Abstract

Restrictions on the use of polybrominated diphenyl ethers (PBDEs) have resulted in the increased use of alternate flame retardant chemicals to meet flammability standards. However, it has been difficult to determine which chemical formulations are currently being used in high volumes to meet flammability standards since the use of flame retardant formulations in consumer products is not transparent (i.e. not provided to customers). To investigate chemicals being used as replacements for PentaBDE in polyurethane foam, we analyzed foam samples from 26 different pieces of furniture purchased in the United States primarily between 2003 and 2009 using gas chromatography mass spectrometry. Samples included foam from couches, chairs, mattress pads, pillows, and, in one case, foam from a sound proofing system of a laboratory grade dust sieve. Fifteen of the foam samples contained the flame retardant tris(1,3-dichloro-2-propyl) phosphate (TDCPP; 1–5% by weight), four samples contained tris(1-chloro-2-propyl) phosphate (TCPP; 0.5 –2.2 % by weight), one sample contained brominated chemicals found in a new flame retardant mixture called Firemaster 550 (4.2% by weight), and one foam sample collected from a futon likely purchased prior to 2004 contained PentaBDE (0.5% by weight). Due to the high frequency of detection of the chlorinated phosphate compounds in furniture foam, we analyzed extracts from 50 house dust samples collected between 2002 and 2007 in the Boston, MA area for TDCPP, TCPP, and another high volume use organophosphate-based flame retardant used in foam, triphenylphosphate (TPP). Detection frequencies for TDCPP and TPP in the dust samples were >96% and were log normally distributed, similar to observations for PBDEs. TCPP was positively detected in dust in only 24% of the samples, but detection was significantly limited by a co-elution problem. The geometric mean concentrations for TCPP, TDCPP and TPP in house dust were 570, 1890, and 7360 ng/g, respectively, and maximum values detected in dust were 5490, 56,080 and 1,798,000 ng/g, respectively. These data suggest that levels of these organophosphate flame retardants are comparable, or in some cases, greater than, levels of PBDEs in house dust. The high prevalence of these chemicals in foam and the high concentrations measured in dust (as high as 1.8 mg/g), warrant further studies to evaluate potential health effects from dust exposure, particularly for children.

Keywords: Flame Retardants, Polyurethane Foam, House Dust, TDCPP, Triphenyl phosphate

INTRODUCTION

Flame retardant chemical additives have been used for several decades to reduce the flammability of resins and polymers found in commercial products such as furniture, mattresses, electronics (e.g. televisions, cell phones) and even children’s products such as car seats, strollers and baby clothing (1–4). These chemicals are designed to increase the time available to escape from fires by delaying the combustion of the treated materials. However, these flame retardants have been shown to leach or otherwise escape from these products over time and accumulate in both indoor and outdoor environments, raising concerns about human exposure and potential health effects (5–7)

Prior to 2004, polybrominated diphenyl ethers (PBDEs) were one of the most common flame retardant mixtures used in furniture and electronic products. PBDEs were sold commercially as three different formulations referred to as PentaBDE, OctaBDE, and DecaBDE, each having different applications. However, due to their persistence, bioaccumulation, and potential health effects, PentaBDE and OctaBDE were banned or voluntarily phased out from use beginning in 2002 in many regions of the world, and will soon be added to the list of banned chemicals included in the Stockholm Convention on Persistent Organic Pollutants(8). PentaBDE was historically used in the highest volumes in North America (primarily U.S. and Canada) to treat polyurethane foam in furniture (9). The higher use of PentaBDE in North America led to elevated levels of the PentaBDE congeners in the U.S. population relative to European and Asian populations, likely due to a higher exposure from house dust (10–17). Several studies have recently found associations between human body burdens of PBDEs (primarily PentaBDE) and health effects such as thyroid hormone and androgen abnormalities, cryptorchidism, and low birth weights (18–21).

The phase-out of PentaBDE has led to the development of alternate flame retardant formulations and the increased use of existing flame retardant chemicals to meet flammability standards for polyurethane foam (22). We recently identified the brominated components of a PentaBDE replacement mixture suspected of high volume use in polyurethane foam (23); however, for many flame retardants, basic information such as chemical identity and their consumer product applications is typically not available. Lack of information significantly restricts environmental and human health assessments for these chemicals, which is of considerable concern, particularly since the PentaBDE replacement chemicals recently identified were also detected in U.S. house dust (23). Occurrence in house dust suggests that human exposure to these flame retardants will also occur, and raises concerns regarding the potential for exposure to other PBDE replacements that have yet to be identified. Though several studies have reported the environmental fate and effects of PBDEs, very little information on the occurrence, fate and toxicity of their replacement chemicals exists.

In our previous study, we identified two brominated compounds in a flame retardant mixture (Firemaster® 550) now being used as a replacement for PentaBDE in polyurethane foam (23). However it has been suggested that organophosphate compounds, some chlorinated, are also currently used or have historically been used as flame retardant chemicals in high volumes (24). Tris (1,3-dichloro-2-propyl) phosphate (TDCPP) and triaryl phosphates such as triphenyl phosphate (TPP), have been used for decades as flame retardants and plasticizers in a wide variety of applications, resulting in widespread environmental contamination (25, 26). Production and use of these flame retardants in furniture foam may have increased due to the phase out of PBDEs.

Based on this information, we designed this study to identify potential organophosphate flame retardant chemicals currently being used in polyurethane foam in residential and office furniture purchased in the United States. To do this we specifically targeted furniture items produced by a major furniture retailer in the U.S. which claimed to have phased-out the use of brominated flame retardants. A second objective was to determine whether these alternative flame retardants were accumulating in house dust. Fifty house dust samples collected between 2002 and 2007 in Boston, MA, which were initially analyzed for PBDEs and other brominated flame retardants were screened for organophosphate flame retardants identified in the foam. Lastly, we estimated the cumulative exposure to a suite of flame retardant chemicals now being detected in house dust to adults and children.

MATERIALS AND METHODS

Materials

Internal and surrogate standards used in this study were purchased from Chiron (Trondheim, Norway) and Wellington Laboratories (Guelph, Ontario). PBDE quantification standards were purchased from Accustandard (New Haven, CT), and bistribromophenoxyethane (BTBPE) and decabromodiphenyl ether (DBDPE) were purchased from Wellington Laboratories. The 2-ethylhexyl 2,3,4,5-tetrabromobenzoate (TBB) and bis (2-ethylhexyl) tetrabromophthalate (TBPH) standards were purchased from Wellington Laboratories. Tris(1-chloro-2-propyl) phosphate (TCPP) and tris(1,3-dichloro-2-propyl) phosphate (TDCPP) were purchased from Pfaltz & Bauer (Waterbury, CT) and Chem Service (West Chester, PA), respectively. Triphenyl phosphate (TPP, 99% pure) was purchased from Sigma-Aldrich (St. Louis, MO). All solvents used throughout this study were HPLC grade.

Sample Collection

Foam samples were donated by friends, family, and colleagues of the authors residing in numerous cities around the U.S. after soliciting a request for samples. Foam samples, approximately 2–10 cm3 in volume, were cut out of furniture pieces, wrapped in aluminum foil, sealed in a plastic bag, and mailed to Duke University for analysis. All foam samples analyzed in this study were from furniture pieces purchased in the United States; however, most of the furniture was manufactured outside the U.S. Dust was collected from vacuum cleaner bags from homes in Boston, MA area between 2002 and 2007; the samples were not collected from the same locations as the foam samples. Details on collection, treatment and storage of the dust samples are provided elsewhere (20).

Sample Extraction

Our method for the analysis of the brominated flame retardants measured in this study is reported in Stapleton et al. (23). The analysis of the foam and dust samples for the organophosphate compounds is briefly outlined here. Approximately 0.3 to 0.5 grams of sieved dust was accurately weighed, spiked with 50 to 100 ng of two internal quantification standards (4’fluoro-2,3’,4,6-tetrabromodiphenyl ether (F-BDE 69) and 13C-labeled decabromodiphenyl ether (13C BDE 209)), and extracted in stainless steel cells using pressurized fluid extraction (ASE 300, Dionex Inc.). Cells were extracted three times with 50:50 dichloromethane:hexane at a temperature of 100°C and at 1500 psi. Foam samples of approximately 0.2–0.3 grams in weight were also extracted using the same solvents on the ASE system but no internal standards were spiked into the ASE cell. Final extracts were reduced in volume to approximately 1.0 mL using an automated nitrogen evaporation system (Turbo Vap II, Zymark Inc.). Foam sample extracts of approximately 3.5 mL in volume were then accurately weighed in a 4 mL amber vial and a 50 µL aliquot was transferred to an autosampler vial, spiked with 100 ng of a carbon-labeled chlorinated diphenyl ether (13C CDE 141), and prepared for gas chromatography mass spectrometry (GC/MS) analysis. Dust extracts were purified by elution through a glass column containing 4.0 g of 6% deactivated alumina. All analytes were eluted with 50 mL of a 50:50 mixture of dichloromethane:hexane. The final extract was then reduced in volume to 0.5 mL and 50 ng of the recovery standard, 13C CDE 141, was added prior to GC/MS analysis. For the foam extracts, an aliquot of the extract was transferred to an autosampler vial and spiked with the recovery standard and analyzed by GC/MS.

Sample Analysis

All samples were analyzed using an Agilent (Wilmington, DE) gas chromatography (model 6890N) mass spectrometer (model 5975). Foam extracts were scanned in both electron impact (EI) and electron capture negative ionization mode (GC/ECNI-MS) over a scan range of 50 – 1050 amu and EI spectra were compared to the NIST mass spectral database (2005). Dust sample extracts were analyzed in electron impact mode (GC/EI-MS) for the detection of TCPP and TPP, or by GC/ECNI-MS for TDCPP and the brominated flame retardants. A 0.25 mm (I.D.) × 15 m fused silica capillary column coated with 5% phenyl methylpolysiloxane (J&W Scientific, 0.25 µm film thickness) was used for separation of the analytes. Pressurized temperature vaporization (PTV) injection was employed in the GC. The inlet was set to a temperature of 80 °C for 0.3 minutes and then a 600 °C/min ramp to 275 °C was employed to efficiently transfer the samples to the head of the GC column. The oven temperature program was held at 40 °C for 1 min followed by a temperature ramp of 18 °C /min to 250 °C, followed by a temperature ramp of 1.5°C /min to a temperature of 260 °C, followed by a final temperature ramp of 25 °C/min to 300 °C which was held for an additional 20 min. The transfer line temperature was maintained at 300 °C and the ion source was held at 200°C. PBDEs were quantified by monitoring bromide ions (m/z 79 and 81). 13C BDE-209 was monitored by m/z 494.6 and 496.6; TDCPP was quantified by monitoring m/z 319 and 317, TCPP was quantified by monitoring m/z 277 and 201, and TPP was quantified by monitoring m/z 326 and 325.

Quality Assurance

As part of our data quality assurance we examined levels of these specific analytes in laboratory blanks (n=4), replicate samples (n=3), and matrix spikes (n=3). Sample measurements were blank corrected by subtracting the average mass measured in the laboratory blanks. Laboratory blank masses for TCPP, TDCPP and TPP were 16.7 ± 8.5, 11.7 ± 6.6 and 15.7 ± 11.9 ng, respectively. Method detection limits equaled the average plus three times the standard deviation of the blank levels. Matrix spikes were prepared by adding 25 – 100 ng of TCPP, TDCPP and TPP to ASE cells filled with sodium sulfate powder. Matrix spikes were extracted using the same method used for dust and examined for percent recovery using 50 ng of 13C CDE 141 as an internal standard. Recoveries averaged 76 ± 20, 86 ± 7, and 89 ± 2% for TCPP, TDCPP, and TPP, respectively.

RESULTS AND DISCUSSION

Foam Analysis

Foam samples were collected from 26 pieces of furniture that included chairs, couches, futons, ottomans, pillows, a baby stroller, and in one case, foam insulation from a piece of laboratory equipment, a dust sieve shaker unit. A small piece of each foam sample (approximately 1 cm3) was first screened for chemical additives by extracting the foam and analyzing the extract in scan mode on a gas chromatograph equipped with a mass spectrometer (GC/MS). Extracts were scanned in both electron impact mode (GC/EI-MS) and negative chemical ionization mode (GC/ECNI-MS). Chromatograms generated for each foam sample were examined and all significant peaks were compared to the NIST mass spectral database (2005) for identification. Figure S1 displays a chromatogram collected from a foam sample which was found to have a positive match for TDCPP in the NIST database. Foam extracts were also examined for the presence of bromine in GC/ECNI-MS mode, as bromine containing compounds generally generate a strong bromide signal (e.g. m/z 79 and 81). The primary chemical additives detected in each foam sample are presented in Table 1. Positive identification of all compounds was made by comparison to authentic standards.

Table 1.

Information on the polyurethane foam samples analyzed in this study.

| Sample ID | Source | Year Purchased | Flame Retardant Detected |

% by Weight of Flame Retardant |

|---|---|---|---|---|

| 1 | Chair | 2004 | Unidentified | |

| 2 | Mattress Pad | 2009 | N/D | |

| 3 | Leather Couch | 2005 | Unidentified | |

| 4 | Sofa Bed | 2008 | TDCPP | 1.3 |

| 5 | Chair | 2008 | N/D | |

| 6 | Foam from Footstool | 2006 | TCPP | 2.2 |

| 7 | Headrest of Chair | 2008 | TCPP | 0.5 |

| 8 | Chair | 2006 | TDCPP | 3.2 |

| 9 | Chair | 2004 | TDCPP | 3.0 |

| 10 | Chair | 2007 | TCPP | 1.5 |

| 11 | Futon | N/A | PentaBDE | 0.5 |

| 12 | Ottoman | 2007 | TCPP | 0.7 |

| 13 | Chair | 2003 | TDCPP | 1.0 |

| 14 | Chair | 2006 | TDCPP | 2.9 |

| 15 | Pillow | 2006 | TDCPP | 2.8 |

| 16 | Chair | 2007 | TDCPP | 3.8 |

| 17 | Chair | 2005 | TDCPP | 3.2 |

| 18 | Mattress Pad | 2006 | TDCPP | 1.2 |

| 19 | Couch | 2007 | TDCPP | 5.0 |

| 20 | Chair | 2005 | TDCPP | 2.5 |

| 21 | Office Chair | 2005 | N/D | |

| 22 | Futon | 2008 | TDCPP | 2.8 |

| 23 | Nursery Glider/Rocker | 2009 | TDCPP | 2.9 |

| 24 | Foam Insulation from Sieve/Shaker |

2008 | TDCPP | 2.2 |

| 25 | Baby Stroller | 2009 | TDCPP | NM |

| 26 | Couch | 2007 | TBB, TBPH | 4.2 |

N/A – Not available.

N/D – Not detected.

NM- not measured due to low mass of foam available

TDCPP – Tris(1,3-dichloro-2-propyl)phosphate

TCPP – Tris(1-chloro-2-propyl)phosphate

Of the 26 extracts scanned, only two generated a strong bromine signal after analysis in GC/ECNI-MS mode. One was found to contain PBDE congeners 47, 99, 100, 153 and 154 in ratios identical to those reported for PentaBDE commercial mixtures (27). This sample was collected from a futon purchased in the U.S. secondhand, thus the manufacture date is unknown. The presence of PentaBDE indicates that it was likely produced prior to the 2004 phase-out and ban of PentaBDE. The second sample was from a couch purchased in 2007 in California and contained two brominated components found in a new formulation called Firemaster 550 (FM 550): 2-ethylhexyl 2,3,4,5-tetrabromobenzoate (TBB) and bis(2-ethylhexyl) tetrabromophthalate (TBPH). Concentrations by weight of these compounds are reported in Table 1.

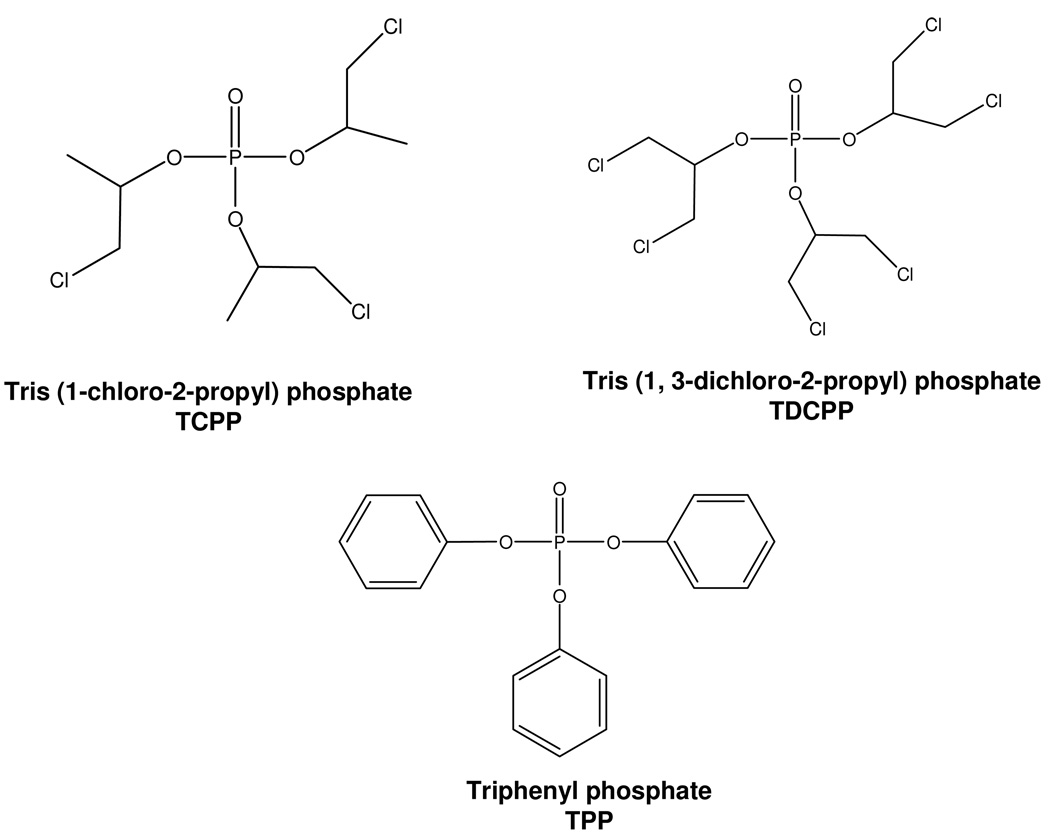

Among the remaining 24 samples, 15 contained tris(1,3-dichloro2-propyl) phosphate (TDCPP; CAS# 13674-87-8) and 4 contained tris(1-chloro-2-propyl) phosphate (TCPP; CAS# 13674-84-5). Structures for these two phosphate compounds are presented in Figure 1. Two samples produced strong responses for two different unknown chemicals which appeared in the GC/MS chromatograms. These may be unknown flame retardants; no bromine signals (m/z 79/81) were detected. In three samples no trace of any flame retardant could be observed in the GC/MS chromatograms (i.e. no peaks observed). Using authentic TDCPP and TCPP standards, the flame retardant concentration in the foam samples was measured. Concentrations of TDCPP and TCPP varied from 1–5% and 0.5 – 2.2% by weight of the foam, respectively (Table 1). This is similar to reported concentrations of PentaBDE measured previously in polyurethane foam (5).

Figure 1.

Structure of the organophosphate flame retardants measured in this study.

Based on these results it appears that TDCPP and TCPP are common replacements for PentaBDE in polyurethane foam. TDCPP is a chlorinated phosphate flame retardant additive that was previously used in children’s pajamas in the 1970s and early 1980s but was phased out of use in this application after a study suggested it was a weak mutagen (28). TDCPP replaced the structurally similar tris(2,3-dibromopropyl) phosphate (Tris-BP) which was banned from use in children’s sleepwear in 1977 after studies documented it was mutagenic, carcinogenic, and absorbed by children wearing the tris-BP treated sleepwear (2, 3, 28). However, unlike tris-BP, use of TDCPP continued. In addition to polyurethane foam, other reported applications for TDCPP include plastics, resins, textiles, and polyisocyanurate foams (29). TDCPP has been sold by several chemical companies under trade names such as Fyrol FR2, Firemaster T33P, and Antiblaze 195 and is marketed for use in polyester, polyether, and polyurethane foams. The U.S. EPA Inventory Update Reporting (US EPA IUR) regulation requires manufacturers and importers of certain chemical substances included on the TSCA Chemical Substance Inventory to report site and manufacturing information for chemicals manufactured (including imported) in amounts of 25,000 pounds or greater at a single site (http://www.epa.gov/iur/). In reporting years 1986 and 1990, between 1 and 10 million pounds of TDCPP was produced, but in reporting years 1994, 1998, 2002, and 2006, production increased to between 10 and 50 million pounds.

TCPP has been in use since the mid-1960s and was used as a replacement for tris(chloroethyl) phosphate (TCEP) (29). TCPP is structurally similar to TCEP, which has been identified as a carcinogen by the World Health Organization (30) and the State of California (http://www.oehha.org/prop65.html). In the 1986 reporting of the US EPA IUR, between 1 and 10 million pounds of TCPP was produced, but in reporting years 1990, 1994, 1998, 2002, and 2006, production increased to between 10 and 50 million pounds.

We had limited detection of new or alternate types of halogenated flame retardants (e.g. FM 550, hexabromocyclododecane (HBCD), bistribromophenoxyethane (BTBPE), hexabromobenzene (HBB), or 1,2-Dibromo-4-(1,2-dibromoethyl)cyclohexane (TBECH)). FM 550 is a new flame retardant mixture marketed as a replacement for PentaBDE in polyurethane foam and contains both TBB and TBPH. Our research group recently identified TBB and TBPH in house dust samples. However, detection of FM 550 in only one sample may be explained by the fact that most of the foam samples analyzed in this study were manufactured in either Scandinavia (likely Sweden) or in China. FM 550 may be used primarily in foam products manufactured in the United States. As our foam samples were not designed as a random sample, they may not represent the prevalence of alternative flame retardants currently found in the US market.

Dust Concentrations

The use of TCPP and TDCPP as chemical additives in furniture foam suggests that they may leach out over time, accumulating in indoor environments, and lead to human exposure, similar to the fate of other additive flame retardants (e.g. PBDEs). Because few data are available on the levels of these organophosphate compounds in house dust samples from the U.S., we analyzed 50 dust samples collected from the Boston, MA area between 2002 and 2007 for TCPP and TDCPP. In addition, we included triphenylphosphate (TPP) in our analysis since it is a major component of FM 550.

All three organophosphate compounds were detected in house dust samples (see Supporting Information for Dust Chromatograms). The detection frequency of TPP and TDCPP was >96%, while the detection frequency of TCPP was only 24%. However, it is possible that the low detection frequency for TCPP in the dust samples was a result of a co-elution problem. TCPP was monitored in GC/EI-MS mode by tracking ions 277 and 201. The expected ratio of these two ions was 65 ± 20% based on responses from the authentic standard. In a majority of the dust samples, ion 277 [M-CH2Cl]+ and 201 [M-C2H4Cl2]+ were observed at the correct GC retention time; however, the area of ion 277 was very high in many samples, resulting in a quant/qual ion ratio ranging from 90–400%. Thus co-elution of a compound producing a signal for m/z 201 may have interfered with our ability to adequately quantify TCPP. Improvements in our method development are needed to overcome this potential challenge.

Concentrations of TPP, TCPP and TDCPP ranged from <MDL to 1,800,000 ng/g, <MDL to 5490 ng/g, and from <MDL to 56,090 ng/g, respectively. Geometric mean values were 7360, 572, and 1890 ng/g, respectively. TPP and TDCPP were log-normally distributed, similar to the distribution of PBDEs in these samples, and similar to previous reports for the distribution of PBDEs and other alternate brominated flame retardants in dust samples (14, 23). The organophosphate chemical concentrations are in the same range as the PBDEs concentrations measured in these dust samples (Table 2) and in house dust from both the U.S. and Canada measured in previous studies (11, 14, 31). In fact, higher concentrations of TPP were measured in these dust samples compared to PBDEs.

Table 2.

Concentration (ng/g) and detection frequencies for the flame retardants detected in house dust samples (n=50).

| Flame Retardant | % Detection | Minimum | Maximum | Geometric Mean |

|---|---|---|---|---|

| TPP | 98 | <150 | 1,798,000 | 7360 |

| TCPP | 24 | <140 | 5490 | 572 |

| TDCPP | 96 | <90 | 56,090 | 1890 |

| Total PBDEs | 100 | 980 | 44,550 | 4740 |

| BTBPE | 100 | 1.4 | 950 | 21 |

| HBCD | 92 | <2 | 2,750 | 166 |

| TBB | 44 | <450 | 75,000 | 840 |

| TBPH | 60 | <300 | 47,110 | 650 |

TPP- triphenyl phosphate

TCPP – tris(1-chloro-2-propyl) phosphate

TDCPP – tris(1,3-dichloro-2-propyl) phosphate

Total PBDEs: Sum of PBDEs: 30, 17, 25, 28/ 33, 75, 49, 71, 47, 66, 100, 119, 99, 116, 85/155, 154, 153, 138, 156, 183, 191, 181, 190, 203, 205, 208, 207, 206, 209

BTBPE - bistribromophenoxyethane

HBCD – total hexabromocyclododecane

TBB –ethylhexyl 2,3,4,5-tetrabromobenzoate

TBPH – bis(2-ethylhexyl) tetrabromophthalate

Several Swedish studies found high concentrations of TPP on computer wipes (3300–4000 µg/g), in several public and residential dust samples (25), and identified video display units as an emission source of TPP(32). TPP is used as both a plasticizer and flame retardant in a variety of applications (plastics, resins, rubber); thus the high levels detected here could have resulted from its use in either application. TDCPP dust concentrations measured here are similar to concentrations recently reported for dust collected in hotels in Japan (33). This same study also measured TPP in eight dust samples and found concentrations ranging from 110 – 2600 ng/g, lower than concentrations measured in these US house dust samples. TPP, TCPP and TDCPP were detected in air samples collected from residential and public areas in Sweden with concentrations ranging from <0.3 to 570 ng/m3 (34, 35), concentrations that are much higher than PBDE levels measured in indoor environments in the U.S (36).

The dust samples in this study were collected from home vacuum cleaners and were previously analyzed for PBDEs and several alternate halogenated flame retardants (HBCD, BTBPE, TBB, TBPH and Dechlorane Plus; data not published yet). No significant correlations were found between the levels of organophosphate flame retardants and PBDEs. However, there was a moderate correlation (Spearman r = 0.4) between TPP, TBB, and TBPH in the dust, which are all components of FM 550, a PentaBDE replacement mixture designed for use in polyurethane foam.

Significance for Human Exposure

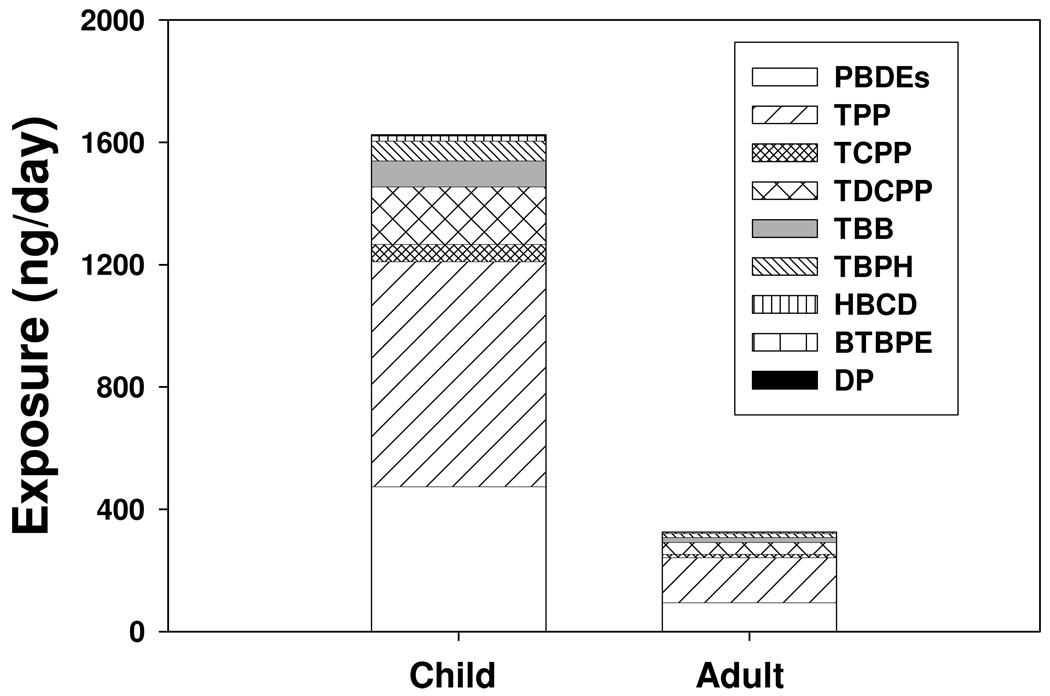

The presence of these organophosphate flame retardants in house dust suggests that people, and especially children, are being exposed to these compounds from dust, presumably in a manner similar to what has been reported for PBDEs (12, 13, 37, 38). Exposure estimates for house dust often rely upon uncertain estimates of dust ingestion for different age classes. The U.S. EPA estimates that children ages 1–5 ingest on average approximately 100–200 mg dust/day, while adults ingest about 20–50 mg dust/day (13, 39, 40). Using the lower bound dust ingestion estimates and the geometric mean concentrations of each flame retardant measured in these dust samples, we calculated the cumulative average exposure for U.S. children and adults for the summation of nine types of flame retardant chemicals (Figure 2). The average estimated cumulative exposure to flame retardants from dust for children is calculated to be about 1600 ng/day, whereas for an adult it is about 325 ng/day, a factor 3–10 times higher than recently reported for exposure to PBDEs alone in Canada and the U.S.(13, 14). A majority of this exposure is due to exposure from PBDEs, TPP, and TDCPP.

Figure 2.

Estimated daily dust ingestion for a child and adult assuming a child ingests 100 mg/dust per day and an adult ingests 20 mg dust/day. (PBDEs- total polybrominated diphenyl ethers; TPP- triphenylphosphate; TCPP- tris(1-chloro-2-propyl) phosphate; TDCPP- tris(1,3-dichloro-2-propyl)phosphate; TBB- ethylhexyl 2,3,4,5- tetrabromobenzoate; TBPH – bis(2-ethylhexyl) tetrabromophthalate; HBCD- total hexabromocyclododecane; BTBPE – bistribromophenoxyethane; DP- total dechlorane plus).

It is also interesting to note that the distributions of these flame retardants are quite different among the dust samples (See Table S1 in Supporting Information). The sum total of the nine flame retardants measured in this study for each dust sample ranged from 3690 to 1,857,000 ng/g. The 95th percentile of this sum is 770,000 ng of flame retardants/g dust. If we assume that these dust samples from Boston, MA are representative of the U.S., approximately 5% of homes could have very high levels of flame retardants in the house dust, and any children living in these homes may be exposed to as much as 77,000 ng of flame retardants/day. Given this, it may be important for scientists to start evaluating potential health effects from exposures to mixtures of these compounds. Currently no data are available to indicate if exposure to these mixtures would be additive, antagonistic, or perhaps synergistic, and thus risk evaluations that routinely consider exposure on a chemical specific basis may underestimate potential risk.

For comparison purposes we calculated the potential inhalation exposure to the organophosphate compounds based on measurements in indoor air recently reported in Finland, Sweden and Japan (41–43). Assuming an inhalation rate of 15 m3/day for an average adult, inhalation exposure to TPP in certain occupational settings could be as high as 750 to 12,800 ng/day, depending on the work environment (e.g. circuit board factory, electronics dismantling factory), compared to our estimated median exposure from inadvertent dust ingestion in homes (147 ng/day). The estimated occupational exposure to TDCPP from inhalation would be in the range of <900–1350 ng/day compared to our estimates of dust ingestion of 38 to 189 ng/day for adults and children in homes, respectively. Little data is available on the levels of these organophosphate flame retardants in indoor air from homes; however, Staaf and Ostman et al. (41) and Saito et al. (43) reported concentrations ranging from <DL to 17 and <DL to 8.7 ng/m3 in home and office air for TPP and TDCPP, respectively, in Sweden and Japan. This suggests that inhalation exposure to these compounds may be comparable to dust ingestion in some indoor environments; however, further studies are needed to evaluate the levels of these flame retardants in indoor air in the U.S.

Our data suggest that levels of these organophosphate flame retardants in indoor dust are comparable, or in some cases greater than, levels of PBDEs in dust. Studies have reported that TDCPP is mutagenic (22, 28) and carcinogenic in rats (29); it is also absorbed by humans (30). The U.S. Consumer Product Safety Commission considers TDCPP a probable human carcinogen (22) while the US EPA considers it a moderate cancer hazard (24). The U.S. EPA also considers TDCPP to be a moderate hazard for reproductive and developmental effects (24). Given the high prevalence of these flame retardants in foam and the high concentrations of all flame retardants measured in dust (e.g. as high as 1.8 mg/g), further studies are warranted to evaluate health effects from exposure to these organophosphate flame retardants in dust and from exposure to mixtures of these flame retardants, particularly for children.

Supplementary Material

Acknowledgments

Dr. Heather M. Stapleton was funded and supported by a grant from the National Institute of Environmental Health Sciences, R01ES016099. Dr. Webster is partly supported by R01ES015829 from the National Institute of Environmental Health Sciences. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institute of Environmental Health Sciences or the National Institutes of Health.

References

- 1.Hale RC, La Guardia MJ, Harvey E, Mainor TM. Potential role of fire retardant-treated polyurethane foam as a source of brominated diphenyl ethers to the US environment. Chemosphere. 2002;46(5):729–735. doi: 10.1016/s0045-6535(01)00237-5. [DOI] [PubMed] [Google Scholar]

- 2.Blum A, Ames BN. Flame-Retardant Additives as Possible Cancer Hazards. Science. 1977;195(4273):17–23. doi: 10.1126/science.831254. [DOI] [PubMed] [Google Scholar]

- 3.Blum A, Gold MD, Ames BN, Kenyon C, Jones FR, Hett EA, Dougherty RC, Horning EC, Dzidic I, Carroll DI, Stillwell RN, Thenot JP. Children Absorb Tris-Bp Flame-Retardant from Sleepwear - Urine Contains Mutagenic Metabolite, 2,3-Dibromopropanol. Science. 1978;201(4360):1020–1023. doi: 10.1126/science.684422. [DOI] [PubMed] [Google Scholar]

- 4.Alaee M, Arias P, Sjodin A, Bergman A. An overview of commercially used brominated flame retardants, their applications, their use patterns in different countries/regions and possible modes of release. Environment International. 2003;29(6):683–689. doi: 10.1016/S0160-4120(03)00121-1. [DOI] [PubMed] [Google Scholar]

- 5.Allen JG, McClean MD, Stapleton HM, Webstert TF. Linking PBDEs in house dust to consumer products using X-ray fluorescence. Environmental Science & Technology. 2008;42(11):4222–4228. doi: 10.1021/es702964a. [DOI] [PubMed] [Google Scholar]

- 6.Birnbaum LS, Staskal DF. Brominated flame retardants: Cause for concern? Environmental Health Perspectives. 2004;112(1):9–17. doi: 10.1289/ehp.6559. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Webster TF, Harrad S, Millette JR, Holbrook RD, Davis JM, Stapleton HM, Allen JG, McClean M, Ibarra C, Abdallah MAE, Covaci A. Identifying Transfer Mechanisms and Sources of Decabromodiphenyl Ether (BDE 209) in Indoor Environments Using Environmental Forensic Microscopy. Environmental Science & Technology. 2009;43(9):3067–3072. doi: 10.1021/es803139w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Stockholm Convention on Persistent Organic Pollutants. 2009 http://chm.pops.int/

- 9.Hale RC, Alaee M, Manchester-Neesvig JB, Stapleton HM, Ikonomou MG. Polybrominated diphenyl ether flame retardants in the North American environment. Environment International. 2003;29(6):771–779. doi: 10.1016/S0160-4120(03)00113-2. [DOI] [PubMed] [Google Scholar]

- 10.Sjodin A, Papke O, McGahee E, Focant JF, Jones RS, Pless-Mulloli T, Toms LML, Herrmann T, Muller J, Needham LL, Patterson DG. Concentration of polybrominated diphenyl ethers (PBDEs) in household dust from various countries. Chemosphere. 2008;73(1):S131–S136. doi: 10.1016/j.chemosphere.2007.08.075. [DOI] [PubMed] [Google Scholar]

- 11.Stapleton HM, Dodder NG, Offenberg JH, Schantz MM, Wise SA. Polybrominated diphenyl ethers in house dust and clothes dryer lint. Environmental Science & Technology. 2005;39(4):925–931. doi: 10.1021/es0486824. [DOI] [PubMed] [Google Scholar]

- 12.Wu N, Herrmann T, Paepke O, Tickner J, Hale R, Harvey E, La Guardia M, McClean MD, Webster TF. Human exposure to PBDEs: Associations of PBDE body burdens with food consumption and house dust concentrations. Environmental Science & Technology. 2007;41(5):1584–1589. doi: 10.1021/es0620282. [DOI] [PubMed] [Google Scholar]

- 13.Jones-Otazo HA, Clarke JP, Diamond ML, Archbold JA, Ferguson G, Harner T, Richardson GM, Ryan JJ, Wilford B. Is house dust the missing exposure pathway for PBDEs? An analysis of the urban fate and human exposure to PBDEs. Environmental Science & Technology. 2005;39(14):5121–5130. doi: 10.1021/es048267b. [DOI] [PubMed] [Google Scholar]

- 14.Allen JG, McClean M, Stapleton HM, Webster TF. Critical Factors in Assessing Exposure to PBDEs via House Dust. Environment International. 2008;34:1085–1091. doi: 10.1016/j.envint.2008.03.006. [DOI] [PubMed] [Google Scholar]

- 15.Hites RA. Polybrominated diphenyl ethers in the environment and in people: A meta-analysis of concentrations. Environmental Science & Technology. 2004;38(4):945–956. doi: 10.1021/es035082g. [DOI] [PubMed] [Google Scholar]

- 16.Sjodin A, Patterson DG, Bergman A. A review on human exposure to brominated flame retardants - particularly polybrominated diphenyl ethers. Environment International. 2003;29(6):829–839. doi: 10.1016/S0160-4120(03)00108-9. [DOI] [PubMed] [Google Scholar]

- 17.Harrad S, Ibarra C, Diamond M, Melymuk L, Robson M, Douwes J, Roosens L, Dirtu AC, Covaci A. Polybrominated diphenyl ethers in domestic indoor dust from Canada, New Zealand, United Kingdom and United States. Environment International. 2008;34(2):232–238. doi: 10.1016/j.envint.2007.08.008. [DOI] [PubMed] [Google Scholar]

- 18.Chao HR, Wang SL, Lee WJ, Wang YF, Papke O. Levels of polybrominated diphenyl ethers (PBDEs) in breast milk from central Taiwan and their relation to infant birth outcome and maternal menstruation effects. Environment International. 2007;33(2):239–245. doi: 10.1016/j.envint.2006.09.013. [DOI] [PubMed] [Google Scholar]

- 19.Turyk ME, Persky VW, Imm P, Knobeloch L, Chatterton R, Anderson HA. Hormone Disruption by PBDEs in Adult Male Sport Fish Consumers. Environmental Health Perspectives. 2008;116(12):1635–1641. doi: 10.1289/ehp.11707. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Meeker JD, Johnson PI, Camann D, Hauser R. Polybrominated diphenyl ether (PBDE) concentrations in house dust are related to hormone levels in men. Science of the Total Environment. 2009;407(10):3425–3429. doi: 10.1016/j.scitotenv.2009.01.030. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Main KM, Kiviranta HHEVES, Tuomisto JT, Tuomisto J, Vartiainen T, Skakkebaek NE, Toppari J. Flame Retardants in Placenta and Breast Milk and Cryptorchidism in Newborn Boys. Environmental Health Perspectives. 2007;115(10):1519–1526. doi: 10.1289/ehp.9924. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Babich MA. Commission, U. C. P. S., Ed. Vol. Bethesda, MD: USCPSC; 2006. CPSC Staff Preliminary Risk Assessment of Flame Retardant (FR) Chemicals in Upholstered Furniture Foam. available at www.cpsc.gov/library/foia/foia07/brief/ufurn2.pdf. [Google Scholar]

- 23.Stapleton HM, Allen JG, Kelly SM, Konstantinov A, Klosterhaus S, Watkins D, McClean MD, Webster TF. Alternate and new brominated flame retardants detected in US house dust. Environmental Science & Technology. 2008;42(18):6910–6916. doi: 10.1021/es801070p. [DOI] [PubMed] [Google Scholar]

- 24.USEPA, editor. USEPA; 2005. Furniture Flame Retardancy Partnership: Environmental Profiles of Chemical Flame Retardant Alternatives. 742-R-05-002A. [Google Scholar]

- 25.Marklund A, Andersson B, Haglund P. Screening of organophosphorus compounds and their distribution in various indoor environments. Chemosphere. 2003;53(9):1137–1146. doi: 10.1016/S0045-6535(03)00666-0. [DOI] [PubMed] [Google Scholar]

- 26.Marklund A, Andersson B, Haglund P. Organophosphorus flame retardants and plasticizers in Swedish sewage treatment plants. Environmental Science & Technology. 2005;39(19):7423–7429. doi: 10.1021/es051013l. [DOI] [PubMed] [Google Scholar]

- 27.La Guardia MJ, Hale RC, Harvey E. Detailed polybrominated diphenyl ether (PBDE) congener composition of the widely used penta-, octa-, and deca-PBDE technical flame-retardant mixtures. Environmental Science & Technology. 2006;40(20):6247–6254. doi: 10.1021/es060630m. [DOI] [PubMed] [Google Scholar]

- 28.Gold MD, Blum A, Ames BN. Another Flame-Retardant, Tris-(1,3-Dichloro-2-Propyl)-Phosphate, and Its Expected Metabolites Are Mutagens. Science. 1978;200(4343):785–787. doi: 10.1126/science.347576. [DOI] [PubMed] [Google Scholar]

- 29.W.H.O. Geneva: Environmental Health Criteria 209; Flame Retardants: Tris (chloropropyl) phosphate and tris (2 chloroethyl) phosphate. 1998

- 30.Hudec T, Thean J, Kuehl D, Dougherty RC. Tris(Dichloropropyl)Phosphate, a Mutagenic Flame-Retardant - Frequent Occurrence in Human Seminal Plasma. Science. 1981;211(4485):951–952. doi: 10.1126/science.7466368. [DOI] [PubMed] [Google Scholar]

- 31.Wilford BSM, Harner T, Zhu J, Jones KC. Polybrominated D iphenyl Ethers in Indoor Dust in Ottawa, Canada: Implications for Sources and Exposure. Environmental Science & Technology. 2005;39(18):7027–7035. doi: 10.1021/es050759g. [DOI] [PubMed] [Google Scholar]

- 32.Carlsson H, Nilsson U, Ostman C. Video display units: An emission source of the contact allergenic flame retardant triphenyl phosphate in the indoor environment. Environmental Science & Technology. 2000;34(18):3885–3889. [Google Scholar]

- 33.Takigami H, Suzuki G, Hirai Y, Ishikawa Y, Sunami M, Sakai S. Flame Retardants in Indoor Dust and Air of a Hotel in Japan. Environment International. 2009;35:688–693. doi: 10.1016/j.envint.2008.12.007. [DOI] [PubMed] [Google Scholar]

- 34.Marklund A, Andersson B, Haglund P. Organophosphorus flame retardants and plasticizers in air from various indoor environments. Journal of Environmental Monitoring. 2005;7(8):814–819. doi: 10.1039/b505587c. [DOI] [PubMed] [Google Scholar]

- 35.Carlsson H, Nilsson U, Becker G, Ostman C. Organophosphate ester flame retardants and plasticizers in the indoor environment: Analytical methodology and occurrence. Environmental Science & Technology. 1997;31(10):2931–2936. [Google Scholar]

- 36.Allen JG, McClean MD, Stapleton HM, Nelson JW, Webster TF. Personal exposure to Polybrominated Diphenyl Ethers (PBDEs) in residential indoor air. Environmental Science & Technology. 2007;41(13):4574–4579. doi: 10.1021/es0703170. [DOI] [PubMed] [Google Scholar]

- 37.Lorber M. Exposure of Americans to polybrominated diphenyl ethers. Journal of Exposure Science and Environmental Epidemiology. 2008;18(1):2–19. doi: 10.1038/sj.jes.7500572. [DOI] [PubMed] [Google Scholar]

- 38.Harrad S, Hazrati S, Ibarra C. Concentrations of polychlorinated biphenyls in indoor air and polybrominated diphenyl ethers in indoor air and dust in Birmingham, United Kingdom: Implications for human exposure. Environmental Science & Technology. 2006;40(15):4633–4638. doi: 10.1021/es0609147. [DOI] [PubMed] [Google Scholar]

- 39.U.S.EPA. Child Specific Exposure Factors Handbook. In: WD, editor. National Center for Environmental Assessment. 2002. EPA-600-P-00-002B. [Google Scholar]

- 40.Canadian Environmental Protection Act: Human Health Risk Assessment for Priority Substances. Ottawa: Ontario; 1994. [Google Scholar]

- 41.Staaf T, Ostman C. Organophosphate triesters in indoor environments. Journal of Environmental Monitoring. 2005;7(9):883–887. doi: 10.1039/b506631j. [DOI] [PubMed] [Google Scholar]

- 42.Makinen MSE, Makinen MRA, Koistinen JTB, Pasanen AL, Pasanen PO, Kalliokoski PI, Korpi AM. Respiratory and Dermal Exposure to Organophosphorus Flame Retardants and Tetrabromobisphenol A at Five Work Environments. Environmental Science & Technology. 2009;43(3):941–947. doi: 10.1021/es802593t. [DOI] [PubMed] [Google Scholar]

- 43.Saito I, Onuki A, Seto H. Indoor organophosphate and polybrominated flame retardants in Tokyo. Indoor Air. 2007;17(1):28–36. doi: 10.1111/j.1600-0668.2006.00442.x. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.