Scheme 3)

Phenol (60 mg), triisopropylsilane (0.15 mL), and water (0.2 mL) were added to trifluoroacetic acid (3.0 mL). The resultant solution (1.0 mL) was added to a vial with compound 10 from above (ca. 10 mg, 0.00249 mmol). The reaction mixture was stirred for 40 min before being diluted with dichloromethane (3 mL), concentrated, and purified by reverse-phase HPLC: Rf = 18.7 (C4 column, 35–75% MeCN in H2O, 30 min) to afford pure product (6.7 mg, 71% yield from 9). The product was >95% pure as judged by LC/MS: Exact mass calcd for C171H247N21O72S [M+2H]2+ : 1891.3; [M+3H]3+ : 1261.2. Found: 1891.4, 1261.5.

Synthesis of compound 11 (step (f), Scheme 3)

The product from above was re-dissolved in degassed 1:1 MeOH/water (10 mL), and degassed 0.03 M NaOH (0.75 mL) was added. The reaction mixture was stirred for 40 h before being neutralized with MAC-3 Dowex resin to pH = 5, filtered and purified by HPLC: Rf = 14.5 (C18 column, 10–85% MeCN in H2O, 30 min) to afford 11 (1.0 mg, 19% yield from 11a, 13% from 9). The product was found to be >95% pure as judged by LC/MS and 1H NMR: 1H-NMR (500MHz, D2O)19 δ 7.46 (d, J = 9.7 Hz, 1H), 7.38 (d, J = 7.4 Hz, 1H), 7.37 (d, J = 7.6 Hz, 2H), 7.32 (t, J = 7.4 Hz, 2H), 7.26 (d, J = 7.0 Hz, 2H), 7.07 (d, J = 8.5 Hz, 2H), 6.87 (d, J = 8.6 Hz, 2H), 6.81 (d, J = 7.4 Hz, 2H), 5.28 (s, 1H), 5.26 (d, J = 3.9 Hz, 1H), 4.70 (dd, J = 5.2, 1.5 Hz, 2H), 4.66 (d, J = 6.9 Hz, 2H), 4.62 (d, J = 8.0 Hz, 1H), 4.60 (d, J = 5.5 Hz, 2H), 4.47 (t, J = 7.5 Hz, 2H), 4.16 (t, J = 6.1 Hz, 2H), 4.10 (at, J = 5.5 Hz, 4H), 4.07 (d, J = 8.5 Hz, 2H), 3,48 (m, 1H), 3.42 (dd, J = 10.0, 2.0 Hz, 1H), 3.28 (t, J = 8.9 Hz, 1H), 3.20 (dt, J = 13.1, 6.4 Hz, 1H), 3.12 (dd, J = 13.5, 6.8 Hz, 1H), 2.58 (dd, J = 12.1, 4.4 Hz, 1H), 2.31 (m, 1H), 2.24 (s, 3H), 2.05 (s, 3H), 2.04 (s, 3H), 2.01 (s, 3H), 1.87 (t, J = 13.2 Hz, 1H), 1.81 (dd, J = 6.5 Hz, 1H), 1.42 (d, J = 8.5 Hz, 3H), 1.26 (d, J = 6.1 Hz, 3H), 1.24 (d, J = 6.6 Hz, 3H), 1.01 (d, J = 6.8 Hz, 3H), 0.99 (d, J = 6.8 Hz, 3H), 0.94 (d, J = 6.3 Hz, 3H), 0.91 (d, J = 6.7 Hz, 3H), 0.89 (d, J = 6.3 Hz, 3H), 0.87 (d, J = 6.7 Hz, 3H). Exact mass calcd for sodium salt C134H208N21NaO54S [M+2H]2+: 1516.7; [M+3H]3+: 1011.5; [M+CF3CO2−]2−: 1572.2. Found: 1517.7, 1012.3, 1572.9.

Preparation of conjugate 1 (step (g), Scheme 3)

Solution of sulfo-SMCC (10 mg/mL, 0.10 mL) in 0.1 M sodium phosphate, 0.9 M NaCl (pH = 7.2) was added to the reconstituted with water solution of KLH (Aldrich, H7017, 10 mg/mL, 1.0 mL). The resultant solution was stirred for 1h and then purified over G-25 sephadex column using 0.1 M sodium phosphate, 0.9 M NaCl, 0.1 M EDTA, pH =7.2 for elution. The fractions containing KLH were collected and combined giving the total volume of 3.0 mL. Compound 11 (2 mg, 0.665 µmol) in 0.2 mL of the pH = 7.2 buffer was treated with TCEP gel for 2h, filtered, combined with the solution of KLH (0.6 mL), and reacted under argon for 2h. The resultant solution was purified by repetitive centrifugation over molecular filter (30 kDa cut off) resulting in ca. 1 mL of the final solution of the vaccine construct. The degree of the epitope incorporation was estimated to be 210 epitopes per molecule of KLH using Bradford protein assay with KLH as a standard and Svennerholm sialic acid assay to determine the carbohydrate concentration.16,17

Supplementary Material

Acknowledgment

This work was supported by the National Institutes of Health (Grant CA28824 to SJD). PN thanks the National Institutes of Health for a Ruth L. Kirschstein postdoctoral fellowship (CA125934-02), WHK is grateful for a Korea Research Foundation Grant funded by Korean government (KRF-2007-357-c00060), and DL is thankful for support provided by the Terri Brodeur Breast Cancer Foundation.

Footnotes

Supporting Information Available. 1H, 13C NMR spectra for compounds 4, and 5, LC/MS data for compounds 7, 8a, 8, 9, 10b, 10, 11a, 11 and selected intermediates, 1H NMR spectra for compounds 7, 8a, 9, 10b, 11a, 11. This material is available free of charge via the internet at http://pubs.acs.org.

References

- 1.Khleif SN. Tumor Immunology and Cancer Vaccines. New York: Springer-Verlag; 2005. [Google Scholar]

- 2.For an overview of our synthetic carbohydrate-based vaccine program see: Danishefsky SJ, Allen JR. Angew. Chem. Int. Ed. Engl. 2000;39:836–863. doi: 10.1002/(sici)1521-3773(20000303)39:5<836::aid-anie836>3.0.co;2-i.Keding SJ, Danishefsky SJ. Proc. Natl. Acad. Sci. USA. 2004;101:11937–11942. doi: 10.1073/pnas.0401894101..

- 3.Zegers ND, Boersma WJA, Claassen E. Immunological Recognition of Peptides in Medicine and Biology. Boca Raton: CRC Press; 1995. 1995. p. 105. [Google Scholar]

- 4.(a) Rudensky AY, Preston-Hurlbort P, Hong S-Ch, Barlow A, Janeway CA., Jr Nature. 1991;353:622–627. [PubMed] [Google Scholar]; (b) Bona CA, Casares S, Brumeanu TD. Immunology Today. 1998;19:126–133. doi: 10.1016/s0167-5699(97)01218-8. [DOI] [PubMed] [Google Scholar]; (c) Musselli C, Livingston PO, Ragupathi G. J. Cancer Res. Clin. Oncol. 2001;127:20–26. doi: 10.1007/BF01470995. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.(a) Dziadek S, Hobel A, Shmitt E, Kunz H. Angew. Chem. Int. Ed. 2005;44:7630–7635. doi: 10.1002/anie.200501594. [DOI] [PubMed] [Google Scholar]; (b) Buskas T, Ingale S, Boons G-J. Angew. Chem. Int. Ed. 2005;44:5985–5988. doi: 10.1002/anie.200501818. [DOI] [PubMed] [Google Scholar]; (c) Ingale S, Wolfert MA, Gaekwad J, Buskas T, Boons G-J. Nature, Chem. Biol. 2007;3:663–667. doi: 10.1038/nchembio.2007.25. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Zhang S, Cordon-Cardo C, Zhang HS, Reuter VE, Adluri S, Hamilton WmB, Lloyd KO, Livingston PO. Int.J.Cancer. 1997;73:42–49. doi: 10.1002/(sici)1097-0215(19970926)73:1<42::aid-ijc8>3.0.co;2-1. [DOI] [PubMed] [Google Scholar]

- 7.(a) Allen JR, Danishefsky SJJAmChem. Soc. 1999;121:10875–10882. [Google Scholar]; (b) Mong TK-K, Lee HK, Duron SG, Wong C-H. Proc. Natl. Acad. Sci. USA. 2003;100:797–802. doi: 10.1073/pnas.0337590100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Dickler MN, Ragupathi G, Liu NX, Musselli C, Martino DJ, Miller VA, Kris MG, Brezicka F-T, Livingston PO, Grant SC. Clin. Cancer Res. 1999;5:2773–2779. [PubMed] [Google Scholar]

- 9.Southwood S, Sidney J, Kondo A, del Guercio MS, Appella E, Hoffman S, Kubbo RT, Chesnut RW, Grey HM, Sette AJ. Immun. 1998;160:3363–3373. [PubMed] [Google Scholar]

- 10.(a) Keding SJ, Atsushi E, Biswas K, Zatorski A, Coltart DM, Danishefsky SJ. Tetrahedron Lett. 2003;44:3413–3416. [Google Scholar]; (b) Wan Q, Cho YS, Lambert TH, Danishefsky SJ. J.Carb. Chem. 2005;24:425–440. [Google Scholar]; (c) Ragupathi G, Koide F, Livingston PO, Cho YS, Endo A, Wan Q, Spassova MK, Keding SJ, Allen J, Ouerfelli O, Wilson RM, Danishefsky SJ. J.Am. Chem. Soc. 2006;128:2715–2725. doi: 10.1021/ja057244+. [DOI] [PubMed] [Google Scholar]

- 11.For a comprehensive review on the subject refer to: Herzner H, Reipen T, Schulz M, Kunz H. Chem. Rev. 2000;100:4495–4537. doi: 10.1021/cr990308c..

- 12.Wang Z-G, Warren JD, Dudkin VY, Zhang X, Iserloh U, Visser M, Eckhardt M, Seeberger PH, Danishefsky SJ. Tetrahedron. 2006;62:4954–4978. [Google Scholar]

- 13.Biswas K, Coltart DM, Danishefsky SJ. Tetrahedron Lett. 2002;43:6107–6110. [Google Scholar]

- 14.Pittelkow M, Lewinsky R, Christensen JB. Synthesis. 2000;15:2195–2202. [Google Scholar]

- 15.Glunz PW, Hintermann S, Williams LJ, Schwarz JB, Kuduk SD, Kudryashov V, Lloyd KO, Danishefsky SJ. J. Am. Chem. Soc. 2000;122:7273–7279. [Google Scholar]

- 16.Bradford M. Anal. Biochem. 1976;72:248–254. doi: 10.1016/0003-2697(76)90527-3. [DOI] [PubMed] [Google Scholar]

- 17.Svennerholm L. Biochim. Biophys. Acta. 1957;24:604–611. doi: 10.1016/0006-3002(57)90254-8. [DOI] [PubMed] [Google Scholar]

- 18.(a) Frechet JMJ, Haque KE. Tetrahedron Lett. 1975;35:3055–3056. [Google Scholar]; (b) Novabiochem catalog. 2006/2007. [Google Scholar]

- 19.Due to the high degree of the NH exchange, the presence of the multiple peptide rotomers in the solution as well as the high overlap, there is an ambiguity associated in the tabulation and interpretation of the 1H NMR data. Please refer to the attached 1H NMR spectrum in the SI section for additional details

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.