Abstract

Exposure to volatile organic compounds (VOCs) from bridge painting was measured in New York City and New Jersey during the summer and fall seasons from 2005 to 2007. The effect of painting activities (paint coating layer, confinement setup, and application method) and meteorological conditions (temperature, humidity, and wind speed) on solvent exposure to aromatic, ketone, ester, and alkane compounds were individually evaluated. Mixed-effect models were used to examine the combination effects of these factors on the air concentration of total VOCs as the individual compound groups were not present in all samples. Air concentration associated with spraying was not affected by meteorological conditions since spraying was done in a confined space, thus reducing their impact on solvent air concentration. The mixed models for brushing and rolling samples included two fixed factors, i.e. application method and temperature, and one random factor, i.e. sampling day. An independent dataset (daily air samples) was used to validate the mixed model constructed for brushing and rolling samples. The regression line of the predicted values and actual measurements had a slope of 1.32 ± 0.15 for daily brushing and rolling samples, with almost all points being within the 95% confidence bands. The constructed model provides practical approaches for estimating the solvent exposure from brushing and rolling activities among construction painters. An adjusted mean air concentration derived from the activity-specific spray samples was the best estimate for that painting application.

Keywords: construction, occupational exposure, oil-based paints, painting, solvents

INTRODUCTION

Steel bridges need to be rehabilitated and repainted regularly to prevent rust and corrosion. Oil-based paint is widely used for bridge maintenance despite its declining usage in other settings (Bratveit et al., 2004). Oil-based paint solvents are a mixture of chemicals, including aliphatic and aromatic hydrocarbons (e.g. toluene and xylene), oxygenated solvents (e.g. ketones and methyl ethyl ketones), alcohols (e.g. ethanol and butanol), and esters (e.g. n-butyl acetate) (Seedorff and Olsen, 1990). Since paint solvents are volatile organic compounds (VOCs), they are readily released into the air during and after applying paint to surfaces. Thus, construction painters are continuously exposed to solvents throughout their working lifetime.

Long-term solvent exposure has been associated with neurobehavioral impairments (Baker, 1994; Ruijten et al., 1994; Seeber et al., 1996) but not consistently across all the studies due to differences in study design, methods of neuropsychological evaluations, and misclassification of exposure (Anshelm Olson 1982; Spurgeon et al., 1992; Dick et al., 2000). Accurate estimation of long-term solvent exposure is particularly challenging since historical solvent exposure data are often incomplete or never collected. Specific chemical components and their proportions in paint have varied over time in order to meet consumer expectations for high quality and performance at a low cost, as well as the legal regulations for air pollution emissions (Weiss, 1997). Furthermore, bridge painters are generally exposed to complex and varying mixtures of solvents, which make quantitative estimation of their historical exposure levels even more difficult.

Cumulative lifetime exposure estimation has been proposed as one approach with sufficient accuracy to evaluate lifetime exposure to total hydrocarbons (Seeber et al., 1996). Cumulative lifetime exposure in the workplace is based on organic solvent exposure monitoring and information on each painter's job history. A common approach to determine a painter's job history is through detailed painting questionnaires. However, very few quantitative solvent exposure measurements from bridge painting have been reported. The link between the solvent exposure levels and influencing factors, such as painting activities and meteorological conditions, has also not been documented. Improvements in lifetime solvent exposure estimation can greatly facilitate the construction of an exposure–response relationship from which potential risk to develop neurological diseases among bridge painters can be determined. The objective of the current study is to investigate the relationship between air concentrations of VOCs during bridge painting and potential influencing factors, including paint application methods (spraying, rolling, and brushing), paint coating type (primer, intermediate, and finish coatings), and meteorological conditions (temperature, humidity, and wind speed) through multivariate regression models. These regression models then can be used to predict solvent exposure during bridge painting.

METHODS

Air samples

Sample collection.

All air samples during bridge painting were collected using personal samplers: 3M Organic Vapor Monitors (OVM 3500). Outdoor paint is applied to steel at air temperatures between 4°C and 32°C and relative humidity of <85% for their optimal performance. Thus, most samples in this study were collected in summer and fall, the two main working seasons for bridge painting. The study protocol for collection of personal air samples was approved by the Institutional Review Board for Human Subjects from the University of Medicine and Dentistry of New Jersey. All participants signed informed consent forms.

There were two types of air samples collected in this study: activity-specific air samples (N = 57, from 16 sampling days) and daily workday air samples (N = 30, from 10 subjects) (Table 1). The activity-specific samples measured personal air concentrations during specific painting activities (1–4 h), which were expected to be the peak exposures to a painter. The sampling duration for the activity-specific sample was the time period that a painter engaged in one specific application method. The daily workday air samples represent the cumulative personal solvent exposure during a full work shift (∼8 h), including both painting activities and non-painting activities. The break time for lunch was recorded but not included in the time duration when calculating the air concentration for both activity-specific samples and daily workday samples. No record of whether shorter breaks were taken was documented.

Table 1.

Comparison of two types of air samples from bridge painting

| Activity-specific air samples | Daily workday air samples | |

| Time | 2005–2007 | 2006–2009 |

| Location | New York City and New Jersey | New York, New Jersey, and Pennsylvania |

| Sampling device | OVM | OVM |

| Number of samples | Fifty-seven samples collected in 16 field trips. Each field trip: three to four samples from three to four painters and one field blank | Thirty samples collected by 10 subjects. Each subject: three samples from three working days and one field blank |

| Sampling duration | 1–2 h for spray samples (in confinement). 3–4 h for brush/roller samples (mostly in open space) | A full work shift (∼8 h) |

| Questionnaire | Brand of paint, coating layers, meteorological conditions, application methods, and duration | Brand of paint, application methods, sampling duration, and duration for each painting activity |

| Transportation | Stored in a cooler and sent back to the laboratory in the same day | Mailed back to the laboratory at room temperature within 1 week |

| Analyzing methods | NIOSH 1500/1501 | NIOSH 1500/1501 |

| Data analysis | Model construction | Model evaluation (prediction) |

Sample analysis and quality controls.

A standard analytical procedure (NIOSH 1500/1501) was used to analyze the air samples within 1 month of their receipt. Briefly, the organic chemicals were desorbed from the charcoal pads of badges using a mixture of acetone:CS2 (2:1 in volume) and analyzed by Gas Chromatography - Mass Spectrometry (GC-MS, HP6890) operated in the split mode. Twenty-seven major chromatogram peaks were identified in both activity-specific samples and daily samples based on a comparison of retention times and mass spectra to peaks from a calibration standard, Japanese Indoor Air Standards Mix (Supelco, 47537-U). The chemical compounds identified in the air samples were grouped into four classes of compounds: aromatic compounds, esters, alkanes, and ketones plus alcohols represented as a ketone group. A chemical with a concentration lower than its method detection limits (MDL) was assigned ½ MDL as its concentration.

One field blank was collected within each field trip for activity-specific samples and one field blank was collected along with the three daily samples returned by each subject by mail (Table 1). All the field blanks were analyzed following the same procedure as the air samples. To monitor any potential loss during the mailing process, 5 ng of each target compound was spiked onto five OVM badges in the laboratory. These spiked badges were sent out and mailed back within 1 week. The recovery rates of the spiked standards from these five badges, which were considered as positive controls, ranged from 71 to 90%, so no correction for losses of compounds during collection or storage of badges was applied to the samples.

Auxiliary information collected

For the activity-specific sampling, study personnel recorded information on application methods, working environments, paint brands, and paint coatings. For the daily solvent exposure monitoring, each participant completed a simple log sheet describing the paint brands, application methods, overall sampling duration, and duration for each painting activity. The completed log sheets and the collected air samples were returned to us by mail. Meteorological conditions for both activity-specific samples and daily samples were time-averaged values and obtained from the National Climatic Data Center.

Three common application methods, spraying, rolling, and brushing, are used for bridge painting. Current regulations require spraying to be conducted in a confined working space to minimize environmental release of toxic compounds. Wearing protective equipment, both half-face mask and appropriate clothing, is mandated during spraying operation. Rolling and brushing are more often conducted in an open working space. Rolling is a more efficient and even painting method than brushing. On the other hand, brushing is good to use on uneven surfaces or the spots hard to reach (e.g. corner or very narrow areas).

A three-coat system (primer, intermediate, and finish coatings) using a single paint brand is currently the most widely used system for bridge painting (National Steel Bridge Alliance, 2010). The major chemicals present in different coating layers vary due to their specific function in the painting process. But the chemical compositions in each coating layer are quite similar across different paint brands. Thus, rather than paint brands, the influence of paint coatings on the VOC emissions from painting was assessed.

Statistical analysis

Activity-specific exposure samples were used to explore the associations between the air concentrations of four groups of compounds and the potential influencing factors, including painting method, paint coating type, meteorological condition, and if the painting was done in a confinement (SigmaPlot for Windows version 10.0). To account for any potential interaction among these factors, a multivariate regression model then was constructed based on activity-specific samples. Since not all compounds were present in all samples, there were too few data points to fit a multivariate linear regression model separately to each of the four groups of compounds. Thus, multivariate analysis was only applied to the total volatile organic compound (TVOC) concentrations (SAS for Windows version 9.1). There were between three and five activity-specific exposure samples collected on a single sampling day. To account for between-day variability, a mixed-effect model was constructed with sampling day as the grouping factor.

A three-step model selection procedure was performed in this study based on Akaike’s Information Criterion (AIC). AIC score, which takes into account both the goodness of fit and the complexity of an estimated statistical model, was used as an evaluation criterion for model selection. Briefly, we first constructed simple mixed models for each individual factor separately. Then, a multivariate mixed model was constructed including the factors that were statistically significant from the individual models. Finally, the multivariate mixed model was compared with the individual models with significant variables and a full mixed model with all factors to select the best model based on the evaluation criterion. Lower values of AIC indicate the preferred model, i.e. the one with the fewest parameters that still provided an adequate fit to the data.

The prediction ability of the mixed model was assessed using an independent dataset, the daily exposure samples. The daily exposure samples included the solvent exposure from painting activities and non-painting activities within one work shift, collected from different painters, and on different days than the activity-specific samples. The predicted exposure level for each painting activity in daily samples was estimated from the mixed models separately, which assumed independent contributions to the solvent exposure from sequential painting activities. The total exposure levels for each daily sample with multiple painting tasks were calculated as the sum of the time-weighted predicted values for each painting task from the model.

RESULTS AND DISCUSSION

Descriptive statistics

For activity-specific samples, the relations between solvent exposure from four groups of compounds and application methods, paint coating layers, and meteorological conditions were investigated separately.

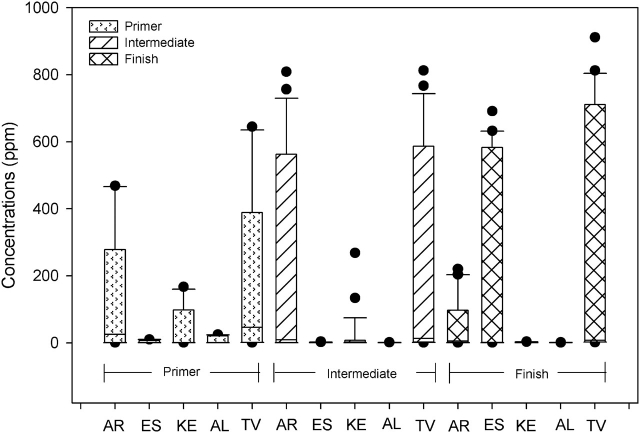

Application methods.

Air samples were collected while painting using three application methods: spraying, rolling, and brushing. The concentrations of aromatics, esters, and ketones during spraying are one to two orders of magnitude higher than those from the other two methods (Fig. 1a). Two reasons for the higher exposure concentrations from spraying are that the amount of paint used per hour in spraying is much higher than rolling and brushing, and the spraying was conducted in a confined working space due to legal regulations. Thus, air concentrations accumulate over the time that spraying takes place. Rolling and brushing were usually conducted in the open space that allowed the emissions to disperse. The solvent exposure level from rolling is about an order of magnitude higher than brushwork, except for a few ‘outliers’ in aromatics and alkane groups of compounds during brushwork (Fig. 1b). The two outliers in the air concentrations during the brush application were collected on the same day when brush painting was conducted in a confined space following preparing the bridge surface using a blasting technique. During blasting, a confinement is erected to avoid the spread of potentially contaminated particles to the surrounding neighborhood. The air concentration measured when brushing was done in a confinement was an order of magnitude higher than the median value of the air concentration when brushing was done in an open space, though still an order of magnitude lower than the median spraying value. Thus, the type of painting application methods and the usage of working confinement influence the potential solvent exposure greatly.

Fig. 1.

Concentrations of aromatics, esters, ketones, alkanes, and TVOCs from (a) spraying painting and (b) rolling and brushing painting.

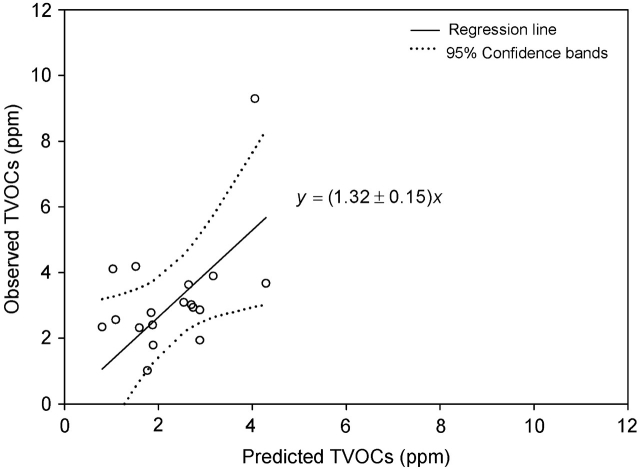

Coatings.

A three-coating layer painting system (primer, intermediate, and finish coatings) has been applied on all the bridges where we collected air samples in this study. Figure 2 shows the distribution of four groups of compounds in the air samples collected while each coating layer was used. While measurable concentrations of aromatic compounds were present when each of the three coating layers was being applied, the highest levels occurred with the primer and intermediate coatings. Esters were only associated with the finish coating. Ketones and alkanes mainly existed when the primer coating was applied. Since most of the activity-specific samples from spray painting (15 of 18 samples) were collected when intermediate or finish coatings were applied, the alkane compounds in these samples were very low (Fig. 1a). Thus, the chemical composition in the air varied when different coating layers were applied during painting. The specific compound classes observed were consistent with the composition reported in the paint manufacturer's material safety data sheets.

Fig. 2.

Concentrations of aromatics (AR), esters (ES), ketones (KE), alkanes (AL), and TVOCs (TV) from primer, intermediate, and finish coatings.

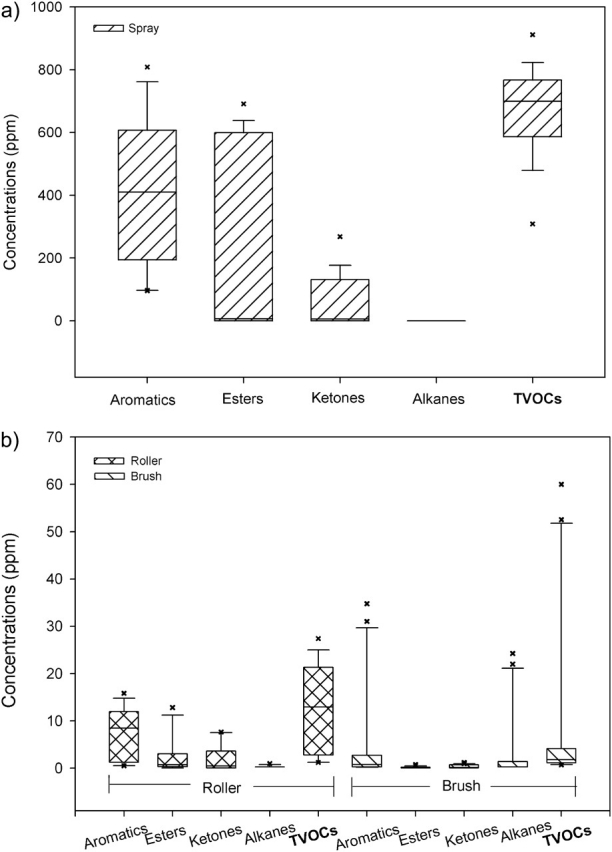

Meteorological conditions.

Meteorological conditions recorded in this study included temperature, wind speed, and relative humidity. The meteorological conditions, especially wind speed, had little impact on solvent air concentrations during spraying activities, which were conducted in a confined space. The concentrations of daily average TVOCs for brushing and rolling samples generally increased with increasing temperatures (Fig. 3a), decreasing wind speed (Fig. 3b), but had no consistent pattern with relative humidity (Fig. 3c). Higher temperature increases volatilization of chemical compounds resulting in higher emission rates. Wind speed dilutes air concentrations for similar emission rates reducing solvent exposure, especially for the samples collected in an open working space. However, the trend of the air concentrations decreasing with increasing wind speed is weak (R2 = 0.26). Wind direction and its relative position to the painters could not be determined because of the local eddies resulting from traffic movement and structures near where the work was being done and the continued movement of the painters as they work. Thus, the average wind speed measured at a central monitoring site is not a good reflection of what was being encountered when the painting was being done.

Fig. 3.

Concentrations of daily averaged TVOCs, alkanes, esters, ketones, and aromatics vary with (a) temperature (°C), (b) wind speed (m.p.h.), and (c) humidity (%) for brushing and rolling samples. Regression lines in (a) and (b) are for TVOCs.

Mean and median concentrations along with the standard deviations of both activity-specific samples and daily samples are summarized in Table 2. The mean exposure concentrations and standard deviations in activity-specific samples are much higher for three of the four groups of compounds (except alkanes) than the daily sample values. One reason for the large differences in the mean concentrations between the two types of samples is daily samples were collected across an 8-h work shift as reported on the log sheets that includes time required for setup and break down of a work shift in addition to the actual painting. Thus, the time-weighted average concentration of daily samples could be reduced accordingly. Alkanes were not in present in two coatings applied by spraying when both activity-specific samples and daily samples were taken, resulting in their concentrations being near their detection limit (Table 2). The usage of painting method, particularly spraying, shows a dominant contribution to solvent exposure. Compared to the other painting applications, the emission rate from spray painting is higher and the air concentration associated with an emission accumulates when a confinement is present.

Table 2.

Concentrations of aromatics, esters, ketones, and alkanes in activity-specific exposure samples and daily solvent exposure samples

| Chemical groups | Activity-specific exposure concentration (N = 57) |

Daily exposure concentrationa (N = 30) |

||||||||||

| Spray (N = 18) (concentration in p.p.m.) |

Brush and roller (N = 39) (concentration in p.p.m.) |

Spray (N = 12) (concentration in p.p.m.) |

Brush and roller (N = 18) (concentration in p.p.m.) |

|||||||||

| Mean | Median | SD | Mean | Median | SD | Mean | Median | SD | Mean | Median | SD | |

| Aromatics | 410.1 | 409.5 | 242.1 | 6.5 | 1.4 | 9.3 | 87.3 | 91.0 | 60.6 | 1.1 | 0.9 | 1.2 |

| Esters | 209.0 | 6.0 | 300.6 | 1.0 | <0.1 | 2.6 | 23.7 | <0.1 | 35.4 | <0.1 | <0.1 | NC |

| Ketones | 50.1 | 5.4 | 80.8 | 0.9 | 0.4 | 1.8 | 0.2 | 0.2 | 0.2 | 0.3 | <0.1 | 0.8 |

| Alkanes | <0.3 | <0.3 | NC | <3.0 | <0.3 | 6.9 | <0.4 | <0.4 | NC | 1.7 | 1.7 | 0.9 |

| TVOCs | 669.5 | 699.1 | 138.3 | 11.5 | 2.9 | 16.2 | 112 | 104 | 43.9 | 3.2 | 2.9 | 1.7 |

N, number of air samples; NC, could not be calculated; SD, standard deviation.

Samples collected during mixing paints and cleaning paints with solvents or in a ventilated working environment were not included.

It was observed that five daily samples from three subjects measured during spraying were about two orders of magnitude lower than the air concentrations from activity-specific samples. After contacting the subjects, we learned that these daily spraying samples were collected in a ventilated working environment which would decrease the expected air concentrations and for which we did not have matching activity-specific samples. Additional activities associated with solvent-based painting, such as paint mixing/thinning and solvent-based cleaning, could also have solvent concentrations several times higher than encountered during brushing and rolling. However, that information was also not recorded in our current activity-specific samples. Thus, these daily samples are not included in the Table 2 for comparison.

Exploring the associations between the air concentrations and each of the factors separately does not account for potential interaction effects between the factors. In addition, those analyses did not allow for quantification of the relative contributions of the factors for predicting solvent exposure based on painting behavior. The within-day variance (10,590.) for activity-specific spray sample is about one-third of the between-day variance (39,580.) and the within-day variance (30.37) for activity-specific brush and roller samples is about one-fifth of the between-day variance (146.4) indicating that the within-day variances are much smaller than the between-day variances. Therefore, mixed multivariate regression model was used next to evaluate the combination effects from these multiple factors on TVOCs for the activity-specific samples.

Multivariate analysis

Because the air concentrations of solvents during spray painting were all collected in a confinement and were significantly higher than those during brushing and rolling (Table 2), separate mixed models were fitted to spraying samples and to brushing and rolling samples.

The TVOC concentrations from spraying samples approximate a normal distribution. None of the coefficient estimates were statistically significant at a level of 0.05 in the individual mixed models, consistent with the results found in the scatter plots between solvent concentration in spraying samples and each of the factors (meteorological conditions and coating types, data not shown). All the spraying activities were legally required to be conducted in a confined space, which limits the influence of meteorological conditions on their air concentrations. Types of coating showed some potential influences on solvent exposure. However, other factors not recorded, such as pot pressures (to provide enough material to the spray gun and atomize the material as well) and spray gun techniques (FHWA, 1998), probably play more important roles in determining the VOC exposure from spraying. Thus, in the current study, the mean concentration alone is a good estimator of the VOC exposure during spray painting.

The distribution of TVOC concentrations for brushing and rolling samples is right skewed. Natural log transformation was therefore applied before fitting the regression model. The application method (P = 0.0034) and temperature (P = 0.024) are the two significant factors from the individual mixed model. Based on the AIC score, the best mixed selected model for brushing and rolling samples only include these two fixed factors and one random factor, i.e. sampling days (Table 3). The coefficient estimates of the application methods indicate that the solvent exposure during rolling contribute more exposure than brushing, consistent with results in Fig. 1b. A positive coefficient estimate in the temperature indicates a higher exposure concentration in a working environment with higher temperature. However, the confinement was not a significant factor as we expected. The possible reason is that too few brushing and rolling samples were collected in a confined space (total five samples) although air concentration was one order of magnitude higher when a confinement was used.

Table 3.

Outputs from the Mixed models for TVOCs

| Mixed model | Brushing and rolling samples |

||

| Fixed effects | Estimate | Standard error | Pr (>|t|) |

| Intercept | −0.19 | 0.74 | 0.80 |

| Method (rolling) | 1.04 | 0.38 | 0.011 |

| Temperature (°C) | 0.067 | 0.036 | 0.073 |

| Random effects | Sampling days σb = 0.59 | ||

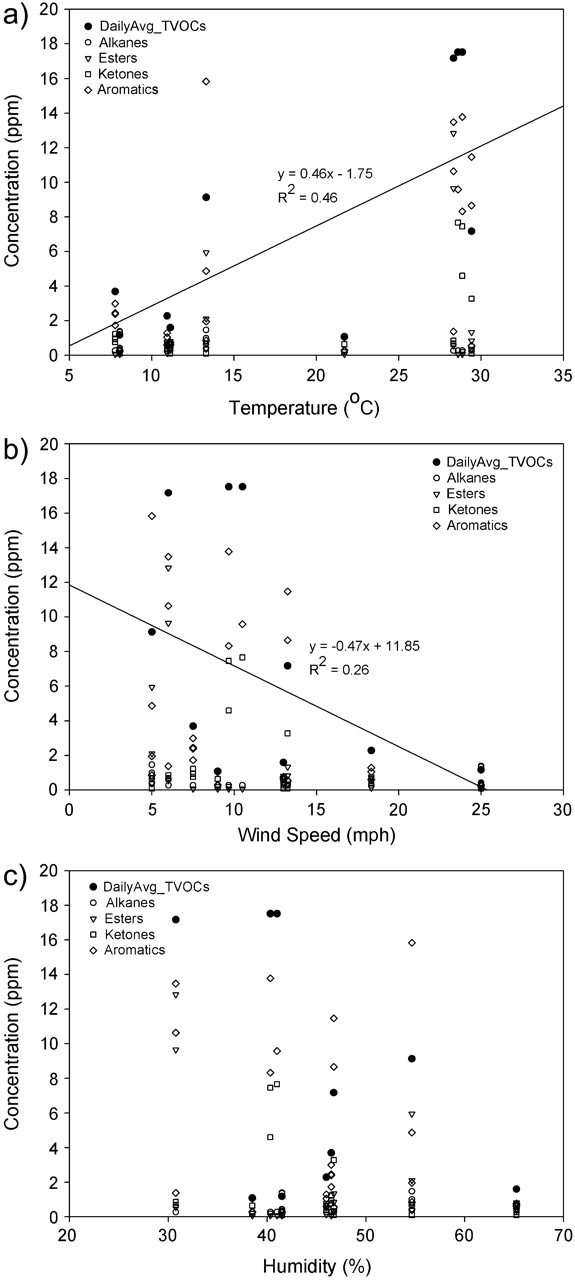

Model applications

The mixed model based on application method and temperature using the activity-specific samples was used to predict the TVOC concentrations for the daily brushing and rolling samples. The inputs for the model were obtained from the log sheets to determine application method and from the National Climatic Data Center for the meteorological data matching to the day and time period the sample was collected. The measured and predicted TVOC air concentrations from the model scatter around a regression line with a slope of 1.32 ± 0.15 for the daily brushing and rolling samples (Fig. 4), indicating that the predicted exposure estimates from the model are good estimates of the actual personal air concentration measured. The regression line was forced to go through the origin since the prediction value should be zero when painting was not being done. The 95% Working–Hotelling confidence bands were constructed around this line, enabling us to see the region in which the entire regression line lies and the uncertainty of the estimates for the predicted samples (Kutner et al., 2004). There are only a few values outside the confidence bands (Fig. 4), indicating the appropriateness of the fitted regression function.

Fig. 4.

Predicated values versus actual measurements of daily TVOCs for brushing and rolling samples with fitted regression line and its 95% confidence bands.

However, the mean air concentration of activity-specific samples from spraying is ∼6-fold higher than that of daily spraying samples (Table 2). Several different conditions existed between the daily and activity-specific samples that could affect the air concentrations. All the daily samples in the study were collected from a single group of painters who were spraying paint in a much larger confined working space than was used by the painters when the activity-specific spraying samples were collected. Thus, for a similar spray rate, this would result in lower air concentrations due to greater dilution that would occur in the larger confinement. The daily samples were also collected between the end of November and the beginning of December when the ambient temperatures were <42°F, an unusual meteorological condition for bridge painting since paint typically needs warmer temperatures to properly adhere to surfaces. To compensate for the low ambient temperatures, a series of heaters were placed in the confinement. However, the temperature at the surface of the bridge would be expected to approach the ambient air temperature and the entire confinement was not heated, which would reduce the evaporation rate of the solvent vapor, again resulting in a lower air concentration than would be expected during the conditions sampled for the activity-specific field conditions. Lastly, the estimated concentrations of daily samples assumed that the time recorded on log sheet was spent solely painting without considering additional activities that a painter may engage in during a typical workday, e.g. time spent preparing the painting site, cleaning after painting, or downtime between painting. These auxiliary activities would likely be classified by a painter as time spent in painting activities but are expected to result in lower exposures than encountered during actual painting. We observed that painters often move around to set up the painting equipment and prepare the paint before each paint application and those activities can account for several hours during the workday. Spray painting conducted in a confinement usually takes longer time to set up and remove all the equipment compared to brushing and rolling work, which is more often done in an open space. Thus, using the mean concentration from the activity-specific samples is likely to result in an overestimation of the actual personal air concentration monitored during daily spraying operations and for the winter time painting activity.

Occupational exposure to organic solvent mixtures has been evaluated for various painting activities, such as painting automobiles (Moen and Hollund, 2000; Vitali et al., 2006), aircraft (Uang et al., 2006), within shipyards (Lee et al., 2005), and during building construction and maintenance (Riala et al., 1984; Bigelow and Buchan, 2004). Solvent-based paints are also used during bridge painting, but the exposure levels have not been reported. In the current study, personal air samples were analyzed for VOCs during highway/subway steel bridge painting. The average air concentrations of TVOCs were 670 ± 138 p.p.m. for spraying samples and 11.5 ± 16.2 p.p.m. for brushing and rolling samples. While painting the interior of buildings, the air concentrations measured for painters using solvent-based paints were at 235 p.p.m. using spray painting and 194 p.p.m. using roller and brush painting in the rooms without mechanic ventilations (but with door open) (Riala et al., 1984). The authors also indicated that the concentration of solvent vapor for brushing and rolling samples was reduced to 38 p.p.m. by the strong draft created by opening the doors and windows, similar to the conditions that the roller and brush painting done outdoors. For spraying samples, the actual personal inhalation exposure should be much lower than the levels measured considering the reduction in exposure from the use of personal protection equipment (respirators) during spraying operation. When the samplers were worn inside the personal respiratory equipment during a car-painting process, the mean air concentration of spraying samples was as low as 13.7 p.p.m. (Moen and Hollund, 2000). Thus, the dose from exposure for spray painters who wear respirators all the time could be lower than that for brush or roller painters who often did not wear respirators. This modification factor needs to be considered when estimating the actual inhaled solvent exposure dose in risk assessment.

The air concentration during painting depends not only on the type of painting being done but also on other parameters related to the paint itself and meteorological conditions, which can be used to indirectly estimate acute solvent exposure when measurement data are not available. In the current study, we constructed a mixed-effect model to quantify the contributions of important influencing factors on a solvent exposure during bridge painting. Application methods were the most critical factors affecting solvent exposure for all the samples, with temperature also contributing to the variability in the solvent exposure levels for brushing and rolling samples. This approach, constructing a linear regression model based on activity information, was also used in Bigelow and Buchan (2004) study to predict solvent exposure during painting of buildings. However, a different set of variables, including type of paint products (alkyd paint, lacquer, sand sealer, and stain), paint supplies, application location (indoor/outdoor), and temperature, were included in the model. The differences between most of the factors included probably reflect the different working environments in two studies. Comparing the four types of paint products in Biglow's study, the TVOC contents from three types of coating layers (solvent-based paints) in the current study did not differ significantly despite different chemical compositions across the coating layers. And also the application location and paint supplies in our study were almost the same within each painting activity: spraying paint in confinement with spraying guns or brushing and rolling painting in an open space with open 5-gal pail of paint. The mixed model constructed in our study was validated by an independent dataset (daily samples), which was not performed in Biglow's study. The validated mixed model then can be used to predict solvent exposure concentrations during bridge painting based on their application method and temperature for brushing and rolling samples. The air concentrations associated with spraying can be estimated using the mean concentrations of activity-specific spraying samples adjusted by the time spend spraying relative to the amount of preparation time. Certainly, including information in the future to quantify the solvent exposure contributions from ventilated working environments or mixing paint and solvent-cleaning paint activities could extend the accuracy of the models in predicting daily solvent exposure.

Characterization and quantification of solvent exposure for construction painters is a key component in analyzing epidemiological studies to establish a dose–response relationship and for risk assessment from exposure to solvents during painting. Various approaches have been used to estimate lifetime solvent exposure in epidemiological studies, such as using years of exposure as a surrogate dose (Johnson, 1986), questionnaire data (Fidler et al., 1987), or job-exposure matrix (Glass et al., 1994). These approaches generally provide a ranking of exposure in order to determine if individuals with greater exposure more likely show health effects (e.g. cognitive impairments), however, do not provide a quantitative estimate of exposure during painting as required for a risk assessment. Glass et al. (1994) used the above three approaches to evaluate potential hazards to solvents during the manufacturing of paint and indicated that years alone at a specific job allocation was not satisfactory in estimating exposure, but when air monitoring data collected as part of an occupational hygiene program was combined with a job-exposure matrix, the estimated exposures were within the occupational standards. Air monitoring data among construction painters are limited; therefore, epidemiological studies of construction painters have generally relied on years of exposure or using estimates of gallons of paint applied with a job matrix questionnaire describing different applications methods to develop an exposure matrix (Fidler et al., 1987; Grosch et al., 1996). The results from the current study provide estimates of air concentrations during the three primary application methods, spraying, rolling, and brushing, which facilitate a historical solvent exposure reconstruction for use in epidemiological studies of construction painters and for risk characterization from solvent exposures.

FUNDING

National Institute for Occupational Safety and Health (RO1 OH008198); National Institute of Environmental Health Sciences–sponsored University of Medicine and Dentistry, New Jersey, Center for Environmental Exposures and Disease (P30ES005022).

Acknowledgments

The authors thank the New York City, New Jersey, and Pennsylvania working unions and New Jersey Department of Transportation for field sampling support. The statements, findings, conclusions, views, and recommendations are those of the authors and do not necessary reflect the views of the organization. One author (H.Q.) also appreciates the receipt of a scholarship from the Air Pollution Educational and Research Grant Program of the Mid-Atlantic States Section of the Air & Waste Management Association.

References

- Anshelm Olson B. Effects of organic solvents on behavioral performance of workers in the paint industry. Neurobehav Toxicol Teratol. 1982;4:703–8. [PubMed] [Google Scholar]

- Baker EL. A review of recent research on health effects of human occupational exposure to organic solvents (a critical review) J Occup Med. 1994;36:1079–91. doi: 10.1097/00043764-199410000-00010. [DOI] [PubMed] [Google Scholar]

- Bigelow PL, Buchan RM. Development of an exposure matrix for construction painters based on specific work tasks. CDC/NIOSH 1 K01 OH00138-01. Fort Collins, CO: Department of Environmental Health, Colorado State University; 2004. [Google Scholar]

- Bratveit M, Hollund BE, Moen BE. Reduced exposure to organic solvents by use of water-based paint systems in car repair shops. Int Arch Occup Environ health. 2004;77:31–8. doi: 10.1007/s00420-003-0483-0. [DOI] [PubMed] [Google Scholar]

- Dick F, Semple S, Chen R, et al. Neurological deficits in solvent-exposed painters: a syndrome including impaired colour vision, cognitive defects, tremor and loss of vibration sensation. Q J Med. 2000;93:655–61. doi: 10.1093/qjmed/93.10.655. [DOI] [PubMed] [Google Scholar]

- FHWA. US Department of Transportation Federal Highway Administration Field Manual for Bridge Painting Inspection (FHWA-RD-98-084) 1998 Available at http://www.tfhrc.gov/hnr20/bridge/intro.htm. Accessed 2010. [Google Scholar]

- Fidler AT, Baker EL, Letz RE. Estimation of long term exposure to mixed solvents from questionnaire data: a tool for epidemiological investigations. Br J Ind Med. 1987;44:133–41. doi: 10.1136/oem.44.2.133. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Glass DC, Spurgeon A, Calvert IA, et al. Retrospective assessment of solvent exposure in paint manufacturing. Occup Environ Med. 1994;51:617–25. doi: 10.1136/oem.51.9.617. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Grosch JW, Neale AV, Demers RY. Neurobehavioral and health-related deficits in solvent-exposed painters. Am J Ind Med. 1996;30:623–32. doi: 10.1002/(SICI)1097-0274(199611)30:5<623::AID-AJIM11>3.0.CO;2-5. [DOI] [PubMed] [Google Scholar]

- Johnson ES. Duration of exposure as a surrogate for dose in the examination of dose response relations. Br J Ind Med. 1986;43:427–9. doi: 10.1136/oem.43.6.427. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kutner MH, Nachtsheim C, Neter J. Applied linear regression models. 4th. Boston, NY: McGraw-Hill/Irwin; 2004. [Google Scholar]

- Lee CR, Jeong KS, Kim Y, et al. Neurobehavioral changes of shipyard painters exposed to mixed organic solvents. Ind Health. 2005;43:320–6. doi: 10.2486/indhealth.43.320. [DOI] [PubMed] [Google Scholar]

- Moen BE, Hollund BE. Exposure to organic solvents among car painters in Bergen, Norway. Ann Occup Hyg. 2000;44:185–9. [PubMed] [Google Scholar]

- National Steel Bridge Alliance. (2010) Steel bridge design handbook, chapter 23: corrosion protection of steel bridges. Available at http://www.aisc.org/contentNSBA.aspx?id=20244. Accessed 2010. [Google Scholar]

- Riala R, Kalliokoski P, Pyy L, et al. Solvent exposure in construction and maintenance painting. Scand J Work Environ Health. 1984;10:263–6. doi: 10.5271/sjweh.2332. [DOI] [PubMed] [Google Scholar]

- Ruijten MW, Hooisma J, Brons JT, et al. Neurobehavioral effects of long-term exposure to xylene and mixed organic solvents in shipyard spray painters. Neurotoxicology. 1994;15:613–20. [PubMed] [Google Scholar]

- Seeber A, Sietmann B, Zupanic M. In search of dose-response relationships of solvent mixtures to neurobehavioural effects in paint manufacturing and painters. Food Chem Toxicol. 1996;34:1113–20. doi: 10.1016/s0278-6915(97)00082-3. [DOI] [PubMed] [Google Scholar]

- Seedorff L, Olsen E. Exposure to organic solvents—I. A survey on the use of solvents. Ann Occup Hyg. 1990;34:371–8. doi: 10.1093/annhyg/34.4.371. [DOI] [PubMed] [Google Scholar]

- Spurgeon A, Gray CN, Sims J, et al. Neurobehavioral effects of long-term occupational exposure to organic solvents: two comparable studies. Am J Ind Med. 1992;22:325–35. doi: 10.1002/ajim.4700220306. [DOI] [PubMed] [Google Scholar]

- Uang SN, Shih TS, Chang CH, et al. Exposure assessment of organic solvents for aircraft paint stripping and spraying workers. Sci Total Environ. 2006;356:38–44. doi: 10.1016/j.scitotenv.2005.02.029. [DOI] [PubMed] [Google Scholar]

- Vitali M, Ensabella F, Stella D, et al. Exposure to organic solvents among handicraft car painters: a pilot study in Italy. Ind Health. 2006;44:310–7. doi: 10.2486/indhealth.44.310. [DOI] [PubMed] [Google Scholar]

- Weiss KD. Paint and coatings: a mature industry in transition. Prog Polym Sci. 1997;22:203–45. [Google Scholar]