Abstract

Poly(dimethylsiloxane) or PDMS is an excellent material for replica molding, widely used in microfluidics research. Its low elastic modulus, or high deformability, assists its release from challenging molds, such as those with high feature density, high aspect ratios, and even negative sidewalls. However, owing to the same properties, PDMS-based microfluidic devices stretch and change shape when fluid is pushed or pulled through them. This paper shows how severe this change can be and gives a simple method for limiting this change that sacrifices few of the desirable characteristics of PDMS. A thin layer of PDMS between two rigid glass substrates is shown to drastically reduce pressure-induced shape changes while preserving deformability during mold separation and gas permeability.

INTRODUCTION

Poly(dimethylsiloxane) (PDMS) is an elastic polymer well suited for microfluidic and soft lithography research.1, 2 Numerous authors emphasized its desirable properties; these include optical transparency, chemical inertness, low surface free energy, good adhesion to surfaces, nontoxicity, and gas permeability.3, 4, 5 In particular, its high elasticity and high elongation at break assist in mold release.6 However, this same high elasticity leads to features that deform significantly under pressure, altering the performance of devices built to rigorous specifications.

This paper reviews the typical construction technique for PDMS microfluidic devices, highlighting relevant material properties and shows experimental and simulated deformation due to fluid pressure in an array of pillars. Strategies to limit this change, including UV-cured optical glue and hard PDMS (h-PDMS) are discussed. It describes the fabrication method of a glass-PDMS-glass device that shows greatly reduced deformation under pressure. Glass-PDMS-glass devices have been described before but the mechanical advantages of this construction have not been described.7

The most common formulations of PDMS used in microfluidics research laboratories are Silgard 184 (Dow Corning, Midland, MI) and RTV615 (Momentive Performance Materials, Albany, NY). A notable but less common formulation, RG01 (Gelest Inc., Morrisville, PA), is claimed to be suitable for mass production. All three are supplied as two component siloxane liquids, to be mixed 10:1 w∕w and cured at room temperature or with heat. The prepolymers are mixtures of siloxanes (Si–O–Si–⋯) having combinations of methyl (–CH3), vinyl (–CH2), and∕or hydro (–H) side and terminal groups. The curing agent is a shorter siloxane polymer with an excess of hydrogroups and a platinum catalyst. The catalyst cross-links the siloxane polymers by the transferring hydrogen atoms and converting carbon sp2 to sp3 hybridization.

For chip fabrication the two components of PDMS are mixed together then placed in a vacuum chamber for about 20 min. The mixture is then poured onto a master mold where it creates a conformal coating. As the diffusivity and permeability of air in PDMS is high (DN2=3400 μm2∕s, comparable to that of air in water5), it dissolves any trapped pockets of air and the polymer is able to completely fill dead-end structures such as deep, narrow holes. After curing, the daughter mold is peeled off the master. Here its high elongation at break (50%),6 high Poisson ratio (0.5),8 and low surface free energy allow challenging chip features, such as pillars to elongate, narrow, and release from the master with relatively little force. After its release the daughter mold can be reversibly or permanently sealed to a variety of surfaces.

The strength of a reversible bond depends on the cleanliness and history of the surfaces but typically, such bonds leak at a few psi (a few tens of kPa). A permanent bond can be made in many ways but the most common way is to treat both surfaces with a low power air or oxygen plasma before placing them in contact. An alternative and more reliable permanent bond is made using a thin layer of uncured or partially cured PDMS.9 If the mold is permanently sealed, the bond will hold positive pressure up to the breaking limit of PDMS, around 700 kPa. However, even at pressures well below the breaking strength, the deformation of PDMS chip features is significant. The deformation will depend on the local geometry but will generally lead to deeper and wider microfluidic channels than originally intended.

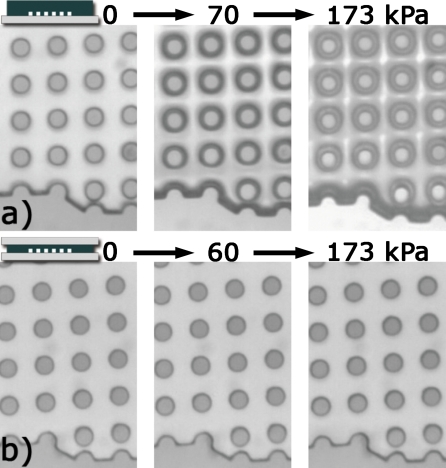

Figure 1a shows top-view micrographs of a PDMS device designed for particle separation under various pressures. The output of the device is sealed so there is no flow and the pressure is uniform throughout. In typical operation the pressure inside the devices, and subsequent deformation, decreases from input to output. The pillars here are 22 μm in diameter and 40 μm tall with a pitch of 44 μm. The gap is a critical dimension and it has increased by more than 15% at 173 kPa. Figure 2a shows a plot of the change in the post-to-post gap under various pressures for those same devices. Clearly significant changes are occurring at typical operating pressures and these need to be addressed.

Figure 1.

Micrographs of two PDMS devices before and during pressurization. (a) A PDMS-glass device at 0, 70, and 173 kPa. (b) A glass-PDMS-glass device at 0, 60, and 173 kPa.

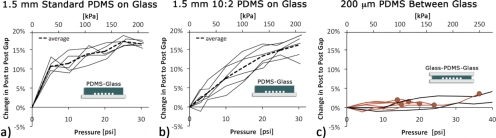

Figure 2.

Plots of measured deformation in devices under fluid pressure at zero flow. Each curve represents one device. (a) Percent change in post-to-post gap for devices formed by bonding a 1.5 mm thick, PDMS mold to a glass slide. (b) Percent change for devices formed by bonding a 1.5 mm thick, over-cross-linked (10:2) PDMS block to a glass slide. (c) Percent change for devices formed by the method described in this article. These devices show much less deformation than devices made using the other methods. Large circles indicate the leak pressure for reversibly sealed devices. This represents a fivefold improvement in leak pressure over conventional reversible sealing.

ALTERNATIVES TO STANDARD PDMS

There are a number of alternatives to molding in standard PDMS that overcome the problem of pressure-induced stretching. These include optical glue molding and the use of h-PDMS. Optical glue molding from either a PDMS master or from a hard master, such as SU-8 resist, produces hard devices that can be bonded to glass.10, 11 The Young’s modulus of Norland Optical Adhesive (NOA) 81 is 1.4×103 MPa, roughly three orders of magnitude higher than that of PDMS. This approach is relatively easy with a low setup cost. The procedure is also well suited for multilayer structures. One problem is that the polymer is not gas permeable so wetting has to be done by fluid flow and not all structures wet in this way without trapping air. The devices used here, when molded in NOA 81 from PDMS masters, could not be completely wet. The suitability of these types of polymers for various biological works is also largely unknown.

An immediately available option is to increase the hardness of standard PDMS by adding additional cross linking agent. Armani et al.8 measured the elastic modulus of an un-named brand of PDMS at the standard 10:1 ratio, and with twice the amount of cross-linker, a 10:2 ratio. Young’s modulus increased from 750 to 870 kPa, only a 16% increase. Experiments using 10:2 PDMS are described in Sec. 3.

Hard PDMS or h-PDMS was developed at IBM Zurich for nanoscale soft lithography.6, 12 It is a highly cross-linked, four-component version of PDMS. The tensile modulus of h-PDMS is 4.5 times that of standard PDMS.13 For convenience, the recipe is reproduced here. [3.4 g vinyl prepolymer VDT-731 (Gelest Inc.), 0.5\% w∕w or 18 μl platinum catalyst SIP6831.2LC (Gelest Inc.), 0.1\% w∕w (one drop, assumed to be 50 μl) modulator 2,4,6,8-tetramethyltetravinylcyclotetrasiloxane (Sigma Aldrich), and 1 g hydroprepolymer HMS-301 (Gelest Inc.). Gelest no longer makes SIP6831.1, but SIP6831.2LC is reported to be a suitable replacement.]The mixture is typically spun onto a master mold to form a thin layer. Once the h-PDMS has cured, a thicker layer of standard PDMS is formed on top of the h-PDMS, allowing removal of the rigid layer while minimizing cracking in the h-PDMS layer.

EXPERIMENTAL

Three alternatives to the standard PDMS construction were investigated here: PDMS with twice the recommended amount of cross-linker, h-PDMS, and the glass-PDMS-glass construction. The first construction that was tested is the standard one. A 1–2 mm thick PDMS device is bonded to a glass slide. The bond was made by spin coating a thin (∼50 μm) layer of 10:1 PDMS onto a glass slide, curing that for 8.5 min in a 75 °C oven, then bonding the device.14 A single hole was bored through the PDMS using a blunt syringe. A tube was inserted into the hole and glued, then connected to a syringe and manometer. A bright-field microscope using a five times objective and digital camera was used to record images of the pillar arrays at various pressures. Figure 1a shows what the pillars look like with no applied pressure, at 70 and 173 kPa (25 psi). The posts have narrowed and other deformations are apparent. Figure 2a shows the percent change in the gap between the posts as the pressure is increased. Measurements of the maximum gap were taken between posts in the middle of the array. Upon releasing the pressure the original dimensions were recovered.

The first alternative construction used PDMS with twice the recommended amount of cross-linker, 10:2 RTV 615. Other aspects of the construction were as described above. Figure 2b shows the change in post-to-post gap for devices molded in 10:2 RTV 615. The 10:2 PDMS deforms less at lower pressures, but by 200 kPa the degree of deformation is roughly the same, as seen with standard PDMS, about 16%.

Hard PDMS molds, the second alternative, failed to release from the structures used here. Many of the 22 μm diameter, 40 μm tall posts broke off and were left in the mold. No further measurements were made.

The third alternative is the glass-PDMS-glass construction. It is made as follows: A line of standard degassed PDMS is poured onto the master mold and squished under a glass microscope slide. The amount of PDMS should be just enough for the area under the glass slide to be filled by capillary forces before or during curing. After curing, a razor blade is used to separate the glass slide and PDMS film from the master mold. The resulting PDMS layer is typically around 200 μm thick. The steps of this procedure are shown in a movie, linked to Fig. 3. Separating the rigid device from the mold requires much more force than for bulk PDMS. So it is recommended that the master mold be supported on a flat surface. If the master is a wafer, then taping or gluing it to a glass plate can prevent it from breaking. This glass-supported, thin PDMS device can now be reversibly or permanently sealed to a flat surface.

Figure 3.

Still image from video showing fabrication of a glass-PDMS-glass device from a 3 in. silicon wafer master (enhanced online) 1.

The images in Fig. 1a and the data in Fig. 2c are from glass-PDMS-glass devices. These figures show that there is little or no change in the appearance of the PDMS features after applying 173 kPa. Comparing the standard construction to the glass-PDMS-glass devices, we see roughly ten times less deformation at 70 kPa (10 psi).

All devices are made using RTV615 that was mixed for 3 min, degassed for 20 min, and cured for 2 h at 75 °C. Each device is created from the same master mold, which contains six, 1 mm wide, and 5 cm long arrays of pillars. The pillars are 22 μm in diameter and 40 μm high with a period of 44 μm in an approximately square array.

Fluidic connections in standard devices are usually made by boring a hole in the PDMS then press fitting or gluing in a tube. In the glass-PDMS-glass construction, holes must be made in one of the glass plates and these are typically made by microsandblasting, but diamond grinding or ultrasonic drilling are also possible.

In addition to reducing deformation, the method enhances the strength of reversible bonding and eliminates the possibility of a sagging or collapsing roof. Two of the glass-PDMS-glass devices were permanently bonded to glass slides by air plasma, while the other six were not treated in any way. Instead, they relied on the weak, spontaneous PDMS-glass adhesion. The last measured pressure before leakage occurred is shown by a large dot that terminates their curves in Fig. 2c. After cleaning with detergent and water, the devices were resealed and reused. No correlation between reuse and bond strength was seen.

Devices constructed here using standard PDMS on glass without bonding leaked and delaminated at 21±1.6 kPa (3.0±0.2 psi) N=5, consistent with previous observations.1 The same devices in the glass-PDMS-glass format held pressures ranging from 97 to 250 kPa (14–36 psi). This increase of at least fivefold means that permanent bonding is usually not necessary and devices can be used, disassembled, cleaned, and used again.

MODELING

Models were created in COMSOL MULTIPHYSICS to clarify the deformation that has been observed. The models were created to match device geometry and used material properties from literature. RTV-615 PDMS: Elastic modulus (E) is 1.54 MPa for strain less than 0.45, υ=0.499. Glass: E=2×105 MPa and υ=0.33. Recent work by Schneider et al.15 gave precise data for modulus versus strain, which increases rapidly for strain larger than 0.5.15 Due to the difficulty in modeling rubberlike materials, this nonlinear character was not included in the model; however, the model data presented here are limited to a regime where strain is less than 0.45.

It is clearly not reasonable to model the entire microfluidic device with its 155 000 pillars. For the PDMS-glass device, the reduced model [Fig. 4a] contains three pillars, the glass beneath them, and 200 μm of PDMS above. The PDMS is allowed to move vertically (z) but the outer boundary is not allowed to swell in the x or y directions because of the surrounding material. The model is 44 μm deep (x), and 3×44 μm wide (y). The bottom surface of the glass block is constrained in all directions. Pressure is applied in a direction normal to each surface in the microfluidic channel: The floor, roof, and post surfaces.

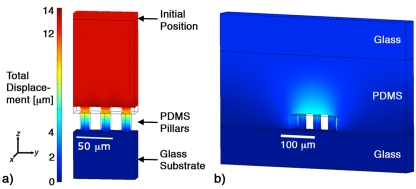

Figure 4.

Results of structural simulations of fluid pressure-induced deformation. (a) The reduced model for the PDMS on glass construction. (b) The reduced model for the glass-PDMS-glass construction. In each case the wire frame shows the initial shape/position and the deformed shape is colored using the scale shown to show total displacement. The fluid pressure in each is 100 kPa.

The reduced model of the glass-PDMS-glass device [Fig. 4b] contains three pillars at the bottom of a 200 μm PDMS slab sandwiched between two glass plates. The depth of the model is 44 μm. The width of the device is 682 μm. It is made this way so that the ratio of pillared area to bonded area is 6∕25, the same as the full device that contains six, 1-mm wide arrays under a 25- mm wide glass slide. Again the bottom surface of the lower glass block is completely constrained, the walls are constrained in the x and y directions.

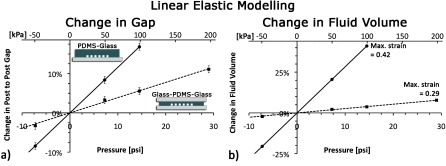

The nature of the deformation is always the same: For positive pressure the uppermost surface of the model moves upward, the fluidic channel roof also moves up in the z-direction becoming curved and the posts narrow. For negative pressure the posts become shorter and fatten through most of their height and the roof begins to curve inward. Figure 4 shows the solutions to both models at 100 kPa with coloring to indicate displacement of between 0 μm (blue) and 14 μm (red). Figure 5a shows the change in the post-to-post gap for the two models. The glass-PDMS-glass model shows three times less deformation than the standard PDMS on glass model. Because PDMS is incompressible, any change in the height of the top surface comes through an increase in the microfluidic channel volume. This change in fluid volume is shown in Fig. 5b.

Figure 5.

Plots showing (a) the percent change in post-to-post gap and (b) fluid volume for the two models. Error bars, resulting from the grid size, in (b) are ±0.3% and are smaller than the data points.

DISCUSSION

Standard PDMS with double the recommended amount of cross-linker showed some reduced deformation at low pressure, but no significant difference at the higher pressure of 200 kPa (30 psi). Hard PDMS would likely show very little deformation, but due to its much lowered elongation at break (only 6%, compared to 50%–100% for standard PDMS), it was unable to release from the molds used here. It would be highly desirable to have a two stage curable PDMS: One that could be heat cured to something similar to standard PMDS, then UV cured after mold separation and device construction to a rigid material, such as h-PDMS; however, such material is not available. In the meantime, a simple change in construction can dramatically reduce pressure-induced deformation in standard PDMS devices without sacrificing desirable properties, such as gas permeability or deformability, during mold separation.

The deformation seen in the standard PDMS-glass devices [Fig. 2a] is nonlinear, with an 11% change occurring by 70 kPa (10 psi) and only 5% further change seen at 210 kPa (30 psi). Clearly a level of strain is reached that leads to an increase in the elastic modulus and a decrease in the slope of the curves. The deformation remains more linear in the glass-PDMS-glass device as the total strain is smaller and the modulus has not yet begun to increase. The model and experiment both show significantly reduced deformation when using the glass-PDMS-glass construction compared to conventional bulk PDMS on glass.

The good performance of the glass-PDMS-glass device is explained by the thin PDMS layer and the close proximity of the features to both upper and lower plates. The plates distribute the load over a large area so that any change in channel height comes at the cost of vertically stretching a large area of PDMS. Moreover, a thin PDMS layer stretches less in absolute terms than a thick layer under the same load. A thin, unsupported PDMS layer would receive none of this load distribution effect and is expected to deform even more than the devices measured in Fig. 2a.

Thinner PDMS layers in the glass-PDMS-glass construction can be made but lead to unacceptably high mold separation forces. The incompressibility of PDMS is also believed to be crucial, and small air bubbles in the material would allow it to compress, negating the effect of the glass-PDMS-glass construction. It may be possible to reduce deformation by layering a glass slide over thin PDMS, but thin PDMS films are fragile and air bubbles between the layers would reduce the effectiveness of the method.

There are other benefits to this glass-PDMS-glass construction as well. The reversible bond formed between PDMS and glass normally delaminates and leaks at low pressures, but when a thin PDMS layer is sandwiched between two rigid planes, delamination occurs at higher pressures. Furthermore, this construction prevents roof sagging, allowing fabrication of wide unsupported chambers.

CONCLUSION

Pressure-induced deformation is not a universal disadvantage; it is of course the essential material property enabling the Quake valve.16 However, especially when syringe pumps are used or when high throughputs are sought, it should not be overlooked as pressures can be quite high. Deformability is especially problematic in deterministic lateral displacement devices where the distance between pillars is a critical dimension that should not change during operation or throughout the device.17 It is also relevant to other particle separation approaches that use obstacles and to microfluidic sheathing in PDMS.18, 19, 20 Limitations to this technique include more difficult input and output connections and the need for a clean, flat surface.

The significance of PDMS to the field of microfluidics cannot be overstated, but it has limitations. The deformability of PDMS clearly assists in its mold replication capabilities, but is a shortcoming once the device has been constructed. PDMS devices may never be mass produced but PDMS is very convenient for prototyping and research applications where it will continue to be a significant material for prototype chip fabrication. This paper shows how to manage the tendency of PDMS to change shape under pressure. Until a better material is developed, this method will help the research community to take advantage of the strengths and work with the weaknesses of PDMS.

ACKNOWLEDGMENTS

This work was supported by the Australian Research Council (Grant No. DP0880205) and the Fluorescence Applications in Biotechnology and Life Sciences (FABLS) Network. I am grateful for support from Professor Ewa Goldys and MQ Photonics and for thoughtful advice from Varun K.A.S.

References

- McDonald J. C. and Whitesides G. M., Acc. Chem. Res. 35, 491 (2002). 10.1021/ar010110q [DOI] [PubMed] [Google Scholar]

- Xia Y. and Whitesides G. M., Annu. Rev. Mater. Sci. 28, 153 (1998). 10.1146/annurev.matsci.28.1.153 [DOI] [Google Scholar]

- Cai D. K., Neyer A., Kuckuk R., and Heise H. M., Opt. Mater. (Amsterdam, Neth.) 30, 1157 (2008). 10.1016/j.optmat.2007.05.041 [DOI] [Google Scholar]

- Lee J. N., Park C., and Whitesides G. M., Anal. Chem. 75, 6544 (2003). 10.1021/ac0346712 [DOI] [PubMed] [Google Scholar]

- Merkel T. C., Bondar V. I., Freeman B. D., and Pinnau I., J. Polym. Sci., Part B: Polym. Phys. 38, 415 (2000). [DOI] [Google Scholar]

- Schmid H. and Michel B., Macromolecules 33, 3042 (2000). 10.1021/ma982034l [DOI] [Google Scholar]

- Plecis A. and Chen Y., Microelectron. Eng. 84, 1265 (2007). 10.1016/j.mee.2007.01.276 [DOI] [Google Scholar]

- Armani D., Liu C., and Aluru N., IEEE Conference on MEMS, 1999, p. 222.

- Eddings M. A., Johnson M. A., and Gale B. K., J. Micromech. Microeng. 18, 067001 (2008). 10.1088/0960-1317/18/6/067001 [DOI] [Google Scholar]

- Bartolo D., Degre G., Nghe P., and Studer V., Lab Chip 8, 274 (2008). 10.1039/b712368j [DOI] [PubMed] [Google Scholar]

- Kim S. H., Yang Y., Kim M., Nam S. W., Lee K. M., Lee Y. Y., Kim Y. S., and Park S., Adv. Funct. Mater. 17, 3493 (2007). 10.1002/adfm.200601203 [DOI] [Google Scholar]

- Odom T. W., Love J. C., Wolfe D. B., Paul K. E., and Whitesides G. M., Langmuir 18, 5314 (2002). 10.1021/la020169l [DOI] [Google Scholar]

- Choi K. M. and Rogers J. A., J. Am. Chem. Soc. 125, 4060 (2003). 10.1021/ja029973k [DOI] [PubMed] [Google Scholar]

- Wu H., Huang B., and Zare R. N., Lab Chip 5, 1393 (2005). 10.1039/b510494g [DOI] [PubMed] [Google Scholar]

- Schneider F., Draheim J., Kamberger R., and Wallrabe U., Sens. Actuators, A 151, 95 (2009). 10.1016/j.sna.2009.01.026 [DOI] [Google Scholar]

- Unger M. A., Chou H. P., Thorsen T., Scherer A., and Quake S. R., Science 288, 113 (2000). 10.1126/science.288.5463.113 [DOI] [PubMed] [Google Scholar]

- Huang L. R., Cox E. C., Austin R. H., and Sturm J. C., Science 304, 987 (2004). 10.1126/science.1094567 [DOI] [PubMed] [Google Scholar]

- Chen X., Cui D. F., Liu C. C., and Li H., Sens. Actuators B 130, 216 (2008). 10.1016/j.snb.2007.07.126 [DOI] [Google Scholar]

- Choi S., Song S., Choi C. and Park JK J. K., Lab Chip 7, 1532 (2007). 10.1039/b705203k [DOI] [PubMed] [Google Scholar]

- Choi S., Song S., Choi C. and Park JK J. K., Small 4, 634 (2008). 10.1002/smll.200700308 [DOI] [PubMed] [Google Scholar]