Abstract

The Biopharmaceutics Classification System (BCS) is not only a useful tool for obtaining waivers for in-vivo bioequivalence studies but also for decision making in the discovery and early development of new drugs. Measurement of solubility and permeability in the discovery/development settings is described. These data can be utilized for the preliminary BCS classification of pipeline compounds. A decision tree is described in the prioritization of salt and polymorph screening studies prior to in vivo studies in animals. For BCS class 1 and 3 compounds, polymorphism is less likely to impact on bioavailability. The polymorph screening study may be postponed after animal studies. The BCS classification can also be used in the design of animal and human formulations. A BCS-based animal formulation development decision tree is presented. A compound is triaged based on a series of decision points into one of the five formulation strategies. Human formulation has different requirements than animal formulation. A comparison between animal and human formulation strategies is presented. In conclusion, for non-BCS 1 compounds, the right-first-time polymorph and formulation selection ensures consistent pharmacokinetic performance and avoids bridging BA/BE studies. It is in line with FDA’s initiative to reduce R&D cycle time through quality by design for pharmaceutical products.

Key words: biopharmaceutics classification, decision tree, formulation, polymorphism, salt

INTRODUCTION

The Biopharmaceutics Classification System (BCS) (1) is not only a useful tool for obtaining waivers for in vivo bioequivalence studies but also for decision making in the discovery and early development of new drugs. It is because BCS is based on a scientific framework describing the three rate limiting steps in oral absorption. The three necessary steps for a drug to be absorbed are (1) release of drug from dosage forms, (2) maintenance of dissolved state throughout gastrointestinal (GI) track, and (3) permeation of drug molecules through GI membrane into hepatic circulation. There is a fourth step, i.e. enterohepatic metabolism that influences the systemic availability as well as release of metabolites into the systemic circulation. The Biopharmaceutical Drug Disposition Classification System (BDDCS) proposed by Y. Wu and L. Z. Benet (2) completes the absorption process by including the fourth rate-limiting step of first pass effect.

The evaluation of these four steps of oral absorption is critical to the discovery of orally efficacious drugs. Consequently the determination of solubility, permeability, and metabolic stability have been fully integrated by most pharmaceutical companies as an integral part of high throughput screening (HTS) and lead optimization. These oral absorption screening tests are often referred as pharmaceutical profiling (3) and automated 96 well systems are available from commercial sources. It is argue-able that application of BCS in lead compound selection for optimal chemistry may be more important than using BCS in biostudy waiver at a later development stage. After all, the aim of pharmaceutical industry is to discover better compounds not in doing less biostudies.

The pharmaceutical scientist in early development routinely utilizes pharmaceutical profiling data to establish the preliminary BCS classification for the lead compound. Because BCS has ramification in drug approval process from FDA and other regulatory agencies, it carries some weight when used as a tool of communication. During the discovery of new drugs, classification of a compound to BCS 2, BCS 3 or BCS 4 communicates to Discovery the need to improve solubility and/or permeability for subsequent compounds. In the same vein, a BCS classification other than 1 communicates to Manufacturing that may lead to higher formulation risks during drug development. Most importantly, it warns the clinician of the potential for a large variability in exposure and a significant food effect.

With the advent of high throughput screening around 1990, a shift of lead compound biopharmaceutical characteristics into less drug-like has propelled discovery departments in pharmaceutical companies to utilize computational chemistry to optimize solubility and permeability such as Lipinski’s “rule of 5” (4). This shift is recently reflected in the different distributions among the four BCS classes between the marketed (5) and the new pipeline compounds (6,7). The new drug pipeline tends to have lower solubility resulting in an increase of BCS 2 compounds from ~30% to 50–60% and the corresponding decrease of BCS 1 compounds from ~40% to 10–20%. It is critical for the industry to continuously integrate the BCS principles into new drug discovery. Moreover, BCS classification may be utilized as the basis for polymorph/salt and formulation selections in early drug development as discussed in this paper.

The BCS based drug discovery strategy imparts quality by designing the lead compound with a set of solubility, permeability and metabolic properties. The BCS based polymorph/salt form and formulation strategies can often lead into a minimum design for higher efficiency and lower cost. It is in line with FDA’s year 2000 risk management and 2004 critical path initiatives to streamline new drug development.

MEASUREMENT OF SOLUBILITY AND PERMEABILITY IN THE DISCOVERY/DEVELOPMENT SETTINGS

Discovery of drug starts with the identification of a pharmacophore by screening library or recombinant chemical series using a biological assay such as binding to a receptor or inhibition of an enzyme. The representative hit compounds are then subject to HTS pharmaceutical profiling. The compounds with desired biological and pharmaceutical properties are then tested in vivo for proof of mechanism followed by additional lead optimization via chemical synthesis.

Solubility Determination

The HTS solubility measurement typically starts from a DMSO solution of a library compound. This stock solution is robotically added to a pH 7 phosphate buffer one microliter at a time until compound precipitation (8). The light scattering effect resulted from the precipitated material is picked up by a UV detector or directly from laser nephelometry (9). Alternatively, the DMSO-buffer suspension can be equilibrated and filtered. The filtrate is then measured by a direct UV assay. These automated solubility systems have been commercialized for HTS (10).

The use of DMSO stock solution is out of necessity since a solid sample is not always available from compound library. Precipitation from the DMSO stock solution is dependent on nucleation kinetics and therefore represents kinetic solubility. However, equilibrium solubility is required by FDA for BCS classification. The shake flask method which remains largely manual is used to measure equilibrium solubility at various pH’s. The pH solubility profile is typically not done until after the lead candidate selection. The kinetic solubilities are usually parallel but somewhat higher than the equilibrium solubilities.

Permeability Determination

The HTS permeability measurement has widely been utilized with automated 24 wells of tissue cultured human colon adenocarcinoma (Caco-2) cell system (11). In this system, a monolayer of cells is grown onto a filter support separating the drug donor (apical side) and acceptor (basolateral side) compartments. Permeability is assessed by measuring the appearance of drug in the acceptor compartment using direct UV or LC-MS assay.

While the Caco-2 cell system is an automated and established HTS method, it is not without drawbacks. For compounds transported via passive transcellular route, the Caco-2 permeability is a valid method to predict human permeability. For compounds transported via paracellular or transporter mediated process or very insoluble, the Caco-2 permeability tends to underestimate human permeability for the following three reasons: (1) over expression of p-glycoprotein (Pgp) efflux pumps, (2) reduction of the paracellular route of transport due to absence of the liquid pores, and (3) Non-specific binding of insoluble compounds onto the filter support and plastic components leading to a reduction of apparent permeability (12). As a compound moves from discovery to development, more labor intensive methods such as the in-situ rat gut perfusion method (13) is utilized to correct the false negative bias from Caco-2. This way many compounds are reclassified from low permeability (BCS 3 and 4) to high permeability (BCS 1 and 2) upon entry into development phase.

Because the Caco-2 cells take 21 days to grow into a monolayer of integrity, an alternative dog kidney (MDCK) cell line requiring only 3–7 days has gained popularity in recent years (14). The MDCK cells suffer the same drawbacks as the Caco-2 cells in generating false negative results of low permeability. The MDCK cells have the additional drawback of low expression of various efflux pumps and are not suitable for screening of chemical series with known efflux problems. Both the in-vitro Caco-2/MDCK and the in-situ rat perfusion methods are acceptable to FDA for the purpose of BCS classification.

BCS BASED SALT/POLYMORPH FORM SCREENING STRATEGY

In the past decades, pharmaceutical manufacturers have experienced disrupted supply or recalled commercial products when polymorph changes occurred in the manufacture of API or during drug product storage (15). It is because polymorphic forms differ in their crystal lattice energy that results in different solubility and therefore dissolution rates and eventually bioavailability. As a result, polymorph screening has become an important activity in most pharmaceutical companies. Unlike salt screening that is done early based on regulatory requirement to use the same salt across preclinical and clinical studies, polymorph screening is typically performed late in the development cycle. This could create a problem particularly for insoluble compounds. Late discovery of Rotonavir thermodynamic stable form with a lower solubility and oral bioavailability led to a 6 month disruption in drug supply, loss of millions of dollars in sales, and suboptimal therapy for thousands of patients. It is not unusual that polymorphism issues have delayed either toxicological or clinical programs throughout the industry. With the shortened development cycle, some companies have recognized the need to move polymorph screening into early development right next to salt screening. In this way, consistent pharmacokinetic exposure may be obtained from one study to another right from the beginning. The overarching goal is to select a thermodynamically stable, formulate-able and bioavailable polymorph/salt form right the first time prior to any animal studies.

FDA also recognized the importance of polymorphism. Upon issuance of BCS guidance in 2000, FDA immediately issued a draft polymorphism guidance highlighting the utility of BCS in determining whether a polymorph specification is required for the drug substance and/or drug product. In the final guidance issued in July 2007 (16), FDA states “For a drug whose absorption is only limited by its dissolution, large differences in the apparent solubilities of the various polymorphic forms are likely to affect BA/BE. On the other hand, for a drug whose absorption is only limited by its intestinal permeability, differences in the apparent solubilities of the various polymorphic forms are less likely to affect BA/BE. Furthermore, when the apparent solubilities of the polymorphic forms are sufficiently high and drug dissolution is rapid in relation to gastric emptying, differences in the solubilities of the polymorphic forms are unlikely to affect BA/BE.” In other words, FDA is saying that polymorphism is not critical for BCS class 1 and 3 compounds but is for BCS class 2 and 4 compounds. The FDA guidance has applied BCS nicely in the establishment of polymorph specification.

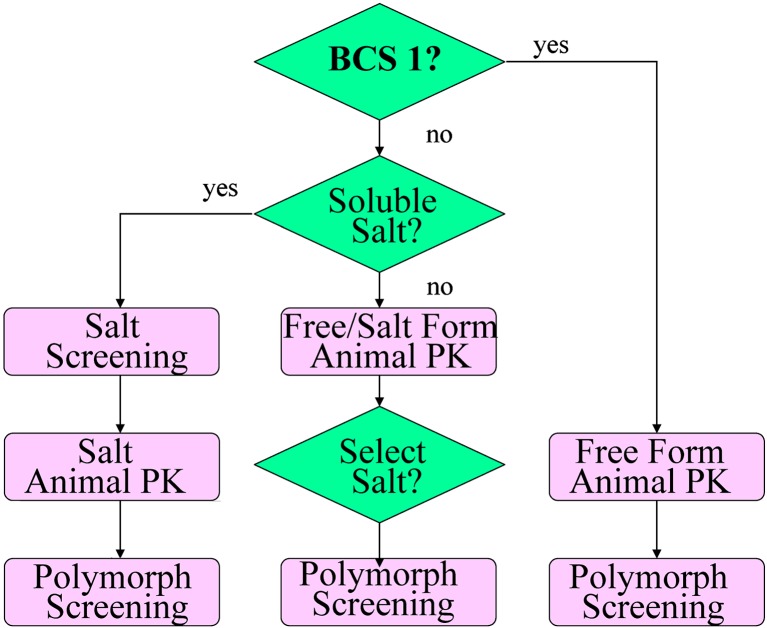

Although polymorph/salt screening should ideally be performed to select the optimum solid form upon selection of the lead compound prior to animal pharmacokinetic (PK) studies, these screening studies can be costly and time consuming. Since preliminary BCS classification is available through HTS pharmaceutical profiling, BCS can be used to rationalize the timing of these studies. A decision tree is presented in Scheme 1 as an efficient way to prioritize salt and polymorph screening studies prior to animal work. For BCS 1 compounds, polymorphism or salt form is unlikely to impact on bioavailability and can be dealt with post animal studies. A salt form may still be of value if the physical properties or stability is improved for a BCS 1 compound. A typical scenario is to convert an oily free base to a free flowing powdered salt. On the other hand, for non-BCS 1 compound, the use of salt to increase solubility/bioavailability should be considered early. In Scheme 1, “Soluble Salt” is defined as a salt form that enables the human dose soluble in 250 ml water. Should a soluble salt be discovered that provides improved bioavailability, animal PK studies may start prior to polymorph screening. Should the salt be still not soluble, the value of the salt should be gauged in consideration of the additional cost in the salt conversion step.

Scheme 1.

BCS based polymorph/salt form decision tree

The dose volume of 250 ml is used herein consistent with BCS high solubility definition. However, for a highly permeable compound, a dose volume higher than 250 ml may still provide good absorption. It is especially true for compounds easily solublized by gastrointestinal surfactants. A dose volume as high as 5,000 ml has previously been used as the breakpoint for selection of a solubilized dosage form for BCS class 2 compounds (6).

In conclusion, polymorph screening should be done prior to animal PK studies for non-BCS 1 compound irrespective of free or salt form. Adoption of a salt form should be based on the enhanced PK performance and/or manufacturability against the free form.

BCS-BASED FORMULATION STRATEGY

The BCS classification can not only be used in the rationalization of salt/polymorph selection strategy but also in the design of animal and human formulations.

Animal Formulation

Animal formulation development is often more challenging than human formulation development due to the higher dose range required to explore toxicity for the establishment of adequate animal safety margins prior to human studies. It is not uncommon to dose animals up to a high dose of 1,000 or 2,000 mg/kg body weight whereas human doses are rarely as high as 1,000 mg per person or for a 70 kg person at 14 mg/kg body weight. The hurdle to solubilize the high animal doses often requires the use of vehicles containing organic solvents that can elicit toxicity by themselves.

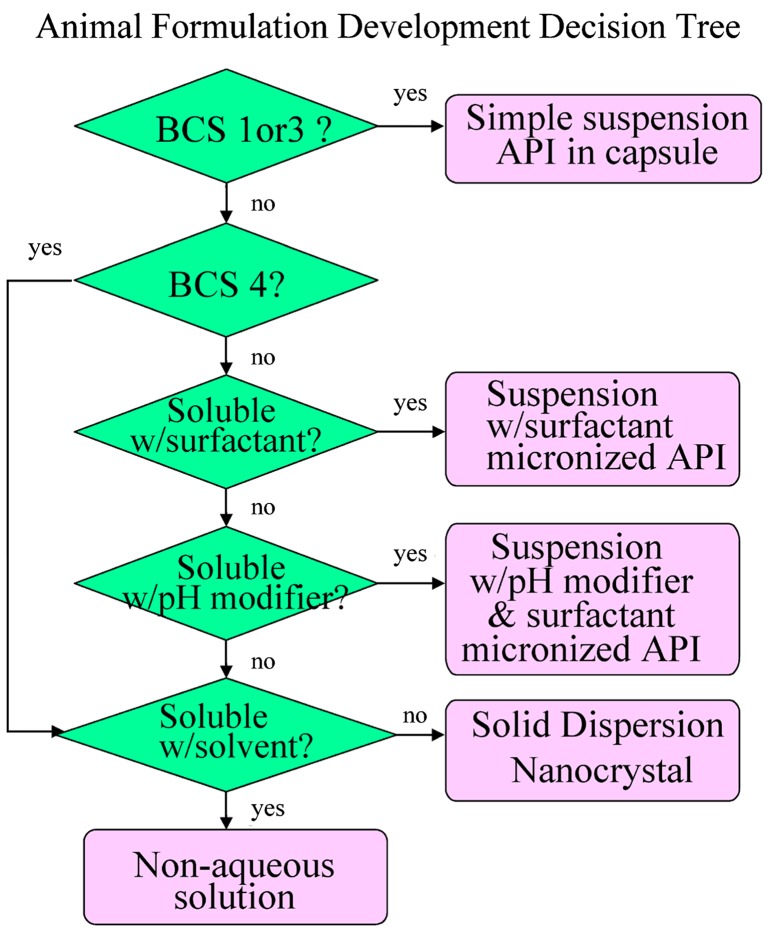

A BCS-based animal formulation development decision tree is presented in Scheme 2. For Class 1 compounds, the preferred vehicle is API in a capsule for dog and a simple solution or suspension for mouse, rat and monkey. For class 3 compounds with high solubility and low permeability, absorption enhancers may be considered for human formulation but perhaps not for animal formulation. For a dose of 1,000 mg/kg body weight, a modest 1:2 drug/excipient ratio will require a dose of the excipient at 2,000 mg/kg body weight. This amount is often too high for the excipient to be safe without eliciting excipient-related-toxicity. API in a capsule, a simple solution or suspension remains to be the choice toxicological formulations for BCS class 3 compounds.

Scheme 2.

BCS based Animal formulation decision tree

For BCS 2 compounds, a wide range of formulation choices exist. Firstly the API should be micronized to increase surface area and speed up dissolution. Secondly surfactants or solubilizers should be added to improve wetting and dissolution. In cases where the compound is ionizable, a pH modifier (acid or base) may be used to enhance solubility. However, the use of pH modifiers should be evaluated against in-gut precipitation due to GI pH gradient. For instance, a basic compound with pKa around 7 can be solubilized 1,000-fold at pH 4 with the addition of citric acid. However, the compound dissolved initially in the citric acid vehicle may precipitate out at pH 7 in the lower GI. This phenomenon often accompanies a truncated absorption phase of short Tmax (less than one hour post dosing at fasted state). Addition of surfactants may inhibit nucleation and slow down in-gut precipitation provided the surfactant travels together with the drug in the GI track. Combined use of pH modifiers and surfactants may be more effective in the enhancement of absorption than pH alone.

In some cases, animal exposure from suspensions containing a surfactant/pH modifier is still too low for toxicology studies, a high energy solid or a non-aqueous solution may be considered. A high energy solid can be manufactured either via dispersion in a polymer matrix as a solid dispersion or by extensive grinding to nanosized particles. The amorphous-like state has inherent higher energy with faster dissolution. Alternatively, if a compound is very soluble in pharmaceutical solvents such as polyols, glycerides, and phospholipids, a non-aqueous solution may be considered. Again a high drug loading that limits the dose of the excipient is critical for the vehicle to be safe. For BCS class 3 and 4 compounds, the high driving force from solution formulations offers the added advantages in overcoming the low permeability barrier. The iteration of formulation and animal testing may take considerable time. Collaboration with toxicologists is necessary to ensure that the placebo vehicle does not produce adverse effects by itself.

Human Formulation

The current pharmaceutical industry trend follows two approaches for first-in-human (FIH) formulations: (1) active-only formulations, e.g. powder-in-bottle or powder-in-capsule, or (2) bonafide formulations. There are advantages and disadvantages of both approaches. While the active-only approach can move quickly into phase 1 clinical trial, it can not be manufactured in scale and is not feasible beyond phase 1. Development of a scale-able clinical phase 2 formulation would need to start as soon as phase 1 begins. A bridging PK study in humans may also be necessary to ensure the consistent safety and efficacy with the new formulation. For compounds with poor solubility and/or poor permeability, bioequivalence between the above two types of formulations may be disparate rendering the adjustment of dosages necessary. A bonafide formulation approach that provides a scalable phase 2 enabling formulation can reduce the transition time between clinical phases and shorten the overall drug development cycle.

Human formulation has different requirements than animal formulation. A solid formulation (capsule/tablet) rather than a bottle of solution/suspension is a must for patient acceptability except in certain life-saving conditions. The amount of excipient used in a solid oral formulation is very limited (less than 1 g). Therefore excipient toxicity is rarely seen in human. The choice of excipients for human formulation is wider than those for animal formulation. However, the low weight of a tablet or the small volume of a capsule requires very high drug loadings. The solubilized formulation is often not feasible for high dose/low potency compounds. A comparison between animal and human formulation strategies is presented in Table I.

Table I.

BCS-based formulation strategies

| BCS class | Animal formulation strategy | Human formulation strategy |

|---|---|---|

| High solubility high permeability | API in capsule for dog | Simple capsule or tablet |

| Simple suspension for rat and monkey | ||

| Low solubility high permeability | Surfactant enhanced suspension with micronized API | Micronized API and surfactant |

| pH modified surfactant enhanced suspension with micronized API | Nano-particle technology | |

| Suspension with nanosized API and surfactant | Solid dispersion | |

| Non-aqueous solution | Melt granulation/extrusion | |

| Liquid or semisolid filled capsule | ||

| Coating technology | ||

| High solubility low permeability | API in capsule for dog | Simple capsule or tablet |

| Aqueous solution for rat and monkey | Absorption enhancers | |

| Low solubility low permeability | Combination of BCS 2 and absorption enhancers | Combination of BCS 2 and absorption enhancers |

With clinical phase 2 proof-of-concept (POC) studies being the bottleneck in drug development, the bonafide formulation approach providing right-first-time formulation is a critical quality-by-design element in the reduction of drug development cycle. However, development of a bonafide formulation could take considerable time and resources. Considering the higher failure rate in early clinical studies, the formulation development effort needs to be streamlined and focused on improving human PK performance. A FIH formulation development strategy based on BCS classification has previously been proposed in the literature (6).

The Enabling Technology Trap

With the advent of high throughput screening and the quest for nanomolar potency in IC50 or EC50, more and more lipophilic and hydrophobic compounds are being discovered. These pipeline compounds tend to be insoluble in water, not permeable to the GI membrane and to have a large molecular size with a high molecular weight exceeding 500 Da. The use of a simple formulation with traditional excipients often fails to elicit biological potency and/or sufficient exposure for a healthy safety margin. Therefore, the use of sophisticated formulations with non-conventional excipients has gained popularity in recent years as a means to enable the preclinical and clinical development of these compounds. However, a broad access of these enabling formulation technologies may mislead discovery scientists in the selection of even less soluble/permeable candidates for development. The author believes that these enabling formulation technologies should be reserved for first-in-class or best-in-class compounds with clear therapeutic advantages and should only be used when lead optimization fails to produce compounds with desirable biopharmaceutical properties. Because of the technology challenges and the added cost often associated with these formulations, compounds with this liability often take longer time and more money to develop and are at a disadvantage in competing with compounds without this liability.

CONCLUSION

In conclusion, the formulation strategy can be streamlined with BCS classification considerations. The objective of FIH formulation is to achieve dose linearity and reduce inter- or intra-subject variability and to render the non-BCS 1 compound develop-able. The right-first-time formulation is essential to ensure the consistence in the clinical database and to reduce R&D cycle time. This BCS based strategies are in line with FDA’s year 2000 risk management and 2004 critical path initiatives to streamline clinical trials and speed up new drug development through quality by design for pharmaceutical product.

References

- 1.Amidon G. L., Lennernas H., Shah V. P., Crison J. R. A theoretical basis for a biopharmaceutics drug classification: the correlation of in vitro drug product dissolution and in vivo bioavailability. Pharm. Res. 1995;12:413–420. doi: 10.1023/A:1016212804288. [DOI] [PubMed] [Google Scholar]

- 2.Chi-Yuan W., Benet L. Z. Predicting drug disposition via application of BCS: transport/absorption/elimination interplay and development of a biopharmaceutics drug disposition classification system. Pharm. Res. 2005;22:11–23. doi: 10.1007/s11095-004-1189-z. [DOI] [PubMed] [Google Scholar]

- 3.Kerns E. H., Di L. Multivariate pharmaceutical profiling for drug discovery. Curr. Top. Med. Chem. 2002;2:87–98. doi: 10.2174/1568026023394470. [DOI] [PubMed] [Google Scholar]

- 4.Food and Drug Administration. Guidance for industry, waiver of in vivo bioavailability and bioequivalence studies for immediate-release solid oral dosage forms based on a biopharmaceutics classification system, Food and Drug Administration, Rockville, MD, 2000. Available at http://www.fda.gov/cder/guidance/index.htm.

- 5.World Health Organization. Proposal to waive in vivo bioequivalence requirements for WHO model list of essential medicines immediate-release, solid oral dosage forms. World Health Organization, Technical Report Series no. 937 (2006). Available at http://www.who.int/prequal/info_general/documents/TRS937/WHO_TRS_937__annex8_eng.pdf

- 6.Ku M. S. An oral formulation decision tree based on the biopharmaceutical classification system for first in human clinical trials. Bull. Tech. Gattefosse. 2006;99:89. [Google Scholar]

- 7.J. Baldoni. Role of BCS in drug development. AAPS/FDA workshop on BE, BCS and Beyond, May 21–23, 2007.

- 8.Lipiniski C. A., Lombardo F., Dominy B. W., Feeney P. J. Experimental and computational approaches to estimate solubility and permeability in drug discovery and development settings. Adv. Drug Deliv. Rev. 1997;23:3–25. doi: 10.1016/S0169-409X(96)00423-1. [DOI] [PubMed] [Google Scholar]

- 9.Bevan C., Lloyd R. S. A high-throughput screening method for the determination of aqueous drug solubility using laser nephelometry in microtiter plates. Anal. Chem. 2000;72:1781–1787. doi: 10.1021/ac9912247. [DOI] [PubMed] [Google Scholar]

- 10.A. Avdeef. High throughput measurements of solubility profiles. In B. Testa, H. van de Waterbeemd, G. Folkers, R. Guy (eds.) Pharmacokinetic Optimization in Drug Research: Biological, Physiological, and Computational Strategies, Verlag Helvetica Chimica Acta, Zurich, 2001, pp 305–326.

- 11.Artursson P., Palm K., Luthman K. Caco-2 monolayers in experimental and theoretical predictions of drug transport. Adv. Drug Deliv. Rev. 1996;22:67–84. doi: 10.1016/S0169-409X(96)00415-2. [DOI] [PubMed] [Google Scholar]

- 12.P. V. Balimane, Y. Han, and S. Chong. Current industrial practices of assessing permeability and p-glycoprotein interaction. The AAPS Journal 8(1) Article 1, E1-E13 (2006). [DOI] [PMC free article] [PubMed]

- 13.Doluisio J. T., Billups N. F., Dittert L. W., Sugita E. T., Swintosky J. V. Drug absorption. I. An in situ rat gut technique yielding realistic absorption rates. J. Pharm. Sci. 1969;58:1196–1200. doi: 10.1002/jps.2600581006. [DOI] [PubMed] [Google Scholar]

- 14.Irvine J. D., Takahashi L., Lockhart K., Cheong J., Tolan J. W., Selick H. E., Grove J. R. MDCK (Madin–Darby canine kidney) cells: a tool for membrane permeability screening. J. Pharm. Sci. 1999;88:28–33. doi: 10.1021/js9803205. [DOI] [PubMed] [Google Scholar]

- 15.Byrn S., et al. Pharmaceutical solids: a strategic approach to regulatory considerations. Pharm. Res. 1995;12(7):945–954. doi: 10.1023/A:1016241927429. [DOI] [PubMed] [Google Scholar]

- 16.Guidance for industry, ANDAs: pharmaceutical solid polymorphism. Draft, Food and Drug Administration, Rockville, MD, 2007. Available at http://www.fda.gov/cder/guidance/7590fnl.pdf.