Abstract

Dimethacrylate dental composite resins exhibit inherently low toughness. Toughening of these materials may reduce the incidence of marginal and bulk fracture of composite restorations. Objective: To determine if dimethacrylate dental restorative materials can be rubber-toughened, and if so, to identify a possible mechanism. Methods: A filler composed of aggregates of polybutadiene/silica as well as irregularly-shaped silica slabs was produced by mixing silica with polybutadiene in dichloromethane. The dried filler was subsequently ground and sieved to <25μm. Polybutadiene/silica ratios were varied from 0:1 (control) to 0.5:1. EDAX analysis verified the composition of the complex filler. Filler was added to a bis-GMA/bis-EMA/TEGDMA resin system and fractured in 3-point bend test mode at a crosshead speed of 1mm/min. In addition, 1 bar was fractured at a crosshead speed of 0.001mm/min in order to identify a possible mechanism for toughening. Results: In specimens fractured at 1mm/min, flexural modulus is increased or maintained and flexural strength and energy to break increase as the amount of polybutadiene in the aggregates increases. Cavitation of high-rubber-containing aggregates is demonstrated. In the one specimen fractured at 0.001mm/min, a marked increase in size of high-rubber-containing aggregates along with severe shear damage in the surrounding matrix is shown, suggesting that cavitation with subsequent absorption of energy during shear yielding is the likely mechanism behind the increase in energy to break in bars fractured at 1mm/min. Significance: These results indicate that dimethacrylate dental composite materials can be rubber toughened, which may potentially reduce marginal and bulk fractures of composite restorations, and consequently extend their service lifetime.

INTRODUCTION

Thermosetting dimethacrylates, which commonly comprise the resin matrix of commercially available dental composite resins, exhibit inherently low toughness[1]. Marginal and bulk fractures of composite restorations continue to be reported and account for the majority of early failures[2, 3]. Typically, toughening of composites has been achieved by the addition of silane-treated silica[4], which enhances the fracture toughness by increasing the modulus and by either crack-pinning and/or crack deflection[5]. Investigations have also been performed in order to improve fracture toughness by the addition of silane-treated quartz fibers[6], or of silane-treated silicon nitride or silicon carbide fibers[7]. Other studies have used low molecular weight butadiene and butadiene-styrene based rubbers to improve the impact strength of denture-base resins[8, 9]. Polybutadiene/Bis-phenol A copolymers, comprised of both hard and soft segments, have also been shown to enhance toughness of resins for dental applications[10]. A methacrylate-terminated poly(butadiene-acrylonitrile-acrylic acid) terpolymer showed adequate solubility in bis-GMA and resulted in significantly improved fracture toughness[11].

Toughening of brittle thermosets can also be achieved by the dispersion of a lower modulus material, such as rubber particles, throughout the matrix. Rubber toughening of a thermosetting epoxy has been achieved by the dispersion of small (<1μm) particles consisting of a rubbery core and a rigid shell[12]. An enormous amount of experimental and modeling work has been reported, describing the relationships between macroscopic and morphological properties[13-17]. The most widely accepted micromechanical deformation mechanisms responsible for the increase in fracture toughness of rubber-modified systems are internal cavitation of the rubber particles and the formation of shear bands[18]. Shear bands are lens-like areas in which large plastic shear has occurred, embedded in unsheared matrix. Easily cavitating rubber particles promote shear banding, and the majority of toughness is achieved by the dissipation of energy through shear band formation.

The objective of this work was to determine if the presence of rubbery inclusions could result in toughening of dimethacrylate dental composites, and if so, to identify a possible mechanism.

MATERIALS AND METHODS

Preparation and characterization of filler

A series of fillers with increasing rubber content were formulated in order to prepare composites and monitor changes in mechanical properties and deformation mechanisms. Fillers were formed by adsorption of polybutadiene of MW 2-3 million (SigmaAldrich, St. Louis, MO) onto fumed silica (300m2/g, Degussa, Germany) from dichloromethane (SigmaAldrich) at room temperature. Polybutadiene/silica ratios varied from 0:1 (control) to 0.5:1 wt.%. Ten grams of silica were vigorously stirred into 500ml dichloromethane in which the appropriate amount of polybutadiene had been previously dissolved. For example, in order to prepare a filler composed of 0.5:1 polybutadiene/silica, 0.5g of polybutadiene was dissolved in 500 ml dichloromethane at room temperature before incorporation of 10g of silica. The filler/dichloromethane mixtures were poured into flat, glass dishes and allowed to dry. After drying and grinding, particles were sieved to <25μm using a sonic sifter (Model L3P, Advantech Mfg., New Berlin, WI). This preparation method produced three distinct forms of polybutadiene/silica or silica alone, which will be described in the Results section. The filler so produced will hereafter be referred to as “complex filler”.

Elemental identification of complex filler (0.25:1 polybutadiene/silica) was performed using an energy dispersive X-ray analysis (EDAX) attachment (on a Jeol 6610) operated at an accelerating voltage of 15 kV. Samples were sputtered with gold/palladium.

Preparation of bar specimens for mechanical tests

Complex filler was added to a bis-GMA/bis-EMA/TEGDMA (Esstech, Philadelphia, PA) resin system (3:3:2 by weight, 0.86 wt.% camphorquinone (SigmaAldrich) and 2.14 wt.% dimethylaminoethylmethacrylate (SigmaAldrich)) at 9 volume %, injected into 2x2mm square glass tubing (Fiber Optic Center, Inc., New Bedford, MA) of length 30mm, and light-cured as 2×2×25mm bars in a Cure-Lite Plus curing oven (Jeneric/Pentron, Wallingford, CT), with an unfiltered quartz-halide light source, for 10 minutes. Fumed silica increases the viscosity of dimethacrylate monomers very quickly. Nine volume % was chosen as the maximum amount of fumed silica that could be added to the monomers and still allow the uncured composite mixture to be syringed into the glass tubing molds. Bars were allowed to sit at room temperature for 24 hours after preparation, and were then immersed in water for 24 hours before mechanical testing.

Mechanical testing

Twelve bars in each group (0:1 (control) to 0.5:1) were fractured using an Instron Universal Testing machine in 3-point bend test mode at a crosshead speed of 1mm/min. In addition, one bar containing 0.5:1 polybutadiene/silica was tested at the very low crosshead speed of 0.001mm/min in order to obtain information relevant to a possible deformation mechanism. The purpose for using the lower crosshead speed was to allow additional time during deformation for molecular rearrangement and potential birefringence, which could possibly provide information relevant to the mechanism behind an increase in energy to break.

Statistical analysis

Data from mechanical tests carried out at 1mm/min were compared using ANOVA with a Tukey post hoc test to determine any significant differences among groups (p<0.05).

Microscopy

Bars fractured in 3-point bend test mode were examined using two microscopic methods. First, a Zeiss optical microscope with crossed polarizers was used to determine if fracturing resulted in birefringence in the matrix, a possible indication of molecular realignment resulting from shear yielding. Second, thin sections (600nm, LEICA EM UC6 ultra microtome) of the bars were prepared, stained with toluidine blue and examined using the optical microscope for evidence of cavitation of rubbery particles. Cavitation is the growth of internal voids in rubbery inclusions under appropriate stress conditions, and co-occurs with shear yielding of the surrounding matrix.

RESULTS

Elemental analysis of complex filler

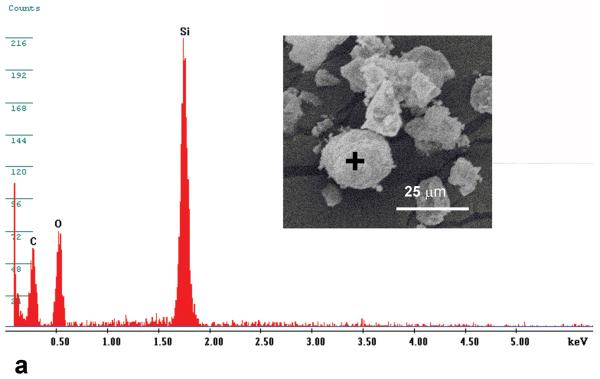

EDAX results indicate that two distinct forms of the complex filler are composed of carbon, silicon and oxygen, Fig. 1. The spherical particle, Fig. 1a, was composed of 83.2 atomic % carbon, with the remainder silica. The irregular slab, Fig. 1b, was composed of 11.1 atomic % carbon, with the remainder silica.

Figure 1.

EDAX results and SEM images of complex filler (0.25:1 polybutadiene/silica). The spherical particle, Fig. 1a, was composed of 83.2 atomic % carbon, with the remainder silica. The irregular slab, Fig. 1b, was composed of 11.1 atomic % carbon, with the remainder silica. Areas analyzed by EDAX are marked by (+).

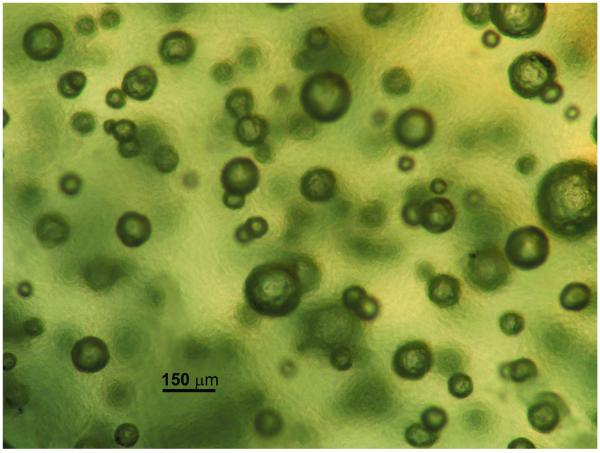

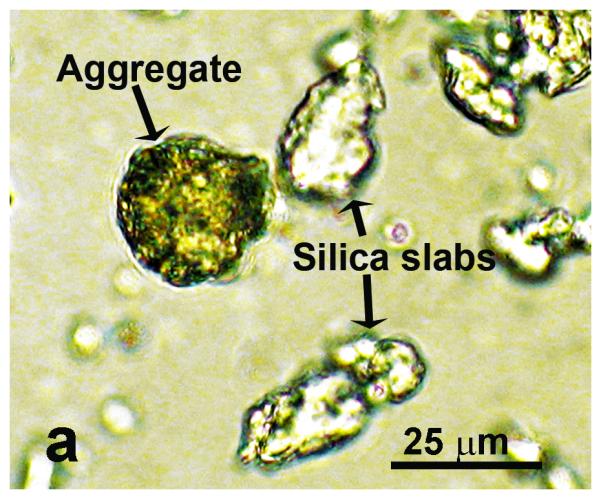

Microscopic examination of complex filler

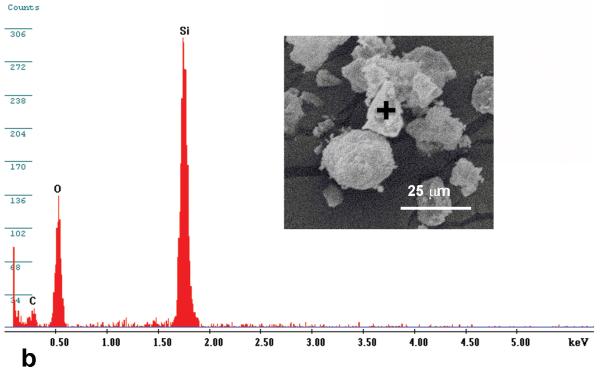

Optical examination of the complex filler before incorporation into the matrix monomer showed that the filler was composed of orange-colored, spherical polybutadiene/silica aggregates ranging in size from 5-25μm, Figs. 2a and 2b, in addition to uncolored, irregularly-shaped slabs of silica. Silica slabs outnumbered polybutadiene/silica aggregates by approximately 10:1. This ratio appeared to be similar across all filler formulations. In addition, TEM examination showed that <1% of the total silica was present as discrete nanoparticles (data not shown), which is the form of the originally added silica.

Figure 2.

Spherical polybutadiene/silica aggregates (0.25:1) of size a: 25μm and b: 10μm and several irregular silica slabs, components of the complex filler used in this work.

Visual appearance of bars

The visual appearance of cured composite specimens was identical across all filler formulations and was similar to the control specimens, which contained only silica. These observations indicate that the rubber-containing specimens either scattered light in a way similar to that of the control or that the rubber inclusions were present in too low a quantity to affect esthetics.

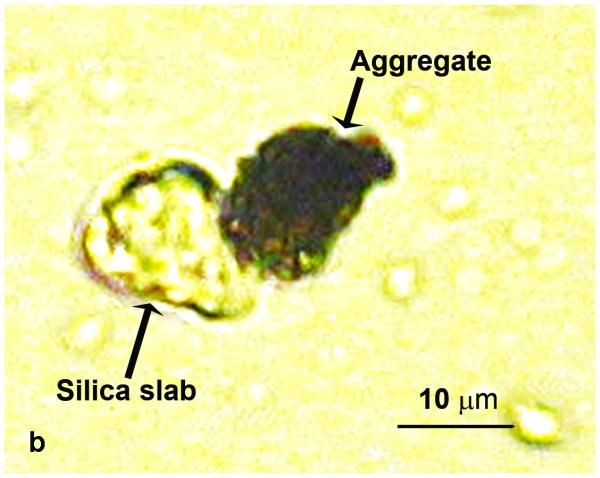

Mechanical properties of bars fractured at 1mm/min

In bars fractured at a crosshead speed of 1mm/min, flexural strength increased 19% and energy to break increased 93% as the polybutadiene/silica ratio in the aggregates increased, Fig. 3. Specimens containing lower amounts of polybutadiene (0.00005:1 to 0.05:1 polybutadiene/silica) showed a modest increase of 12% in modulus as polybutadiene/silica ratio in the aggregates increased, with a significant drop in modulus at higher rubber contents. However, moduli of these higher-rubber-containing groups (0.25:1 and 0.5:1 polybutadiene/silica) were indistinguishable from that of the control at p<0.05.

Figure 3.

Flexural modulus, flexural strength and energy to break in bis-GMA/bis-EMA/TEGDMA with 9 vol.% silica or aggregate. Arrows indicate groups with means significantly different from those of the controls (P<0.05). Crosshead speed – 1mm/min.

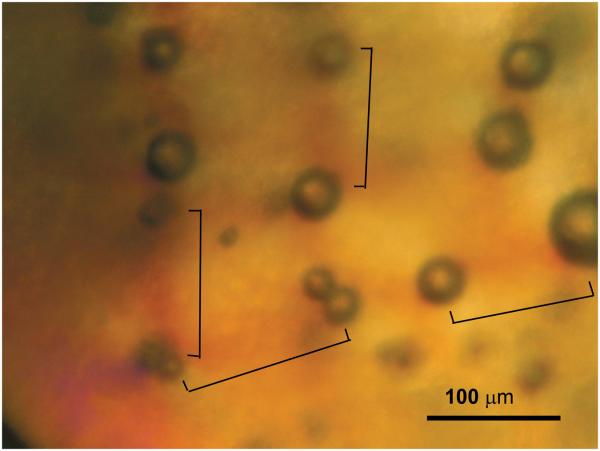

Optical microscopy of bars fractured at 1mm/min

Optical examination of a bar (0.5:1 polybutadiene/silica) fractured at a crosshead speed of 1mm/min showed uniform dispersion of aggregates but no or faint birefringence, Fig. 4. However, a number of the aggregates are several times larger than the sieve size of 25μm and possibly indicate cavitation of the rubbery aggregates during fracture.

Figure 4.

A specimen (0.5:1 polybutadiene/silica) fractured at 1mm/min. Note the large increase in size of many of the aggregates, possibly indicating cavitation of aggregates.

The high molecular weight polybutadiene used in this work was yellow-orange-colored, rendering the aggregates optically visible. The silica plates, however, were not optically visible since Aerosil 300 has a refractive index of 1.46[19], very near that of the components of the matrix resin (1.54, 1.535 and 1.46 for bis-GMA, bis-EMA and TEGDMA respectively[20]). In addition, optical microscopes have narrow depths of field. Fig. 4 is an optical image of a 2mm thick specimen. Therefore, some planes are necessarily out of focus.

A specimen containing a small amount of rubber (0.00005:1 polybutadiene/SiO2) exhibited cracks (arrows) at aggregate equators in the plane parallel to the fracture surface, Fig. 5, indicating a brittle deformation mode.

Figure 5.

A specimen (0.00005:1 polybutadiene/silica) fractured at 1mm/min. Note the cracks originating at aggregate equators, indicating a brittle mode of deformation.

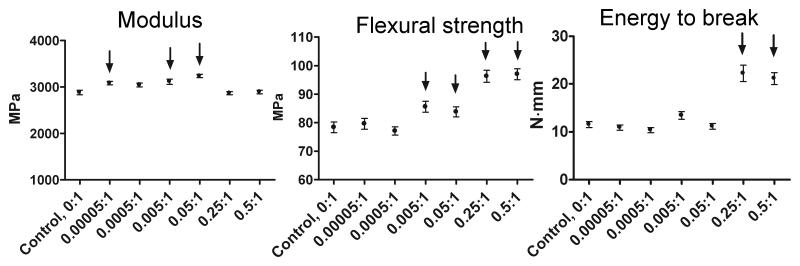

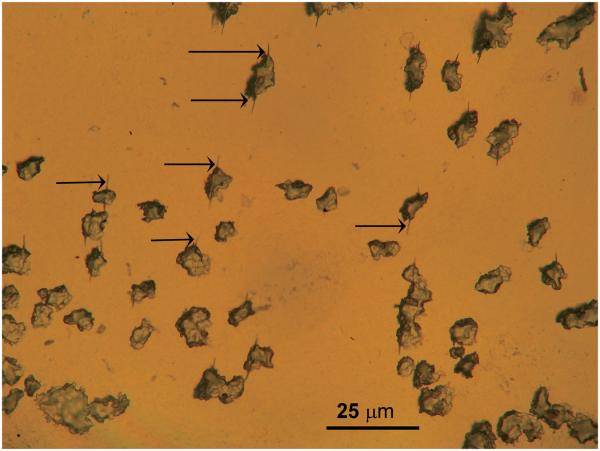

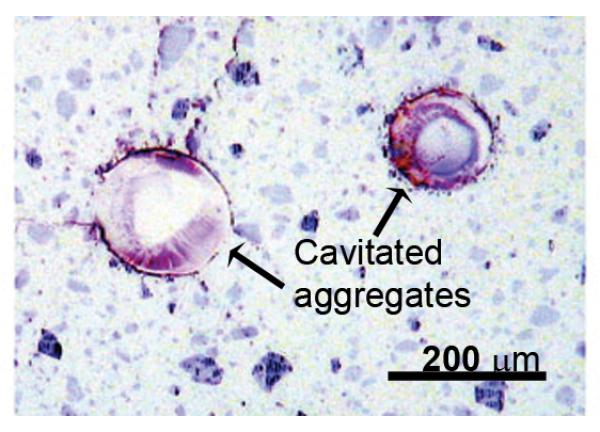

Evidence of cavitation in bars fractured at 1mm/min

Cavitation of polybutadiene/silica aggregates (0.25:1 polybutadiene:SiO2) in a bar fractured at 1mm/min. was evident in a thin section stained with toluidine blue, Fig. 6. Cavitation in this specimen indicates a possible mechanism leading to the increase in energy to break noted in Fig. 3. No cavitation of polybutadiene/silica aggregates was found in toluidine-stained thin sections of a composite containing little rubber (0.00005:1 polybutadiene:SiO2) (data not shown).

Figure 6.

Cavitated aggregates (0.25:1 polybutadiene/silica) from a thin (600nm) section of a specimen fractured at 1mm/min. Silica plates are seen as blue stained areas. Toluidine blue stain.

It was additionally noted that toluidine blue also resulted in the staining of silica and blue-stained silica slabs were evident but showed no signs of cavitation. Vertical lines within the silica slabs are artifacts caused by skipping of the knife across the specimen during sectioning.

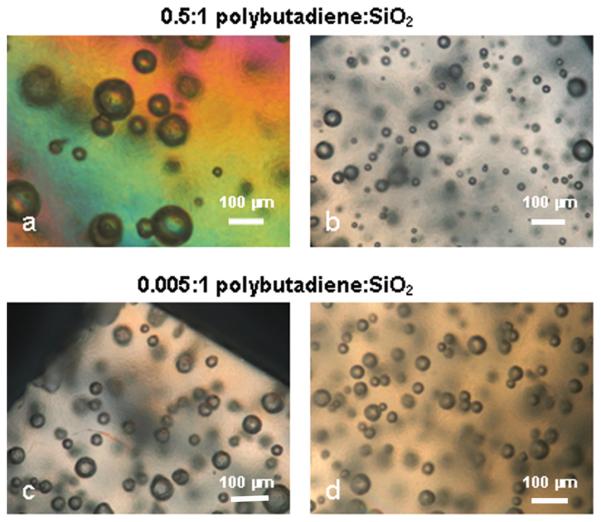

Optical microscopy of bars fractured at 0.001mm/min

We additionally broke one bar at the very low crosshead speed of 0.001mm/min. The purpose for using the lower crosshead speed was to allow additional time during deformation for molecular rearrangement and potential birefringence, which could possibly provide information relevant to the mechanism behind the large increase in energy to break seen in Fig. 3. These results are shown in Fig. 7.

Figure 7.

Optical microscope images near (a,c) and far (b,d) from fracture surfaces. Note extensive shear damage and markedly increased size of aggregates, possibly due to cavitation, in (a). Much less shear damage is evident in (c). Some planes are out of focus. Examined under crossed polarizers. Crosshead speed – 0.001mm/min.

Viewed under crossed polarizers, fractured bars with aggregates containing a large amount of rubber (0.5:1 polybutadiene/SiO2) showed extensive shear damage and markedly increased size of aggregates, possibly occurring with cavitation, near the fracture surface, Fig. 7a, when compared to far from the fracture surface, Fig. 7b, indicating a ductile deformation mode. The matrix region turned bright in the presence of crossed polarizers, due to the partial orientation of elastic chains produced by massive shear yielding of the matrix, leading to an anisotropic material and birefringence. In contrast, a specimen containing a smaller amount of rubber (0.005:1 polybutadiene:SiO2) exhibited much less shear damage near the fracture surface, 7c, and little or no change in aggregate size compared to far from the fracture surface, 7d, indicating a less ductile deformation mode.

In Fig. 8, an optical image taken farther from the fracture surface than that shown in Fig. 7a shows shear interactions between particles evident as broad colored lines (brackets) between aggregates, possibly indicating the presence of shear bands.

Figure 8.

Optical micrograph using crossed polarizers showing shear interactions (red bands, shown in brackets) among particles. The interactions are possibly nano-sized shear bands.

DISCUSSION

Polybutadiene is a rubber that yields under very low stresses and appears to function well as a compliant material in the bis-GMA/bis-EMA/TEGDMA resin system. High molecular weight rubbers exhibit greater ductility because of their larger number of entanglements, which are able to unfold under tensile stress. Molecular weights above 2-3 million were not investigated in this work, and their usefulness may be limited by their insolubility in dichloromethane and otherwise suitable solvents.

Evidently, the aggregate preparation method results in both agglomeration of polybutadiene with silica, forming spherical aggregates, and also in silica slabs. The filler preparation method involves adding silica to a solution of polybutadiene in dichloromethane, stirring, pouring the mixture into a flat glass dish and allowing evaporation of dichloromethane. The resulting dried filler is a discontinuous layer about 4mm thick. The filler is ground and sieved to <25μm. The slabs probably formed as a result of agglomeration of silica during solvent evaporation, resulting in tightly packed slabs. Additional grinding would likely reduce the size of the silica slabs. In addition, EDAX results indicate the presence of small amounts of carbon, and therefore, polybutadiene, in the irregular slabs. Slabs were not found to participate in cavitation. We do not have an explanation for why polybutadiene partitioned as it did in the presence of silica. However, we can say that batch to batch, filler prepared in an identical manner had the same effect on mechanical properties as that reported here.

A filler of this complexity will impart various properties to the composite and a series of composites containing increasing amounts of rubber is a convenient way to monitor changes in deformation mechanisms. The presence of distinct silica slabs and silica nanoparticles, with their reinforcing tendencies, is likely the reason for maintenance of flexural modulus as the amount of polybutadiene in the aggregates increases. The modest increase in modulus (12%) found in lower-rubber-containing aggregates (0.00005:1 to 0.05:1 polybutadiene/silica) suggests additional reinforcement by the aggregates, which are mainly composed of closely packed silica. A low energy to break, and a brittle mode of deformation, is demonstrated by the presence of cracks at the equators of aggregates, evident in specimens containing little rubber (0.00005:1 polybutadiene/silica), Fig. 5.

The increase in energy to break as amount of polybutadiene in the aggregates increases likely reflects the large difference in moduli between the rigid matrix polymer and the rubbery aggregates. Under load, the stress in the matrix adjacent to the equator of an aggregate with high rubber content is likely higher than the overall applied stress. Kinloch states that the stress intensity factor for spherical rubber inclusions is approximately two[5]. The stress fields around individual aggregates begin to overlap, thereby further increasing the stress in the adjacent matrix material. A triaxial stress field is generated in the matrix in the vicinity of the advancing crack tip, thus promoting dilatational processes such as cavitation and crazing[21]. Crazing is seldom found in highly cross-linked thermosets. Cavitation relieves the triaxial stress state and the plane strain constraint induced by the thick specimen and the sharp crack; the octahedral shear stress component around the crack tip is, as a result, greatly raised and causes extended yielding of the matrix. Thus, the rubber-toughening effect is achieved by inducing yielding deformation within a much larger volume of the matrix polymer by using the stress-concentrating effect of rubbery particles to initiate local yielding of the matrix material around and between the particles[12]. Local yielding effectively blunts the sharp crack and results in increased toughness.

Controversy exists regarding the sequence of events associated with the toughening process. On one hand, Yee and Pearson argued that rubber particle cavitation relaxes tensile stress triaxiality at the crack tip, which then facilitates the formation of a network of energy-absorbing shear bands[22-24]. By contrast, Huang and Kinloch[25] concluded that shear bands initiate first at the stress concentration surrounding the rubber particle (cavitated or not) and then terminate at an adjacent particle. Based on finite element analysis[26], they determined that the sequence of events between cavitation and shear banding depended on the Young's modulus and Poisson's ratio of the rubber particles.

Cavitation of high-rubber-containing aggregates found in this work, Fig. 6, supports the proposals of many workers that cavitation and shear yielding co-occur in some manner to produce an increase in toughness. We propose that this is the likely mechanism behind the increase in energy to break found in specimens fractured at 1mm/min, Fig. 3. The combination of properties of the matrix and polybutadiene chosen are evidently appropriate to result in cavitation and a shear yielding process when subjected to the stress conditions generated while fracturing in 3-point bend test mode at a crosshead speeds of 1mm/min and 0.001mm/min.

Individual shear bands from rubber particles less than 1μm cannot be observed (due to the resolution of the optics) and only a diffuse sheared region is observed. Shear bands in the nanometer size range (20-100nm) have been reported from replica TEM examination of internal surfaces of polystyrene samples loaded in compression[27, 28]. Shear bands typically initiate and terminate on particles. Interactions between particles evident in Fig. 8 are possibly nano-sized shear bands and reflect overlapping stress fields between particles.

Flexural strength describes the stress carrying capacity of a material and reflects both toughness and inherent flaw size. Flexural strength was found in this work to increase as polybutadiene content in the aggregates increased. Any mechanism capable of delaying crack propagation and increasing toughness, such as toughening resulting from rubber inclusions, would be expected to result in an increase in flexural strength.

The bond between the rubber particles and the matrix makes little or no difference except to disperse the rubber particle in the matrix. SEM examination of fracture surfaces of specimens in this work showed that particle debonding occurred during fracture, and that fracture did not occur through the particles (data not shown).

It is possible that the presence of polybutadiene in the complex filler would reduce bond strength of these composites to tooth structure. Bonding sites with methacrylate monomers in current commercial dental adhesives do not exist on polybutadiene. For example, a composite filled with 9 vol% of 0.5:1 polybutadiene/silica would contain approximately 4.9 vol.% polybutadiene, although the majority of the rubber is present within the aggregates and not on their surfaces. However, bond strength may be a significant problem with more highly filled composites.

Crosslinked epoxy resins typically rely on reinforcement by rubber particles to improve toughness, but with significant sacrifice of elastic modulus[29]. Rubber toughening is effective in those crosslinked materials in which the molecular weight between crosslinks is sufficiently large to permit a degree of shear deformation. While dental restorative resins are highly crosslinked glassy polymers, we have shown that a monomer system typical of commercially available composite resins is capable of toughening by compliant aggregates, without loss of elastic modulus.

In addition to the improvement in mechanical properties that we have shown to occur with the complex filler used in this work, we are interested in the potential of rubber inclusions to reduce polymerization shrinkage and contraction stress. We have been able to show that the present complex filler reduces shrinkage during polymerization[30] without loss of mechanical properties. We have also shown that nano-sized rubber/silica particles, in the presence of a plasticizer, reduce contraction stress associated with polymerization[31]. Future work will extend these studies to nano-sized compliant particles, which will present a very large compliant surface area to the matrix polymer.

CONCLUSIONS

These results demonstrate that a monomer system typical of commercially available composite resins is capable of being toughened by rubber inclusions. Cavitation and energy absorption during shear yielding of the matrix has been identified as a likely mechanism responsible for a large increase in energy to break in high-rubber-containing composites. Toughening of brittle commercially available composite resins should result in a reduction in marginal and bulk fracture of composite restorations and, consequently, longer-lasting restorative materials.

ACKNOWLEDGEMENTS

Supported by NIH/NIDCR Grants T32 DE14318, P01 DE11668 and R21DE018353.

REFERENCES

- 1.Anusavice KJ, editor. Phillips' Science of Dental Materials. 11 ed. Elsevier Science; St. Louis: 2003. [Google Scholar]

- 2.Hickel R, et al. Longevity of occlusally-stressed restorations in posterior primary teeth. American Journal of Dentistry. 2005;18(3):198–211. [PubMed] [Google Scholar]

- 3.Manhart J, Garcia-Godoy F, Hickel R. Direct posterior restorations: clinical results and new developments. Dental Clinics of North America. 2002;46(2):303–39. doi: 10.1016/s0011-8532(01)00010-6. [DOI] [PubMed] [Google Scholar]

- 4.Cook WD, Beech DR, Tyas MJ. Structure and properties of methacrylate based dental restorative materials. Biomaterials. 1985;6(6):362–368. doi: 10.1016/0142-9612(85)90094-8. [DOI] [PubMed] [Google Scholar]

- 5.Kinloch AJ, Young RJ. Fracture Behavior of Polymers. Applied Science; London: 1983. [Google Scholar]

- 6.Petersen RC. Discontinuous fiber-reinforced composites above critical length. Journal of Dental Research. 2005;84(4):365–370. doi: 10.1177/154405910508400414. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Xu HHK, et al. Effects of different whiskers on the reinforcement of dental resin composites. Dental Materials. 2003;19(5):359–367. doi: 10.1016/s0109-5641(02)00078-7. [DOI] [PubMed] [Google Scholar]

- 8.Rodford RA. Further development and evaluation of high impact strength denture base materials. Journal of Dentistry. 1990;18(3):151–7. doi: 10.1016/0300-5712(90)90056-k. [DOI] [PubMed] [Google Scholar]

- 9.Rodford RA, Braden M. Further observations on high impact strength denture-base materials. Biomaterials. 1992;13(10):726–8. doi: 10.1016/0142-9612(92)90135-b. [DOI] [PubMed] [Google Scholar]

- 10.Matsukawa S, Hayakawa T, Nemoto K. Development of high-toughness resin for dental applications. Dental Materials. 1994;10(6):343–6. doi: 10.1016/0109-5641(94)90057-4. [DOI] [PubMed] [Google Scholar]

- 11.Kerby RE, et al. Fracture toughness of modified dental resin systems. Journal of Oral Rehabilitation. 2003;30(8):780–4. doi: 10.1046/j.1365-2842.2003.01153.x. [DOI] [PubMed] [Google Scholar]

- 12.Sue HJ, Garcia-Meitin EI, Orchard NA. Toughening of epoxies via craze-like damage. Journal of Polymer Science, Part B: Polymer Physics. 1993;31(5):595–608. [Google Scholar]

- 13.Yee AF. YIELD AND DEFORMATION BEHAVIOUR OF SOME POLYCARBONATE BLENDS. Journal of Materials Science. 1977;12(4):757–765. [Google Scholar]

- 14.Guild FJ, Young RJ. Predictive model for particulate filled composite materials. Part 2. Soft particles. Journal of Materials Science. 1989;24(7):2454–2460. [Google Scholar]

- 15.Cheng C, et al. Comparison of some butadiene-based impact modifiers for polycarbonate. Journal of Applied Polymer Science. 1994;53(5):513–525. [Google Scholar]

- 16.Kinloch AJ, Guild FJ. In: Toughened Plastics II: Novel Approaches in Science and Engineering. Kinloch C.K.R.a.A.J., editor. Vol. 252. American Chemical Society; 1996. [Google Scholar]

- 17.Plummer CJG, Be?guelin P, Kausch HH. On the influence of particle morphology on microdeformation in rubber modified poly(methyl methacrylate) Polymer. 1996;37(1):7–10. [Google Scholar]

- 18.Pearson RA, Yee AF. Influence of Particle-Size and Particle-Size Distribution on Toughening Mechanisms in Rubber-Modified Epoxies. Journal of Materials Science. 1991;26(14):3828–3844. [Google Scholar]

- 19.Refractive index of Aerosil 300. 2009 Available from: http://www.evonik.us/region/north_america/en/Pages/default.aspx.

- 20.Refractive indices of bis-GMA, bis-EMA and TEGDMA. 2009 Available from: http://www.esstechinc.com/.

- 21.Williams JG. Fracture Mechanics of Polymers. Ellis Horwood Ltd; New York: 1984. [Google Scholar]

- 22.Yee AF, Pearson RA. TOUGHENING MECHANISMS IN ELASTOMER-MODIFIED EPOXIES. PART 1: MECHANICAL STUDIES. Journal of Materials Science. 1986;21(7):2462–2474. [Google Scholar]

- 23.Pearson RA, Yee AF. Toughening mechanisms in elastomer-modified epoxies - Part 2 Microscopy studies. Journal of Materials Science. 1986;21(7):2475–2488. [Google Scholar]

- 24.Yee AF, Pearson RA. Toughening of Plastics II. Plast. Rub. Inst.; London: 1985. p. 2/1. [Google Scholar]

- 25.Huang Y, Kinloch AJ. The role of plastic void growth in the fracture of rubber-toughened epoxy polymers. Journal of Materials Science Letters. 1992;11(8):484–487. [Google Scholar]

- 26.Huang Y, Kinloch AJ. THE SEQUENCE OF INITIATION OF THE TOUGHENING MICROMECHANISMS IN RUBBER-MODIFIED EPOXY POLYMERS. Polymer. 1992;33(24):5338–5340. [Google Scholar]

- 27.Brady TE, Yeh GSY. Yielding behavior of glassy amorphous polymers. Journal of Applied Physics. 1971;42(12):4622–4630. [Google Scholar]

- 28.Brady TE, Yeh GSY. Similarity between craze morphology and shear-band morphology in polystyrene. Journal of Materials Science. 1973;8(8):1083–1094. [Google Scholar]

- 29.Chikhi N, Fellahi S, Bakar M. Modification of epoxy resin using reactive liquid (ATBN) rubber. European Polymer Journal. 2002;38(2):251–264. [Google Scholar]

- 30.Lee VA, Rawls HR. Compliant phase reduces polymerization shrinkage in dental composite resin. Journal of Applied Polymer Science. 2005;97(6):2306–2310. [Google Scholar]

- 31.Lee VA, C. HL, Rawls HR. Compliant Aggregates Reduce Polymerization Contraction Stress in Dental Composite Resins. IADR Abstracts. 2007 Abstract 1588. [Google Scholar]