Introduction

Ceramic-on-ceramic bearings for total hip arthroplasty were pioneered by Boutin in France during the 1970s1. The first generation of alumina ceramic experienced unacceptably high fracture rates2,3. In the 1980s and 1990s, advances in ceramic manufacturing produced alumina components of higher density and smaller grain size, substantially reducing the risk of fracture. The use of ceramics proliferated throughout Europe, although concerns about fracture, raised in the United States, resulted in its classification as a Class-III medical device by the U.S. Food and Drug Administration (FDA). These circumstances, coupled with the consequences of ceramic fracture, led to the dominance of polyethylene bearings for hip arthroplasty in the United States at the end of the twentieth century.

However, in the middle to late 1990s, concern about osteolysis secondary to polyethylene wear prompted a reevaluation of alternate bearings. The fracture rate of second-generation alumina was reported by ceramic producers to be reduced to a figure on the order of 1 in 10,000. The wear resistance of ceramic bearings was known to be superior to the conventional polyethylene of the day, which at that time was not highly cross-linked and was still sterilized with gamma radiation in air. By the mid-1990s, therefore, several manufacturers had launched multicenter, prospective, randomized trials through the FDA for ceramic-on-ceramic bearings. At the turn of the millennium, as these trials were reaching completion, an international producer of zirconia ceramic, St. Gobain Desmarquest, announced its withdrawal from the medical market because of unacceptably high fracture rates associated with changes in its manufacturing process. Although Desmarquest's withdrawal in 2001 involved a different ceramic, the FDA responded with strong scrutiny of the alumina ceramic manufacturers. Compliance with heightened regulatory requirements delayed FDA approval for the use of ceramic bearings in the United States until 2003. Before 2005, squeaking was not recognized as a clinically important complication of ceramic bearings in any of the trials being conducted for the FDA.

Over the past four years, the squeaking phenomenon has become well documented but is as yet poorly understood. The prevalence has been reported to range from under 1% to 10%4-7 and has been reported in abnormal circumstances such as mismatched ceramic couples8, after a ceramic liner fracture9,10, and in a case of cup malposition with severe impingement11. An increased risk of squeaking has been demonstrated with acetabular component malposition as well as with younger, heavier, and taller patients6. Some authors have suggested that the noise is a result of vibration where the neck of the femoral component impinges on the edge of the acetabular component11. However, it may also occur in properly matched ceramic bearings with an ideal acetabular component position and in the absence of neck-to-rim impingement4–6.

Reproduction of this effect has been reported in vitro12. In rare cases, the squeaking has been intolerable to the patient, prompting revision. Thus, squeaking has emerged as a new and previously unanticipated clinical failure mode for ceramic bearings in the twenty-first century.

In this paper, we report data that have been progressively accumulated from a series of studies undertaken by our group to investigate the mechanisms of noise production associated with ceramic-on-ceramic bearings. We compared demographic data between patients with squeaking hips and those with silent hips. Radiographic analysis was used to compare component placement, and an analysis of retrieved squeaking bearings showed the pattern of wear in these hips. Finite element analysis provided us with a model to better understand the mechanics of squeaking, and through acoustic and modal analysis we have been able to suggest the origin of the noise. The long-term goals of our research are to develop an understanding of the mechanisms of squeaking, to provide an approach to its investigation and treatment, and to develop countermeasures for squeaking in the future.

Which Hips Squeak?

Demographic and Radiographic Analyses

One of our first investigations into the squeaking phenomenon was an effort to understand whether patient-related and surgical factors were associated with noise production. We previously reported on a group of squeaking hips6, each of which was matched with a control for primary diagnosis, implant type, sex, age (within twelve months), height (within 2 cm), weight (within 5 kg), and date of surgery (within six months). Control patients came from our prospectively accumulated database of 2397 patients with ceramic-on-ceramic bearings.

The anteversion and inclination of the acetabular component were calculated on radiographs. Eleven patients also had a computed tomography scan performed of the squeaking hip (Fig. 1). If the acceptable ranges are defined to be between 15° and 35° of anteversion and between 35° and 55° of inclination, only six (35%) of the seventeen squeaking hips were in the acceptable range, whereas sixteen (94%) of the seventeen control hips were in the acceptable range (p = 0.0003). Therefore, if the acetabular orientation is outside this range, the hip is twenty-nine times (95% confidence interval, 3 to 279) more likely to squeak. However, a similar analysis in another group of patients found no increased prevalence of component malposition in squeaking hips compared with controls5.

Fig. 1.

A computed tomography scan of bilateral ABG II ceramic-on-ceramic hip replacements (Stryker Howmedica Osteonics, Allendale, New Jersey). In the previously reported case of this patient24, the right hip had excessive acetabular anteversion and it squeaked with walking. The left hip with ideal anteversion did not squeak. (Reprinted, with permission, from: Walter WL, O'Toole GC, Walter WK, Ellis A, Zicat BA. Squeaking in ceramic-on-ceramic hips: the importance of acetabular component orientation. J Arthroplasty. 2007;22:496-503.)

The demographic data demonstrated that squeaking hips are more likely in taller, heavier, and younger patients (Table I).

TABLE I.

Demographic Data on Thirteen Patients with Ceramic-on-Ceramic Total Hip Replacements That Squeaked Compared with All Other Patients with a Primary Total Hip Replacement

| Squeaking Hip Repalacements* (N = 13) | Other Primary Total Hip Replacements* (N = 2384) | P Value | |

|---|---|---|---|

| Height (cm) | 179 (165-186) | 169 (137-198) | 0.0003 |

| Weight (kg) | 90 (60-110) | 76 (40-130) | 0.001 |

| Age (yr) | 56 (35-79) | 65 (18-95) | 0.01 |

The values are given as the mean, with the range in parenthesis.

Retrieval Analysis

In order to further explain the relationship between acetabular component malposition and squeaking, we studied bearings retrieved from squeaking hips, in particular looking for evidence of edge loading13. We analyzed twelve alumina ceramic-on-ceramic bearings collected by eleven different surgeons in three different countries. There were four different designs of femoral components and four different designs of acetabular components. Eleven acetabular components had an elevated metal rim that was proud of the ceramic and one did not. All bearings were manufactured from third-generation alumina ceramic (BIOLOXforte, CeramTec, Plochingen, Germany). Three bearings had a 36-mm diameter; seven, a 32-mm diameter; and two, a 28-mm diameter. All hips were revised for noise or noise and pain. Seven of the twelve patients were men, and their average age was forty-eight years (range, twenty-six to sixty-five years). The original hip arthroplasty was done through a modified Hardinge approach in five hips and through a posterior approach in seven hips. The activity that produced the squeak was walking in ten hips and bending in one hip, and was unknown in another hip. The bearings were retrieved after an average of twenty-three months (range, eleven to sixty-one months) in service.

Wear length and width were measured with a digital caliper, and the rim of the titanium acetabular shell was studied for signs of impingement. We used a Roundtest machine (RA300; Mitutoyo, Andover, United Kingdom) to measure the depth of the wear scar, allowing us to calculate the volume. The clearance was measured on nine of the twelve bearings and on a control group of twelve bearings from a previously reported series14.

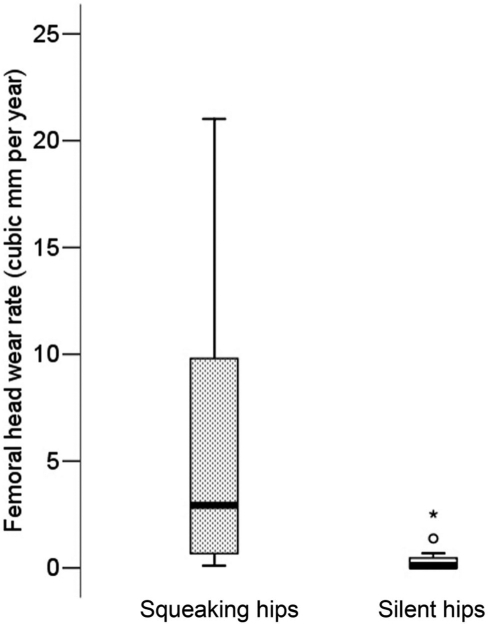

All twelve squeaking retrievals showed evidence of edge-loading wear. The median wear rate per year was 2.9 mm3 (range, 0.1 to 21.0 mm3) on the femoral heads and 3.4 mm3 (range, 0.2 to 20.6 mm3) on the acetabular components. This is much higher than a median of 0.1 mm3 and 0.04 mm3, respectively, for the thirty-three silent retrievals previously reported14 (Fig. 2). The mean clearance was 94 μm (range, 61 to 153 μm) in the squeaking retrievals and 72 μm (range, 59 to 87 μm) in the silent control group. This difference was not significant (p = 0.23).

Fig. 2.

Box plot comparing the volumetric wear rate of the squeaking retrievals13 with that of a historical control14.

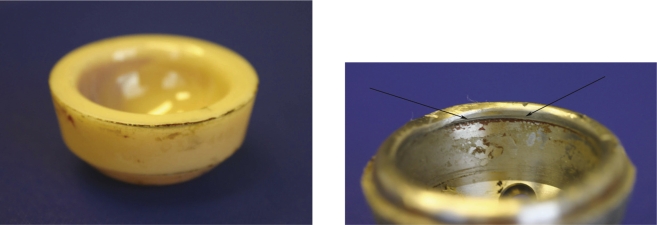

The numbers were too small to compare the wear among the 36-mm, 32-mm, or 28-mm bearings. There was no chipping or fracture of any of the ceramic components. Seven of the twelve implants also had evidence of impingement of the femoral neck against the elevated metallic rim or the ceramic insert or both (Figs. 3-A and 3-B). Closer inspection of the backside of the ceramic inserts revealed evidence of movement of the ceramic inserts within the titanium shell in several squeaking retrievals (Figs. 3-C and 3-D).

Figs. 3-A Figs. 3-B.

Figs. 3-A through 3-D Previously described in a case report6, these components were retrieved from a patient after sixty months because of pain and squeaking. (Reprinted, with permission, from: Murali R, Bonar SF, Kirsh G, Walter WK, Walter WL. Osteolysis in third-generation alumina ceramic-on-ceramic hip bearings with severe impingement and titanium metallosis. J Arthroplasty. 2008 Apr 2. E pub ahead of print.) Fig. 3-A There is evidence of impingement of the neck of the femoral component against the retrieved acetabular shell. Fig. 3-B Opposite the point of impingement on the rim, there is edge loading of the ceramic insert and a corresponding area of wear on the femoral head (the wear area has been colored with a blue surgical marking pen).

Figs. 3-C Figs. 3-D.

Fig. 3-C Closer inspection of the backside of the ceramic insert shows titanium metal transfer onto the edge. Fig. 3-D The titanium metal transfer onto the edge corresponds to a scored line (identified between the arrows) inside the titanium shell, evidence of tilting of the ceramic insert in the titanium shell.

Finite Element Analysis of Edge Loading

Although impingement was present in a majority of the squeaking retrievals, it does not appear to be necessary for squeaking to occur. The common factor is edge-loading wear, which may well be a critical mechanism. Furthermore, the backside evidence of liner tilting in the shell prompted further questions. To evaluate edge loading further, we conducted finite element analysis13. Computed tomography scans of an intact pelvis were obtained from the Visible Human Data Set (VHD; National Library of Medicine, Bethesda, Maryland). Slices were taken at a 1-mm thickness with no interslice distance through the entire pelvis. The computed tomography files were then read into a contour extraction program and saved into an IGES (Initial Graphics Exchange Specification) file format, which was imported into Patran (MSC Software, Los Angeles, California) to develop the pelvic geometry. The pelvis was meshed with ten-noded, modified tetrahedral elements. The model was reconstructed with a 54-mm titanium-alloy generic acetabular shell and a 28-mm alumina ceramic liner, similar to the implants used in the case shown in Figure 1. The acetabular shell and ceramic liner were meshed with use of eight-noded hexahedral elements. The shell-liner modular taper junction incorporated an 18° angle. The implant contact conditions (Lagrangian multiplier) allowed the liner and shell to slide with a friction coefficient of 0.9. Tied contact conditions were applied between the acetabular shell and the bone representing bone ongrowth. Bone material properties were extracted from the computed tomography files by taking the Hounsfield value and the coordinates, and mapping to the element in the model, allowing us to calculate the Young modulus for each element. Material properties for the shell and liner were based on published values15 for titanium alloy and alumina ceramic (Table II).

TABLE II.

Material Properties of Titanium Alloy and Alumina Ceramic

| Material | Elastic Modulus (MPa) | Poisson Ratio | Density (g/cm3) |

|---|---|---|---|

| Ti6al4V | 115 | 0.3 | 4.42 |

| Al2O3 | 390 | 0.3 | 3.97 |

Fixed boundary conditions were applied at the pubis and sacrum. Loading was applied over twenty nodes in a semielliptical manner at the outer edge of the liner to simulate edge loading at the toe-off position of the gait cycle. Two different conditions were tested, representing the two different alignments on the right and left sides of the case shown in Figure 1, that is, 45° of inclination and either 42° or 24° of ante-version.

The results of the analysis show that there is a stiffness incompatibility between the acetabular shell and the liner. The shell tends to deform, uncoupling the shell-liner taper system. The liner tends to tilt out of the acetabular shell opposite the applied load (Figs. 4-A and 4-B). With 42° of anteversion, there was 40 μm of separation of the surfaces opposite the load, and, with 24° of anteversion, there was only 4 μm of separation. It is this separation that may allow the acetabular shell to become an oscillator and emit a squeaking sound. The next section investigates this further.

Figs. 4-A 4-B.

Figs. 4-A and 4-B Finite element analysis of edge loading. Fig. 4-A The liner is in its normal position. Fig. 4-B The liner is “tilting” within the shell during edge loading.

What Is It That Squeaks?—Acoustic Analysis

Squeaking noises in hip replacements result from a forced vibration that comprises a driving force and a dynamic response16.

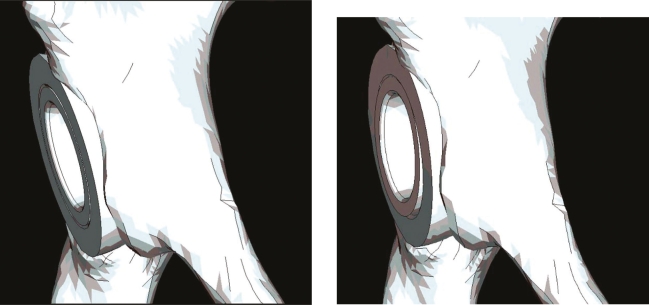

The driving force is a frictional driving force and results from the high friction seen in hard-on-hard bearings when there is a loss of fluid film lubrication17-19 (Fig. 5). Fluid film lubrication requires a rather delicate balance of a number of factors, including sliding speed, lubricating fluid viscosity, bearing roughness, clearance, and contact pressure19,20. A breakdown of fluid film lubrication may result from edge loading (a reduction in contact area), third bodies (such as ceramic debris) in the articulation10, damage to the articular surface (increased roughness), mismatched bearing diameters8, or perhaps other causes. Finite element analysis demonstrated that, with edge loading, the shell deforms and the shell-liner system uncouples, with the liner tilting in the shell. The friction of the movement between the liner and the shell is another potential driving force.

Fig. 5.

This graph illustrates the Stribeck curves for different bearing combination materials. Under ideal in vivo conditions, we assume that a ceramic-on-ceramic (CoC) bearing will be operating with fluid film lubrication with a coefficient of friction of around 0.0618. Metal-on-polyethylene bearings, on the other hand, operate under conditions of boundary lubrication with a coefficient of friction of around 0.0418,25, and an increase in contact pressure in this situation does not lead to an increase in the coefficient of friction25. In ceramic articulations, a loss of fluid film lubrication may result in a coefficient of friction as high as 0.7 or 1.019. MoM = metal on metal.

The dynamic response is resonance of a part of the device (the oscillator) at a frequency that is influenced by the natural frequency of the part21. By measuring the frequency of squeaking hip replacements and comparing it with the natural frequency of the component's parts, we can determine which part or parts could potentially be the oscillator.

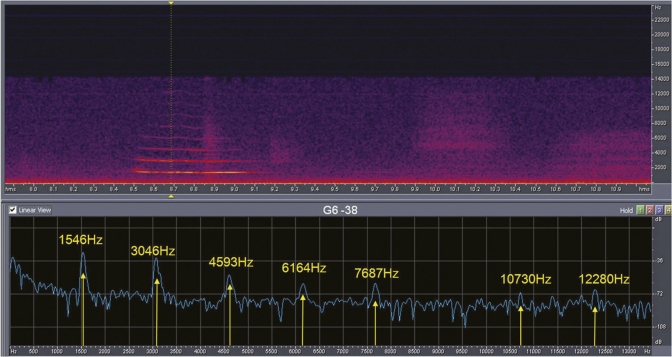

In Vivo Acoustic Analysis

In order to determine the frequency and nature of the sound emitted from squeaking hips, we performed an in vivo acoustic analysis22. Sound recordings from thirty-one patients with squeaking ceramic-on-ceramic hips were collected with use of a digital video camera recorder (DCR-DVD101E; Sony Electronics, San Diego, California) with an external microphone (MCE 87; beyerdynamic, Heilbronn, Germany) with a frequency response that ranges from 50 Hz to 18,000 Hz. Recordings from other institutions were made with use of a variety of devices. Sound files were captured on a personal computer as 16-bit monophonic files at a sample rate of 48,000 Hz and were analyzed with acoustic software (Adobe Audition 1.5; Adobe Systems, San Jose, California). Each recording was previewed in the spectral view mode, which allows easy visual identification of the squeak. In addition, all sound recordings were played to listen for the squeak. Once a squeak was identified, we performed a fast Fourier transform, which allowed the major frequency components of the squeaking to be easily measured (Fig. 6). We were able to determine the frequency range of the recording device by observing the frequency range of the background noise on the recording. We found that if a squeak was audible on the recording, we had no difficulty determining its frequency, regardless of the quality of the device used to make the recording or the amount of background noise.

Fig. 6.

A screen capture of the acoustic analysis software. In the spectral view at the top of the image, the squeak can be seen as a series of parallel lines. A fast Fourier transform of this squeak shows a harmonic series of frequency peaks with a fundamental at 1546 Hz. This is evidence of resonance.

The demographic profile of the patients was similar to that described above. They had a mean age of fifty-four years (range, twenty-three to seventy-nine years), a mean height of 171 cm (range, 152 to 186 cm), and a mean weight of 79 kg (range, 52 to 111 kg). There were seventeen female and fourteen male patients. All bearings were alumina ceramic with a variety of titanium shells and cementless or cemented stems. Ethics committee approval for this project was obtained from our institution and from the referring institutions, and informed consent was obtained from the patients.

The typical Fourier transform pattern was a harmonic series with a fundamental frequency between 400 Hz and 7500 Hz. Each patient had at least one characteristic fundamental frequency that recurred with each squeak. Three patients who were recorded on two separate occasions, separated by three, eight, and eleven months, had identical frequency signatures on both occasions.

Modal Analysis

The harmonic series seen on the acoustic analysis is evidence that squeaking sounds are produced by resonance. In order to improve our understanding of how the parts resonate, we performed a modal analysis. Generic three-dimensional models of a titanium-alloy anatomic femoral stem with a 12-mm dia-physeal diameter and a 28-mm ceramic femoral head were generated in Patran, and we used several different acetabular component models, including the acetabular component described above. The femoral stem was meshed with use of ten-noded tetrahedral elements and eight-noded hexahedral elements with use of the material properties shown in Table II.

Boundary conditions were applied to the components to replicate the in vivo environment as closely as possible. A modal analysis was performed for the femoral stem with the femoral head attached. A modal analysis was performed for the acetabular shell and liner combined with contact boundary conditions to simulate a fully matched taper junction, contact occurring only at the mouth of the acetabular shell and contact only occurring at the base of the taper junction. The acetabular shell and ceramic liner were also analyzed as separate pieces. All modal analysis was performed with use of ABAQUS software (ABAQUS, Pawtucket, Rhode Island) with twenty natural frequencies extracted for each analysis run.

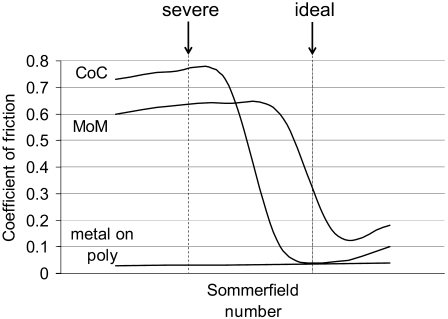

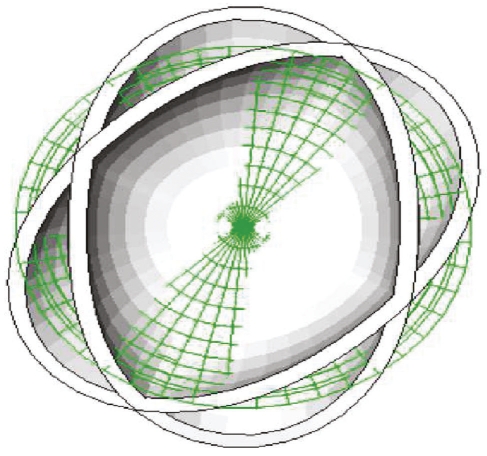

The results of the modal analysis showed multiple possible modes of resonance for the femoral stem and head. These were different combinations of bending and twisting in different planes. There were no relevant modes seen with the combined acetabular shell and ceramic liner because the ceramic liner effectively locked the rim of the shell, preventing resonance except at very high frequencies well above the audible range.

The acetabular shell as a separate piece resonated in an elliptical configuration known as the (2,0) mode, which is typical of wine glasses and bells (Fig. 7). The ceramic liner as a separate piece also resonated in the (2,0) mode but at a substantially higher frequency because of the material and geometric differences.

Fig. 7.

Modal analysis of a thin-walled generic acetabular shell resonating in the (2,0) mode.

Alumina ceramic and titanium alloy have similar densities (3.9 g/cm3 and 4.4 g/cm3, respectively) but very different elastic moduli (390 GPa and 115 GPa, respectively). Furthermore, the ceramic inserts have a similar thickness but a smaller diameter than the titanium shells, resulting in higher natural frequencies.

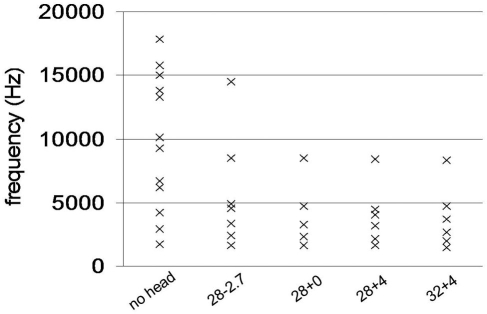

In Vitro Determination of Natural Frequencies

Modal analysis suggested that resonance of the ceramic components would occur only at frequencies above the human audible range and that resonance of the metal parts would occur at frequencies within the audible range. Furthermore, it suggested that resonance of the combined ceramic insert and titanium shell would not be within the audible range. To test this hypothesis, we performed an acoustic analysis. The natural frequency of hip replacement components was determined experimentally with an impulsive stimulus and a simple acoustic emission analysis. We tested titanium femoral stems and ceramic femoral heads, both assembled and unassembled, and modular ceramic and titanium acetabular components, which included testing the titanium shell and the respective ceramic inserts, both assembled according to the manufacturers' instructions and unassembled.

We captured the sound onto a personal computer with the same external microphone used for the in vivo acoustic analysis, and the frequency was determined with use of Adobe Audition. We tested four different designs of acetabular components and four different femoral components. A range of sizes for each component was tested according to availability from our retrieval collection.

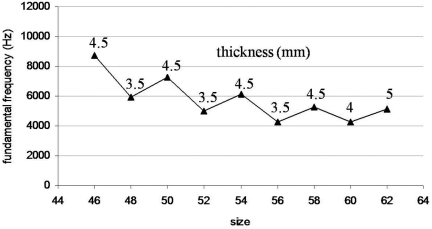

No resonance was detected in the audible range in any of the modular ceramic and titanium acetabular components when they were correctly assembled. No resonance was detected in the audible range in any of the ceramic liners or ceramic heads when they were tested unassembled.

Audible resonance was detected in all of the titanium shells when they were tested unassembled. The fundamental frequency of the titanium shell ranged from 4300 Hz to 9800 Hz, with higher modes extending into the higher frequencies. The thinner and larger shells tested had the lower frequency. We found a saw-tooth pattern of frequency variation as a result of changing shell thickness with increasing size (Fig. 8).

Fig. 8.

Graph representing the frequency of titanium shells resonating in the (2,0) mode. This design of titanium shell is typical in that the external diameter of the shell (which corresponds to the size in millimeters) changes by 2 mm every size, but the internal diameter changes every second size. Therefore, the thickness alternately increases and decreases usually by 1 mm. This results in a saw-tooth pattern.

The titanium femoral components have a minimum frequency of approximately 1500 Hz and multiple natural frequencies in the human audible range between 2 kHz and 20 kHz (Fig. 9).

Fig. 9.

Natural frequencies for this titanium stem are shown with and without a ceramic head attached. Attachment of the head makes very little difference to the frequency, although only the lower modes could be detected in some cases.

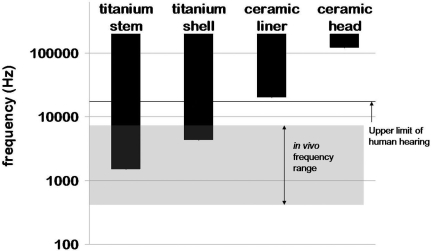

In the case of ceramic-on-ceramic bearings, the natural frequency of the ceramic parts is ≥20 kHz, and therefore resonance of these parts is not likely to play a role in squeaking. The natural frequencies, however, of the titanium shells and metallic femoral components are much lower and more likely to be factors (Fig. 10).

Fig. 10.

Graph of the natural frequencies of total hip replacement components. These frequencies, which were recorded in air, are modulated in vivo. The damping effect of the viscoelastic tissues tends to lower the frequency.

Discussion

This paper presents a progressive accumulation of data from a series of studies that have been undertaken to understand the mechanisms of noise production associated with ceramic-on-ceramic hip bearings. We have demonstrated that squeaking in ceramic-bearing hip arthroplasty components is related to patient factors, surgical factors, and component factors. Squeaking occurs in younger, heavier, and taller patients. We found a higher prevalence of acetabular component malposition in squeaking hips, and edge loading appears to be a causative factor. Finite element analysis revealed a stiffness mismatch between the shell and liner, which may cause the liner to tilt out of the shell and allow the shell to oscillate, producing an audible squeak. Acoustic analysis and modal analysis showed that the natural frequencies of the titanium acetabular and metallic femoral components are related to the actual squeaking noise in the clinical setting, suggesting that resonance occurs in the metallic, not the ceramic, parts.

Our analysis suggests that squeaking is due to a forced vibration with a frictional driving force and a dynamic response. The high levels of friction produced by hard-on-hard bearings when there is a breakdown of fluid film lubrication provide more energy to the system than can be dissipated in the usual way (as heat or subaudible noise). Under the right conditions, the metallic parts amplify this vibratory driving force into an audible event. A number of patient, surgery, and implant-related factors must combine to produce this phenomenon. Some, but not all, of the factors contributing to squeaking are within the control of the surgeon. Careful placement of the acetabular component, checking for possible neck-to-rim impingement in extension external rotation and in flexion internal rotation, may help to prevent edge loading. Care must be taken to prevent tilting of the ceramic insert in the taper at the time of insertion. Soft-tissue balancing of ceramic hip replacements may be important and, on occasion, it may be necessary to reduce the bulk of the anterosuperior capsule if it is thickened and causing posterior subluxation in flexion.

If a patient presents with a squeaking ceramic hip, we first exclude ceramic breakage with a computed tomography scan because a broken ceramic insert can cause squeaking9,10 and it may not be obvious on plain radiographs. The computed tomography scan also provides an accurate measure of the acetabular component anteversion. If the noise itself is infrequent, and occurs only with a specific activity, then revision surgery may not be necessary. We would counsel the patient and follow them closely. However, if the noise itself is troubling, if there is gross component malposition, if there is impingement, or if the patient has symptoms of pain, then we recommend revision surgery. At the time of surgery, component malposition and soft-tissue impingement can be corrected and the bearing can be revised to another ceramic-on-ceramic, metal-on-metal, or polyethylene bearing.

We focused on edge loading because it seems to be the dominant causative factor in our patients, but there are undoubtedly other causes. Other studies have found no increased prevalence of acetabular component malposition in patients with squeaking hips, and, in those patients, the squeak did not seem to be limited to a specific activity, suggesting a different mechanism5,23. Incorrect seating of the liner at the time of surgery may allow the shell to resonate, and damage to the articular surface may provide the severe condition. Ceramic fragments have been aspirated from squeaking hips, suggesting that third bodies may be responsible10. Others have speculated that neck-to-rim impingement or clearance mismatch may be a cause11. There will undoubtedly prove to be a variety of different mechanisms by which the necessary conditions of high friction and low-frequency dynamic response can be met.

Further work is required to improve our understanding of the squeaking phenomenon. More in-depth clinical analysis will provide additional insight into the in vivo conditions that produce squeaking. We propose further finite element analysis to compare the performance of different acetabular component designs under edge-loading conditions, and a more sophisticated acoustic analysis may reveal further insights. Perhaps there will be design changes and modifications to surgical technique that can be adopted to mitigate this problem. Ceramic-on-ceramic bearings are an attractive option because of the extremely low wear rates14 and low prevalence of osteolysis7 and, for these reasons, they remain our bearing of choice, especially in the young active patient.

Disclosure: In support of their research for or preparation of this work, one or more of the authors received, in any one year, outside funding or grants in excess of $10,000 from CeramTec, Stryker, and the National Institutes of Health (Grant AR47904). In addition, one or more of the authors or a member of his or her immediate family received, in any one year, payments or other benefits in excess of $10,000 or a commitment or agreement to provide such benefits from commercial entities (Stryker, DePuy, and Finsbury Orthopaedics). Also, commercial entities (Stryker, DePuy, and Finsbury Orthopaedics) paid or directed in any one year, or agreed to pay or direct, benefits in excess of $10,000 to a research fund, foundation, division, center, clinical practice, or other charitable or nonprofit organization with which one or more of the authors, or a member of his or her immediate family, is affiliated or associated.

References

- 1.Boutin P. [Total arthroplasty of the hip by fritted aluminum prosthesis. Experimental study and 1st clinical applications]. Rev Chir Orthop Reparatrice Appar Mot. 1972;58:229-46. French. [PubMed] [Google Scholar]

- 2.Knahr K, Böhler M, Frank R Plenk H, Salzer M. Survival analysis of an unce-mented ceramic acetabular component in total hip replacement. Arch Orthop Trauma Surg. 1987;106:297-300. [DOI] [PubMed] [Google Scholar]

- 3.Boutin P, Blanquaert D. [A study of the mechanical properties of alumina-on-alumina total hip prosthesis (author's transl)]. Rev Chir Orthop Reparatrice Appar Mot. 1981;67:279-87. French. [PubMed] [Google Scholar]

- 4.Jarrett CA, Ranawat AS, Bruzzone M, Rodriguez JA, Ranawat CS. The squeaking hip: an under-reported phenomenon of ceramic-on-ceramic total hip arthroplasty. Read at the Annual Meeting of the American Academy of Orthopaedic Surgeons; 2007. Feb 14-17; San Diego, CA. Podium no 198.

- 5.Rothman RH. Noisy ceramic hip: is component malpositioning the problem?Read at the American Association of Hip and Knee Surgeons Annual Meeting;2006. Nov 3-5; Dallas, TX.

- 6.Murali R, BonarSF, Kirsh G, Walter WK, Walter WL. Osteolysis in third-generation alumina ceramic-on-ceramic hip bearings with severe impingement and titanium metallosis. J Arthroplasty. 2008. Apr 2 [Epub ahead of print]. [DOI] [PubMed]

- 7.Lusty PJ, Tai CC, Sew-Hoy RP, Walter WL, Walter WK, Zicat BA. Third-generation alumina-on-alumina ceramic bearings in cementless total hip arthroplasty. J Bone Joint Surg Am. 2007;89:2676-83. [DOI] [PubMed] [Google Scholar]

- 8.Morlock M, Nassutt R, Janssen R, Willmann G, Honl M. Mismatched wear couple zirconium oxide and aluminum oxide in total hip arthroplasty. J Arthroplasty. 2001;16:1071-4. [DOI] [PubMed] [Google Scholar]

- 9.Suzuki K, Matsubara M, Morita S, Muneta T, Shinomiya K. Fracture of a ceramic acetabular insert after ceramic-on-ceramic THA—a case report. Acta Orthop Scand. 2003;74:101-3. [DOI] [PubMed] [Google Scholar]

- 10.Toni A, Traina F, Stea S, Sudanese A, Visentin M, Bordini B. Early diagnosis of ceramic liner fracture: guidelines based on a 12-year clinical experience with 3710 modern ceramic prostheses. Exhibited at the Annual Meeting of the American Academy of Orthopaedic Surgeons; 2006. Mar 22-24; Chicago, IL. Scientific exhibit no 14.

- 11.Eickmann TH, Clarke IC, Gustafson GA. Squeaking in a ceramic on ceramic total hip. In: Zippel H, Dietrich M, editors. Ceramics in orthopaedics: bioceramics in joint arthroplasty. 8th BIOLOX Symposium proceedings. Darmstadt: Steinkopff Verlag; 2003. p 187-92.

- 12.Taylor S, Manley MT, Sutton K. The role of stripe wear in causing acoustic emissions from alumina ceramic-on-ceramic bearings. J Arthroplasty. 2007;22(7 Suppl 3):47-51. [DOI] [PubMed] [Google Scholar]

- 13.Walter WL, Kurtz SM, Hozack WJ, Garino JP,Tuke MA, Parvizi J, Kirsh G, Ellis AM. Retrieval analysis of squeaking alumina ceramic-on-ceramic bearings. Read at the Annual Meeting of the American Academy of Orthopaedic Surgeons; 2007 Feb 14-17; San Diego, CA. Podium no 196.

- 14.Lusty PJ, Watson A, Tuke MA, Walter WL, Walter WK, Zicat B. Orientation and wear of the acetabular component in third generation alumina-on-alumina ceramic bearings. An analysis of 33 retrievals. J Bone Joint Surg Br. 2007;89:1158-64. [DOI] [PubMed] [Google Scholar]

- 15.Callister WD. Materials science and engineering: an introduction. 2nd ed. Toronto: John Wiley and Sons; 1991.

- 16.Main IG. Vibrations and waves in physics. 3rd ed. Cambridge: Cambridge University Press; 1993.

- 17.Andersson P, Blomberg A. Alumina in unlunbricated sliding point, line and plane contacts. Wear. 1993;170:191-8. [Google Scholar]

- 18.Scholes SC, Unsworth A. Comparison of friction and lubrication of different hip prostheses. Proc Inst Mech Eng [H]. 2000;214:49-57. [DOI] [PubMed] [Google Scholar]

- 19.Smith SL, Dowson D, Goldsmith AAJ. The lubrication of metal-on-metal total hip joints: a slide down the Stribeck curve. Proc Inst Mech Eng [J]. 2001;215:483-93. [DOI] [PubMed] [Google Scholar]

- 20.Overney R, Tyndall G, Frommer J. Kinetics and energetics in nanolubrication. In: Bhushan B, editor. Springer handbook of nanotechnology. Berlin: Springer-Verlag; 2004. p 883-96.

- 21.AkayA. Acoustics of friction. J Acoust Soc Am. 2002;111:1525-48. [DOI] [PubMed] [Google Scholar]

- 22.Walter W, Gillies R, Donohoo S. Acoustic analysis of squeaking hips. Read at the Australian Orthopaedic Association 67th Annual Scientific Meeting; Gold Coast, Australia. 2007. Oct 7-12. Paper HP21.

- 23.Ranawat AS, Ranawat CS. The squeaking hip: a cause for concern-agrees. Orthopedics. 2007;30:738, 743. [DOI] [PubMed] [Google Scholar]

- 24.Walter WL, O'Toole GC, Walter WK, Ellis A, Zicat BA. Squeaking in ceramic-on-ceramic hips: the importance of acetabular component orientation. J Arthroplasty. 2007;22:496-503. [DOI] [PubMed] [Google Scholar]

- 25.Charnley J. Low friction arthroplasty of the hip: theory and practice. Berlin: Springer-Verlag; 1979.