Abstract

Archaeological excavations at a U-shaped pyramid in the northern Lake Titicaca Basin of Peru have documented a continuous 5-m-deep stratigraphic sequence of metalworking remains. The sequence begins in the first millennium AD and ends in the Spanish Colonial period ca. AD 1600. The earliest dates associated with silver production are 1960 ± 40 BP (2-sigma cal. 40 BC to AD 120) and 1870 ± 40 BP (2-sigma cal. AD 60 to 240) representing the oldest known silver smelting in South America. Scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) analysis of production debris indicate a complex, multistage, high temperature technology for producing silver throughout the archaeological sequence. These data hold significant theoretical implications including the following: (i) silver production occurred before the development of the first southern Andean state of Tiwanaku, (ii) the location and process of silverworking remained consistent for 1,500 years even though political control of the area cycled between expansionist states and smaller chiefly polities, and (iii) that U-shaped structures were the location of ceremonial, residential, and industrial activities.

Keywords: Andes, craft specialization, metallurgy

The site of Huajje is a 128,000-m3 mound located on the northern shores of Lake Titicaca (Fig. 1), in the center of the resource-rich Puno Bay, Peru (Fig. 2). Huajje is situated in a region famous since Colonial times for the rich Laicacota silver ore mines located above the city of Puno. A few key archaeological sites throughout the Puno Bay also have metal manufacturing debris on the surface (1). However, until now, we had been unable to determine whether the silver processing was strictly a Spanish Colonial phenomenon or whether it had its origins in the pre-Colonial period. The data reported here indicate beyond any doubt that there was a prehistoric tradition of silver extraction in the Titicaca Basin using fairly complex smelting, scorification, and cupellation-related technologies going back to at least the first century AD.

Fig. 1.

Location of the Lake Titicaca Basin on the continent of South America with an inset showing the project location within the country of Peru. Numbered location on the Peru map correspond to the following places mentioned in the text; 1: Lake Titicaca, 2: Lima, Peru and the archaeological site Ancón. North arrows in all figures indicate true north with the magnetic declination in Puno, Peru at 2° west of north.

Fig. 2.

The Lake Titicaca Basin of Peru and Bolivia. The Puno Bay research area and the archaeological sites Tiwanaku and Pukara are located.

A deep excavation placed inside the mound platform between the two arms of the U-shaped structure (Fig. 3) revealed a stratified set of construction episodes and living surfaces that contained abundant waste materials from metal working. Metallurgical analysis of the waste products indicates silver production at Huajje that used a complex, multistage, labor-intensive process.

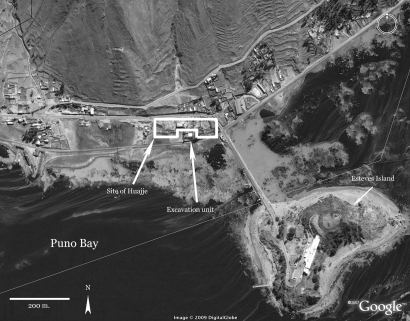

Fig. 3.

The site area of Huajje showing the adjoining island complex of Isla Esteves, the excavation area, and rough outlines of the U-shaped structure. The mound and surrounding settlement has been badly damaged in recent years from modern construction and looting.

The assemblage of artifacts also included ritual paraphernalia, weaving tools, and other items that indicate the full range of residential activities and specialized labor. The nature of U-shaped structures is not well-known, making this find of co-occurring ritual, industrial, and residential debris particularly significant. Ritual paraphernalia included incense-burners, flat-bottomed bowls, polychrome zone-incised ceramics, and incision-decorated button ornaments. Household debris included storage and serving vessels, agricultural tools, and food remains.

Evidence of silver production—including crucibles, matte, slag, and vitrified ceramics characteristic of high temperature processing—was found in every level in the 2 × 2 m test unit from 0.30 m to 4.80 m below the modern surface.

Published research on the origin of silver production in the Andes utilizes lake sediment profiles, where investigators interpreted the increases in deposition of volatized, initially airborne lead as a by-product of silver smelting (2–4). Work in Lake Taypi Chaka in Bolivia, for instance, registered an increase in sedimentary lead levels ca. AD 400, as a possible indirect byproduct of silver production (4). This time period is broadly contemporaneous to that of the northern coast of Peru, where silver-lead reduction finds from the site of Ancón have been dated to ca. AD 600 (5). The Taypi Chaka dates contrast with lake sediment samples from northern (3) and southern (2) Andean lakes where lead deposition significantly increases only after ca. AD 1000. The published information, when combined, suggests that Lake Titicaca was an early center of silver working in the Andes. Data from Huajje confirm this suggestion with direct archaeological evidence. Our data establish an initial date for silverworking that is at least three centuries earlier than previous studies had indicated.

Pottery fragments on the surface of the archaeological site of Huajje indicate a founding date of ca. 500 BC, when that settlement would have been a small village associated with the Pukara and Terminal Qaluyu cultures. In the test excavation, the human deposition began with a major building episode ca. AD 100, followed by successive constructions and re-occupations for several centuries. The mound was built over generations by using midden materials as architectural foundations. Each building episode created a stratigraphic lens, marked by the inclusion of chronologically later diagnostic artifacts, mixed with the continued presence of earlier ceramic forms.

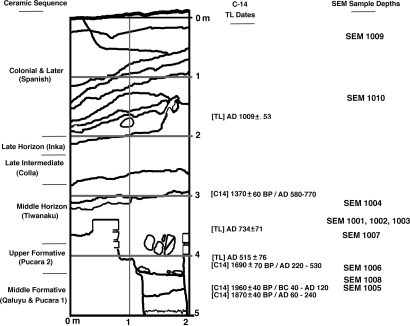

Three independent lines of evidence establish the chronological integrity of the deposit: 1) a ceramic sequence in uninterrupted stratigraphic layers, 2) absolute radiocarbon dates, and 3) absolute ceramic thermoluminescence (TL) dates (1). Fig. 4 indicates that the two absolute dating methods are internally consistent, and that these match the relative sequence derived from analyzing the diagnostic pottery or ceramics. The unit excavated at Huajje represents a rare instance of an intact, well-demarcated stratigraphic deposit that allows us to precisely define the material changes through time in silver production.

Fig. 4.

The Huajje excavation Unit 1 west wall profile, relative ceramic chronology, radiocarbon (C14), pottery thermoluminescence (TL) dates and scanning electron microscope (SEM) smelting assemblage sample locations. C14-calibrated dates are 2-sigma/95% probability calculations provided by Beta Analytic. TL dates are shown with standard deviation 1-sigma error terms. TL dates represent minimum ages due to signal fading of constituent feldspars.

The village was converted into a large ceremonial and residential center in its early periods ca. AD 100. Huajje was then incorporated into the Tiwanaku state ca. AD 600–700 as part of a larger political entity that included the island of Esteves, a few hundred meters to the southeast. Regional survey demonstrates the intrusion of Tiwanaku artifacts and iconography in this area that was otherwise culturally-affiliated with the northern Qaluyu and later Pukara cultural traditions (1). The construction of a stylistically-Tiwanaku pyramid and ritual/residential site on the nearby island of Esteves provides clear evidence of Tiwanaku investment in Puno Bay. Tiwanaku influence in the region declined ca. AD 900–1000. The site functioned as a smaller center throughout the post-Tiwanaku and Inka periods and continued to be occupied in the Spanish period up to the present day.

The steps required for silver extraction include mining, beneficiation (i.e., crushing of the ore and sorting of metal-bearing mineral), optional roasting to remove sulfur via oxidation, followed by smelting, and cupellation (described below). During smelting, silver and lead-rich ores are combined in the furnace. The lead ore acts as a collector for the silver metal, securing better separation of silver from the gangue (i.e., mineral impurities in the silver-bearing ore). Smelting produces metal, typically a silver-containing lead (bullion) containing variable amounts of metal sulfides (matte), and slag. Matte is defined as a matrix of metal sulfides with only minor amounts of silicates. Slag, by definition, has a matrix of silicates, sometimes with minor inclusions of matte or metal.

Before cupellation of the bullion, a silver cake of intermediate purity may be produced by scorification, typically by oxidizing some of the lead and other base metals on a flat ceramic surface. The diagnostic waste of this activity is a rim of vitrified silicate and litharge (lead oxide) on the ceramic support comprising mixed oxides of common metals that have separated from the silver. Similar remains can form during the refining or remelting of raw or recycled silver.

The final cupellation takes place on a hearth lined with porous ash or calcareous material which absorbs the lead oxide/litharge as it forms. In cupellation the lead-rich metal is heated above 900 °C in an oxygen-rich environment with a thick layer of porous ash. In this molten liquid state, the liquid metallic lead containing silver and other base metal oxides is oxidized, while the more noble silver remains as an unoxidized metal. It results in pure silver and a cake of cupellation hearth material, comprising about 50 wt% lead oxide and the original hearth lining material.

The location of mining sites is of course determined by geology, while beneficiation and roasting can occur either at the mining site or the smelting site. Evidence for the location and design of pre-Hispanic silver smelting furnaces is rare; data from the Bolivian altiplano point to the use of windblown huayrachina furnaces as an indigenous technology for silver smelting (6, 7), followed by cupellation in a separate installation elsewhere.

Archaeological or ethnographic evidence for most of these steps is extremely scarce, making this a very significant assemblage for our understanding of early silver production. A total of 3,457 (7,215.84 g) smelting-related artifacts were collected. Debris types included a single fragment of hammered copper sheet, two matte cakes, 104 pieces of matte and slag, 289 crucible fragments, 1,028 slag and matte-encrusted crucible fragments, and 23 fragments of ore rock.

There was further evidence of pyrotechnic activities in the form of 1,984 pieces of vitreous vesicular slag, thermally altered ceramics, and fragments of furnace lining. Additionally, there were three small (1.63 g) pieces of chalk raw material and three crucible fragments lined with a chalky residue.

Results

Ten artifacts were selected for SEM and EDS analysis to test whether (a) these were the result of metal refining and (b) if confirmed, to determine the kinds of metals extracted. This method indicates the presence, but not relative quantity, of constituent elements. The results show silver metal processing throughout the history of the stratigraphic unit (Table 1).

Table 1.

Complete results of the SEM analysis by sampling depth

| SEM | Level | Category | Elements present |

|---|---|---|---|

| 1009 | 030–040 | large diameter slagged ceramic | slag: Al, Si, K, Fe, Cu, Ba, Pb ceramic: Mg, Al, Si, K, Fe |

| 1010 | 130–140 | light weight vesicular slag | Na, Mg, Al, Si, P, K, Ca, Ti, Fe, Cu, Ag, Ba, Pb |

| 1004 | 310–320 | matte cake | Si, S, P Cu, Ag, Pb |

| 1001 | 340–350 | slagged ceramic | slag: Si, S, Fe, Zn, Pb ceramic: Al, Si, K, Ba, Pb |

| 1002 | 340–350 | matte cake | S, Cu, Ag, Pb, |

| 1003 | 340–350 | vesicular slag | Na, Mg, Al, Si, P, S, K, Ca, Ti, Mn, Fe, Pb |

| 1007 | 360–370 | matte | Al, Si, S, Cu, As, Ag, Pb |

| 1006 | 430–440 | ore | Si, S, Ca, Cu, As, Ag |

| 1008 | 440–450 | slagged ceramic | slag: Al, Si, K, Ca, Fe, Ba, Pb ceramic: Al, Si, K |

| 1005 | 450–460 | slagged ceramic | slag: Mg, Al, Si, S, K, Ca, Cu, Ag, Ba, Pb ceramic: Si, Ti, Fe |

The earliest sample (SEM 1005) in the excavation was matte within a crucible, composed of silver and lead metal in a matrix of copper-sulfide. Barium is also present. SEM 1008, obtained from the immediately superposed level, was a slagged crucible. The SEM results show a homogeneous lead silicate glass with trace components of calcium and iron without the crystallization seen in other samples. This homogeneous glass may indicate higher operating temperatures than in the other slags that had re-crystallized upon cooling (e.g., SEM 1001). SEM 1006 likely represents the type of ore processed at this site. Analysis identified it as an arsenical copper ore with silver sulfide inclusions.

Samples 1001, 1002, 1003, 1004, and 1007 are Tiwanaku period specimens. These include both matte and slag, showing continuity of silver processing at Huajje when that site was under Tiwanaku control. SEM 1001 is a crucible fragment with a thick lens of slag adhering to the interior surface. Backscattered electron imaging and EDS examination of the slag found a matrix of lead-bearing silicate glass with globular inclusions of lead metal and lead mixed with sulfur, as well as angular inclusions of iron. There is also an iron-bearing phase with zinc occasionally substituting for iron.

SEM 1002 is a heavy matte cake with a near circular shape. SEM imaging showed dendrites and very fine crystallized phases, both indicative of very rapid crystallization, lodged in a multiphase matrix primarily containing copper and sulfur with lead. The crystallized portions are lead with varying amounts of sulfur. Within these are areas of pure lead metal and silver sulfide.

SEM 1003 is a piece of vesicular slag. This sample can be generally characterized as a calcium and potassium-rich silicate glass, with lead-rich and lead-poor regions. It contains a greater variety of elements than the other samples as seen in Table 1. These results suggest that vesicular slag represents vitrified material from the ceramic crucibles.

Sample SEM 1004 is the second of two matte cakes in the assemblage from the Tiwanaku strata. It has the greater qualitative weight of metal and is disc-shaped. The matrix is primarily copper sulfide with lead and silver metals present as small crystals embedded in the matrix.

The results from SEM 1007 showed that it was a piece of matte with an oxidized and mineralized exterior. Like previously analyzed matte fragments, it is composed of a matrix containing copper and sulfur with interstitial matter containing lead, silver, arsenic, and sulfur.

Samples 1009 and 1010 were from upper levels, dating to the period after Spanish contact. Both are lead silicate slags. Neither contained sulfur, indicating the introduction of ore roasting. Sample 1009 is representative of a generally larger style of crucible that was found above 150 cm in the excavation unit. Sample SEM 1010 is representative of a lighter type of vesicular slag found above 140 cm. Otherwise, there is technological continuity across time periods.

Discussion

Samples SEM 1002, 1004, 1005, and 1007 appear to be matte, an intermediary stage byproduct of smelting operations. The shape of the matte cake samples 1002 and 1004 corresponds to detachment scars found in slags, many within crucibles (1). The inclusions of silver-rich bullion most likely represent the metal phase with which the matte formed. Re-melting this raw bullion in a crucible at Huajje resulted in the separation of the lighter matte from the denser metal, and partial oxidation of the lead metal. The fact that these matte cakes appear regularly in the archaeological record here indicates that they were discarded as waste. The lead-silicate slag in the crucibles formed from the reaction of the lead oxide with the ceramic and/or additional quartz from the gangue.

The assemblage of ore, slag, matte and ceramic dishes represents an intermediate stage of silver production at Huajje. The content of the assemblage strongly suggests that silver production at this site included the intermediate processing of bullion. Further analysis of the slags will be required to determine the processes of their formation.

The data suggest the following pattern: the smelting of a rich silver ore conducted elsewhere (likely the site of Punanave), followed by transportation of the raw bullion to a central and well-supervised site (in this case, Huajje) for further processing. Re-melting of the raw bullion in crucibles here would result in the separation of matte that may have been mixed with the bullion, and a partial oxidation of lead metal, forming lead silicate slag in the crucible through reaction with quartz mineral. The refined bullion from this operation would then have been fit for cupellation to pure silver. The absence of litharge or cupellation hearth material is either due to a spatial separation of this step away from the site here (during the Middle Horizon period of the Tiwanaku state, likely at Isla Esteves), or the re-smelting of litharge as part of the furnace charge. The quality of the refined bullion can only be very roughly deduced from the metal inclusions in the matte cakes; it may have reached 30% silver.

Cooke et al. (4) correlate silver smelting with the southern Andean state of Tiwanaku. Tiwanaku evolved along the southern shore of Lake Titicaca around AD 400 and collapsed between AD 900–1100 (8–10). Elemental analyses of bronzes from the capital site of Tiwanaku identify it as a locus of innovation and experimentation in metalworking throughout its lifespan as a political center (11).

The data from Puno Bay, reported in this article, indicate that high temperature silver purification began before the Tiwanaku state and continued well after its collapse. These data also indicate that intensive metal working predates Tiwanaku expansion into the northern Titicaca Basin.

The Tiwanaku state simply coopted the location and process of silver working in Puno Bay. Silver extraction likewise continued with the collapse of Tiwanaku and the onset of the Inka and Spanish empires in the region. In short, the local tradition began in the first century AD and continued for centuries in several different political landscapes. This critical source of silver ore continued to be exploited with little interruption despite the shifting political regimes that emerged and declined throughout the region. Beginning as a place of metal extraction in prestate, chiefly contexts, Huajje was appropriated by the Tiwanaku state, continued to produce silver after state collapse, and was absorbed by both the Inka and Spanish Empires.

One key finding we wish to emphasize is that these results corroborate other research showing that complex metal production can occur in nonstate contexts (12, 13). There exists some evidence (increase in artifacts per cubic meter) that the intensity of production increased in state contexts, but the process of metal extraction, production and chemical signatures remained effectively unchanged over the entire sequence. The only exception is the Spanish Colonial period in which we see the introduction of ore roasting. A second key finding is that we now know that craft activities and metalworking also characterized some of the U-shaped structures, which are a common architectural style of early (first millennium BCE) nonstate, complex societies throughout the Andes. While they are most common on the north coast of Peru, the U-shaped architectural style is found throughout virtually the entire Andes (14). These architectural mounds are usually interpreted as ceremonial in function (15). The data presented here alter our understanding of U-shaped structures and indicate that along with their ceremonial functions, the structures also were used for industrial metal working. In effect, the pre-Middle Horizon centers such as Huajje were complex, multifunctional settlements with residential, ceremonial, and industrial functions that co-existed for centuries in a variety of sociopolitical contexts.

Materials and Methods

The samples discussed in this study were examined in the Department of Earth and Space Sciences at the University of Washington at Seattle. The samples were cut with a diamond trim saw, mounted with epoxy on 1 × 2 inch glass slides and polished using a final grit size of 0.3 μm. The polished samples were coated with approximately 20 nm of carbon for electrical conductivity and then examined with a JEOL 733 electron microprobe operating at 15 kV accelerating voltage. A variety of beam currents were used to optimize particular imaging and microanalysis situations.

Digital images were acquired using a GATAN, Inc., Digiscan—DigitalMicrograph system. Qualitative phase identification was made using a Tracor Northern Energy-Dispersive Spectometer (EDS) system with Princeton Gamma-Tech (PGT) eXcalubur software. Unless otherwise noted, wavelength dispersive spectrometers (WDS) were used to clarify elements, such as sulfur (S) and lead (Pb), whose peak positions are unresolvable within the resolution limits of the EDS system. Elements with atomic number below sodium (O, C, N, F, etc.) are not identifiable using this system. However, the difference between Pb metal, for example, and Pb(OH)2 is easily seen in BSE images where brightness of a phase is determined by its average atomic number.

Acknowledgments.

We thank the Instituto Nacional de Cultura in Lima and Puno and our Peruvian collaborators, including Rolando Paredes, Edmundo de la Vega, Cecilia Chávez Justo, project co-director Fernando John Sosa Alcón, Javier Challcha Saroza, Henry Flores Villasante, David Oshige Adams, Barbara Carbajal, Norfelinda Cornéjo Gallegos, Amadeo Mamani Mamani, and Javier Pilco Quispe. This work was supported by National Science Foundation Stanish Grant BCS 9905138; the University Research Expeditions Program; and the University of California at Los Angeles, through the Department of Anthropology, the Cotsen Institute of Archaeology, the Institute of American Cultures, and the Latin American Studies Center.

Footnotes

The authors declare no conflict of interest.

This article is a PNAS Direct Submission.

Data deposition: The majority of archaeological materials are stored in Puno Bay, Peru. The smelting assemblage was exported under permit number 1238-INC-2003-DREPH, issued on August 14, 2003 by the Instituto Nacional de Cultura (INC) in Lima, Peru. The assemblage is currently housed in the Archaeometallurgy Laboratory of the Cotsen Institute of Archaeology at University of California at Los Angeles, A210 Fowler Building/Box 951510, Los Angeles, California 90095-1510.

References

- 1.Schultze CA. Ph.D. dissertation, Anthropology. Los Angeles: University of California; 2008. [Google Scholar]

- 2.Abbott M, Wolfe A. Intensive pre-Incan metallurgy recorded by lake sediments from the Bolivian Andes. Science. 2003;26:1893–1895. doi: 10.1126/science.1087806. [DOI] [PubMed] [Google Scholar]

- 3.Cooke C, Abbott M, Wolfe A. Late Holocene atmospheric lead deposition in the Peruvian and Bolivian Andes. Holocene. 2008;18:353–359. [Google Scholar]

- 4.Cooke C, Abbott M, Wolfe A, Kittleson J. A millennium of metallurgy recorded by lake sediments from Morococha, Peruvian Andes. Enviro Sci Technol. 2007;41:3469–3474. doi: 10.1021/es062930+. [DOI] [PubMed] [Google Scholar]

- 5.Lechtman H. A metallurgical site survey in the Peruvian Andes. J Field Archaeol. 1976;3:1–42. [Google Scholar]

- 6.Van Buren M, Mills B. Huayrachinas and tocochimbos: Traditional smelting technology of the Southern Andes. Lat Am Antiquity. 2005;16:3–25. [Google Scholar]

- 7.Peele R., Jr A primitive smelting furnace. School Mines Quart. 1893;15:8–10. [Google Scholar]

- 8.Alconini Mujica S. La Paz, Bolivia: Universidad Mayor de San Andrés; 1993. M.A. thesis. [Google Scholar]

- 9.Couture N. In: Tiwanaku: Ancestors of the Inca. Young-Sánchez M, editor. Denver, CO: Denver Art Museum; 2004. [Google Scholar]

- 10.Janusek JW. In: Foundation of Power in the Prehispanic Andes. Vaughn K, editor. Arlington, VA: American Anthropological Association; 2005. [Google Scholar]

- 11.Lechtman H. In: Tiwanaku and Its Hinterland: Urban and Rural Archaeology 2. Kolata A, editor. Washington D.C.: Smithsonian Institution; 2003. [Google Scholar]

- 12.Shimada I. Craft Production in Complex Societies: Multicraft and Producer Perspectives. Salt Lake City, UT: University of Utah Press; 2007. [Google Scholar]

- 13.Vaughn K. La Ballena: A mining base camp in the Southern Nasca Region, Peru. Antiquity. 2008;82:34–38. [Google Scholar]

- 14.Stanish CS. The origin of state societies in the South America. Ann Rev Anthropol. 2001;30:41–64. [Google Scholar]

- 15.Burger RL. Chavin. London: Thames and Hudson; 1995. [Google Scholar]