Abstract

Several recent accidents with fatal outcomes occurring during discharge of logs and wood chips from ships in Swedish ports indicate the need to better understand the atmospheric conditions in holds and connecting stairways. The principal aim of the present study was to assess the air levels of oxygen and toxic gases in confined spaces following sea transportation of logs and wood chips. The focus of the study was the conditions in the stairways, as this was the location of the reported accidents. Forty-one shipments of logs (pulpwood) and wood chips carried by 10 different ships were investigated before discharge in ports in northern Sweden. A full year was covered to accommodate variations due to seasonal temperature changes. The time from completion of loading to discharge was estimated to be 37–66 h (mean 46 h). Air samples were collected in the undisturbed air of altogether 76 stairways before the hatch covers were removed. The oxygen level was measured on-site by handheld direct-reading multi-gas monitors. On 16 of the shipments, air samples were additionally collected in Tedlar® bags for later analysis for carbon dioxide, carbon monoxide, and hydrocarbons by fourier transform infrared spectroscopy. The mean oxygen level was 10% (n = 76) but in 17% of the samples the oxygen level was 0%. The oxygen depletion was less pronounced during the cold season. The mean CO2 and CO levels were 7.5% (n = 26) and 46 p.p.m. (n = 28), respectively. More than 90% of the hydrocarbons were explained by monoterpenes, mainly α-pinene (mean 41 p.p.m., (n = 26). In conclusion, the measurements show that transport of logs and wood chips in confined spaces may result in rapid and severe oxygen depletion and CO2 formation. Thus, apparently harmless cargoes may create potentially life-threatening conditions. The oxygen depletion and CO2 formation are seemingly primarily caused by microbiological activity, in contrast to the oxidative processes with higher CO formation that predominate in cargoes of wood pellets. Improved technical and organizational measures are considered necessary to prevent future accidents. Recommendations given regarding safe entry procedures and technical preventive methods may also apply to other oxygen-depleting products.

Keywords: confined spaces, hazard assessment, seamen

INTRODUCTION

Organic materials are subject to decomposition over time, principally due to either microbiological (anaerobic or aerobic) or autoxidative processes. Various gaseous products are then formed including carbon monoxide (CO), carbon dioxide (CO2), hydrogen sulfide (H2S), and hydrocarbons. When organic materials are stored in confined spaces, these decomposition products will accumulate in the air and may eventually reach toxic levels. Oxygen depletion will occur, simultaneously.

The cargo holds and communicating spaces in bulk carriers are examples of confined spaces where such toxic atmospheres may develop. Ocean and sea transportation of bulk cargoes of an organic nature, such as wood and agricultural products, is a major industrial activity worldwide. Limited time slots for the discharge of cargoes do not always allow for proper ventilation and several fatal accidents have occurred when people have entered unventilated stairways. This occupational hazard is not properly recognized in the scientific literature and the number of unrecorded cases may be high. In the single study retrieved in the scientific literature (Svedberg et al., 2008), off-gassing of carbon monoxide (up to 14 650 ppm) and oxygen depletion (reaching 0.8% O2) was reported in cargo holds and connecting spaces during shipment of wood pellets, a study initiated after the occurrence of a fatal accident in Sweden during a cargo discharge in November 2006. Information collected from the Maritime Environment Section of the Swedish Transport Agency shows that similar accidents also occurred in August 2005, December 2006, and May 2007. In total, five fatalities and several injuries have been reported in Swedish ports under similar circumstances within a 2-year period. All victims had entered inadequately ventilated stairways communicating with cargo holds.

Regulations governing the sea transport of solid bulk cargoes are published by the International Maritime Organization (IMO) in the Code of Safe Practice for Solid Bulk Cargoes (BC Code) (IMO, 2005). Advice on their properties and methods of handling is given in the schedules for individual cargoes. The BC Code lists the following cargoes as potentially oxygen depleting: brown coal briquettes, charcoal, coal, copra, direct reduced iron, ferrous metal borings (shavings, turnings or cuttings), fish (in bulk), fish meal (fish scrap), iron oxide (iron sponge), metal sulfide concentrates, mineral concentrates, silico manganese, tapioca, peat moss, seed cake, ammonium nitrate-based fertilizers, sawdust, wood pellets, wood chips, wood pulp pellets [sic!], limestone, and linted cotton seed. Although not exhaustive, the information given in the BC Code regarding the oxygen-depleting properties and the potential formation of toxic gases provides guidance on precautionary steps such as air measurement, ventilation, stowage, weather precautions, and emergency procedures. However, several recent fatalities involving wood products suggest that this information is not properly appreciated and indicate that the inherent risks need further elucidation.

The principal aim of the present study was to assess the air levels of oxygen and toxic gases in confined spaces following sea transportation of logs and wood chips. The measurements focused on the stairways connected to the cargo holds as this was the location of all the fatal accidents reported in Sweden. The gases of primary interest were oxygen, carbon dioxide (CO2), carbon monoxide (CO), and hydrocarbons. As the atmospheric conditions in the stairways may vary with seasonal temperature changes, a full year of shipments was covered to accommodate such variations. The study provided an opportunity to investigate the performance of handheld multi-gas monitors used by ships’ crews in these exceptional environments and to compare the results with Fourier transform infrared spectroscopy (FTIR) measurements. In order to facilitate the interpretation of results, microbiological activities in wood chips, bark, and wood pellets were investigated in parallel.

METHODS

Vessels and cargoes

Ten different ships were included in the study. The selection of ships was based on arrival schedules at the ports in northern Sweden. No ship refused to participate; on the contrary, a genuine interest and willingness to take part was experienced. Some ships were investigated several times while others were visited only once. Altogether, 41 incoming shipments of wood chips and logs (pulp wood) were investigated before discharge of the cargo. The cargoes had been loaded between May 2007 and July 2008 in different ports around the Baltic Sea, most of them in Estonia, Latvia, Lithuania, Russia, or Sweden.

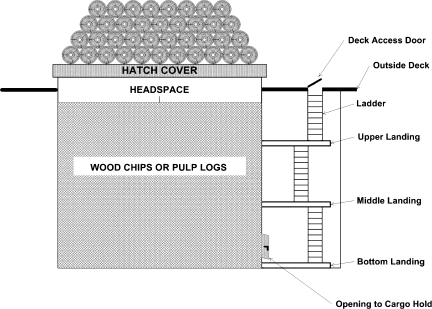

The information about each cargo was collected from the ship's crew at the time of sampling. The estimated time from completion of loading to discharge was 37–66 (mean 46) h. The types of wood carried were pine, spruce, birch, and aspen. The storage time on land for logs varied from recent harvesting to several years. In a few cases, the logs had been stored in water. The vessels were bulk carriers with one or two cargo holds. Wood chips were always transported inside the holds while logs were transported either in the holds or as deck cargo on top of the hatch covers, as illustrated in Fig. 1. A stairway led to each individual hold with an opening into the hold located at the lowest landing. The access doors to the stairways were normally reached from the outer deck. However, in a few ships, a separate storage or utility room had to be entered to reach the access door to the stairway. The access doors were closed throughout the voyages.

Fig. 1.

Schematic drawing of a typical hold and its connecting stairway. The cargo on top of the hatch cover is symbolized by logs. The opening into the hold at the lower landing is symbolized by a door. This opening was sometimes covered with boards to prevent the cargo from falling into the stairway.

Gas measurements

Measurement of toxic gases was carried out using a direct-reading handheld multi-gas monitor. In addition, air samples were collected in Tedlar® bags for later analysis in the laboratory by FTIR. The samples were collected from the undisturbed air in the stairways before removal of the hatch covers. The access door was temporarily opened and a sampling tube was lowered as far as possible, typically between 4 and 8 m depending on the design of the stairway. The access door was left ajar allowing enough space for the sampling tube. In total, 76 individual staircases were sampled in the 41 shipments investigated. One of the participating ships assisted by doing their own sampling, and 22 of the 41 shipments were sampled with a handheld monitor by a crew member on the specific vessel. The crew member was carefully instructed how to perform the measurements.

The handheld multi-gas monitors used were of type RKI GX-2001 (Riken Keiki Co. Ltd, Tokyo, Japan) with a galvanic cell oxygen sensor (0.1% accuracy) and an electrochemical CO sensor (1 ppm accuracy). This type of instrument is commonly used in industry and has proved useful for quick checks before entering areas with a suspected toxic atmosphere. The RKI instrument was additionally equipped with an electrochemical hydrogen sulfide (H2S) sensor and a catalytic combustion hydrocarbon sensor for lower explosive limit (LEL) determinations. Calibration was done with clean ambient air and the manufacturer's span gas mixture of 50 ppm CO, 25 ppm H2S, 2.2% methane, and 12% oxygen, all in nitrogen.

On 16 shipments, parallel to the direct-reading recordings, air samples were collected in sample bags and analyzed within 48 h for CO, CO2, and hydrocarbons by FTIR (MB 100; Bomem, Quebec, Canada). The concentrations of CO and CO2 were determined by fitting a set of precalibrated spectra based on the Hitran2000 spectral database (Griffith, 1996; Rothman et al., 2003) to the sample spectrum. The hydrocarbon concentrations were expressed as α-pinene equivalents as this was the principal hydrocarbon detected. The FTIR method has an overall uncertainty of ∼5%, made up of the absolute uncertainty in the absorption cross-sections in the spectral databases and the uncertainty in the fitting procedure itself. The stability of the sample in the Tedlar® bag was investigated and no change in concentration was noted over 48 h. Most samples were analyzed within a few hours after collection.

Initially, the intention was to include all data collected by the RKI instrument. However, we unexpectedly experienced relatively high readings of H2S and ∼40% higher values for CO and total hydrocarbons than obtained by FTIR, suggesting a cross-sensitivity in these environments. Thus, the data on H2S, CO, and total hydrocarbons were omitted and only oxygen data were reported for this instrument. In an experimental follow-up, an attempt was made to identify the components causing the cross-sensitivity. Atmospheres of CO, CO2, and α-pinene in clean air were generated in sample bags and measured in parallel with the RKI instrument, a similar handheld instrument from Dräger (X-AM 2000) and the FTIR instrument.

Microbiological sampling

In order to assess the microbiological activity of wood chips, logs, and wood pellets, single grab samples of fresh bark and fresh wood chips and wood pellets (∼2 days after production, dry and humid samples) were collected in the month of March from a sawmill and a wood pellet factory, respectively. Bark was sampled as it represents the major surface area of the log. The humid wood pellet sample (disintegrated into sawdust) was collected from the surface of a pellet pile where humidity from inside the warm pile had risen to the surface and condensed. The samples were placed in paper bags and shipped immediately to a microbiological laboratory (Eurofins Environment Sweden AB, Uppsala, Sweden) for cultivation. The microbiological activity is expressed as the number of colony-forming units per gram of material (cfu g−1).

RESULTS

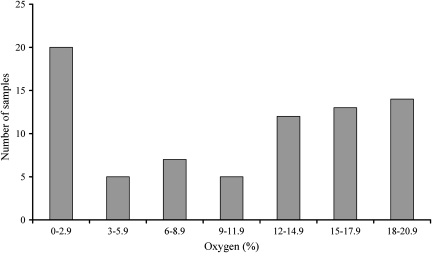

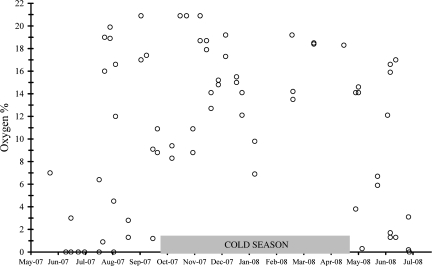

Varying degrees of oxygen reduction and CO2 elevation were seen in the stairway air samples from the ships. The mean oxygen level was 10 ± 7.3% (mean ± standard deviation, n = 76). The levels ranged from normal ambient air concentration of 20.9% to complete depletion. In nearly one-fifth of the samples, the oxygen level was 0% and in one-third it was <6% (Fig. 2). Notably, complete depletion was observed even in samples taken as early as ∼37 h after loading, although no correlation between estimated transport time and oxygen level was seen. As anticipated, a seasonal variation in oxygen depletion was seen. During the cold season, the depletion was less pronounced and no zero readings were recorded (Fig. 3). Unsafe conditions with oxygen levels <6% were seen to develop with both softwood and hardwood.

Fig. 2.

Frequency distribution of oxygen levels measured with a handheld gas monitor in the 76 stairways.

Fig. 3.

Temporal distribution of oxygen levels measured with a handheld gas monitor in the 76 stairways. Each dot represents the oxygen level in an individual stairway. One or two stairways were sampled in each ship. The shaded area indicates the cold season when less oxygen depletion was seen.

The CO2 levels ranged from 0.5 to 15%, i.e. far above the normal ambient air level of ∼0.035%. The mean CO2 level was 7.5 ± 5.2% (n = 26). The CO levels ranged from 2 to 174 ppm. The mean CO level was 46 ± 47 ppm (n = 28).

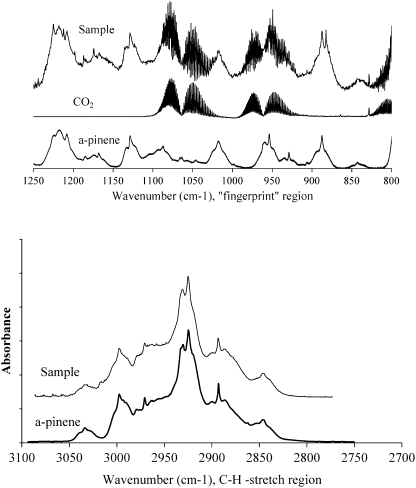

The FTIR analysis revealed that >90% of the hydrocarbons were explained by monoterpenes, mainly α-pinene, as determined by peak area comparison of the C-H stretch region of 2800–3050 cm−1 and the ‘fingerprint’ region of 750–1250 cm−1 in the spectrum (Fig. 4). The mean hydrocarbon concentration expressed as α-pinene equivalents was 41 ± 51 ppm (n = 26). Ethylene was occasionally detected in the 10-ppm range. Hydrocarbons may constitute a risk of explosion. No literature reference of the LEL value for α-pinene was found; however, it is expected to be close to that of turpentine (a mixture of mono-terpenes) at 8000 ppm (NIOSH, 1994). The highest recorded α-pinene concentration in our study was 160 ppm, corresponding to 2% of the LEL for turpentine. Under the conditions described in the present study, it appears unlikely that any of the gases present will reach the LEL.

Fig. 4.

FTIR spectrum of a representative air sample from a stairway. The fingerprint region and the C-H stretch region (the collective peak of all C-H bonds in hydrocarbons) are depicted. The spectral features in the sample are well described by the combined library spectra of α-pinene and CO2.

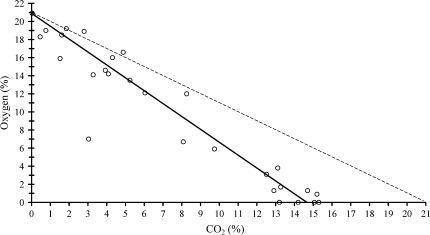

A highly statistically significant correlation was obtained (r = −0.95, P < 0.001, n = 26) between oxygen and CO2, (Fig. 5). The slope of the regression line of −1.45 suggests that ∼70% of the oxygen loss is recovered as CO2 in the gas phase. A statistically significant correlation was also seen between oxygen and α-pinene (r = −0.57, P < 0.01, n = 26) and between CO2 and α-pinene (r = 0.61, P < 0.001, n = 26).

Fig. 5.

Relation between simultaneously measured oxygen and CO2 levels in 26 stairway air samples. The slope of the regression line of −1.425 (forced through the normal ambient atmospheric conditions of 20.9% O2 and 0.035% CO2 at the y-intercept) suggests that the CO2 released in to the air corresponds to close to 70% of the oxygen depletion. The dashed line describes the stoichiometric relation of 1 between oxygen depletion and CO2 formation.

The results from the microbiological analysis are presented in Table 1. The microbiological activity was high in samples of fresh wood chips and bark, while neither the dry nor the humid wood pellet samples showed any microbiological activity.

Table 1.

Microbiological analysis of four grab samples collected from a wood pellet factory (about two day old wood pellets) and a saw mill (freshly produced wood chips and bark). The results are expressed in colony-forming units per gram of material (cfu g−1).

| Sample | Bacteria (cfu g−1) | Fungi (cfu g−1) |

| Dry wood pellets | <9 | <9 |

| Wet wood pellets | <13 | <13 |

| Fresh wood chips | 9.4 × 105 | 7.1 × 105 |

| Bark | 5.7 × 106 | 4.9 × 106 |

Parallel measurements of shipment air samples showed that the handheld instruments consistently overestimated the CO levels compared to the FTIR. The experimental follow-up study staged to investigate possible cross-sensitivities did not resolve this issue. However, during the follow-up experiments, it was shown that 453 ppm CO in clean air gave a reading of 19 ppm H2S with the RKI sensor. In addition, both the Dräger and the RKI H2S sensors indicated increasing levels of H2S (the experiment was discontinued at 27 and 90 ppm, respectively) when 500 ppm α-pinene was added to clean air. In contrast, the LEL sensors did not respond at all to the 500-ppm α-pinene challenge (6% of the assumed LEL). The oxygen sensors did not appear to suffer from cross-sensitivity and showed between the RKI and Dräger sensors consistent values.

DISCUSSION

In this study, we describe gas measurements in air samples from stairways connected to holds containing wood chips and logs. To our knowledge, this is the first time that such measurements have been undertaken. The cargoes had only been on board for 37–66 h, as estimated from interviews with crew members, yet the measurements revealed varying degrees of severe oxygen depletion, accompanied by corresponding increases in CO2 (Fig. 2). Almost one-fifth of the samples showed a complete lack of oxygen and one-third were <6%, i.e. were immediately life threatening (Bingham et al., 2001). In all, 71 of the 76 samples displayed oxygen levels below the minimum requirement of 19.5% oxygen (148 torr) at sea level according to the US National Institute for Occupational Safety and Health (Bollinger, 2004).

This hazardous situation is further aggravated by the formation of CO2. Thus, 10 of the 26 CO2 measurements were >10%, a level that may cause convulsions, coma, and death (Langford, 2005) and 23 were above the Swedish occupational exposure limit of 5000 ppm (0.5%) whereas one-third of the samples were above the immediately life-threatening level of 6%. The severe effects of low oxygen or high CO2 may become even more severe when exposure is combined. However, we found limited information in the scientific literature regarding potential additive or synergistic effects between the two gases. According to Levin, for the male rat, 30-min lethal concentration (LC50) for oxygen is 5.4% oxygen in the absence of CO2 (Levin, 1996). In the presence of 5% CO2, the LC50 value increases to 6.4%, suggesting that CO2 has a slight protective effect. Similarly, Lin et al. (1983) found, in a series of rebreathing experiments in human volunteers with and without oxygen addition to or CO2 removal from the recirculated air, that that the oxygen-induced bradycardia was attenuated by CO2.

This pilot study was not designed to assess the time course of oxygen depletion and CO2 formation. Thus, each hold was only analyzed once and the history of the cargo was only obtained from interviews. Yet, the short time of ∼2–3 days required to reach life-threatening conditions in the holds and stairways is alarming. Contributing to the risk is the absence of inherent warning signals. Neither reduced oxygen nor high concentrations of CO2 (or CO) carry with them odor, color, or other indications of danger. On the contrary, these cargoes emit a pleasant fragrance from terpenes. Several of the deaths and injuries occurred when people attempted rescue operations, thinking the victim had merely fallen.

The rapid decrease in oxygen and increase in CO2, in combination with the lack of warning signals, render transportation of wood chips and logs, apparently harmless products, in confined spaces a highly dangerous activity, unless precautionary measures are taken. From the workers’ safety perspective, the inherent risks justify a review of the routines and practices surrounding the handling of these cargoes.

The disappearance of oxygen from the atmosphere in the cargo holds could be the result of, but not limited to, two plausible mechanisms: (a) bioconversion of oxygen to CO2 by microorganisms and (b) oxidation of wood constituents. Based on the relation between oxygen and CO2 levels (Fig. 5), we estimate that ∼70% of the oxygen consumed is recovered as CO2 in the gas phase. The high concentration and rapid formation of CO2 is a strong indication of extensive microbiological activity in cargoes of logs and wood chips. This contrasts with our previous finding in measurements of wood pellet storages, where slower auto-oxidative degradation processes producing CO predominate (Svedberg et al., 2004). The difference in microbiological activity is further supported by the high number of microorganisms present in wood chip and bark samples, and the absence of microorganisms in wood pellets (Table 1). Similar results have been reported by Madsen et al. (2004), who found high bacterial activities in dusts from straw and wood chips (8 × 104 and 3.1 × 106 cfu mg−1, respectively) and low activities in dusts from briquettes and wood pellets (20 and 60 cfu mg−1, respectively). A plausible explanation for the differences in microbiological activity is that wood chips and logs are fresh wood products with a water content of up to 50%, whereas wood pellets are dried at up to 500°C in the production process so as to have a water content <8%. Both the high temperature and the low water content create very unfavorable conditions for microbiological activity in the pellets.

The seasonal variation in oxygen depletion (Fig. 3) suggests that the microbiological activity is temperature dependent. Nevertheless, one fatal accident during unloading of logs took place in the cold month of December in 2006, indicating that there is no ‘safe season’.

The 70% recovery of consumed oxygen as CO2 in the air is intriguing as one might expect almost complete recovery. One explanation may be the different solubility of CO2 and oxygen, the former being almost 30 times more soluble in water (Windholz, 1983). Thus, whereas the oxygen is consumed directly from the air, some of the CO2 formed is retained as carbonic acid (H2CO3) in the water within the wood material or the hold itself. The equilibrium between CO2 and H2CO3 and, hence, the solubility of CO2 is temperature dependent. The variability around the regression line in Fig. 5 may partly be explained by differences in water content and temperature between the shipments.

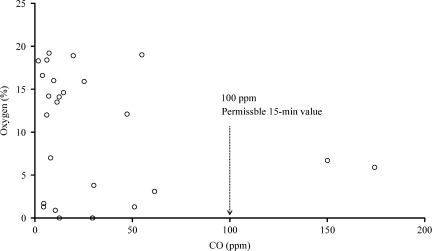

The emission of gases during the storage of wood pellets, through autoxidation processes of wood constituents such as fatty acids and other organic material in wood, was investigated in a previous study (Svedberg et al., 2004). Major emissions were CO and aldehydes and it was suggested that the same autoxidative mechanisms were behind the extremely high CO levels (1460–14 650 ppm) found in shipments of wood pellets (Svedberg et al., 2008). The kinetics of these emissions has been further described in experimental studies where the temperature dependence in particular was illustrated (Kuang et al., 2008). The CO levels found in the present study were modest compared to the levels previously found in shipments of wood pellets and generally below the Swedish 15-min exposure limit of 100 ppm (Fig. 6). The two highest CO concentrations were recorded at an oxygen level of ∼6%, a level that is already fatal in itself. However, the possibility cannot be excluded that a cargo with dry wood chips, i.e. more similar to wood pellets, could emit CO to the point where toxic levels are reached. It has previously been shown that during the kiln drying of lumber, the formation of CO increased as the lumber got drier (Svedberg et al., 2004).

Fig. 6.

Relation between oxygen and CO levels in simultaneously collected stairway air samples (CO measured by FTIR). The vertical arrow at 100 ppm indicates the Swedish occupational short-term value for CO (SWEA, 2005).

Our limited measurements suggest that, maybe partly due to differences in humidity and temperature between shipments as discussed above, oxygen depletion does not correlate as well as might be expected with the CO2 formation. Thus, in one of the 26 parallel measurements, CO2 was quite high (2.8%), yet the oxygen level (18.9%) was close to normal (20.9%) (Fig. 5). Thus, the CO2 recovery was higher than 100% in this single case raising concerns about the instrument accuracy. Regardless of the causes of variability, from a safety point, it appears important to measure oxygen as well as CO2 and CO prior to entering confined spaces containing wood chips and logs. Occupational short-term exposure limits [STELs; e.g. the Swedish short-term values (SWEA, 2005)], as well as acute exposure guidance levels (NAC/AEGL, 2008) and levels considered immediately dangerous to life or health concentration [IDLH (NIOSH, 1994)] may be used as set points. Factors that may aggravate the toxic effects are the combined effects of high CO2 and low oxygen levels, particularly during heavy physical work.

However, from a practical viewpoint, it may be difficult to always measure all three gases. The minimum requirement is then to ensure that the oxygen level remains close to the ambient level of 20.9%. The Swedish 15-min STEL for CO2 is 10 000 ppm (SWEA, 2005). This corresponds in the cargo holds to an oxygen reduction in the atmosphere of at least 1% since practically all CO2 (except the background of 350 ppm) originates from oxygen-dependent processes and since the CO2 yield is only ∼70%. Further, all CO measurements are well below the Swedish STEL of 100 ppm (SWEA, 2005), except in two samples where the oxygen level is ∼6% (Fig. 6). Hence, disregarding the single sample discussed above, oxygen levels >20% seem safe also with regards to CO2 and CO. Notably, this applies only to short stays in confined spaces containing wood chips and logs. The conditions may be very different for other organic materials such as wood pellets.

The reliability and validity of the monitoring equipment is important. Underestimation of concentrations is dangerous while false alarms may cause unnecessary agitation and costly delays. Our limited measurements suggest that commonly used handheld H2S detectors are cross-sensitive and erroneously signal the presence of H2S, whereas the LEL detector fails to detect a relatively high α-pinene level of 500 ppm. Since this type of handheld instrument will typically be used by ships’ crews for safety checks, cross-sensitivities should be investigated in a systematic way. This, however, was beyond the scope of the present study. Further, manufacturers must provide information about possible cross-sensitivities in extreme environments with low oxygen and high CO2 levels. Such information was not available at the time of writing this article.

RECOMMENDATIONS

In spite of the long history of the international and national shipping of logs and wood chips, the recent accidents have caught the shipping industry off guard regarding workers’ exposure to oxygen depletion and hazardous emissions. Although it is impossible to be prepared for all contingencies, it is obvious that stricter operational controls and technical improvements will be needed to prevent future accidents. Our recommendations for increased safety related to the shipping of wood chips and logs are in part the same as those we have already suggested for wood pellets (Svedberg et al., 2008). However, some elaboration seems prudent in light of the findings in the present study.

Repeated training of crew members in all aspects of safety issues related to hazardous cargoes is of key importance. The essential role and training of the Maritime Inspectors should not be overlooked if compliance with existing regulations is to be established. The provision of Material Safety Data Sheets for these cargoes would announce of the inherent hazards in addition to the information already given in the BC Code. However, the present safety recommendations regarding hazardous cargoes are generally heavily dependent on organizational arrangements and, thus, susceptible to human error. Technical preventive measures are largely nonexistent. An important undertaking is therefore to seek technical methods to prevent accidental entry into confined spaces.

Regardless of the reason behind the toxic atmosphere, the weak points are the stairways connecting to the holds, and in the longer term, there should be changes to ship design that carry bulk cargo. Natural ventilation of stairways can be slow and several hours may be required to reach safe levels, as demonstrated in our previous study of wood pellets (Svedberg et al., 2008). Unless a self-contained breathing apparatus is used, mechanical ventilation may be the only effective solution if the stairway needs to be accessed within a reasonable time. Fresh air should be injected at the bottom of the stairway, thus displacing contaminated air to the outside. However, mechanical ventilation may be insufficient when the stairway has a large open entrance to the hold, a design that was the most common in the vessels included in the present study. In such cases, the only safe way is to remove the cargo from the hold before the stairway is ventilated and entry is allowed. Natural ventilation may then suffice.

The access doors to the stairways are sometimes located inside a separate room. Our experience shows that such rooms often share air with the cargo through minute openings, giving the air inside the room the same toxic properties as that in the hold itself. In addition, these ‘entrance’ rooms were often used for storage. They should also be considered confined spaces and the same strict entry procedures should be applied as for the stairways themselves.

An effective preventive measure is to lock access doors leading to confined spaces during the voyage and ensure that the key is kept by a responsible person until safe entry can be arranged. Access doors should be labeled on the outside and the inside with warning signs about low oxygen content, toxic atmosphere, or the skull and crossbones symbol, visible both when the door is open and closed. A door opened for the purpose of ventilating the stairway may be regarded as an invitation to enter by an uninformed person. A chain or rope with a warning sign positioned across the door opening could prevent such accidental entry. The storage of tools or supplies inside confined spaces should be prohibited since fatal accidents have occurred when people have entered to fetch these items.

The oxygen level should always be measured before anyone enters a confined space with suspected air communication with a cargo hold where wood products are stored or have just recently been stored. Since unventilated pockets of air may exist, a personal oxygen monitor should be worn when entering such a confined space. Although the requirement for measurements is already stipulated in the IMO BC Code, for several types of bulk cargoes, the majority of the investigated ships did not have access to proper measurement equipment, or the crew was not properly trained or the instrumentation was not in an operable condition. The recommendations suggested regarding safe entry procedures and technical preventive methods may also apply to the other oxygen-depleting products listed in the IMO BC Code.

FUNDING

Västernorrland County Council, Sweden; Swedish Transport Agency (11117-0); Swedish National Board of Health and Welfare.

References

- Bingham E, Cohrssen B, Powell CH. Patty's toxicology. New York: John Wiley & Sons, Inc.; 2001. [Google Scholar]

- Bollinger N. NIOSH respirator selection logic. Cincinnati, OH: National Institute for Occupational Safety and Health; 2004. [Google Scholar]

- Griffith D. Synthetic calibration and quantitative analysis of gas-phase FT-IR spectra. Appl Spectrosc. 1996;50:59–70. [Google Scholar]

- IMO. Code of safe practice for solid bulk cargoes, 2004: BC code. London: International Maritime Organization; 2005. [Google Scholar]

- Kuang X, Shankar TJ, Bi XT, et al. Characterization and kinetics study of off-gas emissions from stored wood pellets. Ann Occup Hyg. 2008;52:675–83. doi: 10.1093/annhyg/men053. [DOI] [PubMed] [Google Scholar]

- Langford NJ. Carbon dioxide poisoning. Toxicol Rev. 2005;24:229–35. doi: 10.2165/00139709-200524040-00003. [DOI] [PubMed] [Google Scholar]

- Levin BC. New research avenues in toxicology: 7-gas N-Gas Model, toxicant suppressants, and genetic toxicology. Toxicology. 1996;115:89–106. doi: 10.1016/s0300-483x(96)03497-x. [DOI] [PubMed] [Google Scholar]

- Lin YC, Shida KK, Hong SK. Effects of hypercapnia, hypoxia, and rebreathing on circulatory response to apnea. J Appl Physiol. 1983;54:172–7. doi: 10.1152/jappl.1983.54.1.172. [DOI] [PubMed] [Google Scholar]

- Madsen AM, Martensson L, Schneider T, et al. Microbial dustiness and particle release of different biofuels. Ann Occup Hyg. 2004;48:327–8. doi: 10.1093/annhyg/meh016. [DOI] [PubMed] [Google Scholar]

- NAC/AEGL. National Advisory Committee for Acute Exposure Guideline Levels for Hazardous Substances; 2008. Acute exposure guideline levels (AEGLs) carbon monoxide. Available at http://www.epa.gov/oppt/aegl/pubs/carbon_monoxide_interim_jul_2008_v1.pdf. Accessed 6 May 2009. [Google Scholar]

- NIOSH. Documentation for immediately dangerous to life or health concentrations. 1994. NTIS Publication No. PB-94-195047.: National Institute for Occupational Health and Safety. Available at http://www.cdc.gov/niosh/idlh/intridl4.html. Accessed 6 May 2009. [Google Scholar]

- Rothman LS, Barbe A, Benner CD, et al. The HITRAN molecular spectroscopic database: edition of 2000 including updates through 2001. J Quant Spectrosc Radiat Transf. 2003;82:5–44. [Google Scholar]

- Svedberg U, Högberg H-E, Högberg J, et al. Emission of hexanal and carbon monoxide from storage of wood pellets, a potential occupational and domestic health hazard. Ann Occup Hyg. 2004;48:339–49. doi: 10.1093/annhyg/meh015. [DOI] [PubMed] [Google Scholar]

- Svedberg U, Samuelsson J, Melin S. Hazardous off-gassing of carbon monoxide and oxygen depletion during ocean transportation of wood pellets. Ann Occup Hyg. 2008;52:259–66. doi: 10.1093/annhyg/men013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- SWEA. 2005. Occupational exposure limit values and measures against air contaminants. Provision (AFS) 2005: 17. Solna, Sweden: Swedish Work Environment Authority (In Swedish, English version at http://www.av.se/dokument/inenglish/legislations/eng0517.pdf) [Google Scholar]

- Windholz M. The Merck index. Rahway, NJ: Merck & CO., Inc; 1983. [Google Scholar]