Abstract

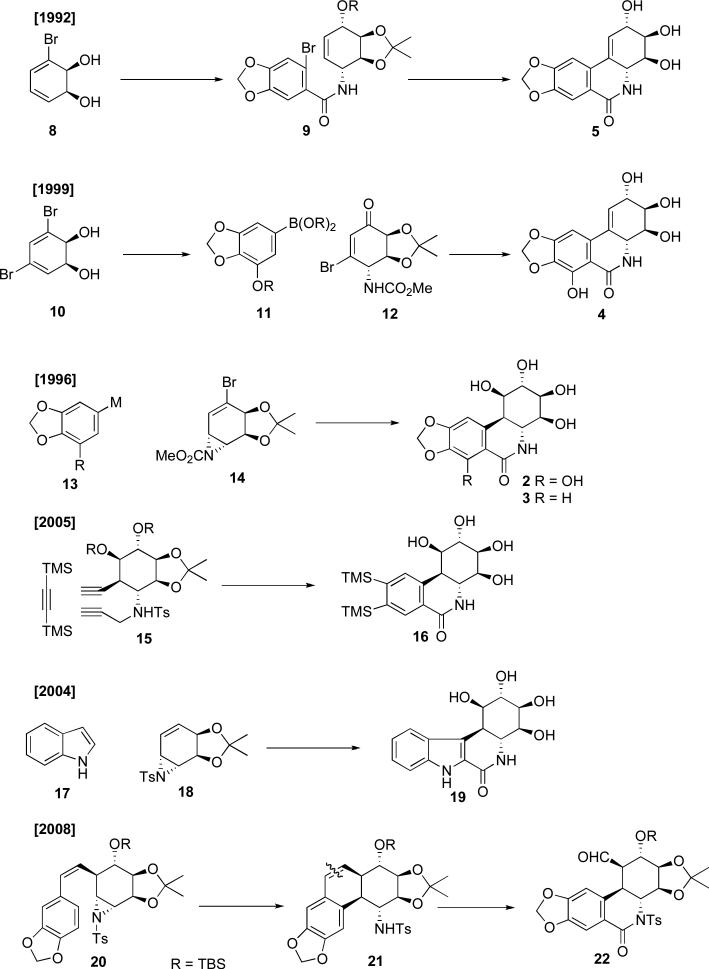

An efficient synthesis of C-1 derivatives of 7-deoxypancratistatin is reported. The key steps include the following: selective opening of an epoxide with aluminum acetylide in the presence of an aziridine; solid-state silica-gel-catalyzed opening of an aziridine; oxidative cleavage of a phenanthrene core and its recyclization to phenanthridone to provide the key C-1 aldehyde 22. The conversion of this aldehyde to C-1 acetoxymethyl and C-1 hydroxymethyl derivatives is described along with the evaluation of their biological activity against several cancer cell lines and in an apoptosis study. The C-1 acetoxymethyl derivative has shown promising activity comparable to that of the natural product. In addition, a total synthesis of trans-dihydrolycoricidine and a formal total synthesis of 7-deoxypancratistatin are reported from aldehyde 22. Detailed experimental and spectral data are provided for all new compounds.

Introduction

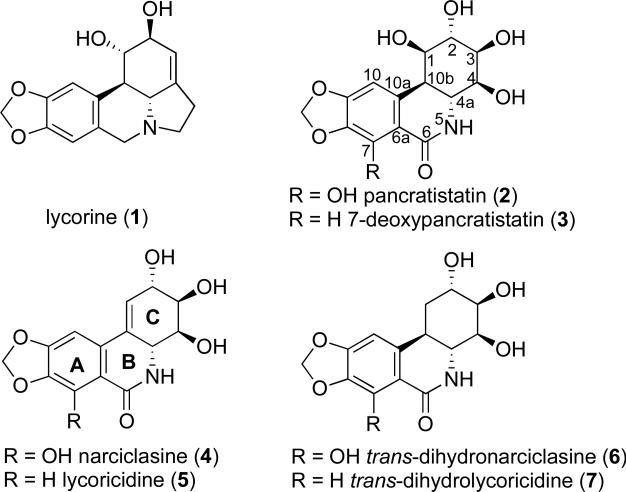

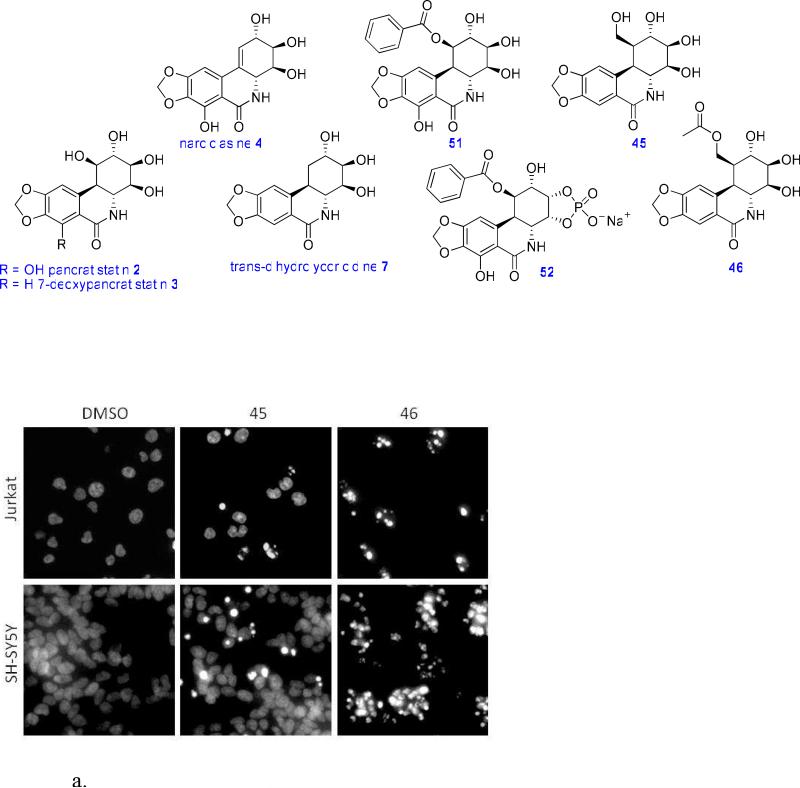

More than 100 constituents have been isolated from various Amaryllidaceae species since the identification of lycorine (1) in 1877.2 The medicinal value of the plants of the Amaryllidaceae family had been known for centuries but only in the past few decades were the active cytotoxic principles isolated and subjected to medicinal evaluation as promising anti-tumor agents. From such studies pancratistatin (2) and narciclasine (4), Figure 1, emerged as the most active compounds, with the corresponding 7-deoxy congeners, 7-deoxypancratistatin (3) and lycoricidine (4), less active.3 The drop in activity was attributed to be the consequence of the missing donor-acceptor quality of the phenanthridone-phenol functionality in the latter group of compounds. The saturated constituents 6 and 7, lack C-1 functionality and are also less active.

Figure 1.

Representative members of the Amaryllidaceae constituents.

The synthetic community took active notice of these constituents starting in the 1970s with the first synthesis of lycoricidine4 by Ohta in 1975. The total syntheses of the constituents followed: lycorine5 in 1975 by Tsuda, 7-deoxypancratistatin6 in 1976 by Ohta, trans-dihydrolycoricidine7 in 1978 by Isobe, pancratistatin8 in 1989 by Danishefsky, narciclasine9 in 1997 by Rigby, and trans-dihydronarciclasine10 in 2007 by Cho.

The activity in total synthesis has not diminished as evidenced by the number of creative approaches that continue to appear in the literature as well as the number of reviews published on the topic of total synthesis and biology.11 Our research program in this area started with the chemoenzymatic total synthesis of lycoricidine in 1992 and continued with the first asymmetric synthesis of pancratistatin in 1995. Since that time we have focused our program on two major goals, the first being the provision of practical and scaleable synthesis of pancratistatin or narciclasine in order to solve the supply problem of these compounds. The second goal, pursued in collaboration with Pettit's group, aims at the design and synthesis of unnatural derivatives of Amaryllidaceae constituents that would have improved solubility and bioavailability with full retention or even enhancement of activities.

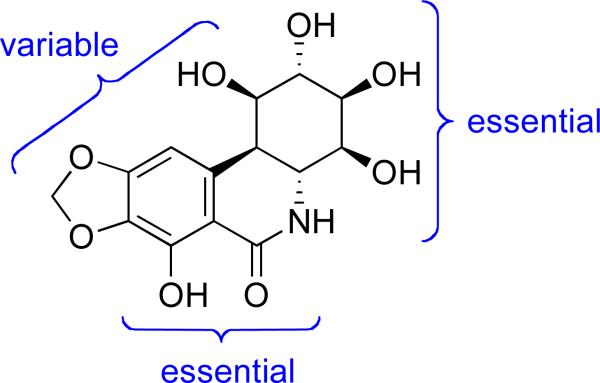

The pioneering research of Pettit on the investigation of biological activities of Amaryllidaceae constituents have eventually led to a proposal for the essential pharmacophore of pancratistatin as depicted in Figure 2.

Figure 2.

Proposed pharmacophore of pancratistatin.

The current efforts of our group, McNulty, and Kornienko have produced many unnatural derivatives of pancratistatin, some with modest activities. For example, McNulty investigated the importance of hydroxylation12 and constitution13 of the aminoinositol ring. Kornienko has also explored various truncations of the C ring.14 In the course of their semi-synthesis of pancratistatin, Pettit and coworkers generated a C-1 benzoyl derivative of pancratistatin that displayed remarkably potent activity.8h In an effort to improve the aqueous solubility of various Amaryllidaceae constituents, the Pettit group has synthesized 7-O-phosphate prodrug analogues of 2,15 3,4-O-cyclic phosphate analogues of 2, 4-7, and the C-1 benzoyl analog.16 These phosphate prodrugs are currently being evaluated on a preclinical level. We have prepared an indole mimic of 7-deoxypancratistatin,17 several truncated derivatives,18 a cis-fused epimer of 7-deoxypancratistatin,19 which was completely devoid of activity, and bis-trimethylsilyl analogues20 attained by cobalt-catalyzed cyclotrimerization of acetylene-equipped scaffolds. Chapleur prepared lactone analogs of lycoricidine and found such compounds completely inactive.21 From the results of biological testing of these derivatives it became evident that full hydroxylation and trans-fused ring junction are essential for activity. Furthermore, the donor-acceptor functionality of pancratistatin is also essential for activity, which is greatly diminished in the constituents lacking the C-7 phenol. Finally, the efforts of Gabrielsen22 established that the Amaryllidaceae constituents also exhibit antiviral activity. It may very well be that the amino mannose configuration of the amino inositol ring is responsible for such biological activity. To complete the activity testing of the Amaryllidaceae constituents will require supply of the compounds from sources other than isolation.

The first goal, the attainment of practicality would require a total synthesis of less than eight steps as well as serious optimization, and so far this requirement would seem out of reach as the shortest of our syntheses is 11 steps long. To reach the second goal we have to date prepared a number of truncated derivatives that did display moderate activities when tested against the standard human cancer cell lines. The quest for both of the defined goals is now in its 8th generation effort. In this paper we report a concise chemoenzymatic synthesis of several C-1 derivatives of 7-deoxypancratistatin by an efficient strategy involving the phenanthrene-phenanthridone transform via oxidative cleavage and recyclization. Two of the derivatives displayed high and promising activities, which are reported herein. In addition, formal total syntheses of 7-deoxypancratistatin and trans-dihydrolycoricidine have also been completed.

Results and Discussion

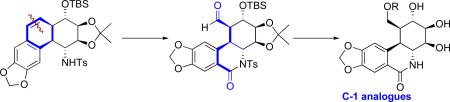

Almost twenty years ago we have implemented a general chemoenzymatic strategy toward the four major Amaryllidaceae constituents. The design for lycoricidine and narciclasine envisioned the generation of the aminocoduritol moiety via hetero Diels-Alder reaction of cis-dihydrodiols such as 8 and 10, derived from bromobenzene and m-dibromobenzene, respectively. The introduction of the aryl fragment then relied on an appropriate Heck or Suzuki coupling, Figure 3. For the more highly functionalized pancratistatin and its 7-deoxy congener attachment of the aryl residue was performed by the nucleophilic opening of aziridine 14 or its N-Tosyl derivative. These two strategies yielded the total syntheses of these alkaloids in reasonably short sequences, further improved in subsequent generations. An additional strategy for 7-deoxypancratistatin was implemented via cobalt–catalyzed cyclotrimerization of a fully functionalized amino inositol scaffold 15 yielding the TMS derivative of 7-deoxypancratistatin 16. Solid-phase silica-gel-catalyzed reaction of indole with aziridine 18 led to the preparation of the indole mimic of Amaryllidaceae constituent, namely 19. It was the success of the solid-phase synthesis that provided for the latest design for 7-deoxypancratistatin via the intramolecular opening of aziridine 20 that provided phenanthrene 21 whose oxidative cleavage and recyclization yields, after full deprotection, C-1 derivatives, such as the aldehyde 22, suitable for further functionalization to unnatural derivatives. The entire strategy aimed at the synthesis of aldehyde 22 was based on the expectation that extended functionalization of C-1 alcohol in 7-deoxypancratistatin would be arduous because of the dense substitution of the amino inositol ring.

Figure 3.

Evolution of diverse strategies toward Amaryllidaceae constituents.

Synthesis of 7-deoxypancratistatin C-1 carboxaldehyde

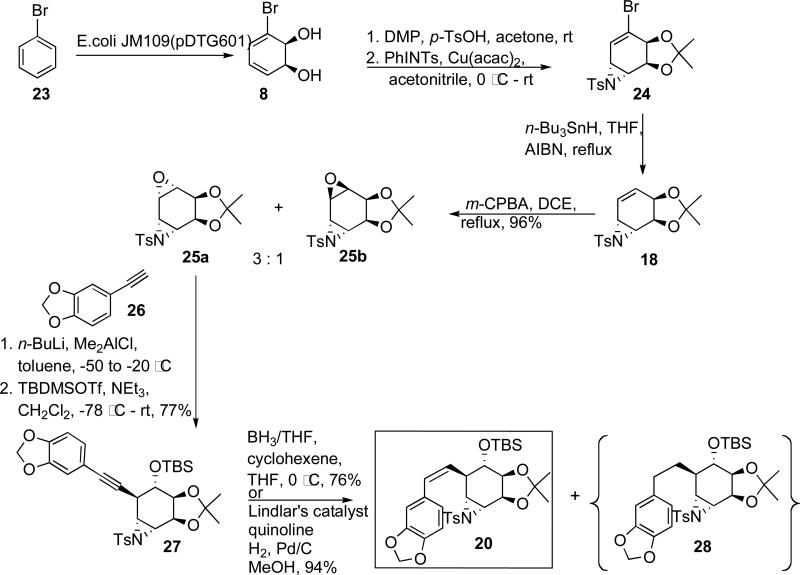

The synthesis of this key aldehyde begins with diol 8, produced by fermentation of bromobenzene with E. coli JM 109 (pDTG601),23 protected as its acetonide, and subjected to the Yamada-Jacobsen-Evans protocol of aziridination24 to yield the known N-tosyl aziridine 24,25 used in previous generations of pancratistatin synthesis, Scheme 1.

Scheme 1.

Dehalogenation of the vinyl bromide (n-Bu3SnH, AIBN, 76%) produced cleanly vinylaziridine 18 whose epoxidation with m-CPBA furnished epoxy aziridines 25a and 25b in 96% yield as a 3:1 mixture of diastereomers. Successive recrystallizations from isopropyl alcohol allowed for enrichment of the ratio up to 10:1 (25a:25b) but in general two recrystallizations provided a workable ratio of 7:1. Addition of the mixture of epoxy aziridines to the alane derived from aryl acetylene 26 (n-BuLi, Me2AlCl, -50 - 0 °C) produced an intermediate acetylenic alcohol which was immediately protected to give its silyl ether 27 (TBDMSOTf, Et3N, -78 °C, 77%). Initial attempts at the epoxide opening provided the desired product in poor yield and further investigation revealed that strict control of temperature, both in the formation of the alane and in the addition of the epoxide, was necessary to attain reproducible yields. Deviation from this protocol led to decreased yields, attributed to either the incomplete formation of the alane or various side reactions of the epoxy aziridine. Predominant side products included those derived from the nucleophilic opening of the aziridine and/or epoxide with chloride anion as well as opening of the aziridine with the alkyne (structures are not shown). It was also discovered that for complete conversion of the epoxy aziridine two equivalents of the alane were required. Fewer equivalents of the alane resulted in incomplete conversion of starting material while more equivalents yielded increased production of the byproducts mentioned above. Silyl ether 27 was subjected to either the Lindlar hydrogenation protocol (Lindlar's catalyst, quinoline, 94%) or the treatment with dicyclohexylborane (BH3/SMe2, Cyclohexene, 0 °C, 76%) followed by protonolysis to afford the required cis-alkene 20, Scheme 1. In the absence of quinoline, this hydrogenation protocol provided mixtures of alkene 20 and its fully reduced alkane 28.

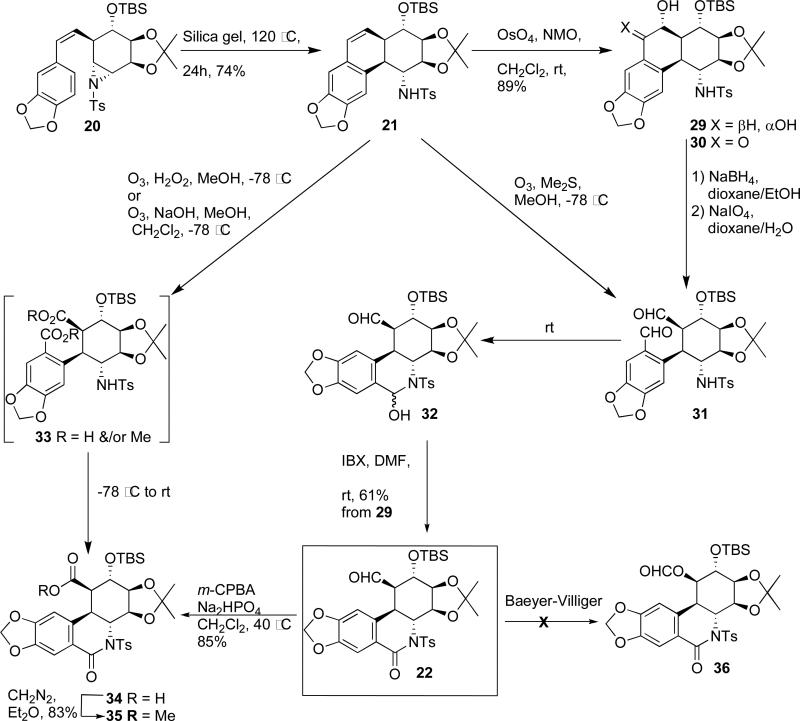

Adsorption of the aziridine on activated silica followed by heating at 120 °C under argon for 24 hours provided, after elution of the material with hexanes:ethyl acetate, 8:1 – 5:1, the key phenanthrene skeleton 21 in 74% yield, Scheme 2. Oxidative cleavage of this material was investigated in detail and several methods were compared for overall efficiency in the generation of the dialdehyde 31.

Scheme 2.

Osmylation of 21 produced the required cis-diol 29 as a mixture with over-oxidized keto alcohol 30 (OsO4, NMO, rt) This crude mixture was reduced completely to cis-diol 30 (NaBH4, dioxane/EtOH, rt,) before the oxidative cleavage with periodate to dialdehyde 31 (NaIO4, dioxane/H2O, rt, 83% over 3 steps). The use of excess equivalents of co-oxidant (NMO) in the osmylation step allowed for isolation of hydroxy ketone 30 as the sole product in 89% yield.

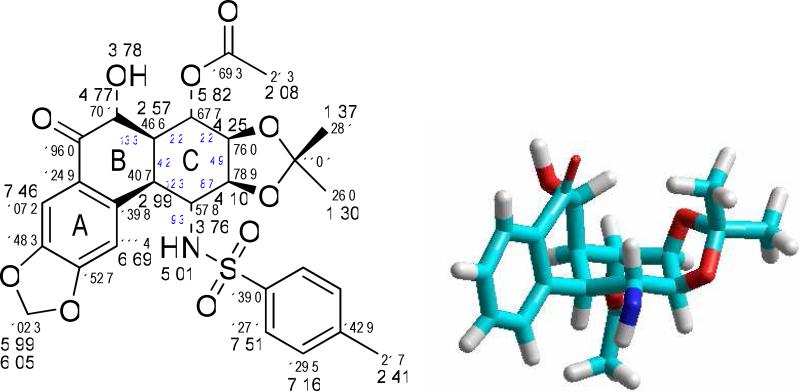

The complete assignment of stereochemistry in 30 was determined by extensive NMR analysis of its acetate 37, as shown in Figure 4. First, the complete assignments of the 1H and 13C chemical shifts were made based on the 1H-1H and 1H-13C (one-bond and long-range) couplings seen in the DQCOSY, gHMQC and gHMBC spectra, correspondingly. The connectivity in 37 was confirmed during this assignment.

Figure 4.

Full assignment of stereochemistry for the acetate 37, derived from hydroxy ketone 30 (For clarity, the tosyl group was removed in the 3D model).

The stereochemistry of 37 was inferred from 1H-1H coupling constants and confirmed by nOes. The coupling constant between 2.57 and 2.99 is 4.2 Hz, which means that the junction of rings B and C is cis. 4.77 and 2.57 have a coupling constant of 13.3 Hz, therefore they are both axial on ring B. The conformation of ring C is chair, as demonstrated by the nOe of 1.30 with 4.25, which is much larger than the nOe of 1.30 with 4.10. 1.37 has large nOes with both 3.76 and 4.77. 3.76 couples with 2.99 and 4.10 with coupling constants of 12.3 and 8.7 Hz, respectively, therefore they are all axial on ring C. Both 2.57 and 4.25 are equatorial on ring C, and, as expected, their coupling constants with 5.82 are small. The nOe of 5.82 with 4.77 demonstrates that 5.82 is cis to ring B.

Hydroxy ketone 30 was then converted to dialdehyde 31 by the same reduction-oxidative cleavage sequence as described above. At room temperature, dialdehyde 31 appeared to be a complex mixture of phenanthridol 32 and various atropoisomers of dialdehyde 31 (vide 1H NMR). Oxidation of 32 allowed for ready conversion to the complete phenanthridone skeleton of 7-deoxypancratistatin, C-1 aldehyde 22 (IBX, DMF, rt, 61% from 30). We had initially intended to oxidize aldehyde 22 with m-CPBA directly to formate 36, a protected form of 7-deoxypancratistatin. This attempt was based on relatively few reports in the literature describing a Baeyer-Villiger oxidation of cyclohexane carboxaldehyde to the corresponding formate;26 most other aliphatic aldehydes are known to yield carboxylic acids.27 In this case, the oxidation with buffered m-CPBA in dichloromethane led in 85% yield to the C-1 acid 34, which was converted to its methyl ester 35 with diazomethane in 83% yield.

A potentially more efficient route to acid 34 was envisioned via direct ozonolysis of phenanthrene 21 followed by oxidative workup. This transformation was indeed attempted by means of ozonolysis followed by an oxidative workup and a mixture of carboxylate derivatives 33 was obtained, composed of diacids, diesters, as well as mono-acid/mono-esters), as indicated in Scheme 2. Upon warming of the reaction mixture cyclization of the various derivatives 33 to phenanthridones 34 and 35 occurred in low yields, inferior to those obtained via dialdehyde 31.

Synthesis of C-1 derivatives of 7-deoxypancratistatin

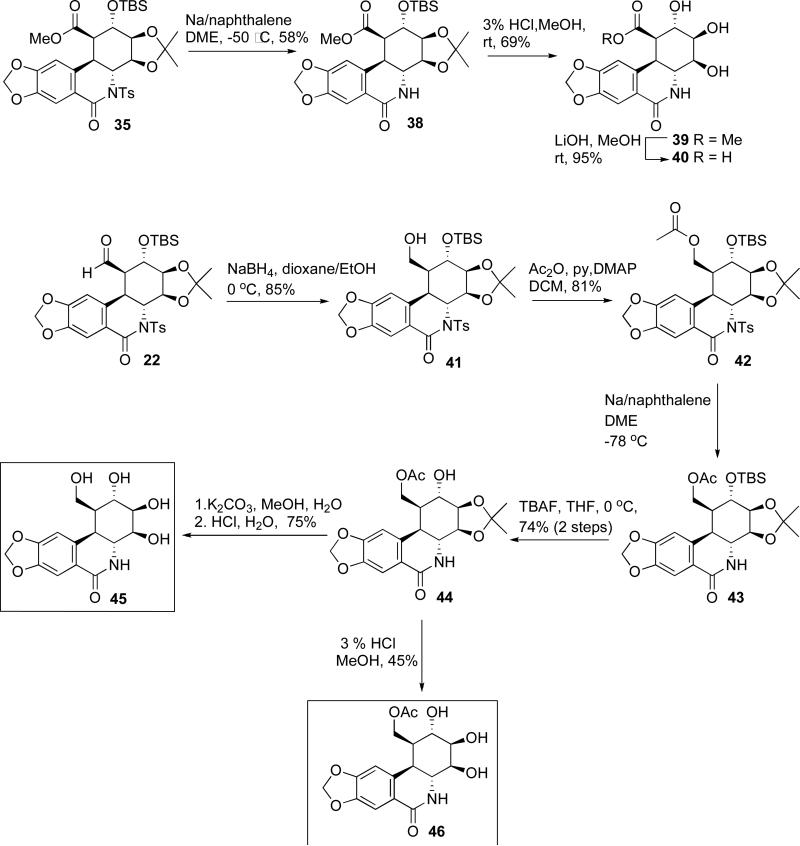

In the course of Pettit's relay synthesis of pancratistatin the activity studies of a C-1 benzoate ester, derived from narciclasine, were reported.28 This C-1 analogue was shown to possess potent activity, particularly against the murine leukemia cell line (ED50 0.0017 μg/mL). This activity is comparable to that of narciclasine (ED50 0.0044 μg/mL) and an order of magnitude greater than pancratistatin (ED50 0.032 μg/mL) against the same cell line. We therefore set out to make several C-1 derivatives of 7-deoxypancratistatin that we could evaluate for biological activity. This anti-cancer activity could then be compared with the known data for 7-deoxypancratistatin, itself generally an order of magnitude less active than pancratistatin. Should such activities show promise a full scale lead optimization would then be undertaken. A reasonable first choice seemed to be the synthesis and evaluation of the C-1 aldehyde and the corresponding acid and ester, as well as the C-1 hydroxymethylene and its acetate. The synthesis of these compounds was relatively straightforward and is shown in Scheme 3. Thus ester 35 was subjected to detosylation to phenanthridone 38 (Na/naphthalene, -58 °C, 58%), whose deprotection (3% HCl in MeOH, 69%) provided the fully hydroxylated ester 39. Base-catalyzed hydrolysis (LiOH, rt, 95%) furnished the corresponding acid 40. The aldehyde 22 was reduced to alcohol 41 (NaBH4, 0 °C, 85%). In this case, reduction reactions performed above 0 °C resulted in competitive reduction of the activated phenanthridone. The alcohol 41 was further converted to its acetate 42 (Ac2O, pyridine, DMAP, 81%) prior to detosylation. Phenanthridone 43 was converted without isolation to alcohol 44 (TBAF, 0 °C, 74% over 2 steps). Exhaustive hydrolysis of this compound (K2CO3 then 3% HCl in MeOH, 75%) gave the completely hydroxylated derivative 45 while the acid-catalyzed deprotection (3% HCl in MeOH, 45%) furnished the C-1 acetoxymethylene derivative 46. Four of these compounds, the C-1 acid 40, its methyl ester 39, and the hydroxymethylene derivatives 45 and 46 were subjected to screening against the human cancer cell lines (see the last section for the summary of biological activities).

Scheme 3.

Formal synthesis of 7-deoxypancratistatin and total synthesis of dihydrolycoricidine

The failure to produce formate 36 directly from the protected aldehyde 22 by Baeyer-Villiger oxidaton was disappointing as that manouver would have led to the shortest synthesis of 7-deoxypancratistatin to date. We have attempted to convert the aldehyde and the silyl ether functionalities in 22 to an olefin, which would correspond to a formal synthesis of 7-deoxypancratistatin but a set of very unusual problems was encountered. First, the oxidative decarboxylation employed by Wender in his synthesis of retigeranic acid29 failed to produce the olefin from the β-hydroxy acid derived from 34 by removal of the silyl protecting group. Second, we attempted the creation of the olefin via oxetane, as was done by Grieco in his synthesis of compactin,30 and followed Nicolaou's three-step protocol,31 utilized in his taxol synthesis, for oxetane generation from 1,3-diol derived from 34. Neither strategy met with success and we attempted the conversion of acid 34 to the C-1 bromide via Hunsdiecker reaction, also to no avail. Conversion of the C-1 aldehyde in 22 to the methyl ketone and Baeyer-Villiger oxidation of the latter led cleanly to methyl ester 35, accompanied by the lactone derived from the ester and C-3 hydroxyl as a result of the acetonide hydrolysis. Base-catalyzed elimination of the β-silyloxy group from either acid 34 or ester 35 did not lead to the corresponding unsaturated carbonyl compound; the inertness of the C-1/C-2 functionalities to the above variety of conditions remains unexplained.

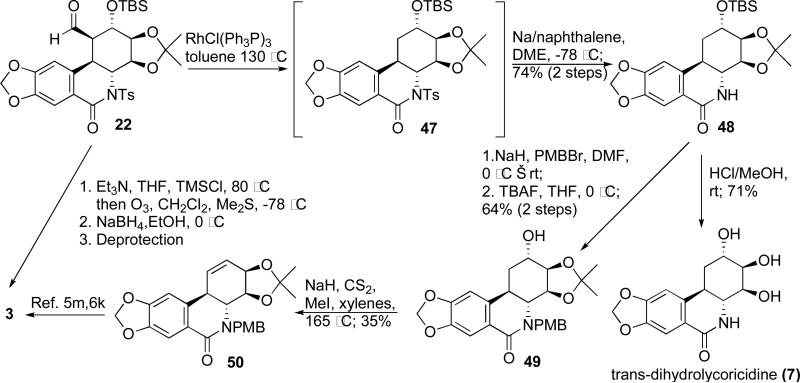

Having failed in the manipulations of functional groups in aldehyde 22 or the acid 34 we subjected 22 to Wilkinson decarbonylation (RhCl(PH3)3, toluene, 130 °C) to produce 47, which was smoothly detosylated to phenanthridone 48 (Na/naphthalene, -78 °C, 74% over 2 steps). Treatment of 48 with acidic methanol (3% HCl, MeOH, 71%) allowed for hydrolysis of the remaining protecting groups and completed the total synthesis of trans-dihydrolycoricidine (7) ([α]d22 28.6 (c 0.25, DMSO), lit.32[α]d25 138 (c 0.96, DMSO). The formal total synthesis of 7-deoxypancratistatin was also completed by first protection of lactam 48 (NaH, PMBBr, 0 °C) as its p-methoxybenzyl derivative followed by cleavage of the silyl ether (TBAF, 0 °C, 64% over 2 steps) yielding alcohol 49. Chugaev elimination of the C-2 alcohol (NaH, CS2, MeI, xylenes, 165 °C, 35%) provided olefin 50, an intermediate in Padwa's synthesis of 7-deoxypancratistatin (mp 172-174 °C (ethyl acetate/hexanes), lit. 171-173 °C).4m A more direct route to 7-deoxypancratistatin was envisioned by the oxidative cleavage of trimethylsilyl enol ether derived from 22 followed by deprotection of the C-3 silyl ether and a directed reduction of the C-1 carbonyl (NaBH4, EtOH). This protocol, performed in a preliminary manner, yielded the C-1/C-2 diol leaving only the detosylation and hydrolysis to provide 3 in a shorter sequence.

Biological evaluation of C-1 derivatives

To date the search for a more active or more bioavailable synthetic analogue of the Amaryllidaceae constituents has yielded relatively few compounds that showed promise. In continuation of this effort the novel C-1 analogues of 7-deoxypancratistatin, synthesized in this work, were evaluated for antitumor activities in cancer cell lines in vitro. While the C-1 acid 40 and its methyl ester 39 were found inactive, the hydroxymethyl analogue 45 and its acetate 46 displayed useful levels of activities. Therefore, to assess their potential, these two compounds were further evaluated for antiproliferative activities in a panel of human cancer cell lines. In addition, their ability to induce apoptosis in human leukemia and neuroblastoma cells was also examined.

Cancer cell line growth inhibitory activities

Table I provides the antiproliferative potencies of several relevant Amaryllidaceae constituents, compounds 45 and 46, and synthetic C-1 benzoyl derivatives 51 and 52, previously synthesized by Pettit's group and found to be the most potent Amaryllidaceae isocarbostyril analogues identified to date. Although the C-1 analogues 45 and 46 provide antiproliferative potencies somewhat inferior to the natural isocarbostyrils pancratistatin and narciclasine, this fact is consistent with the overriding influence of the 7-hydroxyl phenolic functionality, present in 2 and 4, but not in 45 and 46. However, these compounds appear to be at least as good as or better than 7-deoxypancratistatin, pointing to the beneficial effect of the C-1 derivatization. Furthermore, it appears that large lipophilic C-1 substituents are preferred, whereas elevated polarity at C-1 is not tolerated. Indeed, the C-1 acid 40 and its methyl ester 39 (presumably undergoing intracellular hydrolysis to 40) are inactive, while acetate 46 is somewhat more potent than the parent alcohol 45. These findings are consistent with the beneficial effect of the C-1 benzoyl moiety in 51 as found by Pettit. It is not entirely clear at this point whether the benzoyl in 51 and the acetyl in 46 are part of the pharmacophore or if they merely assist the parent hydroxyl compounds in cell penetration and then undergo intracellular hydrolytic removal. The answer to this question will have to await further studies involving the preparation and testing of analogues with non-hydrolyzable large lipophilic substituents at C-1.

Table 1.

Human Cancer Cell Line and Murine P-388 Lymphocytic Inhibitory Activities. P388 Murine Lymphoceutic Leukemia and Human Cancer Cell Results [μg/mL] (ED 50)

| Compound | leukemia | pancreas | breast | CNS | lung-NSC | colon | prostate | leukemia | neuroblastoma |

|---|---|---|---|---|---|---|---|---|---|

| P388 | BxPC-3 | MCF-7 | SF-268 | NCI-H460 | KM20L2 | DU-145 | Jurkat | Shsy5y | |

| 2 | 0.039 | 0.028 | 0.032 | 0.017 | 0.048 | 0.062 | 0.016 | 0.163 | 0.163 |

| 3 | 0.44 | – | – | – | 0.29 | 0.22 | – | – | – |

| 4 | 0.001 | 0.026 | 0.019 | 0.021 | 0.032 | 0.021 | 0.011 | – | – |

| 7 | 0.029 | 0.046 | 0.034 | 0.059 | 0.043 | 0.051 | 0.040 | – | – |

| 51 | 0.0016 | 0.0019 | 0.00031 | 0.00055 | 0.0001 | 0.00037 | 0.00021 | ||

| 52 | 0.061 | 0.25 | 0.041 | 0.17 | 0.029 | 0.13 | 0.13 | ||

| 45 | 0.19 | 0.65 | 0.09 | 0.26 | 1.615 | 1.615 | |||

| 46 | 0.11 | 0.29 | 0.11 | 0.37 | 0.183 | 0.183 |

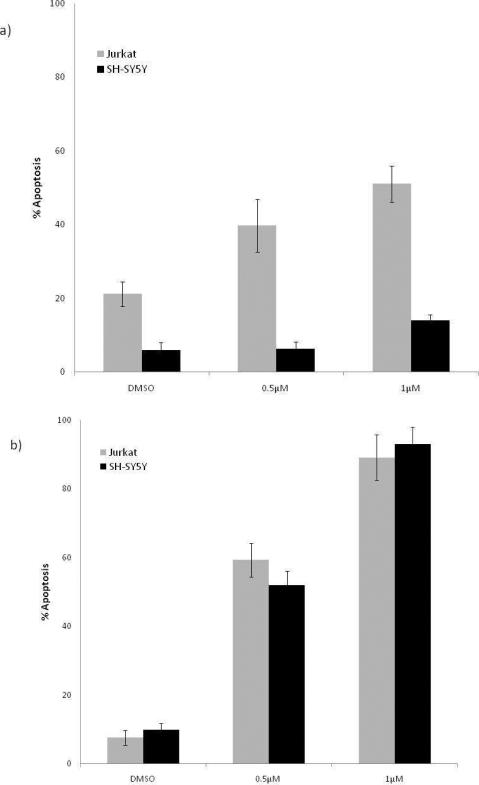

Apoptosis induction

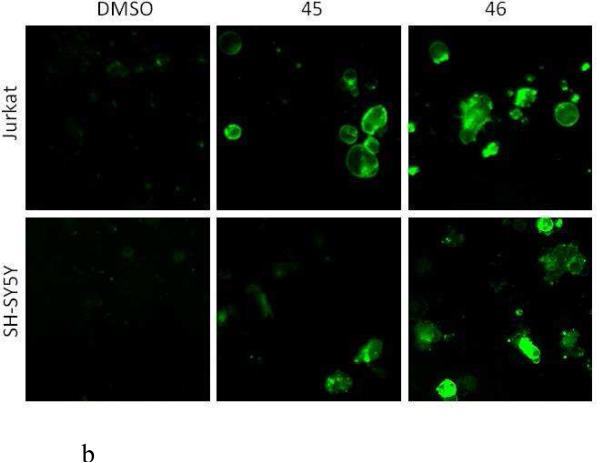

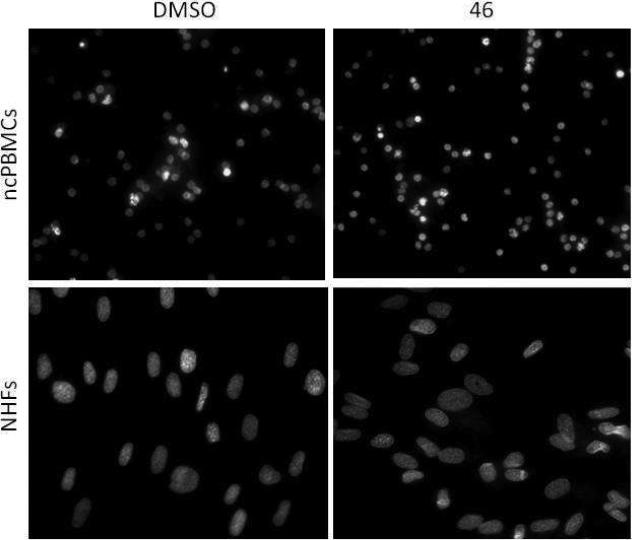

Apoptotic morphology was observed in Jurkat and SH-SY5Y cells after 72 hours treatment with compound 45 or 46 (Figure 5) through Hoechst staining and Annexin-V binding. The effective dose at which 50% of cells were apoptotic (ED50) for compound 45 in Jurkat cells was 1 μM and in SH-SY5Y cells was 10 μM. Compound 46 had greater apoptotic efficacy than 45 in both Jurkat and SH-SY5Y cells, as the ED50 was determined to be 0.5 μM for both cell types (Figure 6). This indicates that 46, much like 2, has the ability to induce apoptosis specifically in cancerous cells. Most importantly, compound 46 did not induce apoptosis in non-cancerous normal human cells such as normal human fibroblasts (NHFs) and peripheral mono-nucleated blood cells (PMBC) prepared from blood obtained from healthy volunteers (Figure 7). These results indicate that compound 46 is selectively targeting cancer cells to induce apoptosis, and could be a safer alternative to toxic chemotherapy.

Figure 5.

Hoechst cell permeable dye and Annexin-V binding were used to observe nuclear morphology after exposure to compound 45 or 46. Cells with brightly stained, condensed nuclei are considered to be apoptotic (a). Apoptosis was confirmed by Annexin-V binding after 48hr exposure to either 45 or 46 at 0.5 μM concentration (b).

Figure 6.

Apoptosis is induced by compounds 45 (a) and 46 (b) in Jurkat and SH-SY5Y cells after 72hrs exposure. Cells were stained with Hoechst dye and counted to determine the percentage of apoptotic cells; a minimum of 5 fields containing at least 100 cells per field was counted.

Figure 7.

Compound 46 does not induce apoptosis in non-cancerous human cells. Normal Human Fibroblasts (NHFs) and Non-cancerous peripheral blood mononuclear cells (ncPBMC) were treated with compound 46 and stained with Hoechst as described in materials and methods. Apoptotic nuclear morphology is not visible in normal human fibroblasts (NHFs) or peripheral mono-nucleated blood cells (PMBC) prepared from blood obtained from healthy volunteers treatment with 46.

Conclusions

We have completed a short and potentially practical synthesis of several C-1 derivatives of 7-deoxypancratistatin, two of which (45 and 46) exhibited promising biological activities in several cell lines as well as in apoptosis screens. Given that these compounds, lacking the crucial 7-hydroxyl group, exhibited good activities it stands to reason that the next step in this program should be the evaluation of the corresponding C-1 acetoxymethyl and related compounds that contain the otherwise complete pharmacophore of pancratistatin. We would expect that such derivatives should equal the natural product in potency and would therefore provide the rationale for further lead optimization toward more soluble and bioavailable derivatives. As a side benefit, a total synthesis of trans-dihydrolycoricidine 7 was accomplished form aldehyde 22 along with a formal total synthesis of 7-deoxypancratistatin.

Experimental Section

Cell Culture

The Human neuroblastoma (SH-SY5Y) and B-cell leukemia (Jurkat) cell lines were purchased from ATCC (Manassas, VA). Cells were maintained and grown at 37°C, 95% humidity and 5% CO2. Jurkat cells were grown with RPMI-1640 media (Sigma-Aldrich, Oakville, ON, Canada) supplemented with 10% fetal bovine serum (FBS) and 10 mg/ml Gentamycin (Gibco BRL, Mississauga, ON, Canada). SH-SY5Y cells were grown with Dulbecco's Modified Eagles Medium (DMEM) HAM F12 (Sigma-Aldrich), supplemented with 2 mM L-Glutamine, 10 mg/ml Gentamycin, and 10 % FBS. Normal Human Fibroblasts (NHFs) obtained from Coriell Institute for Medical Research (New Jersey, USA) were cultured in Earle's Minimum Essential Medium (MEME) (Sigma Chemical Company, Mississauga, Ontario, Canada) completed with 15% fetal bovine serum, 2mM L-Glutamine, 10 mg/ml Gentamycin, 1.5 g/l sodium bicarbonate, 1% vitamins, and essential (2%) and non-essential amino acids (1%) (Gibco BRL, VWR, Mississauga, ON, Canada).

Human non-small cell lung cancer line NCI-H460 (ATCC # HTB-177) and human pancreatic adenocarcinoma cancer cell line BxPC-3 (ATCC # CRL-1687) were cultured in RPMI-1640 medium supplemented with 10% fetal bovine serum (FBS) (Gibco, Carlsbad, CA), 100 mg/L penicillin G and 100 mg/L streptomycin and (Cellgro, Manassas, VA). Human prostate carcinoma cells DU-145 (ATCC # HTB-81) were cultured in Dulbecco's modified Eagle Medium (Cellgro) supplemented with 10% FBS, 100 mg/L penicillin G and 100 mg/L streptomycin. Human mammary carcinoma cells MCF-7 (ATCC # HTB-22) were cultured using Dulbecco's modified Eagle Medium supplemented with 10% FBS, 100 mg/L penicillin G, 100 mg/L streptomycin, 1.0 mM Glutamax and 1.0 mM sodium pyruvate, (Gibco).

Peripheral blood was obtained from healthy non-smoking volunteers aged 25-50 y upon written and informed consent (University of Windsor REB #04-147). Whole blood samples were collected in BD Vacutainer™ Cell Preparation Tube and mononuclear cells were separated by density gradient centrifugation. The isolated cells were maintained in RPMI 1640 media supplemented and maintained as was the Jurkat culture.

MTT Assay

To evaluate the cytotoxic effects of the C-1 derivatives of 7-deoxypancratistatin, mitochondrial dehydrogenase activities were measured. Jurkat and SH-SY5Y cells were grown and treated for 24, 48, and 72 hrs. Cells were treated with concentrations ranging from 0.25 to 10 μM of each derivative dissolved in DMSO Similarly, ncPBMCs and NHFs were treated to assess the effects of the C-1 derivatives on non-cancerous cells. In addition, the BxPC-3, CRL-1687, DU-145 and MCF-7 lines were assessed by seeding 4 × 103 cells per well into microplates. The cells were grown for 24 hrs before treatment at concentrations ranging from 0.01 to 10 μM and incubated for 48 hrs. MTT reagent (5 mg/mL, MP Biomedical, Solon, OH) was added to each well and incubated further for 2 hrs. The resulting formazan crystals were dissolved in DMSO and the OD was determined at a wavelength of 490 nm. The experiments were repeated at least twice for each compound per cell line. Cells treated with 0.1% DMSO were used as a control.

Cellular Staining

Nuclear morphology was visualized using a final concentration of 10 μM of Hoechst 33342 dye (Molecular Probes, Eugene, OR, USA). Phosphatidyl serine flipping, (an apoptotic biochemical marker) was visualized with Annexin-V-FITC binding assay as per manufacturer's protocol (Molecular Probes, Eugene OR, USA). Cells were observed with a fluorescent microscope (Leica DM IRB, Germany); apoptotic indices were determined by counting brightly stained condensed nuclei (apoptotic cells) from at least 5 fields at 40X objective. Apoptotic cells were expressed as a percentage of the total number of cells counted. Standard error was calculated from at least 3 separate experiments.

General Experimental Details

All non-hydrolytic reactions were carried out under an argon atmosphere. Glassware used for moisture-sensitive reactions was flame-dried under vacuum and subsequently purged with argon. THF, DME, and toluene were distilled from potassium/benzophenone. Methylene chloride and acetonitrile were distilled from calcium hydride. Flash column chromatography was performed using Kieselgel 60 (230-400 mesh). Analytical thin-layer chromatography was performed using silica gel 60-F254 plates. Melting points are reported uncorrected. IR spectra were recorded as neat samples or in KBr pellets. 1H and 13C NMR spectra were obtained on either a 300-MHz or 600 MHz instrument. Data are reported as (s = singlet, d = doublet, t = triplet, q = quartet, m = multiplet, br = broad; coupling constants(s) in Hz, integration. Specific rotation measurements are given in deg cm3 g-1 dm-1. Mass spectra and high resolution mass spectra were performed by the analytical division at Brock University.;l

(1S, 2S, 4R, 5S, 6S, 7S)-5,6-(isopropylidenedioxy)-3-(4’-methylphenylsulfonyl)-8-oxa-3-aza-tricyclo[5.1.0.0]octane (25a), (1S, 2S, 4R, 5S, 6S, 7R)-5,6-(isopropylidenedioxy)-3-(4’ methylphenylsulfonyl)-8-oxa-3-aza-tricyclo[5.1.0.0]octane (25b)

A solution of m-CPBA (10.5 g, 46.7 mmol) in 1,2-dichloroethane (150 mL) was dried over Na2SO4 and filtered into a flask containing aziridine 18 (5.0 g, 15.6 mmol). The resulting solution was heated to reflux until total consumption of starting material (6 hours). The reaction mixture was allowed to cool to room temperature at which time m-chlorobenzoic acid crystallized out as a white solid. The reaction mixture was filtered and concentrated. The residue was taken up EtOAc (350 mL) and washed sequentially with NaHSO3 (2 × 100 mL), carbonate (2 × 100 mL), and brine (35 mL). The organic phase was dried over Na2SO4, filtered, and concentrated to yield a 2.89:1 mixture of epoxides 25a and 25b (5.035g. 96 %) as slightly yellow solid. The epoxide could be used without further purification or enriched in favor of the major isomer by successive recrystalizations form isopropanol. A small sample of the mixture taken and the two epoxides were separated by flash column chromatography (10% deactivated silica gel, hexanes/ethyl acetate 7:1 – 4:1) to provide analytical samples of epoxide 25a and 25b.

Epoxide 25a

Rf 0.43 (hexanes/ethyl acetate, 2:1); mp 115-116 °C (isopropanol); [α]D21 - 79.36 (c 1.0, CHCl3); IR (film) ν2988, 2936, 1597, 1383, 1373, 1329, 1251, 1218, 1158, 1091, 1055 cm-1; 1H NMR (300 MHz, CDCl3) δ: 7.90 (d, J = 8.3 Hz, 2H), 7.36 (d, J = 8.3 Hz, 2H), 4.4 (d, J = 6.2 Hz, 1H), 4.26 (d, J = 6.0 Hz, 1H), 3.53 (t, J = 3.7 Hz, 1H), 3.38 (dd, J = 6.8 Hz, J = 3.8 Hz, 1H), 3.13 (dd, J = 3.5 Hz, J = 0.9 Hz, 1H), 3.04 (dd, J = 6.8 Hz, J = 1.1 Hz, 1H), 2.46 (s, 3H), 1.46 (s, 3H), 1.36 (s, 3H); 13C NMR (75 MHz, CDCl3) δ: 144.9, 134.5, 129.9, 128.0, 110.2, 70.8, 69.8, 50.1, 46.7, 37.3, 35.7, 27.4, 25.2, 21.7; HRMS-EI Calcd for C16H19NO5S (M+-15): 322.0749, Found: 322.0744; Anal. calcd for C16H19NO5S C, 56.96; H, 5.68; found C, 56.83; H, 5.61

Epoxide 25b

Rf 0.43 (hexanes/ethyl acetate, 2:1); mp 179-180 °C (isopropanol); [α]D21 – 62.82 (c 1.0, CHCl3); IR (film) ν2985, 2929, 1602, 1384, 1366, 1324, 1245, 1222, 1163, 1153, 1041, 1001 cm-1; 1H NMR (600 MHz, CDCl3) δ: 7.83 (d, J = 8.1 Hz, 2H), 7.39 (d, J = 8.1 Hz, 2H), 4.40 (d, J = 6.3 Hz, 1H), 4.31 (dd, J = 6.2 Hz, J = 2.3 Hz, 1H), 3.58 (dd, J = 3.9 Hz, J = 2.4 Hz, 1H), 3.44 (dd, J = 6.7 Hz, J = 2.0 Hz, 1H), 3.27 (d, J = 3.5 Hz, 1H), 3.18 (t, J = 6.8 Hz, 1H), 2.48 (s, 3H), 1.54 (s, 3H), 1.35 (s, 3H); 13C NMR (150 MHz, CDCl3) δ:145.3, 133.7, 130.0, 128.1, 111.1, 71.9, 69.9, 52.4, 25.0, 39.3, 38.6, 26.6, 25.9, 21.7; HRMS-EI Calcd for C16H19NO5S (M+-15): 322.0749, Found: 322.0753; Anal. calcd for C16H19NO5S C, 56.96; H, 5.68; found C, 56.23; H, 5.61

(1S,2R,3R,4R,5S,6R)-3,4-(Isopropylidenedioxy)-5-[(tert-butyldimethylsilyl)oxy]-6-2-Benzo[1.3]dioxol-5-ylethynyl-(4’-methylphenylsulfonyl)-7-azabicyclo[4.1.0]heptanes (27)

To a solution of acetylene 26 (0.43 g, 2.96 mmol) in 8 mL dry toluene at -50 °C was added 1.46 mL of a solution of nBuLi in hexanes (2.01 M, 2.96 mmol) over 5 min. The solution was stirred for 15 minutes before 2.97 mL of a solution of Me2AlCl (1.0M in CH2Cl2, 2.96 mmol) was added dropwise over 10 min. The reaction flask was kept at -50 °C for 0.5 h and then moved to an ice bath and stirred an additional 0.5 h before being allowed to warm to room temperature and stir for 0.5 h. The reaction flask was then cooled to -20 °C and 8 mL of a solution of epoxide 25a:25b (7:1 mixture of isomers) (0.5 g, 1.48 mmol) in toluene was added dropwise over 20 min before being allowed to slowly warm to room temperature over 5 h. The reaction mixture was cooled in an ice bath and quenched with 1 M HCl (1 ml). Ethyl acetate (50 mL) was added and the layers where separated. The aqueous phase was extracted with 3 × 50 mL EtOAc and the combined organic layers dried over Na2SO4. Concentration under reduced pressure gave 0.883 g of crude alcohol intermediate which was immediately subjected to protection protocol. A small sample for characterization was purified by flash column chromatography (hexanes:ethyl acetate, 7:1 to 4:1) afforded alcohol (3aS,4R,5R,6R,7S,7aR)-6-(1,3-benzodioxol-5-ylethynyl)-2,2-dimethyl-8 [(4-methylphenyl)sulfonyl]hexahydro-4,5-epimino-1,3-benzodioxol-7-ol as a clear and colorless oil; [α]22D -113.05 (c 0.5, CHCl3); Rf 0.30 (hexanes:ethyl acetate, 2:1); IR (film) ν 3491, 2988, 1163 cm-1; 1H NMR (300 MHz, CDCl3) δ: 7.78 (d, J = 8.1 Hz, 2H), 7.38 (d, J = 8.1 Hz, 2H), 6.91 (dd, J = 8.2 Hz, 1.8 Hz 1H), 6.83 (d, J = 1.5 Hz, 1H), 6.73 (d, J = 7.9 Hz, 1H), 5.97 (s, 2H), 4.47 (d, J = 6.4 Hz, 1H), 4.22 (dd, J = 6.1, 4.4 Hz, 1H), 3.98 (m, 1H), 3.40 (d, J = 6.4 Hz, 1H), 3.24 (m, 2H), 3.06 (d, J = 9.6 Hz, 1H), 2.47 (s, 3H), 1.49 (s, 3H), 1.32 (s, 3H) ppm; 13C NMR (75 MHz, CDCl3) δ: 148.1, 147.5, 145.7, 134.2, 130.4, 128.1, 126.4, 116.2, 111.8, 110.3, 108.6, 101.5, 84.2, 83.8, 75.4, 70.1, 68.7, 42.3, 40.5, 31.1, 27.4, 25.2, 21.9 ppm; HRMS (FAB M+) calcd for C25H25NO7S 484.1430, found 484.1428.

The free alcohol intermediate (0.8 g, crude) was dissolved in 20 mL of CH2Cl2 and triethylamine (0.484 mL, 3.48 mmol) was added. The reaction flask was cooled to -78 °C and t-butyldimethylsilytriflate (0.457 mL, 0.1.99 mmol) was added dropwise to the stirring solution. After stirring for 30 minutes at -78 °C the reaction mixture was quenched with water (20 ml) and the two phases separated. The aqueous phase was extracted with CH2Cl2 (3 × 50 mL) and the combined organic solution was washed sequentially with 5% citric acid (2 mL) and brine (2 mL) before drying over sodium sulfate. The solvent was removed under reduced pressure and the residue was purified by flash column chromatography (hexane:ethyl acetate, 9:1 to 2:1) affording 27 (0.677g, 77%) as a colorless oil.; [α]24D +57.7 (c 0.5, CHCl3); Rf 0.49 (hexanes:ethyl acetate, 2:1); IR (film) ν 2953, 2929, 2892, 2856, 1599,1490 cm-1; 1H NMR (300 MHz, CDCl3) δ: 7.83 (d, J = 8.1 Hz, 2H), 7.38 (d, J = 8.1 Hz, 2H), 6.94 (d, J = 8.1 Hz, 1H), 6.84 (s, 1H), 6.77 (d, J = 8.1 Hz, 1H), 5.99 (s, 2H), 4.45 (d, J = 5.1 Hz, 1H), 3.83 (m, 2H), 3.26 (m, 2H), 2.84 (d, J = 7.5 Hz), 2.47 (s, 3H), 1.52 (s, 3H), 1.35 (s, 3H), 0.87 (s, 9H), 0.11 (s, 6H) ppm; 13C NMR (75 MHz, CDCl3) δ: 147.8, 147.3, 134.7, 129.8, 127.9, 126.1, 111.6, 109.7, 108.4, 101.3, 86.3, 83.5, 71.7, 43.2, 39.53, 34.58, 27.9, 25.8, 25.79, 25.7, 21.7, 18.12, -4.4, -4.7 ppm; HRMS-EI Calcd for C27H30NO7SSi: 540.1481; Found, 540.1487.

(1S,2R,3R,4R,5S,6R)-3,4-(Isopropylidenedioxy)-5-[(tert-butyldimethylsilyl)oxy]-6-2-Benzo[1,3]dioxol-5-ylethenyl-(4’-methylphenylsulfonyl)-7-azabicyclo[4.1.0]heptane (20)

A) Alkyne 27 (500 mg, 0.837 mmol) was taken up in 45 mL MeOH and quinoline (34 mg, 0.168 mmol) added. Lindlar's catalyst (35 mg, 0.335 mmol) added. The reaction mixture was purged with aspirator vacuum and flushed with H2 before being placed under H2 using a balloon, and stirred for 3 hours. The reaction mixture was filtered through a short plug a celite and the solvent was removed under reduced pressure. The crude residue was purified by flash column chromatography (hexanes/ethyl acetate, 4:1) to give the title compound as a clear and colorless oil (480 mg, 95%)

B) To a 1.0 M solution of BH3.THF complex (2.5 mL, 2.5 mmol) was added cyclohexene (0.484 mL, 4.77 mmol) at 0 °C. After 10 minutes a heavy precipitate was formed. The reaction mixture was kept at 0 °C for 1 h before acetylene derivative 27 (0.356 mg, 0.596 mmol) in 4.5 mL of THF was added. The reaction mixture was stirred at 0 °C until total consumption of starting material (2 h, TLC) before being quenched with 1 mL HOAc. 60 mL EtOAc were added and the reaction mixture was washed with saturated aq. NaHCO3 (2 × 15 mL), H2O (2 × 15 mL), and brine (10 mL) before drying over sodium sulfate. The solvent was removed under reduced pressure and the residue was purified by flash column chromatography (hexanes:ethyl acetate, 8:1) affording 0.271 g of 20 (76%).; [α]23D -26.14 (c 1.0, CHCl3; Rf 0.35 (hexanes:ethyl acetate, 4:1); IR (film) ν 2986, 2930, 2894, 2856, 1598,1489 cm-1; 1H NMR (300 MHz, CDCl3) δ: 7.78 (d, J = 8.1 Hz, 2H), 7.29 (d, J = 8.1 Hz, 2H), 6.65 (m, 3H), 6.51 (d, J = 11.7 Hz, 1H), 5.97 (s, 2H), 5.54 (t, J = 11.3 Hz, 1H), 4.43 (d, J = 6, 1H), 3.85 (t, J = 6.3, 1H), 3.61 (t, J = 7.2 Hz), 3.18 (d, J = 6.6, 1H), 2.91 (m, 2H), 2.44 (s, 3H), 1.52 (s, 3H), 1.33 (s, 3H), 0.79 (s, 9H), 0.02 (s, 3H), -0.04 (s, 3H) ppm; 13C NMR (150 MHz, CDCl3) δ: 147.5, 146.6, 144.6, 134.7, 132.0, 129.8, 129.7, 128.5, 122.5, 109.35, 109.0, 108.1, 100.9, 83.2, 78.0, 72.6, 71.8, 43.7, 39.9, 39.5, 30.1, 27.8, 25.8, 25.79. 25.75, 25.72, 25.51, 23.7, 21.7, 18.1, -4.3, -4.7 ppm; HRMS-EI Calcd for C31H41NO7SSi: 599.2373; Found, 599.2376; Anal. calcd for C31H41NO7SSi C, 62.28; H, 6.58; found C, 61.30; H, 6.63. [Compound is a heavy oil, retaining residula solvent].

(1S,2R,3R,4R,5S,6R)-3,4-(Isopropylidenedioxy)-5-[(tert-butyldimethylsilyl)oxy]-6-2-Benzo[1,3]dioxol-5-ylethanyl-(4’-methylphenylsulfonyl)-7-azabicyclo[4.1.0]heptane (28)

Alkyne 27 (100 mg, 0.168 mmol) was taken up in 10 mL MeOH and Lindlar's catalyst (35 mg, 0.34 mmol) added. The reaction mixture was purged with aspirator vacuum and flushed with H2 before being placed under H2 using a balloon, and stirred for 24 hours. The reaction mixture was filtered through a short plug a celite and the solvent was removed under reduced pressure. The crude residue was purified by flash column chromatography (hexanes:ethyl acetate, 4:1) to give the title compound as a clear and colorless oil (95 mg, 94%).; [α23D] -477.2 (c 1.8, CHCl3) Rf 0.35 (hexanes/ethyl acetate, 2:1); IR (film) ν 2986, 2954, 2929, 2891, 2857,1598,1504,1489 cm-1; 1H NMR (500 MHz, CDCl3) δ: 7.87 (d, J = 7 Hz, 2H), 7.37 (d, J = 7 Hz, 2H), 6.70 (d, J = 6.5 Hz, 1H), 6.55 (s, 1H), 6.51 (d, J = 7 Hz, 1H), 5.93 (s, 2H), 4.41 (d, J = 5 Hz, 1H), 3.79 (t, J = 5 Hz, 1H), 3.43 (m, 1H), 3.18 (d, J = 6 Hz, 1H), 2.84 (m, 1H), 2.60 (m, 1H), 2.45 (s, 3H), 2.40 (m, 1H), 2.05 (m, 1H), 1.68 (s, 3H), 1.34 (s, 3H), 0.83 (s, 9H), 0.06 (s, 3H), 0.03 (s, 3H); 13C NMR (250 MHz, CDCl3) δ: 146.6, 145.7, 144.8, 135.1, 134.9, 129.8, 128.0, 127.9, 121.2, 109.2, 108.9, 1081, 100.8, 78.6, 72.5, 71.9, 43.2, 39.9, 39.5, 32.9, 32.7, 27.8, 25.9, 25.8, 25.5, 21.7, 18.2, -4.0, -4.8; HRMS-EI Calcd for C31H43NO7SSi: 601.2530; Found, 601.2534;

N-[(1R,2aS,4aS,5S,5aR,12bR)-5-(tert-Butyl-dimethyl-silanyloxy)-3,3-dimethyl-1,2a,4a,5,5a,12b-hexahydro-phenanthro[2,3-d][1,3]dioxol-1-yl]4-methyl-benzenesulfonamide (21)

A flame-dried 25-mL flask was charged with olefin 20 (336 mg, 0.561 mmol) and silica gel which has been activate by heating under vacuum at 120 °C overnight (1.5 g). The starting materials were suspended in 10 mL freshly distilled methylene chloride and the solvent removed under reduced pressure. The silica gel supporting the absorbed reactants was heated externally at 120 °C under nitrogen atmosphere for 24 h, after which time the silica gel was loaded onto flash silica gel column and eluted with hexanes:ethyl acetate, 8:1 – 5:1 to give 249 mg (74%) of olefin 21 as a clear and colorless oil.; [α]23D -123.7 (c 1.0, CHCl3); Rf 0.35 (hexanes:ethyl acetate, 2:1); IR (film) ν 3268, 2929, 2887, 2857, 1598,1503, 1485 cm-1; 1H NMR (600 MHz, CDCl3) δ: 7.43 (d, J = 7 Hz, 2H), 7.13 (d, J = 7 Hz, 2H), 6.49 (s, 2H), 6.34 (d, J = 8 Hz, 1H), 5.95 (s, 1H), 5.86 (s, 1H), 5.76 (d, J = 8 Hz, 1H), 4.51 (d, J = 7 Hz, 1H), 4.28 (m, 1H), 4.11 (m, 1H), 3.99 (m, 1H), 3.79 (m, 1H), 2.82 (m, 1H), 2.62 (dd, J = 11.1 Hz, J = 5.4 Hz, 1H), 2.40 (s, 3H), 1.43 (s, 3H), 1.33 (s, 3H), 0.89 (s, 9H), 0.11 (s, 3H), 0.07 (s, 3H) ppm; 13C NMR (150 MHz, CDCl3) δ: 146.7, 145.9, 142.1, 138.9, 128.9, 128.6, 127.7, 126.8, 126.3, 126.2, 110.4, 109.2, 107.0, 79.0, 78.3, 70.3, 54.1, 42.5, 41.5, 38.9, 27.8, 26.3, 25.7, 25.3, 22.7, 21.5, 18.0, -5.0, -5.0 ppm; HRMS-EI Calcd for C31H41NO7SSi: 599.2373; Found, 599.2370; Anal. calcd for C31H41NO7SSi C, 62.07; H, 6.89; found C, 62.16; H, 6.94

N-[(1R,2aS,4aS,5S,5aS,12bR)-5-(tert-Butyl-dimethyl-silanyloxy)-6-hydroxy-3,3-dimethyl-7-oxo-1,2a,4a,5,5a,6,7,12b-octahydro-phenanthro[2,3 d][1,3]dioxol-1-yl]4-methyl benzenesulfonamide (30)

To a solution of olefin 21 (0.24 mg, 0.4 mmol) in methylene chloride (10 mL) was added 4-methylmorpholine N-oxide (96.7 mg, 0.8 mmol). The reaction mixture was allowed to stir for 10 minutes before the introduction of a single crystal of osmium tetroxide and two drops of water. The reaction mixture was stirred until total consumption of starting material (10 h) before being quenched with a saturated solution of saturated sodium bisulfite (6 mL). The two layers were separated and the aqueous phase was extracted with ethyl acetate (3 × 30 mL). The organic phase was dried over sodium sulfate, filtered, and concentrated in vacuo to provide hydroxyketone 30 as a white crystalline solid (0.227 g, 89%) that was used without further purification; Rf 0.42 (hexanes:ethyl acetate, 1:1); mp >200 °C (hexanes/ethyl acetate); IR (film) ν 3478, 3263, 2929, 2857, 1670, 1614, 1504, 1482, 1444, 1386, 1330, 1252, 1218, 1156, 1075, 1039 cm-1; 1H NMR (600 MHz, CDCl3) δ: 7.54 (d, J = 7.8 Hz, 2H), 7.49, (s, 1H), 7.18 (d, J = 7.8 Hz, 2H), 6.70 (s, 1H), 6.07 (s, 1H), 6.00 (s, 1H), 4.79 (d, J = 8.7 Hz, 1H), 4.71 (m, 2H), 4.19 (m, 1H), 4.08 (m, 1H), 3.74 (m, 2H), 3.08 (dd, J = 10.2 Hz, J = 1.8 Hz, 1H), 2.45 (m, 1H), 2.41 (s, 3H), 1.36 (s, 3H), 1.31 (s, 3H), 0.87 (s, 9H), 0.12 (s, 3H), 0.07 (s, 3H) ppm; 13C NMR (150 MHz, CDCl3) δ: 196.6, 152.5, 147.9, 142.6, 140.5, 138.9, 129.1, 126.9, 124.7, 111.2, 109.6, 106.9, 102.1, 78.9, 78.7, 70.3, 65.9, 57.9, 49.4, 39.7, 27.9, 25.7, 21.5, 17.95, -5.1 ppm; HRMS-EI Calcd for C27H32NO9SSi (M+-57): 574.1567, Found: 574.1572

(3aS,3bR,10bR,11R,12S,12aS)-12-(tert-Butyl-dimethyl-silanyloxy)-2,2-dimethyl-5-oxo-4-(toluene-4-sulfonyl)-3a,3b,4,5,10b,11,12,12a-octahydro-1,3,7,9-tetraoxa-4-aza-dicyclopenta[a,h]phenanthrene 11 carbaldehyde (22)

To a 10 mL round bottomed flask was added hydroxyl ketone 30 (0.4 g, 0.63 mmol) and 6 mL of a 1:1 mixture of ethanol:dioxane. The reaction flask was cooled externally in an ice bath and NaBH4 (24 mg, 0.63 mmol) was added in one portion. The reaction mixture was removed from the bath and allowed to warm to room temperature over 1 h, and was then quenched with 1 N HCl (4 mL) and separated. The aqueous phase was extracted with CH2Cl2 (3 × 20 mL) and the organic phase combined before drying over sodium sulfate. The crude mixture was concentrated in a 25 mL round bottomed flash and taken up in dioxane (8 mL). The reaction mixture was stirred while sodium periodate (0.332, 1.5 mmol) was added. The flask was covered to exclude light and H2O (15 drops) added. Stirring was continued until total consumption of starting material (23h) as monitored by TLC. The reaction mixture was quenched with H2O (10 mL) and separated. The aqueous phase was extracted with CH2Cl2 (3 × 50 mL) and the combined organic phases dried over sodium sulfate. Concentration provided hemi-aminal (3aS,11R,12S,12aS)-12-{[tert-butyl(dimethyl)silyl]oxy}-5-hydroxy-2,2-dimethyl-4-[(4-methylphenyl)sulfonyl] 3a,3b,4,5,10b,11,12,12a-octahydrobis[1,3]dioxolo[4,5-c:4',5'-j]phenanthridine-11-carbaldehyde 32.

To a solution of hemi-aminal 32 (394 mg, 0.62 mmol) in N,N-Dimethylformamide (3 mL) was added 2-Iodoxybenzoic acid (520 mg, 1.86 mmol). After total consumption of starting material (by TLC), the reaction mixture was diluted with diethyl ether (200 mL) and washed sequentially with saturated aqueous sodium bisulfite (10 mL), sodium bicarbonate (3 × 10 mL), H2O (10 × 1mL), and brine (10 mL). The organic phase was dried over magnesium sulfate, filtered and concentrated. The final product 22 was isolated by column chromatography (hexanes:ethyl acetate, 4:1). Yield: 225 mg, 61%, white solid; Rf 0.31 (hexanes:ethyl acetate, 4:1); mp >200 °C, recrystallized from hexanes/ethyl acetate 4:1; [α]D21 + 31.67 (c 0.5, CHCl3); IR (film) ν 2929, 2857, 1725, 1689, 1619, 1505, 1484, 1386, 1361, 1287, 1255, 1220, 1172, 1077, 1036 cm-1; 1H NMR (600 MHz, CDCl3) δ: 9.49 (s, 1H), 8.3 (d, J = 8.2 Hz, 2H), 7.58 (s, 1H), 7.33 (d, J = 8.2 Hz, 2H), 7.28 (s, 1H), 6.55 (s, 1H), 6.04 (d, J = 5 Hz, 2H), 5.81 (dd, J = 8.4 Hz, J = 5.2 Hz, 1H), 4.79 (m, 1H), 4.50 (dd, J = 12.7 Hz, J = 8.4 Hz, 1H), 4.27 (dd, J = 5.2 Hz, J = 2.7 Hz, 1H), 3.83 (dd, J = 12.6, J = 4.0 Hz, 1H), 3.31 (m, 1H), 2.45 (s, 3H), 1.42 (s, 3H), 1.32 (s, 1H), 0.99 (s, 9H), 0.26 (s, 3H), 0.25 (s, 3H) ppm; 13C NMR (150 MHz, CDCl3) δ: 196.2, 166.0, 153.0, 147.1, 143.9, 138.8, 137.0, 128.9, 128.8, 110.1, 109.4, 104.2, 102.2, 72.4, 66.6, 65.5, 55.6, 35.4, 31.0, 27.9, 26.9, 25.7, 22.7, 21.7, 18.1, 14.2, -4.7, -4.9 ppm; HRMS-EI Calcd for C30H36NO9SSi (M+-15): 614.1879, Found: 614.1870; Anal. calcd for C31H39NO9SSi C, 59.12; H, 6.24; found C, 59.31; H, 6.29.

(3aS,3bR,10bR,11R,12S,12aS)-12-(tert-Butyl-dimethyl-silanyloxy)-2,2-dimethyl-5-oxo-4-(toluene-4-sulfonyl)-3a,3b,4,5,10b,11,12,12a-octahydro-1,3,7,9-tetraoxa-4-aza-dicyclopenta[a,h]phenanthrene-11-carboxylic acid (34)

To a solution of aldehyde 22 (144 mg, 0.229 mmol) in dry methylene chloride (5 mL) was added sodium phosphate dibasic (81 mg, 0.57 mmol). The suspension was stirred while 3-chloroperbenzoic acid (130 mg, 0.57 mmol) was added. The reaction flask was sealed and heated at 40 °C overnight. The reaction mixture was diluted with methylene chloride (80 mL) and washed sequentially with saturated aqueous sodium bisulfite (10 mL), sodium bicarbonate (10 mL), and dried over sodium sulfate. The organic phase was filtered and concentrated in vacuo to provide carboxylic acid 34 as a white crystalline solid (0.125g, 85%) that was used without further purification; ; Rf 0.1 (hexanes/ethyl acetate, 1:1); mp >200 °C (chloroform/ether); [α]D22 - 35.09 (c 1.25, CHCl3); IR (KBr) ν 3246, 2930, 2891, 2857, 1710, 1688, 1619, 1505, 1484, 1361, 1240, 1220, 1172, 1078, 1033 cm-1; 1H NMR (300 MHz, CDCl3) δ: 8.29 (d, J = 8.3 Hz, 2H), 7.53 (s, 1H), 7.32 (d, J = 8.3 Hz, 2H), 7.28 (s, 1H), 6.56 (s, 1H), 6.02 (d, J = 3 Hz, 2H), 5.77 (dd, J = 8.30 Hz, J = 5.3 Hz, 1H), 4.85 (dd, J = 12.5 Hz, J = 8.4 Hz, 1H)), 4.84 (t, J = 4.7 Hz, 1H), 4.22 (dd J = 5.22, J = 2.8 Hz, 1H), 3.76 (dd, J = 12.4 Hz, J = 4.1 Hz, 1H), 3.38 (t, J = 3.5 Hz, 1H), 2.45 (s, 3H), 1.40 (s, 3H), 1.27 (s, 1H), 0.96 (s, 9H), 0.21 (s, 6H) ppm; 13C NMR (150 MHz, CDCl3) δ: 174.3, 166.2, 152.8, 146.9, 143.8, 138.9, 137.7, 129.0, 128.8, 122.4, 109.8, 109.2, 103.4, 102.1, 72.8, 68.2, 64.9, 48.0, 35.5, 27.4, 26.9, 25.7, 21.7, 18.0, -4.9, -5.0 ppm; HRMS-EI Calcd for C27H30NO10SSi (M+-57): 588.1359, Found: 588.1354; Anal. calcd for C31H39NO10SSi C, 57.65; H, 6.09; found C, 58.01; H, 6.37

(3aS,3bR,10bR,11R,12S,12aS)-12-(tert-Butyl-dimethyl-silanyloxy)-2,2-dimethyl-5-oxo-4-(toluene-4-sulfonyl)-3a,3b,4,5,10b,11,12,12a-octahydro-1,3,7,9-tetraoxa-4-aza-dicyclopenta[a,h]phenanthrene-11-carboxylic acid methyl ester (35)

To a solution of carboxylic acid 34 (45 mg, 0.069 mmol) in diethyl ether (3 mL) was added freshly prepared diazomethane solution in diethyl ether until the persistence of yellow color and total consumption of starting material (by TLC). The reaction mixture was quenched with one drop of acetic acid followed by saturated sodium bicarbonate solution (1 mL), diluted with diethyl ether (30mL) and washed with saturated sodium bicarbonate solution (2 × 1 mL), dried over magnesium sulfate, filtered and concentrated. The crude reaction mixture was passed through short silica plug using hexane:ethyl acetate 1:1 as eluent and concentrated to provide methyl ester 35 that was used without further purification. Yield: 38mg, 83%, white crystalline solid; Rf 0.45 (hexanes:ethyl acetate, 1:1); mp >200 °C (hexane/ethyl acetate); [α]D22 - 25.6809 (c 0.75, CHCl3); IR (KBr) ν 2986, 2953, 2931, 2896, 2858, 1739, 1692, 1620, 1598, 1505, 1485, 1361, 1289, 1264, 1173 cm-1; 1H NMR (300 MHz, CDCl3) δ: 8.30 (d, J = 8.4 Hz, 2H), 7.55 (s, 1H), 7.32 (d, J = 8.3 Hz, 2H), 6.58 (s, 1H), 6.02 (s, 2H), 5.78 (dd, J = 8.30 Hz, J = 5.4 Hz, 1H), 4.9 (dd, J = 12.5 Hz, J = 8.3 Hz, 1H), 4.78 (t, J = 3.0 Hz, 1H), 4.24 (dd J = 5.36 Hz, J = 2.9 Hz, 1H), 3.79 (dd, J = 12.4, J = 4.2 Hz, 1H), 3.56 (s, 3H), 3.40 (t, J = 3.7 Hz, 1H), 2.45 (s, 3H), 1.41 (s, 3H), 1.35 (s, 1H), 0.98 (s, 9H), 0.24 (s, 3H), 0.23 (s, 3H) ppm; 13C NMR (75 MHz, CDCl3) δ:169.4, 166.3, 152.8, 146.8, 143.7, 139.0, 138.2, 128.9, 128.8, 122.4, 109.8, 109.2, 103.5, 102.0, 72.9, 68.2, 65.2, 51.9, 48.1, 35.9, 27.5, 26.8, 25.7, 21.6, 18.0, -4.8, -4.9 ppm; HRMS-EI Calcd for C28H32NO10SSi (M+-57): 602.1516, Found: 602.1516

(3aS,3bR,10bR,11R,12S,12aS)-12-(tert-Butyl-dimethyl-silanyloxy)-2,2-dimethyl-5-oxo-3a,3b,4,5,10b,11,12,12a-octahydro-1,3,7,9-tetraoxa-4-aza dicyclopenta[a,h]phenanthrene-11-carboxylic acid methyl ester (38)

To a solution of 35 (52 mg, 0.079 mmol) in dry THF (1 mL) at -50 °C was added a 0.5 M solution of Na/naphthalene in DME until a green color persisted and total consumption of starting material was observed (by TLC). The solution was stirred for 10 minutes before the reaction mixture was quenched with saturated aqueous ammonium chloride solution (1 mL), warmed to room temperature, and extracted with CH2Cl2 (6 × 15 mL). The combined organic phase was dried over sodium sulfate, filtered, and concentrated. The final product was isolated by column chromatography (hexanes:ethyl acetate, 5:1 to 2:1). Yield: 23 mg, 58%, clear oil; Rf 0.28 (hexanes:ethyl acetate, 1:1); [α]D22 – 14.51 (c 0.50, CHCl3); IR (film) ν3320, 2952, 2930, 2895, 2857, 1743, 1669, 1619, 1504, 1484, 14601385, 1369, 1321, 1288, 1260, 1222 cm-1; 1H NMR (600 MHz, CDCl3) δ: 7.62 (s, 1H), 6.56 (s, 1H), 6.02 (s, 2H), 5.96 (s, 1H), 4.86 (t, J = 2.6, 1H), 4.41 (dd, J = 13.6 Hz, J = 8.2 Hz, 1H), 4.18 (dd, J = 8.25 Hz, J = 4.8 Hz, 1H), 4.11 (m, 1H), 3.66 (s, 3H), 3.40 (dd, J = 13.6 Hz, J = 3.7 Hz, 1H), 3.33 (m, 1H), 2.06 (s, 1H), 1.40 (s, 3H), 1.37 (s, 3H), 0.92 (s, 9H), 0.21 (s, 3H), 0.20 (s, 3H) ppm; 13C NMR (150 MHz, CDCl3) δ:169.6, 165.4, 151.4, 146.6, 135.4, 122.6, 110.5, 108.6, 103.3, 101.7, 69.2, 53.1, 51.9, 45.9, 33.4, 27.6, 26.5, 25.7, 17.9, -4.9, -5.0 ppm; HRMS-EI Calcd for C25H35NO8Si (M+): 505.2132, Found: 505.2131

(1R,2S,3R,4S,4aR,11bR)-2,3,4-Trihydroxy-6-oxo-1,2,3,4,4a,5,6,11b-octahydro-[1,3]dioxolo[4,5-j]phenanthridine-1-carboxylic acid methyl ester (39)

To a solution of the detosylated methyl ester 38 (23 mg, 0.046 mmol) in methanol (2 mL) was added 3% HCl in methanol (0.5 mL). The reaction mixture was stirred until total consumption of starting material (3 days). The solvent was removed under reduced pressure and the residue was purified by flash column chromatography using a 30:1 to 20:1 gradient of methylene chloride:methanol as eluent to provide methyl ester 39 (11 mg, 69%) as a white crystalline solid.; mp >200 °C (methylene chloride/methanol); Rf 0.06 (methylene chloride/methanol, 20:1); [α]D22 + 24.53 (c 0.25,MeOH); IR (KBr) ν3311, 2913, 1732, 1648, 1609, 1497, 1462, 1349, 1259, 1037 cm-1; 1H NMR (300 MHz, MeOD) δ: 7.33 (s, 1H), 6.59 (s, 1H), 5.93 (d, J = 3.7, 2H), 4.50 (t, J = 3.12, 1H), 4.21 (dd, J = 13.1 Hz, J = 10.1 Hz, 1H), 3.86 (m, 1H), 3.79, (dd, J = 10.1, J = 3.0, 1H), 3.51 (s, 3H), 3.39 (m, 1H), 3.29 (dd, J = 13.1, J = 4.1, 1H) ppm; 13C NMR (75 MHz, MeOD) δ: 170.8, 166.4, 151.7, 146.4, 137.3, 121.7, 106.9, 103.7, 101.8, 72.2, 71.9, 70.9, 51.4, 50.6, 44.8, 35.4 ppm; HRMS-FAB: (m/z) (M + H)+: Calcd for C16H17NO8: 352.0947, Found: 352.0941

(1R,2S,3R,4S,4aR,11bR)-2,3,4-Trihydroxy-6-oxo-1,2,3,4,4a,5,6,11b-octahydro-[1,3]dioxolo[4,5-j]phenanthridine-1-carboxylic acid (40)

To a solution of 39 (6 mg, 0.017 mmol) in methanol (0.5 mL) was added LiOH (1 mg, 1.5 mmol). The reaction mixture was heated at 45 °C and stirred until total consumption of starting material (2 days) as monitored by TLC. The reaction mixture was made slightly acidic with the addition of HCl (5 drops, 1M) and concentrated to provide acid 40 (5 mg, 95%) as a white crystalline solid.; mp >200 oC (methanol); Rf 0.06 (methylene chloride:methanol, 4:1); IR (KBr) ν 3412, 2920, 2115, 1641, 1505, 1471, 1409, 1462, 1363, 1267 cm-1; 1H NMR (300 MHz, MeOD) δ: 7.41 (s, 1H), 6.72 (s, 1H), 6.02 (d, J = 3.7, 2H), 4.64 (t, J = 3.12, 1H), 4.35 (dd, J = 13.1 Hz, J = 10.1 Hz, 1H), 3.99 (m, 1H), 3.89, (dd, J = 10.1, J = 3.0, 1H), 3.45 (m, 1H), 3.38 (m, 1H) ppm; 13C NMR (75 MHz, MeOD) δ: 172.1, 166.4, 151.7, 146.4, 137.6, 121.7, 106.8, 103.8, 101.8, 72.4, 71.9, 71.1, 51.34, 45.03, 35.4 ppm;

(3aS,3bR,10bR,11S,12S,12aS)-12-(tert-Butyl-dimethyl-silanyloxy)-11-hydroxymethyl-2,2-dimethyl-4-(toluene-4-sulfonyl)-3b,4,10b,11,12,12a-hexahydro-3aH-1,3,7,9-tetraoxa-4-aza dicyclopenta[a,h]phenanthren-5-one-(41)

To a solution of aldehyde 22 (175 mg, 0.278 mmol) in EtOH/dioxane (1:1, 5 mL) at 0°C was added NaBH4 (3 mg, 0.08 mmol). The reaction mixture was allowed to warm to room temperature over 1.5 hours before being quenched with a solution of saturated NH4Cl (1 mL). The EtOH/dioxane mixture was removed under reduced pressure and the aqueous residue was extracted with CH2Cl2 (3 × 25 mL). The organic phases were combined, dried over sodium sulfate, filtered, and concentrated to provide alcohol 41 which was used without further purification. Yield: 150 mg, 85%, clear oil; ; Rf 0.44 (hexanes:ethyl acetate, 1:1); [α]d22 – 47.72 (c 1.50, CHCl3); IR (film) v 3547, 2986, 2932, 2586, 1692, 1616, 1594, 1508, 1481, 1360 cm-1; 1H NMR (300 MHz, CDCl3) δ: 8.28 (d, J = 8.3 Hz, 2H), 7.54 (s, 1H), 7.30 (d, J = 8.2 Hz, 2H), 6.77 (s, 1H), 6.04 (d, J = 1.6 Hz, 2H), 5.65 (dd, J = 8.8 Hz, J = 5.6 Hz, 1H), 4.57 (d, J = 1.8 Hz, 1H), 4.32 (d, J = 4.6 Hz, 1H), 4.16 (dd J = 12.8, J = 8.9 Hz, 1H), 3.78 (m 2H), 3.38 (dd, J = 11.3 Hz, J = 3.6 Hz, 1H), 2.55 (bs, 1H), 2.43 (s, 3H), 1.96 (bs, 1H), 1.43 (s, 3H), 1.35 (s, 3H), 0.96 (s, 9H), 0.20 (s, 6H) ppm; 13C NMR (75 MHz, CDCl3) δ: 166.4, 153.1, 147.1, 143.7, 138.9, 137.0, 129.0, 128.7, 123.2, 109.1, 108.7, 104.9, 102.1, 73.1, 67.3, 64.8, 60.0, 46.9, 37.4, 28.1, 26.3, 25.8, 21.6, 18.0, -4.8, -4.9 ppm; HRMS-EI Calcd for C31H41NO9SSi (M+-15): 616.2032, Found: 616.2032.

Acetic acid (3aS,3bR,10bR,11S,12S,12aS)-12-(tert-butyl-dimethyl-silanyloxy)-2,2-dimethyl-5-oxo-4-(toluene-4-sulfonyl)-3a,3b,4,5,10b,11,12,12a-octahydro-1,3,7,9-tetraoxa-4-aza-dicyclopenta[a,h]phenanthren-11-ylmethyl ester (42)

To a solution of 41 (150 mg, 0.237 mmol) in dry CH2Cl2 (10 mL) was added DMAP (1.5 mg, 0.012 mmol), followed by pyridine (0.1 mL, 1.187 mmol). Ac2O (45 μL, 0.475 mmol) was added and the reaction mixture was stirred for 1 hour before being quenched with saturated sodium bicarbonate (5 mL) and diluted with Et2O (75 mL) and separated. The aqueous layer was extracted with Et2O (2 × 75 mL) and the combined organic phases were washed with H2O (10 mL), brine (10 mL), dried over magnesium sulfate, filtered, and concentrated. The final product was isolated by column chromatography using 5:1 mixture of hexanes: ethyl acetate as eluent. Yield: 128 mg, 81%, clear oil; Rf 0.51 (hexanes/ethyl acetate, 1:1); [α]D22 – 41.081 (c 3.0, CHCl3); IR (film) ν2988, 2952, 2930, 2858, 1742, 1694, 1619, 1598, 1505, 1485, 1395, 1362, 1254; 1H NMR (600 MHz, CDCl3) δ: 8.29 (d, J = 8.3 Hz, 2H), 7.54 (s, 1H), 7.31 (d, J = 8.2 Hz, 2H), 6.84 (s, 1H), 6.03 (d, J = 12.6 Hz, 2H), 5.62 (dd, J = 8.7 Hz, J = 5.6 Hz, 1H), 4.50 (s, 1H), 4.31 (d, J = 5.3 Hz, 1H), 4.18 (t, J = 11.1 Hz, 1H), 3.97 (dd, J = 13.0 Hz, J = 8.8 Hz, 1H), 3.85 (dd, J = 11.0 Hz, J = 3.6 Hz, 1H), 3.80 (dd, J = 13.0, J = 4.2, 1H), 2.7 (d, J = 5.2, 1H), 2.44 (s, 3H), 2.03 (s, 3H), 1.42 (s, 3H), 1.36 (s, 3H), 0.96 (s, 9H), 0.19 (s, 1H); 13C NMR (150 MHz, CDCl3) δ:170.7, 166.2, 153.2, 147.3, 143.8, 138.8, 136.2, 129.1, 128.7, 123.2, 108.9, 108.8, 105.0, 102.2, 78.4, 73.0, 66.3, 64.4, 60.8, 44.0, 37.0, 28.3, 26.2, 25.8, 25.78, 25.75, 25.6, 21.6, 20.8, 18.1, -4.8, -5.0; HRMS-EI Calcd for C32H40NO10SSi (M+-15): 658.2142, Found: 658.2152

((3aS,3bR,10bR,11S,12S,12aR)-12-hydroxy-2,2-dimethyl-5-oxo-3a,3b,4,5,10b,11,12,12a-octahydrobis[1,3]dioxolo[4,5-c:4',5'-j]phenanthridin-11-yl)methyl acetate (44)

To a solution of 42 (137 mg, 0.203 mmol) in dry DME (5 mL) at -78 °C was added a 0.5 M solution of Na/naphthalene in DME until a green color persisted and total consumption of starting material was observed (by TLC). The solution was stirred for 10 minutes then it was quenched with saturated aqueous ammonium chloride solution (2 mL). The reaction was warmed to room temperature, concentrated to remove DME, and extracted with CH2Cl2 (3 × 40 mL). The combined organic phase was dried over sodium sulfate, filtered, and concentrated. The resulting crude acetate was taken up in THF (2.5 mL) and cooled to 0 °C. TBAF (0.1 mL, 1M in THF) was added dropwise over 2 minutes. The reaction mixture was stirred until total consumption of starting material was observed (TLC) before the stirring bar was removed, silica (200 mg added), and the mixture concentrated to dryness. The final product was isolated by column chromatography using 1:1 mixture of hexanes/ethyl acetate as eluent. Yield: 61 mg, 74%, white solid; mp >200 oC (ethyl acetate/hexanes); Rf 0.059 (hexanes/ethyl acetate, 1:1); [α]D22 – 38.301 (c 1.35, DMSO); IR (film) ν3303, 2982, 2922, 2901, 2853, 1734, 1655, 1652, 1612, 1483, 1459, 1364, 1246, 1235, 1215; 1H NMR (300 MHz, DMSO) δ: 7.76 (s, 1H), 7.35 (s, 1H), 7.03 (s, 1H) 6.09 (d, J = 1.8, 2H), 5.48 (d, J = 4.2, 1H), 4.35, (s, 1H), 4.24 (d, J = 5.3, 1H), 4.19 – 4.10 (m, 3H), 3.46 (dd, J = 14.0 Hz, J = 8.2 Hz, 1H), 3.21 (dd, J = 13.9 Hz, J = 3.8 Hz, 1H), 2.80 (bs, 1H), 2.02 (s, 1H), 1.39 (s, 3H), 1.31 (s, 3H); 13C NMR (75 MHz, DMSO) δ:170.9, 163.9, 151.3, 146.7, 134.5, 124.2, 108.9, 107.6, 105.4, 102.2, 77.9, 77.2, 65.3, 61.2, 53.5, 34.7, 28.3, 26.4, 21.2; HRMS-EI Calcd for C20H23NO8 (M+): 405.1424, Found: 405.1431

((1S,2S,3R,4S,4aR,11bR)-2,3,4-trihydroxy-6-oxo-1,2,3,4,4a,5,6,11b-octahydro-[1,3]dioxolo[4,5-j]phenanthridin-1-yl)methyl acetate (46)

To a solution of acetate 44 (21 mg, 0.052 mmol) in MeOH (1 mL) was added an HCl solution (3 % in MeOH, 3 mL). The reaction mixture was stirred until total consumption of starting material as monitored by TLC (3 h) before being quenched to basic pH with saturated sodium bicarbonate solution. The crude reaction mixture was concentrated to dryness. The final product was isolated by column chromatography (methylene chloride:methanol, 5:1). Yield: 6 mg, 45%, white solid; mp >200 °C (methylene chloride/methanol); Rf 0.41 (methlene chloride: methanol, 5:1); [α]d22 97.32 (c 0.3, DMSO); 1H NMR (600 MHz, DMSO) δ: 7.36 (s, 1H), 7.01 (s, 1H), 6.76, (s, 1H), 6.10, (s, 2H), 5.14, (bs, 3H), 4.38 (t, J = 10.7 Hz, 1H), 4.15 – 4.10 (m, 2H), 3.84 (s, 1H), 3.70 (dd J = 9.8 Hz, J = 2.9 Hz, 1H), 3.50 (dd J = 13.2 Hz, J = 9.9 Hz, 1H), 3.27 (dd J = 13.3 Hz, J = 4.0 Hz, 1H), 2.69 (bs, 1H), 2.03 (s, 3H) ppm; 13C NMR (150 MHz, DMSO) δ: 171.0, 164.1, 151.3, 146.6, 135.3, 123.8, 107.5, 105.5, 102.2, 73.1, 71.3, 69.1, 61.9, 51.6, 36.9, 21.3 ppm; HRMS-FAB Calcd for C17H20NO8 (M + 1): 366.1082, Found: 366.1088.

(1S,2S,3R,4S,4aR,11bR)-2,3,4-trihydroxy-1-(hydroxymethyl)-1,2,3,4,4a,5-hexahydro-[1,3]dioxolo[4,5-j]phenanthridin-6(11bH)-one (45)

To a solution of acetate 44 (25 mg, 0.062 mmol) at 0 °C, in MeOH (5 mL) was added K2CO3 (40 mg, 0.62 mmol) and H20 (1 mL). The suspension was stirred until total consumption of starting material (TLC) before being quenched with HCl (4 drops, 6N). The reaction mixture was allowed to warm to room temperature and stir (4 h). The pH of the reaction was made basic with the addition of saturated sodium bicarbonate solution and the methanol removed under reduced pressure. The resulting aqueous phase was concentrated overnight on a freeze-dryer. The salts were triturated with MeOH (5 × 5 mL) and the MeOH washes collected and concentrated. The final product was isolated by column chromatography (methylene chloride: methanol, 5:1). Yield: 15 mg, 75%, white solid; mp >200 °C (methylene chloride/methanol); Rf 0.20 (methlene chloride: methanol, 5:1); [α]d22 90.91 (c 0.25, DMSO); IR (film) ν3361, 2916, 1646, 1608, 1503, 1460, 1385, 1361, 1252; 1H NMR (600 MHz, DMSO) δ: 7.34 (s, 1H), 6.97 (s, 1H), 6.66, (s, 1H), 6.09, (d, J = 0.78, 2H), 5.04 – 4.97, (m, 3H), 4.47 (dd J = 6.6 Hz, J = 3.8 Hz, 1H), 4.19 (s, 1H), 3.89 (q, J = 7.86 Hz, 1H), 3.82 (s, 1H), 3.69 – 3.64 (m, 1H), 3.42 (dd J = 13.2 Hz, J = 9.9 Hz, 1H), 3.39 – 3.32 (m, 1H), 3.15, (dd J = 13.3 Hz, J = 4.5 Hz, 1H), 2.41 (s, 1H) ppm; 13C NMR (150 MHz, DMSO) δ: 164.2, 151.2, 146.3, 136.3, 123.7, 107.4, 105.6, 102.1, 73.3, 71.6, 69.7, 57.8, 51.8, 44.4, 37.3 ppm; HRMS-FAB Calcd for C15H18NO7 (M + 1): 324.1085, Found: 324.1084.

(3aS,3bR,10bR,12S,12aS)-12-(tert-butyldimethylsilyloxy)-2,2-dimethyl-3b,4,10b,11,12,12a-hexahydrobis[1,3]dioxolo[4,5-c:4',5'-j]phenanthridin-5(3aH)-one (48)

To a solution of aldehyde 22 (192 mg, 0.305 mmol) in toluene (10 mL) was added RhCl(PPh3)3 (424 mg, 0.458 mmol). The reaction vessel was sealed, lowered into a preheated oil bath (130 °C), and stirred until total consumption of starting material as monitored by TLC (7.5 h). The crude reaction mixture was filtered through a silica plug using a mixture of 2:1 Hexanes : Ethyl Acetate as eluent and allowed to stand overnight. The resulting yellow crystals were removed by filtration and the crude reaction mixture was concentrated under reduced pressure and dried under vacuum. The crude was taken up in DME (8 mL) and cooled to -60 °C. To the acetonide solution was added a 0.5 M solution of Na/naphthalene in DME until a green color persisted and total consumption of starting material was observed (by TLC). The solution was stirred for 10 minutes before the reaction mixture was quenched with saturated aqueous ammonium chloride solution (3 mL), warmed to room temperature, concentrated to remove DME, and extracted with CH2Cl2 (3 × 50 mL). The combined organic phase was dried over sodium sulfate, filtered, and concentrated. The final product was isolated by column chromatography using 3:1 mixture of hexanes: ethyl acetate as eluent. Yield: 101 mg, 74%, clear and colorless oil; Rf 0.49 (hexanes/ethyl acetate, 1:1); [α]D22 – 20.929 (c 1.5, CHCl3); IR (film) ν3360, 2952, 2929, 2894, 2857, 1670, 1615, 1505, 1482, 1459, 1384, 1345, 1270, 1256, 1243, 1219; 1H NMR (600 MHz, CDCl3) δ: 7.59 (s, 1H), 6.77 (s, 1H), 6.28 (s, 1H) 6.03 (d, J = 5.28, 2H), 4.42 (d, J = 2.10, 1H), 4.18, (dd, J = 8.3 Hz, J = 4.8 Hz, 1H), 4.11 (m, 1H), 3.43 (dd, J = 13.2 Hz, J = 8.6 Hz, 1H), 3.12 (t, J = 13.5 Hz, 1H), 2.26 (d, J = 13.6 Hz, 1H), 1.77 (t, J = 13.9 Hz, 1H), 1.46 (s, 3H), 1.41 (s, 3H), 0.91 (s, 9H), 0.15 (s, 3H), 0.14 (s, 3H); 13C NMR (150 MHz, CDCl3) δ:165.7, 151.4, 146.7, 136.5, 122.9, 109.9, 108.4, 104.3, 101.7, 77.7, 66.9, 57.9, 31.9, 31.6, 28.3, 26.5, 25.7, 25.6, 21.1, 17.9, -4.8, -4.9 ppm; HRMS-EI Calcd for C23H33NO6Si (M+): 447.2077, Found: 447.2083

(3aS,3bR,10bR,12S,12aR)-12-Hydroxy-4-(4-methoxy-benzyl)-2,2-dimethyl-3b,4,10b,11,12,12a-hexahydro-3aH-1,3,7,9-tetraoxa-4-aza-dicyclopenta[a,h]phenanthren-5-one (49)

To a solution of acetonide 48 (21 mg, 0.047 mmol) in DMF (0.24 mL) at 0 °C was added NaH (spatula tip, 60 % dispersion in mineral oil). The reaction mixture was stirred at 0 °C for 10 min and then at rt for 20 min. The reaction mixture was cooled in ice again before p-methoxy benzylbromide (11 μL, 0.07 mmol) was added and then being allowed to warm to rt over 2 h. The mixture was taken up in Et2O (5 mL) and quenched with H2O (2 mL), transferred to a separatory funnel and diluted further with Et2O (50 mL). The ether layer was wased with H2O (6 × 0.5 mL), brine (1 × 1 mL), dried over magnesium sulfate, flitered, and concentrated under reduced pressure. The crude residue was taken up in THF (1 mL) and cooled to 0 °C. TBAF (56 μL, 0.056 mmol, 1 M in THF) was added and the reaction mixture was stirred for 20 minutes. Silica (0.2g) added and the mixture concentrated to dryness. The final product was isolated by flash column chromatography (hexanes : ethyl acetate, gradient 2:1-1:1). Yield: 13.6 mg, 64%, slight yellow oil; Rf 0.041 (hexanes:ethyl acetate, 2:1); [α]D22 + 40.90 (c 0.50, CHCl3); IR (film) v IR (film) v 3550, 2920, 1642, 1516, 1453 cm-1; 1H NMR (600 MHz, CDCl3) δ: 7.63 (s, 1H), 7.24 (d, J = 8.6 Hz, 2H), 6.82 (d, J = 8.6 Hz, 2H), 6.75 (s, 1H), 6.03, (s, 2H), 5.21 (d, J = 15.8 Hz, 1H), 4.90 (d, J = 15.5 Hz, 1H), 4.39 (dd, J = 7.6, J = 6.2 Hz, 1H), 4.23 (m, 1H), 4.12 (t, J = 5.61 Hz, 1H), 3.78 (s, 3H), 3.71 (dd, J = 13.4, J = 7.9 Hz, 1H), 3.19 (td, J = 12.4, 5.0 Hz, 1H), 2.36-2.28 (m, 2H), 2.01 (qd, J = 13.6, 11.9, 4.9 Hz, 1H), 1.387 (s, 3H), 1.34 (s, 3H) ppm; 13C NMR (150 MHz, CDCl3) δ: 165.2,158.4, 151.1, 146.8, 135.4, 131.8, 128.2, 123.1, 113.7, 109.5, 108.6, 104.2, 101.6, 78.1, 75.9, 66.6, 61.6, 61.9, 55.3, 46.3, 32.3, 21.0, 28.0, 26.1 ppm; HRMS-EI Calcd for C25H27NO7 (M+): 453.1788, Found: 453.1787.

4-(4methoxybenzyl)-2,2-dimethyl-3b,4,10b,12a-tetrahydro-3aH-1,3,7,9-tetraoxa-4-aza-dicyclopenta[a,h]phenanthren-5-one (50)

To a solution of alcohol 49 (15 mg, 0.033 mmol) in THF (1 mL) at 0 °C was added a spatula tip of NaH (60 % dispersion in mineral oil). The reaction mixture was stirred at 0 °C for 10 min before being allowed to warm to rt and stir for 45 min. The reaction was cooled externally to 0 °C again before CS2 (12 μL, 0.198 mmol) was added. After stirring for 1 h at 0 °C MeI (25 μL, 0.397 mmol) was added and the reaction was allowed to warm to rt slowly over 5 h before being quenched with sat. NH4Cl (2 mL). The reaction mixture was concentrated to remove THF, the aq residue was extracted with EtOAc (3 × 30 mL), and the organic phases combined and dried over sodium sulfate. Following filtration, the EtOAc was removed under reduced pressure, the residue taken up in o-zylene (2 mL) and heated at reflux for 21 h. The reaction mixture was concentrated under reduced pressure at 50 °C and the crude residue loaded onto silica (100 mg). The final product was isolated by flash column chromatography (hexanes : ethyl acetate, 4:1). Yield: 5 mg, 35%, white solid; mp 172-174 °C (ethyl acetate/hexanes); Rf 0.51 (hexanes:ethyl acetate, 1:1); [α]D22 + 37.48 (c 0.20, CHCl3); IR (film) v 2920, 1647, 1511, 1451 cm-1; 1H NMR (600 MHz, CDCl3) δ: 7.67 (s, 1H), 7.27 (d, J = 8.6 Hz, 2H), 6.92 (s, 1H), 6.84 (d, J = 8.6 Hz, 2H), 6.34 (d, J = 10.2 Hz, 1H), 6.11 (dt, J = 10.0 Hz, J = 3.1 Hz, 1H), 6.05 (s, 2H), 5.43 (d, J = 15.6 Hz, 1H), 4.98 (d, J = 15.5 Hz, 1H), 4.64-4.61 (m, 1H), 4.39 (dd J = 9.3, J = 7.1 Hz, 1H), 3.80 (s, 3H), 3.66 (dd, J = 11.9, J = 9.3 Hz, 1H), 3.49 (d, J = 12.1, 1H), 1.38 (s, 3H), 1.35 (s, 3H) ppm; 13C NMR (150 MHz, CDCl3) δ: 165.5, 158.3, 151.1, 146.9, 133.6, 132.6, 128.2, 127.9, 126.1, 123.7, 113.7, 109.3, 109.2, 103.8, 101.7, 74.8, 71.9, 60.8, 55.3, 45.8, 38.6, 27.6, 25.3 ppm; HRMS-EI Calcd for C25H25NO6 (M+): 435.1682, Found: 435.1683

7-deoxy-trans-dihydrolycoricidine (7)

To a solution of acetonide 48 (13 mg, 0.29 mmol) in MeOH (1 mL) was added a 10% solution of HCl in MeOH (10 mL). The reaction mixture was stirred until total consumption of starting material as monitored by TLC (3 days). The final product was isolated by flash column chromatography (chloroform : methanol, gradient 7:1-5:1). Yield: 6.1 mg, 71%, white solid; mp > 200 °C (MeOH); Rf 0.25 (methylene chloride : methanol, 5:1); [α]D22 28.6 (c 0.25, DMSO); IR (KBr) v 3559, 3488, 3450, 3429, 1671, 1471, 1263 cm-1; 1H NMR (600 MHz, DMSO-d6) δ: 7.30 (s, 1H), 6.95 (s, 1H), 6.94 (s, 1H), 6.08 (s, 2H), 4.99 (d, J = 3.4 Hz, 1H), 4.96 (d, J = 5.9 Hz, 1H), 4.84 (d, J = 3.2 Hz, 1H), 3.89, (br s, 1H), 3.72 (br s, 2H), 3.30 (d, J = 12.3 Hz, 1H), 2.89 (td, J = 12.4, J = 3.6 Hz, 1H), 2.15 (dt, J = 13.0, J = 3.0 Hz, 1H), 1.65 (td, J = 12.9, J = 2.2 Hz, 1H) ppm; 13C NMR (150 MHz, DMSO-d6) δ: 164.7, 151.1, 146.4, 138.5, 123.7, 107.4, 104.8, 102.0, 72.1, 70.1, 69.1, 55.6, 34.7, 28.8 ppm; HRMS-EI Calcd for C14H16NO6 (M++1): 294.0978, Found: 294.1011.

Supplementary Material

Scheme 4.

Acknowledgments

The authors are grateful to the following agencies for financial support of this work: Natural Sciences and Engineering Research Council of Canada (NSERC), (Idea to Innovation and Discovery Grants); Canada Research Chair Program, Canada Foundation for Innovation (CFI), Research Corporation, TDC Research, Inc.; Brock University; and the Ontario Partnership for Innovation and Commercialization (OPIC) and Lotte and John Hecht Memorial Foundation grant to SP. AER and AK thank the National Institutes of Health (P20 RR016480) for financial support and Professor Snezna Rogelj for her kind assistance with the cell culture.

Footnotes

Supporting Information Available: Copies of 1H NMR and 13C NMR spectra for all new compounds. This material is available free of charge via the Internet at http://pubs.acs.org.

References

- 1.For a preliminary account see: Collins J, Drouin M, Sun X, Rinner U, Hudlicky T. Org. Lett. 2008;10:361. doi: 10.1021/ol702440f.

- 2.Gerrard AW. Pharm. J. 1877;8:214. [Google Scholar]

- 3.Evidente A, Kornienko A. Phytochem. Rev. 2009;8:449. (b) For a recent summary of biological activities of narciclasine and congeners see reference 12k.

- 4.Lycoricidine: Ohta S, Kimoto S. Tetrahedron Lett. 1975;27:2279. Ohta S, Kimoto S. Chem. Pharm. Bull. 1976;24:2977. Paulsen H, Stubbe M. Tetrahedron Lett. 1982;23:3171. Paulsen H, Stubbe M. Liebigs Ann. Chem. 1983:535. Chida N, Ohtsuka M, Ogawa S. Tetrahedron Lett. 1991;32:4525. Hudlicky T, Olivo HF. J. Am. Chem. Soc. 1992;114:9694. Chida N, Ohtsuka M, Ogawa S. J. Org. Chem. 1993;58:4441. Martin SF, Tso HH. Heterocycles. 1993;35:85. Hudlicky T, Olivo HF, McKibben B. J. Am. Chem. Soc. 1994;116:5108. Keck GE, Wager TT. J. Org. Chem. 1996;61:8366. (ent-lycoricidine) Elango S, Yan TH. Tetrahedron. 2002;58:7375. Padwa A, Zhang H. Org. Lett. 2006;8:247. doi: 10.1021/ol052524f. Padwa A, Zhang H. J. Org. Chem. 2007;72:2570. doi: 10.1021/jo0626111. Matveenko M, Kokas OJ, Banwell MG, Willis AC. Org. Lett. 2007;9:3683. doi: 10.1021/ol701552r. (ent-lycoricdine)

- 5.Lycorine: Tsuda Y, Sano T, Taga J, Isobe K, Toda J, Irie H, Tanaka H, Tagaki S, Yakami M, Murata M. Chem Commun. 1975:333. Yamaki M, Murata M, Takagi S, Tsuda Y, Sano T, Taga J, Isobe K, Tanaka H, Irie H, Uyeo S. Heterocycles. 1976;5:163. Moeller O, Steinberg EM, Torssell K. Acta Chem. Scand., Ser. B. 1978;32:98. Tsuda Y, Sano T, Taga JI, Isobe K, Toda J, Takagi S, Yamaki M, Murata M, Irie H, Tanaka H. J. Chem.. Soc., Perkin Trans. I. 1979:1358. Umezawa B, Hoshino O, Sawaki S, Sashida H, Mori K. Heterocycles. 1979;12:1475. Sano T, Kashiwaba N, Toda J, Tsuda Y, Irie H. Heterocycles. 1980;14:1097. Martin SF, Tu C-Y. J. Org. Chem. 1981;46:3763. Martin SF, Tu C-Y, Kimura M, Simonsen SH. J. Org. Chem. 1982;47:3634. Umezawa B, Hoshino O, Sawaki S, Sashida H, Mori K, Hamada Y, Kotera K, Iitaka Y. Tetrahedron. 1984;40:1783. Boeckman RK, Goldstein SW, Walters MA. J. Am. Chem. Soc. 1988;110:8250. Hoshino O, Ishizaki M, Kamei K, Tauchi M, Nagao T, Iwaoka K, Sawaki S, Umezawa B, Iitaka Y. Chemistry Letters. 1991;8:1365. Schultz AG, Holoboski MA, Smyth MS. J. Am. Chem. Soc. 1996;118:6210. (ent-lycorine) Hoshino O, Ishizaki M, Kamei K, Tauchi M, Nagao T, Iwaoka K, Sawaki S, Umezawa B, Iitaka Y. J. Chem. Soc., Perkin Trans. I. 1996:571. Yamada K, Yamashita M, Sumivoshi T, Nishimura K, Tomioka K. Org. Lett. 2009;11:1631. doi: 10.1021/ol9003564.

- 6.7-Deoxypancratistatin: Ohta S, Kimoto S. Chem. Pharm. Bull. 1976;24:2969. Ohta S, Kimoto S. Chem. Pharm. Bull. 1976;24:2977. Paulsen H, Stubbe M. Liebigs Ann. Chem. 1983:535. Tian X, Maurya R, Königsberger K, Hudlicky T. Synlett. 1995:1125. Keck GE, McHardy SF, Murry JA. J. Am. Chem. Soc. 1995;117:7289. Chida N, Jitsuoka M, Yamamoto Y. Heterocycles. 1996;43:1385. Keck GE, Wagner TT, McHardy SF. J. Org. Chem. 1998;63:9164. Keck GE, McHardy SF. J. Org. Chem. 1999;64:4465. Akgün H, Hudlicky T. Tetrahedron Lett. 1999;40:3081. (ent-7-deoxypancratistatin) Acena JL, Arjona O, Leon ML, Plumet J. Org. Lett. 2000;2:3683. doi: 10.1021/ol000268v. Padwa A, Zhang H. Tetrahedron Lett. 2006;47:3905. Hakansson AE, Palmelund A, Holm H, Madsen R. Chem. Eur. J. 2006;12:3243. doi: 10.1002/chem.200501429.

- 7.trans-Dihydrolycoricidine: Isobe K, Taga J-I, Tsuda Y. Heterocycles. 1978;9:625. Chida N, Jitsuoka M, Yamamoto Y, Ohtsuka M, Ogawa S. Heterocycles. 1996;43:1385. Fujimura T, Shibuya M, Ogasawara K, Iwabuchi Y. Heterocycles. 2005;66:167. Szanto G, Hegedus L, Mattyasovszky L, Simon A, Simon A, Kadas I. Tetrahedron Lett. 2009;50:2857. Szanto G, Hegedus L, Mattyasovszky L, Simon A, Simon A, Bitter I, Toth G, Toke L, Kadas I. Tetrahedron. 2009;65:8412.; by hydrogenation of lycoricidine: Gabrielsen B, Monath TP, Huggins JW, Kefauver DF, Pettit GR, Groszek G, Hollingshead M, Kirsi JJ, Shannon WM, Schubert EM, Dare J, Ugarkar B, Ussery MA, Phelan MJ. J. Nat. Prod. 1992;55:1569. doi: 10.1021/np50089a003. Pettit GR, Ducki S, Eastham SA, Melody N. J. Nat. Prod. 2009;72:1279. doi: 10.1021/np9001948.

- 8.Pancratistatin: Danishefsky S, Lee JY. J. Am. Chem. Soc. 1989;111:4829. Tian X, Hudlicky T, Königsberger K. J. Am. Chem. Soc. 1995;117:3643. Trost BM, Pulley SR. J. Am. Chem. Soc. 1995;117:10143. Hudlicky T, Tian X, Königsberger K, Maurya R, Rouden J, Fan F. J. Am. Chem. Soc. 1996;118:10752. Doyle TJ, Hendrix M, VanDerveer D, Javanmard S, Haseltine J. Tetrahedron. 1997;53:11153. Magnus P, Sebhat IK. J. Am. Chem. Soc. 1998;129:5341. Rigby JH, Maharoof USM, Mateo ME. J. Am. Chem. Soc. 2000;122:6624. Pettit GR, Melody N, Herald DL. J. Org. Chem. 2001;66:2583. doi: 10.1021/jo000710n. Kim S, Ko H, Kim E, Kim D. Org. Lett. 2002;4:1243. doi: 10.1021/ol0256419. Li M, Wu A, Zhou P. Tetrahedron Lett. 2006;47:3707. Madsen R, Dam JH. Eur. J. Org. Chem. 2009;37:4666.

- 9.Narciclasine: Rigby JH, Mateo ME. J. Am. Chem. Soc. 1997;119:12655. Keck GE, Wager TT, Rodriquez JFD. J. Am. Chem. Soc. 1999;121:5176. Gonzalez D, Martinot T, Hudlicky T. Tetrahedron Lett. 1999;40:3077. Rigby JH, Maharoof USM, Mateo ME. J. Am. Chem. Soc. 2000;122:6624. Hudlicky T, Rinner U, Gonzalez D, Akgun H, Schilling S, Siengalewicz P, Martinot TA, Pettit GR. J. Org. Chem. 2002;67:8726. doi: 10.1021/jo020129m. Elango S, Yan T-H. J. Org. Chem. 2002;67:6954. doi: 10.1021/jo020155k. Matveenko M, Banwell MG, Willis AC. Tetrahedron. 2008;64:4817. (ent-narciclasine, ent-lycoricidine)

- 10.trans-Dihydronarciclasine: Shin I-J, Choi E-S, Cho C-G. Angew. Chem., Int. Ed. 2007;46:2303. doi: 10.1002/anie.200604612. Jana CK, Studer A. Chem. Eur. J. 2008;14:6326. doi: 10.1002/chem.200800903. Choi E-S, Cho C-G. Tetrahedron. 2008;64:2172.; by hydrogenation of narciclasine: Mondon A, Krohn K. Chem. Ber. 1975;108:445. Pettit GR, Ducki S, Eastham SA, Melody N. J. Nat. Prod. 2009;72:1279. doi: 10.1021/np9001948.

- 11.Reviews: Cook JW, Loudon JD. In: Alkaloids of the Amaryllidaceae, The Alkaloids. Manske RHF, Holmes HL, editors. II. Academic Press; New York: 1952. p. 331. Hartwell JL. Lloydia. 1967;30:379. Wildman WC. In: The Alkaloids. Manske RHF, editor. Academic Press; New York: 1968. p. 307. Fuganti C. In: The Alkaloids. Manske RHF, editor. Academic Press; New York: 1975. p. 83. Martin SF. In: The Alkaloids. Brossi AR, editor. Vol. 40. Academic; New York: 1987. p. 251. Polt R. In: Organic Synthesis: Theory and Applications. Hudlicky T, editor. Vol. 3. JAI Press; Greenwich, CT: 1997. p. 109. Ruan L. Yaoxue Tongbae. 1988;23:453. Hoshino O. In: The Alkaloids. Cordell GA, editor. Vol. 51. Academic; New York: 1998. p. 323. Rinner U, Hudlicky T. Synlett. 2005:365. Chapleur Y, Chretien F, Ahmed I, Khaldi M. Curr. Org. Synth. 2006;3:331. Kornienko A, Evidente A. Chem. Rev. 2008;108:1982. doi: 10.1021/cr078198u. Manpadi M, Kornienko A. Org. Prep. Proced. Int. 2008;40:107. doi: 10.1080/00304940809458083. Jin Z. Nat. Prod. Rep. 2009;26:363. doi: 10.1039/b718044f.

- 12.a McNulty J, Mao J, Give R, Mo R, Wolf S, Pettit GR, Herald DL, Boyd MR. Bioorg. Med. Chem. Lett. 2001;11:169. doi: 10.1016/s0960-894x(00)00614-4. [DOI] [PubMed] [Google Scholar]; b McNulty J, Larichev V, Pandey S. Bioorg. Med. Chem. Lett. 2005;15:5315. doi: 10.1016/j.bmcl.2005.08.024. [DOI] [PubMed] [Google Scholar]

- 13.McNulty J, Nair JJ, Griffin C, Pandey S. J. Nat. Prod. 2008;71:357. doi: 10.1021/np0705460. [DOI] [PubMed] [Google Scholar]