Abstract

We present a hybrid system for rapid detection and analysis of benzene, toluene, ethylbenzene, and xylenes (BTEX). The system combines selective and sensitive sensing elements with a fast and miniaturized chromatographic separation method. The sensing elements are an array of microfabricated quartz crystal tuning forks modified with selective molecularly imprinted polymers, and the separation method uses optimized short columns. The high sensitivity and selectivity of the sensing elements together with the help of the separation provides fast detection and analysis of BTEX in real samples containing highly concentrated interfering agents without preconcentration or heating of columns. The low cost, low power consumption, and small size of the hybrid device are particularly suitable for occupational health, industrial safety, and epidemiological applications.

Detection and quantification of trace chemicals in the air are basic and necessary requirements for many applications, including environmental, epidemiological, occupational safety, and toxicological studies. In spite of recent advances, the tasks of analyzing multiple chemicals in a complex environment with thousands of interfering chemicals and substances, using a miniaturized and inexpensive device in real time, remains a difficult challenge. A common strategy in sensor development is to rely on specific binding between a probe and a target molecule, or molecular recognition. This strategy can lead to highly selective and sensitive detection of the analyte if the binding is strong and specific, but it has two inherent drawbacks. First, the strong binding results in slow recovery of the sensing elements, making it difficult for real-time monitoring of analytes with concentrations that vary with time. Second, this strategy cannot be applied to target analytes, such as aromatic hydrocarbons that are weakly interactive and do not have a probe molecule to interact with. A compromise strategy is based on pattern recognition, which uses an array of sensing elements. Another widely used strategy is separation-based techniques, including gas chromatography/mass spectrometry (GC/MS). Conventional GC/MS equipment is bulky, slow, and expensive. Portable GC devices using different detectors1–10 have been developed, but their sensitivity and selectivity are limited, cost is high, and physical size is still bulky for many applications.11 As an effort to miniaturize GC, micromachined columns and preconcentrators have been investigated in combinations with SAW and chemresistor detectors.8,12,13 On-column microGC with capillary-based ring resonators have also been developed.14,15

In the present work, we combine and integrate the two strategies, specific binding and chromatographic separation, synergistically into a miniaturized palm-size device that can quickly detect volatile organic compounds (VOCs) in complex environments (Scheme 1). Using the integrated device, we have been able to detect a few part per million-levels of benzene, toluene, ethylbenzene, and xylenes (BTEX), the most common traffic related air pollutants, within 2–3 min, without the need of preconcentration. In addition, the device has wireless capability for instantaneous data transmission and remote control. The usefulness of the system is demonstrated with the analysis of BTEX content in real samples and validation of the results with a conventional GC/MS method.

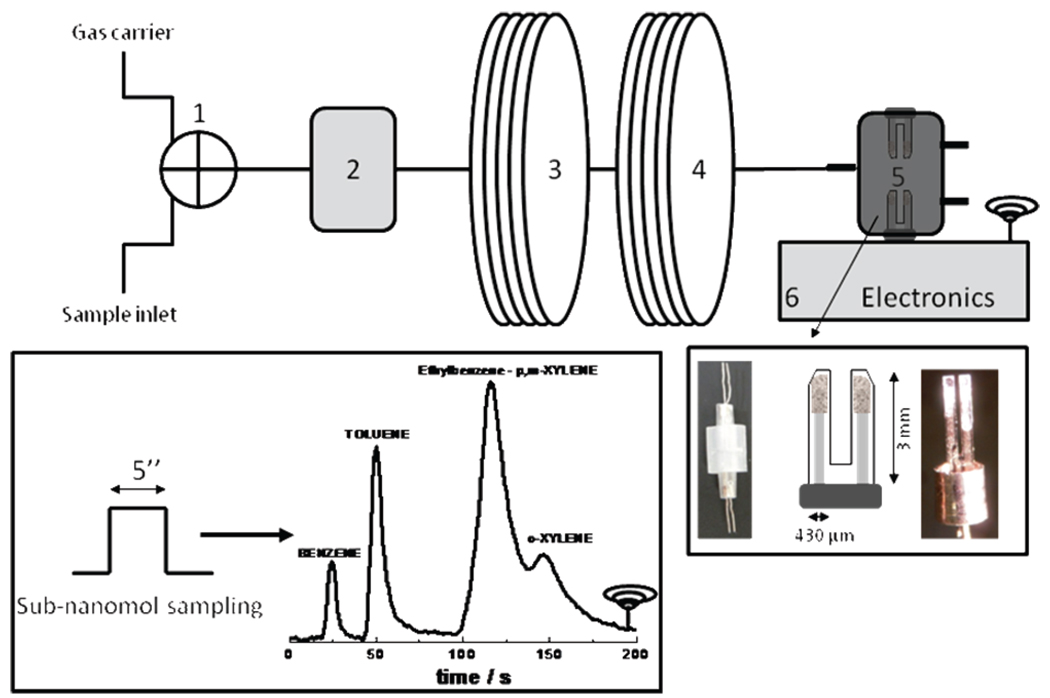

Scheme 1.

Schematic Representation of the Handheld Sensing System for Detection of BTEX (Top) a and a Typical Chromatogram of the BTEX Separation Process Corresponding to the Injection of Subnanomole Amounts of Analytes for 5 Seconds (Inset at Bottom Left)

a The system is formed by two main subsystems: a sensor array detector based on tuning fork resonators (TF) with tuned selectivity for detection of the analytes in complex environments and a separation column subsystem. The system include (1) a miniature valve, (2) a mini gas pump, (3 and 4) bonded stainless steel capillary columns, and a novel detector formed by (5) a sensor chamber, array of polymer-modified tuning forks, and (6) a wireless high-frequency resolution detection circuit.

EXPERIMENTAL SECTION

Target Analytes

BTEX is a group of aromatic volatile organic compounds (VOCs) associated with traffic pollution and represents more than 80% of automobile exhaust and other related traffic processes. Many epidemiological studies have associated BTEX to adverse effects in human health mainly on the nervous and hematopoietic systems with some incidence on cancer development.16 However, fundamental uncertainties persist due to the lack of appropriate tools for their detection and analysis in an efficient, fast, inexpensive, easy, and reliable way.

Quartz Crystal Tuning Forks (TFs) Sensors

These are microelectromechanical resonators that provide intrinsic sensing properties, including low noise, low power consumption, and high quality factor (~10 000 in ambient air) associated to high sensitivity of mass or force (pN) detection (~4 pg/mm2).17–19 The tuning forks have a resonance frequency of 32.768 kHz (Newark Inone Electronics), a small size of 250 µm × 430 µm × 3 mm and an effective spring constant of 20 kN m−1. The thermal noise of the tuning fork is small with a rms oscillation amplitude of 4 × 10−4 nm for the prongs at room temperature.17,20,21 A high-performance digital counter was built which allows us to measure the resonance frequency with ~2 mHz resolution, or equivalently 4 pg/mm2 of mass detection limit. In addition, a Bluetooth chip connected to a microcontroller gives wireless capability to the detector. This enables transmission of data to other wireless-enabled systems, such as a computer or a cell phone, improving signal processing, storage, and further transmission capabilities.

Sensing Materials Modifying the TF Sensors

To obtain the desired selectivity22–26 for detection of BTEX components in complex environmental matrixes, the tuning forks must be modified with appropriate sensing materials. For this purpose, molecularly imprinted polymers (MIPs) were synthesized and screened to provide the needed selectivity as well as sensitivity, response time, and reversibility (Figure SI-1 in the Supporting Information). A highly cross-linked polystyrene formed by divinylbenzene (Sigma), a high density of binding sites generated by the biphenyl (BP) (Sigma) template, and the porogen solvent (ethylbenzene + o-,p-,m-xylenes) (Mallinckrodt) gave the best performance. Synthesis of this polymer was performed according to (ref 27).27 On the basis of the chemical nature of the materials, the MIP binding sites bind to the target analytes primarily via multiple π–π and van der Waals interactions, which allows for selective but reversible binding. A fluoroalcohol polysiloxane polymer (SC-F201, Seacoast Science, Inc.) at a concentration of 20 mg mL−1 in toluene was used to coat a second sensing element. The polymer is acidic and hydrophobic which can discriminate non-BTEX components. The use of multiple sensing elements with complementary functions improves the selectivity of the system, which is critical for real sample analysis.

The tuning forks were first coated with a hydrophobic layer by immersing them in toluene containing 10% (v/v) phenyltrimethoxysilane for 24 h. After the tuning forks were rinsed with toluene and dried out with clean air, they were dipped in 20 mM dodecanetiol in isopropanol for 60 min. In this way, the quartz surface and also the electrodes of the tuning forks became hydrophobic. Subsequently the tuning forks were coated with BP-MIP (MIP-TF) and SC-F201 (SCF-TF) polymer. The masses of the polymer coatings ranged from 0.5 to 3 µg, and the sensitivities of the tuning forks vary within 20%.

Chromatographic Separation

Gas samples were prepared by injecting microliter amounts of the liquid analyte into 40 L Tedlar bags filled with synthetic air (breathing quality) in order to get the desired concentration. Additional dilutions of samples were performed with a precision gas diluter or by mixing the contents of the Tedlar bag with air, using an inert gas pump and timed valve switching. An inert gas pump provides a constant flow of air through a coupled stainless steel capillary column, made of two 2 m long columns in series. The inner filling materials of the two columns are carbowax and cyanopropylphenylsilicone (Quadrex Inc.), respectively, to provide optimal separation performance. The outlet of the coupled capillary column was connected to a 50 µL chamber in which the tuning fork sensors are housed (pictures of the system components are included in Scheme SI-1 in the Supporting Information).

RESULTS AND DISCUSSION

Polymer-Modified Tuning Fork Based Detector

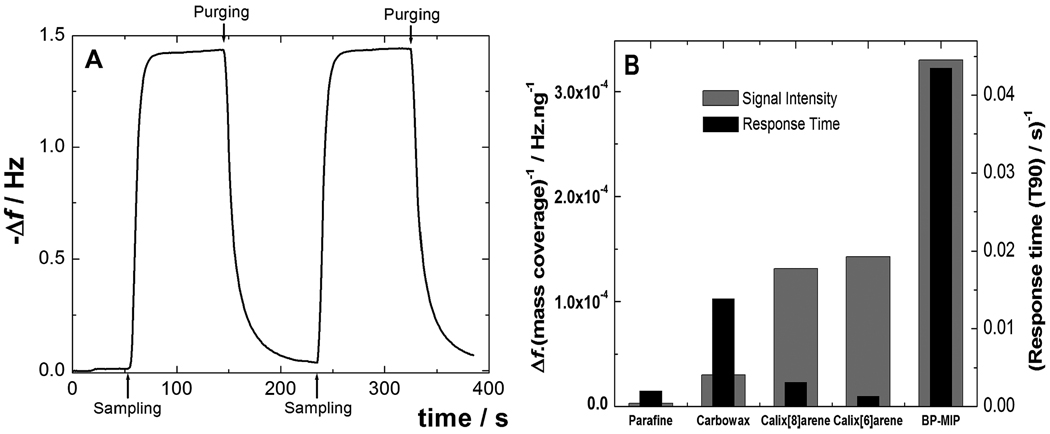

As shown in Scheme 1, the device consists of three key components: (1) an injection unit consisting of a sample trap loop, a miniaturized valve, and a gas pump capable of sampling and purging the system; (2) a separation unit using a coupled capillary column; and (3) a detector based on quartz crystal tuning forks. While all the components are important, the detector unit is particularly critical for the detection of BTEX. The detector was made of TFs coated with BP-MIP, and its response to toluene is shown in Figure 1A. The response time taken at 90% of saturation response (T90) ranged from 15 to 25 s for sensors with typical mass coverage of 500–700 ng. More importantly, the BP-MIP-coated TFs showed a rapid desorption process, which is critical for real-time detection of analytes. Fast responses are also found for benzene and mixtures of ethylbenzene and xylenes. The superior performance of the BP-MIP-coated TFs is demonstrated by comparing them with commercial materials. Figure 1B and Figure SI-2 in the Supporting Information compares the response time and sensitivity of BP-MIP with commercial materials: (1) compact bulk polymers, such as paraffin and carbowax; (2) compounds containing cavity structures, such as calixarenes, which have been used for the detection of analytes similar to BTEX; and (3) various hydrophobic materials (Supporting Information). The BP-MIP synthesized in this work is superior for BTEX detection in terms of both response time and sensitivity. The detection limits of BP-MIP-modified TFs are several tens to a few hundreds parts per billion by volume (ppbv), which are suitable for occupational and industrial hygiene applications (Table 1, first and third columns entries).

Figure 1.

(A) Response of BP-MIP modified tuning fork to 40 ppmv toluene in air. Flow rate: 250 mL min−1. (B) Mass normalized response and reciprocal of response time for tuning forks modified with different polymers. Sample: 40 ppmv toluene. Flow rate: 250 mL min−1.

Table 1.

Comparison between Intrinsic Detection Limit of the MIP-TF Sensing Element, Separation-TF Detection Device (Sep-TF), and Occupational, Safety and Health Administration Permisible Exposure Levels (OSHA PEL)

| detection limitsa | |||

|---|---|---|---|

| MIP-TF/ppbv | GC–TF/ppmv | OSHA PELb/ppmv | |

| benzene | 700 | 10 | 10 |

| toluene | 230 | 4 | 200 |

| p,m-xylenes | 70 | 3 | 100 |

Detection limits correlate with 3 times the noise level.

OSHA PEL: OSHA regulations. Standards 29CFR 1910.1000.

Although the detection limits of the MIP-TF sensing element are below 1 ppmv, it should be noted that the chromatographic separation, i.e., the Sep-TF detection, has detection limits of few parts per million by volume levels. The difference is due to the flow rate dependence of the MIP-TF sensing element. Signal response for the MIP-TF sensor depends strongly on the sampling flow rate, reaching a steady state signal for flow rates higher than 100 mL min−1; however, this high flow rate cannot be reached with the chromatographic separation mainly because of two aspects: first one, the separation is not efficient at this high flow rate value, and second, such big flow rates cannot be reached with miniaturized gas pumps that are needed for a wearable device. The volume and geometry of the detection chamber that houses the tuning forks could also have an effect on the detection limits. We have examined the dead volume of the chamber and found no obvious change in the detection limits for dead volumes varying from 50 to 500 µL.

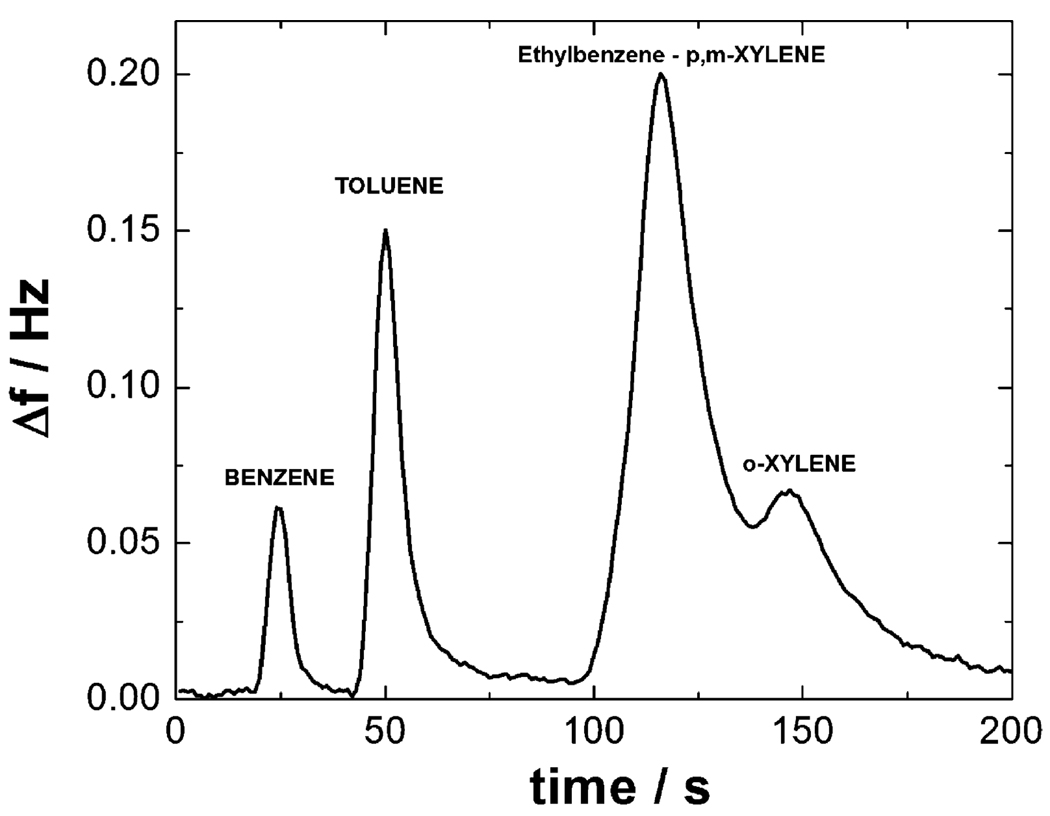

Separation of BTEX

The selectivity of BP-MIP has been systematically tested using common interfering agents, such as alcohols, ketones, and humidity (Figure SI-3 in the Supporting Information). Although BP-MIP provides selective detection of the BTEX family, based on both different vapor pressures of the analytes28 and partial specific binding of BP-MIP to BTEX, it is highly desirable to include an additional mechanism to further improve the selectivity for real samples that contains many different interference molecules. For this purpose, we have integrated the separation mechanism into the system. It is important to emphasize that we wish to achieve the hybrid device without compromising the simplicity and time response of the system. Unlike the conventional portable GC, we do not need to use preconcentrators owing to the high sensitivity of the TFs detector, which not only speeds up the detection time but also lower the cost and power consumption and reduces the size of the entire device. We do not heat the separation columns either, which is possible partially due to the selectivity of the sensing elements of the detector. In addition, instead of using a purified inert gas from a cylinder as the carrier gas, as is commonly done in conventional GC, we use ambient air that passes through a simple filter. Finally, we further improve performance of the device by using short (2 m) and optimized separation columns made of carbowax and cyanopropylphenyl silicone connected in series to achieve high run-speed without significantly lowering the separation capability. Using the integrated device, we are able to detect BTEX mixtures in less than 200 s with peak widths of 6, 7, and 15 s for benzene, toluene, and ethylbenzene and xylenes, respectively (Figure 2). It should be noted that under the developed experimental conditions it is not possible to separate ethylbenzene from m,p-xylenes because they have very close boiling points between 138–139 °C; however, o-xylene with a boiling point of 144 °C can be resolved from the other ones. This lack of efficiency in the separation, also observed during GC/MS determinations, could be solved using flow restrictors at the middle point between the coupled capillary columns or using different compositions for the inner material of the capillary columns in order to get specific interactions that can differentiate between ethylbenzene and m,p-xylenes. Both of these later approaches are under development.

Figure 2.

Analysis of a BTEX mixture using the separation-TF detection system. Flow rate: 8 mL min−1. Injection time: 5 s. Gas carrier: clean air. Sample composition: 50 ppmv benzene, 50 ppmv toluene, 11 ppmv ethylbenzene, 29 ppmv m-xylene, and 11 ppmv o-xylene.

Several calibration tests indicate a linear dynamical range from ~5 ppmv and up to 250 ppmv without hysteresis after the analysis of high concentrations. Beyond this, a stability test with the same sensing platform during 7 months shows less than 5% of dispersion for BTEX detection; more than 200 tests with different concentrations were performed during this period of time.

It is worthy to mention that columns based on silica particles packed in ⅛ in. internal diameter Teflon tubing of ~10–15 cm were also effective for separation of BTEX and offered an alternative for separation (Figure SI-4 in the Supporting Information). However, the separation time of BTEX components is longer (~10 min), and for this reason we decided to keep the capillary columns.

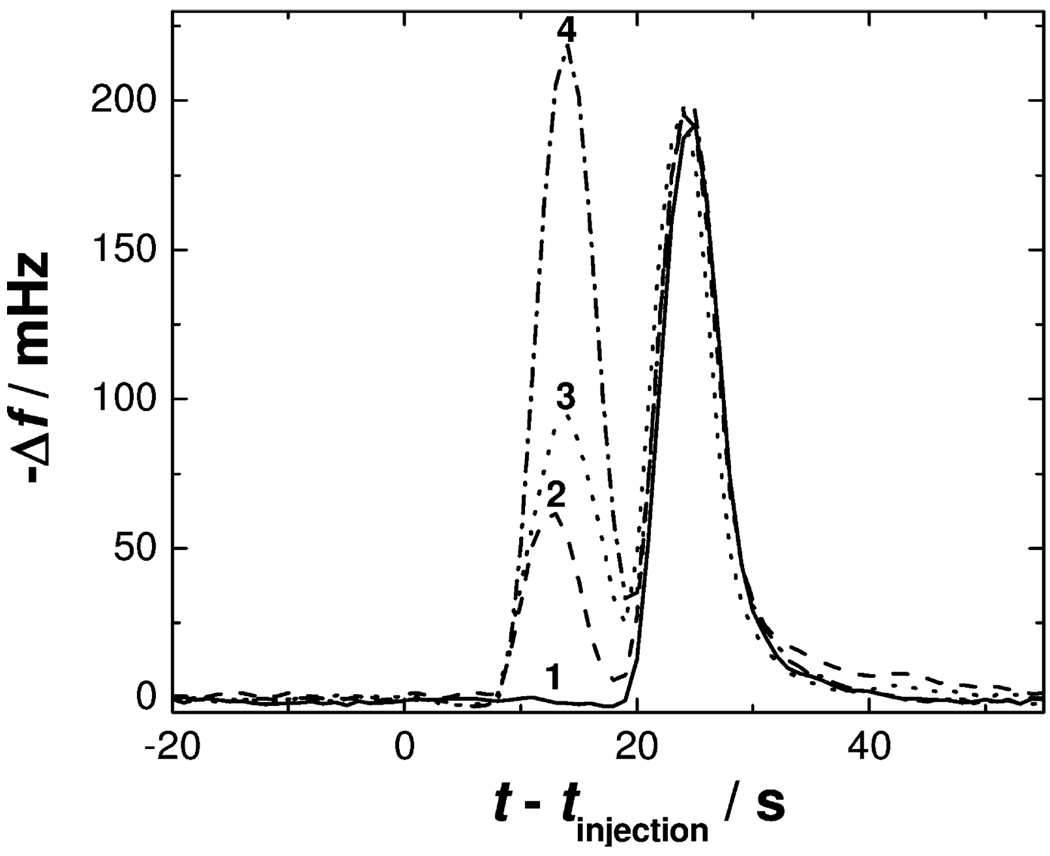

Selective Detection of BTEX with the Hybrid Device

In order to ensure a reliable analysis of BTEX mixtures without false positives or false negatives for real samples, we have tested the hybrid system using various interfering agents commonly found in ambient air. The selectivity coefficients, defined as the ratio of the response to each of the analytes to the interfering agents, range between 3 and 40 for common interfering agents, such as polar hydrocarbons, chlorinated hydrocarbons, and some aliphatic hydrocarbons (Table 2). These selectivity coefficients were determined with samples having concentrations for the interfering agents at least 3 times higher than for the BTEX sample (BTEX sample, 40–50 ppmv; interfering agent, 150 ppmv). We found good discrimination capability, due to the hybrid selective bind–separation approach. First, the BP-MIP TFs provide an intrinsic selective detection of benzene, toluene, and ethylbenzene and xylenes. Second, the separation mechanism allows us to separate analytes from the interfering agents in the time domain and provide additional discrimination capability. Figure 3 shows an example of detection of benzene in the presence of highly concentrated acetone, ethanol, and hexane (total interfering agent concentration: 450 ppmv). It is clear that the benzene signal with an elution time of 24 s is not affected by the presence of the highly concentrated interfering agent and its signal is not changing when the concentration of the interfering agent is varied.

Table 2.

Estimated Selectivity Coefficients for Detection of BTEX Using the Separation-TF Device

| estimated selectivity coefficientsa | |||

|---|---|---|---|

| benzene | toluene | xylenes | |

| acetone | 33 | 75 | 115 |

| ethanol | 42 | 95 | 146 |

| dichloromethane | 4.2 | 21 | 28 |

| 1,3,5-trimethylbenzene | 8.9 | 39 | 155 |

| 1,2,4-trichlorobenzene | 27 | 12 | 5.2 |

| heptane | 1.8 | 32 | 212 |

| cyclohexanone | 11 | 23 | 15 |

| naphtalene | 4.6 | 24 | 231 |

| dodecane | 66 | 150 | 240 |

Estimated selectivity coefficients are the ratio of the signals between the analyte and the interfering agent. Signals were taken at the analyte elution time.

Figure 3.

Response of 150 ppmv benzene after successive additions of different interfering agaents to the same sample: (1) benzene, (2) acetone, (3) ethanol, and (4) hexane. The experimental conditions are the same as in Figure 2.

As a matter of fact, the signal for benzene at 150 ppmv does not depend on the concentration of acetone when this latter one is changing from 50 to 250 ppmv (see Figure SI-5 in the Supporting Information); the same behavior is observed for different concentrations of ethanol or hexane. On the contrary, 1,2,4-trichlorobenzene and cyclohexanone at high concentrations influence the sensor selectivity (Table 2). They present broad peaks with elution times close to the elution time for xylenes, which reduce the selectivity coefficients xylenes/trichlorobenze and xylene/cyclohexanone down to 5.2 and 15.

Detection of BTEX in Real Samples

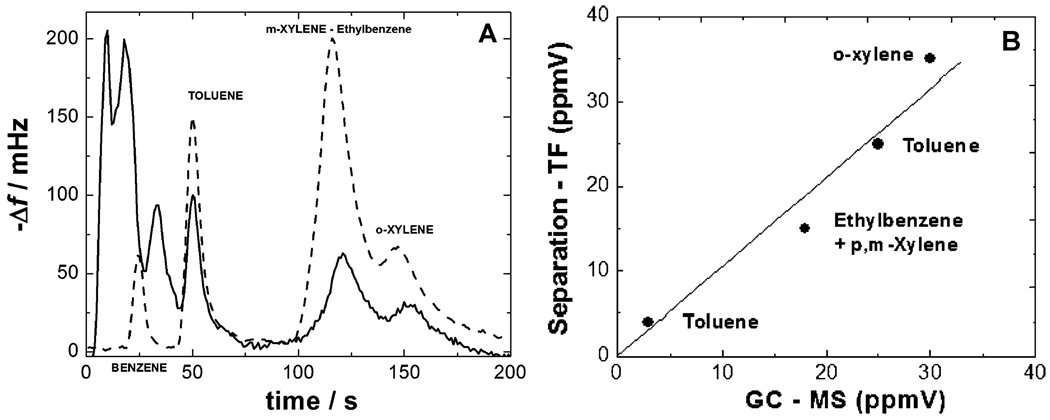

Gasoline vapors, one of the most complicated real samples,29 were used to test the performance of the hybrid device. Figure 4A compares the results of a 50 ppmv BTEX mixture (dashed line) and air sample taken near the opening of a car’s gas tank (solid line). Peaks corresponding to toluene (at 50 s) and ethylbenzene–xylenes (at 116 s) were well separated from the peaks arising from other components of the sample. However, at short elution times (less than 40 s), multiple peaks appeared corresponding to short hydrocarbons and other polar components at high concentrations in the sample (Supporting Information and the next section). For comparison, we have carried out a similar analysis using a commercial GC/MS system. Figure 4B shows that despite the simplicity of our system, the results are in good agreement with the reference GC/MS method with a correlation slope close to 1 (slope = 1.05) and an average dispersion of less than 10%. We note that the GC/MS analysis requires 15 min sample preconcentration in a poly(dimethylsiloxane) solid phase microextraction fiber (SPME) and another 12 min run for the separation (Figure SI-6 in the Supporting Information). In contrast, our hybrid device does not need preconcentration, and the entire analysis is as short as 3–4 min. Furthermore, our system is palm size, which is critical for many field applications. Finally, we demonstrate below that the analytical capability of the system improves by including additional sensing elements functionalized with sensing materials with complementary chemical properties to BP-MIP.

Figure 4.

Real sample analysis of a car’s gas tank using the separation-TF system and conventional GC/MS with SPME preconcentration. (A) Dashed line: BTEX mixture (sample composition: 50 ppmv benzene, 50 ppmv toluene, 11 ppmv ethylbenzene, 29 ppmv m-xylene, and 11 ppmv o-xylene.); solid line, car’s gas tank sample. Flow rate: 8 mL min−1. Injection time: 5 s. (B) Correlation between the separation-TF detection system and the GC/MS method for a car’s gas sample. Preconcentration on the SPME fiber was performed for 5 min.

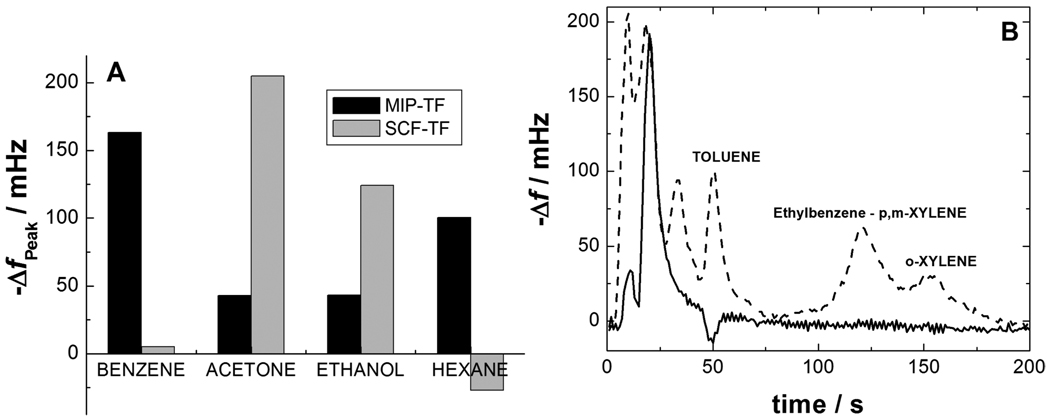

Detector Based on Multiple Tuning Fork Sensors

We have added another TF sensing element modified with fluoroalcohol polysiloxane (SCF-TF). In contrast to BP-MIP, SCF-TF is particularly selective and sensitive to polar VOCs, which is used to detect low molecular weight interfering agents at short elution times. Figure 5A compares the responses obtained for different compounds using the BP-MIP-TF and the SCF-TF sensors. The SCF-TF sensor showed a large response to acetone and ethanol (polar VOCs) but negligible responses to benzene and other BTEX. Moreover it shows a positive shift in frequency in the presence of hexane, probably due to a change in the stiffness constant of the coating.

Figure 5.

(A) Comparison of responses given by the MIP-TF and SCF-TF sensors to different analytes. (B) Analysis of a car’s gas sample using the separation-TF detection system with an array of polymer-modified tuning forks. Dashed line: MIP-TF. Solid line: SCF-TF.

Figure 5B depicts the analysis of the gasoline vapor sample with the hybrid device including the BP-MIP and SCF sensors. It shows that the MIP-TF sensor detects toluene, ethylbenzene, and p,m,o-xylenes but also some other compounds at short elution times. In contrast, the SCF-TF sensor does not detect BTEX components and detects only compounds eluting at short times (<50 s). By analysis of the relative responses of both sensing elements (Figure 5A) and the run (Figure 5B), it is possible to discriminate the composition of the sample in the region where peaks overlap for each of the sensing elements (t <50s) and conclude that the compounds eluting at short times are mostly polar components and short alkyl hydrocarbons, which typically elute at short times (<40 s). We note that most real samples are not as complicated as gasoline vapors (see another example in Figure SI-7 in the Supporting Information), and both tuning fork sensors can work independently with good selectivity for the BTEX mixture and also for polar components like acetone and ethanol. In most of the cases, it is possible to resolve a sample with different polar and BTEX components and BTEX concentrations equal or well below the Occupational Safety and Health Administration permissible exposure levels (Table 2, second column entry).

CONCLUSIONS

This work has successfully demonstrated that it is possible to perform real-time detection and analysis of BTEX components in real samples using an inexpensive and miniaturized hybrid specific binding–separation device. The system allows the detection and analysis of low parts per million by volume detection of BTEX in complex samples within 3–4 min. The hybrid device is more selective than sensors based on specific binding only and faster, simpler, and more miniaturized than conventional portable GCs. It achieves the improved performance without preconcentration, programmed heating elements, and processes. The system is appropriate for occupational health and safety applications as well as for toxicological population studies.

Supplementary Material

ACKNOWLEDGMENT

This work has been supported by NIH/NIEHS (Grant U01 ES0106064-01) via the GEI program.

Footnotes

SUPPORTING INFORMATION AVAILABLE

Additional information as noted in text. This material is available free of charge via the Internet at http://pubs.acs.org.

References

- 1. www.agilent.com/chem/microgc.

- 2. www.varianinc.com.

- 3. www.hnu.com.

- 4. www.photovac.com.

- 5. http://microsensorsystems.com.

- 6. http://www.raesystems.

- 7. http://www.estcal.com.

- 8.Elmi I, Zampolli S, Cozzani E, Mancarella F, Cardinali GC. Sens. Actuators, B: Chem. 2008;135:342–351. [Google Scholar]

- 9.Kanda K, Maekawa T. Sens. Actuators, B: Chem. 2005;108:97–101. [Google Scholar]

- 10. http://www.torion.net/

- 11. http://www.raesystems.com/products/ultrarae-3000.

- 12.Chia-Jung L, Steinecker WH, Tian WC, Oborny MC, Nichols JM, Agah M, Potkay JA, Chan HKL, Driscoll J, Sacks RD, Wise KD, Pangad SW, Zellers ET. Lab Chip. 2005;5:1123–1131. doi: 10.1039/b508596a. [DOI] [PubMed] [Google Scholar]

- 13.Zampolli S, Elmi I, Sturmann J, Nicoletti S, Dori L, Cardinali C. Sens. Actuators, B: Chem. 2005;105:400–406. [Google Scholar]

- 14.Shopova SI, White IM, Sun Y, Zhu HY, Fan XD, Frye-Mason G, Thompson A, Ja SJ. Anal. Chem. 2008;80:2232–2238. doi: 10.1021/ac702389x. [DOI] [PubMed] [Google Scholar]

- 15.Sun YZ, Shopova SI, Frye-Mason G, Fan XD. Opt. Lett. 2008;33:788–790. doi: 10.1364/ol.33.000788. [DOI] [PubMed] [Google Scholar]

- 16.C. S. i. E. M. B. T. A. f. T. S. a. D. R. A. 2006. 2006 [Google Scholar]

- 17.Ren MH, Forzani ES, Tao NJ. Anal. Chem. 2005;77:2700–2707. doi: 10.1021/ac048320e. [DOI] [PubMed] [Google Scholar]

- 18.Tsow F, Forzani ES, Tao NJ. Anal. Chem. 2008;80:606–611. doi: 10.1021/ac7016162. [DOI] [PubMed] [Google Scholar]

- 19.Ren MH, Tsow T, Forzani ES, Tao NJ. Abstr. Pap. Am. Chem. Soc. 2005;229 396-ANYL. [Google Scholar]

- 20.Tsow F, Tao N. Appl. Phys. Lett. 2007;90 [Google Scholar]

- 21.Boussaad S, Tao NJ. Nano Lett. 2003;3:1173–1176. [Google Scholar]

- 22.Fu Y, Finklea HO. Abstr. Pap. Am. Chem. Soc. 2003;225 133-ANYL. [Google Scholar]

- 23.Dickert FL, Tortschanoff M, Bulst WE, Fischerauer G. Anal. Chem. 1999;71:4559–4563. [Google Scholar]

- 24.Dickert FL, Hayden O. Adv. Mater. 2000;12:311–314. [Google Scholar]

- 25.Dickert FL, Hayden O. TrAC, Trends Anal. Chem. 1999;18:192–199. [Google Scholar]

- 26.Matsuguchi M, Uno T. Sens. Actuators, B: Chem. 2006;113:94–99. [Google Scholar]

- 27.Lieberzeit PA, Gazda-Miarecka S, Halikias K, Schirk C, Kauling J, Dickert FL. Sens. Actuators, B: Chem. 2005;111–112:259. [Google Scholar]

- 28.Grate JW, Patrash SJ, Abraham MH. Anal. Chem. 2002;67:2162. doi: 10.1021/ac950518z. [DOI] [PubMed] [Google Scholar]

- 29.Sacks R, Klemp M, Akard M. Field Anal. Chem. Technol. 1996;1:97–102. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.