Abstract

Introduction

Patients who suffer from chewing and swallowing disorders, i.e. dysphagia, may have difficulties ingesting normal food and liquids. In these patients a texture modified diet may enable that the patient maintain adequate nutrition. However, there is no generally accepted definition of ‘texture’ that includes measurements describing different food textures.

Objective

Objectively define and quantify categories of texture-modified food by conducting rheological measurements and sensory analyses. A further objective was to facilitate the communication and recommendations of appropriate food textures for patients with dysphagia.

Design

About 15 food samples varying in texture qualities were characterized by descriptive sensory and rheological measurements.

Results

Soups were perceived as homogenous; thickened soups were perceived as being easier to swallow, more melting and creamy compared with soups without thickener. Viscosity differed between the two types of soups. Texture descriptors for pâtés were characterized by high chewing resistance, firmness, and having larger particles compared with timbales and jellied products. Jellied products were perceived as wobbly, creamy, and easier to swallow. Concerning the rheological measurements, all solid products were more elastic than viscous (G′>G″), belonging to different G′ intervals: jellied products (low G′) and timbales together with pâtés (higher G′).

Conclusion

By combining sensory and rheological measurements, a system of objective, quantitative, and well-defined food textures was developed that characterizes the different texture categories.

Keywords: dysphagia, modified food texture, rheology, sensory analysis

Chewing and swallowing disorders, i.e. dysphagia, is common among elderly people. The variation in dysphagic symptoms is large and span from dryness in the mouth to not being able to swallow. Persons who suffer from these dysfunctions may have difficulties in ingesting foods and liquids. In these persons, food with a modified texture may facilitate safe oral intake (1, 2). Germain et al., 2006, reported that institutionalized elderly people suffering from dysphagia may increase their oral intake and thereby increase their body weight if they are served food with modified texture (3). Stefanovic-Andersson and Bülow (4) also showed that the elderly people in a nursing home increased their oral intake if they were given food with a modified texture. Other studies have pointed out the importance of modified textures as a part of therapeutic strategies for dysphagic patients (5, 6). However, for a successful therapeutic outcome, it is necessary that everyone involved in the management of the patient use the same terminology while recommending a texture-modified diet. Penman and Thomson (7) found in a review that there was a broad variation in how modified textures were defined. These descriptions of diet varied from two to five categories of modified solid food and from one to six categories of liquids. The most widely used diets are series of graded consistencies, such as liquidized/thin puree, thick puree/soft and smooth, soft/finely minced and minced/normal. However, none of the diet definitions are based on objective measurements.

The effectiveness of dysphagia therapies is dependent on the recommended viscosity (thickness). Rheology is the scientific exploration of the deformation and flow of materials and can describe the properties of materials ranging from liquids (viscous) to solids (elastic). However, almost all materials, and this is especially true for foods, show rheological behavior that places them between liquids and solids, as they possess both viscous and elastic properties, i.e. viscoelastic materials (8). Such rheological properties may affect pharyngeal swallowing as they influence bolus transport (9). Making objective measurements of thickened liquid flow is a complex task. Different studies have highlighted the necessity of precise definitions and objective measurements both regarding the preparation of a texture-modified diet, the serving temperature, and the stability of viscosity over time (10–16). Steele et al. (17) compared clinicians' subjective impressions with objective rheological measurements of different food products. Their study provided evidence that rheological standards are needed within the domain of texture-modified foods and liquids for dysphagia management. While rheological measurements analyze the physical properties of food samples, sensory analysis is used to evaluate texture attributes perceived by the human senses. A trained analytical sensory panel is able to develop objective descriptions of perceived sensory attributes, thereby making it possible to discover quantitative differences between foods (18).

A guide for texture-modified food was developed in an earlier Swedish research project (19) in collaboration between dieticians, speech and language pathologists, and a food company specialized in texture-modified diets (Tables 1 and 2). The purpose of the guide was to develop definitions of different food textures. The guide was based on different Swedish documents (20) and was influenced by guidelines developed by the British Dietetic Association in association with the Royal College of Speech and Language Therapists (21). In these documents and guidelines, the terms and definitions were not based upon objective measurements. The present study is an attempt to bridge the gap between the subjective terms used to describe the modified food textures commonly used today and the growing demand for objective classifications of modified food textures. We hypothesize that this can be done through a combination of rheological measurements and sensory analyses. National guidelines for a standard dysphagia diet, similar to the American National Dysphagia Diet (22), the Australian Guidelines (23), and the British National Descriptions for texture modification in adults (24), would be of great benefit to clinicians in their management of people with impaired chewing and/or swallowing.

Table 1.

Descriptions of the consistencies in the texture guide

| Category | Description | Example |

|---|---|---|

| Regular or cut | Normal texture possibly cut into smaller pieces | Whole or cut meat, whole fish, meat or sausage dishes, vegetables, potatoes, and gravy. Fresh fruit or canned fruit with whipped cream or ice cream |

| Coarse pâtés | Grainy, porous, soft texture with coarse grains, like a juicy and soft meatloaf. Easy to cut with a fork | Coarsely meat pâté or whole steamed fish, coarse vegetable pâté or well-cooked vegetables, whole or pressed potatoes, and gravy. Canned fruit in pieces with whipped cream or ice cream |

| Timbales | Smooth, soft, short, and uniform consistency like an omelet. Can be eaten with a fork or spoon | Meat or fish timbale/soufflé, vegetable timbale/puree, mashed potatoes or pressed potatoes, and gravy. Fruit mousse with whipped cream or ice cream |

| Jellied products | Soft and slippery food, like mousse. Can be eaten with a fork or spoon | Cold jellied meat or fish, vegetable puree or cold jellied vegetables, mashed potatoes, and thick gravy. Jellied fruits with whipped cream or ice cream |

| Liquids | Smooth and liquid consistency, such as tomato soup. Fluid runs off the spoon. Cannot be eaten with a fork | Enriched meat, fish or vegetable soup with whipped cream or creme fraiche. Fruit soup with whipped cream or ice cream |

| Thickened liquids | Smooth and viscous, such as sour cream. Fluid drops off the spoon. Cannot be eaten with a fork | Enriched viscous meat, fish or vegetable soup with whipped cream or creme fraiche. Viscous fruit soup with whipped cream or ice cream |

Table 2.

Products

| Category | Product | Description/Ingredients |

|---|---|---|

| Pâté | Fruit cocktail | Chopped canned fruit |

| Pâté | Bean pâtéa | Pâté of minced green beans |

| Pâté | Beef pâtéa | Pâté of minced beef meat |

| Timbale | Broccoli timbaleb | Soufflés of puréed broccoli |

| Timbale | Beef timbaleb | Soufflés of puréed beef |

| Jellied products | Fruit mousse | Fruit dessert set with gelatin |

| Jellied products | Jellied vegetables | Puréed broccoli set with gelatin |

| Jellied products | Jellied meat | Puréed beef set with gelatin |

| Mango sherbet | Sherbet of mango | |

| Low viscosity fluids | Soup of exotic fruit | Soup of puréed fruit/Puréed fruit soup |

| Low-viscosity fluids | Vegetable soup | Soup of puréed broccoli |

| Low-viscosity fluids | Meat soup | Soup of puréed beef |

| High-viscosity fluids | Thickened soup of exotic fruit | Soup of puréed fruit, addition of thickening agent |

| High-viscosity fluids | Thickened vegetable soup | Soup of puréed broccoli, addition of thickening agent |

| High-viscosity fluids | Thickened meat soup | Soup of puréed beef, addition of thickening agent |

awsp, with small particles.

bwap, without particles.

The purpose of this study was to objectively define and quantify categories of texture-modified food by conducting rheological measurements and sensory analyses. A further objective was to facilitate the communication and recommendations of appropriate food textures for patients with dysphagia.

Materials and method

A total of 15 products, two or three products from five of the six categories in Table 1, were analyzed (Table 2). The chosen products represented extremes, according to manufacturing processes and ingredients, in each texture category. Four varieties of prefabricated food, manufactured by Findus AB, and ingredients for nine other test food samples were delivered deep frozen and stored at −20°C until the day of analysis. A fruit cocktail consisted of chopped canned fruit (Del Monte). Mango sherbet (SIA Glass AB, Slöinge, Sweden) was also analyzed since sherbet is often used as a test food sample in video radiography.

The soups, both thickened and unthickened, were prepared from concentrate (Findus AB); a starch-based thickener (Thick & Easy™, Hormel Health Labs, GA, USA) was added for the high-viscosity soups. The meat and vegetable soups were heated to 80°C in a pan while stirred and then cooled to serving temperature. Jellied products were prepared from concentrates by adding 1.5% gelatin (AB Törsleff & Co., Stockholm, Sweden), heating to 80°C and then cooling to 8°C. Fruit products were analyzed at 8°C, while meat and vegetable products were heated in a (microwave) oven at 60°C. The temperatures selected were based on regulations stating that prepared food must have a temperature of 60°C and cold foods 8°C for transport from caterers to units (25).

Sensory evaluation

Sensory training and evaluation were carried out over a period of 2 weeks by a trained external panel (SIK, Sweden). The panel comprised eight women employed by SIK as professional sensory judges who were selected and trained according to ISO 8586-1993 guidelines (or standards) (26). The sensory analysis was made using Quantitative Descriptive Analysis (QDA). In this test a trained sensory panel developed objective descriptions of perceived sensory attributes of products (18). In four 2-h training sessions, the judges generated a set of texture attributes (Table 3) and developed consensus regarding the evaluation of each attribute. The judges evaluated the perceived intensities of the selected attributes on a continuous 100-mm line scale, labeled ‘low intensity’ at 10 mm and ‘high intensity’ at 90 mm (Visual Analog Scale). In three sessions (45 min each), the judges were rated triplicates of each product. The intensity ratings were recorded and converted into numbers by a computerized system (FIZZ Biosystémes, version 2.31E, France). The samples were coded with three-digit numbers and presented in random order according to a Latin square design. The judges rinsed their mouths with tap water and neutral wafers between the samples.

Table 3.

Sensory attributes

| Attribute | Definition |

|---|---|

| Chewing resistance | Feeling in oral cavity during chewing |

| 0 = water; low intensity, fluid gel; high intensity, solid pâtés | |

| Grainy | Particles in oral cavity |

| (meat products and jellied foods) | 0, water; low intensity, small particles; high intensity, large particles |

| Particles | Particles in oral cavity |

| 0, water; low intensity, small pieces; high intensity, large pieces | |

| Porous | Fluffy, containing air |

| 0, water; low intensity, fluid; high intensity, mousse | |

| Wobbling | 0, water; low intensity, fluid; high intensity, gel |

| Melting | The food becomes thin in the mouth, like gel and sorbet. |

| 0, water; low intensity, fluid; high intensity, sorbet | |

| Rough | The opposite to smooth |

| Low intensity, smooth; high intensity, sandpaper | |

| Creamy | Creamy feeling in the oral cavity |

| Firmness | The opposite to liquid |

| 0, water; low intensity, runny; high intensity, firm | |

| Ease of swallow | Degree to which the sample can be swallowed easily |

| Homogeneous | Smooth, like a mixed soup |

| Low intensity, particles in the product; high intensity, gel | |

| Particles | Amount of particles left in oral cavity after swallowing |

| Low intensity, water; high intensity, meat product (pâté/timbale) |

Rheological analyses

Rheology is the study of the deformation and flow of materials and can describe the properties of materials ranging from liquids to elastic solids. Many materials also show a dependence, for example, on temperature, deformation rate and time in a range that is relevant for their uses. Common methods are viscometry, giving viscosity and how it depends on parameters, such as temperature and deformation rate, and oscillatory tests, in which the material's dependence on time, temperature, and frequency can be studied. Table 4 shows the methods used in our study for the solid and liquid products.

Table 4.

Rheology – methods, parameters and descriptions

| Method | Parameter | Description |

|---|---|---|

| Solid products | ||

| Penetration test | Maximum load | The maximum force reached when pushing a probe through the sample |

| Penetration test | Strain at maximum load | Percentage of the sample penetrated when the maximum force is reached |

| Penetration test | Young's modulus | A measure of the stiffness of the sample derived from the penetration test |

| Oscillatory test | G′ (storage modulus)/G″ (loss modulus) | G′ represents the elastic behavior of the sample. G″ represents the viscous behavior of the sample. A higher value means more resistance to deformation |

| Oscillatory test | ||

| Oscillatory test | Δ (phase angel) | Relation between G′ and G″. 0° is a completely elastic material and 90° a completely viscous material |

| Liquid products | ||

| Shear viscosity | K and n are derived from model adaptation to viscosity measurements at several different shear rates. This allows the behavior of a fluid over a range of shear rates to be described with two parameters | |

| Shear viscosity | K (Consistence index) | K is a measure of the fluid thickness. K is equal to the viscosity at the shear rate 1s–1 |

| Shear viscosity | n (Shear thinning exponent) | Describes a fluid's behavior depending on shear rates. 1, Newtonian; <1, shear thinning (i.e. the samples had a lower viscosity at higher rate); >1, shear thickening (i.e. samples have a higher viscosity at higher rate) |

| Extensional viscosity | Kext and next are derived from model adaptation to extensional viscosity measurements at several different extension rates. This allows the behavior of a fluid over a range of extension rates to be described with two parameters | |

| Extensional viscosity | Kext | Kext is a measure of the fluid thickness. Kext is equal to the extensional viscosity at the extension rate 1s–1 |

| Extensional viscosity | next (Tension thinning exponent) | Describes a fluid's behavior depending on extension rates. |

| 1, Newtonian; <1, tension thinning (i.e. the samples had a lower viscosity at higher rate); >1, tension thickening (i.e. samples have a higher viscosity at higher rate) | ||

Solid products

A penetration test was used to measure the texture of the solid foods. In a penetration test a cylindrical probe is pushed into a sample at a constant rate and the resulting resistance is monitored. We used an Instron 5542 rheometer with a 4.8-mm cylindrical probe at a rate of 1 mm/min (Instron Ltd, Canton, MA, USA). The maximum load applied during the test, the strain at the maximum load, and Young's modulus, a measure of the stiffness of a material, were extracted and used to describe the solid foods.

The solid food textures were further characterized using small amplitude oscillatory shear (SAOS) measurements. This technique determines the linear viscoelastic properties of a material. The SAOS measurements give a measure of the elastic modulus (stiffness) through the storage modulus, G′, and simultaneously measure viscosity through the loss modulus, G″, at deformations that do not destroy the cohesion of the solid. The degree of the viscous versus the elastic character of the material is expressed by the phase angle, Δ, and the relation between the parameters is tan Δ = G″/G′. A viscous fluid has Δ = 90° and a solid material Δ = 0°.

These SAOS tests were carried out in a Stresstech HR Rheometer (Reologica Instruments, Lund, Sweden) with stress-controlled oscillations in parallel plate geometry (30 mm diameter) using a 5 mm gap. Stress sweeps, 0.02–500 Pa at 1 Hz, were used to identify the linear viscoelastic region for each product in which G′ and G″ are independent of the degree of deformation. All further measurements were made within this linear viscoelastic region using fresh samples. Mechanical spectra measurements were recorded between 0.1 and 10 Hz at three temperatures: 37, 8, and 60°C. This allows the detection of thermally induced structural changes, such as gelling and melting. Temperature sweeps were performed at constant stress and constant frequency, 1 Hz. All measurements were made in triplicate.

Liquid products

Three flow curves at shear rates, , 1–500 s−1 were plotted for each sample using a Stresstech Rheometer (Reologica Instruments, Lund, Sweden) with a bob (25 mm diameter conformed to ISO 3219) and cup geometry. The flow curves were fitted to the power law model () giving the consistency index, K, and the shear thinning exponent, n. K is a measure of the fluids thickness and n describes the change in viscosity depending on shear rate. A liquid can be Newtonian, the viscosity is independent of the shear rate, n=1, shear thinning, the viscosity decreases with increasing shear rate, n<1, or shear thickening, the viscosity increases with increasing shear rate, n>1. In addition to measurements at 8 or 60°C, measurements were made at 37°C to mimic the temperature at which the foods are swallowed. Samples were filtered through a 0.5 mm sieve in order to remove larger particles.

When a viscoelastic liquid food is forced through a contraction, such as in the pharynx, the liquid must extend to maintain a constant volume. This extension produces a resistance in the same way as shear does in ordinary flow. The extensional viscosity, ηe, is at least three times as large as the shear viscosity and is thus an important parameter in swallowing. The extensional viscosity of the liquids was measured in a hyperbolic contraction flow device (27, 28) using an Instron 5542 (Instron Corporation, Canton, USA). The hyperbolic contraction flow device comprised a feeding piston, a cylindrical sample cell and a contraction nozzle at the end. The extensional properties of the samples were measured at five rates (0.05, 0.1, 0.5, 1, and 5 mm/s) with a feeding length for each rate to give a constant flow for 2 sec. The sample cell was loaded with a sufficient amount of sample to measure all five extension rates in one loading. The lowest extension rate was measured first and the transient stress was recorded. Before measuring at the next extension rate, the sample was allowed to relax for 2 min and the load was adjusted to zero. Exotic fruit soups were measured at 8 and 37°C. Meat and vegetables soups were measured only at 37°C due to instrumental limitations. Measurements were made in triplicate. The shear contribution to the measured stress was subtracted. The power law model was fitted to curves of the extensional viscosity results (), and parameters K ext extensional consistency index, and n ext tension thinning exponent, were extracted. K ext and n ext describe the dependence of extensional viscosity on extension rate and are equivalent to K and n used to describe a fluid's shear behavior.

Statistical analyses

Sample mean values were calculated for each sensory attribute and rheological measurement (Excel Microsoft Office, 2003). Two-way analysis of variance (ANOVA) with samples and assessors as fixed factors was performed on the sensory data (SYSTAT, version 10.0, SPSS Inc., Chicago, IL). One-way ANOVA was performed on rheological data. Tukey's multiple comparison tests were performed when significant differences were found in the ANOVAs. Differences are stated as significant when p ≤ 0.05.

Sensory and rheological data were further evaluated with multivariate statistics in order to get an overview of the samples and their properties as well as to find out whether sensory and rheological data could be related to each other. Principal component analysis (PCA) gives an overview and partial least square (PLS) describes relations between sensory and rheological data (SIMCA-P+, version 11.0.0.0, Umetrics, Sweden). The analyses were performed on averaged data.

The judges' performance was evaluated using PanelCheck (Version 1.3.2, Nofima, Norway). The individual judges were tested for their ability to differentiate between samples and to repeat their assessments with the same results. Low p and MSE values from ANOVA calculations demonstrate the reliability of the sensory analysis (29). p corresponds to probability and p ≤ 0.05 indicates significant difference of 95%. MSE corresponds to Mean Square Error, the value is dependent on the size of the scale used in each study and therefore no fixed value of MSE can universally be set.

Results

Sensory analysis

The analysis of the panel performance showed that all the judges were highly reliable since their p and MSE values were very low (p-values <0.1 and most MSE values <200).

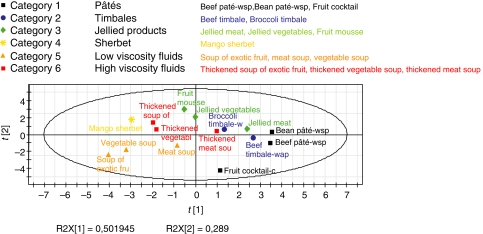

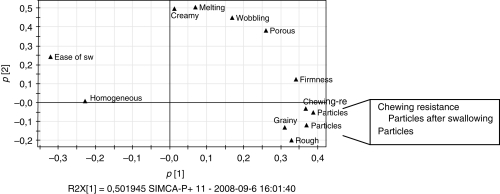

Mean sensory attributes are shown in Tables 5 and 6. The texture-modified products fell into the five predefined categories (pâtés, timbales, jellied products, low- and high-viscosity fluids) plus mango sherbet, visualized by different colors in the PCA score plot in (Fig. 1). The PCA explained approximately 80% of the variance in the sensory data. The statistical analysis showed that the pâtés differed from timbales and jellied products with regard to chewing resistance and perceived particle size. Timbales were perceived as more porous, wobbly, creamy, and melting than pâtés. Jellied products had a lower degree of perceived chewing resistance and firmness but a higher degree of melting and creaminess compared to timbales and pâtés. The score plot (Fig. 1) further indicates that the variance in the pâté category seemed to be higher compared to the other categories. It should thus be noted that one of the products in this category, fruit cocktail, was not made with the same texture agent (egg) nor did it have the same milling degree as the other two products in this category. The high-viscosity fluids, which contained a starch-based thickener, were perceived as more melting, easier to swallow and creamy than unthickened fluids. These low-viscosity fluids were perceived to have a lower degree of chewing resistance, firmness and porosity, and a wobbly consistence. The principal components 1 and 2 (PC1 and PC2), Fig. 2, of the PCA showed that the attributes chewing resistance and particles explained the largest variation in data (PC1), while creamy, melting, and homogenous explained the second largest variation (PC2). This indicates that these attributes are the most prominent in the texture-modified products.

Table 5.

Sensory intensity ratings of solid products given as mean values

| Fruit cocktail | Bean pâté | Beef pâté | Broccoli timbale | Beef timbale | Fruit mousse | Jellied vegetables | Jellied meat | |

|---|---|---|---|---|---|---|---|---|

| Chewing resistance | 83 | 81 | 77 | 61 | 62 | 19 | 18 | 36 |

| Grainy | 21 | 11 | 52 | 20 | 39 | 8 | 15 | 42 |

| Particles | 21 | 81 | 34 | 12 | 23 | 8 | 7 | 17 |

| Porous | 13 | 53 | 34 | 44 | 47 | 86 | 37 | 35 |

| Wobbling | 3 | 38 | 39 | 35 | 38 | 75 | 84 | 83 |

| Melting | 8 | 34 | 26 | 44 | 26 | 66 | 68 | 49 |

| Rough | 47 | 27 | 62 | 22 | 58 | 10 | 22 | 58 |

| Creamy | 7 | 49 | 33 | 46 | 35 | 79 | 69 | 53 |

| Firmness | 87 | 80 | 84 | 81 | 81 | 58 | 66 | 73 |

| Ease of swallow | 50 | 49 | 41 | 51 | 53 | 77 | 70 | 54 |

| Homogeneous | 81 | 22 | 64 | 81 | 82 | 86 | 87 | 78 |

| Particles after swallowing | 27 | 73 | 61 | 16 | 57 | 8 | 11 | 52 |

Table 6.

Sensory intensity ratings of liquid products given as mean values

| Soup of exotic fruits | Thickened soup of exotic fruits | Vegetable soup | Thickened vegetable soup | Meat soup | Thickened meat soup | |

|---|---|---|---|---|---|---|

| Chewing resistance | 4 | 14 | 7 | 15 | 8 | 19 |

| Grainy | 5 | 8 | 10 | 11 | 27 | 38 |

| Particles | 3 | 5 | 2 | 5 | 6 | 18 |

| Porous | 7 | 24 | 10 | 22 | 16 | 30 |

| Wobbling | 8 | 33 | 8 | 25 | 18 | 35 |

| Melting | 10 | 37 | 12 | 26 | 16 | 34 |

| Rough | 9 | 12 | 18 | 12 | 35 | 45 |

| Creamy | 16 | 80 | 27 | 67 | 37 | 72 |

| Firmness | 9 | 30 | 10 | 22 | 15 | 30 |

| Ease of swallow | 65 | 83 | 71 | 78 | 71 | 74 |

| Homogeneous | 90 | 91 | 84 | 90 | 77 | 64 |

| Particles after swallowing | 5 | 6 | 6 | 9 | 37 | 39 |

Fig. 1.

Principal component analysis (PCA) of sensory data. Score plot for all products.

Fig. 2.

Principal component analysis (PCA) of sensory data. Loading plot.

Rheology analysis – solid products

According to the mean values in the penetration test, the fruit cocktail had the highest resistance to during deformation, while jellied products had the lowest (Table 7). However, no significant differences in maximum load, strain at maximum load, or Young's modulus were found between the different product categories.

Table 7.

Max load, strain and storage modulus

| Product | Max load (N) | Strain at max load (%) | Storage modulus at 1 Hz G′ (Pa) | Loss modulus at 1 Hz G″ (Pa) |

|---|---|---|---|---|

| Fruit cocktail | 2.38 | 16.4 | 20,400 | 2,820 |

| Bean pâtéa | 0.55 | 34.4 | 10,700 | 1,370 |

| Beef pâtéa | 1.10 | 24.5 | 19,900 | 2,760 |

| Broccoli timbaleb | 0.53 | 25.2 | 15,200 | 1,890 |

| Beef timbaleb | 0.81 | 33.2 | 17,100 | 1,980 |

| Fruit mousse | 0.08 | 17.6 | 1,310 | 190 |

| Jellied vegetables | 0.08 | 22.0 | 820 | 97.9 |

| Jellied meat | 0.26 | 27.8 | 1,600 | 120 |

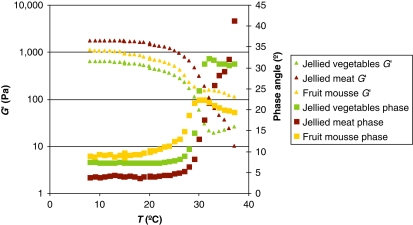

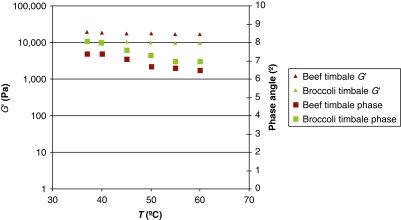

The frequency sweep test showed that all the solid products were more elastic than viscous (G′>G″) (Table 7). However, the three solid product categories belonged to two statistically different G′ intervals; interval 1 (jellied products) had G″~1,200 Pa and interval 2 (timbales and pâtés) had G~17,000 Pa. In terms of G″, the categories were grouped in a similar way. The repeatability of the measurements was within a 5% limit.

Figs. 3 and 4 show the temperature dependence of the jellied products and the timbales, respectively. All jellied products showed strong temperature dependence and melted at around 30°C, while the timbales showed little temperature dependence between 37 and 60°C.

Fig. 3.

Solid food textures measured as small amplitude oscillatory shear (SAOC). G′ is indicated by triangles and phase angle by squares.

Fig. 4.

Solid food textures measured as small amplitude oscillatory shear (SAOC). G′ is indicated by triangles and phase angle by squares.

Rheological analysis – liquid products

Flow curves for the soups and shear thinning exponent (n) (Table 8) showed that all samples were shear thinning, n<1, and there were no significant differences in n between the two product categories. The unthickened soups had significantly lower viscosities (K) than the thickened ones. All soups were tension thinning, n ext<1, and no significant differences in K ext or n ext (Table 8) were found between the thickened and unthickened soups. The repeatability of the measurements was within a 5% limit.

Table 8.

Power law and extensional parameters

| Product | T (°C) | n | K (Pasn) | next | Kext (Pasnext) |

|---|---|---|---|---|---|

| Soup of exotic fruits | 8 | 0.42 | 1.94 | 0.19 | 122 |

| Thickened soup of exotic fruits | 8 | 0.43 | 8.50 | 0.35 | 412 |

| Vegetable soup | 60 | 0.49 | 1.00 | 0.11 | 230 |

| Thickened vegetable soup | 60 | 0.34 | 7.61 | 0.18 | 803 |

| Meat soup | 60 | 0.37 | 3.33 | 0.31 | 518 |

| Thickened meat soup | 60 | 0.43 | 12.04 | 0.39 | 1,261 |

Correlation of sensory and rheology results

For liquid products, PLS analysis indicated that the sensory attribute of ease of swallow was positively related to K ext. For solid products, the sensory attributes of firmness and chewing resistance were positively related to G′, maximum load and Young's modulus.

Definition of textures – new guidelines

Table 9 summarizes the results of the objective sensory description and texture measurements. The intention is for facilities and product developers to find the definitions a good complement to the other descriptions and to implement the system and definitions developed.

Table 9.

Definitions of textures – summary of sensory and rheological analyses

| Objective sensory description | Texture measurement | |

|---|---|---|

| Pâtés | Higher degree of chewing resistance and larger particles compared to timbales and jellied products | Maximum load: 0.6–2.4 N |

| Strain at max load: 16–34% | ||

| G′: 11,000–20,000 Pa | ||

| Δ: 7.4–7.9° | ||

| Timbales | Moderate degree of chewing resistance, creaminess and wobbling. More porous, wobbly, creamy, and melting than pâtés | Max load: 0.5–0.8 N |

| Strain at maximum load: 25–33% | ||

| G′: 15,000–17,000 Pa | ||

| Δ: 6.6–7.2° | ||

| Jellied products | Wobbly, homogenous, and creamy. | Maximum load: 0.1–0.3 N |

| Lower degree of chewing resistance and firmness but higher degree of melting and creaminess compared to timbales and pâtés | Strain at max load: 18–28% | |

| G′: 800–1,600 Pa | ||

| Δ: 4.4–8.4° | ||

| Low viscosity fluids (Soups) | Lower degree of chewing resistance, firmness, porosity, and wobbling compared to high-viscosity fluids | Consistence index in shear: 1.0–3.3 (Pasn) |

| In tension: 120–520 (Pasnext) | ||

| Shear thinning exponent: 0.4–0.5 | ||

| Tension thinning exponent: 0.1–0.3 | ||

| High viscosity fluids (Thickened soups) | More melting, easier to swallow and creamy compared to low-viscosity fluids | Consistence index in shear: 7.6–12.0 (Pasn) |

| In tension: 410–1,260 (Pasnext) | ||

| Shear thinning exponent: 0.3–0.4 | ||

| Tension thinning exponent: 0.2–0.4 |

Discussion

Material and methods

Two different methods, sensory evaluation and rheology analysis, were used to describe the texture properties of a selection of texture-modified foods. Using quantitative descriptive analysis, we were able to discriminate between many of the selected sensory textural properties of texture-modified products. Although various attempts have been reported in the literature to quantify the sensory properties of a food material on the basis of physical and chemical measurements of the product (30, 31), structure and rheological behavior can be strongly affected by oral processing and conditions in the mouth (32, 33). Casanovas et al. (34) suggested a texture classification based on rheological measurements. In this study, however, correlations of sensory and rheological data showed that both sensory evaluation and rheology measurements are needed to characterize textures.

Definition of textures – solid food

According to our sensory analysis, the solid texture-modified products fell into three categories, consistent with both the USA and Australian food texture scales (22, 23). Also some diets used for dysphagia that was presented in Penman and Thomson's review consisted of three gradings of solid food (7). Because of the different cultural aspects of food habits, it may not be appropriate to adopt a texture level guide from another country. Food and textures for which people in the USA or Australia have preferences may be impossible for people in Sweden to accept (1, 35, 36).

In this study, pâtés were found to be different from timbales and jellied products with respect to chewing resistance and particle perception. The meat and vegetable raw materials in timbales and jellied products were based on purees, while the raw materials used in pâtés had a milling degree of 5 or 8 mm. Kaufmann (37) found that particle size influences the perception of melting in texture-modified carrot products and that the perception of melting may be related to homogeneity. This is relevant for the results of our study since timbales were perceived as being more homogenous and melting than pâtés. The jellied products contained gelatin, which had a melting temperature of 28°C. This may explain the high degree of perceived melting and creaminess in those products. The ingredient of meat resulted in a higher degree of perceived graininess, roughness, and larger particles as compared to the vegetable counterpart for timbales and jellied products.

The results of the rheological analysis indicated that the solid products could be separated with regard to elasticity, implying that the jellied products were significantly different from timbales and pâtés in their textural characteristics. The bean pâté had a structure that did not hold together, however, which might explain the lack of a significant difference in G′ between pâtés and timbales. An earlier Swedish research project found that a coarsely ground meat ingredient resulted in a more elastic product (19), with the expectation that a frequency sweep test (G′) could be used to classify products into different categories.

No significant differences were found between the three classes of solid textures in maximum load, strain at maximum load or Young's modulus. The bean pâté had a structure that did not keep together when deformed, however, thus causing an overall low-penetration force. Still, the PLS analysis showed that the sensory attribute of chewing resistance was correlated to maximum load. These results therefore indicated that the three types of solid products were different in their textural characteristics and that a combination of frequency sweep test and penetration test is needed for a proper differentiation.

Definition of textures – liquids

The liquids could be separated into the two predefined categories according to the sensory attributes, which are fewer than those used in the USA, Australia (four levels) and the UK (five levels) (21–23). However, Penman and Thomson (7) pointed out that there might be a risk for discrepancies if too many varying degrees of thickened fluids are offered. The thickened liquid contained a starch-based thickener and was perceived as easier to swallow and more creamy than the low-viscosity soup. According to sensory and rheological studies (38), creaminess can be related to viscosity. An effect of saliva for the perception of texture was demonstrated by de Wijk et al. (32). The mixing of starch thickened food with saliva in the mouth leads to a fast digestion of the starch, resulting in a loss in the viscosity of the product. Because of this, liquids thickened by starch are perceived as ‘melting’ in the mouth.

The results of the rheological analyses implied that the two categories of liquids were significantly different in their textural characteristics. Such knowledge is useful in the management of the dysphagic patient when modified food textures are a necessary part of the treatment. However, it is important to keep in mind that the patients suffering from dysphagia, for example, a delayed initiation of the pharyngeal swallow or pharyngeal retention, need an individual trial, which makes it possible to define the pathophysiology. To be able to decide whether a specific texture should be used it is necessary to perform not only a clinical trial but also an instrumental examination. A modified barium swallow gives important information of how different modified textures affect the physiology of swallowing, and makes it possible for the SLP to recommend the correct type of modified texture. The consistency index (K) can be used to distinguish between the classes of low- and high-viscosity foods. However, the high-viscosity soups showed a relatively high standard deviation, probably depending on the temperature dependence of the thickening agent. Variations in preparation and temperature might also have caused variations in viscosity.

Viscosity was measured at either 60 or 8°C in this study and with a shear rate of (1–500 s−1). It should be noted, however, that the literature describes variations in the viscosity range for thickened fluids (17). It has been reported that the viscosity level can be dependent on the specific thickener and liquid used and that viscosity can rise during the time after mixing (12, 14).

The vegetable soup and the exotic fruit soup showed a more pronounced dependence on the extension rate compared to their thickened counterpart. This could have an effect at the relatively high extension rates present in the mouth and during swallowing. The products would most likely be perceived as less viscous when swallowed, and this may affect the ability of the bolus to deform during swallowing. PLS analysis indicated that the sensory attribute of ease of swallow was positively related to Kext. This is in accordance with Ekberg et al. (39); in the mouth, the food was squeezed between the tongue and the palate, which also caused a primarily extensional flow. The extensional flow during transport might explain the strong correlation between perceived ease of swallow and extensional viscosity.

Limitations

Limitations in time and resources restricted the analysis to no more than 15 product samples. There was no possibility to perform the viscosity measurements over time to detect whether the thickener was time dependent. It should further be noted that the panel consisted of healthy persons with no chewing or swallowing disorders. However, the attribute ease of swallowing was of high interest in order to find indications of how easy each texture category was to swallow. However, in order to provide a diet recommendation to a dysphagic patient, an individual medical investigation is needed.

Conclusion

By a combination of sensory evaluation and rheological measurements we were able to objectively define and characterize the textures of 15 products. A combination of the methods was needed to characterize the different texture categories since there were significant product variations within the different categories regarding some sensory attributes and not all rheological measurements could differentiate between the products analyzed.

Future outlook

It is important that a classification system for the viscosity and texture of foods and liquids for dysphagia management be developed, based on sound empirical evidence. It is also very important to develop standard recipes for texture-modified foods and fluids. Further studies are needed to maintain a valid and quantitatively defined scale of different food and fluid textures. This scale must be tested on patients suffering from different kinds of dysphagic problems under clinical conditions. An utterly important matter for the management and treatment of dysphagia is the implementation of the same terminology. In order to give the dysphagic persons food with the appropriate texture, this texture has to be communicated from health care personnel to the producer of the food. In this chain of communication the objective definitions of textures, given in Table 9, can be of great importance.

Acknowledgements

This study was financially supported by VINNOVA (the Swedish Agency for Innovation Systems), Findus AB and Lyckeby Culinar.

Conflict of interest and funding

There are no conflicts of interest concerning this study.

References

- 1.Ekberg O, Hamdy S, Woisard V, Wuttge-Hannig A, Ortega P. Social and psychological burden of dysphagia: its impact on diagnosis and treatment. Dysphagia. 2002;17:139–46. doi: 10.1007/s00455-001-0113-5. [DOI] [PubMed] [Google Scholar]

- 2.Rothenberg E, Ekman S, Bülow M, Möller K, Svantesson J, Wendin K. Texture-modified meat and carrot products for elderly people with dysphagia – preference in relation to health and oral status. Scand J Nutr. 2007;51:141–7. [Google Scholar]

- 3.Germain I, Dufresne T, Gray-Donald K. A novel dysphagia diet improves the nutrient intake of institutionalized elders. J Am Diet Assoc. 2006;106:1614–23. doi: 10.1016/j.jada.2006.07.008. [DOI] [PubMed] [Google Scholar]

- 4.Stefanovic Andersson K, Bülow M. Malmö stad och Medicinska fakulteten, Lunds universitet. 2006. Kostkonsistens och matglädje. (In Swedish) [Google Scholar]

- 5.Elmståhl S, Bülow M, Ekberg O, Petersson M, Tegner H. Treatment of dysphagia improves nutritional conditions in stroke patients. Dysphagia. 1999;14:61–6. doi: 10.1007/PL00009588. [DOI] [PubMed] [Google Scholar]

- 6.Riso S, Baj G, D'Andrea F. Thickened beverages for dysphagic patients. Data and myth. Mediterr J Nutr Metab. 2008;1:15–7. [Google Scholar]

- 7.Penman JP, Thomson M. A review of the textured diets developed for the management of dysphagia. J Hum Nutr Diet. 2008;11:51–60. [Google Scholar]

- 8.Mezger TG. The rheology handbook. Hannover: Vincentz Network; 2006. [Google Scholar]

- 9.Meng Y, Rao MA, Datta AK. Computer simulation of the pharyngeal bolus transport of Newtonian and non-Newtonian fluids. Food and Bioproducts Process. 2005;83:297–305. [Google Scholar]

- 10.Adeleye B, Rachal C. Comparison of the rheological properties of ready-to-serve and powdered instant food-thickened beverages at different temperatures for dysphagic patients. J Am Diet Assoc. 2007;107:1176–82. doi: 10.1016/j.jada.2007.04.011. [DOI] [PubMed] [Google Scholar]

- 11.Budke J, Garcia JM, Chambers ET. Comparisons of thickened beverages using line spread measurements. J Am Diet Assoc. 2008;108:1532–5. doi: 10.1016/j.jada.2008.06.434. [DOI] [PubMed] [Google Scholar]

- 12.Dewar RJ, Joyce MJ. Time-dependent rheology of starch thickeners and the clinical implications for dysphagia therapy. Dysphagia. 2006;21:264–9. doi: 10.1007/s00455-006-9050-7. [DOI] [PubMed] [Google Scholar]

- 13.Garcia JM, Chambers ET, Matta Z, Clark M. Serving temperature viscosity measurements of nectar- and honey-thick liquids. Dysphagia. 2008;23:65–75. doi: 10.1007/s00455-007-9098-z. [DOI] [PubMed] [Google Scholar]

- 14.Garcia JM, Chambers ET, Matta Z, Clark M. Viscosity measurements of nectar- and honey-thick liquids: product, liquid, and time comparison. Dysphagia. 2005;20:325–35. doi: 10.1007/s00455-005-0034-9. [DOI] [PubMed] [Google Scholar]

- 15.Germain I, Dufresne T, Ramaswamy HS. Rheological characterization of thickened beverages used in the treatment of dysphagia. J Food Eng. 2006;71:64–74. [Google Scholar]

- 16.Mark N, Robbins J. The usefulness of the line spread test as a measure of liquid consistency. Dysphagia. 2007;23:306–11. doi: 10.1007/s00455-007-9086-3. [DOI] [PubMed] [Google Scholar]

- 17.Steele CM, Van Lieshout P, Goff D. The rheology of liquids: a comparison of clinicians' objective impressions and objective measurement. Dysphagia. 2003;18:182–95. doi: 10.1007/s00455-002-0104-1. [DOI] [PubMed] [Google Scholar]

- 18.Lawless H, Heymann H. Sensory evaluation of food – principles and practices. New York: Kluwer Academic/Plenum Publishers; 1998. [Google Scholar]

- 19.Vinnova Sensory design and optimisation of consistency to promote health and comfort in elderly people. 2007. dnr 2003-02659, project no. P20510-2.

- 20.Socialstyrelsen. Näringsproblem i vård och omsorg-Prevention och behandling. SoS. 2000;11:203. (In Swedish) [Google Scholar]

- 21.Working group BDA. Jones S, Copeman J, Yland K, Frensch A, Negus L, Eaton J, SLT. Clark S, Kelly A, Mould H, Samuels R. National descriptors for texture modification in Adults. http://www.bda.uk.com/Downloads/dysphagia.pdf [cited 14 February 2003]

- 22.National Dysphagia Diet Task Force. Chicago, IL: American Dietetic Association; 2002. National dysphagia diet: standardization for optimal care. [Google Scholar]

- 23.Atherton M, Bellis-Smith N, Cichero JAY, Suter M. Texture-modified foods and thickened fluids as used for individuals with dysphagia: Australian standardised labels and definitions. Nutr Diet. 2007;64:53–76. [Google Scholar]

- 24.British Dietetic Association. The British Dietetic Association and the Royal College of Speech and Language Therapists. 2002. May, National descriptors for texture modification in adults. [Google Scholar]

- 25.Livsmedelsverket: SLV rapport 19-2006. Riksprojekt 2005. Centralt producerad mat till särskilt och enskilt boende – mikrobiologi och tillämpning; 2006. Lindblad M, Westöö A. (In Swedish) [Google Scholar]

- 26.ISO 1993 ISO 8586-1. General guidance for selection, training and monitoring of assessors International Organisation for Standardisation. Geneva, Switzerland: [Google Scholar]

- 27.Stading M, Bohlin L. Contraction flow measurements of extensional properties. Trans Nordic Rheol Soc. 2000;8/9:181–5. [Google Scholar]

- 28.Wikström K, Bohlin L. Extensional flow studies of wheat flour dough 1. Extensional method for measurement in contraction flow geometry and application to flours varying in breadmaking performance. J Cereal Sci. 1999;29:217–26. [Google Scholar]

- 29.Tomic O, Nilsen A, Martens M, Naes T. Visualization of sensory profiling data for performance monitoring. Food Sci Tech. 2007;40:262–9. [Google Scholar]

- 30.Szczesniak AS. Objective measurements of food texture. J Food Sci. 1963;28:410–20. [Google Scholar]

- 31.van Vliet T. On the relation between texture perception and fundamental mechanical parameters for liquids and time dependent solids. Food Qual Prefer. 2002;13:227–36. [Google Scholar]

- 32.de Wijk RA, Prinz JF, Engelen L. The role of intra-oral manipulation in the perception of sensory attributes. Appetite. 2003;40:1–7. doi: 10.1016/s0195-6663(02)00172-1. [DOI] [PubMed] [Google Scholar]

- 33.Hutchings JB, Lillford PJ. The perception of food texture – the philosophy of the breakdown path. J Texture Stud. 1988;19:103–15. [Google Scholar]

- 34.Casanovas A, Dolz M, Hernàndez MJ, Mart-Bonmati E. Classification of dysphagia-oriented products based on the clustering of rheological tests data (Poster); Rheology symposium; 2008. Madrid, 11–12 September. [Google Scholar]

- 35.Köster EP. Diversity in the derminants of food choice: a psychological perspective. Food Qual Prefer. 2009;20:70–82. [Google Scholar]

- 36.Cayot N. Sensory quality of traditional foods (a review) Food Chem. 2007;101:154–62. [Google Scholar]

- 37.Kaufmann S. A study of sensory and instrumental characteristics of texture modified carrot products; Diploma work. SIK-Report Nr 751, Göteborg; 2006. [Google Scholar]

- 38.Wendin K, Solheim R, Allmere T, Johansson L. Flavour and texture in sourmilk affected by thickeners and fat content. Food Qual Prefer. 1997;8:281–91. [Google Scholar]

- 39.Ekberg O, Bülow M, Ekman S, Hall G, Stading M, Wendin K. Effect of barium sulphate contrast medium on rheology and sensory texture attributes in a model food. Acta Radiol. 2008;50:131–8. doi: 10.1080/02841850802555638. [DOI] [PubMed] [Google Scholar]