Abstract

Packaging waste forms a significant part of municipal solid waste and has caused increasing environmental concerns, resulting in a strengthening of various regulations aimed at reducing the amounts generated. Among other materials, a wide range of oil-based polymers is currently used in packaging applications. These are virtually all non-biodegradable, and some are difficult to recycle or reuse due to being complex composites having varying levels of contamination. Recently, significant progress has been made in the development of biodegradable plastics, largely from renewable natural resources, to produce biodegradable materials with similar functionality to that of oil-based polymers. The expansion in these bio-based materials has several potential benefits for greenhouse gas balances and other environmental impacts over whole life cycles and in the use of renewable, rather than finite resources. It is intended that use of biodegradable materials will contribute to sustainability and reduction in the environmental impact associated with disposal of oil-based polymers.

The diversity of biodegradable materials and their varying properties makes it difficult to make simple, generic assessments such as biodegradable products are all ‘good’ or petrochemical-based products are all ‘bad’. This paper discusses the potential impacts of biodegradable packaging materials and their waste management, particularly via composting. It presents the key issues that inform judgements of the benefits these materials have in relation to conventional, petrochemical-based counterparts. Specific examples are given from new research on biodegradability in simulated ‘home’ composting systems. It is the view of the authors that biodegradable packaging materials are most suitable for single-use disposable applications where the post-consumer waste can be locally composted.

Keywords: biodegradable, compostable, biopolymers, packaging, environment, waste management

1. Introduction

Many different materials are used for packaging including metals, glass, wood, paper or pulp, plastics or combinations of more than one material as composites. Most of these enter municipal waste streams at the end of their service life. Over 67 million tonnes of packaging waste is generated annually in the EU, comprising about one-third of all municipal solid waste (MSW) (Klingbeil 2000). Plastics contribute 18 per cent of the 10.4 million tonnes of packaging wastes produced annually in the UK (DEFRA 2007). Discarded packaging is also a very obvious source of litter, posing a major waste management challenge (see Barnes et al. 2009; Gregory 2009; Oehlmann et al. 2009; Ryan et al. 2009; Teuten et al. 2009; Thompson et al. 2009a,b).

In recent years, the recycling of packaging materials has increased but the recycling rates for most plastic packaging remain low (Davis & Song 2006; Hopewell et al. 2009). A large number of different types of polymers, each of which may contain different processing additives such as fillers, colourants and plasticizers, are used for packaging applications (Andrady & Neal 2009; Thompson et al. 2009a). These composition complexities together with contamination during use often render recycling uneconomic compared with disposal in landfill. Although the proportion of waste being landfilled has fallen in recent years, around 60 per cent of municipal waste in England still ends up in landfill (http://www.defra.gov.uk/environment/statistics/wastats/bulletin07.htm). This presents environmental concerns, resulting in strengthening of regulations on waste (e.g. Packaging and Packaging Waste Directive (94/62/EEC) and UK Packaging Regulations (1998).

Biodegradable plastics with functionalities and processabilities (Bioplastics 07/08) comparable to traditional petrochemical-based plastic have been developed for packaging applications (e.g. www.european-bioplastics.org). Typically, these are made from renewable raw materials such as starch or cellulose. Interest in biodegradable plastic packaging arises primarily from their use of renewable raw materials (crops instead of crude oil) and end-of-life waste management by composting or anaerobic digestion to reduce landfilling (Murphy & Bartle 2004). The disposal of packaging materials is particularly significant in view of the recent focus on waste generation and management as important environmental aspects of present-day society (DEFRA 2004; Thompson et al. 2009b).

In addition to performance and price, biodegradable plastics must offer advantages for waste management systems in order to realize an overall benefit. This paper discusses the potential impact of biodegradable plastics, with particular reference to packaging, and waste management via landfill, incineration, recycling/reuse and composting. It provides an overview of the key life cycle issues that inform judgements of the benefits that such materials have relative to conventional, petrochemical-based counterparts. Specific examples are given from new research on biodegradability in simulated ‘home’ composting systems.

2. Biodegradable alternatives to conventional plastics

Biodegradable polymers (BDPs) or biodegradable plastics refer to polymeric materials that are ‘capable of undergoing decomposition into carbon dioxide, methane, water, inorganic compounds, or biomass in which the predominant mechanism is the enzymatic action of microorganisms, that can be measured by standardized tests, in a specified period of time, reflecting available disposal condition’ (ASTM standard D6813). A subset of BDPs may also be compostable with specific reference to their biodegradation in a compost system, and these must demonstrate that they are ‘capable of undergoing biological decomposition in a compost site as part of an available program, such that the plastic is not visually distinguishable and breaks down to carbon dioxide, water, inorganic compounds and biomass, at a rate consistent with known compostable materials (e.g. cellulose)’ (ASTM standard D996, also see D6400). Initial steps may involve abiotic (thermal, photo) and biotic processes to degrade the polymer, under suitable conditions, to a low-molecular weight species. However, the resultant breakdown fragments must be completely used by the micro-organisms; otherwise there is the potential for environmental and health consequences (Narayan 2006a,b). The products of an industrial composting process (typically 12 weeks with an elevated temperature phase over 50°C) must meet quality criteria such as heavy metal (regulated) content, ecotoxicity and lack of obvious distinguishable polymer residues.

Depending on their origins, BDPs may be classified as being either bio-based or petrochemical-based. The former are mostly biodegradable by nature and produced from natural origins (plants, animals or micro-organisms) such as polysaccharides (e.g. starch, cellulose, lignin and chitin), proteins (e.g. gelatine, casein, wheat gluten, silk and wool) and lipids (e.g. plant oils and animal fats). Natural rubber as well as certain polyesters either produced by micro-organism/plant (e.g. polyhydroxyalkanoates and poly-3-hydroxybutyrate) or synthesized from bio-derived monomers (e.g. polylactic acid (PLA)) fall into this category. Petrochemical-based BDPs such as aliphatic polyesters (e.g. polyglycolic acid, polybutylene succinate and polycaprolactone (PCL)), aromatic copolyesters (e.g. polybutylene succinate terephthalate) and poly(vinyl alcohol) are produced by synthesis from monomers derived from petrochemical refining, which possess certain degrees of inherent biodegradability (Clarival & Halleux 2005 in Smith 2005). This classification differentiates between renewable (bio-based) and non-renewable (petrochemical-based) resources, but it should be noted that many commercial BDP formulations combine materials from both classes to reduce cost and/or enhance performance.

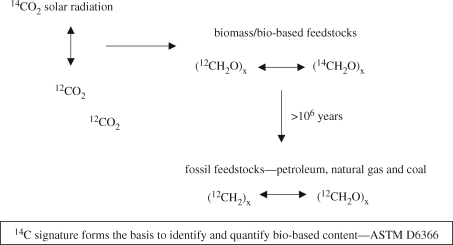

Biodegradable plastics, therefore, often comprise polymer blends that contain partly biogenic (renewable) carbon derived from biomass and partly petrochemical carbon. The per cent biogenic carbon present in a plastic or polymeric product can be readily calculated from the C-14 signature of the product as shown in figure 1 (Narayan 2006a,b). The carbon dioxide (CO2) in the atmosphere is in equilibrium with radioactive 14CO2. Radioactive carbon is formed in the upper atmosphere through the effect of cosmic ray neutrons on 14N. It is rapidly oxidized to radioactive 14CO2, and enters the Earth's plant and animal life through photosynthesis and the food chain. Plants and animals that use carbon in biological food chains take up 14C during their lifetimes. They exist in equilibrium with the 14C concentration of the atmosphere, that is the numbers of C-14 atoms and non-radioactive carbon atoms stay approximately the same over time. As soon as a plant or animal dies, they cease the metabolic function of carbon uptake; there is no replenishment of radioactive carbon, only decay. Since the half-life of carbon is around 5730 years, the petrochemical feedstocks formed over millions of years will have no 14C signature. The quantity of bio-based content can be determined (ASTM standard D-6866) by combusting the test material in a polymer in the presence of oxygen and analysing the CO2 gas evolved to provide a measure of its 14C/12C content relative to the modern carbon-based oxalic acid radiocarbon standard reference material (SRM) 4990c (referred to as HOxII).

Figure 1.

Carbon-14 signature of bio- and petrochemical polymers.

After an early pilot plant phase in the 1990s, subsequent upscaling of biodegradable (bio)plastic production by both small specialized and established companies since 2000 has now reached an industrial scale, and significant proportions of established and emerging biodegradable plastics now have renewable rather than petrochemical origins (www.european-bioplastics.org; www.bioplastics24.com). Details on the chemical compositions, production, processing, structure and properties of a wide range of bioplastics used for packaging can be found elsewhere in the literature (e.g. Smith 2005) (paper-based products are traditionally regarded as a separate material group). Current production capacity for biodegradable plastics worldwide is around 350 000 tonnes (Bioplastics 07/08), representing less than 0.2 per cent of petrochemical-based plastic, at approximately 260 million tonnes (Miller 2005). However, the environmental performance benefits are insufficient on their own to enable bioplastic polymers to be more widely used as alternatives to conventional plastics. They also need to be cost-effective, fit for purpose and, ideally, provide unique benefits in use (Miller 2005). Hence, bioplastic polymers have not yet realized their full potential.

The costs of bioplastic polymers are generally still much higher than that of their traditional plastic counterparts (Petersen et al. 1999). Most fall in the range 2–5 € kg–1 (Bioplastics 07/08) (compared with approx. 1.2 € kg–1 for major petrochemical polymers) and this is a major restriction for more widespread use. However, significant growth rates have been achieved in product capacity over the last decade or so. Bioplastic polymers are expected to become priced more as commodity materials when a critical mass is achieved, driven by a combination of forces including performance and cost improvements, benefits assigned to the use of renewable (bio)resources, increasing oil prices and increasing awareness of environmental impacts and associated legislation.

Processing parameters and technical characteristics of a wide range of commercial bioplastic polymers have been reviewed recently (Bioplastics 07/08). Many bioplastics now have mechanical properties equivalent to that of their conventional counterparts (e.g. polypropylene (PP), polystyrene and polyethylene (PE)) and can be processed using technologies widely used in the polymer industry (e.g. compounding, film processing and moulding). They have found use in many short service life applications where biodegradability is a key advantageous feature (www.european-bioplastics.org) including consumer packaging (e.g. trays, pots, films and bottles in food packaging), convenience food disposables (e.g. cutlery/tableware), bags (shopping, garden or domestic waste), agriculture mulch films, personal-care disposals (e.g. nappies) and even golf tees. Bioplastic polymers have also been used in more durable applications such as in textiles, consumer goods, automotive parts and building and construction where the focus is on the use of renewable (bio)resources and any inherent biodegradability properties need to be suppressed or controlled by careful design.

Bio-based versus biodegradable: it is important to recognize that not all bio-based polymer materials are biodegradable and vice versa. Equally, it is important to recognize that attributes like biodegradability of a given polymer need to be effectively coupled with appropriate waste management in order to capture maximum environmental benefit. For durable products where biodegradability is not a required element for reasons of performance, safety and product life, alternative methods of disposal like waste to energy or recycling need to be identified. Examples of such durable bio-based polymers are bio-polyurethanes based on polyols from vegetable oils for automotive and farm vehicles (Narayan 2006a,b), biofibre composites for industrial and automotive applications and recent developments in bio-polyethylene derived from sugar cane via ethanol to ethylene.

3. Waste management options for BDPs

There are many technologies available for the treatment of conventional plastic packaging waste (Tukker 2002) from household waste including: integrated collection and incineration with energy recovery, selective combustion of plastics with high calorific value (e.g. in cement kilns) and use as a reducing agent in blast furnaces or as feedstock for recycling.

Approximately 1 million tonnes of non-bottle domestic mixed plastic packaging waste arise in the UK each year, and this is estimated to increase between 2 and 5 per cent per annum (WRAP 2006, 2008). A ‘Waste Hierarchy’ proposed by the UK government (DEFRA 2007) as guidance for selecting the options to minimize the impact of waste recognizes reduction and reuse as the most favourable options where the aim is to minimize the material consumption or divert materials from waste streams.

The impacts of biodegradable bioplastics, when entering the waste stream and handled by current available options (recycling, incineration and landfill), are assessed briefly below. As BDPs enable a potential option for waste treatment through composting as a way to recover the materials and to produce a useful product as compost, particular attention will be given to composting biopolymers.

(a). Recycling

Biodegradable plastics that enter the municipal waste stream may result in some complications for existing plastic recycling systems. For example, the addition of starch or natural fibres to traditional polymers can complicate recycling processes (Scott 1995; Hartmann & Rolim 2002). Although it is feasible to mechanically recycle some bioplastic polymers such as PLA a few times without significant reduction in properties (Claesen 2005), the lack of continuous and reliable supply of bioplastic polymer waste in large quantity presently makes recycling less economically attractive than for conventional plastics. Finally, for certain applications such as food packaging (e.g. in modified atmosphere packaging of meat products), multilayer lamination of different biopolymers may be necessary to enhance barrier properties, just as in conventional plastics (Miller 2005), and this will compromise recyclability of the scrap during packaging manufacture and of post-consumer waste. The recycling of plastics is considered in more detail elsewhere in this volume (Hopewell et al. 2009).

(b). Incineration with energy recovery

Most commodity plastics have gross calorific values (GCV) comparable to or higher than that of coal (Davis & Song 2006). Incineration with energy recovery is thus a potentially good option after all recyclable elements have been removed. It is argued that petrochemical carbon, which has already had one high-value use, when used again as a fuel in incineration represents a more eco-efficient option than burning the oil directly (Miller 2005).

Reports by the Environment Committees of the UK Parliament (House of Commons 1993; House of Lords 1994) have supported the view that energy recovery for some types of household plastic wastes is an acceptable waste management option. Trials conducted by the British Plastics Federation demonstrated that modern waste-to-energy plants were capable of burning plastic waste, even those containing chlorinated compounds such as PVC without releasing dangerous or potentially dangerous emissions of dioxins and furans (BPF 1993). In 2005/2006, around 8 per cent (approx. 3 million tonnes) of UK municipal waste was processed through 15 incineration facilities (www.defra.gov.uk/environment/statistics/waste) and over 40 million tonnes were incinerated within the EU in around 230 incineration facilities (Musdalslien & Sandberg 2002). It is envisaged that incineration will face continued resistance in the UK unless the public is convinced about the safety of incineration and its contribution to renewable energy supplies (Miller 2005).

Energy recovery by incineration is regarded as a suitable option for all bioplastic polymers and renewable (bio)resources in bioplastic polymer products are considered to contribute renewable energy when incinerated (www.european-bioplastics.org). Natural cellulose fibre and starch have relatively lower GCV than coal but are similar to wood and thus still have considerable value for incineration (Davis & Song 2006). In addition, the production of fibre and starch materials consumes significantly less energy in the first place (Patel et al. 2003), and thus contributes positively to the overall energy balance in the life cycle. At present, the lack of scientific data on GCV of bioplastic polymers (e.g. relative importance of moisture content (MC), etc.) makes it difficult to accurately determine their value for energy recovery by incineration—further research in the area is required.

(c). Landfill

Landfill of waste plastics is the least favoured option in the UK waste hierarchy. It was attractive historically as it was extremely simple and cheap without necessary separation, cleaning or treatment. Western Europe sent 65 per cent of the total recoverable plastics in household waste (8.4 million tonnes annually) to landfill in 1999 (APME 2002). However, suitable sites for landfill across Europe are running out and public concerns are increasing about the impact of landfill on the environment and health from the amount of toxic materials in land-filled municipal waste and their potential leaching out of landfill sites (Miller 2005). Reducing the quantities of waste that ultimately ends up in landfill has become explicit government policy (e.g. Landfill Directive European Commission 1999/31/EC) in the UK and represents a particularly difficult task to achieve (e.g. approx. 60% municipal waste in England is still landfilled in comparison with approx. 37% in France and approx. 20% in Germany (EEA 2007)).

The landfill of biodegradable materials including bioplastic polymers, garden and kitchen waste presents a particular problem in that methane, a greenhouse gas with 25 times the effect of CO2, may be produced under anaerobic conditions (Hudgins 1999). While such a ‘landfill gas’ can and is captured and used as an energy source, The Landfill Directive (99/31/EC) seeks to reduce the total amount of biodegradable municipal waste (BMW) going to landfill in three successive stages eventually to 35 per cent of the 1995 total of BMW by 2020.

(d). Biological waste treatments: composting or anaerobic digestion

Unlike conventional petrochemical-based polymers, biodegradable and compostable bioplastic polymers can be composted. This can be via aerobic waste management systems such as composting to generate carbon- and nutrient-rich compost for addition to soil. In the UK, there are now more than 300 composting sites that collectively compost about 2 million tonnes of waste annually (roughly 75% of which is household waste, 5% municipal non-household waste and 20% commercial waste: http://www.organics-recycling.org.uk/). The aerobic biodegradation systems are thus of primary importance for BDPs and are dealt with in detail in the following section of this paper.

Certain BDPs are also suitable for anaerobic digestors whereby biowastes can be converted to methane, which can be used to drive generators for energy production. Published reports on the anaerobic digestibility of biodegradable bioplastics are relatively scarce and these systems are not discussed further here (for further information see Ramsay et al. 1993; Mohee et al. 2008).

4. Biodegradability and compostability

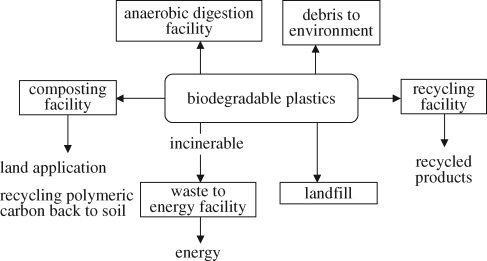

Making or calling a product biodegradable has no inherent value if the product, after use by the customer, does not end up in a waste management system that uses the biodegradability features (Narayan 1993, 1994). Figure 2 illustrates the integration of biodegradable plastics with disposal infrastructures that use this biodegradable function of the plastic product.

Figure 2.

Integration of biodegradable plastics with disposal infrastructures.

(a). Principles and concepts of composting

Composting has the potential to transfer biodegradable waste, including biodegradable plastics, into useful soil amendment products. Composting is the accelerated degradation of heterogeneous organic matter by a mixed microbial population in a moist, warm, aerobic environment under controlled conditions. Biodegradation of such natural materials will produce valuable compost as the major product along with water and CO2. The CO2 produced does not contribute to an increase in greenhouse gases because it is already part of the biological carbon cycle. Composting is also an important disposal infrastructure because it can receive other bio-based wastes in addition to biodegradable plastics—for example, more than 50 per cent of the MSW stream is typically garden and food waste and non-recyclable paper products.

(i). Degradable versus biodegradable

A number of polymers in the market place are designed to be degradable, i.e. they fragment into smaller pieces and may even degrade to residues invisible to the naked eye. While it is assumed that the breakdown products will eventually biodegrade, there are no data to document complete biodegradability within a reasonably short time period (e.g. a single growing season per year). Hence hydrophobic, high surface area plastic residues may migrate into water and other compartments of the ecosystem. In a recent science article, Thompson et al. (2004) reported that plastic debris around the globe can erode (degrade) away and end up as microscopic granular- or fibre-like fragments, and that these fragments have been steadily accumulating in the oceans. Their experiments show that marine animals consume microscopic bits of plastic, as seen in the digestive tract of an amphipod. The Algalita Marine Research Foundation (see www.algalita.org/pelagic_plastic.html) reports that degraded plastic residues can attract and hold hydrophobic elements like polychlorinated biphenyls (PCB) and dichlorodiphenyltrichloroethane (DDT) up to 1 million times background levels. The PCBs and DDTs are at background levels in soil, and diluted out, so as to not pose significant risk. However, degradable plastic residues with these high surface areas concentrate these chemicals, resulting in a toxic legacy in a form that may pose risks in the environment. Japanese researchers (Mato et al. 2001) have similarly reported that PCBs, DDE and nonylphenols (NP) can be detected in high concentrations in degraded PP resin pellets collected from four Japanese coasts. This work indicates that plastic residues may act as a transport medium for toxic chemicals in the marine environment (see discussion in Teuten et al. 2009).

Therefore, designing hydrophobic polyolefin plastics like PE to be degradable, without ensuring that the degraded fragments are completely assimilated by the microbial populations in the disposal infrastructure in a short time period, has the potential to harm the environment more than if it was not made degradable. Heat, moisture, sunlight and/or enzymes can shorten and weaken polymer chains, resulting in fragmentation of the plastic and some cross-linking, creating more intractable persistent residues. It is possible to accelerate the breakdown of the plastics in a controlled fashion to generate these fragments, some of which could be microscopic and invisible to the naked eye, and some elegant chemistry has been done to make this happen as reported in the literature (Scott & Wiles 2001). However, this degradation/fragmentation is not biodegradation per se and these degraded, hydrophobic polymer fragments pose potential risks in the environment unless they are completely assimilated by the microbial populations present in the disposal system in a relatively short period.

(ii). Measurement of biodegradability

Micro-organisms use the carbon substrates to extract chemical energy that drives their life processes by aerobic oxidation of glucose and other readily usable C-substrates (Narayan 1994):

|

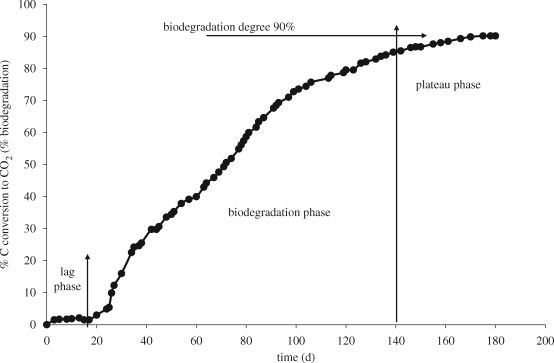

Thus, a measure of the rate and amount of CO2 evolved in the process is a direct measure of the amount and rate of microbial use (biodegradation) of the C-polymer. This forms the basis for various international standards for measuring biodegradability or microbial use of the test polymer/plastics. The rate and extent of biodegradation or microbial use of a test plastic material can be measured by using it as the sole added carbon source in a test system containing a microbially rich matrix-like compost in the presence of air, and under optimal temperature conditions (preferably at 58°C—representing the thermophilic phase). Figure 3 shows typical data obtained when the per cent carbon released (as CO2) from a bioplastic exposed in a composting environment is plotted as a function of time. First, a lag phase occurs during which the microbial population adapts to the available test C-substrate. Then follows the biodegradation phase during which the adapted microbial population begins to use the carbon substrate for its cellular life processes, as measured by the conversion of the carbon in the test material to CO2. Finally, the output reaches a plateau when use of the substrate is largely complete.

Figure 3.

Example data from a biodegradation test of a biodegradable biopolymer assessed as CO2 release over 180 days. CO2 release curve shows typical lag phase, biodegradation phase and plateau phase.

Based on the above concepts, the ASTM committee D20.96 on Biobased and Environmentally Degradable Plastics (www.astm.org) developed a Specification Standard D6400 (see also D6868) for products claiming to be biodegradable under composting conditions or compostable plastics (ASTM, 2002). The above specification standard is in harmony with standards in Europe, Japan, Korea, China and Taiwan. EN13432 ‘Requirements for Packaging Recoverable through Composting and Biodegradation—Test Scheme and Evaluation Criteria for the Final Acceptance of Packaging’ is the European standard (norm) and similar to D6400. The current UK standard BS EN 13432 (2000) covers the requirements for packaging recoverable through composting and biodegradation and test scheme and evaluation criteria for the final acceptance of packaging. At the international level, the International Standards Organization (ISO) has developed ISO 17088, ‘Specification for Compostable Plastics’ which is in harmony with these European and US norms.

The fundamental requirements of these worldwide standards for complete biodegradation under composting conditions are:

conversion to CO2, water and biomass via microbial assimilation of the test polymer material in powder, film or granule form.

Ninety per cent conversion of the carbon in the test polymer to CO2. The 90 per cent level set for biodegradation in the test accounts for a ±10 per cent statistical variability of the experimental measurement; in other words, there is an expectation for demonstration of a virtually complete biodegradation in the composting environment of the test.

Same rate of biodegradation as natural materials—leaves, paper, grass and food scraps.

Time—180 days or less (ASTM D6400 also has the requirement that if radiolabelled polymer is used and the radiolabelled evolved CO2 is measured, then the time can be extended to 365 days).

Two further requirements are also of importance:

Disintegration: <10 per cent of test material mass retained by a 2 mm sieve using test polymer material in the shape and thickness identical to the product's final intended use—see ISO 16929 and ISO 20200.

Safety: the resultant compost should have no impacts on plants, using OECD Guide 208, Terrestrial Plants, Growth Test or similar, such as PAS 100 (BSI 2002). Furthermore, regulated (heavy) metals content in the polymer material should be less than defined thresholds e.g. 50 per cent of EPA (USA and Canada) prescribed threshold.

(b). Composting in practice

The treatment of biodegradable plastics by composting is now considered in many parts of the world to be an appropriate form of material recovery. In the UK, it is a permitted recovery option specified in the Producer Responsibility (Packaging Waste) Regulations as amended in 1997.

In a large-scale study from March 2001, in Kassel, Germany, BDP packaging was introduced into the local retail trade (Klauss 2001). The purpose of this scheme was to introduce biodegradable packaging and manage its source separation by householders so that it could be collected with the organic waste stream to produce compost. The scheme required much planning prior to the launch, to ensure that the public had received sufficient information about the BDPs, their labelling, separation and collection. The mixed packaging and organic waste was composted at a full-scale composting site and was undertaken at a commercial level. The compost feedstock was monitored to ensure a relatively low proportion of one plastic to 99 parts organic waste on a weight basis. The compost produced showed no differences in terms of quality parameters compared with conventional compost comprising solely green waste (no BDPs) and had the same positive effects on soil and plant characteristics (Klauss & Bidlingmaier 2004).

Householder surveys indicated that 82 per cent of Kassel's population could clearly identify the logo printed on compostable polymers and 90 per cent supported the replacement of conventional plastic packaging with compostable packaging. The success of this programme has created a demand for further products that can be digested/degraded in the same way as ‘conventional’ organic waste. The benefits for this are twofold: (i) increased separation and collection efficiency (household or centralized) and (ii) reduced amount of waste to landfill or incineration.

Some legislation, however, imposes a number of constraints on the composting industry. In May 2003, the Animal By-Products Regulation (ABPR) started the UK implementation of an EU Regulation. The ABPR divides animal by-products into three categories and stipulates the means of collection, transport, storage, handling processing and use or disposal for each category: category 1, highest risk materials such as carcasses infected with BSE, scrapie, etc.; category 2, also high-risk materials such as animals that die on farms and animals that are unfit for human consumption; and category 3, materials that are fit (but not intended) for human consumption such as fish, milk, parts of slaughtered animals, etc. Household kitchen waste and, by association, biodegradable food packaging (because it has come into contact with food, meat or non-meat) are classified under Category 3. Categories 2 and 3 materials may be composted or treated via anaerobic digestion following strict requirements on handling, temperature and retention times.

Although the ABPR does not apply to sites accepting only green botanical garden waste, many UK Local Authorities have already started mixed organic waste (garden and kitchen) collections or are considering mixed collections in order to meet legislative targets. For mixed organic waste collections, the majority of the material collected is from botanical sources; however, due to the presence of kitchen/catering waste all the waste must be composted in-vessel in order to meet the requirements. Local Authorities could collect the organic botanical waste separately from the kitchen-derived waste, but this has extensive logistical and cost issues (separate vehicles, crew and composting facility). In-vessel composting is more costly than the open-windrow methods commonly adopted in the UK for pure ‘green waste’. This results in increased composting costs per tonne, gate fees charged to Local Authorities and reduction in the competitiveness of in-vessel composting against other treatment and disposal options such as landfill.

Concerns over the potential ecotoxicity of degradation products have resulted in the formulation and adoption of suitable international standards for compostable polymer products. For example, EN 13432 requires that compostable polymer materials have to fulfill European, or where none exist, national requirements for compostability. In December 2003, the Composting Association in the UK launched a Certification Scheme for Compostable Packaging in order to assist UK Local Authorities with the selection of sacks for organic waste collections. As there is currently no European standard on compost quality (besides the ecological criteria for the award of the EU Eco-label), the UK adopted the BSI PAS 100 in November 2002 (BSI 2002). Other standards such as the ASTM D6400 and ISO 17088 also define product classification and requirements for composts.

(c). Home (domestic) composting

In the UK, home composting has been identified by the Strategy Unit of the Cabinet Office as one of five key measures to reduce the growth rate of household waste (Anon. 2002; Murphy & Bartle 2004). In addition to kitchen and garden waste, home composting of biodegradable packaging materials could divert waste from municipal collection systems and complement industrial composting. It must be noted that it is difficult to regulate home composting, and anaerobic composting conditions occurring in poorly managed systems will result in the generation of methane. Moreover, home composting using compost bins or heaps is more variable and less optimized than industrial composting and the temperature achieved is rarely more than a few °C above ambient temperature. Under such conditions, certain compostable materials certified for industrial composting (EN13432) may not biodegrade sufficiently. The ‘OK Compost Home’ standard, which repeats the EN13432 test protocol at ambient temperature, as shown in table 1, has been established by AIB-VINÇOTTE in Brussels (www.aib-vincotte.com). These temperature conditions do not reflect true composting process principles which require them, by definition, to go through a thermophilic phase (55–65°C) that can last from a few days to a couple of months depending on the composting volume. The thermophilic phase of composting is of importance to ensure the destruction of thermosensitive human and plant pathogens, fly larvae and weed seeds. Regulations by the US Environmental Protection Agency specify that to achieve a significant reduction of pathogens during composting, the compost should be maintained at minimum operating conditions of 40°C for 5 days, with temperatures exceeding 55°C for at least 4 h of this period.

Table 1.

Comparison of standards for industrial and home composting.

| industrial composting (EN 13432) | home composting (vincotte certification) | |

|---|---|---|

| biodegradation | test at 58°C in 180 days | test at 20–30°C in 365 days |

| biodegradation min. 90% | biodegradation min. 90% | |

| disintegration | test at 58°C in 90 days | test at 20–30°C in 180 days |

| sieve 2 mm mesh | sieve 2 mm mesh | |

| disintegration >90% | disintegration >90% | |

| max. 10% of dry weight allowed to be retained by 2 mm sieve | max. 10% of dry weight allowed to be retained by 2 mm sieve | |

| certification | Din Certco/OK Compost | OK Home |

|

|

Some bioplastic polymers, particularly used as bags and pots for horticulture or waste collection bag applications, have been certified by the OK Compost Home scheme while others passed only ‘OK Compost’ standard for industrial composting (http://www.aib-vincotte.com/data) and are not suitable for home composting. This distinction is important and it is vital that clear guidance is communicated to the public who may otherwise assume that any products labelled as ‘biodegradable’, ‘compostable’ or ‘eco-’ under the numerous certification systems can simply be put into their home or garden compost bins. These are unlikely to reach the thermophilic compost temperatures required for both suitable degradation of certain materials and to achieve sanitization.

New research to characterize the extent of biodegradation when a range of biodegradable or potentially biodegradable packaging materials are disposed of in simulated home composting typical of the UK is presented briefly below. The objective was to establish whether potentially biodegradable packaging materials would show appropriate levels of biodegradation when exposed to ‘typical’ home compost conditions (non-thermophilic) together with green garden waste. Small specimens of 12 bio-based materials (six were from materials used commercially and six were from developmental materials that were designed to be biodegradable—see table 2) were assessed as material weight loss over a 24-week winter/spring period between November and May in the southeast of the UK. Whole food packaging units (trays/plate) made from three of the materials were also assessed under the same conditions but were mixed directly into the compost matrix.

Table 2.

Packaging materials used for simulated home composting. (Fast degrader = mass loss approximately 80% after 90 days; medium degrader = mass loss approximately 40% after 90 days; slow degrader = mass loss <5% after 90 days.)

| name | commercial (C)/experimental (E) material | material | principal components (wt%) | small sample | whole unit | rate of degradation |

|---|---|---|---|---|---|---|

| potato starch | C | potato starch-based tray | potato starch (<75%) | ✓ | ✓ | fast |

| starch laminate | C | starch-based tray with a starch/PCL laminate | starch; starch PCL surface overlay | ✓ | fast | |

| paper | C | pressed wood pulp plate | wood pulp 70%; starch size 20%; other 10% | ✓ | ✓ | medium |

| silvergrass | C | pressed silvergrass pulp plate | Miscanthus spp. pulp | ✓ | fast | |

| coconut | C | moulded coconut fibre tray | Cocos nucifera fibre | ✓ | medium | |

| recycled paper | C | moulded recycled paper pulp tray | recycled paper | ✓ | medium | |

| PLA | E | PLA tray | 100% PLA | ✓ | ✓ | slow |

| starch/PCL | E | starch/PCL—extrudate sample | 100% starch/PCL | ✓ | slow | |

| PP(A) | E | PP with biodegradability additive A | 90% PP; 10% bio-additive A | ✓ | slow | |

| PP(B) | E | PP with biodegradability additive B | 90% PP; 10% bio-additive B | ✓ | slow | |

| PP(B)+ | E | PP with biodegradability additive B plus chalk filler | 60% PP; 10% bio-additive B; 30% chalk | ✓ | slow | |

| PP/starch | E | PP compounded with starch granules | 88% PP; 10% starch granules; 2% other | ✓ | slow |

The composting was undertaken outdoors in the home-composter, lidded ‘cone’ systems (volume 160 l) filled with a ‘base mixture’ of approximately 60 per cent green herbaceous and grass clippings and 40 per cent chopped ‘woody’ herbaceous material from the local site that was free of pesticides or herbicides and had previously been composted for 30 days to establish an active microflora/fauna. Twelve packaging materials (approx. 25 × 25 mm sheets) were individually secured into nylon mesh bags and replicate specimens placed into a stainless steel rack for easy retrieval. The sample racks were inserted in the middle of a composting bin between layers of base mixture (approx. 600 mm below the compost mixture surface). Three replicate composter units were established with three replicate specimens of each material removed per composter per sampling time. Additional six composter bins were set up, two of each with 6.4 wt% of one of the three main packaging materials (potato starch trays, PLA trays and paper plate) as whole units mixed in with the green waste base mixture. Two further composter bins containing only the compost base mix and no added biodegradable packaging materials were used as controls for a subsequent seed germination comparison.

The composters were sampled on a monthly basis from November to May for determination of specimen mass loss and MC (od basis), temperature and overall compost volume reduction. Replicate samples of the small test materials or whole units were removed at each sampling interval. ‘Turning’ of the composts was done only on these occasions.

A bioassay of the composts from the whole packaging unit test and the control compost was also conducted in accordance with the ‘Specification for composted materials’ (PAS 100; BSI 2002). F1 tomato seeds (variety Shirley, Sutton Seeds, UK) were placed in the prescribed mixture of a peat-based growth medium (PBGM) and test compost (1 : 2 ratio by volume of compost to PBGM base mix) in seed trays and maintained with regular watering at a temperature of 20–25°C in a natural light greenhouse in early summer 2005 over a 28-day period of the test. Seed germination, fresh plant mass, abnormalities and weed emergence were recorded in accordance with PAS 100.

The compost bin systems functioned as a low temperature composting environment between 15°C and 18°C in November at the start of the experiment. The temperature dropped to a low of approximately 8–10°C in January/February/March and then rose again to approximately 14°C in May. The composter bin temperatures were considerably lower than specified (20–30°C) in the OK Compost Home standard (table 1) but reflect the typical seasonal temperatures in the southeast of the UK. All composter bins showed an acceptable level of reduction in biomass volume (approx. 50%) during the composting period. The temperature profiles of the bins and the degradation of their contents were largely consistent across the whole study.

The visual assessment showed that complete disintegration and incorporation of the starch trays into the compost matrix had occurred after 90 days of composting. The paper-plate material was also extensively broken down over the composting period, although it was possible to distinguish elements of the original plate material after 180 days, despite their being heavily discoloured and lacking structural integrity. The PLA polymer showed no visual evidence of microbial breakdown after 180 days, although some fragments had broken off from the trays. This was not considered to be disintegration as a result of biodegradation but was attributed to disturbance of the bins and mechanical damage when retrieving samples.

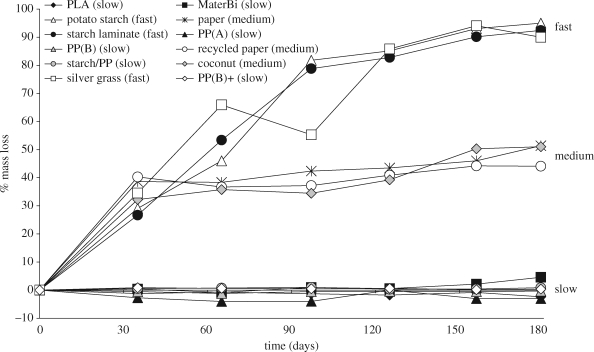

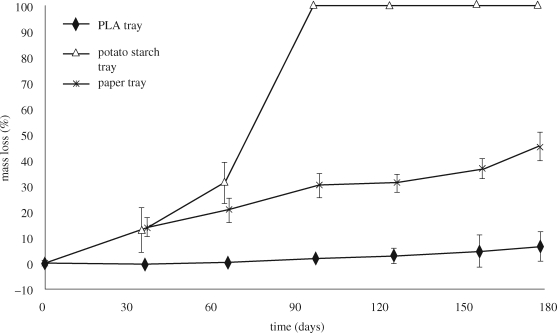

The mass loss (as an indicator of the biodegradation) data for the full range of material types as small specimens are presented in figure 4 and for the whole units in figure 5. From approximately 90 days exposure, three groups of materials could be clearly distinguished:

The fast degraders (starch-based polymers and the plant fibre-base silvergrass) exhibiting mass losses of approximately 80 per cent.

The medium degraders (wood fibre-based paper and the coconut fibre) with mass losses of approximately 40 per cent.

The slow degraders (PLA, PP with additives and starch/PCL) with negligible mass loss <5 per cent.

Figure 4.

Mass loss (wt%) over time—test materials as small samples (Note: PLA, potato starch and paper are also represented as whole packaging units in figure 5) (error bars not shown for clarity, 95% confidence interval ranged between 1% and 20% mass loss). ‘Fast’, ‘medium’ and ‘slow’ refer to rates of degradation indicated in table 2.

Figure 5.

Mass loss (wt%) over time—whole packaging units (Note: PLA tray, potato starch tray and paper plate are also represented as small samples in figure 4) (error bars are 95% confidence intervals).

This differentiation of the three groups was then maintained to the conclusion of the experiment at 180 days (table 2). The fast degraders lost approximately 90 wt% and became visually indistinguishable from their sealed packets; the medium degraders lost approximately 50 wt% and remained recognizable on close inspection. The slow degraders lost typically less than 5 wt% and were clearly recognizable.

The results for MC assessment showed that fast and medium degraders absorbed moisture readily during the composting process, typically ranging from 100 to 300 per cent for the starch and fibre materials over the 30- to 180-day period. The slow degrader group exhibited very low levels of moisture absorption with the starch/PCL, PP/starch and PLA typically below 10 per cent and the PP/modifiers below 1 per cent.

The results of the PAS 100 bioassay (data not shown) showed that composts derived from the composters containing whole packaging units (starch, paper and PLA) and from the controls gave equal or higher seed germination rates and equivalent or better fresh seedling weights compared with the growth medium base alone (an exception was one PLA compost bin that had a 21 per cent reduction in seedling fresh weight). All the amended composts failed the weed criterion of PAS 100, but this is expected because low-temperature composting systems do not achieve sterilization of weed seeds.

This study has shown that biodegradable packaging materials exhibited a wide range of biodegradation properties in this simulated home composting system run under non-thermophilic conditions (a regime where mesophilic micro-organisms dominate). It is clear that this mesophilic home composting condition may be less favourable for biodegradation than those specified in some standards. For instance, the home composting system used in this study operated over a temperature range of approximately 5–18°C rather than the 20–30°C range specified in the OK Compost Home standard. The fast degrader bioplastics, predominantly based on high levels of starch and the grass fibre/starch composite, were readily biodegraded in the home composting system. The medium degraders based on wood or coconut fibres exhibited mass losses of approximately 50 per cent over the composting period. The easily fragmentable nature of the residual material at the end of the 180-day period enabled the medium degraders to be readily incorporated into the compost matrix and we conclude that medium degraders would be acceptable in terms of disintegration. The extent of biodegradation of these materials, however, failed to satisfy the >90 per cent requirement within 180 days of BS EN 13432. How this may change should the test be extended to 360 days (as in the OK Compost Home standard) and whether this can be mitigated (as for cellulose residues in farm compost) remain to be studied further. The slow degraders (e.g. combined starch/biodegradable polyester formulation and PLA), including bioplastic polymers certified as compostable under EN 13432 conditions, exhibited either no or very low levels of biodegradation and fragmentation over the composting period. Although greater degradation may be achieved over longer periods (e.g. expansion to 360 days), elevated temperature around 60°C has been shown to be a crucial parameter, enabling the induction of biodegradation of polymers such as PLA (e.g. Agarwal et al. 1998; Scott & Wiles 2001; Tokiwa & Jarerat 2004). Such temperatures are clearly lacking in home composting systems of the type modelled. The seed germination study indicated that composts made from green waste incorporating approximately 6 per cent by mass of home composted starch or paper trays give growth media that support good seed germination and seedling development. Although similar results were also achieved with compost incorporating non-biodegraded PLA materials, it must be noted that the compost with PLA trays would fail the disintegration requirements set in the OK Compost Home as the PLA trays remained almost intact. Inhibition of seedling development, in composts with degradable PE and control composts from open-windrow systems, has been found by Davis et al. (2005).

It is clear from this research that several biodegradable packaging materials can be processed in home composting systems and yield compost materials suitable for plant growth. This capability will enable such materials to be disposed of in well-run home composting systems and result in waste diversion from municipal waste streams. However, we have also demonstrated that a number of packaging materials that typically biodegrade well in industrial, thermophilic high-temperature composting systems failed to biodegrade adequately in home composting environments that operate as low temperature, mesophilic environments.

At a practical level, these results suggest that it is vital to clearly distinguish biodegradable packaging materials that can be expected to biodegrade under ambient, mesophilic conditions typically found in UK home composting systems from those that biodegrade under the complete thermophilic–mesophilic (55–65°C) regime of an industrial composting systems. Labelling schemes and consumer education and information should support such a distinction.

5. Concluding remarks

Biodegradable polymers will play a greater role in the packaging sector in the future. Post-use biodegradable plastics and other biowastes like paper, food and garden waste are generally unsuitable for landfill due to their potential to release methane under anaerobic conditions and their disposal by this method is inconsistent with policies like the EU Landfill Directive. Biodegradable bioplastics are most suitable for biological waste treatment through industrial and/or domestic composting and, subject to further demonstration, potentially in anaerobic digestion systems. They should ideally be separated at the household level from other, non-biodegradable materials and collected with organic waste, including food waste. By using these biological treatment methods, the total quantities of waste sent to landfill are reduced and the composts generated can be used as valuable soil improvers.

Implementing effective biological treatments for the developing range of biodegradable bioplastics requires the support of clear certification and labelling schemes. Biodegradable plastics that pass the relevant compostability standards will biodegrade well in industrial composting systems. However, as discussed, only some of those plastics will also biodegrade adequately under ambient, mesophilic regimes typical of UK home composters, and this distinction needs to be communicated effectively to the wider public (see Thompson et al. 2009b).

Bioplastic polymers have great potential to contribute to material recovery, reduction of landfill and use of renewable resources. Widespread public awareness of these materials and effective infrastructure for stringent control of certification, collection, separation and composting will be crucial to obtaining these benefits in full.

Acknowledgements

The authors would like to thank the Eng. D. programme of the EPSRC for support for the postgraduate studies of Gareth Davies. We are also grateful to Pactiv UK for their support as the collaborating body in the Eng. D. programme.

Footnotes

One contribution of 15 to a Theme Issue ‘Plastics, the environment and human health’.

References

- Agarwal M., Koelling K., Chalmes J.1998Characterization of the degradation of polylatic acid polymer in a solid substrate environment. Biotechnol. Prog. 14, 517–526 (doi:10.1021/bp980015p) [DOI] [PubMed] [Google Scholar]

- Andrady A. L., Neal M. A.2009Applications and societal benefits of plastics. Phil. Trans. R. Soc. B 364, 1977–1984 (doi:10.1098/rstb.2008.0304) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Anon. 2002Waste not want not: a strategy for tackling the waste problem in England. UK Cabinet Office, Strategy Unit. See. http://www.cabinetoffice.gov.uk/~/media/assets/www.cabinetoffice.gov.uk/strategy/wastenot%20pdf.ashx.

- APME 2002Using waste plastic as a substitute for coal. Warmer Bulletin. no. 83, March 2002, pp. 20–21 [Google Scholar]

- ASTM 2002Standard specification for compostable plastics (Designation: D 6400-99), ASTM International, 100 Barr Harbour Drive, PO Box C700, West Conshohocken, PA 19428-12959, USA. [Google Scholar]

- Barnes D. K. A., Galgani F., Thompson R. C., Barlaz M.2009Accumulation and fragmentation of plastic debris in global environments. Phil. Trans. R. Soc. B 364, 1985–1998 (doi:10.1098/rstb.2008.0205) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bioplastics 07/08 Processing parameters and technical characteristics—a global overview, Bioplastics24.com., ISSN 1863-7299

- BPF 1993SELCHP trials: summary report—energy recovery from plastic waste. British Plastics Federation and the Industrial Films Association. London and Nottingham, UK [Google Scholar]

- BS EN 13432 2000Packaging. Requirements for packaging recoverable through composting and biodegradation. Test scheme and evaluation criteria for the final acceptance of packaging. London, UK: British Standards Institution [Google Scholar]

- BSI 2002Publicly available specification 100 (PAS 100)—specification for composted materials (BSI PAS 100). ICS codes: 65.020.20: 65.080 [Google Scholar]

- Claesen C.2005Hycail—more than the other PLA producer, presentation at RSC Symposium sustainable plastics: biodegradability vs recycling. [Google Scholar]

- Davis G., Song J. H.2006Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind. Crop. Prod. 23, 147–161 (doi:10.1016/j.indcrop.2005.05.004) [Google Scholar]

- Davis G., Bulson H., Harrison D., Billett E.2005An evaluation of polyethylene (PE) sacks in open windrow composting. Compost Sci. Utiliz. 13, 50–59 [Google Scholar]

- DEFRA 2004A strategy for non-food crops and uses London: Department for Environment, Food and Rural Affairs, PB10188 [Google Scholar]

- DEFRA 2007Waste strategy for England 2007 PB12596 London, UK: Department for Environment, Food and Rural Affairs; See http://www.defra.gov.uk/environment/waste/strategy/strategy07/pdf/waste07-strategy.pdf. [Google Scholar]

- EEA (European Environment Agency) 2007The road from landfilling to recycling: common destination, different routes. 978-92-9167-930-0. Copenhagen, Denmark. [Google Scholar]

- EN 13432. 2000. See BS EN 13432. [Google Scholar]

- Gregory M. R.2009Environmental implications of plastic debris in marine settings—entanglement, ingestion, smothering, hangers-on, hitch-hiking and alien invasions. Phil. Trans. R. Soc. B 364, 2013–2025 (doi:10.1098/rstb.2008.0265) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hartmann L., Rolim A.2002Post-consumer plastic recycling as a sustainable development tool: a case study. In GPEC 2002: plastics impact on the environment, Conf. Proc., Detroit, USA, 13–14 February 2002, pp. 431–438 [Google Scholar]

- Hopewell J., Dvorak R., Kosior E.2009Plastics recycling: challenges and opportunities. Phil. Trans. R. Soc. B 364, 2115–2126 (doi:10.1098/rstb.2008.0311) [DOI] [PMC free article] [PubMed] [Google Scholar]

- House of Commons 1993Session 1993–94. Environment Committee, 2nd Report, Recycling,1, 470 [Google Scholar]

- House of Lords 1994The government response to the 2nd report from the House of Commons Select Committee on the Environment White Paper Recycling, November 1994, p. 5 [Google Scholar]

- Hudgins M.1999Aerobic landfill studies from the USA. Paper presented at the 1st Int. Conf. Solid Waste, April 1999, Rome [Google Scholar]

- Klauss M.2001Introducing compostable packaging in Kassel, Germany. Orbit Magazine, 1 July 2001 [Google Scholar]

- Klauss M., Bidlingmaier W.2004Biodegradable polymer packaging: practical experiences of the model project Kassel. Proceedings of the 1st UK Conference and Exhibition on Biodegradable and Residual Waste Management, 18–19 February 2004, Harrogate, UK (eds Papadimitrou E., Stentiford E.), pp. 382–388 Leeds, UK: CalRecovery Europe Ltd [Google Scholar]

- Klingbeil M.2000Working document of biodegradable waste management Brussels: European Commission [Google Scholar]

- Landfill Directive 1999/31/EC European Commission. Official Journal of the European Communities l182/1–19, 16 July 1999 [Google Scholar]

- Mato Y., Isobe T., Takada H., Kahnehiro H., Ohtake C., Kaminuma T.2001Plastic resin pellets as a transport medium for toxic chemicals in the marine environment. Environ. Sci. Technol. 35, 318–324 (doi:10.1021/es0010498) [DOI] [PubMed] [Google Scholar]

- Miller R.2005The landscape for biopolymers in packaging. Miller-Klein Associates report Summary and Full Report available from The National Non-Food Crops Centre, Heslington, York, UK: www.nnfcc.co.uk [Google Scholar]

- Mohee R., Unmar G. D., Mudhoo A., Khadoo P.2008Biodegradability of biodegradable/degradable plastic materials under aerobic and anaerobic conditions. Waste Manag. 28, 1624–1629 [DOI] [PubMed] [Google Scholar]

- Murphy R., Bartle I.2004Summary report, biodegradable polymers and sustainability: insight from life cycle assessment. National Non Food Crops Centre, UK [Google Scholar]

- Musdalslien M., Sandberg P.2002Energy and HCL recovery from PVC in municipal solid waste incineration. In PVC 2002: towards a sustainable future Conf. Proc., Brighton, 23–25 April 2002 London: IOM Communications [Google Scholar]

- Narayan R.1993Science and engineering of composting: design, environmental, microbiological and utilization aspects (eds Hoitink H. A. J., Keener H. M.), p. 339 Columbus, Ohio, USA: Renaissance Publications [Google Scholar]

- Narayan R.1994Biodegradable plastics and polymers (eds Doi Y., Fukuda K.), p. 261 New York: Elsevier [Google Scholar]

- Narayan R.2006aBiobased and biodegradable polymer materials: rationale, drivers, and technology exemplars. American Chemical Society Symposium Ser., 939, Ch. 18, p. 282 [Google Scholar]

- Narayan R.2006bRationale, drivers, standards, and technology for biobased materials. In Renewable resources and renewable energy (eds Graziani M., Fornasiero P.). Boca Raton, FL: CRC Press, Taylor & Francis Group [Google Scholar]

- Oehlmann J., et al. 2009A critical analysis of the biological impacts of plasticizers on wildlife. Phil. Trans. R. Soc. B 364, 2047–2062 (doi:10.1098/rstb.2008.0242) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Patel M., Bastioli C., Marini L., Würdinger E.2003Life-cycle assessment of bio-based polymers and natural fibre composites. In Biopolymers, vol. 10 (ed. Steinbüchel A.). Weinheim, Germany: Wiley-VCH [Google Scholar]

- Petersen K., Nielsen P., Bertelsen G., Lawther M., Olsen M., Nilsson N., Mortensen G.1999Potential of bio-based materials for food packaging. Trend Food Sci. Tech. 10, 52–68 [Google Scholar]

- Producer Responsibility (Packaging Waste) Regulations as amended in 1997 (SI 1997 no. 648). HMSO, UK [Google Scholar]

- Ramsay B. A., Langlade V., Carreau P. J., Ramsay J. A.1993Biodegradability and mechanical properties of poly-(β-hydroxybutyrate-co-β-hydroxyvalerate)-starch blends. Appl. Environ. Microbiol. 59, 1242–1246 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ryan P. G., Moore C. J., van Franeker J. A., Moloney C. L.2009Monitoring the abundance of plastic debris in the marine environment. Phil. Trans. R. Soc. B 364, 1999–2012 (doi:10.1098/rstb.2008.0207) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Scott G.1995Photo-biodegradable plastics. In Degradable polymers: principles and applications (eds Scott G., Gilead D.), pp. 169–184 London: Chapman and Hall [Google Scholar]

- Scott G., Wiles D.2001Programmed-life plastics from polyolefins: a new look at sustainability. Biomacromolecules 2, 615–622 (doi:10.1021/bm010099h) [DOI] [PubMed] [Google Scholar]

- Shaxson L.2009Structuring policy problems for plastics, the environment and human health: reflections from the UK. Phil. Trans. R. Soc. B 364, 2141–2151 (doi:10.1098/rstb.2008.0283) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Smith R.2005Biodegradable polymers for industrial applications Cambridge: Woodhead Publishing [Google Scholar]

- Teuten E. L., et al. 2009Transport and release of chemicals from plastics to the environment and to wildlife. Phil. Trans. R. Soc. B 364, 2027–2045 (doi:10.1098/rstb.2008.0284) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Thompson R. C., Olsen Y., Mitchell R. P., Davis A., Rowland S. J., John A. W. G., McGonigle D., Russell A. E.2004Lost at sea: where is all the plastic? Science 304, 838 (doi:10.1126/science.1094559) [DOI] [PubMed] [Google Scholar]

- Thompson R. C., Swan S. H., Moore C. J., vom Saal F. S.2009aOur plastic age. Phil. Trans. R. Soc. B 364, 1973–1976 (doi:10.1098/rstb.2009.0054) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Thompson R. C., Moore C. J., vom Saal F. S., Swan S. H.2009bPlastics, the environment and human health: current consensus and future trends. Phil. Trans. R. Soc. B 364, 2153–2166 (doi:10.1098/rstb.2009.0053) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tokiwa Y., Jarerat A.2004Biodegradation of poly(l-lactide). Biotechnol. Lett. 26, 771–777 (doi:10.1023/B:BILE.0000025927.31028.e3) [DOI] [PubMed] [Google Scholar]

- Tukker A.2002Plastics waste—feedstock recycling, chemical recycling and incineration. Rapra Rev. Rep. 13, Report 148. [Google Scholar]

- UK Packaging Regulations 1998The Packaging (Essential Requirements) Regulations 1998, Statutory Instrument 1998 No. 1165. ISBN 0 11 079016 2, London, UK: HMSO, The Stationery Office Ltd [Google Scholar]

- WRAP 2006UK plastics waste—a review of supplies for recycling, global market demand, future trends and associated risks. ISBN: 1-84405-254-0. See http://www.wrap.org.uk/downloads/International_Markets_Plastics.bfd1a3be.3952.pdf. [Google Scholar]

- WRAP 2008Domestic mixed plastics packaging waste management options project report. WRAP, Banbury, Oxon: ISBN: 1-84405-396-2. See http://www.wrap.org.uk/downloads/Mixed_Plastic_Final_Report_v15_090608__3_.aaf0dcf9.5479.pdf. [Google Scholar]