Abstract

Many litter-decay fungi secrete heme-thiolate peroxygenases that oxidize various organic chemicals, but little is known about the role or mechanism of these enzymes. We found that the extracellular peroxygenase of Agrocybe aegerita catalyzed the H2O2-dependent cleavage of environmentally significant ethers, including methyl t-butyl ether, tetrahydrofuran, and 1,4-dioxane. Experiments with tetrahydrofuran showed the reaction was a two-electron oxidation that generated one aldehyde group and one alcohol group, yielding the ring-opened product 4-hydroxybutanal. Investigations with several model substrates provided information about the route for ether cleavage: (a) steady-state kinetics results with methyl 3,4-dimethoxybenzyl ether, which was oxidized to 3,4-dimethoxybenzaldehyde, gave parallel double reciprocal plots suggestive of a ping-pong mechanism (Km(peroxide), 1.99 ± 0.25 mm; Km(ether), 1.43 ± 0.23 mm; kcat, 720 ± 87 s−1), (b) the cleavage of methyl 4-nitrobenzyl ether in the presence of H218O2 resulted in incorporation of 18O into the carbonyl group of the resulting 4-nitrobenzaldehyde, and (c) the demethylation of 1-methoxy-4-trideuteromethoxybenzene showed an observed intramolecular deuterium isotope effect [(kH/kD)obs] of 11.9 ± 0.4. These results suggest a hydrogen abstraction and oxygen rebound mechanism that oxidizes ethers to hemiacetals, which subsequently hydrolyze. The peroxygenase appeared to lack activity on macromolecular ethers, but otherwise exhibited a broad substrate range. It may accordingly have a role in the biodegradation of natural and anthropogenic low molecular weight ethers in soils and plant litter.

Recently, a new group of extracellular peroxygenases was described in agaric fungi that are ubiquitous biodegraders of lignocellulose in soils and plant litter. These heme-thiolate enzymes catalyze H2O2-dependent halogenations and hydroxylations of numerous aromatic substrates, and thus show some functional similarity to heme chloroperoxidase and to cytochromes P450 (P450s),3 which are also heme-thiolate proteins (1–4). However, the best-characterized fungal peroxygenase, from Agrocybe aegerita, exhibits low sequence identity (∼25%) with heme chloroperoxidase and no significant sequence identity with the P450s (5). On the other hand, the absorption spectrum of the native peroxygenase and of its carbon monoxide adduct closely resemble those of P450s (6). So far, little is known about the catalytic cycle of the A. aegerita peroxygenase.

The physiological function of these peroxygenases is also unclear, but their extracellular location suggests a role in the biodegradation or detoxification of organic chemicals encountered by the fungi. Ethers stand out as potential substrates for several reasons. First, ether linkages are widespread in soils and litter, not only in abundant natural substances such as lignin, flavonoids, and lignans, but also in anthropogenic compounds that include many solvents, biocides, and surfactants (7–11). Second, an oxidative mechanism is required for the biodegradation of ethers, which are relatively recalcitrant because they do not hydrolyze at physiological pH values (7). Finally, it is already known that functionally similar monooxygenases, including P450s, are capable of ether scission and have a role in the intracellular metabolism of these compounds by some organisms (7, 12–15).

Here we show that the extracellular peroxygenase from A. aegerita cleaves many ethers, including some significant environmental pollutants, and we evaluate some limitations on the etherolytic reactions that the enzyme can accomplish. In addition, we report data from stoichiometrical analyses, steady-state kinetics experiments, an H218O2-labeling study, and intramolecular deuterium isotope effect determinations. These results provide insights into the enzymatic mechanism for ether cleavage.

EXPERIMENTAL PROCEDURES

Reagents

Commercially available chemicals were purchased from Sigma-Aldrich, except for H218O2 (90 atom %, 2% w/v), which was obtained from Icon Isotopes, and terminally brominated polyethylene glycol (PEG, ∼2 kDa), which was purchased from Iris Biotech GmbH. All of the aliphatic ethers used as substrates were the highest grade available, contained no antioxidant, and were received from the manufacturer under nitrogen in small bottles. A new bottle of each aliphatic ether was opened for each experiment and analyzed beforehand by gas chromatography/mass spectrometry (GC/MS). The results showed that none of these ethers contained detectable levels of the alcohols, aldehydes, or ketones that we detected as reaction products in the experiments described below.

Methyl 3,4-dimethoxybenzyl ether was prepared by reacting 3,4-dimethoxybenzyl alcohol in methanol containing p-toluenesulfonic acid as previously described (16), but with modified product purification. At the conclusion of the reaction, the mixture was extracted with several portions of cyclohexane, which were dried over MgSO4 and concentrated on a rotary evaporator to produce a thick syrup. This crude product was fractionated by vacuum column chromatography on silica gel with cyclohexane as the eluant (17). Fractions were analyzed by thin layer chromatography and by 1H NMR analysis, and those showing no detectable impurities were pooled for solvent removal. MS m/z (%) 182 (M+, 44), 166 (3), 151 (100), 139 (7), 124 (4), 107 (14), 91 (9), 77 (12), 65 (5), 51 (4). 1H NMR (CDCl3) δ (ppm) 3.35 (s, 3H, -CH2OCH3), 3.86 (s, 3H, -OCH3), 3.87 (s, 3H, -OCH3), 4.37 (s, 2H, -CH2O-), 6.81 (d, J = 8.1 Hz, 1H, -ArC5H), 6.85 (dd, J = 8.1 Hz, 2.0 Hz, 1H, -ArC6H), 6.87 (d, J = 2.0 Hz, -ArC2H).

Methyl 4-nitrobenzyl ether was prepared from 4-nitrobenzyl alcohol and CH3I as described previously (18) and recrystallized twice at 4 °C, first from petroleum ether and then from water. MS m/z (%) 167 (M+, 4), 166 (11), 136 (11), 121 (14), 120 (35), 108 (13), 107 (100), 106 (14), 105 (13), 91 (27), 90 (25), 89 (85), 78 (47), 77 (81), 65 (11), 63 (27), 51 (28), 50 (16). 1H NMR (CDCl3) δ (ppm) 3.48 (s, 3H, −OCH3), 4.59 (s, 2H, -CH2O-), 7.53 (d, J = 8.6 Hz, 2H, -ArC2,6H), 8.24 (d, J = 8.6 Hz, 2H, -ArC3,5H).

1-Methoxy-4-trideuteromethoxybenzene was prepared from 4-methoxyphenol and CD3I (99.5 atom % D) as described previously (19) and recrystallized twice from aqueous ethanol. MS m/z (%) 141 (M+, 100), 126 (70, -CH3), 123 (62, -CD3), 98 (34, -CH3, -CO), 95 (31, -CD3, -CO). 1H NMR (360 MHz, CDCl3) δ 6.84 (s, 4H, −ArC2,3,5,6H), 3.77 (s, 3H, −OCH3).

PEG terminated with 4-nitrophenyl ethers was prepared by stirring 1 g of dibromo-PEG (∼0.5 mmol) overnight in acetone that contained 10 mmol each of 4-nitrophenol and powdered K2CO3. The acetone was then removed by rotary evaporation, and the product was redissolved in water, after which it was dialyzed twice against 100 mm NaHCO3 and twice against distilled water, using a 1-kDa cutoff bag, and finally lyophilized. Approximately 60% of the PEG end groups were 4-nitrophenyl-substituted by this method, as shown by integration of the 1H NMR signals (in CDCl3) for the aromatic protons (6.99 and 8.20 ppm) and the internal polyoxyethylene protons (3.65 ppm).

The extracellular peroxygenase of A. aegerita (isoform II, 44 kDa) was produced and purified as described previously (2). The enzyme preparation was homogeneous by SDS-polyacrylamide gel electrophoresis and exhibited an A418/A280 ratio of 1.75. The specific activity of the peroxygenase was 117 units mg−1, where 1 unit represents the oxidation of 1 μmol of 3,4-dimethoxybenzyl alcohol to 3,4-dimethoxybenzaldehyde in 1 min at 23 °C (2).

Product Identification

Typical reaction mixtures (0.2–1.0 ml) contained purified peroxygenase (1–2 units ml−1), potassium phosphate buffer (50 mm, pH 7.0), and the ether substrate (1–10 mm). When alkyl aryl ethers were used as substrates, the reactions also contained ascorbic acid (4 mm) to inhibit further oxidation of the phenolic products that were released (20, 21). The reactions were started by the addition of limiting H2O2 (0.1–0.5 mm) and stirred at room temperature for 3 min, at which time chromatographic analyses showed that product formation was complete.

The reaction products 3,4-dimethoxybenzaldehyde and 4-nitrophenol were analyzed by high performance liquid chromatography (HPLC) using an Agilent Series 1100 instrument equipped with a diode array detector and an electrospray ionization mass spectrometer. Reverse phase chromatography was performed on a Luna C18 column (4.6-mm diameter by 150-mm length, 5-μm particle size, Phenomenex), which was eluted at 0.35 ml min−1 and 40 °C with aqueous 0.1% v/v ammonium formate (pH 3.5)/acetonitrile, 95:5 for 5 min, followed by a 25-min linear gradient to 100% acetonitrile. Products were identified relative to authentic standards, based on their retention times, UV absorption spectra, and [M + H]+ or [M - H]− ions.

Aliphatic aldehydes or ketones produced from the ethers were analyzed as their 2,4-dinitrophenylhydrazones after addition of 0.2 volume of 0.1% 2,4-dinitrophenylhydrazine solution in 0.6 n HCl to each reaction mixture. The derivatized products were analyzed using the same HPLC apparatus as above, but the Luna C18 column was eluted with aqueous 0.1% (v/v) ammonium formate (pH 3.5)/acetonitrile, 70:30 for 5 min, followed by a 25-min linear gradient to 100% acetonitrile. With two exceptions, the dinitrophenylhydrazones were identified relative to authentic standards, based on their retention times, UV absorption spectra, and [M - H]− ions. As no standards of the 5-hydroxypentanal or 2-(2-hydroxyethoxy)acetaldehyde derivatives were available, they were tentatively identified based on their [M - H]− ions.

The reaction product 4-methoxyphenol was analyzed by reverse phase HPLC using the above apparatus but with a Gemini Phenyl column (4.6-mm diameter by 150-mm length, 5-μm particle size, Phenomenex). The column was eluted at 1 ml min−1 and 40 °C with aqueous 0.1% (v/v) ammonium formate (pH 10)/acetonitrile, 95:5 for 5 min, followed by a 20-min linear gradient to 100% acetonitrile. The product was identified relative to an authentic standard, based on its retention time and [M - H]− ion.

The reaction product 4-nitrobenzaldehyde was analyzed by GC of a benzene extract, using a Hewlett Packard 6890 chromatograph equipped with a Hewlett Packard 5973 mass spectrometer. GC was performed isothermally at 150 °C, using helium as the carrier gas at a column flow rate of 1 ml min−1 on a 5% polysiloxane column (Zebron ZB-5, 250 μm diameter by 30 m length, 0.25 μm film thickness, Phenomenex). The product was identified relative to an authentic standard by its retention time and by electron impact MS at 70 eV.

The products ethanol, 2-propanol, and t-butanol were detected by subjecting dichloromethane extracts of the aqueous reaction mixtures to GC/MS analysis using the equipment just described. GC was performed using a linear temperature program from 40 to 150 °C (10 °C min−1), using helium as the carrier gas at a column flow rate of 1 ml min−1, on a 5% phenyl-methylpolysiloxane column (DB-5MS, 250-μm diameter by 30-m length, 0.25-μm film thickness, J&W Scientific). The products were identified relative to authentic standards by their retention times and by electron impact MS at 70 eV.

The reaction product methanol was analyzed by GC/MS as described previously (22) using the equipment just described plus a Hewlett Packard 7694 headspace sampler. The aqueous sample solutions (2 ml) were equilibrated at 90 °C in the headspace oven, after which GC was performed isothermally at 45 °C, using helium as the carrier gas at a column flow rate of 1 ml min−1, on the DB-5MS column described above. The methanol was identified relative to an authentic standard by its retention time and by electron impact MS at 70 eV.

To look for evidence that the peroxygenase cleaved ether bonds in 4-nitrophenyl-terminated PEG, we analyzed reaction mixtures by gel permeation chromatography on a column of Sephadex G-25 superfine (1.5-cm diameter, 30-cm length, GE Healthcare) in aqueous Na2SO4 (0.35 m, adjusted to pH 3.5) at room temperature (23). The UV absorbance of the eluant was monitored with a diode array detector to determine whether a shift in the polymer molecular weight distribution had occurred (24).

Product Quantification

Stoichiometrical analyses of tetrahydrofuran cleavage were performed by HPLC as described above, using an external standard curve of 4-hydroxybutanal 2,4-dinitrophenylhydrazone for quantification of UV absorbance at 360 nm. 4-Hydroxybutanal 2,4-dinitrophenylhydrazone standards were prepared by adding aliquot portions of 2-ethoxytetrahydrofuran to excess 0.1% 2,4-dinitrophenylhydrazine solution in 0.6 n HCl. Stoichiometrical analyses of methyl 3,4-dimethoxybenzyl ether cleavage were also performed by HPLC as described above, using an external standard curve of 3,4-dimethoxybenzaldehyde for quantification of UV absorbance at 310 nm. Both standard curves had linear regression values with R2 > 0.99.

Enzyme Kinetics

The kinetics of tetrahydrofuran cleavage were analyzed in stirred reactions (0.20 ml, 23 °C) that contained 0.193 μm of the peroxygenase, potassium phosphate buffer (50 mm, pH 7.0), and 0.060–2.500 mm of the ether. The reactions were initiated with 2.00 mm H2O2 and stopped with 0.400 ml of 0.1% 2,4-dinitrophenylhydrazine solution in 0.6 n HCl after 10 s, at which time less than 6% of the tetrahydrofuran had been consumed. The resulting 4-hydroxybutanal-2,4-dinitrophenylhydrazone was quantified by HPLC as described above, and an apparent value of the Km for tetrahydrofuran was obtained by nonlinear regression using the Michelis-Menten model in the ANEMONA program (25).

The kinetics of methyl 3,4-dimethoxybenzyl ether cleavage were analyzed in stirred reactions (2.00 ml, 23 °C) that contained 0.098 μm of the peroxygenase, potassium phosphate buffer (25 mm, pH 7.0), and 0.500–2.000 mm of the ether. The reactions were initiated with 0.067–0.200 mm H2O2, and the initial velocity of 3,4-dimethoxybenzaldehyde formation was measured by the increase in absorbance at 310 nm (ϵ = 9300 m−1 cm−1) (26) using a Cary 50 UV/visible spectrophotometer. Three kinetic traces were obtained for each pair of substrate concentrations. Kinetic parameters were determined by nonlinear regression using the ping-pong model in the ANEMONA program (25).

18O Labeling Experiment

The reaction mixture (0.50 ml, stirred at room temperature) contained 2 units of the peroxygenase, potassium phosphate buffer (50 mm, pH 7.0), and 0.5 mm methyl 4-nitrobenzyl ether. The reaction was initiated with 2.0 mm H218O2 and stopped after 5 s by rapid mixing with 0.50 ml of benzene. A portion of the upper organic phase was immediately removed with a pipette and analyzed by GC/MS as described above. For each m/z value, the average total ion count within the 4-nitrobenzaldehyde peak was used after background correction to generate the ion count used for mass abundance calculations.

Deuterium Isotope Effect Experiments

The reaction mixtures (0.20 ml, stirred at room temperature) contained 0.4 units of the peroxygenase, potassium phosphate buffer (50 mm, pH 7.0), 4 mm ascorbate, and 0.5 mm 1-methoxy-4-trideuteromethoxybenzene. The reaction was initiated with 2.0 mm H2O2, and 10 s later, a portion was analyzed by LC/MS as described above. For each m/z value, the average total ion count within the 4-methoxyphenol peak was used after background correction to generate the ion count used for mass abundance calculations.

RESULTS AND DISCUSSION

Cleavage of Environmentally Significant Ethers

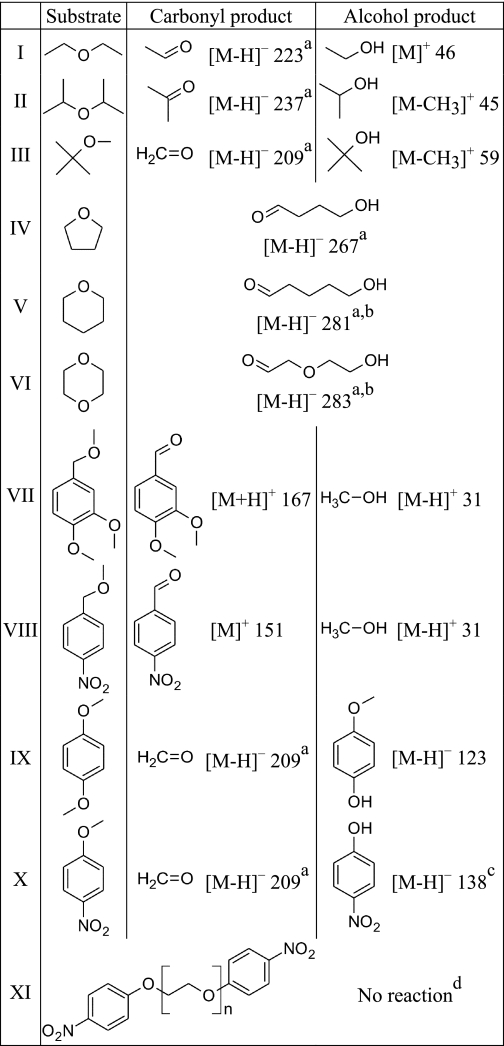

In qualitative experiments done with limiting H2O2, we found that the A. aegerita peroxygenase cleaved alkyl ethers (I-VI, Table 1). The products were carbonyl compounds, which we identified by HPLC/MS as their 2,4-dinitrophenylhydrazones, and alcohols, which we identified directly by GC/MS. Notably, the gasoline additive methyl t-butyl ether (III) yielded formaldehyde and t-butanol, and the widely used solvent tetrahydrofuran (IV) gave the ring-opened product 4-hydroxybutanal. The solvent 1,4-dioxane (VI) was also oxidized, and although in this case no authentic standard was available, the m/z value for the derivatized product was the same as that expected for the 2,4-dinitrophenylhydrazone of the ring-opened product 2-(2-hydroxyethoxy)acetaldehyde. When these reactions were conducted with nonlimiting H2O2, oxidation of the resulting alcohol moieties also occurred, thus generating additional carbonyl groups. For example, 1,4-dioxane was cleaved at both ether linkages and then further oxidized to glyoxal under these conditions (data not shown).

TABLE 1.

Products identified by mass spectroscopy after cleavage of ethers by A. aegerita peroxygenase in the presence of limiting H2O2

The m/z value for the major observed diagnostic ion is shown in each case.

a MS of the 2,4-dinitrophenylhydrazone.

b No authentic standard was available.

c4-Nitrocatechol was also produced.

d n ≈ 45.

A quantitative analysis of tetrahydrofuran cleavage in the presence of limiting oxidant showed that one equivalent of 4-hydroxybutanal was formed per equivalent of H2O2 supplied (Table 2), thus identifying the catalyzed reaction as a two-electron oxidation that splits this ether into one aldehyde and one alcohol. The apparent Km of the peroxygenase for tetrahydrofuran was 2.1 mm, and the initial turnover rate of the enzyme with 2.5 mm of this ether and 2.0 mm H2O2 was 33 s−1 (data not shown). We did not attempt a more complete analysis of tetrahydrofuran oxidation kinetics at a saturating H2O2 concentration, because under these conditions the peroxygenase exhibits an interfering catalase activity.4 Moreover, the cumbersome nature of our HPLC assay for 4-hydroxybutanal formation made initial rate determinations difficult. Instead, we sought an alternative substrate that would provide a more convenient assay.

TABLE 2.

Stoichiometry of tetrahydrofuran oxidation by A. aegerita peroxygenase

The initial tetrahydrofuran concentration was 10 mm.

| H2O2 added | 4-Hydroxybutanal produced | 4-Hydroxybutanal/H2O2 |

|---|---|---|

| μm | μm | |

| 100 | 101 | 1.01 |

| 200 | 194 | 0.97 |

| 300 | 292 | 0.97 |

| 400 | 375 | 0.94 |

| 500 | 489 | 0.98 |

Bisubstrate Kinetics

We found that the peroxygenase cleaved methyl benzyl ethers such as VII and VIII (Table 1), yielding benzaldehydes and methanol, which we identified by HPLC and GC/MS without derivatization. The benzyl alcohols were not detectable as products, even when H2O2 was limiting, and formaldehyde was found only in extended reactions with excess H2O2. These results implied that the benzyl and not the methyl moiety was selectively oxidized during cleavage, the formaldehyde arising only later via oxidation of the released methanol.

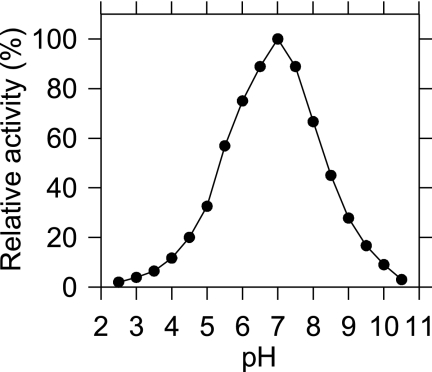

The HPLC/MS results obtained with methyl 3,4-dimethoxybenzyl ether (VII, Table 1) showed in addition that its benzyl ether linkage was cleaved exclusively, with no discernible attack on its methoxyl groups (data not shown). Quantitative analyses of methyl 3,4-dimethoxybenzyl ether cleavage in the presence of limiting H2O2 were consistent with this picture, showing that one equivalent of 3,4-dimethoxybenzaldehyde was produced per equivalent of oxidant supplied (Table 3). The pH optimum for the reaction was 7.0, with 50% activity occurring at pH 5.4 and pH 8.4 (Fig. 1).

TABLE 3.

Stoichiometry of methyl 3,4-dimethoxybenzyl ether oxidation by A. aegerita peroxygenase

The initial methyl 3,4-dimethoxybenzyl ether concentration was 1.0 mm.

| H2O2 added | 3,4-Dimethoxybenzaldehyde produced | 3,4-Dimethoxybenzaldehyde/ H2O2 |

|---|---|---|

| μm | μm | |

| 11 | 12 | 1.09 |

| 22 | 23 | 1.05 |

| 33 | 33 | 1.00 |

| 44 | 43 | 0.98 |

| 55 | 54 | 0.98 |

| 110 | 105 | 0.95 |

FIGURE 1.

Relative rates of methyl 3,4-dimethoxybenzyl ether cleavage by the A. aegerita peroxygenase at various pH values.

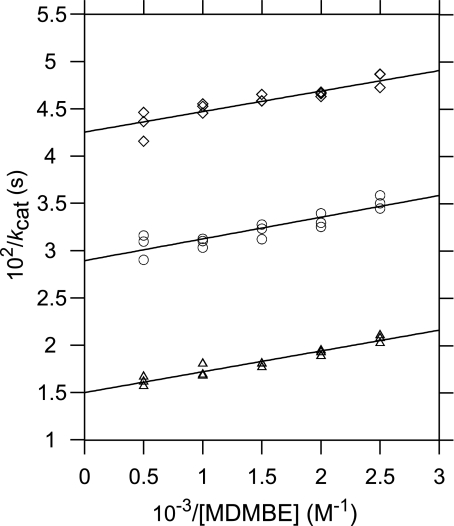

Because a direct spectrophotometric assay is available to monitor the production of 3,4-dimethoxybenzaldehyde (26), we selected methyl 3,4-dimethoxybenzyl ether for initial rate kinetics experiments at pH 7.0, assuming steady-state conditions and using a nonlinear regression method to calculate the kinetic parameters (25). The results gave a kcat of 720 ± 87 s−1, a Km for H2O2 of 1.99 ± 0.25 mm (kcat/Km = 3.6 × 105 m−1 s−1), and a Km for methyl 3,4-dimethoxybenzyl ether of 1.43 ± 0.23 mm (kcat/Km = 5.0 × 105 m−1 s−1). Double reciprocal plots of the same data gave parallel lines (Fig. 2), which is consistent with a ping-pong enzymatic mechanism.

FIGURE 2.

Double reciprocal plots of the kinetics data for methyl 3,4-dimethoxybenzyl ether (MDMBE) cleavage by A. aegerita peroxygenase. The H2O2 concentrations used were 0.067 mm (◇), 0.100 mm (○), and 0.200 mm (▵). The kinetic parameters reported in the text were calculated by a nonlinear regression method (25).

It is interesting to compare the above values with those obtained for functionally similar enzymes. Some P450s that cleave aromatic ethers such as alkoxycoumarins bind them more strongly with Km values around 1–10 μm, but have much lower kcat values in the vicinity of 0.1 s−1 or less (27, 28). Similarly, fungal lignin peroxidases have relatively low Km values around 10–100 μm for H2O2 and for simple aromatic substrates such as 3,4-dimethoxybenzyl alcohol, but also exhibit low kcat values on the order of 1–10 s−1 (26). As a result, the kcat/Km ratios for methyl 3,4-dimethoxybenzyl ether cleavage by the A. aegerita peroxygenase are somewhat higher than those for lignin peroxidase-catalyzed benzyl alcohol oxidations and are much higher than those for P450-catalyzed ether oxidations.

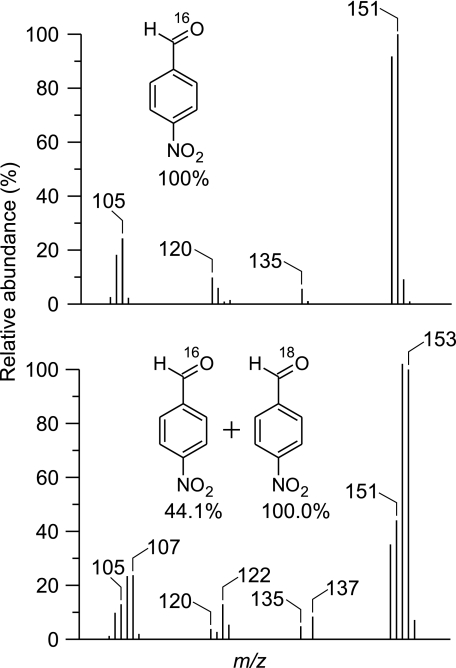

Source of the Oxygen Introduced during Ether Cleavage

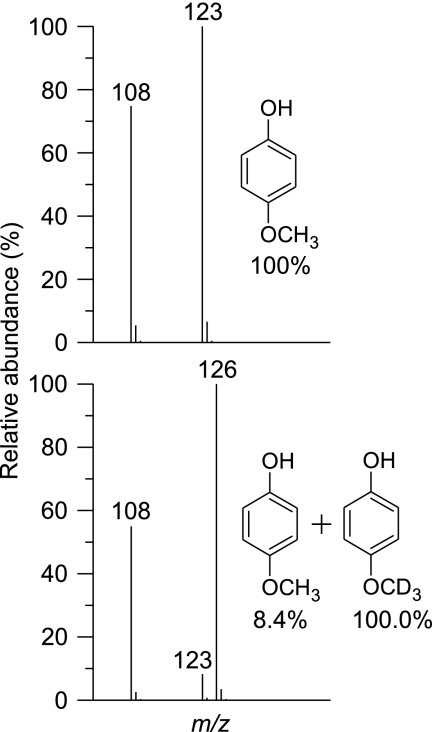

We showed previously by 18O labeling that H2O2 supplies the oxygen atom that the A. aegerita peroxygenase introduces when it hydroxylates aromatic rings (20, 21). The analogous experiment is difficult with alkyl ethers, because the oxygen on the resulting aliphatic aldehyde exchanges rapidly in water. However, benzaldehyde oxygens exchange less rapidly, making the assay feasible with benzyl ethers if a short reaction time is employed (29). We selected methyl 4-nitrobenzyl ether (VIII, Table 1) as the substrate because the nitro substituent in the resulting benzaldehyde has been reported to slow the exchange additionally (30). GC/MS analysis showed that the peroxygenase-catalyzed cleavage of this ether in the presence of 90 atom % H218O2 resulted in 69% 18O incorporation into the carbonyl group of the resulting 4-nitrobenzaldehyde, as evidenced by the shift of the principal molecular ion from m/z 151 to m/z 153 (Fig. 3).

FIGURE 3.

Incorporation of 18O from H218O2 into the carbonyl group of 4-nitrobenzaldehyde after cleavage of methyl 4-nitrobenzyl ether by A. aegerita peroxygenase. Upper, MS of the product obtained with natural abundance H2O2. Structural assignments (37) for m/z values are as follows: [M]+, 151; [M - O]+, 135; [M - NO - H]+, 120; [M - NO2]+, 105. Lower, MS of the product obtained with 90 atom % H218O2.

Evidence for a Hydrogen Abstraction Mechanism

Additional work showed that the A. aegerita peroxygenase cleaved alkyl aryl ethers, yielding aliphatic aldehydes and phenols. The phenols tended to undergo further oxidation to polymeric products and 1,4-benzoquinone because this enzyme exhibits general peroxidase activity (31). However, the phenolic products were readily detectable when ascorbate was included in the assay to suppress their further oxidation (20, 21). By this method we found, for example, that 1,4-dimethoxybenzene (IX, Table 1) was oxidized to 4-methoxyphenol. Because 1,4-dimethoxybenzene is symmetrical and its methoxyl carbons are not prochiral, it is a suitable substrate to determine whether a catalyzed etherolytic reaction exhibits an intramolecular deuterium isotope effect, which gives an approximate value for the intrinsic deuterium isotope effect on cleavage of the ether bond (19, 27, 32).

HPLC/MS analysis showed that the peroxygenase-catalyzed cleavage of 1-methoxy-4-trideuteromethoxybenzene resulted in a marked preponderance of 4-methoxyphenol-d3 (m/z 126, [M - H]−) over 4-methoxyphenol-h3 (m/z 123, [M - H]−) (Fig. 4). The observed mean intramolecular isotope effect [(kH/kD)obs] from three experiments was 11.9 ± 0.4. In general, oxidations that occur via hydrogen abstraction exhibit intrinsic deuterium isotope effects of this magnitude, whereas those that occur via insertion of an oxygen atom show much lower isotope effects with (kH/kD)obs ≈ 2 (27, 32).

FIGURE 4.

Preferential cleavage by A. aegerita peroxygenase of the non-deuterated methoxyl group in 1-methoxy-4-trideuteromethoxybenzene. Upper, MS of 4-methoxyphenol-h3 obtained from the oxidation of natural abundance 1,4-dimethoxybenzene. Structural assignments for m/z values are as follows: [M - H]−, 123; [M - CH3 - H]−, 108. Lower, MS of the 4-methoxyphenol-h3/4-methoxyphenol-d3 mixture obtained from the oxidation of 1-methoxy-4-trideuteromethoxybenzene. The lower MS shown is one of three used to calculate the observed mean intramolecular isotope effect.

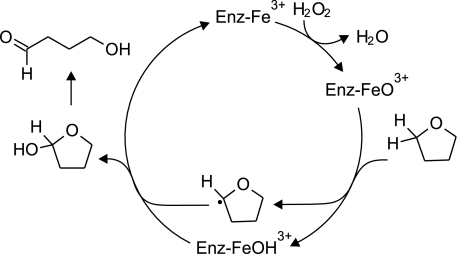

Hypothetical Reaction Mechanism

In summary, our data show that ether cleavage by the A. aegerita peroxygenase exhibits (a) kinetics that are consistent with a ping-pong reaction mechanism, (b) incorporation of H2O2-derived oxygen into the oxidized product, and (c) a high intramolecular deuterium isotope effect that suggests abstraction of an ether β-hydrogen by the enzyme. These results support a mechanism similar to that envisaged for the peroxygenase activity of P450 (12, 13), in which the enzyme heme is oxidized by H2O2 to give an iron species that carries one of the peroxide oxygens and can be depicted formally as FeO3+. This intermediate then abstracts a hydrogen located beta to the ether oxygen, which is followed by rebound of an ·OH equivalent to produce a hemiacetal that subsequently hydrolyzes (Fig. 5).

FIGURE 5.

Hypothetical reaction mechanism for ether cleavage by A. aegerita peroxygenase, with tetrahydrofuran shown as the oxidized substrate.

This working model obviously needs refinement, especially regarding the structure of the oxidized heme. Our attempts to observe oxidized intermediates after titration of the enzyme with H2O2 have been unsuccessful because they result in bleaching of the heme, and further progress will probably require a rapid transient-state kinetics approach. The sequence of substrate binding to the peroxygenase also remains to be established, and additional experiments with molecular clock substrates would be advisable to check whether they yield data consistent with the radical rebound mechanism we have proposed (13).

Scope of Ether Cleavage

We noted some apparent size limitations on ether substrates for the A. aegerita peroxygenase. For example, although the enzyme cleaved 4-nitroanisole (X, Table 1) to 4-nitrophenol, it failed to cleave a 4-nitrophenyl-terminated PEG (XI). The gel permeation chromatography method we used to assess cleavage provides a sensitive assay for random endo scissions of the polyoxyethylene ethers in PEG (24), yet we observed no shift in the molecular weight distribution of the polymer after enzymatic treatment. Moreover, we found no evidence for exo cleavage of model XI, which would have released 4-nitrophenol if it had occurred. In additional experiments, we found that the peroxygenase released n-propanal efficiently from 1,4-di-n-propoxybenzene, but released only traces of n-butanal from 1,4-di-n-butoxybenzene (data not shown). These results suggest that the active site of the A. aegerita peroxygenase is unlikely to accommodate macromolecular ethers such as lignin or polyoxyethylene surfactants.

However, our results indicate a likely role for fungal peroxygenases in the extracellular breakdown of natural and anthropogenic low molecular weight ethers. Some of these reactions are probably fortuitous, as are many of the extracellular xenobiotic oxidations carried out by lignocellulolytic fungi (33). In other cases, ether cleavage may have a physiological function, for example in the biodegradation of lignin fragments, or in the detoxification of fungicidal methoxyaromatic phytotoxins via demethylation and subsequent polymerization (34). It is pertinent that many lignocellulolytic fungi produce the necessary extracellular H2O2 (35), and that this oxidant is also deposited in soils from rainwater (36).

Acknowledgment

We thank Kolby Hirth for spectroscopic analyses of the synthesized peroxygenase substrates.

This work was supported in part by Deutsche Bundesstiftung Umwelt Project Number 13225-32 (to M. H.), European Union Integrated Project Biorenew (to M. H.), and Grant DE-AI02-07ER64480 from the Office of Biological and Environmental Research, United States Dept. of Energy (to K. E. H.).

R. Ullrich, M. Pecyna, M. Kluge, M. Kinne, C. Liers, and M. Hofrichter, Proceedings of the 8th International Peroxidase Symposium, Tampere, Finland, 20-24 August 2008, page 48.

- P450

- cytochrome P450

- PEG

- polyethylene glycol

- GC/MS

- gas chromatography/mass spectrometry.

REFERENCES

- 1.Hofrichter M., Ullrich R. (2006) Appl. Microbiol. Biotechnol. 71, 276–288 [DOI] [PubMed] [Google Scholar]

- 2.Ullrich R., Nüske J., Scheibner K., Spantzel J., Hofrichter M. (2004) Appl. Environ. Microbiol. 70, 4575–4581 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Kluge M., Ullrich R., Dolge C., Scheibner K., Hofrichter M. (2009) Appl. Microbiol. Biotechnol. 81, 1071–1076 [DOI] [PubMed] [Google Scholar]

- 4.Anh D. H., Ullrich R., Benndorf D., Svatos A., Muck A., Hofrichter M. (2007) Appl. Environ. Microbiol. 73, 5477–5485 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Pecyna M. J., Ullrich R., Bittner B., Clemens A., Scheibner K., Schubert R., Hofrichter M. (2009) Appl. Microbiol. Biotechnol., in press [DOI] [PubMed] [Google Scholar]

- 6.Ullrich R., Hofrichter M. (2005) FEBS Lett. 579, 6247–6250 [DOI] [PubMed] [Google Scholar]

- 7.White G. F., Russell N. J., Tidswell E. C. (1996) Microbiol. Rev. 60, 216–232 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Boerjan W., Ralph J., Baucher M. (2003) Annu. Rev. Plant Biol. 54, 519–546 [DOI] [PubMed] [Google Scholar]

- 9.Whiting D. A. (2001) Nat. Prod. Rep. 18, 583–606 [DOI] [PubMed] [Google Scholar]

- 10.Isaacson C., Mohr T. K., Field J. A. (2006) Environ. Sci. Technol. 40, 7305–7311 [DOI] [PubMed] [Google Scholar]

- 11.Scow K. M., Hicks K. A. (2005) Curr. Opin. Biotechnol. 16, 246–253 [DOI] [PubMed] [Google Scholar]

- 12.Guengerich F. P. (2001) Chem. Res. Toxicol. 14, 611–650 [DOI] [PubMed] [Google Scholar]

- 13.Ortiz de Montellano P. R., de Voss J. J. (2005) in Cytochrome P450. Structure, Mechanism, and Biochemistry (Ortiz de Montellano P. R. ed), 3rd Ed., pp. 183–245, Kluwer Academic/Plenum Publishers, New York, NY [Google Scholar]

- 14.Lopes Ferreira N. L., Malandain C., Fayolle-Guichard F. (2006) Appl. Microbiol. Biotechnol. 72, 252–262 [DOI] [PubMed] [Google Scholar]

- 15.Mahendra S., Petzold C. J., Baidoo E. E., Keasling J. D., Alvarez-Cohen L. (2007) Environ. Sci. Technol. 41, 7330–7336 [DOI] [PubMed] [Google Scholar]

- 16.Schmidt H. W., Haemmerli S. D., Schoemaker H. E., Leisola M. S. (1989) Biochemistry 28, 1776–1783 [Google Scholar]

- 17.Pedersen D. S., Rosenbohm C. (2001) Synthesis, 2431–2434 [Google Scholar]

- 18.Lawson T., Gannett P. M., Yau W. M., Dalal N. S., Toth B. (1995) J. Agric. Food Chem. 43, 2627–2635 [Google Scholar]

- 19.Foster A. B., Jarman M., Stevens J. D., Thomas P., Westwood J. H. (1974) Chem.-Biol. Interact. 9, 327–340 [DOI] [PubMed] [Google Scholar]

- 20.Kinne M., Poraj-Kobielska M., Aranda E., Ullrich R., Hammel K. E., Scheibner K., Hofrichter M. (2009) Bioorg. Med. Chem. Lett. 19, 3085–3087 [DOI] [PubMed] [Google Scholar]

- 21.Kinne M., Ullrich R., Hammel K. E., Scheibner K., Hofrichter M. (2008) Tetrahedron Lett. 49, 5950–5953 [Google Scholar]

- 22.Li H., Zhan H., Fu S., Liu M., Chai X. S. (2007) J. Chromatogr. A 1175, 133–136 [DOI] [PubMed] [Google Scholar]

- 23.Cooke M. P., Archer B. G., Krakauer H. (1974) Biochem. Biophys. Res. Commun. 57, 1032–1037 [DOI] [PubMed] [Google Scholar]

- 24.Kerem Z., Jensen K. A., Hammel K. E. (1999) FEBS Lett. 446, 49–54 [DOI] [PubMed] [Google Scholar]

- 25.Hernández A., Ruiz M. T. (1998) Bioinformatics 14, 227–228 [DOI] [PubMed] [Google Scholar]

- 26.Tien M., Kirk T. K., Bull C., Fee J. A. (1986) J. Biol. Chem. 261, 1687–1693 [PubMed] [Google Scholar]

- 27.Yun C. H., Kim K. H., Calcutt M. W., Guengerich F. P. (2005) J. Biol. Chem. 280, 12279–12291 [DOI] [PubMed] [Google Scholar]

- 28.Kim D., Guengerich F. P. (2004) Arch. Biochem. Biophys. 432, 102–108 [DOI] [PubMed] [Google Scholar]

- 29.Tien M., Kirk T. K. (1984) Proc. Natl. Acad. Sci. U.S.A. 81, 2280–2284 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Samuel D., Silver B. L. (1965) Adv. Phys. Org. Chem. 3, 121–186 [Google Scholar]

- 31.Ullrich R., Hofrichter M. (2007) Cell. Mol. Life Sci. 64, 271–293 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Nelson S. D., Trager W. F. (2003) Drug Metab. Dispos. 31, 1481–1498 [DOI] [PubMed] [Google Scholar]

- 33.Tortella G. R., Diez M. C., Duran N. (2005) Crit. Rev. Microbiol. 31, 197–212 [DOI] [PubMed] [Google Scholar]

- 34.Delserone L. M., McCluskey K., Matthews D. E., Vanetten H. D. (1999) Phys. Mol. Plant Pathol. 55, 317–326 [Google Scholar]

- 35.Leonowicz A., Matuszewska A., Luterek J., Ziegenhagen D., Wojtaś-Wasilewska M., Cho N. S., Hofrichter M., Rogalski J. (1999) Fungal Genet. Biol. 27, 175–185 [DOI] [PubMed] [Google Scholar]

- 36.Kok G. L. (1980) Atmos. Environ. 14, 653–656 [Google Scholar]

- 37.McLafferty F. W., Tureček F. (1993) Interpretation of Mass Spectra, 4th Ed., University Science Books, Sausalito, CA [Google Scholar]