Abstract

Clostridium botulinum produces the most poisonous natural toxin known and is a perennial concern to the food industry and to regulatory agencies due to the potential threat of food-borne botulism. To ensure the botulinal safety of foods, rigorous food challenge testing to validate food-processing conditions and food formulations has been routinely performed. Detection of the botulinum neurotoxin is performed by using a mouse bioassay and/or in vitro assays. There has been considerable interest by the food industry and regulatory agencies in minimizing or even replacing the use of animals in these challenge studies. In addition, due to stringent select-agent regulations, the testing of various foods using toxigenic C. botulinum strains requires facilities and personnel that are certified for work with this organism. For this purpose we propose to generate sets of nontoxigenic C. botulinum strains from proteolytic and nonproteolytic groups that differ from the wild-type strains only by their inability to produce botulinum neurotoxin. In this initial study we describe the generation of a nontoxigenic mutant of C. botulinum strain 62A using the ClosTron mutagenesis system by inserting a group II intron into the botulinum neurotoxin type A gene (bont/A). The mutant clones were nontoxigenic as determined by Western blots and mouse bioassays but showed physiological characteristics, including growth properties and sporulation, that were similar to those of the parent strain in laboratory media. Additional studies will be required to evaluate comparable characteristics in various food matrices. The availability of suitable nontoxigenic C. botulinum strains for food challenge studies will be beneficial for enhancing the botulinal safety of foods as well as increasing the biosafety of workers and may eliminate the use of laboratory animals.

Clostridium botulinum is a Gram-positive, spore-forming, anaerobic bacterium that causes the severe neuroparalytic illness in humans and animals known as botulism (33). While food-borne botulism is a rare disease, the consequences are often significant, resulting in fatalities or lengthy hospital treatment with assisted respiration, often with high financial impact (18). A large-scale botulism outbreak would be devastating, requiring significant medical and financial resources for its control (1).

C. botulinum causes food-borne botulism through the production of botulinum neurotoxin (BoNT), the most poisonous natural substance known (29), in foods. There are seven serologically distinct types of botulinum neurotoxin, designated types A to G. BoNTs are synthesized as inactive ∼150-kDa single-chain polypeptides that are activated by proteolytic cleavage to form a disulfide-linked double-chain molecule composed of a 50-kDa light chain (LC) and a 100-kDa heavy chain (HC) (9). BoNTs are produced as progenitor toxin complexes in which the neurotoxin is associated with nontoxic protein and RNA components (27, 29). Due to the extreme potency of BoNTs and their potential use as a bioterrorism agent, the Centers for Disease Control and Prevention (CDC) have listed BoNTs as category A select agents (5). The study of C. botulinum and its neurotoxins requires specialized facilities and safety measures, and research on this pathogen and its neurotoxins cannot be performed in most microbiology laboratories.

The species C. botulinum is separated into four physiological groups (groups I to IV) based on their metabolic and physiological properties (13). Group I includes proteolytic strains of types A, B, and F, while group II includes primarily nonproteolytic strains of types B, E, and F. C. botulinum serotypes A, B, and E are responsible for the majority of human botulism cases worldwide (9). C. botulinum is widely distributed in soils and in sediments of oceans and lakes. Therefore, foods may be contaminated with spores from many possible sources. Due to the increased consumer demand for ready-to-eat foods containing natural ingredients and with the absence of preservatives, the safety and quality of these products rely on mild processing conditions and refrigerated storage (11, 25). Such conditions, especially temperature abuse, can significantly compromise the botulinal safety of foods. Several outbreaks of botulism have occurred due to changes in processing procedures and formulations (12, 18, 25, 32).

To ensure the botulinal safety of foods, rigorous microbiological challenge testing has been routinely performed (10, 11). Microbiological challenge testing is frequently conducted by inoculating foods with a mixture of proteolytic or nonproteolytic C. botulinum strains and incubating these inoculated foods at different temperatures (10, 11). Sample extracts are then prepared and used for the detection of botulinum neurotoxin by a mouse lethality bioassay and/or in vitro assays (10, 31, 34). The presence of botulinum neurotoxin in the samples will indicate the ability of the food products to support the growth of C. botulinum. These tests also play an important role in the validation of processing methods that are intended to kill or attenuate a target organism or group of target organisms in foods (14). Due to stringent CDC/FDA regulations, the testing of various foods using toxigenic C. botulinum strains requires facilities and highly trained personnel that are certified for work with this organism (5). For some applications, surrogate microorganisms have been used in food challenge studies in place of specific pathogens (3). Since the introduction of pathogenic microorganisms into a food-processing facility is hazardous, the use of appropriate surrogates of target pathogens is necessary for the testing of certain food-processing methods that cannot be replicated in the laboratory. Many surrogates are closely related to but not necessarily the same species as the target pathogen. Genetically and phenotypically, Clostridium sporogenes, often used as a surrogate for type A C. botulinum (4, 19), is very similar to type A C. botulinum, but these two species differ in certain properties such as spore heat resistance (35). An ideal surrogate would comprise a genetically stable strain of the target pathogen that retains all other characteristics except virulence or toxicity. This report describes the construction of a nontoxigenic C. botulinum type A strain by specifically inactivating only the botulinum neurotoxin gene. C. botulinum strain 62A, a primary strain in certain standard food challenge spore mixtures (10), was used for the generation of the mutant. The physiological characteristics, including growth and sporulation properties, of the nontoxigenic mutant strain were compared to those of the wild-type strain and were shown to be indistinguishable.

MATERIALS AND METHODS

Bacterial strains and growth conditions.

C. botulinum strain 62A was obtained from the bacterial culture collection of the Food Research Institute (FRI) at the University of Wisconsin—Madison. This C. botulinum strain has been used for decades for food challenge studies at the FRI. C. botulinum cultures were grown in TYG medium (26) for the isolation of mutants and in TPGY medium (2) for strain characterizations. Escherichia coli strain DH10B (Invitrogen, Carlsbad, CA) was used for the cloning and maintenance of the retargeted ClosTron vector (15, 16). Antibiotics were used at the following concentrations: cycloserine at 250 μg/ml, thiamphenicol at 15 μg/ml, and erythromycin at 2.5 μg/ml for C. botulinum and chloramphenicol at 25 μg/ml in agar plates and 12.5 μg/ml in broth for E. coli. All bacterial medium components and chemicals were purchased from Becton Dickinson Microbiology Systems, Sparks, MD, and Sigma-Aldrich, St. Louis, MO. The reducing agent l-cysteine or thioglycolate was added to all bacterial media at a final concentration of 0.1%; 2 μg/ml resazurin was added to solid media and to TPGY tubes (for growth experiments) as an indicator of anaerobic conditions. Broth in culture tubes was flushed with nitrogen prior to sterilization, and broth in flasks and agar plates was prereduced by overnight incubation in an anaerobic chamber (1025/1029; Thermo Scientific, Marietta, OH). Clostridial cultures were continually maintained under anaerobic conditions, and all bacterial manipulations were performed in an anaerobic chamber (initial gas mixture comprised of 80% N2, 10% CO2, and 10% H2).

For initial comparative growth studies, wild-type C. botulinum strain 62A and mutant clones (see description below) were inoculated into the TPGY tubes and incubated at 27°C and 37°C in water baths to ensure a constant temperature during the experiment. For inocula, C. botulinum cultures were started from frozen stocks and grown overnight at 37°C to the late log phase (A600 of ∼1.1 to 1.2), and the optical density was adjusted to an A600 of 1.0 with fresh broth (∼1 × 108 CFU/ml). One hundred microliters (∼106 cells) of each strain was inoculated into 10 ml of TPGY broth in anaerobic Bellco culture tubes sealed with butyl rubber septum stoppers and caps (Bellco Glass, Inc., Vineland, NJ), and triplicate samples of each strain were analyzed. The optical density of the cultures was measured every hour for the first 24 h and then every 12 h until 72 h. Cultures were mixed very gently by inverting the tubes once prior to each measurement in order to minimize growth disturbances due to the movement of the culture tubes.

For obtaining plate and spore counts, wild-type strain 62A and one mutant clone, 62A/tox−, were grown in the batch culture (in duplicate) inside an anaerobic chamber at 27°C. Late-log-phase cultures grown overnight were adjusted to an A600 of 1.0 and used for the inoculation of 500 ml of TPGY medium in culture flasks; the initial count of the cells in the cultures was ∼103 cells/ml. Aliquots were removed at 1-h intervals for the first 24 h of growth and then at 36, 48, 72, 96, 120, 144, and 168 h, and serial dilutions of the cultures were spread plated at the start of the experiment (0 h), every 2 to 3 h until 24 h, and then at 36, 48, 72, 96, 120, 144, and 168 h to obtain viable plate counts. The optical density of the cultures was measured at all the indicated time points, and strains were analyzed microscopically for the presence and the appearance of endospores. At 24 h and at all following time points, additional 10-ml culture aliquots were removed, and the tubes were heat shocked for 20 min at 80°C to inactivate vegetative cells and then immediately cooled in an ice-water bath. Serial dilutions were spread plated to obtain spore counts. The experiment was repeated three times.

Construction of the retargeted intron vector for the inactivation of the botulinum neurotoxin gene.

Target sites in the botulinum neurotoxin gene were identified, and intron-retargeting PCR primers were designed by using a computer algorithm at the Targetron Design site provided by Sigma-Aldrich, St. Louis, MO. Reagents provided in the Targetron gene knockout system kit were used to construct the retargeted intron according to the manufacturer's instructions. Primers IBS-580|581s, EBS1d-580|581s, EBS2-580|581s, and EBS Universal (Table 1) were purchased from Sigma-Aldrich (St. Louis, MO) and used for one-tube SOEing (splicing by overlap extension) PCR to assemble and amplify a 353-bp intron fragment for targeting the BoNT gene at nucleotide position 580 on the sense strand. The resulting PCR product was purified and cloned into vector pMTL007C-E2 (15) using restriction endonucleases HindIII and BsrGI by standard cloning techniques (28). Transformants were selected from E. coli strain DH10B based on chloramphenicol resistance, and plasmid DNA was isolated by using a plasmid minipreparation kit (Fermentas Inc., Glen Burnie, MD). Plasmids were analyzed by restriction analysis with HindIII and BsrGI, and the correct sequence of the intron was verified by sequencing using primer pMTL007-R1 (Table 1). Sequencing reactions were performed by using an ABI Prism BigDye Cycle Sequencing Ready Reaction kit (Applied Biosystems, Foster City, CA), and the reaction mixtures were then purified according to the manufacturer's instructions and analyzed at the University of Wisconsin Biotechnology Center. The nucleotide sequences were aligned and analyzed with Vector NTI sequence analysis software (Invitrogen, Carlsbad, CA). Plasmid DNA from one of the clones containing the correct intron sequence for targeting the BoNT gene was named pMTL007C-E2:Cbo:bont-580s and was transformed into E. coli conjugation donor strain CA434.

TABLE 1.

Oligonucleotide primers used in the study

| Oligonucleotide function and primer name | Sequence (5′-3′) |

|---|---|

| Intron retargeting | |

| IBS-580|581s | AAAAAAGCTTATAATTATCCTTACAGATCTTACATGTGCGCCCAGATAGGGTG |

| EBS1d-580|581s | CAGATTGTACAAATGTGGTGATAACAGATAAGTCTTACATTTTAACTTACCTTTCTTTGT |

| EBS2-580|581s | TGAACGCAAGTTTCTAATTTCGGTTATCTGTCGATAGAGGAAAGTGTCT |

| EBS Universal | CGAAATTAGAAACTTGCGTTCAGTAAAC |

| Intron sequencing | |

| pMTL007-R1 | AGGGTATCCCCAGTTAGTGTTAAGTCTTGG |

| Screening of clones and generation of hybridization probes | |

| LC/F | ATGCCATTTGTTAATAAACAATTTAATTATAAAGATCCTG |

| LC/R | CCTTTATCTAATGATTTAGTTTTAGAAGTTATTATCCCTC |

| Erm-F | CCGATACCGTTTACGAAATTGGAACAGG |

| Erm-R | TTATTTCCTCCCGTTAAATAATAGATAACT |

Isolation and PCR screening of the mutant clones.

Plasmid pMTL007C-E2:Cbo:bont-580s was transferred into C. botulinum strain 62A by conjugation from E. coli donor strain CA434 as described previously (16). After mating, the cell mixture was removed from the mating plates, diluted, and plated onto fresh medium supplemented with cycloserine (selection for C. botulinum) and thiamphenicol (selection for the vector). Thiamphenicol-resistant colonies were restreaked onto fresh plates to ensure their purity and then plated onto medium supplemented with erythromycin to select for clones that had undergone the integration event that activated the erythromycin gene. Single colonies of integrants were then replica plated onto erythromycin and thiamphenicol plates to screen for plasmid loss by the thiamphenicol-sensitive phenotype. Eight randomly selected erythromycin-resistant and thiamphenicol-sensitive clones were selected for further analysis. Chromosomal DNA from wild-type C. botulinum and the eight randomly selected Ermr/This mutant clones was isolated by using a ChargeSwitch gDNA kit (Invitrogen, Carlsbad, CA) according to the manufacturer's instructions. The initial screening of the mutants was performed by PCR using primers LC/F and LC/R (Table 1), designed to amplify a ∼1.3-kb DNA fragment encoding the light-chain region of the BoNT gene in the wild-type strain or a 3.1-kb fragment in the mutant clones containing the intron inserted into the BoNT gene. PCR was performed with AmpliTaq High Fidelity DNA polymerase, buffer, and deoxynucleoside triphosphates (dNTPs) (Applied Biosystems, Foster City, CA) by using a GeneAmp 9700 PCR system (Applied Biosystems) according to the manufacturer's instructions. PCR primers were purchased from Integrated DNA Technologies, Inc. (Coralville, IA). Amplicons were separated on 1% Tris-acetate-EDTA gels (pH 8.0), stained with ethidium bromide, and photographed by using a gel imaging system (Bio-Rad, Hercules, CA) with UV transillumination.

PFGE and Southern hybridizations.

Pulsed-field gel electrophoresis (PFGE) samples from wild-type and mutant strains of C. botulinum strain 62A were prepared as described previously (21). Digests of the samples were performed with restriction endonuclease SmaI, and the samples were separated by using a clamped homogenous electric field system (CHEF-DRII; Bio-Rad, Hercules, CA) at 200 V for 25 h with a pulse time of 1 to 20 s at 14°C. Hybridization probes specific to the intron (erm) and the botulinum neurotoxin gene (bont) were amplified by PCR. Forward primer Erm-F and reverse primer Erm-R (Table 1) were used for PCR amplification to generate a 650-bp DNA probe for erm. Primers LC/F and LC/R (Table 1) were used to amplify a 1.3-kb DNA probe for the light chain of the botulinum neurotoxin gene. The erm and bont probes were purified from agarose gels by using a Qiagen extraction kit (Qiagen, Valencia, CA) and radioactively labeled with 32P using the Megaprime DNA labeling system according to manufacturer's instructions (GE Healthcare Bio-Sciences, Piscataway, NJ). The chromosomal DNA samples separated by PFGE were transferred onto a positively charged nylon membrane (Immobilon-NY+; Millipore, Bedford, MA) overnight by downward capillary transfer in 0.4 M NaOH-1.5 M NaCl. The membrane was neutralized in 2 M Tris-HCl (pH 7.0) for 10 min, rinsed with 2× SSC (1× SSC is 0.15 M NaCl plus 0.015 M sodium citrate), and fixed at 80°C for 30 min under a vacuum. Hybridization was performed at 42°C for 16 h in a solution containing 5× Denhardt solution, 6× SSC, 50% formamide, 1% SDS, 100 μg/ml herring sperm DNA (Promega, Madison, WI), and 2 × 106 cpm/ml 32P-labeled probe. All hybridization solutions and buffers were prepared according to standard protocols (28). After hybridization was complete, the membrane was washed twice for 5 min each at room temperature with 2× SSC-0.1% SDS and twice for 30 min each with 0.1× SSC-0.1% SDS at 42°C. Autoradiography of the membrane was performed for 12 to 24 h at −70°C by using a Kodak BioMax MS film with a BioMax intensifying screen (Eastman Kodak, Rochester, NY).

Western blot analysis.

Wild-type strain 62A and four BoNT mutant clones were grown anaerobically for 96 h in TPGY broth. Protein samples from the cultures were prepared by trichloroacetic acid (TCA) precipitation as described previously (2). Protein samples were reduced by the addition of dithiothreitol (DTT) to a final concentration of 10 mM. Equal quantities of the reduced protein samples were separated by SDS-PAGE using 4 to 12% Bis-Tris NuPage Novex gels in MOPS (morpholinepropanesulfonic acid) running buffer (Invitrogen, Carlsbad, CA). Reduced and nonreduced samples of purified serotype A botulinum neurotoxin were used as controls. Two parallel gels were prepared: one was stained with Coomassie blue, and the other was transferred onto a polyvinylidene difluoride (PVDF) membrane (Millipore Corp., Bedford, MA) by semidry transfer according to standard procedures (28). The membrane was incubated with polyclonal affinity-purified rabbit IgG specific for the serotype A botulinum neurotoxin prepared in our laboratory. The botulinum neurotoxin was detected by using the anti-rabbit chemiluminescent Western Breeze kit (Invitrogen, Carlsbad, CA) according to the manufacturer's instructions.

Mouse bioassay.

A mouse bioassay was used to detect the presence of active botulinum neurotoxin in C. botulinum cultures (34). The 96-hour cultures were centrifuged at 12,000 × g for 10 min to remove cellular debris, and 0.5-ml aliquots of the clarified culture supernatants from the wild type and the mutant strains were administered by intraperitoneal (i.p.) injection into two mice per sample. Following injection, animals were observed for signs of botulism, and the time to death was recorded. Minutes to death were then converted to i.p. 50% lethal doses (LD50)/ml of sample by using standard curves previously prepared by our laboratory (24).

RESULTS

C. botulinum serotype A strain 62A, a primary strain in the standard botulinum spore food challenge cocktail (10), was chosen for mutant construction. The insertional inactivation of the botulinum neurotoxin gene was achieved by using the ClosTron mutagenesis system, which is based on a mobile group II intron (15, 16). Potential intron target sites in the botulinum neurotoxin gene were identified by using a specific computer program provided as a part of the Targetron gene knockout system kit. The Targetron algorithm identifies potential insertion sites and rates each site with an E value. Lower E values correspond to a higher predicted intron insertion efficiency; the sites with an E value of <0.5 are predicted to be efficient introns. It is desirable to insert the intron closer to the N terminus of the toxin gene in order to prevent the synthesis of any neurotoxin subfragments. A target site between nucleotides 580 and 581 on a sense strand with an E value of 0.328 was closest to the 5′ end of the gene and had the lowest E value and was thus chosen for the generation of the targeting intron. The intron fragment was amplified by PCR as described in Materials and Methods and inserted into ClosTron vector pMTL007C-E2 between restriction sites HindIII and BsrGI (15), yielding a construct, pMTL007C-E2:Cbo:bont-580s. The intron construct was then transferred into C. botulinum strain 62A by conjugation from E. coli donor strain CA434. Following mating, the cells were plated onto agar supplemented with thiamphenicol to select for C. botulinum clones carrying the intron plasmid. After the plasmid was established in C. botulinum and the intron was expressed under the control of a constitutive C. sporogenes fdx promoter, the transconjugants were plated onto agar supplemented with erythromycin to select for intron integrants. Erythromycin-resistant colonies were then screened for plasmid loss by a thiamphenicol-sensitive phenotype. Plasmid loss from the cells is easily achieved due to the pCB102 replicon, which is only moderately stable in C. botulinum (17).

Several hundred erythromycin-resistant and thiamphenicol-sensitive colonies were obtained, indicating that integrants arose from this intron very efficiently. Eight randomly selected integrants were chosen for PCR analysis to determine if the intron had been inserted into the correct position in the botulinum neurotoxin gene. PCR primers were designed upstream and downstream of the insertion site to amplify the region containing the insertion element (Fig. 1A and B). Four of the eight mutant clones (clones 2, 3, 5, and 6) (Fig. 1C) analyzed produced ∼3.1-kb PCR fragments, as expected if the intron has been inserted into the target position. The other clones (clones 1, 4, 7, and 8) revealed a fragment that was the same size as that of the wild-type strain (1.3 kb), indicating that the intron was not inserted into the toxin gene but elsewhere on the genome. Thus, 50% of the integration events contained the desired mutants. The four toxin mutant clones were further analyzed by Southern hybridizations, Western blot analyses, and mouse bioassays to confirm the nontoxigenic phenotype and a single integration event in the BoNT gene.

FIG. 1.

Mutant screening by PCR. (A and B) Schematic presentation of wild-type (A) and mutated (B) botulinum neurotoxin genes. The ClosTron insertion site is shown with a vertical arrow and an asterisk. The locations of PCR primers F (LC/F) and R (LC/R) are shown with horizontal arrows on either side of the ClosTron insertion site, and the sizes of the PCR products are indicated. (C) PCR products of eight putative mutant clones (lanes 1 to 8) and wild-type strain 62A (lane 9). M, 1-kb Plus ladder (Invitrogen); WT, wild type.

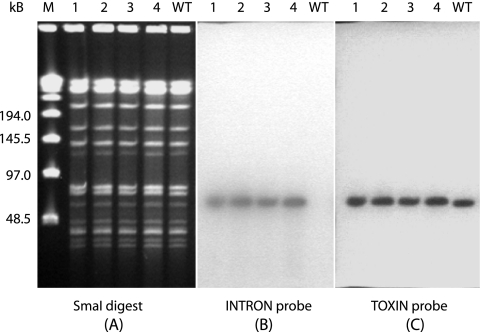

PFGE samples were prepared from the four mutant clones and the wild-type strain. The chromosomal DNA samples were digested with the restriction endonuclease SmaI, which does not cleave the insertion element. No differences in the restriction banding patterns between the mutant and the wild-type strains were observed (Fig. 2A). The DNA fragments from the PFGE gel were transferred onto a nylon membrane for Southern hybridization analysis using an intron-specific erm probe. All four mutant clones hybridized with only one DNA band and to the same-sized fragment (Fig. 2B). As expected, no hybridization signals were observed with the wild-type strain. The membrane was stripped and rehybridized with the probe specific to the neurotoxin gene. Only one DNA fragment in all strains hybridized with the toxin probe. The same DNA band also hybridized with the intron probe in all four mutants (Fig. 2C). These results confirm the insertion of a single copy of the intron into the botulinum neurotoxin gene in the mutant strains.

FIG. 2.

Pulsed-field gel electrophoresis (PFGE) and Southern hybridization analyses of the toxin mutant clones and wild-type C. botulinum strain 62A. (A) PFGE of SmaI-digested chromosomal DNA. (B) Southern hybridization with the intron probe (ermB). (C) Southern hybridization with the botulinum neurotoxin gene probe. Lanes 1 to 4, SmaI digests of four individual mutant clones; WT, SmaI digest of wild-type strain 62A; M, lambda ladder, PFGE marker (New England Biolabs).

In order to confirm that the mutants do not produce BoNT, the selected mutant clones were analyzed by Western blots using polyclonal antibodies specific to a serotype A botulinum neurotoxin. As shown in Fig. 3, no protein bands in the samples prepared from the mutant clones reacted with the neurotoxin antibodies. Three prominent protein bands, 150 kDa, 100 kDa, and 50 kDa, were observed in the wild-type strain and in the control lanes with a reduced and nonreduced purified botulinum neurotoxin standard, representing the single-chain holotoxin and the heavy chain and the light chain of the neurotoxin, respectively. These findings confirm that the C. botulinum toxin mutant clones no longer produced botulinum neurotoxin or subfragments of the toxin.

FIG. 3.

Western analysis of neurotoxin expression in C. botulinum wild-type strain 62A and toxin mutant clones. (A) Coomassie-stained SDS-PAGE gel. (B) Western blotting using antibodies raised against serotype A botulinum neurotoxin. Lanes 1 to 4, four individual mutant clones; WT, wild-type strain 62A. M, protein size marker (Invitrogen). Purified botulinum neurotoxin was used as a standard (BoNT reduced and BoNT nonreduced). Abbreviations: BoNT/SC, single-chain botulinum neurotoxin; BoNT/LC, botulinum neurotoxin light chain; BoNT/HC, botulinum neurotoxin heavy chain.

Additionally, a mouse bioassay was performed to further validate the nontoxigenic phenotype of the mutants. Clarified culture supernatants (0.5 ml) of the wild-type strain and mutant clones were injected into mice. Mice injected with sample from the wild-type strain died within 90 min, which corresponds to ∼0.5 × 105 LD50/ml of botulinum neurotoxin (24). Mice injected with culture supernatants from the mutant strains did not show any symptoms of botulism during 4 days of observation. The results of the Western blot analysis and the mouse bioassay confirm that the mutant strains no longer produce botulinum neurotoxin.

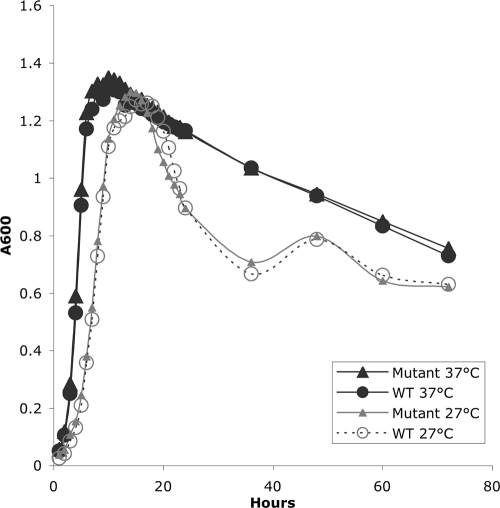

In order to assess the physiological properties of the mutants compared to the wild-type strain, growth characteristics and sporulation properties of the botulinum toxin mutant clones were compared to those of the wild-type strain. The wild-type and mutant strains showed very similar growth patterns at both 37°C and 27°C (Fig. 4). For confirmatory characterization and comparison of the growth and sporulation properties of the toxin mutant and the wild-type strains, one mutant strain was selected for further studies along with a wild-type strain. Three experiments were performed by using duplicate samples of each strain, and similar results were obtained. The wild type and the toxin mutant strain exhibited nearly identical growth patterns and sporulation characteristics (Fig. 5). The formation of the endospores started after 48 h of incubation at 27°C, reaching 50% sporulation after 120 h. Both the wild-type and nontoxigenic mutant strains showed similar spore yields.

FIG. 4.

Growth curves of C. botulinum wild-type strain 62A and nontoxigenic mutant strain 62A/tox− at 37°C and 27°C. The optical density at 600 nm (OD600) of the cultures was measured during 72 h of growth at the indicated time points.

FIG. 5.

Comparison of growth and sporulation properties of C. botulinum wild-type strain 62A and nontoxigenic mutant strain 62A/tox−. The cultures were grown anaerobically in TPGY medium at 27°C. Total plate and spore counts (log CFU/ml) for both strains were determined at the indicated time points.

DISCUSSION

The goal of this study was to generate a nontoxigenic C. botulinum strain, 62A/tox−, and demonstrate that it is phenotypically identical to the wild-type strain and thus can be used in food challenge studies instead of its toxigenic counterpart. We describe the construction of C. botulinum type A mutant strains by inactivating the botulinum neurotoxin gene, followed by genetic analysis of the mutants to confirm the nature of the neurotoxin gene interruption and a nontoxigenic phenotype. Experiments were also performed to determine if the mutant strain retains the same growth and sporulation properties as the wild-type strain.

The ability to obtain directed gene knockout mutants in C. botulinum using classical recombination methods has been hindered due to a lack of effective genetic tools for host-mediated recombination mutagenesis in this species. In this study we used an alternative approach, a recombination-independent strategy based on a mobile group II intron from the ltrB gene of Lactococcus lactis that does not require host factors (22, 23). This methodology has been recently adapted by several laboratories for gene inactivation in Clostridium perfringens (6-8), C. acetobutylicum (16, 30), C. difficile, C. sporogenes, and C. botulinum (15, 16, 17). We used the ClosTron mutagenesis system to insertionally inactivate the botulinum neurotoxin gene in C. botulinum type A strain 62A. This system permits positive selection for the integrational events of the element, in contrast to the other Clostridium intron vectors used to date (15, 16). The ClosTron group II intron contains an antibiotic resistance gene (ermB), which itself is interrupted by a self-splicing group I intron. The antibiotic resistance system, referred to as the retrotransposition-activated marker (RAM) (36), is strictly coupled to integration and therefore can be used to positively select for integrational events. The procedure has proven to be highly efficient and reproducible for several Clostridium species: following the loss of the intron vector and the LtrA enzyme, the mutants are very stable (15, 16).

In this study we have constructed and isolated nontoxigenic C. botulinum mutants using the ClosTron system. DNA sequencing data and PFGE/Southern hybridization results confirmed that the mutant strains were genetically identical to the toxigenic parent except for the disruption of the neurotoxin gene. These mutants were demonstrated to be nontoxigenic by mouse bioassays and also to not produce neurotoxin protein by Western blotting. The strains were examined for key physiological properties including growth patterns at 27°C and 37°C and sporulation in laboratory media, and these phenotypic characteristics were indistinguishable from those of the parent.

The genes encoding C. botulinum neurotoxin and its associated nontoxic components are organized into toxin gene clusters (20). The neurotoxin and nontoxic nonhemagglutinin (NTNH) genes are expressed from a bicistronic mRNA, and hemagglutinin (HA) genes are expressed from a tricistronic mRNA (2). Our initial analyses have demonstrated that the NTNH and hemagglutinin genes are expressed in the mutant. Thus, the growth of the nontoxigenic 62A mutant strain in foods could be assessed by measuring NTNH or HA production by enzyme-linked immunosorbent assay (ELISA) or other methods. Further experiments will be performed to compare NTNH and HA production in wild-type and mutant strains and to determine whether the sensitivity and accuracy of detection of NTNH and HA in the mutant strain are equivalent to neurotoxin formation in the wild-type strain. Furthermore, the presence of mutant C. botulinum strains in food challenge studies can also be determined by selective plating onto growth medium supplemented with erythromycin encoded by the intron. The ClosTron technology also permits the introduction of other selective markers in place of erythromycin for the selective detection of C. botulinum (15).

The strategy employed in this study for obtaining isogenic surrogates that contain a disruption of the neurotoxin gene should have useful applications in assessing the botulinal safety of food processing and formulation changes. The use of surrogate clostridial strains has the potential to reduce the cost and labor involved in food sample testing by eliminating the use of mice and enhancing the safety of personnel performing the testing. In this initial study, the ClosTron system was used for the construction of a C. botulinum type A strain with its toxin gene disrupted. In future studies, as technology becomes available, mutant strains of C. botulinum with toxin genes entirely deleted will be constructed, which will eliminate any possibility, however small, of reversion to the toxigenic state. The strategy of molecular techniques applied for the inactivation of virulence genes in the genome of this pathogen could also be valuable for constructing mutants of other serotypes and subtypes of C. botulinum and other pathogenic clostridia to generate strains with desired phenotypes.

Acknowledgments

This work was sponsored by the Food Research Institute of the University of Wisconsin—Madison and by the NIH/NIAID Regional Center of Excellence for Biodefense and Emerging Infectious Diseases Research (RCE) Program. We acknowledge membership within and support from the Region V Great Lakes RCE (NIH award 1-54-AI-057153).

We thank Kathy Glass, Sabine Pellett, and Ann Larson for help with strain growth and sporulation experiments, helpful discussions, and critical reading of the manuscript.

Footnotes

Published ahead of print on 20 November 2009.

REFERENCES

- 1.Arnon, S. S., R. Schechter, T. V. Inglesby, D. A. Henderson, J. G. Bartlett, M. S. Ascher, E. Eitzen, A. D. Fine, J. Hauer, M. Layton, S. Lillibridge, M. T. Osterholm, T. O'Toole, G. Parker, T. M. Perl, P. K. Russell, D. L. Swerdlow, K. Tonat, and the Working Group on Civilian Biodefense. 2001. Botulinum toxin as a biological weapon—medical and public health management. JAMA 285:1059-1070. [DOI] [PubMed] [Google Scholar]

- 2.Bradshaw, M., S. S. Dineen, N. D. Maks, and E. A. Johnson. 2004. Regulation of neurotoxin complex expression in Clostridium botulinum strains 62A, Hall A-hyper, and NCTC 2916. Anaerobe 10:321-333. [DOI] [PubMed] [Google Scholar]

- 3.Busta, F. F., T. V. Suslow, M. E. Parish, L. R. Beuchat, J. N. Farber, E. H. Garrett, and L. J. Harris. 2003. The use of indicators and surrogate microorganisms for the evaluation of pathogens in fresh and fresh-cut produce. Compr. Rev. Food Sci. Food Saf. 2:179-185. [Google Scholar]

- 4.Carter, A. T., C. J. Paul, D. R. Mason, S. M. Twine, M. J. Alston, S. M. Logan, J. W. Austin, and M. W. Peck. 2009. Independent evolution of neurotoxin and flagellar genetic loci in proteolytic Clostridium botulinum. BMC Genomics 10:115. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Centers for Disease Control and Prevention. 2008. Select agent regulations. Centers for Disease Control and Prevention, Atlanta, GA. http://www.selectagents.gov.

- 6.Chen, Y., L. Caruso, B. McClane, D. Fisher, and P. Gupta. 2007. Disruption of a toxin gene by introduction of a foreign gene into the chromosome of Clostridium perfringens using Targetron-induced mutagenesis. Plasmid 58:182-189. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Chen, Y., B. A. McClane, D. J. Fisher, J. I. Rood, and P. Gupta. 2005. Construction of an alpha toxin gene knockout mutant of Clostridium perfringens type A by use of a mobile group II intron. Appl. Environ. Microbiol. 71:7542-7547. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Cheung, J. K., M. M. Awad, S. McGowan, and J. I. Rood. 2009. Functional analysis of the VirSR phosphorelay from Clostridium perfringens. PLoS One 4:e5849. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Dasgupta, B. R. 1989. The structure of botulinum neurotoxin, p. 53-67. In L. L. Simpson (ed.), Botulinum neurotoxin and tetanus neurotoxin. Academic Press, San Diego, CA.

- 10.Doyle, M. P. 1991. Evaluating the potential risk from extended-shelf-life refrigerated foods by Clostridium botulinum inoculation studies. Food Technol. 45:154-156. [Google Scholar]

- 11.Glass, K. A., and E. A. Johnson. 2004. Antibotulinal activity of process cheese ingredients. J. Food Prot. 67:1765-1769. [DOI] [PubMed] [Google Scholar]

- 12.Glass, K. A., and E. A. Johnson. 2002. Formulating low-acid foods for botulinal safety, p. 323-350. In V. K. Juneja and J. N. Sofos (ed.), Control of foodborne microorganisms. Marcel Dekker, New York, NY.

- 13.Hatheway, C. L. 1993. Clostridium botulinum and other clostridia that produce botulinum neurotoxin, p. 3-20. In H. W. Hauschild and K. L. Dodds (ed.), Clostridium botulinum: ecology and control in foods. Marcel Dekker, New York, NY.

- 14.Hauschild, H. W., and K. L. Dodds (ed.). 1993. Clostridium botulinum: ecology and control in foods. Marcel Dekker, New York, NY.

- 15.Heap, J. T., S. A. Kuehne, M. Ehsaan, S. T. Cartman, C. M. Cooksley, J. C. Scott, and N. P. Minton. 2009. The ClosTron: mutagenesis in Clostridium refined and streamlined. J. Microbiol. Methods. [Epub ahead of print.] doi: 10.1016/j.mimet.2009.10.018. [DOI] [PubMed]

- 16.Heap, J. T., O. J. Pennington, S. T. Cartman, G. P. Carter, and N. P. Minton. 2007. The ClosTron: a universal gene knock-out system for the genus Clostridium. J. Microbiol. Methods 70:452-464. [DOI] [PubMed] [Google Scholar]

- 17.Heap, J. T., O. J. Pennington, S. T. Cartman, and N. P. Minton. 2009. A modular system for Clostridium shuttle plasmids. J. Microbiol. Methods 78:79-85. [DOI] [PubMed] [Google Scholar]

- 18.Johnson, E. A. 2007. Clostridium botulinum, p. 401-421. In M. P. Doyle and L. R. Beuchat (ed.), Food microbiology: fundamentals and frontiers, 3rd ed. ASM Press, Washington, DC.

- 19.Johnson, E. A. 2005. Clostridium botulinum and Clostridium tetani, p. 1035-1088. In S. P. Borriello, P. R. Murray, and G. Funke (ed.), Topley and Wilson's microbiology and microbial infections, 8th ed. Hodder Arnold, London, United Kingdom.

- 20.Johnson, E. A., and M. Bradshaw. 2001. Clostridium botulinum and its neurotoxins: a metabolic and cellular perspective. Toxicon 39:1703-1722. [DOI] [PubMed] [Google Scholar]

- 21.Johnson, E. A., W. H. Tepp, M. Bradshaw, R. J. Gilbert, P. E. Cook, and E. D. McIntosh. 2005. Characterization of Clostridium botulinum strains associated with an infant botulism case in the United Kingdom. J. Clin. Microbiol. 43:2602-2607. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Karberg, M., H. Guo, J. Zhong, R. Coon, J. Perutka, and A. M. Lambowitz. 2001. Group II introns as controllable gene targeting vectors for genetic manipulation of bacteria. Nat. Biotechnol. 19:1162-1167. [DOI] [PubMed] [Google Scholar]

- 23.Lambowitz, A. M., and S. Zimmerly. 2004. Mobile group II introns. Annu. Rev. Genet. 38:1-35. [DOI] [PubMed] [Google Scholar]

- 24.Malizio, C. J., M. C. Goodnough, and E. A. Johnson. 2000. Purification of Clostridium botulinum type A neurotoxin. Methods Mol. Biol. 145:27-39. [DOI] [PubMed] [Google Scholar]

- 25.Peck, M. W., K. E. Goodburn, R. P. Betts, and S. C. Stringer. 2008. Assessment of the potential for growth and neurotoxin formation by non-proteolytic Clostridium botulinum in short shelf-life commercial foods designed to be stored chilled. Trends Food Sci. Technol. 19:207-216. [Google Scholar]

- 26.Purdy, D., T. A. O'Keeffe, M. Elmore, M. Herbert, A. McLeod, M. Bokori-Brown, A. Ostrowski, and N. P. Minton. 2002. Conjugative transfer of clostridial shuttle vectors from Escherichia coli to Clostridium difficile through circumvention of the restriction barrier. Mol. Microbiol. 46:439-452. [DOI] [PubMed] [Google Scholar]

- 27.Sakaguchi, G. 1982. Clostridium botulinum toxins. Pharmacol. Ther. 19:165-194. [DOI] [PubMed] [Google Scholar]

- 28.Sambrook, J., and D. W. Russell. 2001. Molecular cloning: a laboratory manual, 3rd ed. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY.

- 29.Schantz, E. J., and E. A. Johnson. 1992. Properties and use of botulinum toxin and other microbial neurotoxins in medicine. Microbiol. Rev. 56:80-99. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Shao, L., S. Hu, Y. Yang, Y. Gu, J. Chen, W. Jiang, and S. Yang. 2007. Targeted gene disruption by use of a group II intron (Targetron) vector in Clostridium acetobutylicum. Cell Res. 17:963-965. [DOI] [PubMed] [Google Scholar]

- 31.Sharma, S. K., and R. C. Whiting. 2005. Methods for detection of Clostridium botulinum toxin in foods. J. Food Prot. 68:1256-1263. [DOI] [PubMed] [Google Scholar]

- 32.Sleator, R. D., and C. Hill. 2008. Molecular analysis of the microbial food safety implications of food reformulations for improved health. Foodborne Pathog. Dis. 5:499-504. [DOI] [PubMed] [Google Scholar]

- 33.Smith, L. D. S., and H. Sugiyama. 1988. Botulism. The organism, its toxins, the disease, 2nd ed. Charles C Thomas, Springfield, IL.

- 34.U.S. Food and Drug Administration. 2001. Bacteriological analytical manual. Chapter 17: Clostridium botulinum. http://www.fda.gov/Food/ScienceResearch/LaboratoryMethods/BacteriologicalAnalyticalManualBAM/ucm070879.htm. U.S. Food and Drug Administration, Washington, DC.

- 35.U.S. Food and Drug Administration. 2005. Principles of thermal processing. U.S. Department of Agriculture Food Safety and Inspection Service, Washington, DC. http://www.fsis.usda.gov/PDF/FSRE_SS_3PrinciplesThermal.pdf.

- 36.Zhong, J., M. Karberg, and A. M. Lambowitz. 2003. Targeted and random bacterial gene disruption using a group II intron (targetron) vector containing a retrotransposition-activated selectable marker. Nucleic Acids Res. 31:1656-1664. [DOI] [PMC free article] [PubMed] [Google Scholar]