Abstract

A greenhouse gas and carbon accounting profile was developed for the U.S. forest products industry value chain for 1990 and 2004−2005 by examining net atmospheric fluxes of CO2 and other greenhouse gases (GHGs) using a variety of methods and data sources. Major GHG emission sources include direct and indirect (from purchased electricity generation) emissions from manufacturing and methane emissions from landfilled products. Forest carbon stocks in forests supplying wood to the industry were found to be stable or increasing. Increases in the annual amounts of carbon removed from the atmosphere and stored in forest products offset about half of the total value chain emissions. Overall net transfers to the atmosphere totaled 91.8 and 103.5 TgCO2-eq. in 1990 and 2005, respectively, although the difference between these net transfers may not be statistically significant. Net transfers were higher in 2005 primarily because additions to carbon stored in forest products were less in 2005. Over this same period, energy-related manufacturing emissions decreased by almost 9% even though forest products output increased by approximately 15%. Several types of avoided emissions were considered separately and were collectively found to be notable relative to net emissions.

Short abstract

Life cycle concepts are used to characterize the net impact of the U.S. forest products sector on atmospheric greenhouse gases.

Introduction

As efforts intensify to control the increase in atmospheric concentrations of greenhouse gases (GHGs), emissions from the industrial sector are coming under increasing scrutiny, in part because of their magnitude. According to the Intergovernmental Panel on Climate Change (IPCC) (1), direct GHG emissions from the global industrial sector were 7200 TgCO2-eq. (a teragram, or Tg, is 1012 grams, equal to a million metric tonne; CO2-eq. is the time-integrated radiative forcing of various GHGs expressed in terms of the equivalent CO2 emissions) in 2004, whereas total emissions, including indirect emissions associated with electricity used by the sector, were about 12,000 TgCO2-eq. These direct and total emissions represented approximately 15% and 24%, respectively, of the 49,000 TgCO2-eq. of GHG emissions globally in that year (1). In the U.S., the industrial sector’s 2006 total emissions, including those associated with electricity used by the sector, were 2030 TgCO2-eq, with direct and total emissions from the industrial sector representing 19% and 29%, respectively, of U.S. emissions (2).

While such estimates (1,2) are helpful for understanding the role of industry in general as a source of emissions, they are conducted at a broad sector level and fail to reveal the full effects of an industry’s activities. This is especially true of the forest products industry, where carbon sequestration, storage, and end-of-life emissions can be as important as direct emissions. A study of the GHG and carbon profile of the forest products industry at the global level (3) revealed: a) end-of-life emissions from products in landfills appear to be as important as manufacturing-related emissions, and b) emissions along the value chain, including those from end-of-life, are largely offset by forest-sector carbon sequestration and storage, mostly in forest products. The study also suggested that the profile of the industry could vary significantly from one region of the world to another, indicating the value of a closer examination of the sector at the regional or national level.

The objective of the present study was to develop the GHG and carbon profile for the U.S. forest products industry value chain for the years 1990 and 2005. Although we are not providing data for a formal life-cycle assessment (LCA) for a specific product, our emissions and sequestration information indicate “what are” recent annual carbon fluxes like those that would be identified by an attributional LCA. The avoided emissions information indicates the potential impact of changes in production or practices on fluxes that are similar to but not identical with information that would be identified by a consequential LCA (4). Accordingly, with this profile approach (3), we keep information on current actual emissions separate from possible avoided emissions associated with changes in production or practices.

Modeling and Data Development

The present study is organized in three broad sections: emissions, sequestration, and avoided emissions of the U.S. forest products industry. Emissions consist of transfers of GHGs from forest products industry facilities or from elsewhere in the forest products industry value chain to the atmosphere. The emissions consist primarily of carbon dioxide (CO2) from fossil fuel combustion and methane (CH4) from decomposition of discarded products in landfills. Sequestration consists of the removal of carbon from the atmosphere and subsequent storage in forests, forest products, and landfills. Avoided emissions consist of changes in emissions that would occur if production or practices are changed, and are reported separately. We do not include imported wood and paper as part of our U.S. value chain because a) U.S. national GHG reports use the production approach which accounts only for domestically produced wood, and because b) doing so may imply the U.S. forest industry should take credit for the additional storage of carbon simply because the U.S. is a net importer of wood. We do include emissions from making imported logs and chips (that is, roundwood) into products; however, since imported roundwood is less than 0.5% of U.S. wood consumption, its effect is minimal (5).

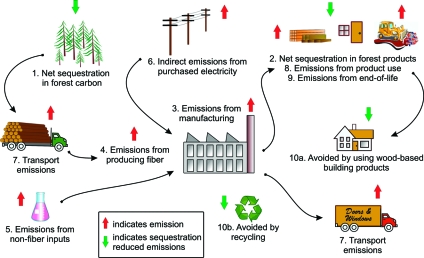

The development of the profile is further divided into 10 elements (6) for characterizing GHG and carbon footprints of paper and paperboard products. These elements and their relationship to forest industry processes are illustrated in Figure 1 and are used as topical headings under sequestration and emissions. Because the approaches to modeling or compiling data for each element are disparate, the methods are presented by element. In general, we compile activity data and multiply the data by emission or conversion factors, similar to IPCC guidance (7). For transparency, data and factors are presented by element in the Supporting Information.

Figure 1.

The elements of the U.S. forest products industry for its greenhouse gas profile. All wood grown in the U.S. is included in all elements; imported logs processed in mills are also included in elements 3−10.

Sequestration

Net Carbon Sequestration in Forests

Approximately 33% (303 million hectares) of the U.S. land area is forested. Most of this forestland (251 million ha) is in the 48 contiguous states. About 203 million of these 251 million ha are classified as timberland, meaning they meet minimum levels of productivity and are available for timber harvest. The remaining forest is either reserved (withdrawn by law from management for production of wood products) or lower productivity forestland that is likely not to be managed for commercial timber production (5,2).

Estimates of carbon sequestration in U.S. forests are based on U.S. Department of Agriculture, Forest Inventory and Analysis (FIA) Program (9) data. The statistically designed survey involves field visits to approximately 130,000 forested plots in the 48 U.S. states as well as plots in Hawaii, Alaska, and the U.S. territories. These data are the basis for forest carbon estimates in the FORCARB2 model, which is a forest carbon budget simulation model that makes estimates for U.S. forests primarily based on inventory data (10,11). The FORCARB2 model calculates carbon stock changes in forests, including all pools: live and dead standing trees, understory vegetation, down dead wood, forest floor, and mineral soil. Soil estimates are not included in the present study because only areas of net land-use change, not gross land-use change, are available. Only knowing net changes makes estimating soil carbon changes difficult because the carbon dynamics of afforestation and deforestation are different. Carbon is estimated and projected by ownership, such as forest industry and public, and forest type. The FORCARB2 base scenario from the 2005 Resources Planning Act Assessment was used to perform this analysis (12).

Carbon Stored in Forest Products

Carbon removed from the forest is transferred into products, delaying its return to the atmosphere. Some of these products are discarded into landfills at the end of their useful lives, where they are stored with limited decay over time. If carbon is added to the pool of products in use faster than it is removed by the retirement of previously manufactured items, then stocks of carbon in the products in use pool increase. The Woodcarb II model (13) was used to estimate changes in harvested wood products held in products (in-use), discards from use, and transfers into and emissions out of unmanaged disposal sites and landfills. (Methane emissions from landfills are also estimated by Woodcarb II and reported here in the element emissions associated with product end-of-life.) We estimated annual additions and losses since 1900, which allows for an estimate of the total carbon stored in products. The production-accounting approach was used, meaning that carbon in products is tracked if the wood came from trees harvested in the United States, including exported wood and paper products but excluding imported products (7). Exports were treated as though they remained in the United States. Emissions associated with creating and transporting products are discussed in the Emissions section.

Emissions

Based on a previous study (3), the most significant emissions are expected to be direct emissions from manufacturing, indirect emissions associated with purchased electricity, and emissions associated with product end-of-life (CH4 from landfills). Other emission types are emissions associated with producing fiber, those associated with producing nonfiber, emissions related to transportation, and those related to product use. The basic method for estimating emissions for each category is to multiply activity data, such as energy consumption, by emission factors, such as CO2 emitted per gallon.

GHGs from Forest Products Manufacturing Facilities

Manufacturing facilities contribute direct emissions of three main types: direct emissions associated with fuel combustion, emissions associated with management of mill wastes, and emissions associated with secondary manufacturing operations. Emissions for these three types had to be estimated separately for the pulp and paper sector and the wood products sector because of sector differences. Direct CO2 emissions associated with fuel combustion were calculated by multiplying energy consumption rates by GHG emission factors (14). Energy data were obtained for the pulp and paper sector (15) and the wood products sector (16,17) as well as factors for CH4 and N2O emissions from biomass fuel combustion. See the Supporting Information, section 2 for details.

The industry satisfies much of its energy requirements by burning biomass for fuel. Release of CO2 from biomass combustion (approximately 113 TgCO2 based on fuel consumption data from (18)) is not included in our GHG totals, in accordance with accepted reporting protocols from the World Resources Institute Greenhouse Gas Protocol (19). This is because the emissions from burning wood are already accounted for by the decrease in carbon stored in forests, and it would be double-counting to include the emissions.

GHGs Associated with Producing Fiber

Emissions are generated in the forest before, during, and after harvest, including emissions associated with use of fertilizers during planting and growth, fuel consumption by harvesting equipment, and non-CO2 emissions associated with pile burning sometimes used to clear harvest debris and prepare a site for replanting and regeneration. Emissions estimates were compiled (2) or estimated from the literature associated with harvest data statistics (22,23) and are described in the Supporting Information, section 3. All emissions related to transport are accounted for separately in the transport category.

GHGs Associated with Producing Nonfiber Inputs and Fuels

Wood fiber constitutes the vast majority of the raw materials associated with forest products manufacturing (20,21), so nonfiber, nonfuel inputs are expected to be minor. Nonfiber fillers for printing and writing grades paper may comprise 10% of sheet weight or more, but these highly filled grades represent a relatively small fraction of the industry’s output of paper and paperboard. Nonfiber inputs are even less important in wood products manufacture. In the case of oriented strand board, for instance, which contains more nonwood components than most wood products, wood and bark comprise over 95% of the raw materials (24). Data from commercial life cycle and forest products industry databases were used to estimate upstream loads associated with chemical inputs needed to manufacture the predominant products manufactured by the U.S. forest products industry. For information on factors, databases, and data see the Supporting Information, section 4.

Indirect Emissions Associated with Purchases of Electricity

Emissions associated with purchased electricity were derived from data on electricity purchases and sales and multiplied by the national purchased electricity emission factor averaged over the years 1998−2000 (168.2 kg CO2/GJ (2)). Supporting Information, section 5 contains activity data and emission factors.

Transport-Related Greenhouse Gas Emissions

Wood is transported from the forest to primary manufacturing facilities such as sawmills and pulp and paper mills, primary products (e.g., rolls of paper) are transported to facilities that make final products (e.g., books), and final products are distributed to retailers. Activity data, the quantities of transported commodities, are presented in the Supporting Information, section 6. Quantities transported were multiplied by the fuel consumption factors for trucks and trains (25). Methane and nitrous oxide emissions are not included because they appear to be small compared with the uncertainty in the estimates of CO2 emissions. Methane and N2O emissions are typically less than 2.5% of CO2 emissions for gasoline and diesel fuel on a CO2 equivalents basis (see ref (7), Vol. 2. Chapter 3, Tables 3.2.1 and 3.2.2).

Emissions Associated with Product Use

There are no emissions associated with forest product use, with one possible exception, which is reported in the element GHGs from forest products manufacturing. The exception is non-CO2 GHG emissions from use of wood for fuels within industry facilities. See the Supporting Information, section 2.1.

Emissions Associated with Product End-of-Life

Forest products can degrade when exposed to anaerobic conditions that exist in most municipal solid waste (MSW) landfills, resulting in formation of CH4 and CO2. However, wood and paper discarded to landfills are subject to limited decay because the lignin portion and the cellulose and hemicellulose protected by lignin are not subject to anaerobic decay. In our analysis framework, as in IPCC guidance for national accounting (7), carbon stored in and emissions from landfills are recognized as well as the higher radiative forcing effect of CH4. Methane emissions corresponding to decay of forest products in landfills were estimated using the Woodcarb II model (13), which we also used to estimate transfer and storage of carbon into products and landfills. An important factor affecting CH4 emissions estimates is the fraction of CH4 recovered or oxidized before it reaches the atmosphere by capture in landfills with CH4-collection systems

Avoided Emissions

A variety of activities associated with the forest products value chain can result in avoided GHG emissions. Avoided emissions require information about the activities that would have occurred in the absence of the activity causing the avoided emissions, which can be very difficult to estimate. However, the effects could be large. This study addresses two types of avoided emissions for which studies exist. First are those associated with decreased CH4 emissions attributable to recycling. These changes were calculated by using the U.S. Environmental Protection Agency’s (EPA) Waste Reduction Model (WARM), which allowed us to examine the CH4 differences between recycling and average existing end-of-life management of paper on a lifecycle basis (26). See the Supporting Information, section 9 for more details. Second are those avoided emissions associated with using wood-based building materials in place of more GHG-intensive alternatives. These avoided emissions factors were taken from Upton et al. (27).

Results and Discussion

We discuss items with the resulting largest or most complex carbon changes: net C sequestration in forests, carbon stored in forest products, direct emissions from forest products manufacturing, and emissions associated with product end-of-life. Uncertainty of the estimates is given in terms of percentage. Results are presented for all elements.

Net Carbon Sequestration in Forests

Improved forest management practices, regeneration of previously cleared forest areas, and harvesting less timber than is grown have resulted in net uptake (i.e., net sequestration) of carbon each year from 1990 through 2006 (2). Results based on FORCARB2 model output are shown in terms of carbon and forested area by productivity and owner category for forests of the conterminous United States in Table 1. Note that the three latter categories are subsets of the previous categories; that is, we would not expect the last three categories to add up to all forests. The total for all forests of the conterminous United States in Table 1 is similar to the average of estimates from U.S. EPA (28,29) from consecutive years because FORCARB2 was calibrated at that time with the available data from those years. The area of forest is relatively stable by owner group (8), although the nature of industry ownership has evolved since these estimates were derived (30). It is not certain how these changes may have affected this analysis, but it is doubtful the effect in the short term would be large.

Table 1. Forest Ecosystem Area (2005, million ha), Carbon Stocks (2000), and Stock Changes: 2000—2005a.

| productivity - owner category | area (million ha) | stocks (PgC) | stock changes (TgC/y) | stock changes (TgCO2-eq./y) |

|---|---|---|---|---|

| all U.S. forests | 248.9 | 25.5 | −125.3 | −459 |

| all timberland | 203.2 | 21.6 | −96.8 | −355 |

| all private timberland | 147.4 | 14.0 | −35.7 | −131 |

| all industry-owned timberland | 27.1 | 2.5 | 3.0 | 11 |

All pools except soil, average annual carbon stock changes; negative number indicates sequestration.

Nonetheless, it is difficult to precisely attribute the effects of the industry’s activities on U.S. forest carbon stocks. Wood used by the U.S. forest products sector comes from a variety of landowners, each with divergent management objectives. Intensive management of industry-owned land for wood production likely reduces demand for wood on other timberlands, which indirectly contributes to the accumulation of carbon on nonindustry-owned timberland. Because wood production is a more important management objective on industrial timberland than on most other types of private timberland, carbon dynamics on industrial timberland generally differ from those on private timberland. Timberlands in total gained carbon between 2000 and 2005 (355 TgCO2-eq./y or about 0.7%/y on a land base of 14.0 PgC, not including soil carbon), while carbon stocks on industry-owned lands decreased a small amount (11 TgCO2-eq./y or about 0.1%/y on a land base of 2.5 PgC, not including soil carbon). The carbon stocks on industry-owned lands are projected to increase slightly in the future, however (see the Supporting Information, section 1). These small increases and decreases are within a range that suggests that carbon stocks on industry-owned timberland are essentially stable. Because the complexity of wood flows precludes a precise estimate of forest carbon impacts attributable to the industry, and because carbon stocks on industry-owned lands appear relatively stable, we assume that forest industry landowners manage their forests so that growth and removals are equal over time, resulting in an average net forest carbon change of zero. The 95% confidence interval of annual change estimates in carbon stored in forests is ±26% (2). Because any percentage of uncertainty around a value of zero results in an absolute value of zero uncertainty, we assume the 95% confidence interval about the estimate absolute terms to be ±20 TgCO2-eq.

Carbon Stored in Forest Products

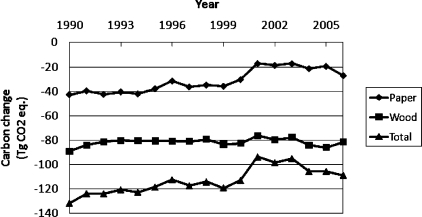

Estimates of annual carbon changes for products in use and in landfills are shown in Figure 2. Additions are greater for wood products than for paper because of the shorter use life of paper. Annual net additions decreased from 132.7 TgCO2-eq. in 1990 to 110 TgCO2-eq. in 2006. These estimates are for carbon in products and landfills where the wood came from U.S. harvest, including exported products in use in other countries. Deposits to landfills include discarded wood from mills, construction, and end uses, and the model discard rate is calibrated so discards match U.S. EPA data on discards to landfills (13). One reason for the decline in annual additions is the decreasing proportion of U.S. consumption that comes from domestic harvest, with an increasing fraction from imported wood and paper. The total stock of carbon in products in use and landfills is estimated to have been 2303 TgCO2-eq. in 2006, with over 60% of that in products in use alone. The 95% confidence interval around annual changes in carbon stored in wood products in use, dumps, and landfills is ±24% (2). The uncertainty evaluation includes uncertainty in data, parameters, and model specification (13).

Figure 2.

Annual changes in carbon in wood and paper products in use and in landfills (TgCO2-eq.) Negative values indicate continued storage out of the atmosphere.

Direct Emissions from Forest Products Manufacturing

Fuel consumption at pulp and paper mills is the largest contributor to direct emissions from forest products manufacturing (Table 2). The other two sources, management of mill wastes and emissions associated with final manufacturing operations, are small. We assume uncertainty is ±15%, which is the uncertainty estimate for CO2 emissions from all industrial sources in the United States (2).

Table 2. Direct Emissions Associated with U.S. Forest Products Manufacturing Facilities.

| direct emissions source | 1990 emissionsa (TgCO2-eq.) | 2004 emissionsa (TgCO2-eq.) |

|---|---|---|

| fuel consumption at pulp and paper mills | 66.9 | 57.7 |

| fuel consumption at wood products facilities | 4.4b | 1.8 |

| management of mill wastes | 2.0c | 2.6c |

| secondary pulp and paper sector manufacturing operationsd | 2.8b | 2.5e |

| total | 76.1 | 64.6 |

Emissions of CH4 and N2O from all combustion processes are included. Biomass-derived CO2 is dealt with in the assessment of forest carbon because biogenic carbon is analyzed separately from fossil fuel carbon; an emission factor of zero is used here to avoid double counting.

Estimates based on 1991 fuel consumption data.

Includes CH4 from mill landfills and from anaerobic zones of wastewater treatment plants, not considering the offset from carbon storage in mill landfills (which would lower these numbers).

That is, converting primary products into final products.

Estimates based on 2002 fuel consumption data.

Emissions Associated with Product End-of-Life

Estimated CH4 emissions from wood and paper in landfills (where wood came from U.S. forests) are shown in Table 3(13). Estimated generated CH4 has increased almost 50% between 1990 and 2005, but the fraction recovered or oxidized by CH4 collection from landfills has more than doubled from 20% to 50% (26). As a result, estimated net emissions decreased from 61 TgCO2-eq. in 1990 to 56 TgCO2-eq. in 2005.

Table 3. Methane Emitted from Wood and Paper Products in Landfills and Products Made from Wood Harvested in the United States.

| CH4 generated (TgCO2-eq.) |

net CH4 emitted (TgCO2-eq.) |

||||||

|---|---|---|---|---|---|---|---|

| year | wood | paper | total | fraction recovered/oxidized | wood | paper | total |

| 1990 | 17.1 | 59.1 | 76.2 | 0.20 | 13.7 | 47.2 | 60.8 |

| 1992 | 18.8 | 64.8 | 83.6 | 0.23 | 14.4 | 49.7 | 64.1 |

| 1994 | 20.2 | 70.1 | 90.4 | 0.27 | 14.9 | 51.5 | 66.4 |

| 1996 | 21.8 | 73.5 | 95.3 | 0.31 | 15.0 | 50.6 | 65.6 |

| 1998 | 23.1 | 77.3 | 100.4 | 0.37 | 14.5 | 48.5 | 63.0 |

| 2000 | 24.4 | 80.8 | 105.3 | 0.43 | 13.8 | 45.8 | 59.7 |

| 2002 | 25.7 | 83.0 | 108.7 | 0.46 | 13.8 | 44.6 | 58.3 |

| 2004 | 26.9 | 84.2 | 111.1 | 0.49 | 13.8 | 43.1 | 56.8 |

| 2006 | 28.1 | 85.4 | 113.5 | 0.50 | 14.1 | 42.7 | 56.8 |

The U.S. Forest Products GHG Profile

The estimates of the U.S. forest products industry GHG and carbon profile in 1990 and 2004−2005 are presented by category and summarized in Table 4. Avoided emissions are not subtracted from other emissions but are included as additional information to help illustrate important connections between the forest products value chain and atmospheric GHGs. Net value chain emissions, considering both emissions and sequestration, were estimated to be 103.5 TgCO2-eq. in 2004−2005. The net sequestration for the U.S. forest products value chain was sufficient to offset all direct emissions plus all indirect emissions associated with purchased electricity (about one-half of total value chain emissions).

Table 4. Greenhouse Gas and Carbon Profile of the U.S. Forest Products Industry.

| greenhouse gas emissions (TgCO2-eq.; negative numbers indicate sequestration) |

||||

|---|---|---|---|---|

| profile element | 1990 | 2004 − 2005 | uncertainty range (%) 2005 | uncertainty range (TgCO2-eq.) 2005 |

| 1. changes in stocks of carbon in forestsa | 0a | 0a | —b | −20 to +20c |

| 2. changes in stocks of carbon in forest products | −132.6 | −108.5 | ±24 | −134.5 to −82.5 |

| 3. direct emissions from forest products manufacturing | 76.1 | 64.6 | ±15 | 54.9 to 74.3 |

| 4. emissions associated with producing fiber | 4.0 | 4.2 | −50 to +100c | 2.1 to 8.4 |

| 5. emissions associated with nonfiber inputs | 24 | 24 | −50 to +200c | 12 to 72 |

| 6. indirect emissions associated with purchased electricity | 42.4 | 43.6 | ±25c | 32.7 to 54.5 |

| 7. emissions related to transport of raw materials and products | 16.9 | 19.6 | −50 to +100c | 9.8 to 39.2 |

| 8. emissions associated with product use | 0 | 0 | 0 | 0 |

| 9. emissions associated with product end-of-life (landfill CH4) | 61 | 56 | −41 to +34 | 33 to 75 |

| net transfers to the atmosphere | 91.8 | 103.5 | −75 to +91 | 25.8 to 197.7 |

| 10a. avoided emissions associated with recycling recovered paper | −d | −13 to −115 | −d | −d |

| 10b. avoided emissions associated with using wood-based building materials | −d | −7.2 | −d | −d |

Stable long-term forest stocks are consistent with the data and the principles of sustainable forest management practices on U.S. industrial timberlands. Other privately owned forestlands continue to accrue large amounts of carbon.

Percentage uncertainty is undefined when based on a value of zero.

Bounds based on the best professional judgment of the authors.

Not estimated.

For some elements, we adopted uncertainties from published studies. Information for uncertainty bounds on the remaining emissions is limited; bounds are based on professional judgment of the authors. Using IPCC methods for combining uncertainties (31), the resulting 95% interval for net transfer to the atmosphere for 2004−2005 is 26−198 TgCO2-eq.

Because of this uncertainty range, the estimated change between 1990 and 2005 in total net transfers may not be significant, although some individual elements exhibit significant change. Between 1990 and 2004/2005, a period over which the industry’s production increased by about 15%, value chain emissions (not considering sequestration) decreased by about 6%, whereas net emissions (with sequestration included) increased by 13%. Some elements of the profile improved over this period and others did not. Overall carbon sequestration attributable to the U.S. forest products sector decreased 18%, primarily reflecting an increased reliance on imported products and reduced amounts of discarded products going to landfills. Direct emissions from manufacturing decreased 15%, whereas those attributable to purchased electricity increased 3%, representing a combined reduction of 9% in manufacturing-related emissions. Emissions of CH4 attributable to decaying forest products decreased 8% and transport-related emissions increased about 15%, a direct result of increases in industry production.

Avoided emissions are difficult to quantify with certainty, but several types of avoided emissions serve to further reduce the forest product industry’s GHG impact. Recycling alone accomplishes an estimated 13−115 TgCO2-eq./y in avoided emissions. The effect of use of wood-based building materials in lieu of steel and concrete is also notable, amounting to 7.2 TgCO2-eq. in 2005 (derived from ref (27)).

The results of this profile can be compared with an analogous profile for the global forest products industry (3). In that study, carbon sequestration appeared to offset a much larger fraction of value-chain emissions than in our study of the U.S. industry. A comparison of the profiles of each study found that production-normalized estimates for most of the key elements were within 15% of each other.

A large difference between the studies was found, however, in estimates of carbon storage in landfills, where the production-normalized estimates in the global forest products industry study were approximately 70% larger than those estimated in this profile of the U.S. forest products industry. It appears that the primary reason is the difference in assumptions about the fraction of used products landfilled. In recent years, the fraction of paper discarded to U.S. landfills (as a percentage of discards before recovery of paper for recycling) was about 33%, whereas for the global study it was about twice that. In spite of this difference, CH4 results are similar because the fraction of discards put into landfills in earlier periods, which are more important to current CH4 emissions, were similar for the two studies.

In terms of improving methods, this study indicates that if imports continue to increase, methods used should better identify the emissions embodied in the imports. A study which examined wood and products trade and the accounting system, aimed at informing policymakers interested in designing policies to encourage lessening of GHG emissions, would be very useful. Reducing the uncertainties in categories of emissions associated with product end-of-life, transport, and associated with nonfiber inputs will most greatly reduce uncertainty in the overall estimates. Further research on estimating avoided emissions related to recycling recovered paper would help confirm recycling activities that most reduce GHG emissions.

Results of this study indicate that improvements in the U.S. industry’s carbon and GHG profile can be achieved by focusing on several areas:

• Continue to reduce direct and indirect emissions intensity (GHG per unit production) attributable to manufacturing operations.

• Expand efforts to keep easily degradable forest products out of landfills.

• Ensure that wood harvested and burned for energy in place of fossil fuel is counted properly.

• Make more extensive use of landfill cover systems that capture and use or destroy CH4.

• Increase the use of forest products, especially in long-lived applications, manufactured from domestically grown wood; in many applications they provide carbon sequestration benefits, and they also avoid emissions by substituting for more GHG-intensive products and fuels.

Acknowledgments

NCASI is an independent, nonprofit research institute that focuses on the technical and scientific aspects of environmental topics of interest to the forest products industry. NCASI receives most of its funding from the United States forest products industry, whose environmental attributes are examined in this research. There were no additional sources of funding provided specifically for this study. For more information, see http://www. ncasi.org.

Supporting Information Available

Detailed information on forest ecosystems and carbon and greenhouse gas emissions from forest products manufacturing facilities. This material is available free of charge via the Internet at http://pubs.acs.org.

Supplementary Material

References

- Bernstein L.; Roy J.; Delhotal K. C.; Harnisch J.; Matsuhashi R.; Price L.; Tanaka K.; Worrell E.; Yamba F.; Fengqi Z.. Industry. In Climate Change 2007: Mitigation, Contribution of Working Group III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change. Metz B., Davidson O., Bosch P., Dave R., Meyer L., Eds.; Cambridge University Press: New York, 2007; pp 447−496. [Google Scholar]

- Environmental Protection Agency (EPA). Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990−2006; U.S. Environmental Protection Agency: Washington, DC, 2008. U.S. Environmental Protection Agency Website http://www.epa.gov/climatechange/emissions/downloads/08_CR.pdf (February 9, 2009). [Google Scholar]

- Miner R.; Perez-Garcia J. The greenhouse gas and carbon profile of the global forest products industry. Forest Prod. J. 2007, 57 (10), 80–90. [Google Scholar]

- Brander M.; Tipper R.; Hutchison C.; Davis G.. 2008. Technical Paper: Consequential and attributional approaches to LCA: a Guide to policy makers with specific reference to greenhouse gas LCA of biofuels; Econometrica Press. [Google Scholar]

- Howard J. L.; Westby R.. U.S. Forest Products Annual Market Review and Prospects, 2005−2009; Research Note FPL-RN-0313; U.S. Dept. of Agriculture, Forest Service: Madison, WI, 2009; 9p. [Google Scholar]

- Confederation of European Paper Industries (CEPI). Framework for the Development of Carbon Footprints for Paper and Board Products; Confederation of European Paper Industries: Brussels, BE, 2007; 50pp. Available at http://www.ncasi.org/programs/areas/climate/footprint.aspx (August 17, 2009). [Google Scholar]

- 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC, Institute for Global Environmental Strategies: Hayama, Kanagawa, Japan, 2006. [Google Scholar]

- Smith W.; Miles P.; Vissage J.; Pugh S.. Forest Resources of the United States: 2002; Gen. Tech. Rep. NC—241; U.S. Dept. of Agriculture, Forest Service, North Central Research Station: St. Paul, MN, 2004; 137 pp. [Google Scholar]

- U.S. Department of Agriculture, Forest Service. Forest Inventory and Analysis National Program; Website http://fia.fs.fed.us/ (August 17, 2009). [Google Scholar]

- Smith J.; Heath L. S. Carbon stocks and projections on public forestlands in the United States, 1952−2040. Environ. Mgmt. 2004, 33 (4), 433–442. [DOI] [PubMed] [Google Scholar]

- Woodbury P. B.; Smith J. E.; Heath L. S. Carbon sequestration in the U.S. forest sector from 1990 to 2010. Forest Ecol. Mgmt. 2007, 241, 14–27. [Google Scholar]

- Haynes R.; Adams D.; Alig R.; Ince P.; Mills J.; Zhou X.. The 2005 RPA Timber Assessment Update; Gen. Tech. Rep. PNW—GTR—699; U.S. Department of Agriculture, Forest Service: Portland, OR, 2007; 212 pp. [Google Scholar]

- Skog K. Carbon storage in forest products for the United States. Forest Prod. J. 2008, 58 (6), 56–72. [Google Scholar]

- Revised 1996 IPCC guidelines for national greenhouse gas inventories: Reference manual (Vol. 3). IPCC National Greenhouse Gas Inventory Program; 1997; IPCC Website http://www.ipcc-nggip.iges.or.jp/public/gl/invs6.htm (March 31, 2008).

- 2007 Statistics, Data through 2006; Paper, Paperboard, and Wood Pulp; Am. Forest and Pap. Assoc.: Washington, DC, 2007. [Google Scholar]

- U.S. Department of Energy. Manufacturing Consumption of Energy 1991; Energy Information Administration: Washington, DC, 1994; Department of Energy Website http://tonto.eia.doe.gov/FTPROOT/consumption/051291.pdf (March 31, 2008) . [Google Scholar]

- Monitoring Progress Toward the AF&PA Climate VISION Commitment; American Forest and Paper Association: Washington, DC, 2008; 40pp. Available at http://www.ncasi.org/programs/areas/climate/footprint.aspx (August 17, 2009). [Google Scholar]

- U.S. Department of Energy. 2002 Manufacturing Energy Consumption Survey (MECS); Energy Information Administration: Washington, DC, 2005; Department of Energy Website http://www.eia.doe.gov/emeu/mecs/mecs2002/data02/shelltables.html (March 31, 2008). [Google Scholar]

- World Resources Institute. The Land Use, Land-Use Change, and Forestry Guidance for GHG Project Accounting; World Resources Institute: Washington, DC, 2006; 95pp. Available at http://pdf.wri.org/lulucf_guidance.pdf (March 31, 2008). [Google Scholar]

- Sonne E. Greenhouse gas emissions from forestry operations: A life cycle assessment. J. Environ. Qual. 2006, 35, 1439–1450. [DOI] [PubMed] [Google Scholar]

- U.N. Food and Agriculture Organization. FAOSTAT Forest Products Data Base; U.N. Food and Agriculture Organization (FAO): Rome, 2008; United Nations Website http://faostat.fao.org (March 31, 2008). [Google Scholar]

- Economics of the Pulp and Paper Industry. Book 1, Papermaking Science and Technology series.Diesen M., Ed.; Helsinki, Fapet Oy (in cooperation with the Finnish Paper Engineers’ Association and TAPPI), 1998;. 186pp.

- Löfgren P. W.Lifecycle inventory for kraft sack paper; Eurosac and CEPI Eurokraft: Brussels, BE, 2005. Available upon request from Eurosac, Paris.

- Kline E.CORRIM: Phase I final report—Module E—Southeast oriented strandboard production; CORRIM: Seattle, WA, 2004; 79pp. [Google Scholar]

- U.S. Department of Energy. Energy intensity indicators—Transportation sector spreadsheet; Office of Energy Efficiency and Renewable Energy: 2006; DOE Website http://www1.eere.energy.gov/ba/pba/intensityindicators/trend_data.html (May 15, 2008).

- U.S. Environmental Protection Agency. Solid waste management and greenhouse gases: A life-cycle assessment of emissions and sinks, 3rd ed.; EPA: Washington, DC, 2006. [Google Scholar]

- Upton B.; Miner R.; Spinney M.; Heath L. The greenhouse gas and energy impacts of using wood instead of alternatives in residential construction in the United States. Biomass Bioenergy 2008, 32, 1–10. [Google Scholar]

- U.S. Environmental Protection Agency. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990−2002; EPA: Washington, DC, 2004; EPA Website http://www.epa.gov/climatechange/emissions/usgginv_archive.html (March 31, 2008). [Google Scholar]

- U.S. Environmental Protection Agency. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990−2003; EPA: Washington, DC, 2005; U.S. Environmental Protection Agency Website (http://www.epa.gov/climatechange/emissions/usgginv_archive.html (March 31, 2008) . [Google Scholar]

- Butler B. Forest ownership. In Forest Resources of the United States, 2007; Gen. Tech. Rep. WO—78; Smith W., et al. coords.;U.S. Department of Agriculture, Forest Service, Washington Office: Washington, DC, 2009. [Google Scholar]

- Good Practice Guidance for Land Use, Land Use Change, and Forestry; Penman J., Gytarsky M., Hiraishi T., et al., Eds.; Institute for Global Environmental Strategies for the IPCC: Hayama, Kanagawa, Japan, 2003. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.