Abstract

This paper describes a technique to superconductively splice multifilament MgB2 wires. To date the technique has achieved joints capable of carrying a superconducting current of 200 A at 10 K in self field. Joints details, as well as testing methods and results are presented here.

Index Terms: HTS/LTS magnet, MgB2 superconductor, NMR magnet, persistent mode

I. INTRODUCTION

Since the discovery of superconductivity in MgB2 at temperature of 39 K in 2001, conductor development has advanced to the stage where MgB2 superconducting wire in kilometer-length is commercially available [1]. A variety of applications have been proposed in making use of the new conductor [2]. In an earlier paper, we reported our progress in the construction and test of an MgB2 superconducting magnet [3]. One important technique that will proliferate adoption of MgB2 conductor in the applications of NMR and MRI magnets is to splice MgB2 wires superconductively. A typical superconducting magnet consists of several coils. In order to operate the magnet in persistent mode, the joints between the coils must be superconducting. The first successful splice, reported in 2005, involves splicing NbTi wire and MgB2 tape for an MgB2 coil operated at 4.2 K in persistent mode [4]. Another MgB2 – MgB2 joint result, based on a field-decay measurement of a MgB2 loop carrying 30 to 40 A at 20 K in zero background field, was reported in 2006, having a joint resistance of < 10−14 Ω [5]. In this paper we report our progress in developing a technique to make superconducting joints between round 18-filament MgB2 wires.

II. JOINT FABRICATION

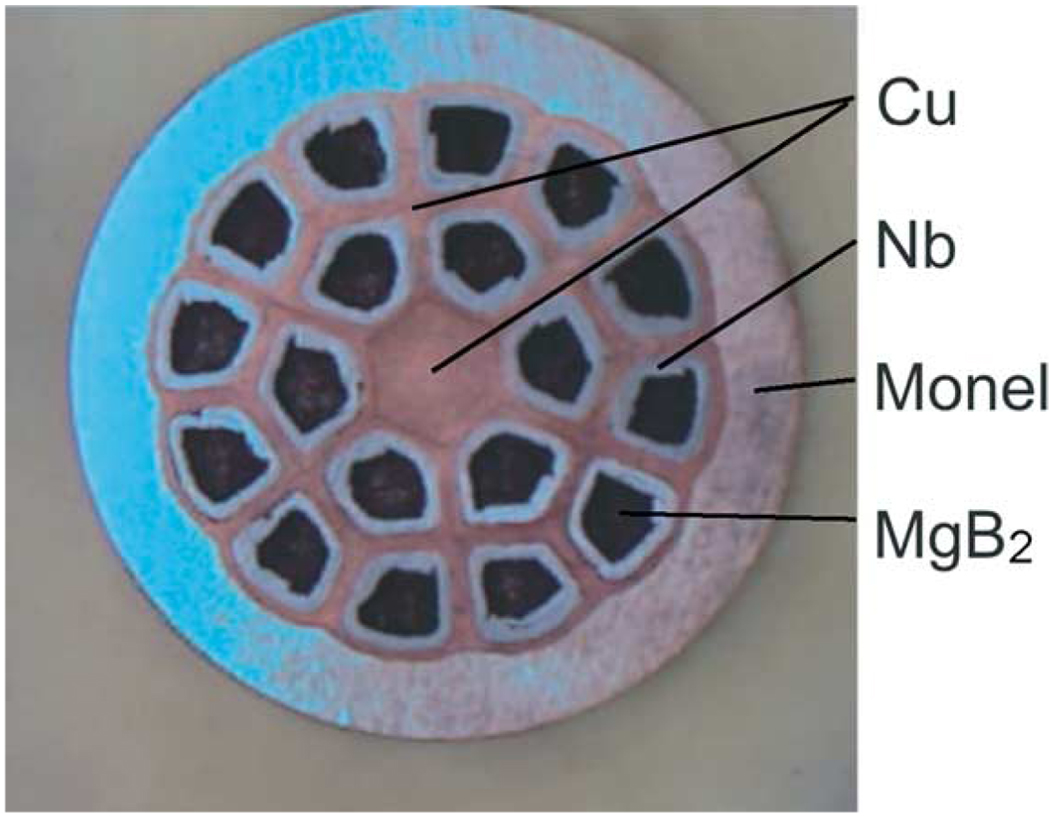

The MgB2 used in this work was developed by Hypertech Research Inc [1]. It is designated as an “18 + 1 Nb/Cu/Monel” multifilament wire. Fig. 1 shows a photograph of the cross section of the wire. The wire is manufactured with the so-called Continuous Tube Filling and Forming (CTFF) process [1]. During this process,Mg + B powder mixed in stoichiometric ratio is wrapped inside niobium strip to form a tube. The tube is then inserted inside a seamless copper tube and drawn to form a monofilament strand. For the “18 + 1” multifilament wire, 18 monofilament strands and one center copper filament are restacked into seamless Monel tube and then drawn into the final size. For the conductor of 0.84 mm in diameter, the final size of each filament is around 76 µm. The conductor came in two forms, reacted and non-reacted. After cold drawing into wire, the reacted conductor undergoes a heat treatment at a temperature between 650 to 700 °C, so the mixture of Mg and B becomes MgB2. In the non-reacted wire, the Mg and B mixture remains in its original form after wire drawing. We experimented with both kinds of conductors in our development of superconducting joints.

Fig. 1.

Photograph of the cross section of 0.84_mm diameter “18 + 1” multifilament MgB2 wire, with key components identified [1].

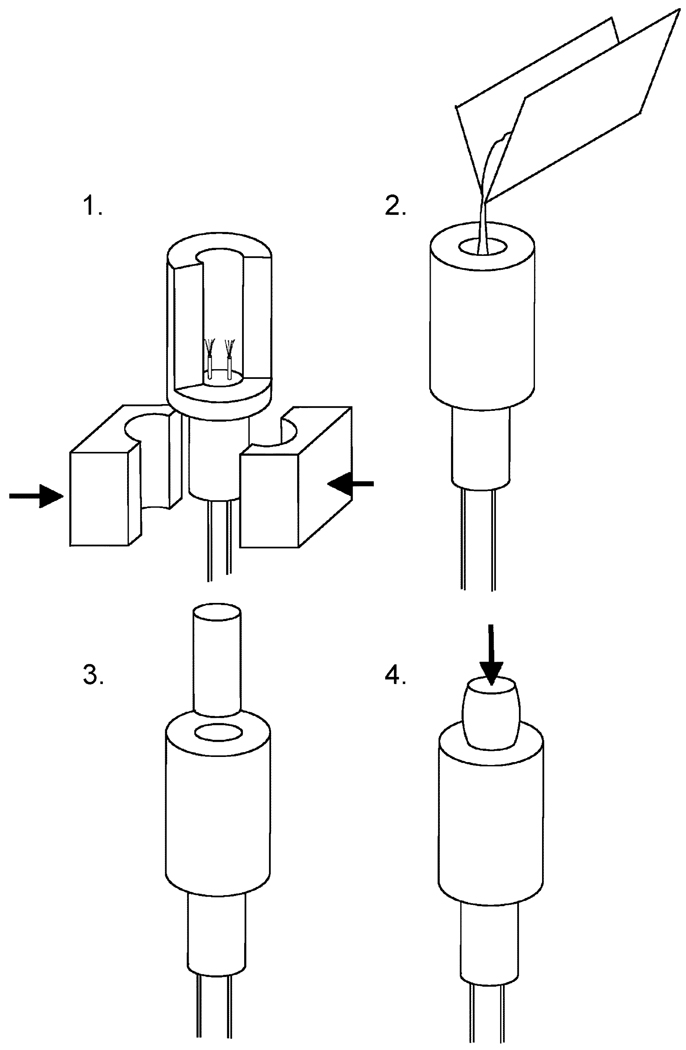

Fig. 2 illustrates a typical procedure in the fabrication of a joint between two pieces of wire. The following explains in detail each step in the procedure. Fig. 3 show the picture of a joint assembly.

Fig. 2.

Fabricating procedure of the MgB2 splice. The details are explained in the text.

Fig. 3.

Photograph of a splice assembly to join two multifilament MgB2 wire inside Cu alloy matrix.

Etch the Cu and CuNi array surrounding the filaments with nitric acid to expose the 18 Nb wrapped filaments. The exposed filaments are 15 to 20 mm long. It usually takes 1–2 hours to remove the Cu and CuNi around filaments. with HNO3 in room temperature, the timing isn’t critical. The end of the wire is bent into a U-shape before submersing into acid. During the etching process, the Mg + B isn’t exposed to acid at all due to protection of the Nb sheath.

The exposed filaments are brittle. A sharp bent with a pair of tweezers will easily break a filament. We usually trim the filaments to about 3 to 5 mm long to expose a fresh cross section of MgB2 (or MG + B mixture).

As shown in Fig. 2, the cylindrical capsule is made of stainless steel rod of 10 mm in diameter. A hole of 6 mm in diameter and 20mmin depth is drilled from one side and two small through holes of 0.9 mm are drilled from the other side.

Insert the two wires to be joined into the small holes and let the exposed filament be inside the ø6 mm space.

Pinch on the wire end of the stainless steel rod with a swaging tool so that the 0.9 mm diameter holes shrink and are sealed by the inserted wire.

Fill the space of 6 mm in diameter with pre-mixed Mg + B precursor, the same kind of powder used in wire fabrication. The typical size of both magnesium and boron particles are less then 10 µm.

Insert a 6 mm diameter stainless steel rod into the open end of the capsule and press the rod to make the power compact.

Place the wire splice assembly inside the stainless steel tube of a tube furnace and evacuate the tube to a pressure below 10−6 mbar. Raise the temperature of the furnace to convert the Mg and B mixture into MgB2.

The sample is furnace cooled to room temperature.

III. TEST METHODS AND RESULTS

The temperature and duration are the two parameters being varied during the heat treatment. Table I lists the performance of the joint heat treated under the different conditions. The temperatures and time listed in the tables are the highest temperatures and the durations at such temperatures during the heat treatment. The temperature of the furnace is usually ramped up to the highest points in 2–4 hours. After the heat treatment, the samples are cooled inside the furnace. The performance of a joint does not seem to be sensitive to temperature ramping rate. It is worth mentioning that we also experimented with 6 filament reacted conductor, with each filament of about 150 µm in width, provided also by Hypertech Research Inc [1]. After heat treatment at 650 °C for 1/2 hour, the short samples show no superconductivity at 4.2 K and 0.5 T field. It seems re-heat treatment may have damaged the MgB2 filaments in the conductors. Such deterioration in the conductor itself did not occur in “18 + 1” filament wires which have finer filaments. The following discussion is based on “18 + 1” filament conductor shown in Fig. 1.

TABLE I.

Heat Treatment and Joint Resistance

| No. | Temperature/time | Ic at 4.2 K | Ic at 4.2 K and 0.45 T |

Ic at 10 K |

|---|---|---|---|---|

| reacted wire | ||||

| 1. | 900C/15min | 0 | 0 | 0 |

| 2. | 700C/15min | 0 | 0 | 0 |

| 3. | 675C/30 min | ~ 150 A | 0 | 0 |

| 4. | 640C/30 min | ~ 150 A | 0 | 0 |

| 5. | 630C/1200 min | ~ 0 A | 0 | 0 |

| 6. | 570C/2400 min | 0 | 0 | 0 |

| non-reacted wire | ||||

| 7. | 630C/1200 min | ~ 25 A | ~ 25 A | < 2 A |

| 8. | 570C/2400 min | ~ 25 A | Not measured | ~ 200 A |

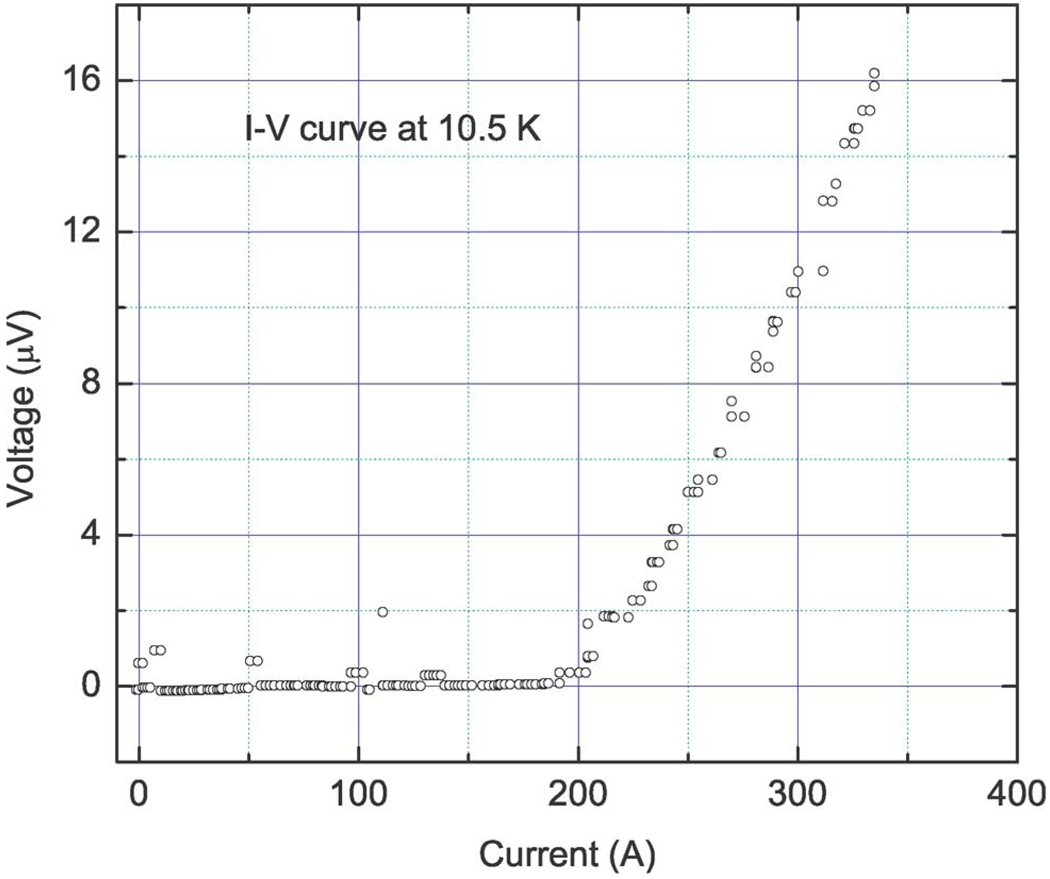

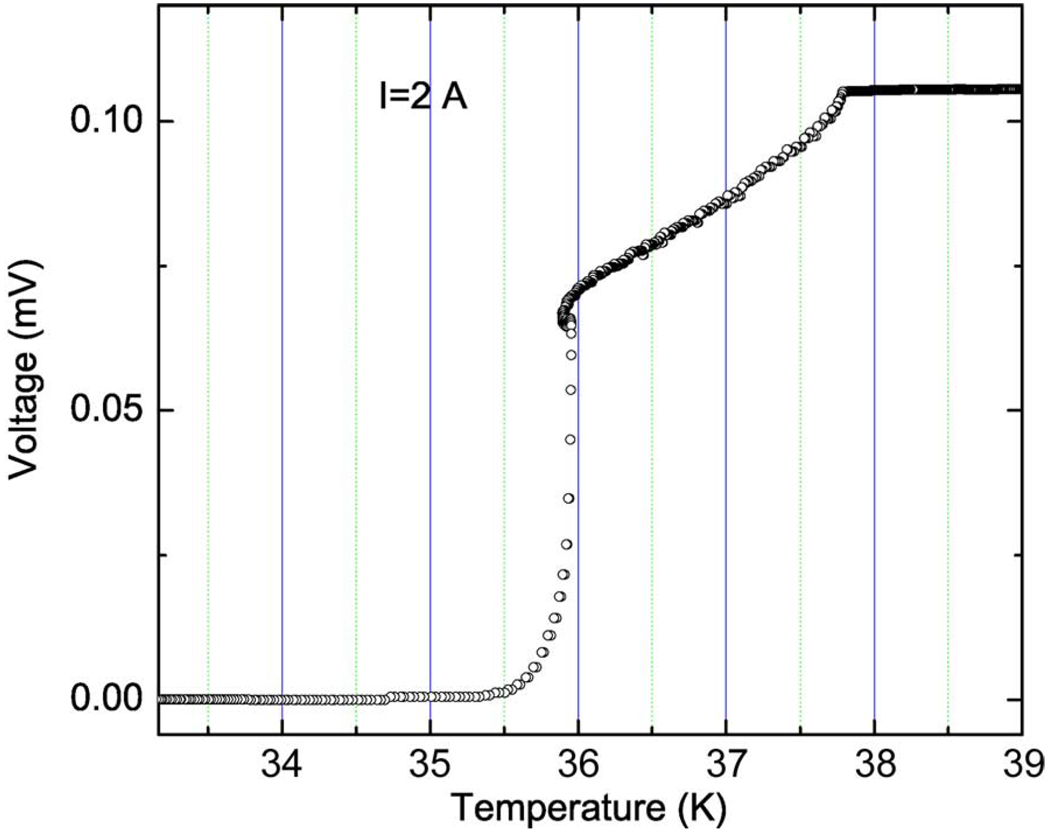

Two methods were used to evaluate splice resistance, 1) four wire measurement and 2) current decay measurement. Fig. 4 shows a typical I–V curve of a superconducting transition of a MgB2 joint with four wire measurement. The resistance of a joint can be determined to a resolution of 10−9 Ω when current is at 100 A level.

Fig. 4.

I–V curve of a typical superconducting joint. The curve in this chart was obtained at 10.5 K in self field for sample 8 listed in Table I.

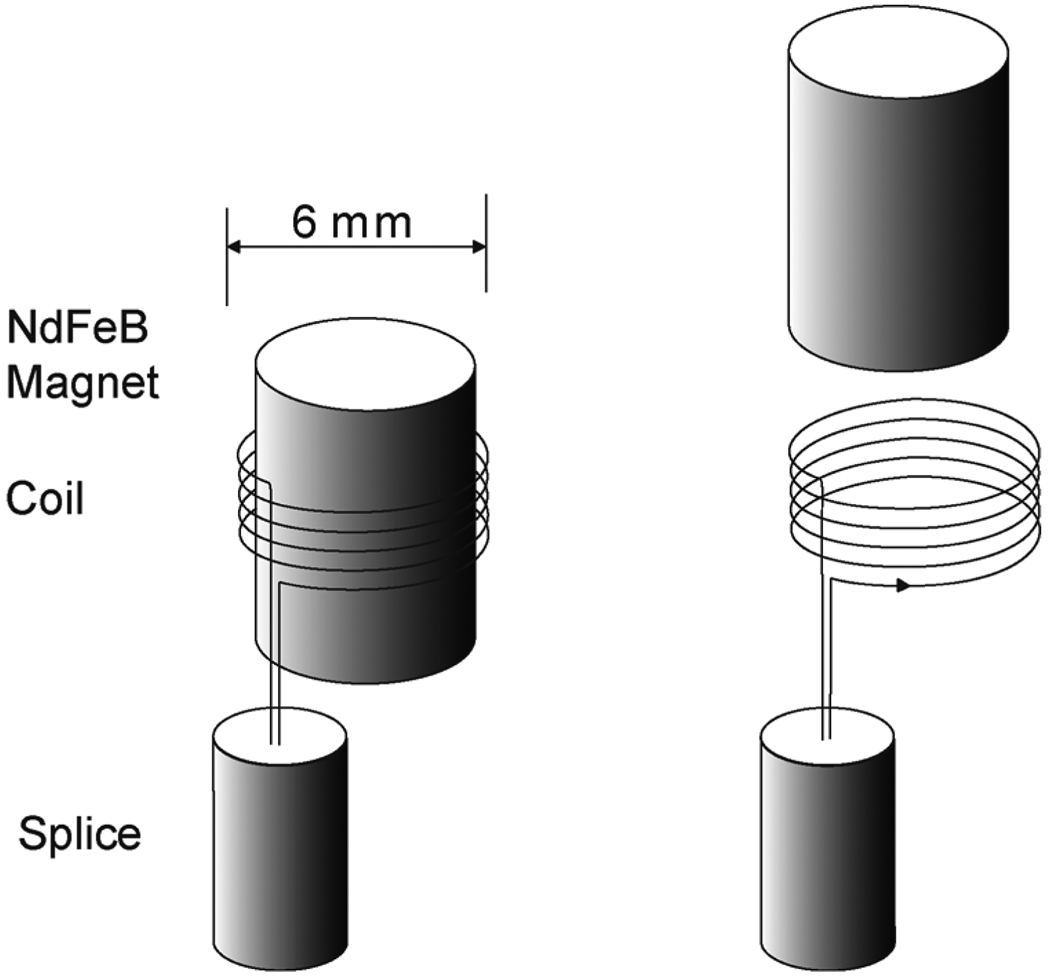

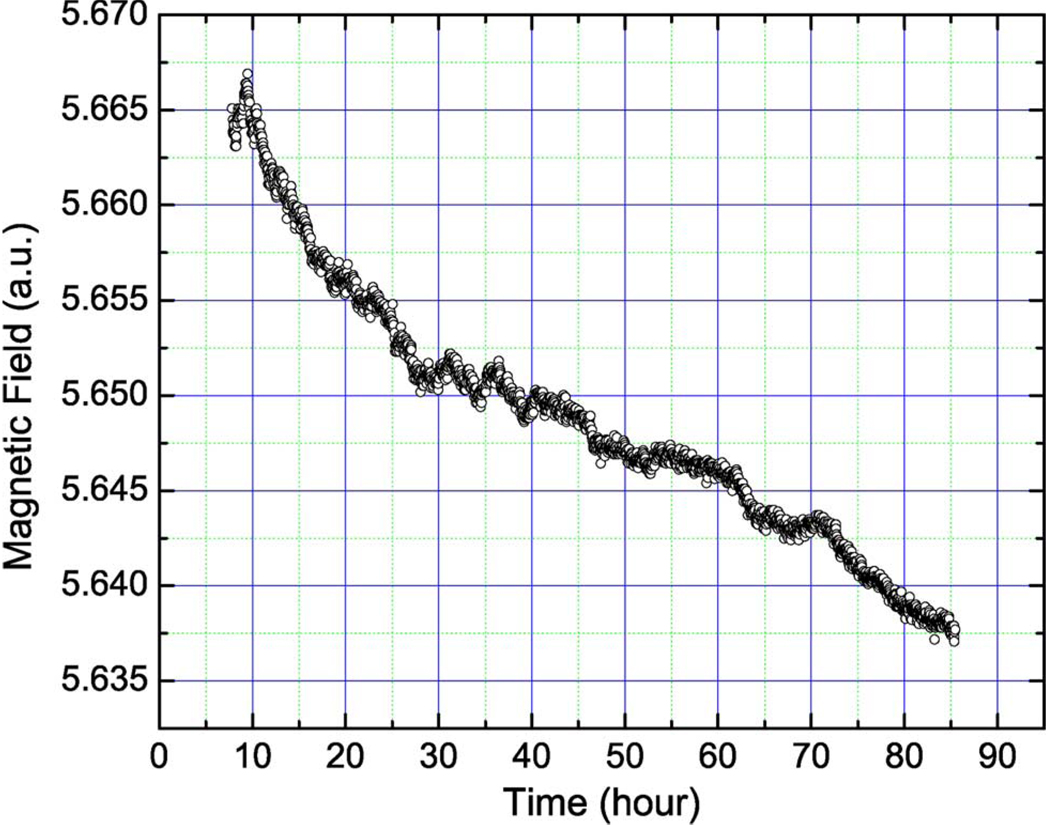

Fig. 5 explains the current decay measurement scheme [6]. The current loop consists of a small coil with an inductance of 1 µH. The two ends of the coil are joined with the technique described here. The coil, placed together with the splice inside the furnace, is heat treated under the same conditions previously described. After a small permanent magnet is inserted in the bore of the coil, the whole assembly is cooled down to 4.2 K in a bath of liquid helium. At 4.2 K, the permanent magnet is removed from the coil, inducing a current inside the loop. The current is monitored by a Hall sensor located next to the coil. By measuring the current decay with time, we can calculate the loop’s total circuit resistance, which we may attribute to the splice resistance. The method can readily evaluate joint resistance of as low as 10−14 Ω. By lifting the coil from liquid helium, we can vary the temperature of the circuit. This allows us to measure the performance of the joint at different temperatures. Fig. 6 is a typical decay curve of the magnetic field produced by the persistent current of a small coil. The Ic listed in Table I are measured with 4-wire method. Field decay is used to verify some of the results.

Fig. 5.

The principle for current decay measurement in evaluating the slice resistance. From the measured decay time τ of the induced current and the inductance of the loop L, one can evaluate the resistance since τ = L/R.

Fig. 6.

The current decay measurement for a coil of 0.6 µH and at a current of 150 A and 4.2 K. The temperature and duration of heat treatment for this sample is the same as sample 4 in Table I.

IV. ANALYSIS

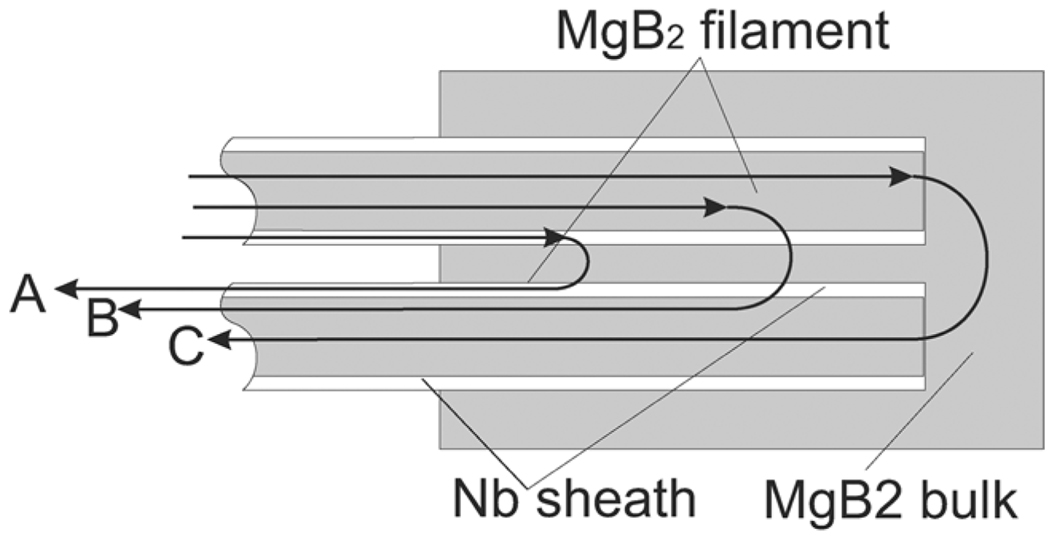

Fig. 7 shows schematically the possible paths for the current to flow through the splice.

Fig. 7.

Paths for superconducting current from one wire to the other via the splice.

Path A, the current flows from the Nb sheath of one wire through the bulk MgB2 in the splice and goes into the Nb sheath of the second wire.

Path B, the current flows from the MgB2 filaments of one wire into the bulk MgB2 via the Nb sheath, and then the current goes into the MgB2 filaments of the other wire via Nb sheath.

Path C, the current flows from MgB2 filaments into bulk MgB2 and then into the MgB2 filaments of the other wire.

Pure Nb has a superconducting transition temperature around 9 K and Hc2 of 0.42 T (at 0 K). By either raising the temperature above 9 K or applying a sufficient high field, we can make Nb non-superconducting. In sufficiently high field, we can make Nb non-superconducting so that neither path A nor B will be superconducting. Furthermore, for either path A or B to be superconducting, the interface between MgB2 and Nb should also be superconducting.

For the samples listed in Table I, samples 3 and 4 are superconducting at 4.2 K in zero field. Either at a raised field of 0.45 T or at a temperature of 10 K, the superconductivity vanishes. We conclude that for these two samples, the bulk MgB2 and the interface between MgB2 and Nb sheath in the splice are superconducting. The superconducting current path is represented by either A or B. The heat treatment did react the magnesium and boron mixture into superconducting MgB2 and also established superconducting connection between Nb and MgB2.

Table I also show that heat treatment at temperatures above 675 °C or below 630 °C results in no superconducting joints for initially reacted conductors. This is the case of samples 1, 2, 5, 6. Samples 5 and 7 were heat treated under the same conditions while the initial conductor for sample 5 had been reacted and for sample 7 not reacted. Sample 7 shows a small superconducting current at 4.2 K and 0.45 T field, which means Path C is established in this sample. Comparing sample 5 and 7, we can also conclude that heat treatment at these conditions does react the magnesium and boron powder and produce a superconducting bulk MgB2 in the joint. But the superconducting connection between the Nb sheath and the bulk MgB2 isn’t established though the Nb itself is superconducting.

In the last situation, the bulk MgB2 makes superconducting contact with the MgB2 between both of the two wire (sample 8). This corresponds to Path C in Fig. 7. The splice has a superconducting transition temperature between 35 and 38 K. Fig. 8 shows the voltage drop across the joint measured at a current of 2 A. The jerk in the slope is due to quick temperature change during the measurement when the joint temperature lags the thermometer. Fig. 4 is an I–V curve measured at 10.5 K for this joint; it has Ic = 200 A. For practical applications of MgB2 wire to magnets operating above 10 K, the current in a joint must flow through Path C.

Fig. 8.

Superconducting transition of sample 8 measured at a current of 2 A.

The superconductivity of MgB2 can be achieved by reacting magnesium and boron powder enclosed inside sheath metals in a wide temperature range reported between 500 to 900 °C, while we observed superconducting splice only for samples heat treated in relatively low temperatures. A possible reason may be that in wire fabrication, magnesium and boron powder are enclosed inside small capillary of sheath metal. During heat treatment, evaporation of magnesium, a serious concern in forming MgB2, is minimal [7]. Although we tried to seal the precursor powder inside the stainless steel capsule, the seal was not tight enough. During the heat treatment, when the temperature exceeded the melting temperature of magnesium, 650 °C, the pressure in tube furnace increased substantially, an indication of excessive evaporation of magnesium. This may explain why Samples 1 and 2 are not superconducting. There may be several reasons why the method isn’t successful for reacted wire. It is likely that fabrication procedure damages the brittle MgB2 filaments. The heat treatment at the relative low temperature isn’t sufficient to re-establish the connections between grain boundaries of MgB2. If heat treatment is done in higher temperatures, we face the issue of loss magnesium which may lead to non-superconducting bulk as in sample 1 and 2.

V. CONCLUSIONS

In this paper, we report a technique to superconductively splice MgB2 wires. To date we have achieved a superconducting splice capable of carrying 200 A at 10 K in self field: two un-reacted MgB2 wires are terminated at a splice and then the whole assembly is reacted at 570 °C for a period of 2400 minutes. With reacted MgB2 wires, the technique has yet to produce a superconducting joint that bypasses the Nb sheath.

ACKNOWLEDGMENT

The authors thank Dr. M. Takayasu (MIT) for loaning us a tube furnace and Dr. M. Rindfleisch (Hypertech Research Inc.) for very helpful discussion.

This work was supported by NIH National Institute of Biomedical Imaging and Bioengineering.

Footnotes

Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org.

REFERENCES

- 1.Tomsic M, Rindfleisch M, Yue J, McFadden K, Phillips J. Overview of MgB2 superconductor applications. Int. J. Appl. Ceram Technol. 2007;vol. 4:250. [Google Scholar]

- 2.Iwasa Y, Larbalestier DC, Okada M, Penco R, Sumption MD, Xi XX. A round table discussion on MgB2 toward a wide market or a niche production? A summary. IEEE Trans. Appl. Supercond. 2006 Jun;vol. 16(no. 2):1457. [Google Scholar]

- 3.Yao W, Bascuñán J, Kim W-S, Hahn S, Lee H, Iwasa Y. A solid nitrogen cooled MgB2 “Demonstration” coil for MRI applications. IEEE Trans. Appl. Supercond. 2008 Jun;vol. 18(no.2):912. doi: 10.1109/tasc.2008.920836. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Takahashi M, Tanaka K, Okada M, Kitaguchi H, Kumakura H. Relaxation of trapped high magnetic field in 100 m-long class MgB2 solenoid coil in persistent current mode operation. IEEE Trans. Appl. Supercond. 2006;vol. 16:1431. [Google Scholar]

- 5.Penco R, Grasso G. Recent development of MgB2 -based large scale applications. IEEE Trans. Appl. Supercond. 2007 Jun;vol. 17(no.2):2291. [Google Scholar]

- 6.Iwasa Y. Superconducting joint between multifilamentary wires (Part II)—Joint evaluation technique. Cryogenics. 1976;vol. 16:217. [Google Scholar]

- 7.Serquis A, Civale L, Hammon DL, Liao XZ, Coulter JY, Zhu YT, Peterson DE, Mueller FM. Role of excess Mg and heat treatments on microstructure and critical current of MgB2 wires. J. Appl. Phys. 2003;vol. 94:4028. [Google Scholar]