Abstract

K4CuNb8O23 doped K0.45Na0.55NbO3 (KNN-KCN) ferroelectric ceramics were found to exhibit asymmetrical polarization hysteresis loops, related to the development of an internal bias field. The internal bias field is believed to be the result of defect dipoles of acceptor ions and oxygen vacancies, which lead to piezoelectric “hardening” effect, by stabilizing and pinning of the domain wall motion. The dielectric loss for the hard lead-free piezoelectric ceramic was found to be 0.6%, with mechanical quality factors Q on the order of >1500. Furthermore, the piezoelectric properties were found to decrease and the coercive field increased, when compared with the undoped material, exhibiting a typical characteristic of “hard” behavior. The temperature usage range was limited by the polymorphic phase transition temperature, being 188°C. The full set of material constants was determined for the KNN-KCN materials. Compared with conventional hard PZT ceramics, the lead-free possessed lower dielectric and piezoelectric properties; however, comparable values of mechanical Q, dielectric loss, and coercive fields were obtained, making acceptor modified KNN based lead-free piezoelectric material promising for high-power applications, where lead-free materials are desirable.

I. Introduction

Ferroelectric ceramics for high-power applications, such as ultrasonic motors, transformers, and high intensity focused ultrasound (HIFU), demand piezoelectrics with high mechanical quality factors (low mechanical loss) and low dielectric loss to deliver high acoustic power without excessive heat generation and/or thermal runaway. In general, to achieve the “hardening” effect, these materials are acceptor doped, e.g., with Fe3+,2+, Mn3+,2+ substitution onto Zr4+/Ti4+ sites, resulting in the development of acceptor-oxygen vacancy defect dipoles. These dipoles align parallel to the polarization direction, leading to an internal bias, as evident in a horizontal offset in the polarization-electric field (P-E) behavior. This offset effectively increases the coercive field (EC) and reduces or clamps domain wall motion/mobility [1]–[6].

Hard PZT ferroelectric materials, including PZT4 and PZT8 (DOD type I and III) [7], have been the mainstay for high-power applications. However, because of the toxicity of lead oxide in PZT ceramics, it is desirable to develop lead-free piezoelectric ceramics with comparable performance to replace lead-based materials. Recently, high d33 (~300 pC/N) piezoelectrics were reported to be achieved from alkaline niobate-based perovskite materials in the KxNa1−xNbO3 (KNN) family [8]–[18], which exhibit “soft” behavior with high dielectric loss, related to the orthorhombic to tetragonal polymorphic phase transition (PPT) compositionally engineered to near room temperature [13]–[15]. In addition to these “soft” KNN-based materials, many researchers have been focusing on “hard” characteristics of KNN based materials, modified by K5.4Cu1.3Ta10O29, K4CuNb8O23, or CuO [19]–[23], with piezoelectric coefficients d33 on the order of <100 pC/N and mechanical quality factors Q ~1000. To further study the theoretical and practical applications of hard lead-free piezoelectric materials, it is desirable to have a full set of material constants, including elastic constants, electromechanical coupling factors, piezoelectric coefficients, and dielectric permittivity, and also understand the temperature-dependent piezoelectric behavior.

In this work, high field ferroelectric behavior and temperature dependence of the dielectric and piezoelectric properties were investigated for hard lead-free ceramics, with the full set of material constants determined according to the IEEE piezoelectric standard [24], [25]. The properties were compared with commercial hard PZT4 and PZT8 ceramics.

II. Experimental

K4CuNb8O23 (KCN) (0.5 mol%) acceptor modified orthorhombic K0.45Na0.55NbO3 (KNN) was selected in this study. Raw materials were weighed according to the nominal compositions, vibration milled in anhydrous ethanol for 24 h, dried, and subsequently calcined at 850°C for 2 h. The acceptor dopant KCN was mixed into the calcined powder, subsequently granulated and pressed into pellets and sintered at 1100 to 1160°C for 2 h. The phase purity was examined by x-ray powder diffraction performed on ground sintered ceramics. The density of the pellets was found to be 4.4 g/cm3 by the Archimedes method for KCN modified KNN, more than 95% of the theoretical. The ceramic disks were polished with a diameter and thickness ratio greater than 20. Fire-on silver paste was applied on the samples as the electrode. The samples were poled at 60 kV/cm and room temperature for 5 min and aged for 24 h before the measurements. The full set of material constants were determined according to the IEEE standard [24] by the resonance and antiresonance frequencies, which were measured using an HP4194A impedance/gain-phase analyzer (Agilent, Santa Clara, CA). The dielectric permittivity and dielectric loss were determined using a multifrequency LCR meter (HP4284A Agilent, Santa Clara, CA) as a function of temperature in a temperature-controlled furnace. High field measurements including polarization hysteresis (P-E) and strain-electric field curves (x-E) were measured at 1 Hz frequency and 40 kV/cm electric fields using a modified Sawyer-Tower circuit and linear variable differential transducer (LVDT), driven by a lock-in amplifier (Model SR 830, Stanford Research Systems, Sunnyvale, CA). The temperature dependence of electromechanical coupling factors were performed on disk samples using an impedance analyzer connected to a high temperature furnace.

III. Results and Discussion

A. Ferroelectric Properties under High Electric Field

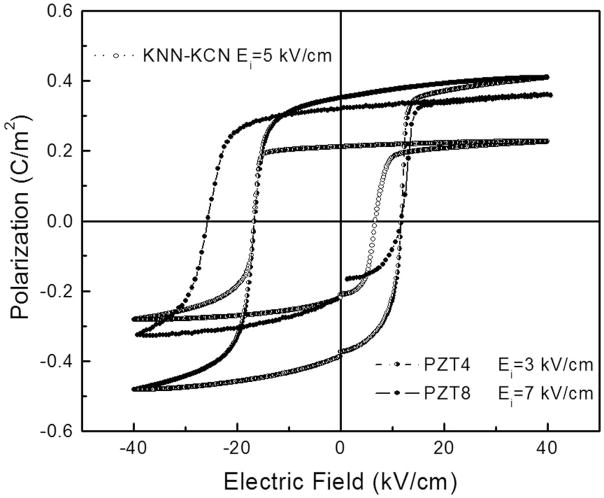

Fig. 1 gives the polarization hysteresis (P-E), measured at a field of 40 kV/cm and frequency of 1 Hz for aged (~one day) KNN-KCN and compared to conventional hard PZT, showing asymmetric loops. This horizontal off-set of the P-E loops is the result of building up of the internal bias field Ei and believed to play an important role in the properties of ceramics [2]–[5]. The mechanisms responsible for the occurrence of an internal bias in the lead-free ferroelectrics are based on the stabilization of domain wall movement. In KCN-modified KNN material, the Cu2+ acceptor ions are incorporated into the Nb5+ site, due to their similar ionic radius. Thus, oxygen vacancies are introduced due to valence compensation. The acceptor-oxygen vacancy defect dipoles can occupy energetically preferred sites in the lattice and then form anisotropic centers locally or within a domain, preferentially align themselves along the spontaneous polarization, or diffuse into the high-stressed areas of domain walls, experimentally revealed as an internal bias field, stabilizing the polarization, pinning, and/or clamping the domain wall motion [2]. Furthermore, it is reported that KCN/CuO additives in KNN materials also act as a sintering aid, which will generate a liquid phase at the sintering temperature, leading to a grain boundary phase and subsequent build-up of space charge at the grain boundaries. The resulting space charge field is equivalent to an internal bias field that impresses an overall preferred direction of polarization on each crystallite, locking in the ferroelectric domains, as also reported in hard PZT [2].

Fig. 1.

Polarization hysteresis for hard lead-free KNN-KCN, compared with commercial PZT, showing the internal bias field on the order of 5 kV/cm.

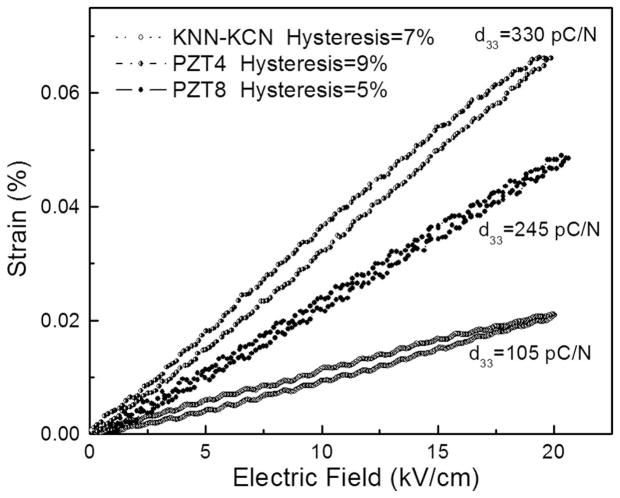

Fig. 2 presents the unipolar strain as a function of the electric field (x-E) for the lead-free KNN-KCN and compares it to hard PZTs. The strain hysteresis, which is related to the piezoelectric loss, can be obtained from the ratio of the widest part of the x-E loop over the maximum strain level. The hysteresis levels are found to be lower than 10% for all the hard ceramics, due to the pinning/clamping of ferroelastic non-180° domain wall motion.

Fig. 2.

Strain hysteresis for hard lead-free KNN-KCN and compared with commercial PZT.

B. Characteristic Properties of Lead-Free Materials Compared with Hard PZT

Table I lists the characteristic properties of hard lead-free KNN-KCN, compared to undoped KNN material and commercial hard PZTs. Compared to undoped KNN material, the KNN-KCN is found to possess lower dielectric permittivities and piezoelectric coefficients, while exhibiting increased mechanical quality factors and lower dielectric loss, indicative of a “hardening” effect. Meanwhile, the coercive fields are found to increase and the remnant polarization decrease and hence the degree of “switchable” polarization is significantly reduced due to domain wall pinning. Of particular interest is the level of the internal bias field for KNN-KCN, while no internal bias is observed for the undoped samples, demonstrating that the acceptor-oxygen vacancy defect dipoles give rise to an internal bias, which leads to domain wall stabilization and thus the “hardening” effect. Compared to conventional hard PZT ceramics, the internal bias field level is found to be on the order of 5 kV/cm, between that of the hard PZT4 (~3 kV/cm) and very hard PZT8 (~7 kV/cm), with higher mechanical quality factors (Q ~1500). The acoustic velocity of KNN based material is found to be higher than PZTs, while the acoustic impedance is decreased, owing to the low density of lead-free materials.

TABLE I.

Characteristic Properties of KNN-Lead-Free Piezoelectric Ceramics, Compared with Commercial, Hard PZTs.

| Material | TC (°C) | TO-T/Td (°C) | loss | Pr (C/m2) | EC (kV/cm) | Ei (kV/cm) | d33 (pC/N) | k33 | Q | ρ(g/cm3) | v3D (m/s) | Z (MRayl) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KNN-KCN | 410 | 188 | 292 | 0.6% | 0.21 | 11.6 | 5 | 90 | 0.55 | 1500 | 4.4 | 6250 | 27.5 | |

| KNN (HP)14 | 420 | 195 | 496 | 1.5% | 0.33 | 5.0 | — | 127 | 0.61 | 240 | 4.4 | 6930 | 30.5 | |

| PZT4 | 328 | — | 1300 | 0.4% | 0.36 | 14.2 | 3 | 289 | 0.70 | 500 | 7.6 | 4570 | 34.7 | |

| PZT8 | 300 | — | 1000 | 0.4% | 0.27 | 19.0 | 7 | 225 | 0.64 | 1000 | 7.6 | 4600 | 35.0 |

C. Dielectric Properties as Function of Temperature

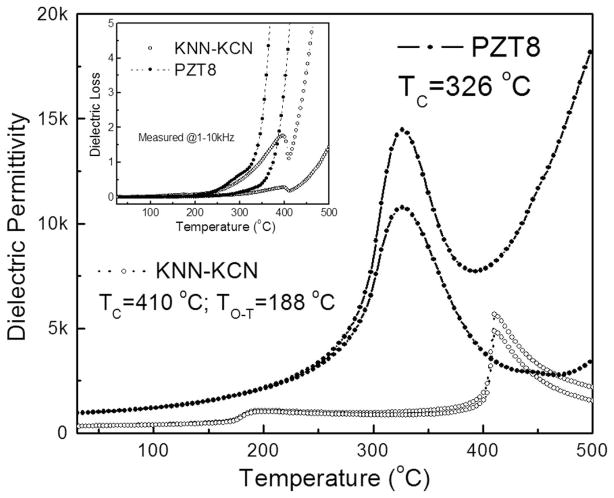

Fig. 3 shows the dielectric permittivity as a function of temperature for KNN-KCN, as compared with a PZT8. The dielectric permittivity is found to be 290 at room temperature for KNN-KCN ceramic, with the Curie temperature on the order of 410°C, higher than the Curie temperature of the PZT. However, a dielectric anomaly exists in KNN-KCN before its Curie temperature, located at a temperature of 188°C, believed to be related to the orthorhombic to tetragonal polymorphic phase transition. The small insert of Fig. 1 shows the dielectric loss as a function of temperature, where the dielectric loss is found to be 0.6% at room temperature, while the dielectric loss increases drastically above the Curie temperature, due to the ionic conduction at elevated temperatures.

Fig. 3.

Dielectric permittivity as a function of temperature for hard lead-free KNN-KCN, compared with commercial hard PZT8 (small insert shows the dielectric loss behavior).

D. Piezoelectric Properties as a Function of Temperature

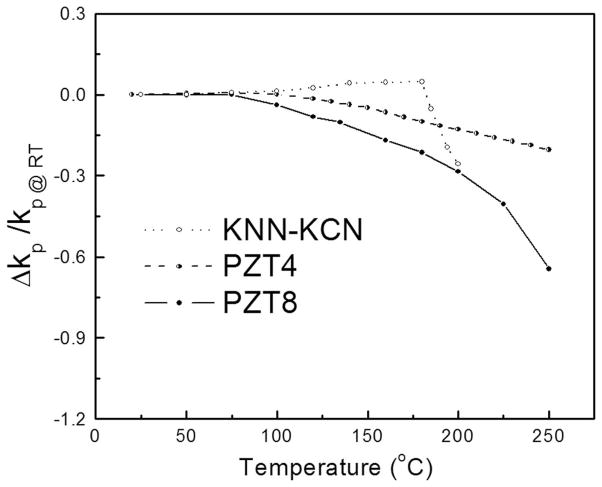

The maximum operating temperature for smart structures is generally limited by piezoelectric materials, so piezoelectric materials with broad temperature usage range are desirable. Generally speaking, the usage temperature range of ferroelectric ceramics is limited to less than half of their respective Curie temperatures due to the reduction of the piezoelectric activity, caused by aging effects [26]. For KNN-based ceramic, it is reported that an orthorhombic to tetragonal polymorphic phase transition exists before its Curie temperature, above which the property is found to be greatly deteriorated [9]. Fig. 4 shows the planar electromechanical coupling factor variation as a function of temperature for KNN-KCN ceramics and compares to hard PZTs. It is found that the planar electromechanical coupling kp increases till 180°C, above which the properties sharply decrease for KNN-KCN material, related to the orthorhombic to tetragonal phase transformation, while for hard PZT4 and PZT8 ceramics, the properties are found to decrease gradually. Of particular interest is the property degradation observed for PZT-based ceramic in the thermal cycle experiments; however, no degradations occur for KNN-KCN before the TO-T.

Fig. 4.

Variation of the planar electromechanical coupling factor as a function of temperature for hard lead-free KNN-KCN and compared with commercial PZT.

IV. Summary

In summary, acceptor-modified KNN lead-free piezoelectrics are prepared by conventional solid-state reaction and characterized. The full set of material constants of lead-free materials, including elastic constants, piezoelectric coefficients, electromechanical coupling factors, and dielectric permittivity, are determined and listed in Tables II, III, and IV and compared with the values of “hard” PZT ceramics. The elastic compliance constants of KNN-KCN are found to be lower than the values of PZT-based hard ceramics, with higher elastic stiffness constants. The piezoelectric strain coefficients dij and piezoelectric stress coefficients eij are found to be decreased when compared with the hard PZT materials, while the piezoelectric voltage coefficients gij and piezoelectric stiffness coefficients hij are increased, due to its low dielectric permittivity, being on the order of ~290.

Table II.

Elastic Compliance sij (10−12 m2/N) and Elastic Stiffness cij (1010 N/m2) Constants for KNN-KCN Ceramic and Compared with Hard PZTs.

| Material | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KNN-KCN | 8.6 | −2.6 | −2.1 | 9.3 | 22.0 | 22.3 | 8.2 | −3.0 | −1.0 | 6.4 | 17.5 | 22.3 | ||||||||||||

| PZT4 | 12.3 | −4.1 | −5.2 | 15.5 | 39.0 | 32.7 | 10.9 | −5.4 | −2.1 | 7.9 | 19.3 | 32.7 | ||||||||||||

| PZT8 | 11.5 | −3.4 | −4.8 | 13.5 | 31.9 | 29.8 | 10.4 | −4.4 | −2.3 | 8.0 | 22.6 | 29.8 | ||||||||||||

| Material |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

| KNN-KCN | 14.6 | 5.6 | 4.7 | 12.9 | 4.6 | 4.5 | 14.8 | 5.9 | 3.6 | 17.2 | 5.7 | 4.5 | ||||||||||||

| PZT4 | 13.9 | 7.6 | 7.1 | 11.5 | 2.6 | 3.1 | 14.5 | 8.0 | 5.7 | 15.9 | 5.2 | 3.1 | ||||||||||||

| PZT8 | 13.7 | 7.2 | 7.5 | 12.3 | 3.1 | 3.4 | 14.0 | 7.5 | 6.4 | 16.1 | 4.4 | 3.4 | ||||||||||||

Table III.

Piezoelectric Coefficients, dij (pC/N), eij (C/m2), gij (10−3 Vm/N), hij (108 V/m), dh (pC/N), Electromechanical Coupling Factors kij of KNN-KCN, Compared with Hard PZT.

| Material | d33 | d31 | d15 | e33 | e31 | e15 |

|---|---|---|---|---|---|---|

| KNN-KCN | 90 | −32 | 125 | 8.4 | −2.2 | 5.7 |

| PZT4 | 289 | −126 | 496 | 15.1 | −5.2 | 12.7 |

| PZT8 | 225 | −97 | 330 | 13.2 | −4.0 | 10.4 |

| Material | g33 | g31 | g15 | h33 | h31 | h15 |

| KNN-KCN | 34.9 | −12.3 | 35.7 | 50.1 | −13.2 | 20.7 |

| PZT4 | 25.1 | −10.7 | 38.0 | 26.9 | −9.3 | 19.7 |

| PZT8 | 25.4 | −10.9 | 29.0 | 25.7 | −7.8 | 13.1 |

| Material | k33 | k31 | k15 | kt | kp | dh |

| KNN-KCN | 0.55 | 0.21 | 0.45 | 0.50 | 0.36 | 26 |

| PZT4 | 0.70 | 0.33 | 0.71 | 0.51 | 0.58 | 37 |

| PZT8 | 0.64 | 0.30 | 0.55 | 0.48 | 0.51 | 31 |

Table IV.

Dielectric Permittivity, εij (ε0), and Dielectric Impermeability Constants, β (10−4/ε0), for KNN-KCN and Compared with Hard PZT.

| Material | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KNN-KCN | 292 | 395 | 190 | 310 | 34.2 | 25.3 | 52.6 | 32.3 | ||||||||

| PZT4 | 1300 | 1475 | 635 | 730 | 7.7 | 6.8 | 15.8 | 13.7 | ||||||||

| PZT8 | 1000 | 1290 | 580 | 900 | 10.0 | 7.8 | 17.2 | 11.1 |

For KNN-KCN, dense samples are obtained since KCN/CuO acts as a sintering aid in KNN material; meanwhile, the valence of the acceptor ions are assumed to be 2+ and substitute onto the Nb5+ site due to the similar ion radius, generating dipole defects, leading to the development of an internal bias field of ~5 kV/cm, clamping the domain wall movement, playing a “hardening” effect, with associated characteristics of a “hard” effect: Q ~1500, loss ~0.6%, and EC ~12 kV/cm. The TC and TO-T are found to be slightly shifted downward when compared with the pure KNN, being on the order of 410 and 188°C, with stable dielectric and piezoelectric behaviors before TO-T. The temperature usage range of KNN-based ceramics is limited by TO-T, unlike PZT, which is limited to resistivity and aging effects, usually 1/2TC. Compared with conventional “hard” PZTs, the KNN-KCN materials possesses lower dielectric and piezoelectric properties; however, they exhibit improved “hard” characteristics, higher acoustic velocity, and lower acoustic impedance, demonstrating that acceptor-doped lead-free ferroelectrics are promising candidates to replace PZT-based hard materials in high-power applications.

Acknowledgments

This work was supported by the ONR and NIH under No. P41-RR11795.

Biographies

Shujun Zhang received the Ph.D. degree from The State Key Lab. of Crystal Materials, Shan-dong University, China, in 2000. He is currently a Research Associate at Material Research Institute and Assistant Professor in the Materials Science and Engineering Department of The Pennsylvania State University, University Park.

Shujun Zhang received the Ph.D. degree from The State Key Lab. of Crystal Materials, Shan-dong University, China, in 2000. He is currently a Research Associate at Material Research Institute and Assistant Professor in the Materials Science and Engineering Department of The Pennsylvania State University, University Park.

Dr. Zhang’s research interests are growth and characterization of single crystals, including nonlinear optical, laser, piezoelectric, and ferroelectric materials. He is now focusing on the structure-property-performance relationship of high-temperature, high-power, and high-performance piezoelectric crystals and ceramics, for sensor and transducer applications.

Jong Bong Lim was born in South Korea and received his M.S. and Ph.D. degrees in materials science and engineering from Korea University, South Korea. He is currently working as a postdoctoral researcher at the Materials Research Institute of The Pennsylvania State University, University Park.

Jong Bong Lim was born in South Korea and received his M.S. and Ph.D. degrees in materials science and engineering from Korea University, South Korea. He is currently working as a postdoctoral researcher at the Materials Research Institute of The Pennsylvania State University, University Park.

Dr. Lim’s research interests are in the field of dielectric ceramics, especially LTCC materials and dielectric thin films for MIM capacitors. He is also interested in the growth and characterization of single crystals, including piezoelectric and ferroelectric crystals. His current research focuses on high-temperature, high-performance piezoelectric crystals and ceramics, including lead-free materials.

Hyeong Jae Lee was born in South Korea and received his B.S. degree in electronics and photonics from The Pennsylvania State University in 2007. He is currently working as an M.S. student at the Material Research Institute of The Pennsylvania State University, University Park.

Hyeong Jae Lee was born in South Korea and received his B.S. degree in electronics and photonics from The Pennsylvania State University in 2007. He is currently working as an M.S. student at the Material Research Institute of The Pennsylvania State University, University Park.

His current research interests include the characterization of ferroelectric materials and manufacturing methods for high-frequency medical imaging transducers and arrays.

Thomas R. Shrout received a B.S. and Ph.D. in ceramic science from The Pennsylvania State University in 1976 and 1981, respectively. He is currently Professor of Materials and Senior Scientist at The Pennsylvania State University. Prior to joining the faculty at Penn State, Dr. Shrout was with Sprague Electric Co. and AVX Co. He holds seventeen patents and has coauthored more than 300 papers in the area of electronic ceramics with an emphasis on processing property relationship.

Thomas R. Shrout received a B.S. and Ph.D. in ceramic science from The Pennsylvania State University in 1976 and 1981, respectively. He is currently Professor of Materials and Senior Scientist at The Pennsylvania State University. Prior to joining the faculty at Penn State, Dr. Shrout was with Sprague Electric Co. and AVX Co. He holds seventeen patents and has coauthored more than 300 papers in the area of electronic ceramics with an emphasis on processing property relationship.

References

- 1.Jaffe B, Cook W, Jaffe H. Piezoelectric Ceramics. New York: Academic; 1971. pp. 135–171. [Google Scholar]

- 2.Carl K, Hardtl KH. Electrical after-effects in Pb(Ti,Zr)O3 ceramics. Ferroelectrics. 1978;17:473–486. [Google Scholar]

- 3.Takahashi S. Effects of impurity doping in lead zirconate-titanate ceramics. Ferroelectrics. 1982;41:143–156. [Google Scholar]

- 4.Okazaki K, Maiwa H. Space charge effects on ferroelectric ceramic particle surfaces. Jpn J Appl Phys. 1992;31:3113–3116. [Google Scholar]

- 5.Hardtl KH. Electrical and mechanical losses in ferroelectric ceramics. Ceram Int. 1982;8:121–127. [Google Scholar]

- 6.Zhang SJ, Xia R, Lebrun L, Anderson D, Shrout T. Piezoelectric materials for high power, high temperature applications. Mater Lett. 2005;59:3471–3475. [Google Scholar]

- 7.Pohanka RC, Smith PL. Recent advances in piezoelectric ceramics. In: Levinson LM, editor. Electronic Ceramics—Properties, Devices and Applications. ch 2. New York: Marcel Dekker; 1987. [Google Scholar]

- 8.Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, Homma T, Nagaya T, Nakamura M. Lead-free piezoceramics. Nature. 2004 Nov;432:84–86. doi: 10.1038/nature03028. [DOI] [PubMed] [Google Scholar]

- 9.Shrout TR, Zhang SJ. Lead free piezoelectric ceramics: Alternatives for PZT? J Electroceram. 2007;19:111–124. [Google Scholar]

- 10.Guo Y, Kakimoto K, Ohsato H. Phase transitional behavior and piezoelectric properties of (K0.5Na0.5)NbO3-LiNbO3 ceramics. Appl Phys Lett. 2004;85:4121–4123. [Google Scholar]

- 11.Zang GZ, Wang JF, Chen HC, Su WB, Wang CM, Qi P, Ming BQ, Du J, Zheng LM, Zhang SJ, Shrout TR. Perovskite (Na0.5K0.5)1−x(LiSb)xNb1−xO3 lead free piezoceramics. Appl Phys Lett. 2006;88 art. no. 212908. [Google Scholar]

- 12.Hollenstein E, Davis M, Damjanovic D, Setter N. Piezoelectric properties of Li- and Ta-modified (K0.5Na0.5)NbO3 ceramics. Appl Phys Lett. 2005;87 art. no. 182905. [Google Scholar]

- 13.Zhang SJ, Xia R, Shrout TR, Zang GZ, Wang JF. Piezoelectric properties in perovskite 0.948(K0.5Na0.5)NbO3-0.052LiSbO3 lead free ceramics. J Appl Phys. 2006;100 art. no. 104108. [Google Scholar]

- 14.Zhang S, Xia R, Shrout T, Zang G, Wang J. Characterization of lead free (K0.5Na0.5)NbO3-LiSbO3 piezoceramic. Solid State Commun. 2007;141:675–679. [Google Scholar]

- 15.Dai YJ, Zhang XW. Phase transitional behavior in (K0.5Na0.5)NbO3-LiTaO3 ceramics. Appl Phys Lett. 2007;90 art. no. 262903. [Google Scholar]

- 16.Wang K, Li JF. Analysis of crystallographic evolution in (Na,K)NbO3-based lead free piezoceramics by x-ray diffraction. Appl Phys Lett. 2007;91 art. no. 262902. [Google Scholar]

- 17.Zhang SJ, Xia R, Shrout TR. Modified (K0.5Na0.5)NbO3 based lead free piezoelectrics with broad temperature usage range. Appl Phys Lett. 2007;91 art. no. 132913. [Google Scholar]

- 18.Zhang SJ, Xia R, Hao H, Liu HX, Shrout TR. Mitigation of thermal and fatigue behavior in (K0.5Na0.5)NbO3-based lead free piezoceramics. Appl Phys Lett. 2008;92 doi: 10.1063/1.2908960. art. no. 152904. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Matsubara M, Kikuta K, Hirano S. Piezoelectric properties of (K0.5Na0.5)(Nb1−xTax)O3-K5.4CuTa10O29 ceramics. J Appl Phys. 2005;97 art. no. 114105. [Google Scholar]

- 20.Matsubara M, Yamaguchi T, Kikuta K, Hirano SI. Sinterability and piezoelectric properties of (K, Na)NbO3 ceramics with novel sintering aid. Jpn J Appl Phys. 2004;43:7159–7163. [Google Scholar]

- 21.Li E, Kakemoto H, Wada S, Tsurumi T. Enhancement of Qm by co-doping of Li and Cu to potassium sodium niobate lead free ceramics. IEEE Trans Ultrason Ferroelectr Freq Control. 2008;55(5):980–987. doi: 10.1109/TUFFC.2008.743. [DOI] [PubMed] [Google Scholar]

- 22.Zuo RZ, Ye C, Fang XS, Yue ZX, Li LT. Processing and piezoelectric properties of (Na0.5K0.5)0.96Li0.04(Ta0.1Nb0.9)1−xCuxO3−3x/2 lead free ceramics. J Am Ceram Soc. 2008;91:914–917. [Google Scholar]

- 23.Lin DM, Kwok KW, Chan HLW. Piezoelectric properties and hardening behavior of K5.4Cu1.3Ta10O29-doped (K0.5Na0.5) NbO3 ceramics. J Appl Phys. 2008;103 art. no. 064105. [Google Scholar]

- 24.IEEE Standards on Piezoelectricity, ANSI/IEEE Standard No. 176, 1987.

- 25.Zhang SJ, Alberta EF, Eitel RE, Randall CA, Shrout TR. Elastic, piezoelectric and dielectric characterization of modified BiScO3-PbTiO3 ceramics. IEEE Trans Ultrason Ferroelectr Freq Control. 2005;52(11):2131–2139. doi: 10.1109/tuffc.2005.1561684. [DOI] [PubMed] [Google Scholar]

- 26.Shrout TR, Eitel R, Randall CA. High performance, high temperature perovskite piezoelectric ceramics. In: Setter N, editor. Piezoelectric Materials in Devices. Switzerland: EPFL Swiss Federal Institute of Technology; 2002. p. 413. [Google Scholar]