Abstract

Southern pine specimens vacuum-treated with nano-zinc oxide (nano-ZnO) dispersions were evaluated for leach resistance and UV protection. Virtually, no leaching occurred in any of the nano-ZnO–treated specimens in a laboratory leach test, even at the highest retention of 13 kg/m3. However, specimens treated with high concentrations of nano-ZnO showed 58–65% chemical depletion after 12 months of outdoor exposure. Protection from UV damage after 12 months exposure is visibly obvious on both exposed and unexposed surfaces compared to untreated controls. Graying was markedly diminished, although checking occurred in all specimens. Nano-zinc oxide treatment at a concentration of 2.5% or greater provided substantial resistance to water absorption following 12 months of outdoor exposure compared to untreated and unweathered southern pine. We conclude that nano-zinc oxide can be utilized in new wood preservative formulations to impart resistance to leaching, water absorption and UV damage of wood.

Keywords: Nano-zinc, Nanometal, Leaching, Wood preservation, UV degradation

Introduction

Zinc oxide has a long history as a UV stabilizer and preservative component in coatings. Recent reports on nano-zinc oxide have primarily examined zinc oxide nanoparticles with respect to exterior coatings to improve photostability [1,2], as a component of UV coatings for nanocomposites [3,4], or modeling UV permeability of nano-ZnO-filled coatings [5]. Relatively few reports exist on impregnating wood with nanometals or the changes that nanometals impart on wood durability [6,7]. Impregnating wood with nano-ZnO offers the advantage over nano-coatings of long-term protection from photo-degradation and biological deterioration, particularly if the nanotreatment is leach resistant and bioactive.

Pyrolytic preparations of nanometals, such as zinc or copper, affect several elemental characteristics such as size, charge and dispersion properties in such a way that may improve their properties for wood preservation compared to similar soluble preparations [8]. Nanometals created by pyrolysis demonstrate precisely controlled particle size in the 1–100-nanometer range that may improve penetrability of the chemical into wood relative to nanometals prepared by milling. Nanometer-size particles of metals have increased surface area when evenly dispersed in a layer. If the particle size was smaller than the diameter of the wood window pit (< 10,000 nm) or the opening of the bordered pit (400–600 nm), complete penetration and uniform distribution would be expected [9]. Nanoparticles demonstrate high dispersion stability, but in concentrated form, they are subject to Van der Waals forces. Surfactants are typically added to increase dispersion stability thereby enabling liquid dispersion of higher concentrations of nanometals. Matsunaga et al. [10] conducted a study on microdistribution of a micronized copper wood preservative (10–700 nm). They observed numerous particle deposits of copper in ray tracheids and pit lumens within the wood. These deposits created a different microdistribution pattern in wood treated with the micronized copper than was observed in wood treated with other copper-based preservatives. Fixation of micronized copper is believed to occur primarily through deposition in pit chambers and on tertiary cell wall layers rather than via chemical reaction [9].

In a preliminary study, Clausen et al. [7] evaluated the feasibility of nano-zinc oxide as a wood preservative. In laboratory tests, they reported that nano-zinc oxide-treated wood inhibited some decay fungi, but not those that are otherwise zinc-tolerant (e.g. Postia placenta). Nano-zinc oxide inhibited termite feeding and caused moderate termite mortality and inhibition. Nano-zinc-treated wood was leach resistant, but weathering results were too preliminary to draw conclusions. Here, we report on weathering characteristics of southern pine vacuum-treated with nano-zinc oxide after 12 months of exposure.

Materials and Methods

Treatment Chemicals

Nano-zinc oxide (Nanophase Technologies Corporation, Romeoville, IL, USA) was provided as an aqueous dispersion containing 50% 30 nm zinc oxide particles with a dispersant. Zinc sulfate was obtained from Mallinckrodt Chemicals, St. Louis, MO, USA.

Specimen Treatment

Test specimens, prepared from sapwood portions of southern pine (SP), were vacuum-impregnated with nano-zinc oxide treatments according to American Wood Protection Association [11] E10-08 standard method for testing wood preservatives. Specimen size varied for leaching and weathering tests according to American Wood Protection Association (AWPA) and American Standard for Testing and Material (ASTM) standard methods. Pre-weighed specimens that were conditioned to 20°C and 65% relative humidity (RH) were vacuum-treated (45-min vacuum at 172 kPa) with aqueous solutions of 30 nm zinc oxide particles diluted in DI water to 1.0, 2.5 and 5.0% based on the metal oxide (ZnO). Zinc sulfate (ZnSO4) was prepared to contain an equivalent amount of Zn for comparison with 1.0% nano-zinc oxide for the leach test. Untreated specimens served as controls. Treated specimens were weighed, dried at 40°C for 3 days and re-conditioned for 2 weeks. Some treated specimens were ground to pass a 30-mesh screen and analyzed for zinc with inductively coupled plasma atomic emission spectrometry (ICP-AES) (Ultima ICP-AES instrument, Jobin–Yvon, Inc., Edison, NJ) according to the standard method A21-00 for analysis of treating solutions [12] to determine chemical retention (Table 1).

Table 1.

Treatment retention pre- and post-weathering

| Nano-ZnO | Retention | |

|---|---|---|

| Concentration (%) | Pre-weathering (kg/m3) | Post-weathering (kg/m3) |

| 1.0 | 1.61 | 1.80 |

| 2.5 | 3.78 | 2.47 |

| 5.0 | 12.96 | 5.43 |

Weathering

Treated and untreated SP specimens (7.6 × 10.2 × 1.3 cm) were weathered outdoors in Madison, WI, for 12 months and visually evaluated for UV damage (i.e. splitting, checking and graying). Three specimens per treatment plus untreated controls were placed horizontally on a screened tray in direct sunlight. The specimen surface in direct light was considered the exposed surface, and the underside of each specimen was considered the unexposed surface for reporting results. Water repellency was based on beading of water on the surface of the specimen by visual examination and water absorption was determined by a modification of ASTM standard D 1037-96a [13]. Weathered specimens, both treated and untreated, and unweathered southern pine were conditioned at 27°C and 80% relative humidity (RH), weighed, submerged vertically in DI water for 24°h and reweighed to determine 24-h water absorption. Weathered specimens were also tested for zinc retention with ICP-AES (Table 1) and end grain checks were counted for all specimens (Table 2).

Table 2.

End grain checking following weathering

| Nano-ZnO (%) | Ave. checks (#) |

|---|---|

| 0.0 | 30.7 |

| 1.0 | 43.3 |

| 2.5 | 31.7 |

| 5.0 | 40.3 |

Chemical Leaching

Leaching procedures were similar to AWPA E11-06 standard method [14] and are described in detail Kartal et al. [6]. Briefly, five specimens (19 × 19 × 19 mm) per treatment were placed into 500-mL beakers, submerged in 100 mL of DI water and subjected to a vacuum to impregnate the specimens with the leaching solution. Samples were mildly agitated for 14 days, and leachates were collected after 6 h, and 1, 2, 4, 6, 8, 10, 12 and 14 days. Leachates were analyzed for zinc with ICP-AES and expressed as ppm zinc for the average leach rate of the 5 blocks per treatment concentration.

Results

Chemical Leaching

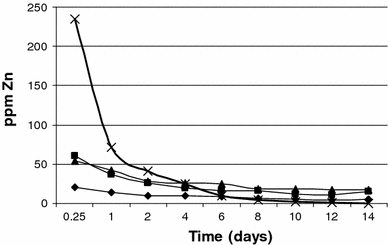

Figure 1 shows the leach rate of three concentrations of nano-ZnO and 1% ZnSO4. In the laboratory leach test, virtually no leaching of nano-ZnO occurred at any treatment concentration, while zinc sulfate readily leached as previously reported by Kartal et al. [6]. Pyrolytic nanometal preparations result in changes in charge properties, and the resulting nanometal dispersions are subject to Van der Waals forces [8]. Such changes in properties may account for the low leaching of nanometals.

Figure 1.

Leach rate of zinc from nano-ZnO (1% filled diamond, 2.5% filled square and 5% filled triangle) and 1% ZnSO4 (×) from SP-treated blocks [6,7]

Weathering

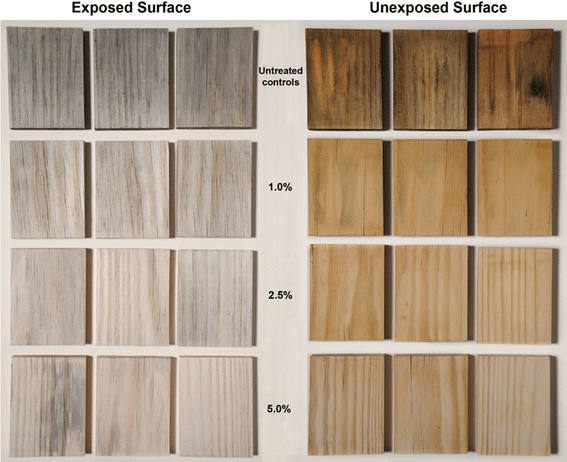

Zinc oxide, a highly effective UV blocker in sunscreen products, may serve a similar function in nanolayers to protect wood from microbial attack and weathering. It can be used as a UV-shielding material because of its strong ultraviolet absorption [2]. After 12 months of outdoor weathering, SP specimens treated with nano-zinc oxide were visibly brighter than untreated controls particularly on the unexposed surface (Fig. 2). Graying was significantly diminished by the nano-zinc treatment, especially at higher treatment concentrations, although it was not completely eliminated by the treatment. Specimens treated with 2.5 and 5.0% nano-ZnO showed mechanical surface changes (i.e. fuzzing) that was not visible in the controls or specimens treated with 1% concentration. Moderate checking also occurred in all treated specimens but was more marked in the specimens treated with 1% nano-Zn than the higher treatment concentrations (Table 2). Water repellency rated by visible water beading on wood surfaces only lasted for 8 weeks. Water absorption following 24-h submersion is summarized in Table 3. After weathering for 12 months, there was nearly 10% reduction in water absorption of specimens treated with 1% nano-Zn, but specimens treated with 2.5 and 5.0% nano-Zn showed a 32% reduction in 24-h water absorption compared to untreated controls suggesting that higher concentrations of nano-ZnO provide substantial water resistance for at least 12 months of outdoor exposure. Weathered specimens were analyzed for ZnO depletion (Table 1). Results revealed no change in ZnO retention in specimens treated with 1% nano-ZnO, but specimens treated with 2.5 and 5.0% nano-ZnO showed a loss of 65 and 58% treatment, respectively.

Figure 2.

Weathering of nano-ZnO treated wood after 12 months of outdoor exposure. Unexposed surface refers to the underside of the individual exposed surface specimens shown on the left

Table 3.

Water absorption of unweathered southern pine and weathered specimens treated with nano-ZnO

| Treatment (%) | Water absorption | |

|---|---|---|

| Wt.a | Vol.b | |

| 0.0 | 45.8 | 0.45 |

| 1.0 | 42.4 | 0.42 |

| 2.5 | 29.5 | 0.29 |

| 5.0 | 28.7 | 0.29 |

aPercent by weight (g)

bPercent by volume (g/cm3)

Conclusion

Nano-zinc oxide-impregnated SP (1.6 kg/m3 retention) demonstrated leach resistance in laboratory tests and following outdoor exposure for 12 months. Nano-zinc oxide also protected wood from water absorption and UV degradation for at least 12 months under conditions of natural weathering. The surface properties of 30-nm zinc oxide may have inhibited zinc-sensitive microbes, i.e. fungi and bacteria, which may be partially responsible for erosion, graying and deterioration of wood surfaces in outdoors exposure. These beneficial properties of nano-zinc oxide suggest that it should be considered as one component in the development of new multi-component wood preservatives.

Misc

The use of trade or firm names in this publication is for reader information and does not imply endorsement by the U.S. Department of Agriculture of any product or service.

The Forest Products Laboratory is maintained in cooperation with the University of Wisconsin. This article was written and prepared by U.S. Government employees on official time, and it is therefore in the public domain and not subject to copyright.

Acknowledgment

We thank Dan Foster, Chemist, for conducting the ICP-AES analyses.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

References

- Hegedus C, Pepe F, Lindenmuth D, Burgard DJ. J. 2008. pp. 42–52. COI number [1:CAS:528:DC%2BD1cXmtFSht7s%3D]

- Yu Y, Jiang Z, Wang G, Song Y. Holzforschung. 2010. [DOI]

- Weichelt F, Emmler R, Flyunt R, Beyer E, Buchmeiser MR, Beyer M. Macromol. 2010. pp. 130–136. COI number [1:CAS:528:DC%2BC3cXitVSktL8%3D]

- Lei H, Xu T, Gao C. J. 2010. pp. 91–97. COI number [1:CAS:528:DC%2BC3cXjtlaluw%3D%3D] [DOI]

- Lowry MS, Hubble DR, Wressell AL, Vratsanos MS, Pepe FR, Hegedus CR. J. 2008. pp. 233–239. COI number [1:CAS:528:DC%2BD1cXltFeqs7w%3D] [DOI]

- Kartal SN, Green F, III, Clausen CA. Int. 2009. pp. 490–495. COI number [1:CAS:528:DC%2BD1MXltlyhtLk%3D] [DOI]

- Clausen CA, Yang VW, Arango RA, Green F. , IIIProc. 2010. pp. 255–260.

- Clausen CA. Int. Res. Group Wood Protect. 2007. p. 15p. IRG/WP/07-30415.

- Freeman MH, McIntyre CR. For. 2008. pp. 6–27. COI number [1:CAS:528:DC%2BD1MXjt1Ohsg%3D%3D]

- Matsunaga H, Kigushi M, Evans P. Int. Res. Group Wood Protect. 2007. p. 7p. IRG/WP/07-40360.

- American Wood Protection Association Standards. 2008a. pp. 364–372.

- American Wood Protection Association Standards. 2008b. pp. 246–249.

- American Society for Testing and Materials. 1998. pp. 136–165.

- American Wood Protection Association Standards. 2008c. pp. 373–375.