Abstract

Botulinum neurotoxin (BoNT) is the most toxic substance known to man and the causative agent of botulism. Due to its high toxicity and the availability of the producing organism Clostridium botulinum, BoNT is regarded as a potential biological warfare agent. Because of the mild pasteurization process, as well as rapid product distribution and consumption, the milk supply chain has long been considered a potential target of a bioterrorist attack. Since, to our knowledge, no empirical data on the inactivation of BoNT in milk during pasteurization are available at this time, we investigated the activities of BoNT type A (BoNT/A) and BoNT/B, as well as their respective complexes, during a laboratory-scale pasteurization process. When we monitored milk alkaline phosphatase activity, which is an industry-accepted parameter of successfully completed pasteurization, our method proved comparable to the industrial process. After heating raw milk spiked with a set amount of BoNT/A or BoNT/B or one of their respective complexes, the structural integrity of the toxin was determined by enzyme-linked immunosorbent assay (ELISA) and its functional activity by mouse bioassay. We demonstrated that standard pasteurization at 72°C for 15 s inactivates at least 99.99% of BoNT/A and BoNT/B and at least 99.5% of their respective complexes. Our results suggest that if BoNTs or their complexes were deliberately released into the milk supply chain, standard pasteurization conditions would reduce their activity much more dramatically than originally anticipated and thus lower the threat level of the widely discussed “BoNT in milk” scenario.

Botulinum neurotoxin (BoNT) is mainly produced by the rod-shaped anaerobic bacterium Clostridium botulinum but can also be produced by unique strains of Clostridium baratii and Clostridium butyricum (15). The toxin is a dichain protein with a molecular mass of 150 kDa, consisting of a heavy chain of 100 kDa and a light chain of 50 kDa which are linked by a disulfide bond. All known BoNT types are secreted bound to nontoxic neurotoxin-associated proteins (NAPs) and assemble into large complexes with molecular masses of 300, 600, or 900 kDa, depending on the toxin type (20, 23, 39). There are seven known antigenically distinct BoNT serotypes, designated types A through G (11, 32). In recent years, the BoNT serotypes have been further grouped into subtypes, e.g., A1 to A5, differentiated on the basis of the variability of the BoNT genes, their deduced protein sequences, and their immunological properties (18, 24, 28, 40). BoNT types A (BoNT/A), /B, /E, and /F are the causative agents of food-borne botulism in humans, a serious paralytic illness which is the result of consuming improperly preserved food contaminated with C. botulinum spores and/or BoNT (16, 26, 31). After oral ingestion, BoNT reaches the intestinal tract, where the NAPs associated with BoNT in the complex are believed to protect the toxin against digestive enzymes during its passage through low-pH gastric juice (25). After crossing the intestinal mucosa, BoNT is circulated through the blood, ultimately reaching the neuromuscular nerve endings (22, 29). Specific binding of the heavy chain to receptors on the nerve cell surface triggers the translocation of BoNT into the lumen of the cell (3, 14, 34). Once BoNT reaches the cytosol of the nerve cell, the release of acetylcholine is inhibited by the endopeptidase activity of the BoNT light chain, leading to symmetric descending, flaccid paralysis (38). There is no reliable data on the exact oral toxicity of BoNT for humans. However, from animal studies using nonhuman primates and from cases of human botulism, it is estimated that the lethal oral dose of BoNT is between 10 ng and 1 μg kg−1 body weight (17, 27). Generally, the lethal toxicity depends on the BoNT serotype and the route of exposure (2, 8), and it may vary among individuals.

Given its extreme toxicity, the Centers for Disease Control and Prevention (CDC, Atlanta, GA) lists BoNT as a Category A bioterrorism agent: these are high-priority agents and organisms that pose a high risk to public health and national security (12). Consequently, there were serious concerns that terrorists could attack the population by contaminating food staples with BoNT or a similar agent. The milk supply, in particular, was considered a likely target since the many transportation and processing steps between cow and consumer represent critical and vulnerable points at which bioterrorism agents could be deliberately released. In addition, milk and other dairy products are distributed rapidly after packaging and, as one of the most widely consumed foodstuffs, reach large parts of the population.

In 2005, Wein and Liu described a theoretical scenario of a bioterror attack on the milk supply chain based on a series of mathematical calculations. It garnered considerable interest among the scientific community, politicians, and intelligence organizations (41). Referring to experiments in which the toxic activity of BoNT in different foodstuffs, but not milk specifically, was determined after heat treatment (42), they based their calculation on roughly 70% thermal inactivation of BoNT during pasteurization, leading to >104 fatalities after the release of 1 g BoNT into raw milk prior to industrial pasteurization. As the scenario was based on theoretical assumptions, it seemed crucial to us to quantify the actual inactivation rate of BoNT in raw milk in a pasteurization process similar to the standard process in the industry, as this would allow us to calculate a reliable scenario.

The heat treatment commonly used by the dairy industry is high-temperature short-time (HTST) pasteurization, a continuous process where a plate heat exchanger is used to rapidly bring the milk up to the required temperature of 72°C and hold it steady at this temperature for at least 15 s. Subsequently, the milk is cooled to 4°C and packaged for consumption. The pasteurization process is controlled by a standard method which measures the activity of milk alkaline phosphatase (ALP) as an intrinsic time-temperature integrator (1, 13, 21, 33). If HTST pasteurization is successful, the activity of ALP falls below 350 mU liter−1, the threshold set by the International Dairy Federation and the International Organization for Standardization (21).

In the current work, we describe the thermal inactivation of BoNT/A, BoNT/A complex, BoNT/B, and BoNT/B complex in cow's milk in a pasteurization process similar to the industry standard. As an internal reference for the experimental setup, we correlate the activity of the toxins with the enzymatic activity of ALP, thereby mimicking the industrial process where the loss of ALP activity is used to indicate correct pasteurization. Unexpectedly, our data show that under industrial pasteurization conditions, the BoNTs and BoNT complexes we analyzed are inactivated by 99.5% or more.

MATERIALS AND METHODS

Milk.

A batch of fresh, full-fat, raw bovine milk (pH 6.6) was purchased from a local retail store, divided into 10-ml aliquots, and stored frozen at −20°C.

Toxins and antibodies.

The study was performed using purified 150-kDa BoNT/A1 (Hall A) and BoNT/B1 (Okra B) and the corresponding BoNT complexes, all of which were purchased from Metabiologics, Inc. (Madison, WI). Mouse monoclonal antibody A1688 [IgG1(κ)] was used to capture BoNT/A and BoNT/A complex, and mouse monoclonal antibody B279 [IgG2a(κ)] to capture BoNT/B and BoNT/B complex in the sandwich ELISA (30). Antibodies were purified from hybridoma supernatants using HiTrap protein G Sepharose columns according to the manufacturer's instructions (GE Healthcare Bio-Sciences AB, Uppsala, Sweden). Purity was determined by sodium dodecyl sulfate-polyacrylamide gel electrophoresis, and protein concentration via absorbance at 280 nm using a NanoDrop ND-1000 (NanoDrop Technologies, Wilmington, DE). For subsequent studies, IgG antibodies were stored in phosphate-buffered saline (PBS; pH 7.3) at 1 mg ml−1. For the detection of BoNT and BoNT complexes, biotinylated polyclonal equine anti-BoNT (anti-BoNT/A, /B, and /E [BoNT/A/B/E]; Novartis Behring, Marburg, Germany) was used. The antibody was coupled to biotin according to the manufacturer's instructions (EZ-Link Sulfo-NHS-LC-biotin; Pierce, Rockford, IL). Biotinylated antibodies were stored in phosphate-buffered saline with 0.2% (wt/vol) bovine serum albumin and 0.05% (wt/vol) NaN3.

Laboratory-scale pasteurization and measurement of ALP activity.

Raw milk was thawed and kept at 4°C before and after thermal treatment. To mimic industrial milk pasteurization, the raw milk was dispensed at volumes of 50 μl into thin-walled 0.2-ml PCR vials (VWR, West Chester, PA) and subjected to heat treatment in an MJ MiniOpticon cycler (Bio-Rad, Hercules, CA) with a lid temperature of 99.9°C. All samples were heated to 15°C at a rate of 2.5 K s−1, maintained there for 30 s, and then heated to 72°C with a slope of 0.5 K s−1 and held at 72°C for 1, 5, 10, 15, 30, 60, 120, or 180 s, respectively. Subsequently, the samples were cooled to 15°C with a slope of 2.5 K s−1 and then to 4°C. Similarly heated samples were pooled for subsequent analysis. Since the accuracy of the heat treatment delivered is a crucial point of the experimental setup, the thermal cycler (Bio-Rad, Hercules, CA) was independently validated using a multichannel temperature acquisition system (Cyclertest, Landgraaf, Netherlands). The results of the validation are shown in Fig. S1 in the supplemental material: exemplarily shown for 70°C, a temperature variation of 69.6°C ± 0.2°C was detected.

ALP was used as an intrinsic time-temperature integrator for the heat treatment of milk. The ISO standard (21) requires that pasteurization protocols lead to the inactivation of ALP activity below the 350 mU liter−1 threshold. For standardized ALP measurement (standard ALP assay) the Fluorophos method (Advanced Instruments, Inc., Norwood, MA) was used. Following the standard protocol, Fluorophos substrate [2′-(2-benzothiazolyl)-6′-hydroxybenzothiazole phosphate] in diethanolamine (DEA) buffer solution at pH 10 was used to detect the dephosphorylating activity of alkaline phosphatase. Two milliliters of Fluorophos was heated to 38°C in a glass cuvette. After 75 μl of milk was added, the sample was vortexed and allowed to reach 38°C in the Fluorophos reader. Measurement of fluorescence was performed at an excitation wavelength of 440 nm and an emission wavelength of 560 nm. Fluorescence was measured every 30 s over a total of 120 s. Calibration of the system and calculation of the enzymatic activities of ALP were performed as described elsewhere (21).

In the miniaturized ALP measurement system (mini ALP assay), 10-μl amounts of milk samples were pipetted in triplicate into the bottom of FluoroNunc F96 MicroWell plates (Nunc, Langenselbold, Germany) which were preheated to 38°C. Amounts of 100 μl of Fluorophos substrate, also heated to 38°C, were added to each sample cavity and immediately mixed with the sample by gentle pipetting. The fluorescence was measured at 38°C with an InfiniTE M200 monochromator (Tecan, Crailsheim, Germany) at an excitation wavelength of 440 nm and an emission wavelength of 560 nm. Fluorescence was measured every 30 s over a total of 120 s. The enzymatic activity of ALP was calculated with the mean fluorescence min−1 of the triplicates, multiplied by the amount of Fluoroyellow in calibration solution B, and divided by the calibration ratio and the sample volume. Due to device-specific limitations, the InfiniTE M200 from Tecan was only able to show a maximum of 100,000 mU liter−1 in the fluorescence measurement of the miniaturized Fluorophos method.

Toxin spiking.

For the measurement of BoNT inactivation, 1 mg ml−1 of each toxin was diluted in raw milk to give a final concentration of 500 ng ml−1. One mouse lethal dose (MLD) was defined as the lowest total amount of toxin that kills 100% of all mice in an experiment. According to this definition, one MLD was determined by mouse bioassay to be 5 pg for purified BoNT/A and BoNT/B and 15 pg for BoNT/A complex and BoNT/B complex. These experiments have been performed with 5 mice for each of the four toxin preparations and have been highly reproducible (data not shown). Accordingly, 500 ng ml−1 comprised 100,000 MLD ml−1 for purified BoNT/A and BoNT/B and 33,333 MLD ml−1 for BoNT/A complex and BoNT/B complex.

At each of the different time points indicated in the text, a total volume of 1,000 μl of milk with toxin at 500 ng ml−1 was divided into 50-μl aliquots, heated in a thermal cycler as described above, and pooled again to 1,000 μl. From this volume, (i) 3 × 10 μl was used for the ALP assay, (ii) 2 × 50 μl was used for the ELISA, and (iii) either 100 μl (in the case of the purified neurotoxins) or 300 μl (in the case of the neurotoxin complexes) was used for the mouse bioassay, corresponding to a total amount of 10,000 MLD each.

Enzyme-linked immunosorbent assay.

MaxiSorp microtiter plates (F96; Nunc, Langenselbold, Germany) were coated with monoclonal antibody A1688/2 (anti-BoNT/A) or B279/5 (anti-BoNT/B) at 10 or 8.7 μg ml−1, respectively, in phosphate-buffered saline (pH 7.2) at 4°C overnight (30). After 60 min of blocking, heated and unheated samples with BoNTs, as well as negative controls, were applied in duplicate and incubated at 25°C for 120 min. Sample cavities were washed and incubated for 60 min with biotinylated polyclonal equine anti-BoNT/A/B/E antiserum (Novartis Behring, Marburg, Germany) at 60 μg ml−1, followed by incubation with streptavidin-coupled horseradish peroxidase (Dianova, Hamburg, Germany) for 30 min at a dilution of 1:2,500. TMB (3, 3′, 5, 5′-tetramethylbenzidine; Sigma-Aldrich, Seelze, Germany) was used as a substrate, and the average absorbance was measured at 450 nm minus absorbance of impurities at a 620-nm wavelength.

Biological activity of BoNT measured by mouse bioassay.

A mouse bioassay was used to estimate the biological potencies of unheated and heat-treated raw milk spiked with BoNT. The assay was performed with female BALB/c mice weighing between 15 and 21 g (35). The BALB/c mice were raised under specific-pathogen-free conditions at the German Federal Institute for Risk Assessment (Berlin, Germany) and were between 6 and 8 weeks old. For the experiments, mice were maintained under barrier conditions at the Robert Koch-Institut (Berlin, Germany). All animal experiments were performed in accordance with the German Animal Protection Law and were approved by the regional authority for health and social affairs (LAGeSo, Berlin, Germany). Considering that 100,000 MLD ml−1 purified BoNTs and 33,333 MLD ml−1 BoNT complexes were spiked into raw milk before the thermal treatment, a total amount of 10,000 MLD was injected into mice intraperitoneally (corresponding to 100 μl in the case of the purified neurotoxins, adjusted to 300 μl with similarly pasteurized milk, or 300 μl in the case of the neurotoxin complexes, respectively). Negative-control mice received raw milk without BoNT, and positive controls received unheated raw milk with BoNT. Samples and controls at each time point were tested in duplicate. For dilutions used to investigate the activities of BoNT complexes after heating, similarly pasteurized milk was again used. For the critical dilutions (1:10- and 1:50-diluted samples [holding times of 1 and 15 s] and 1:10-diluted samples [holding time of 180 s]), five mice were used per group. Injected mice were observed for typical botulism symptoms for up to 96 h. When a wasp-like narrowed waist and immobility due to severe paralysis were observed, the mouse was sacrificed. The absence of botulism symptoms indicated that no toxic activity remained. If mice that received samples with purified BoNT or BoNT complex showed no symptoms, the remaining MLD was considered to be less than one. In all other cases, dilution factors allowed for the approximation of the remaining MLD.

RESULTS

Establishment of laboratory-scale pasteurization process similar to the industry standard.

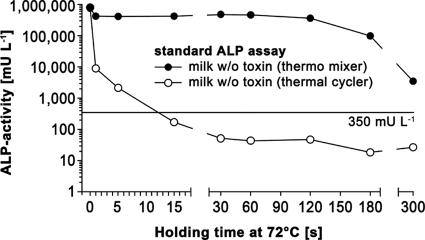

To set up a laboratory-scale pasteurization process similar to the industry standard, raw milk was subjected to thermal treatment at 72°C for 15 s. The efficacy of the thermal treatment was monitored by analyzing the milk alkaline phosphatase (ALP) activity as an intrinsic parameter of successfully completed pasteurization. To monitor the pasteurization process, the ALP activity was measured using a standardized ALP assay (standard ALP assay) which is regularly used in the dairy industry. According to internationally accepted standards, the activity of ALP after HTST pasteurization at 72°C for 15 s must drop below 350 mU liter−1 (21). In order to find the right laboratory parameters and dimensions which would mimic the industrial process, we tested two different experimental setups: a fixed volume of 50 μl raw milk was heated either in a thermo mixer or in a thermal cycler. Using the thermo mixer, samples were subjected to 72°C for different times and then rapidly cooled using liquid nitrogen. Using the thermal cycler, samples were subjected to a heating curve up to 72°C, held at that temperature for different times, and then brought down to 15°C using the in-built cooling system. As shown in Fig. 1, the ALP activities from samples in the thermo mixer reached values below 350 mU liter−1 only after several minutes at 72°C, whereas the thermal cycler already showed values below the threshold after a 15-s holding time at 72°C (Fig. 1 and Fig. 2A). In accordance with these results, while monitoring the activity of ALP in the heated milk, we observed enhanced heat transfer using the thermal cycler. Also, the thermal cycler allowed for better process control with respect to the heating profile, thereby allowing us to compare the efficacies of the heating process and the industrial HTST pasteurization process directly. Consequently, the thermal cycler was used to heat the milk samples in all further experiments.

FIG. 1.

Comparison of results from two different experimental setups for laboratory-scale pasteurization. A small volume (50 μl) of raw milk was heated either in a conventional thermo mixer or in a thermal cycler. For both setups, the reduction of ALP activity in milk held continuously at 72°C for up to 300 s was monitored using the standard ALP assay.

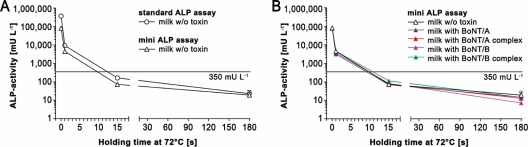

FIG. 2.

Reduction of ALP activity during heating of raw milk in a laboratory-scale pasteurization process using a thermal cycler. (A) ALP activities in raw milk and heated milk (each without toxin) were measured using the standard ALP assay and compared to the activities measured with the mini ALP assay. (B) ALP activities in unspiked raw and heated milk were measured with the mini ALP assay and compared to ALP activity in milk spiked with BoNT/A, BoNT/A complex, BoNT/B, or BoNT/B complex. Data are shown for holding times of 0 (unheated), 1, 15, and 180 s at 72°C. The threshold for successful pasteurization is 350 mU liter−1. Each line represents the means of the results of two independent experiments. Error bars show standard deviations.

To measure ALP activity in milk spiked with BoNT in our small-scale laboratory setup, the industrial standard ALP assay was downscaled from 2,000 μl to a miniaturized ALP assay format (mini ALP assay) using a 100-μl volume (see Materials and Methods). The two assays were compared using unspiked milk heated with the thermal cycler (Fig. 2A). The standard ALP assay showed ALP activities typically found in raw milk, ranging from 200,000 to 500,000 mU liter−1 (33; C. Egger, personal communication), slightly more than those found with the miniaturized method. After a 15-s holding time at 72°C, the ALP activity in milk was reduced to values below the 350 mU liter−1 threshold. As shown in Fig. 2A, the two methods led to almost identical reductions of ALP activity below the indicated threshold at the same holding times. The miniaturized ALP assay, therefore, was used to monitor the loss of ALP activity during thermal treatment in all further experiments.

To exclude the possibility that milk pasteurization is altered by the presence of BoNT, raw milk and raw milk spiked with 100,000 mouse lethal doses (MLD) per ml purified BoNT/A or BoNT/B or 33,333 MLD ml−1 BoNT/A complex or BoNT/B complex were heated in parallel in a thermal cycler and measured with the mini ALP assay. The results presented in Fig. 2B show that the ALP activities in heated milk were consistent, regardless of whether the toxin was present in the milk or not.

Based on the measurement of the intrinsic milk parameter ALP by both the standardized and the miniaturized ALP assay, the results show that heating for 15 s at 72°C in the thermal cycler is sufficient to obtain pasteurized milk. Thus, according to internationally accepted standards, our laboratory-scale pasteurization process can be considered similar to the industry standard, allowing for direct comparison of heat transfer and protein activity.

Thermal inactivation of BoNT/A, BoNT/B, and BoNT complexes as determined by ELISA.

To monitor the thermal inactivation of purified BoNT/A and BoNT/B and the corresponding complexes in milk, we spiked defined amounts of the toxins into raw milk. From the same samples, we subsequently determined (i) the ALP activity using the mini ALP assay as indicated above, (ii) the structural integrity of the toxins by sandwich ELISAs specific for BoNT/A and BoNT/B, and (iii) the functional activity of the toxins using the mouse bioassay.

The results of the two sandwich ELISAs used in this study are indicated in Fig. S2 in the supplemental material and in Table 1. Both ELISAs were based on the combination of a monoclonal capture antibody (clone A1688/2 for BoNT/A and clone B279/5 for BoNT/B) (30) with an equine anti-BoNT/A/B/E antiserum resulting in detection limits between 47 and 136 pg ml−1 for BoNT/A and BoNT/B and 558 and 698 pg ml−1 for the corresponding complexes, both in buffer and in raw milk (Table 1; see Fig. S2A and B in the supplemental material). As shown in Fig. S2 in the supplemental material, both ELISAs were able to discriminate between active and inactive BoNT (where “inactive BoNT” is equivalent to toxin that has been heated for 15 s at 72°C) over a range of about three orders of magnitude of concentration (see Fig. S2C to F in the supplemental material), therefore allowing us to reduce the number of animals used in this study.

TABLE 1.

Sensitivity of sandwich ELISAs for the detection of BoNT/A, BoNT/B, and the corresponding complexes in buffer and raw milk

| Toxin | LODa (pg ml−1) in: |

|

|---|---|---|

| Bufferb | Raw milk | |

| BoNT/A | 53 ± 12 | 47 ± 9 |

| BoNT/A complex | 650 ± 221 | 558 ± 222 |

| BoNT/B | 102 ± 26 | 136 ± 51 |

| BoNT/B complex | 653 ± 184 | 698 ± 245 |

Limit of detection (LOD) was calculated on the basis of the arithmetic mean and the 3-fold standard deviation of the results for 12 to 16 blank samples for three interassay standard curves.

PBS containing 0.1% bovine serum albumin.

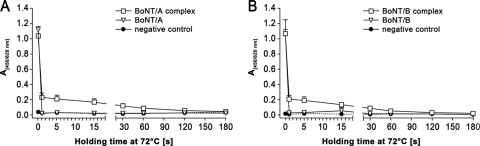

After spiking the milk with 500 ng ml−1 purified BoNT/A or BoNT/B or one of the corresponding complexes (equivalent to 100,000 MLD ml−1 for the purified neurotoxins or 33,333 MLD ml−1 for the toxin complexes, respectively), we performed the laboratory-scale pasteurization as indicated above and measured the presence of the toxins after appropriate dilution of the milk samples. As shown in Fig. 3, BoNT/A and BoNT/B, as well as the respective complexes, could be clearly detected in the spiked, unheated raw milk samples and were not present in the unspiked samples. Applying our heating protocol for different times (1, 5, 15, and up to 180 s at 72°C) resulted in a dramatic reduction in the toxin-specific signal detected via sandwich ELISA, both for the purified neurotoxins and the neurotoxin complexes. In the case of the purified neurotoxins, a holding time of only 1 s at 72°C led to a complete loss of the ELISA signal (Fig. 3). For the neurotoxin complexes, the ELISA signal fell sharply even after a holding time of only 1 s at 72°C. However, it was still detectable at approximately 20% of the signal intensity of the spiked, unheated milk (Fig. 3). For both BoNT complexes, a holding time of 180 s at 72°C was needed before the signal decreased to 1 to 4% of the original value. Even though the ELISA suggested a dramatic loss of BoNT integrity within the first few seconds of heating, a residual functional activity could not be excluded.

FIG. 3.

Structural integrity of BoNT/A, BoNT/B, and the corresponding BoNT complexes in milk during laboratory-scale pasteurization. Purified BoNT/A or BoNT/B or one of the corresponding complexes was spiked into raw milk as indicated in the text and subjected to our laboratory-scale pasteurization using a thermal cycler. After holding the samples at 72°C for the indicated times, sandwich ELISAs were used to analyze them specifically for BoNT/A and BoNT/A complex (A) or for BoNT/B and BoNT/B complex (B). Results for purified neurotoxins (BoNT/A or /B) are depicted by open triangles, and those for BoNT complexes as open squares. Results for unspiked milk samples (negative control) are shown by filled circles. Each line represents the means of the results of two independent experiments. Error bars show standard deviations. A, absorbance.

Thermal inactivation of BoNT/A, BoNT/B, and BoNT complexes as determined by mouse bioassay.

We performed the mouse bioassay to quantify the residual toxic activities of purified BoNTs and BoNT complexes spiked into milk after laboratory-scale pasteurization. Considering that, initially, 100,000 MLD ml−1 purified BoNTs and 33,333 MLD ml−1 BoNT complexes were spiked into raw milk before thermal treatment, a total amount of 10,000 MLD was injected into mice intraperitoneally. The application of unheated raw milk containing 10,000 MLD BoNT/A, BoNT/A complex, BoNT/B, or BoNT/B complex to BALB/c mice led to typical symptoms of botulism, such as a wasp-like narrowed waist and subsequent paralysis.

Interestingly, all mice injected with milk spiked with purified BoNT/A or BoNT/B held at 72°C for 1 s or longer survived without showing any symptoms of botulism. Therefore, this experiment showed that the 10,000 MLD of BoNT originally spiked into milk were reduced to less than 1 MLD, indicating that the heat treatment reduced the toxic activity of purified BoNT/A and BoNT/B by more than 99.99% (Table 2).

TABLE 2.

Toxic activities of BoNT/A, BoNT/B, and the corresponding BoNT complexes in milk after pasteurization

| Toxin | Time sample held at 72°C (s) | Dilution of BoNT-spiked milk | No. of mice surviving/no. of mice tested | MLD before heating/ MLD after heating | Reduction in toxic activity (%) |

|---|---|---|---|---|---|

| BoNT/A | |||||

| Not heated | —a | 0/2 | 10,000/10,000 | 0 | |

| 1 | — | 2/2 | 10,000/<1 | >99.99 | |

| 5 | — | 2/2 | 10,000/<1 | >99.99 | |

| 15 | — | 2/2 | 10,000/<1 | >99.99 | |

| 30 | — | 2/2 | 10,000/<1 | >99.99 | |

| BoNT/A complex | |||||

| Not heated | — | 0/2 | 10,000/10,000 | 0 | |

| 1 | — | 0/2 | |||

| 1:10 | 0/5 | ||||

| 1:50 | 5/5 | 200/<1 | >99.5 | ||

| 1:100 | 2/2 | ||||

| 15 | — | 0/2 | |||

| 1:10 | 0/5 | ||||

| 1:50 | 5/5 | 200/<1 | >99.5 | ||

| 180 | — | 0/5 | |||

| 1:10 | 5/5 | 1,000/<1 | >99.9 | ||

| BoNT/B | |||||

| Not heated | — | 0/2 | 10,000/10,000 | 0 | |

| 1 | — | 2/2 | 10,000/<1 | >99.99 | |

| 5 | — | 2/2 | 10,000/<1 | >99.99 | |

| 15 | — | 2/2 | 10,000/<1 | >99.99 | |

| 30 | — | 2/2 | 10,000/<1 | >99.99 | |

| BoNT/B complex | |||||

| Not heated | — | 0/2 | 10,000/10,000 | 0 | |

| 1 | — | 0/2 | |||

| 1:10 | 0/2 | ||||

| 1:50 | 0/5 | ||||

| 1:100 | 5/5 | 100/<1 | >99.0 | ||

| 15 | — | 0/2 | |||

| 1:10 | 0/5 | ||||

| 1:50 | 5/5 | 200/<1 | >99.5 | ||

| 180 | — | 0/5 | |||

| 1:10 | 5/5 | 1,000/<1 | >99.9 |

—, no dilution.

Yet, when we applied thermally treated milk spiked with BoNT/A complex or BoNT/B complex instead of one of the purified neurotoxins, all mice suffered from typical symptoms of botulism. Stepwise dilutions of the heated milk originally containing 10,000 MLD were used to determine the residual toxicity. A 1:50 dilution, corresponding to 200 MLD of the original spiked milk held at 72°C for 15 s, was no longer toxic when injected into mice, demonstrating that less than 1 MLD was left from the 200 MLD injected. Therefore, the heat treatment reduced the toxicity by at least 99.5%. A similar calculation leads us to conclude that heat treatment at 72°C for 180 s reduces the toxicity of both BoNT complexes by more than 99.9% (Table 2).

Taking the results together, heating under standard milk pasteurization conditions (72°C for 15 s) was sufficient to reduce the toxic activity of purified BoNT/A and BoNT/B by more than 99.99% and that of the corresponding BoNT complexes by more than 99.5%.

DISCUSSION

The results presented in this paper show that current conditions of industrial HTST pasteurization are effective in reducing the toxic activity of both BoNT/A and BoNT/B by more than 99.99% and of the corresponding BoNT complexes by 99.5%. Consequently, these results could provide a significant contribution to scenarios modeling BoNT as a potential biowarfare agent.

Milk and milk-derived products are among the most widely consumed food products worldwide. The per capita milk consumption in 2007 was approximately 80 to 90 liters in the United States and Western European countries (19). For more than 100 years, the thermal treatment of milk has been used effectively to inactivate pathogens that may be present in milk (10). Common heating processes include high temperature short time (HTST; 72°C for 15 to 16 s), extended shelf life (ESL; 80°C and 130°C for 1 to 5 s), and ultra-high temperature (UHT; 135 to 150°C for 1 to 10 s).

Heat-treated milk has proven to be a safe food, and no cases of “natural” food-borne botulism resulting from industrially processed milk have been described. Nevertheless, even when milk production on farms meets modern standards for food quality and hygiene, the production process cannot be completely secured, making the supply chain vulnerable to bioterror attacks. One scenario that could be considered is the deliberate release of the agent into raw milk prior to pasteurization on the farm or while in transit to the dairy company.

For the current study, it was important to consider the food matrix used for the experiments, in this case raw milk, since it has a major impact on the heat inactivation rate of BoNT (37). Early work by Scott and Stewart (published in 1950) demonstrated that vegetable juice increased the heat stability of BoNT/A and BoNT/B due to their being protected by bivalent cations and organic acid anions present in the juice (36). Later, Bradshaw et al. (in 1979) showed that BoNT/A and BoNT/B were more heat stable in beef and mushroom patties than in a phosphate buffer at the same pH (5). Woodburn et al. (in 1979) also observed increased heat stability of BoNT/A when 1% gelatin was added to a phosphate buffer (42). Recently, it has been shown that the molten-globule-like character of BoNT and its interaction with NAPs are responsible for variations in physical stability at different pH values (6, 7). The data showed a stabilizing effect of NAPs on the purified neurotoxins. It is worth considering that if the NAPs were damaged, this could influence the stability of the whole complex and the oral toxicity. Based on the available data, it seemed conceivable that the actual stability of BoNT in milk during the pasteurization process cannot be extrapolated directly from its stability in other food matrices which were analyzed earlier. Rather, measuring the actual stability of the toxins in milk appears critical for the generation of reliable numbers.

Our comparisons of different experimental setups for the thermal treatment of milk highlighted a second critical parameter, namely, the importance of finding experimental conditions for heat transfer that mimicked the industrial process as closely as possible. Our data from comparing the heating of milk with a thermo mixer and with a thermal cycler suggested that strict compliance with pasteurization parameters is necessary to guarantee the degree of inactivation described above. While using a thermo mixer involves heating with an isothermal heat source for a defined time, the thermal cycler allows for temperature-controlled heating with defined holding times, an approach which complies with the industrial HTST pasteurization process. Compared to ESL and UHT processing, HTST pasteurization applies less thermal load and is also the most commonly used and mildest thermal treatment of milk; hence our decision to apply this process to our experiments. Unlike the industrial process, which uses forced convective heat transfer, heating in a thermal cycler is achieved by free heat transfer. Nevertheless, ALP, used as an intrinsic time-temperature integrator for the heat treatment of milk, allowed us to show that laboratory-scale pasteurization in a thermal cycler met dairy industry requirements for successful HTST pasteurization (i.e., inactivation of ALP within 15 s at 72°C to below a threshold of 350 mU/liter) (9). These results are also in accordance with the findings of an earlier study that applied the same methodology of thermal treatment and measuring ALP activity when investigating the effect of pasteurization on herpes virus infectivity in milk (4). Retrospectively, it is not clear whether the classical work cited above (5, 36, 42) is as well defined as our current work with respect to the heat transfer applied, the proven comparability to an industrial process, and the toxin preparations used (neurotoxin or toxin complexes and purity of the material).

Due to their high bioavailability, BoNT complexes present the most toxic form of BoNT if ingested (8, 25), and the deliberate release of this form would be a worst-case scenario. For this reason, we spiked purified BoNT or BoNT complex into raw milk prior to pasteurization. Subsequently, loss of structural integrity and toxic activity were determined by sandwich ELISA and mouse bioassay, respectively. Both the immunological and the functional detection of BoNTs generated similar results, indicating a dramatic loss of protein structure and function. In contrast to the 68.4% heat inactivation of BoNT estimated by Wein and Liu (41), we were able to show in the mouse bioassay that even after only a 1-s holding time at pasteurization temperature, the toxic activities of purified BoNT/A and BoNT/B fell by more than 99.99%. Similarly, we were able to show that BoNT/A complex and BoNT/B complex were inactivated by more than 99.5% under common pasteurization conditions. As observed before, the BoNT complexes showed a slightly higher degree of stability; this was probably due to the stabilizing effect of associated NAPs (6, 7). In the case of the complex proteins, the results of the sandwich ELISAs did not completely reflect those of the functional assay; this might indicate that distinct epitopes of the BoNT complexes detected by ELISA were protected somewhat against thermal inactivation by the accompanying complex proteins and/or by the interaction of the BoNT complex with milk components. However, considering the results of the mouse bioassay, the detected epitopes seem not to be directly linked to the toxic activity of the toxin. Although the ELISA results provide no information on the remaining toxic activity in the heated samples, they reflect the overall stability of the toxin structure under distinct heating conditions.

In the bioterror scenario described by Wein and Liu (41), 1 g of BoNT released into approximately 230,000 liters (50,000 gallons) of raw milk would lead to 3.2 × 104 possible victims, based on 68.4% inactivation of the toxin by heat treatment. However, our experimental results based on a pasteurization process similar to the industry standard showed 99.5% inactivation of BoNT complexes and 99.99% inactivation of purified BoNTs. Assuming a scenario in which 1 g of BoNT complex is deliberately released into raw milk and at least 99.5% of the toxin is inactivated by HTST pasteurization, the amount of biologically active toxin would be reduced to 5 mg in total. Applying our experimental data and assuming a linear relationship, this would mean that following dilution in a 230,000-liter bulk milk tank, an average daily serving of 0.5 liter would contain approximately 11 ng of toxin at most. Considering the estimates for the human lethal oral dose of BoNT, this amount dramatically lowers the threat level of the widely discussed “BoNT in milk” scenario.

Our experimental data show that current conditions of HTST pasteurization are effective in reducing the toxic activities of BoNT/A and BoNT/B and the corresponding BoNT complexes by more than 99.99% and 99.5%, respectively. Therefore, the HTST pasteurization process in the dairy industry dramatically reduces the risk of consumer harm even if larger amounts of BoNT were deliberately released into the milk supply chain. However, other complex food matrices or slight changes to the heating parameters might have a different effect on the stability of BoNT. As a result, we are unable to draw any general conclusions for other matrices and heating parameters. These will have to be the subject of further experiments.

Supplementary Material

Acknowledgments

We thank Reto Zbinden for his thought-provoking contributions to our discussions and Andreas Spahni for his standardized ALP measurement.

This work was supported by a grant from the Swiss Federal Office for Civil Protection to M.-A.A. and a grant from the German Federal Ministry of Health to B.G.D.

Footnotes

Published ahead of print on 2 April 2010.

Supplemental material for this article may be found at http://aem.asm.org/.

REFERENCES

- 1.AOAC International. 2000. AOAC official method 991.24. Alkaline phosphatase activity in fluid dairy products. Fluorometric method. In Official methods of analysis of AOAC International, 17th ed. AOAC International, Gaithersburg, MD.

- 2.Arnon, S. S., R. Schechter, T. V. Inglesby, D. A. Henderson, J. G. Bartlett, M. S. Ascher, E. Eitzen, A. D. Fine, J. Hauer, M. Layton, S. Lillibridge, M. T. Osterholm, T. O'Toole, G. Parker, T. M. Perl, P. K. Russell, D. L. Swerdlow, and K. Tonat. 2001. Botulinum toxin as a biological weapon: medical and public health management. JAMA 285:1059-1070. [DOI] [PubMed] [Google Scholar]

- 3.Binz, T., and A. Rummel. 2009. Cell entry strategy of clostridial neurotoxins. J. Neurochem. 109:1584-1595. [DOI] [PubMed] [Google Scholar]

- 4.Bona, C., B. Dewals, L. Wiggers, K. Coudijzer, A. Vanderplasschen, and L. Gillet. 2005. Short communication: pasteurization of milk abolishes bovine herpesvirus 4 infectivity. J. Dairy Sci. 88:3079-3083. [DOI] [PubMed] [Google Scholar]

- 5.Bradshaw, J., J. Peeler, and R. Twedt. 1979. Thermal inactivation of Clostridium botulinum toxin types A and B in buffer, and beef and mushroom patties. J. Food Sci. 44:1653-1657. [Google Scholar]

- 6.Brandau, D., S. Joshi, A. Smalter, S. Kim, B. Steadman, and C. Middaugh. 2007. Stability of the Clostridium botulinum type A neurotoxin complex: an empirical phase diagram based approach. Mol. Pharm. 4:571-582. [DOI] [PubMed] [Google Scholar]

- 7.Chen, X., and Y. Deng. 2007. Long-time molecular dynamics simulations of botulinum biotoxin type-A at different pH values and temperatures. J. Mol. Model. 13:559-572. [DOI] [PubMed] [Google Scholar]

- 8.Cheng, L. W., B. Onisko, E. A. Johnson, J. R. Reader, S. M. Griffey, A. E. Larson, W. H. Tepp, L. H. Stanker, D. L. Brandon, and J. M. Carter. 2008. Effects of purification on the bioavailability of botulinum neurotoxin type A. Toxicology 249:123-129. [DOI] [PubMed] [Google Scholar]

- 9.Commission of the European Communities. 2005. Commission regulation (EC) no. 2074/2005 of 5 December 2005. Off. J. Eur. Union 338:27-59. [Google Scholar]

- 10.Czaplicki, A. 2007. Pure milk is better than purified milk. Soc. Sci. Hist. 31:411-433. [Google Scholar]

- 11.DasGupta, B. R., and D. A. Boroff. 1968. Separation of toxin and hemagglutinin from crystalline toxin of Clostridium botulinum type A by anion exchange chromatography and determination of their dimensions by gel filtration. J. Biol. Chem. 243:1065-1072. [PubMed] [Google Scholar]

- 12.Department of Health and Human Services. 2005. 42 CFR parts 72 and 73, 42 CFR part 1003: possession, use, and transfer of select agents and toxins; final rule. Fed. Regist. 70:13294-13325. [Google Scholar]

- 13.FDA. 2005. Phosphatase test-Fluorophos ALP test system. Form M-I-05-3. U.S. Food and Drug Administration, Silver Spring, MD.

- 14.Fischer, A., Y. Nakai, L. M. Eubanks, C. M. Clancy, W. H. Tepp, S. Pellett, T. J. Dickerson, E. A. Johnson, K. D. Janda, and M. Montal. 2009. Bimodal modulation of the botulinum neurotoxin protein-conducting channel. Proc. Natl. Acad. Sci. U. S. A. 106:1330-1335. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Hatheway, C. L. 1993. Clostridium botulinum and other clostridia that produce botulinum neurotoxin, p. 3-21. In A. H. W. Hauschild and K. L. Dodds (ed.), Clostridium botulinum: ecology and control in foods. Marcel Dekker, Inc., New York, NY.

- 16.Hauschild, A. H. W. 1993. Epidemiology of human foodborn botulism, p. 69-104. In A. H. W. Hauschild and K. L. Dodds (ed.), Clostridium botulinum: ecology and control in foods. Marcel Dekker, Inc., New York, NY.

- 17.Herrero, B. A., A. E. Ecklung, C. S. Streett, D. F. Ford, and J. K. King. 1967. Experimental botulism in monkeys—a clinical pathological study. Exp. Mol. Pathol. 6:84-95. [DOI] [PubMed] [Google Scholar]

- 18.Hill, K. K., T. J. Smith, C. H. Helma, L. O. Ticknor, B. T. Foley, R. T. Svensson, J. L. Brown, E. A. Johnson, L. A. Smith, R. T. Okinaka, P. J. Jackson, and J. D. Marks. 2007. Genetic diversity among botulinum neurotoxin-producing clostridial strains. J. Bacteriol. 189:818-832. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.IDF. 2008. World dairy situation 2007. Bull. Int. Dairy Fed. 432/2008:87-88.

- 20.Inoue, K., Y. Fujinaga, T. Watanabe, T. Ohyama, K. Takeshi, K. Moriishi, H. Nakajima, and K. Oguma. 1996. Molecular composition of Clostridium botulinum type A progenitor toxins. Infect. Immun. 64:1589-1594. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.ISO. 2006. ISO 11816-1/IDF 155-1:2006. Milk and milk products—determination of alkaline phosphatase activity—part 1: fluorometric method for milk and milk-based drinks. International Organization for Standardization, Geneva, Switzerland.

- 22.Jin, Y., Y. Takegahara, Y. Sugawara, T. Matsumura, and Y. Fujinaga. 2009. Disruption of the epithelial barrier by botulinum haemagglutinin (HA) proteins—differences in cell tropism and the mechanism of action between HA proteins of types A or B, and HA proteins of type C. Microbiology 155:35-45. [DOI] [PubMed] [Google Scholar]

- 23.Johnson, E. A., and M. Bradshaw. 2001. Clostridium botulinum and its neurotoxins: a metabolic and cellular perspective. Toxicon 39:1703-1722. [DOI] [PubMed] [Google Scholar]

- 24.Kalb, S. R., M. C. Goodnough, C. J. Malizio, J. L. Pirkle, and J. R. Barr. 2005. Detection of botulinum neurotoxin A in a spiked milk sample with subtype identification through toxin proteomics. Anal. Chem. 77:6140-6146. [DOI] [PubMed] [Google Scholar]

- 25.Licciardello, J. J., C. A. Ribich, J. T. Nickerson, and S. A. Goldblith. 1967. Kinetics of the thermal inactivation of type E Clostridium botulinum toxin. Appl. Microbiol. 15:344-349. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Lindstrom, M., K. Kiviniemi, and H. Korkeala. 2006. Hazard and control of group II (non-proteolytic) Clostridium botulinum in modern food processing. Int. J. Food Microbiol. 108:92-104. [DOI] [PubMed] [Google Scholar]

- 27.Lund, B. M. 1990. foodborn illness: foodborn disease due to Bacillus and Clostridium species. Lancet 336:982-986. [DOI] [PubMed] [Google Scholar]

- 28.Marshall, K. M., M. Bradshaw, S. Pellett, and E. A. Johnson. 2007. Plasmid encoded neurotoxin genes in Clostridium botulinum serotype A subtypes. Biochem. Biophys. Res. Commun. 361:49-54. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Matsumura, T., Y. Jin, Y. Kabumoto, Y. Takegahara, K. Oguma, W. I. Lencer, and Y. Fujinaga. 2008. The HA proteins of botulinum toxin disrupt intestinal epithelial intercellular junctions to increase toxin absorption. Cell. Microbiol. 10:355-364. [DOI] [PubMed] [Google Scholar]

- 30.Pauly, D., S. Kirchner, B. Stoermann, T. Schreiber, S. Kaulfuss, R. Schade, R. Zbinden, M.-A. Avondet, M. B. Dorner, and B. G. Dorner. 2009. Simultaneous quantification of five bacterial and plant toxins from complex matrices using a multiplexed fluorescent magnetic suspension assay. Analyst 134:2028-2039. [DOI] [PubMed] [Google Scholar]

- 31.Peck, M. W. 2006. Clostridium botulinum and the safety of minimally heated, chilled foods: an emerging issue? J. Appl. Microbiol. 101:556-570. [DOI] [PubMed] [Google Scholar]

- 32.Popoff, M. R., and J.-C. Marvaud. 1999. Structural and genomic features of clostridial neurotoxins, p. 174-201. In J. E. Alouf and J. H. Freer (ed.), The comprehensive sourcebook of bacterial protein toxins, 2nd ed. Academic Press, London, United Kingdom.

- 33.Rocco, R. M. 1990. Fluorometric determination of alkaline phosphatase in fluid dairy products: collaborative study. J. Assoc. Off. Anal. Chem. 73:842-849. [Google Scholar]

- 34.Rummel, A., T. Eichner, T. Weil, T. Karnath, A. Gutcaits, S. Mahrhold, K. Sandhoff, R. L. Proia, K. R. Acharya, H. Bigalke, and T. Binz. 2007. Identification of the protein receptor binding site of botulinum neurotoxins B and G proves the double-receptor concept. Proc. Natl. Acad. Sci. U. S. A. 104:359-364. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Schantz, E. J., and D. A. Kautter. 1978. Microbiological methods: standardized assay for Clostridium botulinum toxins. J. Assoc. Off. Anal. Chem. 6:96. [Google Scholar]

- 36.Scott, W., and D. Stewart. 1950. The thermal destruction of Clostridium botulinum toxin in canned vegetables. Aust. J. Appl. Sci. 1:200-207. [Google Scholar]

- 37.Siegel, L. S. 1993. Destruction of botulinum toxins in food and water, p. 323-341. In A. H. W. Hauschild and K. L. Dodds (ed.), Clostridium botulinum: ecology and control in foods. Marcel Dekker, Inc., New York, NY.

- 38.Simpson, L. L. 2004. Identification of the major steps in botulinum toxin action. Annu. Rev. Pharmacol. Toxicol. 44:167-193. [DOI] [PubMed] [Google Scholar]

- 39.Singh, B. R. 2006. Botulinum neurotoxin structure, engineering, and novel cellular trafficking and targeting. Neurotox. Res. 9:73-92. [DOI] [PubMed] [Google Scholar]

- 40.Smith, T. J., J. Lou, I. N. Geren, C. M. Forsyth, R. Tsai, S. L. LaPorte, W. H. Tepp, M. Bradshaw, E. A. Johnson, L. A. Smith, and J. D. Marks. 2005. Sequence variation within botulinum neurotoxin serotypes impacts antibody binding and neutralization. Infect. Immun. 73:5450-5457. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Wein, L. M., and Y. Liu. 2005. Analyzing a bioterror attack on the food supply: the case of botulinum toxin in milk. Proc. Natl. Acad. Sci. U. S. A. 102:9984-9989. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Woodburn, M. J., E. Somers, J. Rodriguez, and E. J. Schantz. 1979. Heat inactivation rates of botulinum toxins A, B, E and F in some foods and buffers. J. Food Sci. 44:1658-1661. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.