Abstract

The purpose of this work was to improve on sensitivity performance of fiber sensor employed as Fiber Optic Hydrophone Probe (FOHP) by nano-scale thin film gold coating. The fiber is designed to provide a uniform and spatial averaging free response up to 100 MHz by etching down to an active diameter of about 9 μm. The sensitivity performance of straight cleaved (i.e. full size core and cladding) uncoated, tapered uncoated and tapered thin film gold coated fiber sensors were compared in the frequency range of 1.5 MHz to 20 MHz in the presence of acoustic pressure amplitude levels of up to 6 MPa. An unprecedented voltage sensitivity of −245 dB re 1V/uPa (560 mV/ MPa) was measured for thin film gold coated FOHP by optimizing the gold coating thickness.

Introduction

The importance of ultrasound above 20 MHz frequency range has been significantly increasing in clinical applications. Modern ultrasound diagnostic systems routinely use harmonic imaging and operate at center frequencies close to 15 MHz. The existing Food and Drug Administration (FDA) guidelines require the acoustic output characterization using hydrophone probes calibrated to eight times the center frequency of the imaging transducer [1,2]. Successful implementation of medical therapeutic applications requires the detailed characterization of High Intensity Focused Ultrasound (HIFU) fields in terms of real-time pressure-time waveform. The measurement of these fields is difficult as widely used piezoelectric hydrophone probes cannot withstand the temperatures and/or cavitation effects produced by HIFU or similar transducers in the focal region.

The ultrasound field generated by imaging arrays in the 12-15 MHz range should be measured by a calibrated hydrophone probe having bandwidth on the order of 100 MHz. The finite apertures of existing hydrophone probes (~500 μm) are too large and introduce spatial averaging of acoustic fields beyond 3 MHz. In order to eliminate the effects of spatial averaging, the hydrophones should be able to sample the field with at least half-wavelength resolution, which at 100 MHz in water medium would require an active sensor aperture size on the order of 7 μm. It is clear that there is a well defined need for a novel, sub-micron resolution, rugged hydrophone probe that would be able to perform characterization of acoustic fields in the frequency range up to 100 MHz without introducing spatial averaging. This is the domain of acoustic fiber optic sensors.

A number of fiber optic based acoustic pressure sensors have been proposed in literature. Depending on the sensing mechanism, these can be broadly classified as phase modulated, wavelength modulated, and intensity modulated pressure sensors. Internal interferometric phase sensors such as low finesse Fabry-Perot resonant structures have been developed over a wide bandwidth of 50 MHz [3]. High finesse multilayer resonant structures which act as micro-interferometers over a wide bandwidth have also been suggested for pressure sensing applications [4]. In such sensors it is crucial to maintain stability of operating point on the interferometer transfer function and any deviation from the operating point severely affects the voltage sensitivity performance. Also interferometric phase modulated schemes are subject to phase fluctuation, which results in a high intensity noise of the sensor signal. The active area in such sensors is of the order of tens of micrometer. Hence these sensors do not provide a uniform sensitivity response in the frequency range of interest.

Wavelength modulated pressure sensors employing Fiber Bragg grating, and distributed Bragg reflectors have also been proposed [5,6]. The sensing mechanism is based on frequency detection of an acoustically induced shift in the wavelength of optical signal passing through the fiber sensor. This Bragg wavelength shift results in frequency modulation of the optical source and is detected using an FM detector. Such wavelength modulated sensors are usually distributed along the length of the fiber and have sensing dimensions in the order of a few millimeters. Such dimensions introduce spatial averaging of measured ultrasound field and set a limitation on the achieved spatial resolution due to the bandwidth limitations of sensor.

In Intensity modulated acoustic sensors, information is encoded in the intensity of detected optical signal [7-10]. Both reflection as well as transmission type sensing schemes have been proposed. Intensity modulated pressure sensors are not subject to rapid phase fluctuation and temperature variation impacts. The active sensing dimensions are of the order of a few micrometers. These sensors, however, suffer from poor (−302 dB re 1 V/uPa) sensitivity and the sensitivity needs to be boosted in order to make them applicable in practice.

The goal of this work was two-fold: i) to study the impact of various fiber tip geometries on the sensitivity performance of the Fiber Optic Hydrophone Probe (FOHP), and ii) to evaluate sensitivity of the thin film gold coated FOHP as a function of pressure amplitudes of up to 6 MPa.

Methods

Sensing Principle

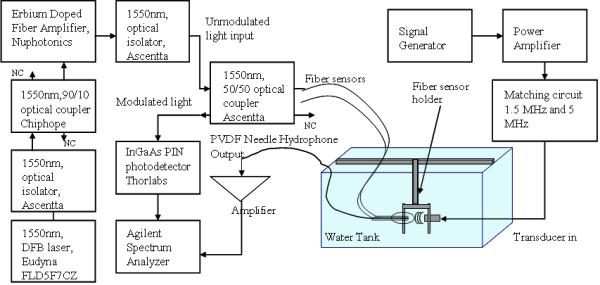

The sensing approach presented in Figure 1 makes use of intensity modulation technique. The principle of intensity modulated optical hydrophone is based on the measurement of change in Fresnel reflectance at the tip of an optical fiber due to modulation of the index of refraction of the water surrounding it. The index of refraction of water depends on the acoustic pressure [7]. Any incident acoustic pressure modulates the index of refraction of water, which in turn changes the amount of Fresnel back-reflected light intensity, thus changing the reflectance at the fiber tip. As pointed earlier, such intensity modulated sensors have extremely low (−302 dB re 1 V/uPa) sensitivity and the sensitivity performance is highly dominated by the intensity noise in the optical system [9]. The sensitivity performance can be improved by increasing the optical source power and by using an amplification stage after the photo-detection. Though these techniques improve the signal level, the optical system noise level also gets amplified, leading to no improvement in the probe’s sensitivity. The transmission line based model as well as initial Finite Element Method (FEM) based numerical analysis indicated that the gold coated down-tapered fibers could provide a 15 dB improvement in sensitivity over that of the uncoated straight cleaved fibers [10,11]. The transmission line model also predicts that the sensitivity of the gold coated fiber sensor is strongly dependent on coating thickness.

Figure 1.

(Color Online)System Block Diagram

Note: Picture width = 5.75” (Double column)

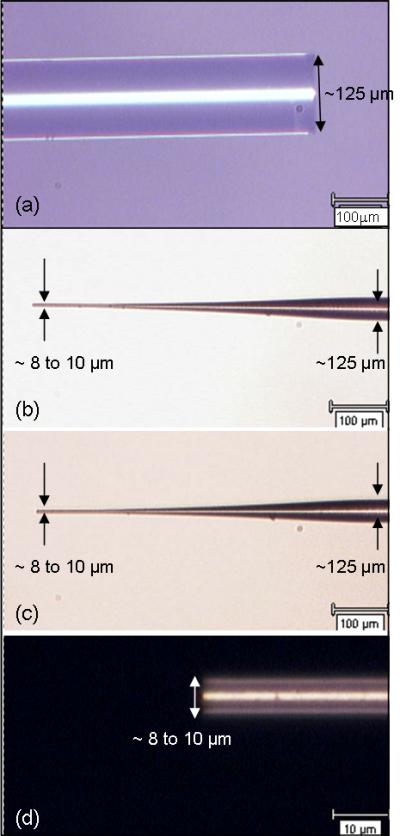

Two versions of uncoated and coated down-tapered (etched-down) fiber sensors were prepared in order to have a broadband improved sensitivity. The fiber samples considered were tapered uncoated sample and straight cleaved samples in addition to down-tapered gold coated (5 sec and 20 sec gold coating) samples that were etched and sputtered as per the procedure described in [10,11]. As plasma sputtering is used for the gold coating of the fiber tip and because of the very small cross sectional fiber tip area (10um in diameter) compared to the plasma cross section area (about 1 cm in diameter), it is most likely that the coating is uniform within few nanometers. A thin film gold coating of 20 second corresponds to the film thickness of around 100nm-150nm, whereas a 5 second thin film gold coating corresponds to a thickness of about 30nm. All of the fiber samples were firmly secured in 125 micron single mode Zirconia ferrules and placed in the acoustic field. In this work, the sensitivity performance of straight cleaved uncoated (i.e. full size core and cladding) fiber sensors, tapered uncoated fiber sensors and tapered thin film gold coated fiber were experimentally compared. Performance of fabricated fiber sensors in the frequency range of 1.5 MHz to 20 MHz using acoustic pressure amplitude levels of up to 6 MPa and input optical power of up to 100mW have also been examined . It is to be noted that due to the high cost of fiber sensors, gold coated tapered fiber samples with coating thicknesses of approximately only 30nm and 120nm have been reported in the current paper to evaluate responsivity performance at two extremes. The 30nm thick film samples were expected to maximize the sensitivity whereas the 120nm thick film samples were chosen to verify the decreasing sensitivity performance. These samples have been tested for repeatability.

Experimental Set-up for acoustic sub-system

The PZT transducer used as an acoustic source was a one element transducer (Sonic Concepts H110AS/N 01) with dual band operation at frequencies of 1.6 MHz and 5.0 MHz. It required a Radio frequency (RF) impedance matching network and 50 ohm over dual bands of 1.41-1.98 MHz and 5.0-5.7 MHz. The transducer had an active diameter of 20 mm and it had a focal length of 34.52 mm. The transducer was driven by an RF power amplifier (ENI 3100LA), which provided a maximum pulsed power level of 100 W with 25% duty cycles and had a gain of 55 dB. The excitation input to the RF power amplifier was provided by the signal generator (Agilent 33251).The positions of the acoustic source and optical hydrophone were controlled by a precision scanning system from Onda Corporation (Sunnyvale, CA). The system provided precise six-axis positioning and data acquisition from any sensor in the water tank for accurate measurements of acoustic fields. The precision of each axis was repeatable within 12 um and had an overall uncertainty of 25 um over 30 cm.

Experimental Set-up for optical sub-system

As depicted in the system block diagram in Figure 1, the optical sub-system is composed of the optical source, optical sensor, and optical receiver assemblies. The fiber optic hydrophone system uses commercially available single mode optical fibers terminated in FC/APC connectors at 1550nm, where the FC/APC connectors with a return loss of better than 55 dB are used to minimize any back-reflections in the fiber link. The optical source is the 1550 nm distributed feedback (DFB) Laser (Eudyna FLD5F7CZ) with an output power of 1mW for a laser bias current of Ib=30mA. The source is coupled to a 10 dB optical coupler (Chiphope, Inc) and the output from 10% coupled arm serves as the input to an EDFA (Erbium Doped Fiber Amplifier) (NuPhotonics NP2000 CORSV303500FCA1) with optical gain of 40 dB and output power of up to 1 W. The 10% output is used as an input to the EDFA in order to prevent saturation of the EDFA. The output of the EDFA is coupled via a 2×2 3 dB optical coupler (Ascentta, Inc. CPS155022-XXSL10FA) to the above mentioned fabricated fiber sensors. Optical isolators have been used at the output of the laser source and the EDFA to prevent any back-reflections. The other output of the 3 dB coupler is immersed in water as reference. This arm of the coupler can also be used for optical power monitoring applications. The back-reflected optical energy from the fiber sensor tip is amplified in a wide band InGaAs photo-detector (ThorLabs PDA 10CF) with a responsivity of 0.95 A/W at 1550nm. The photo-detector has a gain bandwidth of 150 MHz and a trans-impedance gain of 5 kΩ.

Fiber Sensor Holder

In order to determine the reproducibility of the fabricated fiber samples, it is essential to employ a reasonable number of fiber samples and maintain the same experimental conditions for all the samples as comparison is made against the standard acoustic hydrophone. To achieve this, a custom holder was designed. All the 4 sensors were placed on a circle radius of 2.25 mm (tolerance ±0.01mm) from the focal point of the transducer. This circle corresponds to a 10dB drop in pressure amplitude value with respect to the focal point value (maximum). The 3 dB pressure amplitude beam waist of the used transducer was 3mm at 1.52 MHz acoustic frequency. This arrangement was crucial in order to perform a simultaneous measurement of all the fiber sensor samples and compare the sensitivity performance of the fiber optic hydrophone with that of the commercially available piezoelectric polymer (PVDF) needle hydrophone (Force Institute, Denmark) under the same environmental and acoustic conditions. Images of the various fiber sensor tips are shown in Figure 2.

Figure 2.

(Color Online) Raman Spectroscopy images of (a) Straight cleaved uncoated FOHP (10 X) (b) Down-tapered uncoated FOHP (5X) (c) Down-tapered gold coated FOHP (5X) (d) Down-tapered gold coated FOHP tip (50X)

Note: Width = 2.98” (Single Column)

Results and Discussion

The reflected optical signals at 1.5 MHz and 5 MHz acoustic signals and 20 dBm incident optical power were measured for different fiber sensors. Table 1 provides a summary of the experimental sensitivity performances of straight cleaved uncoated, down-tapered uncoated, down–tapered 30nm gold coated and down-tapered 120nm gold coated fiber sensors. The measured mean sensitivity values for the straight cleaved, 30nm gold coated and down-tapered uncoated fibers were −274 dB re 1V/uPa, −245 dB re 1V/uPa and −297 dB re 1V/uPa , respectively with an error bar of ±2dB for gold coated sensors and straight cleaved sensors and an error bar of ±20dB for down-tapered sensors. Maximum sensitivity was obtained using 30 nm thin film gold coated tapered fiber sensor. The sensitivity level of −245 dB re 1V/uPa corresponds to 560 mV/MPa. To the best of the authors’ knowledge such high sensitivity level was not reported in the literature. By increasing the incident optical power to 1W, the sensitivity can be further boosted. Indeed, a few samples exhibited the sensitivity level as high as 2 V/MPa (−234 dB re 1 V/uPa).

Table 1.

Measured signal power of fiber optic hydrophone with various tip geometries and coating thicknesses at 1MPa acoustic pressure level

| Fiber Sample Types with 20 dBm Optical Input Power |

Detected RF Electrical Signal power at 1.5 MHz |

Detected RF Electrical Signal power at 5 MHz |

|---|---|---|

| Straight cleaved #1 | −50 dBm | −80 dBm |

| Straight cleaved #2 | −50 dBm | −76 dBm |

| 30nm Gold coated tapered #1 | −20 dBm | −22 dBm |

| 30nm Gold coated tapered #2 | −20dBm | −23 dBm |

| 120nm Gold coated tapered #1 | −47 dBm | −50 dBm |

| 120nm Gold coated tapered #2 | −50 dBm | −47 dBm |

| Tapered uncoated #1 | −70 dBm | −88 dBm |

| Tapered uncoated #2 | −75 dBm | − 90 dBm |

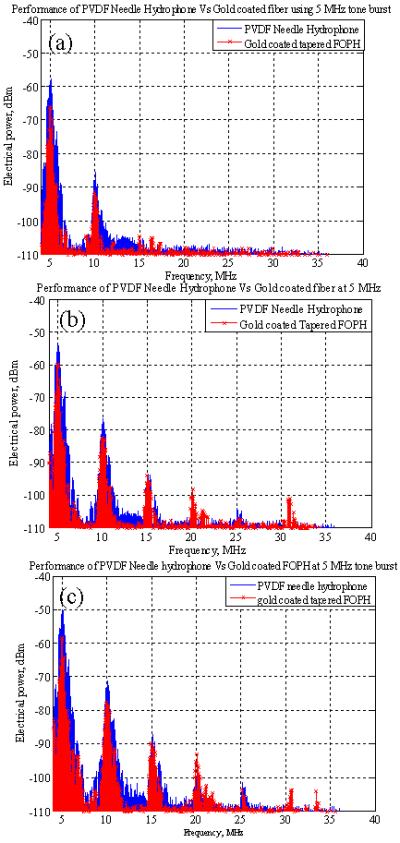

In order to study the sensitivity performance with respect to incident pressure amplitude level, the acoustic sensors in the above set-up were subject to pressure amplitudes in the range of 1 MPa to 6 MPa. Since the amplified Relative Intensity Noise (RIN) of the 1550nm system masked the higher order harmonics, the optical source at 1550nm (composed of DFB laser and up to 30dBm EDFA optical amplifier) was replaced by a 100mW 980nm laser (Lumics, Inc) and the measurements were repeated. The behavior of the 30nm gold coated fiber sensor in comparison with the PVDF needle hydrophone response to varying acoustic pressure amplitude up to 6 MPa is shown in Figure 3. As depicted in this figure, the harmonic content of the detected acoustic field increases as the pressure amplitude is increased. From Table 2, a pressure amplitude increase from 1 MPa to 3 MPa (5dB) corresponds to a 6 dB increase in the measured electrical power (and hence sensitivity) of the gold coated fiber sensor, while a pressure amplitude change from 3 MPa to 6 MPa (3 dB) corresponds to a 3 dB increase in the electrical power of the gold coated fiber sensor at 5 MHz. This linear change shows that the electrical output of the gold coated FOHP varies linearly with pressure up to 6 MPa. This linear behavior was verified through a side-by-side harmonic content comparison of the FOHP output with the output of the of PVDF membrane or needle hydrophones, which exhibit linear pressure to voltage response up to 100 MPa [12]. PVDF based sensors are also used to measure lithotripter pulses which may reach up to 100 MPa peak pressure amplitude in the focal volume [13], [14], and [15].

Figure 3.

(Color Online)Relative sensitivity performance of 30nm gold coated fiber and PVDF needle hydrophone at (a) 1 MPa (b)3 MPa (c) 6 MPa. (Red: 30nm gold coated FOPH. Blue: PVDF needle hydrophone)

Table 2.

Measured sensitivity of 30nm gold coated FOHP Vs excitation pressure amplitude at 5 MHz acoustic frequency

| Pressure amplitude |

Needle PVDF Hydrophone Sensitivity, ref at 1 MPa |

Gold coated FOPH Sensitivity, ref at 1 MPa |

|---|---|---|

| 1 MPa | 0 dB | 0 dB |

| 3 MPa | 5 dB | 6 dB |

| 6 MPa | 8 dB | 8 dB |

A comparison of mean sensitivity values for the uncoated straight cleaved, gold coated tapered and down-tapered uncoated fibers showed that 30nm gold coated tapered sensor provided a 29 dB improvement in sensitivity over that of uncoated straight cleaved sensors and a 52 dB improvement in sensitivity over that of uncoated tapered sensors. Such a high improvement in sensitivity is due to high reflectance from the thin (30nm) metal film at the fiber tip. The mean sensitivity of 30 nm thick gold coated sensor was determined to be 16 dB higher than that of 150nm coating sensors. This corroborates the result of the transmission line modeling reported earlier [10,11], which indicated that the sensitivity of the gold coated fiber sensors was strongly dependent on the thin film coating thickness. Our analytical modeling predicts that the thinner (less than 30 nm) gold coating does not provide sufficiently high light reflectivity coefficient, whereas thicker layer attenuates and does not pick-up the ultrasound wave pressure amplitude. Since the sputtered gold-coated samples are expensive to manufacture, based on the results of the analytical modeling, we have selected two thicknesses, only. The 30nm thick film samples were expected to maximize the sensitivity whereas the 120nm thick film samples were chosen to verify that the sensitivity indeed decreases with increasing thickness. Experiments are underway to verify the sensitivity versus thickness performance with other coating thicknesses. The 30nm gold coated tapered fiber also exhibits a linear sensitivity with respect to pressure up to 6 MPa. As already noted, the maximum pressure amplitude encountered in clinical applications is about 100 MPa. In the current work, the linearity has been tested up to 6 MPa pressure amplitude and as discussed above verified using linear PVDF hydrophones. There is no reason to expect any non linear response from the FOH probe. The lower end of the dynamic range depends on the optical noise intensity of the system. Using balanced detection techniques, the estimated minimum detectable pressure was estimated to be about 5 kPa [11, 16]. Hence, assuming that the maximum pressure amplitude to be measured is 100 MPa [13-15] the dynamic range of the thin film gold coated fiber optic hydrophone can be determined to be 80 dB.

Acknowledgement

The authors wish to acknowledge support of NIH R01EB007117 grant in this work.

Footnotes

OCIS codes: 170.7170,060.2280,060.2370.060.4080,170.1065,160.4236,170.3890,310.6860.

References

- [1].Lewin PA. High frequency biomedical and industrial ultrasound applications; International Congress on Ultrasonics; doi:10.3728/ICUltrasonics(2007).Vienna.1796_lewin_plenary. [Google Scholar]

- [2].Umchid S, Gopinath R, Srinivasan K, Lewin PA, Daryoush AS, Bansal L, El-Sherif M. Development of calibration techniques for ultrasound probes in the frequency range from 1-100 MHz. Ultrasonics. 2008;49(3):306–311. doi: 10.1016/j.ultras.2008.09.011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [3].Morris P, Hurrell A, Beard P. Development of 50 MHz Fabry-Perot type fiber optic hydrophone for the characterization of medical ultrasound fields; Proceedings of the Institute of Acoustics; 2006.pp. 717–725. [Google Scholar]

- [4].Wilkens V, Koch Ch., Molkenstruck W. Frequency response of a fiber-optic dielectric multilayer hydrophone; The Proc. Of the 2000 IEEE Ultrasonics Symposium; Puerto Rico. 2000; pp. 1113–1116. IEEE. [Google Scholar]

- [5].Fomitchov P, Krishnaswamy Sridhar. Response of a Fiber Bragg-Grating Ultrasound Sensor. Optical Engineering. 2003;42(4):956–963. [Google Scholar]

- [6].Guan Bai-Ou, Tam Hwa-Yaw, Lau Sien-Ting, Chan Helen L. W. Ultrasonic hydrophone Based on Distributed Bragg Reflector Fiber Laser. IEEE Photonics technology Letters. 2005;16(1):169–171. [Google Scholar]

- [7].Staudenraus J, Eisenmenger W. Fibre-optic probe hydrophone for ultrasonic and shock-wave measurements in water. Ultrasonics. 1993;31:267–273. [Google Scholar]

- [8].Mu C, Umchid S, Daryoush AS, Lewin PA. Optical Hydrophone for Broadband Medical Ultrasound; International Topical Meeting on Microwave Photonics; France. 2006; pp. 1–4. IEEE. [Google Scholar]

- [9].Parsons JE, Cain CA, Fowlkes JB. Cost-effective assembly of a basic fiber-optic hydrophone for measurement of high-amplitude therapeutic ultrasound fields. J. Acoust. Soc. Am. 2006;119:1432–1440. doi: 10.1121/1.2166708. [DOI] [PubMed] [Google Scholar]

- [10].Daryoush Afshin. S. RF and Microwave Photonics in Biomedical applications. In: Iezekiel Stavros., editor. Microwave Photonics: Devices and applications. John Wiley & Sons; 2009. pp. 241–256. [Google Scholar]

- [11].Gopinath R, Srinivasan K, Umchid S, Bansal L, Daryoush AS, Lewin PA, El-Sherif M. Improved Fiber Optic Hydrophone Sensors; Ultrasonic Symposium; IEEE, NY. 2007; pp. 2319–2322. IEEE. [Google Scholar]

- [12].Lewin Peter A. Practical Implementations and Technology of Measurement Devices. In: Ziskin, Lewin, editors. Ultrasonic Exposimetry. CRC Press; 1992. pp. 185–215. [Google Scholar]

- [13].Lewin PA. In: Gill RW, Dadd MJ, editors. Behaviour of the piezoelectric probe in high pressure amplitude acoustic fields; Proc. WFUMB; Academic. 1985.p. 536. [Google Scholar]

- [14].Meeks S, Ting R. The evaluation of static and dynamic stress on the piezoelectric and dielectric properties of PVDF. J. Acoust. Soc. Am. 1984;74:1010. [Google Scholar]

- [15].Lewin PA, Gilmore JM, Schafer ME. PVDF sensors for quantitative acoustic shock wave measurements; Ultrasonics International ‘89 Conference Proceedings; Butterworths Press, Reading, MA. 1989.p. 548. [Google Scholar]

- [16].Srinivasan K. Master’s Thesis. Drexel University; 2007. Noise Cancelled Optical Receivers in Fiber Optic Hydrophone up to 100MHz? [Google Scholar]