1. Introduction

The science of domestic and restaurant cooking has recently moved from the playground of a few interested amateurs into the realm of serious scientific endeavor. A number of restaurants around the world have started to adopt a more scientific approach in their kitchens,1–3 and perhaps partly as a result, several of these have become acclaimed as being among the best in the world.4,5

Today, many food writers and chefs, as well as most gourmets, agree that chemistry lies at the heart of the very finest food available in some of the world’s finest restaurants. At least in the world of gourmet food, chemistry has managed to replace its often tarnished image with a growing respect as the application of basic chemistry in the kitchen has provided the starting point for a whole new cuisine. The application of chemistry and other sciences to restaurant and domestic cooking is thus making a positive impact in a very public arena which inevitably gives credence to the subject as a whole.

As yet, however, this activity has been largely in the form of small collaborations between scientists and chefs. To date, little “new science” has emerged, but many novel applications of existing science have been made, assisting chefs to produce new dishes and extend the range of techniques available in their kitchens. Little of this work has appeared in the scientific literature,2,3,6–9 but the work has received an enormous amount of media attention. A quick Google search will reveal thousands of news articles over the past few years; a very few recent examples can be found in China,(10) the United States,11,12 and Australia.(13)

In this review we bring together the many strands of chemistry that have been and are increasingly being used in the kitchen to provide a sound basis for further developments in the area. We also attempt throughout to show using relevant illustrative examples how knowledge and understanding of chemistry can be applied to good effect in the domestic and restaurant kitchen.

Our basic premise is that the application of chemical and physical techniques in some restaurant kitchens to produce novel textures and flavor combinations has not only revolutionized the restaurant experience but also led to new enjoyment and appreciation of food. Examples include El Bulli (in Spain) and the Fat Duck (in the United Kingdom), two restaurants that since adopting a scientific approach to cooking have become widely regarded as among the finest in the world. All this begs the fundamental question: why should these novel textures and flavors provide so much real pleasure for the diners?

Such questions are at the heart of the new science of Molecular Gastronomy. The term Molecular Gastronomy has gained a lot of publicity over the past few years, largely because some chefs have started to label their cooking style as Molecular Gastronomy (MG) and claimed to be bringing the use of scientific principles into the kitchen. However, we should note that three of the first chefs whose food was “labeled” as MG have recently written a new manifesto protesting against this label.(14) They rightly contend that what is important is the finest food prepared using the best available ingredients and using the most appropriate methods (which naturally includes the use of “new” ingredients, for example, gelling agents such as gellan or carageenan, and processes, such as vacuum distillation, etc.).

We take a broad view of Molecular Gastronomy and argue it should be considered as the scientific study of why some food tastes terrible, some is mediocre, some good, and occasionally some absolutely delicious. We want to understand what it is that makes one dish delicious and another not, whether it be the choice of ingredients and how they were grown, the manner in which the food was cooked and presented, or the environment in which it was served. All will play their own roles, and there are valid scientific enquiries to be made to elucidate the extent to which they each affect the final result, but chemistry lies at the heart of all these diverse disciplines.

The judgment of the quality of a dish is a highly personal matter as is the extent to which a particular meal is enjoyed or not. Nevertheless, we hypothesize that there are a number of conditions that must be met before food becomes truly enjoyable. These include many aspects of the flavor. Clearly, the food should have flavor; but what conditions are truly important? Does it matter, for example, how much flavor a dish has; is the concentration of the flavor molecules important? How important is the order in which the flavor molecules are released? How does the texture affect the flavor? The long-term aims of the science of MG are not only to provide chefs with tools to assist them in producing the finest dishes but also to elucidate the minimum set of conditions that are required for a dish to be described by a representative group of individuals as enjoyable or delicious, to find ways in which these conditions can be met (through the production of raw materials, in the cooking process, and in the way in which the food is presented), and hence to be able to predict reasonably well whether a particular dish or meal would be delicious. It may even become possible to give some quantitative measure of just how delicious a particular dish will be to a particular individual.

Clearly, this is an immense task involving many different aspects of the chemical sciences: from the way in which food is produced through the harvesting, packaging, and transport to market via the processing and cooking to the presentation on the plate and how the body and brain react to the various stimuli presented.

MG is distinct from traditional Food Science as it is concerned principally with the science behind any conceivable food preparation technique that may be used in a restaurant environment or even in domestic cooking from readily available ingredients to produce the best possible result. Conversely, Food Science is concerned, in large measure, with food production on an industrial scale and nutrition and food safety.

A further distinction is that although Molecular Gastronomy includes the science behind gastronomic food, to understand gastronomy it is sometimes also necessary to appreciate its wider background. Thus, investigations of food history and culture may be subjects for investigation within the overall umbrella of Molecular Gastronomy.

Further, gastronomy is characterized by the fact that strong, even passionate feelings can be involved. Leading chefs express their own emotions and visions through the dishes they produce. Some chefs stick closely to tradition, while others can be highly innovative and even provocative. In this sense gastronomy can be considered as an art form similar to painting and music.

In this review we begin with a short description of our senses of taste and aroma and how we use these and other senses to provide the sensation of flavor. We will show that flavor is not simply the sum of the individual stimuli from the receptors in the tongue and nose but far more complex. In fact, the best we can say is that flavor is constructed in the mind using cues taken from all the senses including, but not limited to, the chemical senses of taste and smell. It is necessary to bear this background in mind throughout the whole review so we do not forget that even if we fully understand the complete chemical composition, physical state, and morphological complexity of a dish, this alone will not tell us whether it will provide an enjoyable eating experience.

In subsequent sections we will take a walk through the preparation of a meal, starting with the raw ingredients to see how the chemical make up of even the apparently simplest ingredients such as carrots or tomatoes is greatly affected by all the different agricultural processes they may be subjected to before arriving in the kitchen.

Once we have ingredients in the kitchen and start to cut, mix, and cook them, a vast range of chemical reactions come into play, destroying some and creating new flavor compounds. We devote a considerable portion of the review to the summary of some of these reactions. However, we must note that complete textbooks have failed to capture the complexity of many of these, so all we can do here is to provide a general overview of some important aspects that commonly affect flavor in domestic and restaurant kitchens.

In nearly all cooking, the texture of the food is as important as its flavor: the flavor of roast chicken is pretty constant, but the texture varies from the wonderfully tender meat that melts in the mouth to the awful rubber chicken of so many conference dinners. Understanding and controlling texture not only of meats but also of sauces, soufflés, breads, cakes, and pastries, etc., will take us on a tour through a range of chemical and physical disciplines as we look, for example, at the spinning of glassy sugars to produce candy-floss.

Finally, after a discussion of those factors in our food that seem to contribute to making it delicious, we enter the world of brain chemistry, and much of that is speculative. We will end up with a list of areas of potential new research offering all chemists the opportunity to join us in the exciting new adventures of Molecular Gastronomy and the possibility of collaborating with chefs to create new and better food in their own local neighborhoods. Who ever said there is no such thing as a free lunch?

2. Senses

Before we begin to look in any detail at the chemistry of food production and preparation, we should take in a brief overview of the way in which we actually sense the food we eat. Questions such as what makes us enjoy (or not) any particular food and what it is that makes one meal better than another are of course largely subjective. Nonetheless, we all share the same, largely chemical based, set of senses with which to interpret the taste, aroma, flavor, and texture of the food. In this section we will explore these senses and note how they detect the various food molecules before, during, and even after we have consumed them.

It is important to note at the outset that our experience of foods is mediated through all our senses: these include all the familiar senses (pain, touch, sight, hearing, taste, and smell) as well as the perhaps less familiar such as chemesthesis. As we will see, our senses of sight and touch can set up expectations of the overall flavor of food which can be very hard to ignore. Try eating the same food using either high-quality china plates and steel or silver cutlery or paper plates and plastic cutlery; the food seems to taste better with the perceived quality of the utensils. Equally, the color of food can affect our perception of the flavor; try eating a steak dyed blue!

However, among all the senses, the most significant for our appreciation of food remain the chemical senses which encompass taste, smell, and chemesthesis. These three distinct systems mediate information about the presence of chemicals in the environment. Taste or gustation detects chemical compounds dissolved in liquids using sensors mostly in the mouth. Smell or olfaction detects air-borne chemicals, both from the external world but also from the internalized compounds emitted from food in our oral cavity. Chemesthesis mediates information about irritants through nerve endings in the skin as well as other borders between us and the environments, including the epithelia in the nose, the eyes, and in the gut. Chemesthesis uses the same systems that inform us about touch, temperature, and pain.

2.1. Sense of Taste

Specialized chemoreceptors on the tongue, palate, soft palate, and areas in the upper throat (pharynx and laryngopharynx) detect sensations such as bitter, for example, from alkaloids, salty from many ionic compounds, sour from most acids, sweet from sugars, and umami, or savory, from some amino acids and nucleotides. Each of these taste sensations probably evolved to provide information about foods that are particularly desirable (e.g., salt, sugar, amino acids) or undesirable (e.g., toxic alkaloids). The receptors reside in taste buds mostly located in fungiform, foliate, and circumvallate but not filiform papillae on the tongue. Taste buds, as the name indicates, are bud-shaped groups of cells. Tastants, the molecules being tasted, enter a small pore at the top of the taste bud and are absorbed on microvilli at taste receptor cells.

In the past decade receptor proteins for bitter,15,16 sweet, and umami17–20 have all been identified. All these receptors are a subclass of the super family of G-protein-coupled receptors (GPCRs) and have been classified as T1R1, T1R2, T1R3, and T2Rs. The activation of GPCRs by external stimulus is the starting point of a succession of interactions between multiple proteins in the cell, leading to the release of chemical substances in the cell also called second messengers. Although the cellular signal cascade is a general pattern of GPCRs, the very large variety of each protein involved renders these mechanisms very complex so that they are under a good deal of ongoing investigation.

Taste receptors share several structural homologies with the metabotropic glutamate receptors. These receptors are composed of two main domains linked by an extracellular cystein-rich domain: a large extracellular domain (ECD) also called the “Venus Flytrap” module, due to the similarity of mechanism by which this plant traps insects, containing the ligand binding site and a seven-transmembrane domain region. Moreover, as in the case of mGluRs, T1Rs assemble as dimers at the membrane and the composition of the heterodimers has been shown to be specific to the taste recognized. Heterodimers T1R2−T1R3 are responsible for sweet sensing, whereas T1R1−T1R3 are responsible for umami tasting. A large number of T2Rs have been shown to function as bitter taste receptors in heterologous expression assays, and several have distinctive polymorphisms that are associated with significant variations in sensitivity to selective bitter tastants in mice, chimpanzees, and humans.

Receptors for sour and salty tastes are essentially ionic channels, but the identity of the salty receptor is still speculative and controversial.21,22 The hunt for a sour receptor has been narrowed down to a ionic channel of the type TRP, transient receptor potential.21,23 Undoubtedly, more receptor proteins for other nutritionally relevant molecules will be identified. For example, recently a specific fatty acid receptor, a multifunctional CD36 glycoprotein, has been demonstrated in rats.(24)

2.2. Sense of Smell

While the taste receptors in the mouth detect small molecules dissolved in liquids, the receptors of the olfactory system detect molecules in the air. The range of receptors provides a wide sensitivity to volatile molecules. Some of the most potent thiols can be detected in concentrations as low as 6 × 107 molecules/mL air (2-propene-1-thiol), whereas ethanol requires around 2 × 1015 molecules/mL air. Thus, there are at least 8 orders of magnitude between our sensitivity to the most and least “smelly” molecules. The sensitivity of the sense of smell varies quite significantly between individuals. Not only do different people have different sensitivity to particular aromas, some people suffer anosmia, odor blindness to specific odorants. People can be trained to become sensitive to some odorants, such as for the unpleasant smelling androstenone. To complicate the picture further, the sense of smell develops during the human lifetime; we tend to lose sensitivity at an older age, especially after the seventh decade.(25)

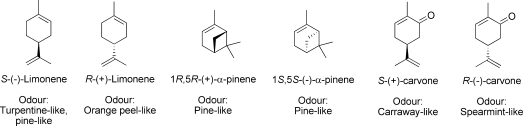

An odor is detected by sensors in the nose, the odorant receptors. The way these sensors recognize aroma molecules is by “combinatorial receptor codes”, i.e., one odorant receptor recognizes a range of odorants and one odorant is recognized by a number of odorant receptors.(26) The distinct odor identity is created by the pattern of odorant receptors activated by the odorant’s shape. Thus, slight changes in an odorant or even in its concentration can change the identity of an odorant. A well-known example relevant to food is the distinct perceptual difference between R-(−)- and S-(+)-carvone, enantiomers only differing in the chirality of the compound. The two compounds are perceived as spearmint and caraway, respectively. However, by no means are all enantiomers perceived differently. For example, Laska and Tuuebner(27) have shown that among 10 different food-relevant enantiomers, subjects as a group were only capable of discriminating three: α-pinene, carvone, and limonene. Structures of some of these molecules are shown in Figure 1.

Figure 1.

Molecular structures of the enantiomers of limonene, α-pinene, and carvone. The enantiomers have distinct odor characteristics (quality and threshold), which are attributed to the enantiomeric configuration. R-(−)-Carvone is the main consitutent in spearmint essential oil, and S-(+)-carvone is the main constituent in the essential oil of carraway and dill. R-(+)-Limonene is the main constituent of the volatile oils expressed from the fresh peel of Citrus spp. fruits. S-(−)-limonene is present in the oil of fir and the needles and young twigs of Abies alba (Pinaceae).

Linda Buck and Richard Axel were jointly awarded the Nobel Prize in Medicine and Physiology in 2004 for their discovery of “odorant receptors and the organization of the olfactory system”.(28) Their work has shown that each olfactory neuron expresses only one type of odorant receptor. The odorant receptors belong to the GPCR 7TM-receptor family.(29) Through in situ hybridization of olfactory neurons in the epithelium of rats, they created an olfactory map.30,31 Around 1000 olfactory receptor cells, all of the same type, converge their nerve signals to distinct microdomains, glomeruli, in the olfactory bulb. This is the most direct link from the external world to the brain. From the olfactory bulb signals are relayed as patterns to other regions in the brain. Notably, there is a direct link to the amygdalae, important structures in the “limbic system”, an evolutionary old part of the brain strongly involved in human emotions. Recent work has suggested that the amygdalae not only plays important roles in evaluating affective valence of stimuli but also seem to participate in the computation and representation of perceived intensity of smells and tastes.32,33 The olfactory system consists of other areas in the temporal and frontal parts of the brain. The orbitofrontal cortex is of particular importance for food behavior since nerve cells in this area play a large role in the computation of hedonic properties of smell stimuli and have also been implicated in the representation of flavors of foods. Smell- and taste-sensitive neurons in the orbitofrontal cortex are also typically modulated by satiety signals and thus play a major role in determining sensory-specific satiety: the effect that appreciation for a food eaten to satiety decreases without a similar decrease in the appreciation of other foods with other sensory characteristics.(34)

2.2.1. Perception of Aroma

Sensory scientists usually refer to smelling through the nostrils as “orthonasal perception”, whereas the aroma compounds that gain access to the olfactory epithelium through the nasopharynx (i.e., molecules released in the mouth) are referred to as being perceived retronasally. The latter is often mistakenly referred to as taste by laymen. It should perhaps more correctly be referred to as flavor, although we prefer to think of flavor as the combination of the perception of taste in the mouth and retronasal aroma in the nose (see section below). It is one of the challenges for Molecular Gastronomy to develop an appropriate language that can be used by chefs, the general public, as well as the scientific community to describe the various ways we interpret the signals from our chemical senses.

When eating a food the initial olfactory stimulation takes place as we smell the aroma of the food before the food is in the mouth. Thus, orthonasal perception is often said to be of the external world. In contrast, the aromas perceived retronasally are said to be of the oral cavity (the interior world).

Small and colleagues(35) compared these two distinct pathways of delivering odorants and found different patterns of neural activation depending on whether the aroma compounds are delivered ortho- or retronasally. Further, a few experiments examined differences in perception of aromas delivered by the two pathways; these have rather variable results. In one study, Aubry and colleagues(36) found no overall difference in the ability of trained sensory panelists to describe a set of Burgundy wines. By contrast, other research examining the dose−response behavior of flavor molecules ortho- and retronasally have revealed differences which depend strongly on the physical characteristics of the aroma compounds.(37) Much further work is needed before we will be able to understand the extent to which individuals perceive odor differently depending on whether they are delivered ortho- or retronasally; at his stage, all we can do is to note that it is likely that there will be a range of where the initial smell (the orthonasal stimulus) may be rather different from their “flavor” (the combination of the taste and retronasal stimulus). One such example that is well known to gourmets is that of the pungent smelling Durian fruit, which has, for most people, a very unpleasant (toilet-like) aroma when smelled orthonasally but, for many, a very pleasing flavor when in the mouth and the aroma is detected retronasally.

2.3. Chemesthesis

As we have already noted, the overall “flavor” of a food is determined by the combination of many stimuli both in the mouth and nose. Most authors argue the important senses are those of taste, (retronasal) smell, as well as the less well-known, mouthfeel and chemesthesis.(38) In this section we will briefly review the sense of chemesthesis.

In humans, sensory nerve endings from branches of the trigeminal nerve are found in the epithelia of the nose and oral cavity. Signals transmitted by these nerves are responsible for the pungency of foods, as exemplified in carbonated drinks, chili, ginger, mustard, and horseradish; accordingly, chemesthesis is also sometimes referred to as the “trigeminal sense”. Hot spices are typical stimulants of trigeminal sensory nerve endings, but most chemicals will stimulate these nerve endings at sufficiently high physical concentration.

Without pungency many foods would be bland; imagine horseradish without the heat or garlic with no bite. Clearly, the sense of chemesthesis must play a crucial role in our the evaluation of the palatability of any food. The sensation of oral pungency differs in many ways from the sense of taste. For example, pungency typically has a slow onset but can persist for prolonged periods, minutes to tens of minutes. This is contrary to the sense of taste, which is most intense for the few seconds the food is in the mouth. This difference in the temporal nature of pungency and taste is of great interest when considering of the palatability of foods and the overall satiety they provide. In many cases, the long-term effects of pungency will make foods both more palatable and more satiating.

Further, the interesting temporal properties of trigeminal sensation may be exploited in the development of new gastronomic meals both for their ability to surprise on a short time scale (seconds) and for reasons of novelty. In the search of “flavor principles”, i.e., rules of thumb of which sensory attributes should be present in a good flavor, trigeminal stimulation certainly will play a large role.

2.4. Texture (Sense of Touch)

Szczesniak(39) succinctly defines of texture as “...the sensory and functional manifestation of the structural, mechanical and surface properties of foods detected through the senses of vision, hearing, touch and kinesthetics”. This definition clearly conveys the important point that texture is a sensory property and thus requires a perceiver. The distinction between texture and structure is sometimes ignored in the terminological practice, such that sensory and instrumental measurements can be confused. It is not touch alone that provides the sensation of the texture of food: vision is active in texture perception when we see the food; additionally, audition, somesthesis, and kinesthesis are active during handling of the food. During consumption, the oral processing, the latter three remain active.(40) Texture plays a major role in our recognition of foods. For example, when presented with blended food products 56 blindfolded young and elderly subjects were, on average, only able to correctly identify 40% of these foods.(41) Our sensitivity to texture under laboratory conditions is very high. The perception of particles in a solution is so sensitive that particles need to be smaller than 3 μm to escape detection. This has been exploited commercially in a number of fat replacers and mimetics (e.g., Simplesse, Litesse, LITA, Trailblazer, Stellar(42)) where spherical microparticulates in the range 0.1−3 μm are the main functional ingredient. When particles are this small they are perceived as smooth and may contribute to creaminess. It has been suggested that the functionality of such small particles is that they rotate relative to each other under shearing conditions present in the mouth, providing a fluidity of the mass of particles with a ‘ball-bearing’ effect.(43)

Further, there is a marked difference between the food that enters the mouth and the wetted bolus that is later swallowed, and it is the summation of sensory impressions during the whole process from seeing the food, picking it up and putting it our mouths, chewing it, and eventually swallowing it that we perceive as the texture of the food. This has been termed the “philosophy of the breakdown path”.(44) In this view, individual foods follow specific paths during oral handling along the axes “degree of structure”, “degree of lubrication” over time, or number of chews. Foods interact with the eater during consumption, the saliva lubricates the food, and enzymes in the saliva affect the viscosity of semisolids and liquids. For example, addition or inhibition of α-amylase in a semisolid food affects a number of different sensory properties, among them the highly desirable creaminess.(45) Finally, we note that astringency is a sensory property that is suggested to result from interaction between proline-rich proteins (PRPs) and polyphenols in the foods. PRPs precipitate polyphenols, causing flocculation and loss of lubrication.(46)

2.5. Temperature

From cold ice cream on a hot summer day to hot cocoa after a trip on the skating rink in winter time, temperature is part of our perception of foods. We have expectations for the serving temperature for most foods and beverages; an inappropriate serving temperatures leads to reduced liking or even rejection of such foods and beverages.(47) We sense the temperature of food in our mouth through nerve endings. Thermal information appears to be coded primarily by activation of ion channels that belong to the transient receptor potential family.48,49 There are six different thermosensitive ion channels. They have distinct thermal activation thresholds (>43 °C for TRPV1, >52 °C for TRPV2, >∼34−38 °C for TRPV3, >∼27−35 °C for TRPV4, <∼25−28 °C for TRPM8, and <17 °C for TRPA1) and are expressed in primary sensory neurons as well as in other tissues. Temperatures above 43 °C and below 15 °C are accompanied by a feeling of pain. However, we routinely consume hot beverages well above both pain and tissue damaging temperatures. A study of ingestive behavior of hot coffee coupled with measures of temperatures during sipping and in mouth showed that minimal cooling occurred during sipping and ingestion. The authors hypothesize that during drinking, the hot coffee is not held in the mouth for a sufficiently long time to heat the epithelial surfaces sufficiently to cause pain or tissue damage.(50)

The perception of temperature changes in the mouth is very precise; under experimental conditions sensitive subjects feel changes in temperature of as little as around 1 °C.(51) The ability to sense changes is asymmetric: increases in temperature are sensed much more rapidly than decreases.(52) The sensation of temperature can be affected by various chemestetic agents, with menthol as a well-known example of cooling and capsaicin for heating.

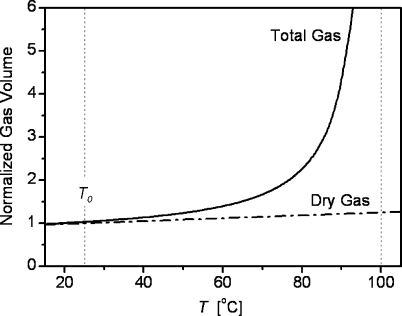

The temperature of a food or beverage affects the release of airborne molecules, with an increase in temperature leading to increased release. For this reason standards in sensory evaluation recommend specific temperatures for products, e.g., milk and other liquid dairy products should be served at 14 ± 2 °C,(53) although this is higher than the common consumption temperature.

2.6. Concept of Flavor

Food provides a multimodal stimulus; it excites more than one sensory system. During the process of eating, all of the five senses are used. With our far senses vision and olfaction we see and smell foods from a distance. With our near senses somatosensation and gustation we feel and taste the food during handling and oral processing. In many cases foods elicit our auditory system as they emit sounds during chewing and other oral processing. We use the term flavor to describe our perception of a food, generally thinking of the senses of only taste and aroma. However, in a scientific context, flavor may be defined as “the complex combination of the olfactory, gustatory and trigeminal sensations perceived during tasting. The flavors may be influenced by tactile, thermal, painful and/or kinaesthetic effects and expectations from visual presentation of the product”. Since flavor is a multimodal sensory experience it has been difficult to relate the concept of flavor with the chemical components of foods.

2.7. Multimodal Integration

In foods there are several examples where the perception in one sense interacts with that of another sense. The taste of a food may be affected by changes in the texture. It has been demonstrated repeatedly that this is a perceptual phenomena, as a harder texture of a gel decreases the perceived intensity but hardly affects the release of aroma compounds, as measured by the concentration in the nasal cavity.54,55 Aroma compounds in a food can also enhance perceived taste intensity of congruent tastes, e.g., the intensity of sweetness in whipped cream can be increased by adding strawberry flavor but not by adding a peanut butter flavor.(56) Frank and Byram(56) also showed that the effect can be eliminated by pinching the nostrils during tasting. The taste-enhancing properties of an aroma depend on conditioning through repeated pairing of an aroma with a taste. This learning occurs very fast and implicitly during few exposures. Completely novel odors paired with tastants take on the tastants’ properties (sweet or sour) with only one exposure.(57) The past decade has seen an explosion in research in the field of multisensory integration. Much of this stems from advances in neuroscience, and recently, interest has expanded from integration in vision, audition, and somatosensation to also encompassing the chemical senses. A very thorough review of the field of human multimodal food perception was performed by Verhagen and Engelen(58) and includes some plausible neuroscientific models and suggestions for future research. Some specific sensory properties are of a more complex nature than others, and these involve more than one sense. A commercially important property in this category is creaminess, originally suggested to be a texture property only. It has been researched intensively in the past decade, and the research suggests that although texture may be most decisive for creaminess, its perception involves several senses, at least including vision, olfaction, gustation, and haptics.59,60

2.8. Adaptation and Suppression

In addition to the actual signals from the sensors, there are further, perhaps surprising ways in which we perceive the environment around us which can significantly affect the flavor of the food we are eating. Two of the most important are adaptation, when we ignore a constant stimulus, and suppression, when we find the effect of a stimulus in a mixture less than on its own. Both are of some significance in the kitchen, so we will describe them in more detail below.

2.8.1. Adaptation

When subject to a constant stimulus, the senses become less responsive. When holding a solution of a tastant (e.g., sucrose) motionless in the mouth, the solution will become completely tasteless after a while.(61)

This phenomenon is well known to us all, although we tend to ignore it. Whenever we leave our homes for a prolonged period, to go on holiday or to a week-long conference, we find on our return that as soon as we walk in the front door our home has a slightly “musty” smell. Thus, we open the windows and “air” the house. The odor quickly goes away. Of course, in actual fact, our homes always have that smell, it is what our friends and neighbors perceive as the smell of our home. However, because it is always present in our environment we rapidly become adapted to it and simply do not notice it at all. When eating, we will quickly become “bored” with a dish which appears to lose its flavor if we are subject to the same taste or aroma continuously for a prolonged period. Variety becomes the spice of life.

If we are aware of this phenomenon we can make all meals more interesting simply by increasing variety, a large number of small differently flavored or textured dishes (such as the Spanish Tapas) will provide greater interest than one single, larger item. Many restaurants provide a diverse range of elements on every plate; some very small items can break up a larger item to provide the necessary changing stimulus to retain the diner’s interest and enjoyment.

In the gastronomic kitchen, some chefs, having recognized the adaptation phenomenon, have tried to create dishes that continually provide a diverse range of stimuli so as to retain (and hopefully enhance) the diner’s interest. One such example comes from the Fat Duck, cauliflower risotto.(62) The central idea here was to take a vegetable, regarded by many as essentially rather uninteresting (i.e., one that in which diners might quickly lose interest as they start to ignore the flavor), but to prepare a dish that has a wide variety of different textures and flavors that constantly stimulate the brain, so preventing any adaptation and (hopefully) turning a plain cauliflower into a very tasty and exciting dish. The result was “cauliflower risotto” (for a photograph see page 323 of The Big Fat Duck Cookbook(62)) a dish that was for some time one of the signature dishes at the Fat Duck.

To achieve the desired effect, Heston Blumenthal used a combination of many different cauliflower preparations (dried cauliflower, cauliflower cream, foamed cauliflower, raw cauliflower, and a risotto made with a cauliflower stock together with other contrasting ingredients such as cocoa jellies) to create a spectacular dish of which no diner is likely to tire.

2.8.2. Mixture Suppression

Mixture suppression is the phenomenon that individual taste and smell characteristics are perceived as less intense in mixtures than alone.(63) Thus, when preparing a complex recipe and mixing several foods with different flavors or tastes, the perceived intensity of the flavors of the separate ingredients is decreased relative to that of the same tastes or aromas of the ingredients on their own. There is a very interesting and useful exception to this phenomenon, Release from suppression; when adapting to one component in a mixture, other components are less suppressed and will then be perceived as more intense.(64) This is routinely used by flavorists and perfumers to analyze competitors’ blends.(65)

Once again, awareness of the issue can quickly provide new ideas to improve cooking. Rather than mixing all the ingredients together in a single pot, it can be much better to present them separately. For example, there may be several different sauces or dips associated with a single dish; if these are presented in separate pots and used individually, rather then in combination, their impact is greater.

3. How Different Food Production Techniques May Affect Flavor and Texture

The first stage of the preparation of any meal is the production of the basic ingredients, something which normally is out of the control of the cook and happens well before any processing of the food begins. In this section we briefly address the question of whether science can help us understand the extent to which the selection of particular ingredients according to the ways in which they are produced actually affects the flavor of a completed dish.

It is often said that the finest food requires the best ingredients. However, how can we begin to define what makes the “best” ingredients? How can we tell whether one carrot is better than another? Of course, there are no specific answers to such questions; not only will there be an element of personal preference as to which carrot is better, but one carrot may be better suited to eating raw in a salad and another to being cooked in a casserole.

Most cooks and chefs hold strong views on what is best; many insist that one particular production technique (such as organic farming) consistently yields better produce; others may insist the key factor is the “freshness” of the ingredients. Unfortunately, as we will see, there is little clear scientific evidence to back up such assertions and what literature that does exist is often vague and contradictory.

However, there are a few cases where the effect of the production, storage, and even transport on foodstuffs has been well investigated and some understanding of the effect on flavor has been achieved. In particular, it is now well established that the flavor of meat is affected by the food eaten by the animals it is produced from, that the flavor and color of dairy products depends on the forage of the animals used to produce the milk, that the flavor of fruit and vegetables is influenced strongly by the variety used, and that growing conditions affect volatile compounds and hence flavor in many vegetables. The way in which animals are slaughtered and the subsequent storage of the meat is also known to affect not only the flavor but also the texture of the final product.

In this section we briefly look at what is known about the extent to which the production methods of food affect the ultimate quality to see how far this knowledge can actually be applied in practice in the kitchen.

3.1. Organic vs Conventional Farming

Most people, if asked, will assume that organic foods taste better than those grown conventionally. However, there is little, if any, real evidence to bear this out. In a comprehensive review of the literature on the nutritional value, sensory quality, and food safety of organically and conventionally produced foods with emphasis on the comparison between organic and conventional growing methods for fruit and vegetables Bourn and Prescott(66) clearly showed that the results from a large number of studies are not only inconclusive but also mutually contradictory. Further, they demonstrated that the scientific methods in many of these studies were questionable with the effects sought after widely being confounded with other factors.

Bourn and Prescott, in common with an earlier review by Woese et al.,(67) note that there was a tendency for some organically grown foods to contain a smaller amount of nitrate than conventionally grown vegetables, probably, they suggest, due to greater quantities of nitrogen being used in conventional farming. However, they also note that it remains to be seen whether this is a general effect across a wide range of organic produce. Whether the nitrate content significantly affects taste (and whether any such affects are positive or negative) is not known; this might prove a fruitful area for future research. In a separate survey of the literature, Williams(68) reached similar conclusions but also noted that vitamin C had been found to be at higher levels in organically grown vegetables than in conventionally grown ones. Zhao et al.(69) found consumers could not tell any difference between the taste and the flavor of organically and conventionally grown vegetables, even though 28% of the consumers had expected organically grown vegetables to taste better than those grown conventionally.

3.2. Effect of Feed on the Flavor of Meat

Common experience, backed up by a number of detailed scientific studies, leaves no doubt that how animals are fed influences the flavor of the meat. However, whether the influence of the feed is to produce “better” flavors is not so clear.

Several studies have shown that the composition of the fatty acids found in the fat tissue of the animal reflects the composition of fatty acids in the lipids fed to the animal. If the animal is fed a diet containing unsaturated fat, then the fat tissue in the animal will contain a larger degree of unsaturated fat than animals fed a normal diet.70,71 Decreases in saturated fats may have health advantages; for example, in one study it was shown that when people eat meat from pigs fed on a diet with added rapeseed oil their cholesterol levels were reduced when compared to a group that ate meat from pigs fed a normal diet.(72) However, since unsaturated fats generally melt at lower temperatures they are more likely to be lost in cooking, leading to potentially drier textures. Importantly, changes in the proportion of saturated fats lead to noticeable changes in meat flavor. Meat with a higher proportion of saturated fat usually has the preferred flavor, although this may simply be an affect of liking that to which we have become accustomed. Perceived changes in flavor with differences in fat saturation are most pronounced in lamb and beef and much less noticeable in pork.(70)

Studies have been performed comparing the flavor of pork, lamb, beef, poultry, red deer, and reindeer with different feed sources for the animals. The main conclusion from these studies is that what the animal eats will be reflected in the flavor of the meat.70,73–76 High-energy grain diets produce a more acceptable or intense flavor in red meat. Other dietary ingredients such as fish products, raw soybeans, and pasture grasses can have an undesired effect on meat flavor. Some researchers have even tried feeding horse manure and spoiled meat scraps to pigs, which, not surprisingly, resulted in foul smelling meat with the undesired flavor located in the lean muscle tissue.(70) Meat with a higher proportion of unsaturated fat usually has more tendency to develop off flavors during cooking as a result of lipid oxidation, see section .3.

It is however worth noting that there is no single “beef” (or lamb, or pork) flavor; rather there is a wide range of flavors that can be achieved depending on the way in which the meat has been produced (and later cooked). In practice, the good chef will try out meats from a wide range of different sources and select that which best suits his particular purpose in any dish, but he would be well advised to ask the butcher for details of the production methods so that he can be sure, in the future, that he will be able to obtain, as nearly as possible, an identical product.

3.3. Effect of Feed on the Flavor and Texture of Dairy Products

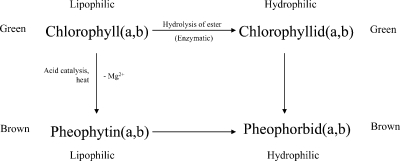

The color and flavor of dairy products are influenced by the forage. Diets high in grass (as grass silage or fresh pasture) give products that are more yellow, whereas diets rich in maize silage yield very white products. The yellow color is due to β-carotene from the forage.(77) Since β-carotene is degraded during hay production,(77) feeding hay to the cows does not have the same effect on the color as pasture. In Northern countries where cattle are generally kept indoors and fed on hay, winter cheeses and butter made from winter milk are whiter than products made from summer milk, when the cows have been on pasture.77,78

The different plant species that grow at high and low altitudes lead to different volatiles in the milk of cows reared at different heights, leading to significant differences in the flavor of “mountain” and “valley” cheeses, especially those from Switzerland.(77)

The texture of dairy products is mainly influenced by a differing degree of saturation of the fat. Increasing the content of unsaturated fat leads to a softer product in, for example, cheese and butter. Cows on pasture will produce milk with more unsaturated fats than cows fed preserved forage.(77) In a study of relationships between chemical and sensory properties of milk from cows fed on different forages, it was shown that milk with a high content of long-chain saturated fatty acids produced milks with high levels of lipolysis, leading to flavors characterized as Roquefort.(79) Subsequent studies have shown that more subtle differences in composition stemming from differences in feed provide recognizable differences in sensory properties.80,81

It is worth noting here that fresh dairy products (milk, cream, etc.) will have properties that depend on local conditions, so that the texture, color and flavor of milk will depend not only on locality but also on the time of year and even on recent climatic conditions. Accordingly, cooks need to be aware that they will, from time to time, have to adapt recipes to allow for such variations.

3.4. Flavor Variation in Fruits and Vegetables

Of course, the flavor of plants depends on many factors, not the least of which is the actual variety of the species being grown. Perhaps the best example comes from the world of wine, where different grape varieties or grapes of the same variety grown in different places impart quite distinct flavor characteristics. It is perhaps less well understood that similar variations occur in more or less all fruits and vegetables. For example, in a study of 89 elderflower varieties Kaack et al.(82) have shown large variations in the concentration of flavor components between different elderflower varieties. Similar studies illustrate that the flavor of tomatoes depends strongly on the variety.(83) This means that it is essential to choose the right variety for the right purpose and that the variety can have a large impact on achieving the desired balance between fruity, spicy, floral, fresh, and sweet flavors.

In one particularly detailed study (of 28 Apricot varieties) Aubert and Chanforan(84) found they could divide the varieties into four groups according to their relative concentrations of 33 volatile components. Group I was characterized by a high content of terpenic compounds (which tend to give a citrus aroma), group II by a high proportion of lactones (coconut and peachy aroma), group III by a high content of esters (with their generally fruity notes) and a low content of terpenes, and group IV by a high proportion of esters.

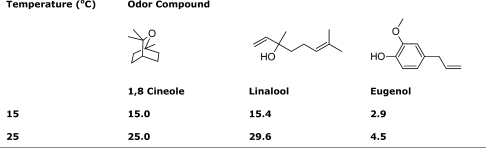

As well as the variety growth conditions, nutrients and minerals in the soil as well as temperature and general climatic conditions all affect the final flavor. For example, Chang et al.(85) have shown that the volatile oil content of basil differs according to the growth temperature. Plants grown at higher temperatures (25 °C rather than 15 °C) had significantly larger contents of volatile oils, eugenol, linalool, and 1,8-cineole, as illustrated in Table 1.

Table 1. Content of Selected Odor Components in Basil (ppm) As Influenced by Growth Temperaturea.

|

Eugenol contributes to the characteristic taste of basil. Adapted from Chang et al.(86)

How fruits and vegetables are treated after harvest also has a large impact on their eating quality. Tomatoes are often stored under reduced levels of oxygen at temperatures below ambient temperature. One study showed that storage at 6 °C or in low-oxygen atmosphere significantly decreased the concentration of several volatile components. In plain language, tomatoes lose their flavor under normal storage conditions.(87)

If stored at ambient temperature rather than being cooled, in the short term most of the volatile components increase in concentration during the 10 days postharvest period. This is however a double-edged sword as in sensory tests the tomatoes not only scored higher in tomato-like flavors (desired) but also in moldy flavors (undesired).(83) In a different study Boukobza and Taylor(87) also showed an increase in volatile components in tomatoes during storage at ambient temperature in an unaltered atmosphere.

Carrots also show quite significant changes in flavor on storage with quite different effects depending on the temperature at which they are stored. Refrigerated storage of carrots for up to 4 months increases the concentration of terpenoids significantly more than frozen storage. An increase in volatile terpenes gives a more “carrot-like” flavor up to a certain concentration, beyond which they cause an undesirable harsh and burning flavor.(88)

4. Food Processing (Cookery)

Of course, it is only with the preparation of the raw ingredients in the kitchen and then combining them and cooking them in the appropriate manner that the true quality of a plate of food is developed. All this can involve many separate processes; some develop flavor, others develop textures, and many affect both. This is the largest section of the review and is divided, largely, into processes that create and develop flavor and those that are more aimed at modifying and creating specific textures.

We have deliberately chosen to consider mainly the processes of small-scale (domestic and restaurant) cooking. However, we will not limit ourselves to processes that are currently used in a domestic environment. Already some techniques from the science laboratory are finding their way into restaurant kitchens; for example, the use of ultrasonic agitation to create emulsions, the use of liquid nitrogen to freeze without allowing the formation of large ice crystals, the use of well-controlled temperature baths for poaching, and the use of vacuum desiccators to remove water from potatoes before roasting; these techniques could soon arrive in our own domestic kitchens.

We begin by looking at how flavor is developed through chemical reactions that produce new volatile “aroma” molecules and then move on to look at how color and texture are developed in the kitchen and examine how the textures affect the flavor, for example, by modifying the rate or order of release of different aroma molecules in a given food.

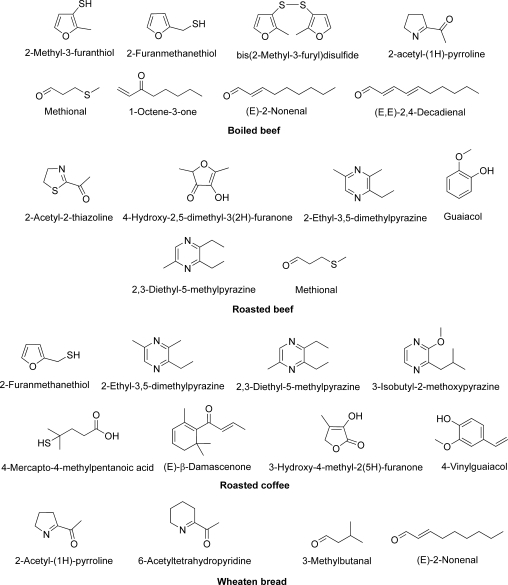

4.1. Flavor Development

To a food chemist, flavor is determined from an analysis of the aroma and nonvolatile molecules present in a foodstuff. It is possible to group volatile molecules by the sort of aromatic notes they provide (meat, fruit, bitter, nutty, etc.) and in some cases to be even more specific. Using aroma extract dilution analysis (AEDA) Grosch and co-workers succeeded in identifying key aroma impact compounds in a range of foods.(89) An example is given in Figure 2 for foods that have undergone a thermal treatment and in Figure 3 for nonheated foods.(89) Even though the TNO collection of volatile compounds in foods (VCF) reports over 10 400 entries,(90) only a very few of these compounds actually contribute to the key flavor notes in foods.

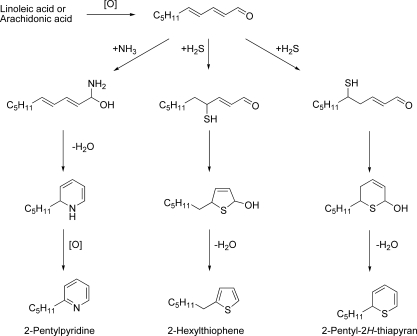

Figure 2.

Aroma impact compounds in heated foods as identified by the AEDA technique.(89)

Figure 3.

Aroma impact compounds in some nonheated foods as identified by the AEDA technique.(89)

Accordingly, much effort has gone into trying to understand the chemical reactions that produce these volatile aroma molecules. Table 2 puts together an example of some important low odor threshold odorants encountered in heated and typical foods. Chefs, by contrast, have an empirical understanding of flavor based on experience and an intuitive understanding of how flavor develops as the cooking progresses, backed up by the continual tasting of everything they prepare. The scientific approach has the advantage that it should be objective and can, in principle, provide instructions that give reasonably reproducible results despite the variability in ingredients. A major problem is that we do not have any way of scientifically describing the nuances of flavor, so the empirical approach of the cook, while it cannot, as yet, be quantified, generally leads to the better result.

Table 2. Some Examples of Odorants Found in Foods and Their Aromas from Data in Food Chemistry(91).

| chemical | aroma description | odor threshold (μg/L water) | some examples where it is found |

|---|---|---|---|

| Ethanal | sharp, fruity, sweet | 15 | Strecker reaction |

| Methyl propanal | malty | 0.7 | Strecker reaction |

| 2-Phenylethanal | honey | 4 | Strecker reaction |

| 4-Hydroxy-2,5 dimethylfuranone (furaneol) | heat-treated strawberries, pineapple | ca. 1 | beer, bread, pineapples, strawberries |

| 2-Acetylthiazole | popcorn | 10 | fried foods |

| 2-Isobutylthiazole | green tomatoes | 3 | fried foods |

| 2-Acetyl-(1H)-pyrroline | white bread crust | 0.1 | popcorn |

| 3-Ethyl-3-methylpyrazine | burnt flavor | 130 | roasted peanuts |

| 2-Isobutyl-3-methoxypyrazine | potatoes | 0.002 | potato products |

| 2-Isobutyl-3-methoxypyrazine | red peppers | 0.002 | paprika |

| 2-Ethyl-3,6-dimethylpyrazine | hazelnuts | 20 | glucose syrup |

| 2-Methoxy-4-vinylphenol | cloves | 5 | coffee, beer, asparagus |

| 4-Methoxy-2-methyl-2-butanethiol | blackcurrants | 0.000002 | olive oils |

However, cooks often tend slavishly to follow a known and practised route to achieve their desired goals, but with a little basic understanding of the key chemical reactions and the conditions under which they produce the different types of aroma molecules there is at least the possibility that the chef can try out and develop with success new ways to achieve his desired final flavor (and even perhaps discover along the way different flavors that might entice the diner).

4.1.1. Microbial Reactions

Microbial reactions due to yeasts and bacteria have been essential to the development of our whole cuisine. Historically the yeasts that cause alcoholic fermentations have been used to make some of the most important staples of our diet, especially breads, beers, and wines. The main reaction of the fermentation(92) process is to convert sugars, including short-chain carbohydrates, to yield carbon dioxide gas, which makes bread rise and gives beer its fizz, and ethanol, which adds flavor and preserves beers and wines as well as providing them with an active effect on the consumer. However, there are many additional side reactions that produce other volatile compounds.93–95 It is these compounds that impart the distinctive, and appealing, flavors to the various cheeses, breads, beers, and wines with which we have become familiar over the centuries.

Initially all these fermentation reactions were produced using wild yeasts carried in the air, on the skins of fruits, or on seed cases of the grains. Not only did this make the processes somewhat hit and miss, it also led to great variability in both the flavor and the quality of the resulting products. Today most manufacturers rely on cultured yeasts to provide consistent products. Those who have tried to make beer at home will almost certainly at some time have encountered the problem that some batches simply do not have the same flavor as others and occasionally are quite undrinkable. While some wild yeasts do make pleasant beers, it is generally best to stick to one of the specially cultured yeasts designed over the years to produced high-quality beers such as S. carlsbergensis.

There is another slightly different fermentation process that occurs when lactic acid bacteria (e.g., Oenococcus oeni) convert malic to lactic acid;(96) this is known as malolactic fermentation. In wine making the malolactic fermentation can be particularly advantageous since lactic acid has a softer, rounder taste than malic acid, which is perceived as rather “tart”. Thus, wines that have undergone malolactic conversion tend to appear softer, have a more rounded mouth feel and have a buttery note that comes from diacetyl produced during the malolactic fermentation.97,98 Conversely, since malic acid has the taste of apples, wines that have not been subject to malolactic conversion tend to have a green apple note.

Malolactic fermentation sometimes occurs unintentionally after the wine is bottled. The result is a slightly carbonated wine that usually tastes bad as the wild bacteria that can cause the malolactic fermentation produce a wide range of “off flavors”. Accordingly, many wine makers tend to inoculate their wines in the vats with a culture of desirable bacteria to avoid any risk of accidental malolactic fermentation in the bottle and thus prevent the possibility of any such off flavors occurring.

Of course, by far the largest application of bacteria that produce lactic acid is in the fermentation of dairy products to produce yogurts, soured creams, acidified milks, and of course cheeses. In general, the bacteria convert lactose in milk to lactic acid, thus decreasing the pH of the milk and causing it to aggregate. Different bacterial strains follow somewhat different routes and can produce a range of side products, including diacetyl (giving a buttery taste), acetaldehyde (characteristic of yogurts), as well as carbon dioxide and ethanol. Some Swiss cheeses owe their characteristic holes to the use of carbon dioxide producing bacteria.

As with the use of fermentation to produce breads, beers, and wines, much of the fermentation of dairy products relied initially on strains of wild bacteria which were generally cultivated in local and domestic production by the simple process of adding a little of the previous batch to the next one to be made (backslopping). Today, with the centralization of production of most dairy products many of these individual strains have been lost along with their unique flavors. This perhaps accounts for the increasing popularity of small “boutique” producers who continue to use more traditional methods and thus provide a range of different and distinctive flavors in their products.

The flavor of fermented dairy products comes from a wide variety of molecules which can be formed during reactions. However, in most of the fermentation processes a range of small oxo compounds are produced. For example, in butter production the difference between sweet butter and acidified butter is the presence of diacetyl resulting from fermentation.93,95,98 Sweet butters are often preferred for certain dishes due to the milder flavor. Another example is that yogurt often develops a rather tart flavor due to the production of acetaldehyde. This is often disguised in fruit yogurts by the addition of sugars, causing the sweet flavor to become dominant.

A similar process has occurred with a range of meat products. In Southern Europe sausages were often fermented with added spices and then air dried to yield specific flavors and good long-term storage properties. In Northern Europe smoke was more often used to dry the sausages giving other flavors while also imparting excellent preservative characteristics. In the intermediate regions such as Hungary fermented sausages were matured for longer times at lower temperatures and covered by molds to help preserve them. Once again, modern centralized production is inevitably leading to the loss of some of the bacterial strains used in these traditional processes and with that the potential loss of some unique flavors.

4.1.2. Chemical Reactions Affecting Flavor

While raw ingredients carry with them a vast array of naturally occurring flavors, think of fragrant strawberries, sweet carrots, mildly acidic apples, and sharp limes, many of our most favored flavors today actually do not occur directly in nature but are created through chemical reactions within and between the food ingredients after harvesting. Without chemistry there would be no chocolate, no coffee, and no “meaty” flavors. There are so many different chemical reactions that go into generating these flavors, and they differ subtly in every kitchen with slightly different ingredients, temperatures, and tools, making it quite impossible to list them all.

Instead, in this section we will simply attempt to extract from the vast literature some of the more salient issues of flavor development from the wide variety of chemical reactions that occur as we prepare our foods. Some of these occur before we start any cooking; they happen either in the mouth as enzymes in saliva react with molecules in the raw ingredients or when the raw ingredients are cut open, bringing enzymes into contact with the substrates upon which they can act. We briefly discuss such reactions in the first part of this section.

In the remainder of the section we briefly review a range of different types of chemical reactions that break larger molecules into small volatile compounds that can (and do) greatly affect the flavor of our foods when we process them further (usually under the influence of heat). These include hydrolysis, oxidation, and the Maillard and caramelization reactions, each of which is discussed separately even though in real cookery all can (and do) occur simultaneously.

4.1.2.1. Physical Processing. The first stage of processing of most fresh ingredients involves cutting or otherwise breaking them into smaller pieces. In many cases the very fact of fracturing the cell walls leads immediately to the release of enzymes and the start of enzymatic reactions that alter the flavor.

In many plants enzymes are separated from their substrate so as to avoid reactions occurring when the plant is growing. However, when the cellular structure is destroyed by, for example, cutting or grinding by the cook or chewing by the diner they come into contact and flavor-producing reactions may occur.

The pungent taste of several plants in the Cruciferae (Brassicaceae) family, including, for example, mustard, horseradish, and wasabi, occurs via breakdown products from glucosinolates. The glucosinolates are hydrolyzed to isothiocyanates when the enzyme myrosinase (thioglucoside glucohydrolase) is released due to plant tissue being mechanically disrupted or injured by, for example, chewing/crushing/grating.99–103

A similar process in Allium species such as onions, leek, and garlic provides the characteristic flavor formed when plant tissue is disrupted, releasing alliinase. The enzyme released in this process breaks down odorless sulfur-containing amino acids (S-alk(en)-yl-l-cysteines) and their sulfoxides. These are cleaved to yield pyruvate, ammonia, and sulfur-containing volatiles (Figure 4), giving the characteristic pungency and lachrymatory effect.104–109

Figure 4.

Formation of potent sulfur-containing compounds in Allium species.(110)

It is important to note that thermal processing of the vegetables denatures the enzymes responsible for these reactions;102,111 hence, preparing, for example, onions and garlic whole in the oven gives a much milder and rather different flavor since the enzyme will never become active. The alliinase can be inactivated irreversibly at low pH (below 3), preventing these reactions to occur. Thus, acid marinating directly after cutting and crushing would result in similar mild flavors.

4.1.2.2. Hydrolysis. Many of the nutritionally important molecules in our food are large polymers, e.g., starches and proteins; these are neither particularly soluble or volatile and so have little if any perceivable taste or aroma. We can only detect their presence in foods though the textures they create and not by any specific taste. However, when degraded into smaller molecules they generate a wide range of tastants and aromatics that we can and do enjoy in the taste and smell of our foods. While there are several different routes through which such degradation can occur, hydrolysis is probably the most important of these and the subject of this section.

The three macronutrients carbohydrate, proteins, and lipids are all able to react with water so that the macromolecules are degraded into smaller pieces which are likely to possess aroma or flavor (which may be pleasant or in some cases unpleasant). Carbohydrates are polymers in which the monomers (sugars) are linked together by glycosidic bonds, which may hydrolyze as a result of acid catalysis or via enzymatic reactions. For example, malting, the initial stage in brewing beer, is an enzymatic hydrolysis of starch which produces smaller carbohydrates, making them available for the yeast to convert to alcohol and carbon dioxide. The sweet taste of malted bread is similarly produced from the small carbohydrates or oligosaccharides produced by hydrolysis.

Proteins may, in addition to the enzymatic and acid-catalyzed hydrolysis seen in carbohydrates, also hydrolyze via base catalysis since the amino acids are linked together by amide bonds. For example, proteins can be hydrolyzed during the ripening of cheese or boiling of meats. In this process shorter peptides are formed which eventually can be cleaved to individual amino acids. In general, the more hydrophobic amino acids taste bitter,(112) while the more hydrophilic amino acids have a neutral or sweet taste.112,113 Thus, peptides with specific combinations of hydrophobic amino acids can be extremely bitter and may ruin the flavor of cheeses if formed in significant quantities. The amino acid glutamic acid (and small peptides with glutamic acid) are often formed during cooking of meat, in soups, and in savory cheeses. These are particularly important as they excite the umami taste sensation, giving these foods their characteristic rounded flavors. Most foodstuffs are either acidic or neutral, so base catalysis is relatively uncommon. However, in fish treated with lime or other alkaline substances (as is traditional in some Scandinavian and Asian countries) hydrolysis through base catalysis plays a significant role in flavor development.

Lipolytic enzymes can hydrolytically cleave the lipids to form free fatty acids; these reactions are particularly important when considering rancidity in oils and fats. For example, olive oil is produced from fruit pulp which has a high lipid content; these lipids are easily hydrolyzed by enzymes so that the oil can contain significant quantities of free fatty acids.(114) A high content of free fatty acids in an oil lowers its thermal stability during frying which may impair its flavor. Similarly, butter may go rancid due to lipid hydrolysis of butterfat to produce short-chained fatty acids such as butyric acid, ruining the flavor.

In some sausages lipid hydrolysis during fermentation and ripening actually provides a more soapy flavor, which is not necessarily negative for the overall flavor.(115) Partially hydrolyzed lipids are surface active and find use as emulsifiers, for example, in bread to reduce staling and starch crystallization.

Mold ripening of cheese yields very complex flavors. The initial ripening occurs through protein hydrolysis and is followed by lipolysis, while for blue cheeses like Danablue and Roquefort free fatty acids make significant contributions to the flavor.

4.1.2.3. Oxidation. A second process that can degrade food molecules is oxidation. Unlike hydrolysis, in nearly all cases oxidation leads to flavors that are not desirable, so we normally strive to reduce or avoid oxidation during storage and processing of fresh ingredients.

Oxidation of foods may be initiated enzymatically, for example, in vegetables post harvest, by catalysis by transition-metal ions, which can occur, for example, when using copper pans for frying, or by exposure to light, as happens with green plant oils. Most food components are vulnerable to oxidation, and oxidation may change their flavor, color, and nutritive value. In the kitchen we are familiar with oxidation especially in relation to lipids; vegetable oils and lard may go rancid during storage, while pork and poultry often develop a so-called “warmed-over flavor”(116) upon reheating. Among the lipids, the degree of unsaturation is crucial. Oils and fats from fish are extremely sensitive to oxidation, while animal fats from ruminants are less sensitive; lard and plant oils have intermediate sensitivity. The propensity to oxidation depends on the degree of unsaturation of the lipids and on the level and nature of any antioxidants present. A convenient illustration can be seen in the best choice of various plant oils for cooking. Heavily unsaturated oils such as pumpkin oil and walnut oil oxidize easily on heating and should never be used for frying, while they are perfect for dressings with their mild and unique taste. More saturated oils such as palm oil, rapeseed oil (canola), and olive oil are almost perfect for frying having high monounsaturated content, while grape-seed oil and soy oil should be used with care due to the increasing amounts of polyunsaturated fatty acids present in the lipids. Olive oil adds a unique flavor to fried vegetables or meat, while canola oil is more neutral and accordingly preferred by some.

The reuse of oil for frying, as is often the case in deep frying, can generate new flavors that are characteristic of the specific oil used; often these flavors can be unpleasant and are classed as “off flavors”. Fatty acids belonging to the Ω-9 family such as oleic acid have the major oxidation product nonanal, while hexanal dominates the oxidation of the Ω-6 fatty acids and propanal the Ω-3 fatty acids. Hexanal has been found to be an important compound in warmed-over flavor.116,117

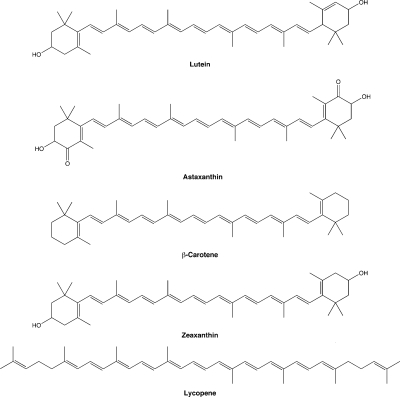

Another important aspect of oxidation of foods in the kitchen is the oxidative polymerization of polyphenoles which causes the enzymatic browning in avocados and apples. Control of enzymatic browning is also important for producing tea. Green teas are obtained by deactivating polyphenoloxidases by heating freshly picked leaves, black teas get their color from polyphenoloxidase activity, while oolong teas obtain their light brown color by strictly controlled heat deactivation of the enzymes. Notably, co-oxidation of carotenoides in the tea leaves is crucial for the development of the flowery notes characteristics for the fermented tea.

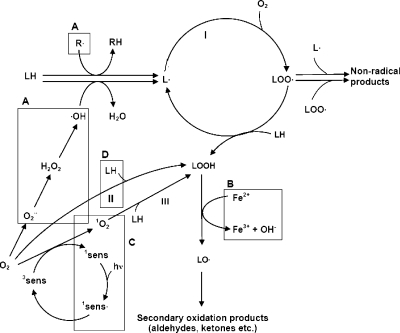

4.1.2.4. Lipid Oxidation and Antioxidants. Lipid oxidation is a chain reaction with free radicals as reactive intermediates.(118) Lipid oxidation depends on oxygen activation or attack by free radicals on the lipids, leading to formation of lipid hydroperoxides without flavor as the primary oxidative products as illustrated in Figure 5. Oxygen activation by metal-ion catalysis may produce the hydroxyl radical capable of initiating the chain reaction (A in Figure 5). Lipoxygenase (D in Figure 5) results in direct formation of the lipid hydroperoxides, and also photosensitization by chlorophylls and other pigments (C in Figure 5) is important. Secondary lipid oxidation products are formed by cleavage of the hydroperoxides to form aldehydes and ketones with low sensory threshold values.

Figure 5.

Lipid oxidation may be initiated by free radicals or enzymatically (A), by transition metal catalysis (B), photochemically (C), or by lipoxygenases (D).

Metal catalysis cleavage of the hydroperoxides may be due to the redox activity of heme pigments. The traditional use of thyme to spice blood sausages in traditional Nordic cooking is an example of the beneficial effect of a natural antioxidant. Thyme prevents any oxidized flavor as phenolic compounds such as thymol and carvacrol present in thyme provide antioxidant protection. Phenolic antioxidants, to which class vitamin E, α-tocopherol, also belongs, are chain breaking as they donate a hydrogen atom to the lipid radical in the reaction marked by A in Figure 5. Another example of a traditional source of natural antioxidants is rosemary; many traditional dishes spiced with rosemary are inherently protected against warmed-over flavor by the phenols from rosemary.(119)

Interestingly, the lipoxygenase enzymes can be active even at the low temperature of frozen storage.(120) This is the reason why blanching of vegetables prior to frozen storage to inhibit such lipid oxidation being initiated by lipoxygenase is important (D in Figure 5).

Carotenoids which are present together with the chlorophylls in the photosynthetic apparatus in plant cells yield protection against photo-oxidation(121) (C in Figure 5). Photo-oxidation is a comparatively slow process and seldom a problem in the kitchen. However, changes due to photo-oxidation will occur in some foods when stored in the light. For example, virgin olive oil and other green vegetable oils should never be stored in light as they will slowly oxidize. Thus, even though a bottle of olive oil in the kitchen window can be very decorative it is not a good idea as the oil will slowly deteriorate.

A third antioxidative mechanism depends on the complexation of pro-oxidative metals by flavonoides(122) (B in Figure 5). Onions, which are rich in quercetin, may be active by this mechanism when added to high-fat fresh sausages and pâtés. Green tea rich in catechin holds the potential for a similar use in other dishes.123,124

The quality of raw material is important for the oxidative stability. For nonruminants the feeding regime is crucial. A large supply of unsaturated lipids in the feed increases the risk of oxidation in the meat, while a rich supply of antioxidants from herbs or other sources such as acorns yields protection. On the Iberian Peninsula pigs for the highly praised dry cured hams finish their lives roaming in the cork oak grooves feeding on acorns rich in antioxidants. Lipid oxidation in such products is characterized by a lag phase, the duration of which depends on the feeding regime. As long as the antioxidants are available at a sufficient level, the lipids are protected, while when they are depleted, oxidation wins and the meat can become rancid very rapidly.

4.1.2.5. Maillard, Strecker, and Caramelization Reactions. We all know from experience that flavor develops when we cook (heat) our food. Thus, the most important reactions, from the perspective of flavor development, are those that are thermally activated. Among these, the Maillard, Strecker, and caramelization reactions are largely responsible not only for the characteristic flavors of cooked meats; but also for the flavors of chocolate and coffee as well the caramel flavors of cooked sugars in sweets and on the crust of freshly baked breads, etc. All of these flavors are produced in chemical reactions and as such are not natural, although most people would regard these flavors as completely natural while considering some extracted essential flavors (from, for example, citrus fruits) which may be added back into food products as artificial. It will be one of the challenges of Molecular Gastronomy to educate people (domestic cooks, chefs, and the wider public) to understand better how flavors arise and appreciate the very subtle differences between so-called “natural” and “synthetic” products.

When foods are heated, reducing sugars and other carbonyl compounds together with amino acids (or other amines including peptides and proteins) undergo a complex network of reactions that produce both volatile and higher molecular weight compounds including colored pigments and heterogeneous polymers. The formation of brown products on heating aqueous mixtures of amino acids and sugars was first described by Louis Maillard in 1912. Since then, Maillard reactions have been subject to many studies in foods and model systems. Maillard and related reactions are complex and difficult to understand fully or predict. However, we do now have a fairly detailed understanding of the reaction pathways involved as well as the role of the reaction products in flavor, browning, and nutrition. Further, the antioxidative, toxicological, and antimutagenic properties of many of the products of these reactions are now reasonably well documented.(125)

Of course, most foods are complex systems with many components that can react when heated. Accordingly, the Maillard reaction often occurs in parallel with other reactions such as the Strecker reactions and caramelization of sugars. Maillard reactions have also been implicated with thermal degradation of lipids, leading to the lack of the desirable flavor generation by producing heterocyclic compounds with aliphatic side chains.(126)

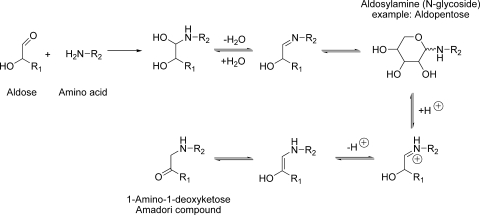

4.1.2.5.1. Principal Mechanisms of Maillard and Associated Reactions. The Maillard reaction has been divided into three stages, consisting of the condensation of an amine with a reducing sugar, to produce an N-substituted glycosylamine. The subsequent Amadori (for aldoses) or Heyns (for ketoses) rearrangement then produces isomeric compounds. These unstable compounds give neither browning nor aroma but serve as important precursors for subsequent reactions (Figure 6). The second stage involves the enolization of the Amadori and Heyns products and elimination of the amino compound under formation of 1-deoxyosones or 3-deoxyosones. These compounds subsequently undergo dehydration and fragmentation reactions when sufficient heat is provided.

Figure 6.

Initial phase of the Maillard reaction showing the formation of Amadori compounds.

The Amadori product can be broken down by either of two pathways. The 1,2-enolization is promoted by protonization of the N atom in the Amadori compound, which is favored under acidic conditions and leads to formation of a 3-deoxyosone. In a more alkaline environment, protonization of the Amadori compound is less effective and, thereby, indirectly stimulates the 2,3-enolization.127,128 Alkaline conditions thus favor the formation of hydroxyfuranones via the 2,3-enolization and formation of a 1-deoxyosone (Figure 7).

Figure 7.

Enolization of the Amadori compounds under different pH conditions.

In the dehydration of the deoxyosones, furfurals and/or furanones are formed. Furthermore, the fission of deoxyosones, e.g., by retro-aldolization, may produce a range of carbonyl compounds such as acetaldehyde, 2-oxopropanal, hydroxypropanone, and butanedione.(128) An example of the degradation of the deoxypentosonone is given in Figure 8. It is at this stage of the Maillard reaction that many different flavor compounds develop in a network of competing reactions.

Figure 8.