Abstract

Background

Climate change is producing major impacts including increasing temperatures in tropical countries, like Costa Rica, where the sugarcane industry employs thousands of workers who are exposed to extreme heat.

Objectives

This article outlines a pilot qualitative evaluation of working conditions and heat in the sugarcane industry.

Design

A literature review, direct observations and exploratory interviews with workers were conducted to reach a preliminary understanding of the dimensions of heat-related health issues in the sugarcane industry, as a basis for the design of future studies.

Results

The industry employs temporary workers from Nicaragua and Costa Rica as well as year-round employees. Temporary employees work 12-hour shifts during the harvest and processing (‘zafra’) season. In many cases, sugarcane field workers are required to carry their own water and often have no access to shade. Sugar mill workers are exposed to different levels of heat stress depending upon their job tasks, with the most intense heat and workload experienced by the oven (‘caldera’) cleaners.

Conclusions

Research is needed to achieve better understanding of the multiple factors driving and interacting with heat exposures in the sugarcane industry in order to improve the health and safety of workers while maintaining worker productivity.

Keywords: sugarcane, Central America, Costa Rica, heat exposure, heat stress, agriculture, climate change

Climate change is producing major impacts worldwide including increasing temperatures, particularly in tropical countries (1). Increasing temperature raises environmental as well as serious human health concerns. Although the human body is remarkably capable of maintaining its core temperature around 37°C, a combination of conditions such as high environmental temperature and high humidity (which decreases the efficiency of sweating), clothing that increases core temperature (and reduces ability to sweat), physical exercise and dehydration can disturb the equilibrium. This can result in heat stress and, when severe, can cause heat stroke and death (2).

Exposure to excessive heat is common in sectors like agriculture, mining, construction and manufacturing plants (‘maquiladoras’), particularly in tropical countries where these sectors comprise a large proportion of the workforce. Increasing temperatures can mean increasing exposure to extreme heat and increasing risk for negative health outcomes for worker populations (3). Although governments, the private sector, NGOs and academia have begun to focus on the economic and environmental impacts of global climate change, there has been little attention to what effects global heating will have on the health and productivity of the worldwide labour force (2).

The sugarcane industry in Costa Rica is an important contributor to the national economy through the production of multiple products for national and international consumption as well its contribution to recent regulatory requirements for bioethanol to be included as a constituent of petroleum-based fuels. The production and processing of sugarcane is a major source of employment in Costa Rica for both Costa Ricans as well as Nicaraguans who travel to work in the harvest and processing (‘zafra’) period. According to the Sugarcane Industrial Agriculture Association (LAICA), the sugar industry in Costa Rica employs 20,000 permanent workers (4). Temporary workers come from both Costa Rica and Nicaragua and are either employed directly by the company or by an individual who offers subcontracting services to companies. Estimates for the number of temporary workers employed by the sugarcane industry vary enormously, without verifiable numbers. In some companies, the number of temporary workers needed for the harvest has actually gone down due to increased use of mechanised harvest techniques (4). During the zafra season, all efforts concentrate on the successful harvest and processing of the year's crop. The large number of workers needed to achieve this goal creates occupational health issues that are complicated by the focus on the harvest, the intense heat and the influx of temporary workers.

Sugarcane is grown in multiple regions throughout the country, with the most sugarcane being produced in Guanacaste in northwest Costa Rica, approximately 250 km from the capital city of San José. In Guanacaste, there are three large plantation companies (with sugar mills and fields) which, together with numerous independent farmers, are collectively responsible for approximately 59% of the total sugarcane harvested and 55% of the total sugar produced in Costa Rica (4).

Guanacaste is one of the hottest and driest regions of Costa Rica and has two main seasons: the rainy season (May–November) and the dry season (December–April). Sugarcane harvesting, planting and processing take place during the hottest (dry) season. Between 1973 and 1994, the monthly averages of daily maximum temperature ranged from 31.1°C in October to 36.0°C in April (Table 1) (5). Official data for more recent years is not publicly available.

Table 1.

Climate data from the National Meteorological Institute of Costa Rica (Daniel Oduber Airport), Liberia, Guanacaste, Costa Rica

| Month | Average maximum temperature (°C) (1973–1994) | Average minimum temperature (°C) (1973–1994) | Average monthly precipitation (mm) (1957–1994) |

|---|---|---|---|

| January | 33.4 | 20.8 | 0.8 |

| February | 34.5 | 21.1 | 2.0 |

| March | 35.5 | 21.6 | 4.5 |

| April | 36.0 | 22.4 | 13.9 |

| May | 34.2 | 23.3 | 191.8 |

| June | 32.1 | 23.0 | 254.2 |

| July | 32.0 | 22.7 | 150.2 |

| August | 32.0 | 22.5 | 201.5 |

| September | 31.3 | 22.3 | 319.4 |

| October | 31.1 | 22.0 | 290.6 |

| November | 31.7 | 21.4 | 91.2 |

| December | 32.6 | 21.1 | 9.8 |

This report outlines a pilot qualitative evaluation to explore the dimensions of heat-related health issues in the sugarcane industry.

Present study

Methods

A brief qualitative assessment of factors related to heat stress and its health effects was conducted between November 2008 and March 2009. Published and unpublished documents about sugarcane production in Central America and heat-related human health effects were identified by searching PubMed as well as Costa Rican and Central American popular press available online. Brief exploratory interviews were held with:

four occupational health researchers with experience in the sugarcane industry;

one occupational health professional from a sugarcane company in Guanacaste;

a company nurse and physician with experience treating sugarcane workers; and

17 workers (12 sugar mill and five field workers).

The interviews contained questions about the tasks that workers complete; the heat conditions they face; strategies for reducing heat-related health effects; the possibilities for measuring worker productivity; health effects and heat stress in future studies; and whether or not they considered it important to conduct research about heat-related health conditions. In addition, during the 2008–2009 harvest, direct observation of the conditions and work loads present in the sugar mill and the field was conducted on multiple visits to one company.

Results

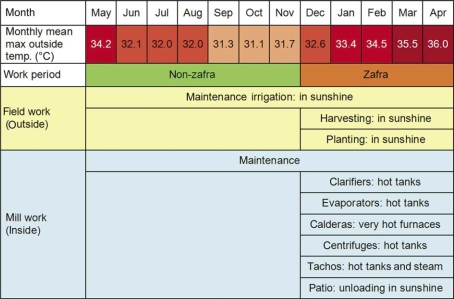

The sugarcane industry includes two main areas in which workers are exposed to extreme heat: field work and processing plant (sugar mill) work (Fig. 1). Both areas include work during the zafra season as well as the maintenance (non-zafra) season. For the purpose of this report, field work includes harvesting and planting during zafra and maintenance of the crop during no-zafra. Work in the sugar mill includes all tasks beginning with unloading the harvested sugarcane from the trucks and ending with the production of refined sugar products during zafra season, and during the non-zafra period repairs and preparations of the machinery and infrastructure in the sugar mill for the next harvest period.

Fig. 1.

Division of work in the sugarcane industry in Costa Rica.

Literature review

Very few scientific findings exist about the risks faced by sugarcane workers in Central America. There have been a few studies in the Americas on specific risks among sugarcane workers such as cancer (6, 7), respiratory conditions (8) and musculoskeletal injuries due to repetitive motion and machete use (9), but none of these studies make links to heat or climate change. There has been some important work done regarding socio-economic and gender-related issues for sugarcane workers (10, 11) which although not directly linked to heat stress, provides important context for understanding heat-related health issues.

Some technical reports have been published on general risks present in the industry, including heat (12, 13). For example, a report from the International Labor Organization (ILO) highlights the exposure of workers to noise; vibration; contact with agricultural chemicals; repetitive motion; machinery-produced heat; environmental heat (temperature and humidity); ultraviolet solar radiation; and visible light in addition to climatic conditions such as rain, wind and lightning (13).

Likewise, within the Program on Work and Health in Central America (SALTRA), a participatory methodology was developed to reduce the risk of accidents and various occupational exposures in the sugarcane industry. Eight participatory workshops were held with workers and managers to identify hazards along with possible solutions. In total, workers identified 311 hazards and mentioned one or more solutions for 89% of the hazards. In addition to exposures such as noise and dust exposure, heat-stress was identified as a main occupational health problem in these workshops (12).

At the regional level, research has been conducted and is ongoing concerning an important human health outcome that directly affects many sugarcane workers and which may be linked to climate. Epidemics of chronic kidney disease (CKD) in sugarcane workers have been reported in El Salvador and Nicaragua (14–18, 25) while Costa Rica and other countries in Central America report higher than expected occurrence of CKD in sugarcane workers (19). One repeatedly mentioned hypothesis is that the high number of sugarcane workers suffering from CKD may be at least partially due to chronic dehydration related to working conditions.

Although there has been little research regarding heat-related health issues, there have been some studies regarding climate change in the Guanacaste Region. A report produced by the Central American Integration System (SICA) (20) as well as the popular press (21) have warned that the northern part of the country will experience temperatures as much as 3°C higher over the next 90 years and there will be a reduction in rainfall of up to 11%.

Nationally, there has been a small increase in research regarding climate change and its links to production of food and export products (22). This is due not only to the increased awareness of climate change, but also the economic crisis, which has fostered renewed interest in national, sustainable and self-sufficient food production (23, 24).

Information from interviews and observations

Harvest

Sugarcane harvesting by hand is an intense job that involves constant exposure to heat and sunlight (see Fig. 2). Many farms burn the sugarcane in the evening or night hours, before the harvest. This is done before both manual and automated (tractor) harvest to decrease the sharpness of the leaves. Sugarcane farmers also report that the burning decreases the probability of snake bites during manual harvest and reduces the weight of the cane for transportation purposes. Some say burning increases the quality of the sugar. Burning is carried out by a group of approximately six workers that start and control the fires making sure that they burn only the amount that is possible to harvest the next morning, to avoid the risk of sugar content in the cane decreasing while waiting for harvest.

Fig. 2.

Sugarcane harvesting in Costa Rica takes place under direct sun, often in fields that have been burnt the night before.

Harvesting starts in the morning and lasts until the early afternoon hours, usually in fields still smoking from the previous night's burning. When the sugarcane is cut by hand with machetes, workers are usually paid by the ton or by the number of rows they cut in teams of three workers. As noted in the ILO report on working conditions in the sugarcane industry in Costa Rica (13), the heat stress for sugarcane harvesters is increased because of the high physical demands on them. Increasingly, larger farms are using automated sugarcane harvesters (see Fig. 3), but still rely on manual labour in sections of fields that are too small or too uneven for the tractors. Tractor drivers are enclosed within air-conditioned cabs.

Fig. 3.

Automated sugarcane harvesters with air-conditioned cabs are increasingly used in many farms, but many workers are still employed to cut sugarcane by hand.

The harvest activities in the field also include the transportation of the sugarcane to the sugar mill. Depending upon the farm or company, transportation may be done with large ‘semi’ trucks with air-conditioned cabs or with tractors (without cabs) that pull a large open wagon containing the harvested sugarcane.

Planting

Sugarcane plants have a productive life between one and five years and when a field needs re-planting, it is done by hand. Planting usually takes place the day after the harvest. In most cases, planting is done between 05:00 and 14:00 and involves several tasks. Some workers prepare sacks of ‘seed’ (the shoots are referred to as ‘seed’ in Costa Rica, although they are actually seedlings or ‘shoots’). Other workers distribute the sacks in the field; while a third group of workers plants the shoots. Most companies sub-contract the planting and a typical contractor employs approximately 150 workers that are responsible for three hectares per day. Reportedly, the workers that prepare the sacks often work longer hours in order to fulfil the quota (approximately 5,000 sacks) that must be ready for the following day. The group of planters travel to a new field each day and workers are usually paid by the number of rows or metres that they plant. Later, planters are sometimes employed to ‘re-cover’ (‘re-tapar’) the plants with soil, a process done days or weeks after the initial planting in which workers make sure each plant is sufficiently covered with soil at its roots. Planting also requires individuals employed as ‘counters’, responsible for confirming the number of metres planted by each worker. Traditionally only men are employed in the tasks related to planting, but there are anecdotal reports that an increasing number of women are also employed in many of these tasks.

Irrigation and general field work

Sugarcane companies directly hire both permanent and temporary workers to carry out irrigation and general field up-keep tasks during the harvest period. The vast majority of these workers are employed starting with the harvest (December), but continue after the harvest ends (usually in the beginning of April) until the rainy season starts (usually in May). During the dry season, irrigation takes place continuously and in most companies, shifts run from 06:00 to 18:00 and then from 18:00 to 06:00. In some companies, workers rotate one week on the day shift and one week on the night shift for the duration of the harvest and planting season. The rotating schedule allows all workers to earn overtime and all of the workers consulted preferred the night shift to the day shift because of the decreased heat and the increased pay.

Irrigation may be water or may be water combined with fertiliser (such as ash or other by-products of the processing, which provide nitrogen and other nutrients to the plants). Irrigators often work alone in large fields. They are exposed to direct sunlight with no trees or other sources of shade. The company bus drops them off at their assigned area for the day and a supervisor passes by throughout the shift to check on progress. Irrigation usually requires continuous walking and considerable physical effort throughout the majority of the 12-hour shift.

Specific tasks for irrigation workers include hooking up the tubes, unplugging rubber stoppers to allow water to flow to a specific region of the field, using a tarp to direct water and continually levelling the soil between the rows to allow the water to enter undisturbed. Irrigation workers carry a shovel with an extra-long handle which they use to level the ground and also to help them cross large irrigation ditches. Most workers consulted for this exploratory study reported taking or not taking breaks depending on ‘how my [irrigation] water is going’. In other words, if the water is flowing well, workers are able to take short breaks, but if the rows where the water enters require a great deal of work with the shovel, it is not possible to take breaks.

Other workers are hired by the company for general maintenance and tasks in the field. These workers include both those hired seasonally as well as those who work for a particular company year-round. Typical tasks include: picking up rocks in the field before the harvesting tractor enters, cutting weeds and grass with a machete, picking up sugarcane left behind by the tractor harvesters in the field, fixing leaks in the irrigation system and keeping the irrigation canals free of debris.

Finally, workers are employed to carry out application of different kinds of pesticides and fertilisers. Depending on the company, these workers can be inside an enclosed tractor cab, use a knapsack sprayer, a ‘boom’ sprayer, a mechanical sprayer behind the back of a four-wheeled motorcycle or in a combination of workers on foot and in a tractor. Both general maintenance workers and pesticide applicators usually work alone and are exposed to direct sunlight, although on some days, they may be near trees or other sources of shade under which they can seek brief respite or where they can leave their lunches and water jugs.

Maintenance (non-zafra) period

The maintenance (non-zafra) period is a calmer period that employs considerably less workers, but still involves working in conditions of exposure to considerable heat and solar radiation. Workers during the maintenance season are almost always full-time, year-round employees of a company hired to carry out tasks such as the application of pesticides and fertilisers, manual weed control and the maintenance of irrigation canals. The majority of the non-zafra season coincides with the rainy season, which tends to be somewhat cooler (see Table 1). Additionally, there is far less pressure to complete tasks at a rapid rate during 12-hour shifts.

Heat-related issues and solutions for field workers

With the maximum daily temperature almost never dropping below 31°C and the intense direct sunlight as a result of Costa Rica's latitude, the potential for heat stress in field workers is high. Furthermore, the fields probably retain additional heat following burning and, as one person stated, ‘you can literally see the ground smoking and fuming’ the morning following a burning. There are anecdotal reports of heat stroke victims resulting in hospitalisation in at least some companies. Intravenous rehydration treatment is reportedly relatively common in the medical clinic of large companies.

Occupational health workers pointed out that severe dehydration cases are often linked to complex social issues, such as workers who fear seeking medical care because they lack documentation and who, therefore, may work in the fields while sick and after not having eaten for several days.

It is speculated that chronic dehydration, exacerbated by exposure to extreme heat may be a serious problem for sugarcane field workers and may, therefore, be linked to the high prevalence of CKD among sugarcane workers (14–19, 25). Workers mention the need to drink water ‘for your kidneys’ and one worker reported ‘many co-workers are affected by kidney problems’.

The main strategy currently in place for dealing with heat stress in the field is hydration, however, health and safety personnel in the sugarcane industry have expressed concern that hydration just with water is not sufficient and that there may be a need to consider nutritional factors and electrolyte levels when providing hydration for workers. In many companies, field workers, whether employed directly by the company or by contractors, are responsible for carrying the water they need for the entirety of their shift. Most field workers consulted said they take between 2 and 10 liters of water into the field with them. Since there is no shade available for most workers, they wrap their water jugs in a wet cloth when they leave their house to keep the water from over-heating in the direct sunlight.

Most workers reported drinking either coffee or ‘fresco’ (fruit juice mixed with water and sugar) during the day and most reported drinking at least one glass of water or fresco before leaving the house and when returning home at the end of the shift. One worker reported that one must be careful not to consume too much water before doing machete work, as to avoid ‘jumbling up and bothering the stomach’. In general, the amount of liquid consumed by workers varied considerably, but is it is likely that, in the majority of cases, it is far below the amount of liquid lost by perspiration under the working conditions of the zafra. It is common to hear workers saying they believe the drinking water available to them at home and work is contaminated and some of these workers believe that the water may be related to the high incidence of kidney disease in sugarcane workers.

In order to protect themselves from solar radiation (as well as the sharp sugarcane leaves) workers use long sleeves, long pants and neck covering either as a cap with a flap in the back or a cap with a handkerchief hanging to cover the neck. Most wear rubber boots and many wear two shirts (one long-sleeved ‘button-down’ shirt underneath and one short-sleeved ‘button-down’ shirt on top) to lessen the burning sensation created by solar radiation.

A half-an-hour lunch break and two 15-minute breaks are required for eight-hour shifts in Costa Rica. However, during the harvest and planting, temporary field workers are trying to make as much money as possible during the four to five months they have employment in the sugarcane industry. Temporary workers said that they are paid by the amount of work they complete and are, therefore often reluctant to take breaks. Temporary and permanent workers said that sometimes their workload prevents them from taking a full lunch period or the permitted 15-minute breaks.

When asked whether they believe the heat or ‘especially hot days’ affect their productivity, most field workers said that they feel they get tired faster, but most of them also qualified their statement saying that they manage to complete their tasks regardless.

Description of sugar mill work

The sugar mill is an intense work environment during the harvest and processing season due to the high number of workers, the 24-hour work schedule, the intense heat and the volume of work, whereas there are very few workers and much calmer conditions during the maintenance period. Workers in the sugar mills may be temporary or year-round, but all are employed directly by the company. Shifts during the zafra period are 12-hour shifts as described above for the field workers.

Typically, the sugar mills are large three-storey buildings with corrugated metal exterior walls and roofs. The infrastructure, including stairs and handrails, is made of metal and the flooring is cement. There are different sections of the plant, some of which have ventilation in the form of an open section in one of the exterior walls while other sections of the plant are more closed off. Most of the processes produce heat and, as a result, the entire plant is warm and many areas are filled with hot vapour. The stairs and handrails are warm to the touch.

The sugar mills are run by electricity produced onsite using steam created by large ovens which burn ‘bagasse’, the parts of the sugarcane plant left after crushing the cane to extract the juice. The ovens are located within the sugar mill and create extremely hot working conditions. The temperature in the sugar mill remains high during day time and night time because the ovens (‘calderas’) keep running all night.

In order to maintain the machines and tubing through which the vapour travels, there are periodic purges of steam, usually several times per shift. Some of these purges are directed outside the plant, but others are actually purged inside the plant. Previous measurements taken in Nicaragua and Costa Rica by the SALTRA programme during the harvest season demonstrate the wet bulb thermometer temperature varies between 30.1 and 37.0°C.

Patio

The ‘patio’ workers (where the sugarcane is unloaded from trucks into the sugar mill) are the only sugar mill workers exposed to direct sunlight as a part of their regular tasks. One worker remains in an air-conditioned control cabin, but the others help with the unloading process and are on their feet in the direct sunlight (during the day shift) for most of the 12 hours.

Tachos

Approximately two workers per shift typically work as ‘tacheros’, controlling the quality of the sugar by controlling pressure and volume in large tanks. The job is quite detail-oriented and requires experienced workers. In a typical sugar mill, the tachos area is located on the third floor which absorbs heat from the tin roof as well as accumulating heat that rises from below, but does have large open spaces at either end that allow for a breeze on windy days. Tacheros are on their feet for most of the shift, but are able to sit for brief periods on wooden benches located near the open spaces. This area of the sugar mill is particularly exposed to the purges of steam (described above). The tachos area is the only one which has an air-conditioned chamber where a computer is stored and where some of the tacheros occasionally seek relief from the heat. Most, however, are reluctant to do so as they feel the extreme changes in temperature are unhealthy.

Centrifuges, clarifiers and evaporators

The centrifuge, ‘clarifying’ and evaporating areas are located within the sugar mill. In all three areas, workers are on their feet and must pay attention to detail, but they are also able to sit down for short periods of time. The centrifuge area is particularly hot because the large tanks present release both heat and steam on a continuous basis.

Calderas (ovens)

The calderas that burn bagasse to produce electricity must be cleaned of ash. A team of 4–5 workers is dedicated to this task which involves opening a large iron door of an oven at 250–270°C. One worker sprays the burning ash with a garden hose until it stops burning, while the others use metal poles and shovels to pull the smouldering ash out and place it on the palette of a forklift. The process takes approximately 2.5 hours and is done twice per 12-hour shift. These workers are exposed to extreme heat, risk of burns and inhalation of particulate matter but also to an extremely intense physical work load. When they are not cleaning the ovens, these workers are responsible for general upkeep tasks or for helping other workers wherever it may be necessary.

Maintenance (‘non-zafra’) period

During the maintenance period, there are fewer workers employed by the company. Those that are employed carry out tasks related to the maintenance of machinery. The plant does not burn material to produce electricity during the maintenance period, significantly reducing the temperature in the sugar mill and the rainy season from May to November also brings decreasing outside temperatures.

Heat-related issues and strategies for sugar mill workers

Hydration is the principal strategy for reducing heat effects for sugar mill workers and in some companies, water tanks are located in several spots throughout the three-storey plant. They are filled with tap water. The workers consulted said that, depending on where the tap is located, the drinking water comes out hot. Some suspect the tap water is contaminated, with one worker even reporting that he and his co-workers add bleach to the water to purify it. Workers said they receive plastic ‘sandwich’ bags full of a rehydration drink once per 12-hour shift and that sometimes if they get two bags, they share them with the workers in the hottest areas. Some workers also mentioned going to the company cafeteria to purchase soft drinks or juice drinks. A few of the workers indicated that it is important not to drink water that is ‘too hot’ or ‘too cold’ because it is ‘bad for the organism’. The caldera workers interviewed reported being able to get a juice drink at the cafeteria for free. Workers varied as to how much liquid they reported drinking, with the average being about 5.5 liters of water per 12-hour shift. Caldera workers reported drinking up to 7 liters during the 2.5 hours it takes them to clean the ovens each time. Most workers, however, were unsure how much liquid they consume.

Workers in the plant reported that the heat affects their productivity, particularly in the case of the workers whose jobs require attention to detail because the heat affects their ability to concentrate. Several workers reported feeling tired from the heat, and said that sometimes they take a caffeinated aspirin pill to combat this feeling, whereas others take acetaminophen for headaches. Most workers wear long sleeves and a hardhat. It is common to see workers take off their gloves due to the heat. Oven cleaners wear a helmet, safety glasses, long sleeves, long pants, rubber boots, a hat and a handkerchief or other piece of cloth (sometimes the hood portion that has been cut off of a jacket which they zip or velcro in front of the mouth and nose). Approximately half of the oven cleaners wear gloves while cleaning the oven, while the other half remove them due to heat. The oven cleaners reported either dumping water on their heads or putting their feet (while in rubber boots) in cool water in order to cool off. All workers said that they preferred working at night because it is cooler.

Discussion

One of the most pressing occupational health hazards for sugarcane workers is exposure to extreme heat. The effects of global climate change have already been shown to be affecting the Guanacaste region of Costa Rica (21, 22) and more negative effects are expected in the coming years (24). Additionally, there have already been studies on the potential effect of climate change or climate variability on the economics, production and pest-related problems in the sugarcane industry (22, 27). There are, however, no studies investigating the effect of climate change and increasing heat on workers’ productivity or health in Costa Rica. The high numbers of Costa Rican and Nicaraguan workers employed in the industry, as well as the economic importance of the industry, make research of utmost importance and urgency, particularly in light of the expected climate changes.

Costa Rica has a regulation in place to protect workers from extreme heat; however, it is a vague document that simply states: ‘The temperature and humidity level of the environment in enclosed workplaces should be maintained (when the nature of the industry allows), between limits that are neither uncomfortable nor dangerous for the health of workers’ (28). The National Advisory Board responsible for determining workplace temperature and humidity limits recommends that companies follow norms set by the Institute for Technical Norms in Costa Rica. This document defines the maximum temperature and humidity levels dependent upon the type of work being carried out (26). These norms do not set limits by industry or by type of work, but rather provide information for making appropriate calculations for work and rest periods. In Costa Rica, each company is responsible for setting its own limits and there is almost no government-level enforcement of the vague guidelines. There is interest on the part of management in most sugarcane companies to look for solutions to reduce workers’ exposure to extreme heat as it affects both health and productivity.

Although some potential solutions are already in place within some companies, such as providing water dispensers inside sugar mills, their effectiveness has not been studied. One potential solution that has been suggested is providing break periods in air-conditioned rooms. Interestingly, this solution may present cultural barriers, and therefore may require a holistic interdisciplinary and participatory approach to research. In particular, there is a strongly held belief in Costa Rica that moving from hot to cold temperatures will cause one to become sick (for example, catch a cold or develop arthritis). Similar beliefs exist about drinking water or other liquids that are cold. There have been no studies to investigate the viability of rest chambers or the provision of cold drinks in terms of the tendency of Costa Ricans to avoid temperature extremes. Other strategies implemented by workers at the individual level may be having negative effects (for example taking caffeinated aspirin pills) or be positive initiatives (for example cooling water in the field by wrapping water jugs in wet cloth, or cooling feet by placing them in cool water while wearing rubber boots) that could be encouraged on a larger scale.

Hydration is another example of a commonly used approach already in place within the sugar mills to decrease potential negative effects of heat exposure. However, health and safety personnel indicated that they believe factors such as nutrition and electrolyte levels should be incorporated into hydration programmes in order to make them more effective. Although companies have expressed interest in a more integral nutrition-based approach to hydration as a means of combating heat stress, there have been no studies to explore the dietary and hydration habits already in place or the possibility of implementing hydration programmes in the sugarcane industry. Particularly in Guanacaste, hydration is complicated by what appears to be a widespread belief that the water is unsafe and can lead to kidney problems. This possibility warrants an integrated research model that includes testing the drinking water for nephrotoxins.

When developing and evaluating solutions for heat stress in the sugarcane industry, it is important to recognise that there is a lack of data on the heat conditions that the sugarcane workers face. It is necessary to measure heat and other climatic conditions (such as humidity, dew point and wind speed) that affect the body's ability to regulate heat. Additionally, it is critical that the workload of each person be described fully and that the work of women in the field is included in the documentation. Finally, it is critical that the socio-economic and cultural dimensions of current and potential solutions be considered, particularly taking into account the workers’ experiences, knowledge and perspectives. Without these indicators, it is difficult to create and evaluate potential solutions that address worker health and productivity. It is also essential that the health-related effects of heat stress be documented through a cohort study that could measure factors ranging from biomarkers of heat stress to psychological effects of heat exposure. Likewise, it is important that climate conditions are being appropriately measured and recorded in order to measure possible climate change.

There seems to be increasing political and public awareness about the link between global climate change and health as well as an appropriate political environment for action (21, 24, 29–31). The Costa Rican government is currently in the process of planning and policy making for adaptation to climate change. Unfortunately, there is a severe lack of research data upon which to base these critical policy-related decisions, making the need to produce data particularly important.

Meanwhile, some solutions for apparent problems can already be implemented, such as creating ways for workers to access to shade in the fields or establishing and enforcing rest breaks for workers and implementing improved access to water or integrated hydration plans. These interventions should be evaluated for both their effectiveness as well as their potential for cultural acceptance.

Strengths and limitations

This brief exploratory description of the heat-related issues faced by sugarcane workers falls short as it does not include heat measurements, nor detailed information from the temporary sugarcane harvesters and planters. This group of workers is probably the most exposed and the most vulnerable, yet it is the least studied. This population also faces socio-economic conditions that require an in-depth understanding of the issues related to their social, living and working environments (4, 10, 11). Integrated, holistic methodologies such as an eco-system health approach (32) are necessary to understand the multiple dimensions of the environmental, health and socioeconomic issues that require sustainable solutions.

Conclusion

The sugarcane industry is extremely important to Costa Rica's economy. Sugarcane workers in Costa Rica face exposure to extreme heat under current climatic conditions, which are likely to worsen with predicted climatic changes. At present, there is strong national political interest in preparing for any negative health effects of climate change. Research is needed to achieve better understanding of the multiple factors driving and interacting with the sugarcane industry in order to improve the health and safety of workers while simultaneously maintaining worker productivity.

Conflict of interest and funding

The authors have not received any funding or benefits from industry to conduct this study.

References

- 1.IPCC. Fourth assessment report. Geneva, Switzerland: Inter-governmental Panel on Climate Change; 2007. International Panel on Climate Change. Report No.: AR4. Available from: http://www.ipcc.ch/publications_and_data/publications_ipcc_fourth_assessment_report_synthesis_report.htm [cited 23 October 2009] [Google Scholar]

- 2.Kjellstrom T. Climate change, health exposure and productivity; Epidemiology; Buffalo, NY: 2000. p. S144. ISEE 2000, 12th conference of the society for environmental epidemiology, August 2000. [Google Scholar]

- 3.Kjellstrom T. Climate change, direct heat exposure, health and well-being in low and middle-income countries. Global Health Action. 2009 doi: 10.3402/gha.v2i0.1958. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Acuña-González G. Diagnostico: la agroindustria de la caña de azúcar en Costa Rica: características, organización y condiciones laborales [The agricultural industry in Costa Rica: characteristics, organization and labor conditions] San José, Costa Rica: asociación servicios de promoción laboral [Association services for labor promotion] (ASEPROLA); 2004. [Google Scholar]

- 5.Stolz-España W, Agüero Porras J. Climatología aeronáutica: aeropuerto internacional Daniel Oduber Quiros [Aeronautic climatology: Daniel Oduber Quiros International Airport]; San José, Costa Rica: Instituto Meteorológico Nacional and El Ministerio de Ambiente y Energía [National Meteorological Institute and the Ministry of Environment and Energy]; 2008. [Google Scholar]

- 6.Coble J, Morris-Brown L, Hayes R, Huang W-Y, Winn D, Gridley G, et al. Sugarcane farming, occupational solvent exposures, and the risk of oral cancer in Puerto Rico. J Occup Environ Med. 2003;45:869–74. doi: 10.1097/01.jom.0000083034.56116.0f. [DOI] [PubMed] [Google Scholar]

- 7.Sinks T, Goodman MT, Kolonel LN, Anderson B. A case-control study of mesothelioma and employment in the Hawaii sugarcane industry. Epidemiology. 1994;5:466–8. doi: 10.1097/00001648-199407000-00015. [DOI] [PubMed] [Google Scholar]

- 8.Sinks T, Hartle R, Boeniger M, Mannino D, Boyd JE, Fernback J, et al. Exposure to biogenic silica fibers and respiratory health in Hawaii sugarcane workers. Occup Med. 1994;36:1329–34. doi: 10.1097/00043764-199412000-00014. [DOI] [PubMed] [Google Scholar]

- 9.Clementson CL, Hansen AC. Pilot study of manual sugarcane harvesting using biomechanical analysis. J Agric Saf Health. 2008;14:309–20. doi: 10.13031/2013.24565. [DOI] [PubMed] [Google Scholar]

- 10.Rossi-Rocha F, Palucci Marziale M, do Carmo Cruz Robazzi M. Poverty as a predisposing factor of illness tendencies in sugarcane workers. Rev Latino-Am. 2007;15:736–41. doi: 10.1590/s0104-11692007000700004. [DOI] [PubMed] [Google Scholar]

- 11.Loría R. La ruta crítica de las mujeres migrantes nicaragüenses: una mirada desde la zona norte fronteriza [From Nicaragua to Costa Rica to Nicaragua. The critical route for women migrants from Nicaragua: a look from the North Frontier Zone] San José, Costa Rica: Alforja; 2002. De Nicaragua a Costa Rica y a Nicaragua. [Google Scholar]

- 12.Vergüizas-Valverde M, van Wendel de Joode B, Rojas Garbanzo M. Metodologías participativas: prevención de riesgos laborales en la agroindustria de caña de azúcar [Participatory methods: prevention of occupational risks in the agricultural industry of sugarcane] Heredia, Costa Rica: SALTRA Technical Series on Work & Health 5; 2007. Available from: http://www.saltra.info/index.php?module=Pagesetter&func=viewpub&tid=11&pid=5 [cited 23 October 2009] [Google Scholar]

- 13.Chinchilla-Vargas E. Su perfil de riesgos y exigencias laborales en el cultivo e industrialización de la caña de azúcar [Study of work processes and operations. An outline of risk and work demands in the cultivation and industrialization of sugarcane] San José, Costa Rica: International Labor Organization (ILO); 1998. Estudio del proceso de trabajo y operaciones. Proyecto: promoción de la seguridad y salud del trabajo agrícola en América Central [Project: promotion of safety and health in agricultural work in Central America]; [Google Scholar]

- 14.García-Trabanino R, Aguilar R, Reyes S, Ortiz M, Leiva M. Nefropatía terminal en pacientes de un hospital de referencia en El Salvador [Terminal nephropathology in patients in a reference hospital in El Salvador] Revista Panamericana de Salud Pública [Pan Am J Pub Health] 2002;12:202–6. doi: 10.1590/s1020-49892002000900009. Available from: http://www.scielosp.org/pdf/rpsp/v12n3/12875.pdf [cited 23 October 2009] [DOI] [PubMed] [Google Scholar]

- 15.García-Trabanino R, Dominguez J, Jansa J, Oliver A. Proteinuria e insuficiencia renal crónica en la costa de El Salvador [Proteinuria and cronic kidney disease on the coast of El Salvador] Nefrología. 2005;25:31–8. Available from: http://www.revistanefrologia.com/mostrarfile.asp?ID=2144 [cited 23 October 2009] [PubMed] [Google Scholar]

- 16.Peraza S, Aragón-Benavides A, García-Trabanino R, Hogstedt C, Leiva R, Wesseling C. Prevalence of chronic kidney disease in five communities of El Salvador; Book of abstracts of the 20th international conference on epidemiology and occupational health and 10th international symposium on neurobehavioral methods and effects in occupational and environmental health; 8–13 June 2008; Heredia, Costa Rica; 2008. p. 164. [Google Scholar]

- 17.Flores-Reyna R, Jenkins Molieri J, Vega Manzano R, Chicas Labor A, Leiva Merino R, Calderón G, et al. Enfermedad renal terminal: Hallazgos preliminares de un reciente estudio en El Salvador [Terminal kidney disease: preliminary findings from a recent study in El Salvador] San Salvador, El Salvador: OPS-Ministerio de Salud de El Salvador; 2003. [Google Scholar]

- 18.Callejas-Callejas L, Alonso-Medrano C, Mendoza B. Insuficiencia renal crónica: Una prioridad en salud pública en zonas de la costa del pacífico de Nicaragua, Mayo-Septiembre 2003 [Cronic kidney insufficiency: a priority for public health in coastal zones of the Pacific region of Nicaragua, May–September 2003] Managua, Nicaragua: US Centers for Disease Control and Prevention (CDC)-Ministerio de Salud Nicaragua [Ministry of Health Nicaragua]. (MINSA-Nicaragua); 2003. [Google Scholar]

- 19.Cuadra S, Jakobsson K, Hogstedt C, Wesseling C. SALTRA Technical Series on Work & Health 2. Heredia, Costa Rica: 2006. Chronic kidney disease: assessment of current knowledge and feasibility for regional research collaboration in Central America. Available from: http://www.saltra.info/index.php?module=Pagesetter&func=viewpub&tid=11&pid=4 [cited 23 October 2009] [Google Scholar]

- 20.SICA. Impacts and adaptation to climate change and extreme events in Central America. San Jose, Costa Rica: University of Costa Rica Geophysical Research Center; 2006. Available from: http://www.cifor.cgiar.org/trofcca/america/docs/CC%20adaptation%20in%20Central%20America%20-%20AIACC%202006.pdf [cited 23 October 2009] [Google Scholar]

- 21.Fonseca P. Cambio climático producirá sequías e inundaciones aquí [Climate change will produce droughts and floods here] La Nación. 2007. Aug 14, Available from: http://www.nacion.com/ln_ee/2007/agosto/14/aldea1199145.html [cited 23 October 2009]

- 22.Moreno M, Alfaro E. Variabilidad climática y producción de caña de azúcar en Costa Rica [Climate variability and the production of sugarcane in Costa Rica] Ambientico. 2007;156:15–8. Available from: http://www.ambientico.una.ac.cr/165.pdf [cited 23 October 2009] [Google Scholar]

- 23.Charpantier F. Crisis alimentaria en Costa Rica y cómo salir de ella [The food crisis in Costa Rica and how to avoid it] Ambientico. 2008;176:10–11. Available from: http://www.ambientico.una.ac.cr/176.pdf [cited 23 October 2009] [Google Scholar]

- 24.San Jose, Costa Rica: Programa Estado de la Nación [Program The State of the Nation]; 2008. Estado de la nación en desarrollo humano sostenible [The state of the nation in sustainable human development] [Google Scholar]

- 25.Alonso-Medrano A, Perea W. Insuficiencia Renal Crónica (ERC) en trabajadores de caña de azúcar, Chinandega, Nicaragua: Febrero–Marzo 2002 [Cronic kidney insufficiency in sugarcane workers, Chinandega, Nicaragua: February–March 2002]: US Centers for Disease Control and Prevention (CDC)-Ministerio de Salud Nicaragua [Ministry of Health Nicaragua] (MINSA-Nicaragua); 2002. [Google Scholar]

- 26.INTECO. San Jose, Costa Rica: Instituto de Normas Técnicas de Costa Rica [Institute for Technical Norms in Costa Rica]; 2002. Higiene y seguridad ocupacional: Exposición a ambientes con sobrecarga térmica [Higiene and occupational health: exposure to environments with excess heat] [Google Scholar]

- 27.Retana JA, Solera M, Solano J, Alvarez H. Vol. 22. San José, Costa Rica: Boletín Meteorológico del Insituto Meteorológico Nacional; 1999. Efecto de la variabilidad climática sobre la fluctuación poblacional de la rata cañera (Sigmon hispidus) en Cañas, Guanacaste. [Effect of climate variability on the population fluctuation of cane rat (Sigmon hispidus) in Cañas, Guanacaste] pp. 1–11. Available from: http://www.imn.ac.cr/publicaciones/estudios/Variab_clima_ratasCR.pdf [cited 23 October 2009] [Google Scholar]

- 28.San Jose, Costa Rica: Ministerio de Trabajo y Seguridad Social [Ministry of Labor and Social Security]; Reglamento general de seguridiad e higiene del trabajo [General regulation of occupational safety and hygiene] [Google Scholar]

- 29.Ávila ML. La salud y el cambio climático [Health and climate change] La Nación. 1970. Available from: http://www.nacion.com/ln_ee/2008/octubre/28/opinion1753073.html [cited 28 October 2008]

- 30.UNDP. PNUD aprueba 450 millones para cambio climático en Costa Rica [UNDP approves 450 million for climate change in Costa Rica] San Jose, Costa Rica: UNDP; 2007. [Google Scholar]

- 31.UNDP. PNUD advierte que cambio climático ya golpea a habitantes de Costa Rica [UNDP announces that climate change has already affected inhabitants of Costa Rica. 2007. Available from: http://www.pnud.or.cr/index.php?option=com_content&view=article&id=242%3Apnud-advierte-que-cambio-climco-ya-golpea-a-habitantes-de-costa-rica&catid=46%3Adesarrollo-humano&Itemid=1 [cited 2 December 2008]

- 32.Boischio A, Sanchez A, Orosz Z, Charron D. Health and sustainable development: challenges and opportunities of ecosystem approaches in the prevention and control of dengue and Chagas disease. Cad Saude Publica. 2009;25:S149–54. doi: 10.1590/s0102-311x2009001300014. Available from: http://www.scielo.br/pdf/csp/v25s1/14.pdf [cited 23 October 2009] [DOI] [PubMed] [Google Scholar]