Abstract

A new synthetic approach to the preparation of intramolecularly collapsed nanoparticles under mild, room temperature conditions has been developed from commercially available vinyl monomers. Reaction of isocyanate functionalized linear copolymers with a diamine in dilute solution leads to the efficient formation of nanoparticles where the diameter of the nanoparticle can be varied by controlling both the molecular weight and mole percentage of isocyanate repeat units. Physical properties for the intramolecularly collapsed nanoparticles were fully consistent with a three-dimensional structure and analysis of the collapse reaction revealed that approximately 75% of the isocyanate groups along the backbone underwent crosslinking with 25% being available for further reaction with mono-functional amines. This stepwise consumption of the isocyanates allows the chemical and physical properties of the nanoparticles to be further tuned and significantly opens up the range of nanoparticles that can be prepared using this mild and highly efficient chemistry.

1. Introduction

The preparation of polymeric nanoparticles with controlled size and pre-determined arrangement of functional groups has become an attractive research topic in recent years. This interest is driven by the use of these tailor-made, functional nanoparticles in a variety of applications in the fields of microelectronics,1 drug delivery,2 polymer processing,3 etc. To address the need for nanoparticles that can serve in these broad capacities, a diverse range of strategies have been developed to increase the scope and availability of these systems including: micro/miniemulsion4 techniques, discrete synthesis of spherical molecules such as dendrimers,5 as well as the self assembly of block copolymers into micelles followed by chemical crosslinking.6 While successful, these strategies generally display a trade off with respect to size and accessibility. Nanoparticles above 20 nm in size are easier to prepare, however structural control is more difficult. In direct contrast, smaller nanoparticles, such as dendrimers, allow access to the potentially more interesting sub-20 nm regime and are structurally well-defined, though significantly more difficult to prepare. To achieve the goal of developing facile synthetic procedures for preparing well defined, sub-20 nm nanoparticles, intramolecular chain collapse strategies have been developed.

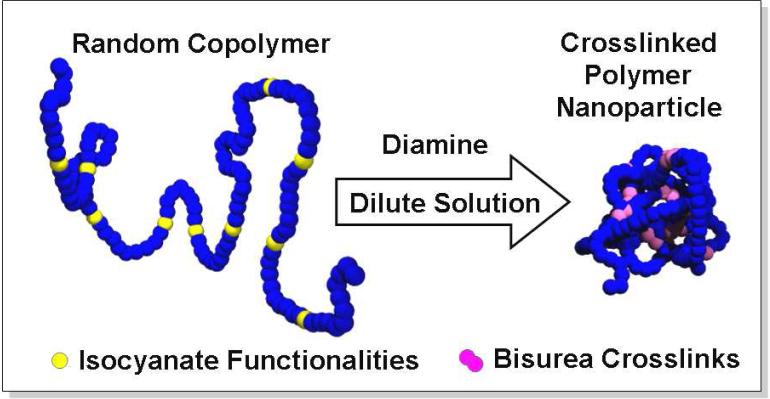

Crosslinking of functionalized, linear polymer chains under dilute conditions allows a wide range of nanoparticles to be prepared with the chain collapse strategy relying heavily on the reactivity and orthogonality of the crosslinking functionality. Simulation studies have shown that the distribution of monomers leads to different macromolecular architectures7 and the ratio of intramolecular to intermolecular crosslinking varies inversely with initial polymer concentration and molecular weight.8 In addition, a similar intramolecular collapse profile has been observed for star polymers and dendrimers9 leading to nanoparticles that have a dramatic effect on a variety of polymeric properties.10 To date, this technique has made use of free-radical crosslinking of vinyl functionalizations,11,12 click chemistry,13 photocrosslinking of cinnamoyl groups,14 non-covalent interactions15 and the thermal crosslinking of benzylcyclobutane (BCB) or BCB precursors.16 While the BCB strategy is arguably the most scalable, as it forms no side products and requires no catalyst, the reaction conditions are harsh (250°C), which may preclude the use of other comonomers and/or functional groups. We report herein a synthetic strategy for the preparation of linear copolymers containing pendant crosslinkable isocyanate functionalities from commercially available monomers and the intramolecular crosslinking/chain collapse of these copolymers with suitable difunctional (diamine) molecules (Figure 1). These polymer nanoparticles are soluble in a variety of organic solvents and can be prepared on gram scales at ambient temperatures.

Figure 1.

Schematic representation of the intramolecular crosslinking of an isocyanate functionalized, linear copolymer with a diamine in dilute solution resulting in the formation of a crosslinked nanoparticle.

2. Experimental

Materials

The chain transfer agent, S-methoxycarbonylphenylmethyl dithiobenzoate (MCPDB), was prepared using literature procedures.17 Styryl and methacrylic monomers were purchased from the Aldrich Chemical Co. and filtered over neutral alumina before use. Tetrahydrofuran (THF), dichloromethane (DCM), chloroform (CHCl3) and hexanes were purchased from Fisher Scientific and dried before use. All other reagents were used without further purification.

Instrumentation

Synthesized materials were characterized by 1H and 13C nuclear magnetic resonance (NMR) spectroscopy using either a Bruker 200 or 500 MHz spectrometer. Gel permeation chromatography (GPC) was performed in tetrahydrofuran on a Waters Alliance HPLC system (Waters 2695 separation module, Millford, MA) equipped with four Waters styragel HR columns. Waters 2414 differential refractometer index and 2996 photodiode array detectors were employed. The molecular weights of the polymers were calculated relative to linear polystyrene standards. Dynamic light scattering (DLS) measurements were carried out on a Brookhaven BI-9000AT digital autocorrelator (Holtsville, NY) equipped with an Avalanche photodiode detector and a MG vertically polarized 35 mW He-Ne 633 nm laser and operated by the 9KDLSW control program. The hydrodynamic diameter and distribution of the nanoparticles were determined by fitting the correlation functions with the ISDA analysis software package (Brookhaven Instruments Co.) and applying the non-negatively constrained least-squares particle size distribution analysis (NNLS). Viscosity measurements were carried out using Schott micro-Ubbelohde viscometer (type No. 53710, Capillary No. M1) with the solutions prepared at least 1 day before the measurement by dissolving the polymer in pure solvent followed by filtering through a 0.45-μm filter.

Synthesis of Poly(isocyanatoethyl methacrylate - methyl methacrylate) [ICEMA-MMA] copolymer (1)

A 10 mL glass ampule was charged with a mixture of methyl methacrylate (1.70 g, 17.0 mmoles) and 2-isocyanatoethyl methacrylate (0.465 g, 3.0 mmoles) in 0.5 mL of dry benzene. S-Methoxycarbonylphenylmethyl dithiobenzoate (MCPDB, 2.69 mg, 0.009 mmoles) and AIBN (0.10 mg, 0.0006 mmoles) were then added, from stock solutions in benzene, and the polymerization mixture degassed by repeated freeze-thaw-evacuate cycles (×3). The ampule was then flame-sealed under vacuum and heated in an oil bath at 75°C for 18 h, at which point the solution became quite viscous. The resulting polymer solution was diluted with 3 mL of DCM and precipitated into 50 mL of dry hexanes. The supernatant was decanted and the solid polymer precipitate was redissolved in a minimum of dichloromethane and transferred into a tared vial. The vial was placed on a rotary evaporator until the majority of solvent was removed and then placed under a high vacuum to dryness, giving 1.41 g of pure copolymer (Isolated yield 67%) Mw = 149 000; PDI = 1.23; IR 3050−2800, 2275, 1731, 1488, 1459, 1394, 1367, 1244, 1193, 1149 and 1070 cm−1; 1H NMR (200 MHz, CDCl3) δ 4.09 (bt, CH2), 3.59 (bs, CH3), 1.82 (bs, CH3), 1.25−0.85 (m, CH2).

Synthesis of Poly(isocyanatoethyl methacrylate - styrene) [ICEMA-Sty] copolymer (4a)

A 50 mL pear-shaped flask was charged with a mixture of styrene (4.68 g, 45.0 mmoles) and 2-isocyanatoethyl methacrylate (0.776 g, 5.0 mmoles). S-Methoxycarbonylphenylmethyl dithiobenzoate (MCPDB, 6.28 mg, 0.021 mmoles) and AIBN (0.23 mg, 0.0014 mmoles) were added, from stock solutions in toluene, to the reaction mixture. The monomer solution was then degassed by sparging with nitrogen for 10 minutes followed by heating in an oil bath at 75°C for 18 h. The resulting polymer solution was diluted with 3 mL of DCM and precipitated into 50 mL of dry hexanes. The hexanes were decanted off and the solid polymer precipitate was redissolved in a minimum of dichloromethane and transferred to a 6 dram vial. The vial was placed on a rotary evaporator until the majority of solvent was removed and then placed under a high vacuum to dryness. After weighing to determine conversion/yield, 1.05 g of pure copolymer was obtained and used without any further purification.

Removal of the dithioester endgroup to give [ICEMA-Sty] copolymer (4)

A 50 mL pear-shaped flask was charged with a solution of 4a (1.20 g, 1.00 mmol equiv. of NCO) in 5 mL of toluene followed by an excess of AIBN (400 mg, 2.44 mmol) and the polymerization mixture degassed by sparging with nitrogen for 10 minutes. The flask was then heated in an oil bath at 75°C for 4 h and the resulting colorless solution precipitated directly into 50 mL of dry hexanes. The supernatant was decanted and the white, solid polymer precipitate redissolved in a minimum of dichloromethane and transferred to a 6 dram vial. The vial was placed on a rotary evaporator until the majority of solvent was removed and then under high vacuum to dryness. After weighing to determine conversion/yield, 0.99 g of copolymer 4 (Isolated yield 95%) was obtained; Mw = 69 000; PDI = 1.09; IR 3080−2850, 2265, 1728, 1599, 1493, 1452, 1375, 1350, 1265, 1170, 1110 and 1070 cm−1; 1H NMR (200 MHz, CDCl3) δ 7.13 (b, styrene) 6.64 (b, styrene) 3.47−2.59 (t, CH2), 1.86−0.59 (m, CH, CH2).

Preparation of linear control copolymers incorporating urea groups (2 and 5)

A 100 mL round bottom flask was charged with a mixture of the previously prepared isocyanate functionalized copolymer 1 (0.51 g, 0.5 mmol equivalents of NCO) in 25 mL of THF. An excess of 2-methoxyethylamine (0.43 g, 0.5 mL, 5.76 mmol) was added to the solution and stirring continued at room temperature for 2 hours. The resulting polymer solution was precipitated into 50 mL of dry hexanes, filtered and the solid dried under high vacuum to give 2 as a white solid (0.53 mg, 98%); Mw = 151 000; PDI = 1.23; IR 3425 (N-H) 3050−2800, 1733, 1690, 1660, 1562, 1486, 1452, 1392, 1274, 1245, 1195 and 1151 cm−1; 1H NMR (200 MHz, CDCl3) δ 6.00 (broad, NH), δ 4.09 (bt, CH2), 3.59 (bt, CH3), 1.82 (bs, CH3), 1.25−0.85 (m, CH2). A similar procedure was used to prepare control samples from the styrene copolymers (4) using dichloromethane as solvent.

General Procedure for Nanoparticle Formation (3 and 6)

The isocyanate functionalized copolymer 1 (500 mg, 0.29 mmol equiv. of NCO) was dissolved in 25 mL of freshly distilled THF. A 100 mL round bottom flask was then charged with 0.5 equivalents of 2,2’-(ethylenedioxy)diethylamine (21.5 mg, 0.145 mmol) combined with 25 mL of THF. The THF solution of 1 was added drop wise via syringe to the flask over a 10 minute period with vigorous stirring and the mixture was allowed to stir for 2 hours. An excess of either benzylamine or 2-methoxyethylamine (0.43 g, 0.50 mL, 5.76 mmol) was added to the solution and after the mixture was stirred for an additional hour, the contents were evaporated to dryness. The residue was redissolved in a minimum amount of DCM and precipitated in 50 mL of dry hexanes. The precipitate was filtered and dried in vacuo to give 3 as a white powder (390 mg, 71%), Mw = 26 600; PDI = 1.27; IR 3403 (N-H) 3050−2800, 1733, 1685, 1652, 1560, 1486, 1450, 1392, 1274, 1245, 1193 and 1149 cm−1; 1H NMR (200 MHz, CDCl3) δ 4.09 (bt, CH2), 3.59 (bt, CH3), 1.82 (bs, CH3), 1.25−0.85 (m, CH2). In the case of the polystyrene copolymers (6) the same reaction conditions were employed, however DCM was used as the solvent.

3. Results and Discussion

In examining the selection of benzocyclobutane (BCB) as a crosslinking group for intramolecular chain collapse,16 the positive features were its stability to radical polymerization, high reactivity under crosslinking conditions and formation of crosslinked units that are unreactive. The disadvantages of BCB are its challenging synthesis and the prohibitive temperatures at which it is activated. For example, the use of 250°C benzyl ether solutions precludes the presence of sensitive functional groups in the nanoparticles and reduces the range of possible structures that can be obtained. Upon examination of the BCB-based process, it becomes apparent that the development of a room temperature crosslinking strategy would significantly open up the range of nanoparticles that could be prepared under intramolecular chain collapse conditions. To address this challenge, a well-known reaction that is both efficient and devoid of side products is the formation of ureas by reaction of isocyanates with amines. This coupling reaction proceeds at ambient temperatures without the need for a catalyst, and the isocyanate group is stable to storage in the absence of water. Finally, the preparation of vinyl polymers containing isocyanate groups is facilitated by the commercial availability of 2-isocyanatoethyl methacrylate, which is a major advantage when compared to BCB–based monomers. The synthetic strategy involves copolymerization of 2-isocyanatoethyl methacrylate with a variety of vinyl monomers to give the desired linear polymers with isocyanate functionalities incorporated along the polymer backbone. Under room temperature conditions, the isocyanates do not undergo crosslinking with each other in a manner similar to BCB at elevated temperatures. In contrast, the isocyanates were coupled to a secondary component in the form of a diamine to affect crosslinking. This 2-component system was considered to be acceptable, due to the extremely rapid and quantitative reaction of isocyanates with amines at room temperature to form urea linkages and, in analogy with the BCB chemistry, the reaction is very efficient with minimal side products.

Initial studies were directed towards a methacrylate-based backbone with RAFT mediated free-radical polymerization of methacrylate comonomers (with MCPDB as chain transfer agent) being performed under standard conditions in benzene. This approach allows accurate control over molecular weight, polydispersity, and level of isocyanate incorporation leading to a library of methacrylic copolymers, 1, with 5−20% ICEMA incorporation and molecular weights, Mw, between 25−150 kDa (Scheme 1). Due to the sensitivity of isocyanates to water, it was found that storing the dried copolymers for extended periods of time (1+ months) led to crosslinking even at −20°C under an inert atmosphere. However, creation of a 0.05 M stock solution of the purified copolymers in dry THF gave a stable solution that could be stored for months without any undesired side reactions of the pendant isocyanate groups.

Scheme 1.

Synthesis of isocyanatoethyl methacrylate-methyl methacrylate (ICEMA-MMA) copolymer 1.

It is clear that for the collapse reaction, either the diamine can be added to a solution of the isocyanate copolymer or vice versa. Initial studies showed that more efficient and reproducible intramolecular chain collapse was observed when a THF solution of the isocyanate copolymer was added to a solution of the diamine, which was maintained at 0.5 equivalents of total isocyanate concentration. From these experiments, it was determined that the onset of gelation occurred at a total chain concentration of approximately 0.3 mM with the collapse reaction being more efficient for higher molecular weight samples and for lower isocyanate loading, which is consistent with modeling studies.8 From these studies it was decided that all collapse reactions would be performed at a concentration of ∼ 0.1 mM and were typically conducted on gram quantities with the diamine of choice being 2,2’-(ethylenedioxy)diethylamine.

As shown in Scheme 2, the synthetic procedure involves continuous dropwise addition of the copolymer to the diamine-containing solution and, after the addition was complete, the reaction was allowed to stir at room temperature for 2 hours to allow the intramolecular reaction to reach completion. Isolation of the nanoparticles at this stage of the process resulted in gelation of the sample, presumably due to the presence of accessible isocyanate and amine groups at the surface of. or within the nanoparticles. These reactive units were then able to undergo inter-nanoparticle reactions leading to crosslinking,18 consistent with simulation studies showing that these functional groups along the backbone of linear polymers and intramolecular crosslinked structures are mobile and accessible.18 To overcome this undesired inter-nanoparticle coupling, unreacted isocyanate groups were capped by reaction with an excess of 2-methoxyethylamine. Following this procedure allowed the reaction mixture to be concentrated and the resulting solid cleanly redissolved in a minimum of DCM and precipitated into hexanes. The collapsed product, a white powder, was stable under ambient conditions and was shown to be soluble in a variety of organic solvents, including DCM, THF, dimethylsulfoxide, etc. Significantly, the nanoparticles typically required some heat or the addition of a few drops of methanol (the particles were insoluble in pure methanol) to redissolve, and this behavior may be attributed to inter-nanoparticle supramolecular, H-bonding interactions between the hydrogen bonding urea groups that are formed upon reaction of the isocyanate groups with the diamine.15,19 A recent paper from Meijer15a elegantly demonstrates the dramatic influence of supramolecular interactions in intramolecular nanoparticle assembly and disassembly.

Scheme 2.

Schematic representation of the intramolecular collapse of 2-isocyanatoethyl methacrylate-co-methyl methacrylate (ICEMA-co-MMA) copolymer 1, to give nanoparticle 3, and reaction with 2-methoxyethylamine to form the control linear copolymer 2.

Having obtained soluble products from the above reaction, complete characterization of the nanoparticles was essential to demonstrate the discrete, intramolecular nature of the collapse process. Comparison of the GPC traces for the collapsed nanoparticles versus the starting linear copolymers is an efficient diagnostic technique for demonstrating the volume change that would be expected for collapse of a random coil polymer to give an intramolecularly crosslinked nanoparticle. As shown in Figure 2 for methyl methacrylate based copolymers containing 5, 10, 15 and 20 mol% of isocyanate-functionalized repeat units, a remarkable increase in retention time is observed on increasing the relative percentage of isocyanate groups along the backbone from 5 mol% to 20 mol%. This increased retention time corresponds to a reduction in hydrodynamic volume with increasing intramolecular crosslink density, fully consistent with prior work.16 A similar trend was observed for higher molecular weight starting copolymers with molecular weights from 45 kDa to 150 kDa (Table 1). An interesting contrast with BCB-based systems was the increased polydispersity for the nanoparticle in general when compared to the starting linear polymers. One possible explanation for this is that the two-component crosslinking reaction leads to a greater dispersity in intramolecular crosslink densities and hence a greater size range.

Figure 2.

Overlay of GPC traces for: (a) the starting ICEMA-MMA copolymer 1 (Mn = 47 000) and nanoparticles 3 with (b) 5 mol% NCO original content (c) 10 mol% NCO original content (d) 15 mol% NCO original content and (e) 20 mol% NCO original content.

Table 1.

Polystyrene equivalent molecular weights and polydispersities for ICEMA-MMA based copolymers, 1, and the corresponding intramolecularly collapsed nanoparticles, 3.

| GPC Data | Copolymer 1 | Nanoparticle 3 | |||

|---|---|---|---|---|---|

| Copolymer | %NCO | Mw | PDI | Mw | PDI |

| ICEMA-MMA | 5 | 47 000 | 1.20 | 44 100 | 1.61 |

| ICEMA-MMA | 10 | 45 300 | 1.26 | 15 400 | 1.56 |

| ICEMA-MMA | 15 | 48 000 | 1.25 | 11 500 | 1.63 |

| ICEMA-MMA | 20 | 50 200 | 1.30 | 8 500 | 1.36 |

| ICEMA-MMA | 5 | 78 300 | 1.23 | 60 600 | 1.48 |

| ICEMA-MMA | 10 | 82 400 | 1.44 | 35 700 | 1.37 |

| ICEMA-MMA | 15 | 84 200 | 1.31 | 26 500 | 1.64 |

| ICEMA-MMA | 5 | 101 000 | 1.25 | 59 500 | 1.35 |

| ICEMA-MMA | 10 | 118 000 | 1.30 | 25 000 | 1.32 |

| ICEMA-MMA | 5 | 135 000 | 1.19 | 59 100 | 1.17 |

| ICEMA-MMA | 10 | 138 000 | 1.23 | 44 500 | 1.29 |

| ICEMA-MMA | 15 | 149 000 | 1.23 | 26 600 | 1.27 |

As a control system, the synthesis of linear control copolymers was performed to ensure that the observed change in retention volume is not an artifact due to the interactions of the polar urea functional groups along the backbone with the GPC packing material. Reaction of 1 with an excess of 2-methoxyethyl amine, essentially one half of the diamine crosslinker, leads to a linear copolymer, 2, which has the same number of backbone repeat units as 1 and 3 and essentially the same polar urea units along the backbone (Scheme 2). These linear control polymers have similar molecular weights and polydispersities to the reactive ICEMA-MMA precursors, 1, with chemically equivalent side groups to the nanoparticles, 3. Additionally, the white color of both the control polymer 2 and the nanoparticle 3 was strong evidence that reaction of the starting copolymers (pink due to the dithioester chain end) with excess amine caused aminolysis19 and loss of the dithioester end groups. Direct comparison of the THF-GPC traces of a 10% isocyanate functionalized starting copolymer to its analogous linear control polymer and nanoparticle products revealed that ureas along the backbone are not responsible for the dramatic reduction in apparent molecular weight. Only a slight difference in retention time was observed between copolymers 1 and 2 when compared to the dramatic difference between 1 and 3, which strongly suggests that the change in hydrodynamic volume is primarily due to a change in macromolecular architecture (Figure 3).

Figure 3.

Overlay of GPC traces for the starting ICEMA-MMA copolymer 1, (Mn = 45 300), the corresponding linear control polymer 2 and nanoparticle 3.

To confirm the globular structure of the intramolecularly crosslinked nanoparticles, solution viscosity and light scattering measurements were conducted. Examination of the nanoparticle, 3, derived from a 15 mol% NCO functionalized, 150 kDa ICEMA-MMA copolymer, 1, and the corresponding, starting linear/control copolymer, 2, by DMF-GPC with MALLS suggested a decrease in hydrodynamic radius from 15 nm to 8 nm for the urea-collapsed nanoparticle, 3 vs. urea-functionalized linear system, 2, while comparison of intrinsic viscosity measurements was consistent with a three-fold lower intrinsic viscosity for the collapsed nanoparticle (45 to 15 mL/g). Similarly, dynamic light scattering (DLS) was performed in THF on the collapsed nanoparticles and their respective linear control polymers. For the 150 kDa copolymer (15 mol%), the results again supported a change in effective diameter between the random coil of the control polymer (25 nm) and the crosslinked, collapse nanoparticle analog (16 nm). Light scattering measurements in either chloroform or toluene gave comparable results and further supports the generation of a chain collapsed, three-dimensional nanoparticle.

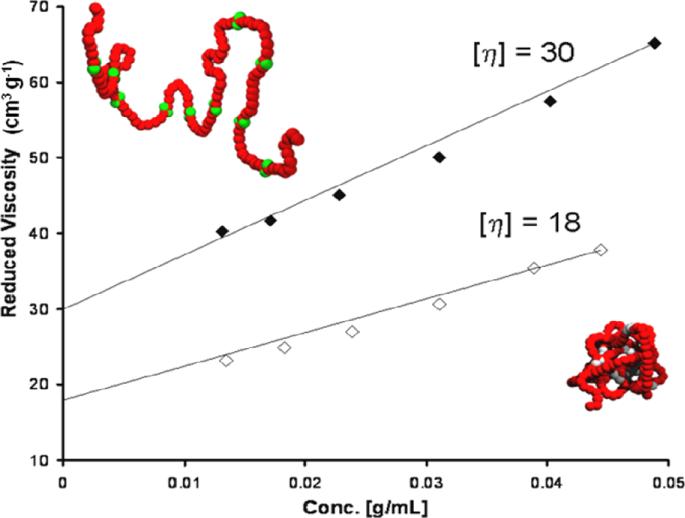

Another dramatic demonstration of the change in physical properties due to a change in macromolecular architecture is represented by the reduced viscosity plot for 2 and 3 , which shows a significant drop in viscosity for a solution of nanoparticles 3 relative to linear uncrosslinked polymer 2 (Figure 4). Interestingly, for the 100 kDa and 150 kDa linear control copolymers, an increase in intrinsic viscosity [η] from 31 to 37 mL/g is observed, which is fully consistent with the increase in molecular weight from the functionalization of 1 to afford 2. In direct contrast, the analogous nanoparticles not only displayed much lower reduced viscosities (below 20 mL/g) but there was no significant difference between the two samples even though the molecular weights differ by 50%. This result is consistent with the Einstein's prediction that the intrinsic viscosity of a constant density sphere is independent of its molecular weight (5/2 divided by the sphere density).21 Clearly, the difference in solution viscosities provides further evidence that urea formation leads to intramolecular crosslinking and formation of three-dimensional nanoparticles.22

Figure 4.

Plot of reduced viscosity versus concentration for control copolymers 2 (■ 150 kDa, ▲ 100 kDa) and (b) their analogous crosslinked nanoparticles 3 (□ 150 kDa, △ 100 kDa) in THF. Both copolymers were prepared from starting polymers incorporating ca. 15mol% NCO functional groups along the backbone.

One significant difference between this strategy and other chain collapse chemistries is the use of a difunctional, small molecule crosslinker that undergoes reaction with the isocyanate groups along the backbone. As a result of steric hindrance and restricted motion, not all of the isocyanates on the copolymers undergo reaction and, conversely, not all of the singly reacted diamines form crosslinks. The resulting nanoparticles would, therefore, be expected to have unreacted isocyanate and unreacted amino groups present within the nanostructure. To examine the level of unreacted isocyanate groups, the collapse chemistry was conducted as described above followed by the addition of a large excess of benzylamine to react with any isocyanate groups that did not participate in the intramolecular crosslinking reaction. The use of benzyl amine was driven by its unique aromatic resonances in the solution 1H NMR spectra of the collapsed nanoparticles. Integration of the aromatic peaks in the NMR spectra and comparison with the methyl ester peaks of the backbone showed that ca. 25% of the total isocyanates along the backbone underwent reaction with benzylamine, suggesting that ca. 75% of the isocyanate groups participated in the intramolecular crosslinking reaction. The amount of uncrosslinked groups clearly depends on the macromolecule's properties (i.e. backbone stiffness, solvent conditions, etc.) and may be tuned with reaction conditions.18 Consumption of isocyanate groups during reaction with the diamine followed by quenching with the monoamine was confirmed by the disappearance of the NCO band in the FT-IR spectra for both the linear control polymer 2 and the nanoparticle 3 (Figure 5). Similarly, excess amino groups were also present and could be identified by reaction with either phenyl isocyanate or benzyl isocyanate followed by 1H NMR analysis. In this case, the level of functionalization was less than 5%, demonstrating that significantly fewer unreacted amino groups are present when compared to unreacted isocyanates. It should be noted, however, that while 100% intramolecular crosslinking was not obtained during reaction with the diamine, the presence of unreacted isocyanate and amino groups is a useful tool for secondary functionalization of the nanoparticles with active components and functional groups.

Figure 5.

Infrared spectra for (a) the starting copolymer 1, (Mn = 149 000, 15 mol%NCO) (b) the control copolymer 2, and (c) the nanoparticle 3. The band for the isocyanate stretch (2275 cm−1) can be clearly seen in the copolymer and is replaced by the bands (1650, 1560 cm−1) for the urea groups in both the control polymer and the nanoparticle.

The use of RAFT-mediated living free radical polymerization for the synthesis of these materials also allows for the preparation of a variety of linear copolymers with other vinyl monomers. As shown in Scheme 3, copolymers based on styrene, 4, could also be employed without any significant changes to the collapse process, giving nanoparticles, 6, which exhibited similar reductions in hydrodynamic volume on comparison with the corresponding linear control copolymer, 5 (Table 2).

Scheme 3.

Schematic representation of the formation and intramolecular collapse of isocyanatoethyl methacrylate-styrene (ICEMA-Sty) copolymer 4, to give nanoparticle 6, and the corresponding reaction with 2-methoxyethylamine to form the linear, control copolymer 5.

Table 2.

Polystyrene equivalent molecular weights and polydispersities for ICEMA-Sty based copolymers, 4, and the corresponding intramolecularly collapsed nanoparticles, 6.

| GPC Data | Copolymer 4 | Nanoparticle 6 | |||

|---|---|---|---|---|---|

| Copolymer | %NCO | Mw | PDI | Mw | PDI |

| ICEMA-Sty | 5 | 36 000 | 1.07 | 22 000 | 1.14 |

| ICEMA-Sty | 10 | 38 000 | 1.07 | 14 000 | 1.12 |

| ICEMA-Sty | 5 | 71 000 | 1.14 | 62 500 | 1.24 |

| ICEMA-Sty | 10 | 72 000 | 1.19 | 50 500 | 1.21 |

| ICEMA-Sty | 5 | 69 000 | 1.09 | 59 000 | 1.31 |

| ICEMA-Sty | 10 | 73 000 | 1.1 | 48 600 | 1.26 |

| ICEMA-Sty | 10 | 114 000 | 1.19 | 56 200 | 1.17 |

For the styrene-based copolymers, removal of the dithioester endgroup of 4a was required23 to facilitate the formation of stable, linear control polymers and nanoparticles. Unlike the MMA-based materials where the dithioester endgroups were cleaved by aminolysis resulting in intramolecular cyclization and formation of a stable thioester group, similar chemistry for the ICEMA-Sty copolymers resulted in the formation of a thiol at the polymer terminus and subsequent chain coupling via disulfide formation and varying amounts of higher molecular weight products were observed. Therefore, it was necessary to remove the dithioester prior to control/collapse conditions and immediately after precipitation of the copolymer 4a, the crude product was allowed to undergo reaction with an excess of AIBN, removing the thiol functionality and giving an isobutyronitrile chain end (Scheme 3).

After intramolecular collapse of the chain end-modified materials, solution viscosity experiments, performed in chloroform, showed the expected differences in behavior between the crosslinked nanoparticle, 6, and the corresponding functionalized linear control copolymer, 5 (Figure 6). Chloroform GPC with multi-angle laser light scattering (MALLS) was also employed to further analyze the ICEMA-Sty materials and the results confirmed a reduction in the radius of gyration from 12.5 nm for a 38 kDa linear control polymer 5 to 8.0 nm for the analogous nanoparticle 6. Dynamic light scattering performed on chloroform solutions of the 38 kDa and 72 kDa nanoparticles (10 mol% NCO, 6, 10 mg/mL) also gave effective particle diameters of 8.7 nm and 11.8 nm, respectively. From these data it can be concluded that a similar volume reduction and crosslinking extent is observed for both the styrenic and methacrylate based materials, illustrating the efficiency and orthogonality of the urea-based intramolecular crosslinking reaction.

Figure 6.

Plot of reduced viscosity (in CHCl3) versus concentration for control copolymers 5 (• 72 kDa, 10mol% NCO) and their analogous crosslinked nanoparticles 6 (○ 72 kDa, 10mol% NCO).

While the chain collapse chemistry was similar for both systems, one significant difference was the solubility for each set of nanoparticles. Attempts to solubilize the styrenic-based nanoparticles or perform the collapse chemistry in THF, which was the preferred solvent for the methacrylate-based systems, resulted in only poorly soluble or intractable materials. Slightly better results were found when the composition of ICEMA-Sty had a reduced amount of the isocyanate functionality (typically 5 mol%), suggesting a subtle interplay between backbone solubility and H-bonding of the urea groups for the non-polar styrenic backbone. However, performing the same reaction in either dichloromethane or chloroform dramatically increased the solubility and led to the formation of highly soluble nanoparticles, 6, in all cases.

4. Conclusions

In summary, a new synthetic approach to the preparation of intramolecularly collapsed nanoparticles is presented. From commercially available vinyl monomers, isocyanate functionalized linear copolymers can be routinely prepared on large scale and subsequent reaction with a diamine in dilute solution leads to the efficient formation of intramolecularly crosslinked polymeric nanoparticles. By varying the molecular weight and mole percentage of isocyanates for the starting linear copolymer, nanoparticles with diameters ranging from 8−20 nm were obtained with these materials showing physical properties fully consistent with a collapsed, three-dimensional structure. In comparison with the corresponding linear control copolymers, prepared by reaction with mono-functional amines, the collapsed products from difunctional amine crosslinking possessed significantly lower viscosities and hydrodynamic radii. Analysis of the collapse reaction revealed that approximately 75% of the isocyanate groups along the backbone underwent crosslinking with 25% being available for further reaction with mono-functional amines. This stepwise crosslinking and functionalization allows the chemical and physical properties of the nanoparticles to be further tuned and significantly opens up the range of nanoparticles that can be prepared using this mild and highly efficient chemistry, with future work examining the synthesis of functionalized nanoparticles.

Acknowledgements

The authors thank Dr. Newman Bortnick (Rohm and Haas) and Professor E.W. Meijer (Eindhoven) for invaluable scientific discussions and insights. Financial support from BASF, the National Science Foundation under the MRSEC Program (DMR-0520415; MRL-UCSB) and the Nanoscale Interdisciplinary Research Team (NIRT) program 0506309, and the National Heart Lung and Blood Institute of the National Institutes of Health as a Program of Excellence in Nanotechnology (HL080729) is gratefully acknowledged.

References

- 1.a Hedrick JL, Miller RD, Hawker CJ, Carter KR, Volksen W, Yoon DY, Trollsas M. Adv. Mater. 1998;10:1049. [Google Scholar]; b Hawker CJ, Hedrick JL, Miller RD, Volksen W. MRS Bull. 2000;25:54. [Google Scholar]; c Yang S, Mirau PA, Pai CS, Nalamasu O, Reichmanis E, Lin EK, Lee HJ, Gidley DW, Sun JN. Chem. Mater. 2001;13:2762. [Google Scholar]

- 2.a Liu M, Fréchet JMJ. Pharm. Sci. Technol. Today. 1999;2:393. doi: 10.1016/s1461-5347(99)00203-5. [DOI] [PubMed] [Google Scholar]; b Du WJ, Xu ZQ, Nystrom AM, Zhang K, Leonard JR, Wooley KL. Bioconjugate Chem. 2008;19:2492–2498. doi: 10.1021/bc800396h. [DOI] [PMC free article] [PubMed] [Google Scholar]; c Niemeyer CM. Angew. Chem., Int. Ed. 2001;40:4128. doi: 10.1002/1521-3773(20011119)40:22<4128::AID-ANIE4128>3.0.CO;2-S. [DOI] [PubMed] [Google Scholar]; d Guillaudeu SJ, Fox ME, Haidar YM, Dy EE, Szoka FC, Frechet JMJ. Bioconjugate Chem. 2008;19:461–469. doi: 10.1021/bc700264g. [DOI] [PubMed] [Google Scholar]; e van der Ende A, Croce T, Hamilton S, Sathiyakumar V, Harth E. Soft Matter. 2009;5:1417–1425. [Google Scholar]; f Sudeep PK, Page Z, Emrick T. Chem. Commun. 2008:6126–6127. doi: 10.1039/b813025f. [DOI] [PubMed] [Google Scholar]; Rowan SJ. Nature Materials. 2009;8:89–91. doi: 10.1038/nmat2365. [DOI] [PubMed] [Google Scholar]

- 3.a Mackay ME, Dao TT, Tuteja A, Ho DL, Van Horn B, Kim H-C, Hawker CJ. Nature Materials. 2003;2:762. doi: 10.1038/nmat999. [DOI] [PubMed] [Google Scholar]; b Krishnan RS, Mackay ME, Duxbury PM, Pastor A, Hawker CJ, Van Horn B, Asokan S, Wong MS. Nano Letts. 2007;7:484–489. doi: 10.1021/nl062866u. [DOI] [PubMed] [Google Scholar]

- 4.a Oh JK. J. Polym. Sci., Part A: Polym. Chem. 2008;46:6983–7001. [Google Scholar]; b Zhang G, Niu A, Peng S, Jiang M, Tu Y, Li M, Wu C. Acc. Chem. Res. 2001;34:249. doi: 10.1021/ar000011x. [DOI] [PubMed] [Google Scholar]; c Matyjaszewski K, Qiu J, Tsarevsky NV, Charleux B. J. Polym. Sci., Part A: Polym. Chem. 2000;38:4724. [Google Scholar]; d Landfester K. Adv. Mater. 2001;13:765. [Google Scholar]; e Pilcher SP, Ford WT. J. Polym. Sci., Part A: Polym. Chem. 2001;39:519. [Google Scholar]; h van Berkel KY, Piekarski AM, Kierstead PH, Pressly ED, Ray PC, Hawker CJ. Macromolecules. 2009;42:1425–1427. [Google Scholar]

- 5.a Bosman AW, Jansen HM, Meijer EW. Chem. Rev. 1999;99:1665. doi: 10.1021/cr970069y. [DOI] [PubMed] [Google Scholar]; b Hecht S, Fréchet JMJ. Angew. Chem., Int. Ed. 2001;40:74. doi: 10.1002/1521-3773(20010105)40:1<74::aid-anie74>3.0.co;2-c. [DOI] [PubMed] [Google Scholar]; c Percec V, Cho WD, Ungar G, Yeardley DJP. J. Am. Chem. Soc. 2001;123:1302. [Google Scholar]; d Moore JS. Acc. Chem. Res. 1997;30:402. [Google Scholar]; e Topp A, Bauer BJ, Klimash JW, Spindler R, Tomalia DA, Amis EJ. Macromolecules. 1999;32:7226. [Google Scholar]; f Hawker CJ, Frechet JMJ. Polymer. 1992;33:1507. [Google Scholar]; g Zhang DH, Hamilton PD, Kao JLF, Venkataraman S, Wooley KL, Ravi N. J. Polym. Sci., Part A: Polym. Chem. 2007;45:2569–2575. [Google Scholar]; h Fukukawa KI, Rossin R, Hagooly A, Pressly ED, Hunt JN, Messmore BW, Wooley KL, Welch MJ, Hawker CJ. Biomacromolecules. 2008;9:1329–1339. doi: 10.1021/bm7014152. [DOI] [PubMed] [Google Scholar]; i Pressly ED, Rossin R, Hagooly A, Fukukawa KI, Messmore BW, Welch MJ, Wooley KL, Lamm MS, Hule RA, Pochan DJ, Hawker CJ. Biomacromolecules. 2007;8:3126–3134. doi: 10.1021/bm700541e. [DOI] [PubMed] [Google Scholar]; j Wooley KL, Hawker CJ, Fréchet JMJ. Angew. Chem. Int. Ed. Engl. 1994;33:82–85. [Google Scholar]; k Hawker CJ, Fréchet JMJ. J. Chem. Soc. Perkin Trans. 1992:2459–2465. [Google Scholar]

- 6.a Huang H, Remsen EE, Kowalewski T, Wooley KL. J. Am. Chem. Soc. 1999;121:3805. [Google Scholar]; b Ma Q, Wooley KL. J. Polym. Sci., Part A: Polym. Chem. 2000;38:4805. [Google Scholar]; c Liu S, Armes SP. J. Am. Chem. Soc. 2001;123:9910. doi: 10.1021/ja011206i. [DOI] [PubMed] [Google Scholar]; d Zhang K, Rossin R, Hagooly A, Chen ZY, Welch MJ, Wooley KL. J. Polym. Sci., Part A: Polym. Chem. 2008;46:7578–7583. doi: 10.1002/pola.23020. [DOI] [PMC free article] [PubMed] [Google Scholar]; e Noh T, Kook YH, Park C, Youn H, Kim H, Oh ET, Choi EK, Park HJ, Kim C. J. Polym. Sci., Part A: Polym. Chem. 2008;46:7321–7331. [Google Scholar]; f Zhou Y, Jiang K, Chen Y, Liu S. J. Polym. Sci., Part A: Polym. Chem. 2008;46:6518–6531. [Google Scholar]

- 7.Kumar A, Nanvati H, Kumaraswamy G. J. Chem. Phys. 2007;127:234901. doi: 10.1063/1.2802296. [DOI] [PubMed] [Google Scholar]

- 8.Li RJ, McCoy J. Macromo. Rapid Commun. 2004;25:1059–1063. [Google Scholar]

- 9.a Lemcoff NG, Spurlin TA, Gewirth AA, Zimmerman SC, Beil JB, Elmer SL, Vandeveer HG. J. Am. Chem. Soc. 2004;126:11420–11421. doi: 10.1021/ja047055b. [DOI] [PubMed] [Google Scholar]; b Van Renterghem LM, Lammens M, Dervaux B, Viville P, Lazzaroni R, Du Prez FE. J. Am. Chem. Soc. 2008;130:10802–10811. doi: 10.1021/ja801055f. [DOI] [PubMed] [Google Scholar]

- 10.Mackay ME, Tuteja A, Duxbury PM, Hawker CJ, van Horn B, Guan ZB, Chen GH, Krishnan RS. Science. 2006;311:1740–1743. doi: 10.1126/science.1122225. [DOI] [PubMed] [Google Scholar]

- 11.a Mecerreyes D, Lee V, Hawker CJ, Hedrick JL, Wursch A, Volksen W, Magbitang T, Huang E, Miller RD. Adv. Mater. 2001;13:204–208. [Google Scholar]; b Jiang J, Thayumanavan S. Macromolecules. 2005;38:5886–5891. [Google Scholar]

- 12.Cherian AE, Sun FC, Sheiko SS, Coates GW. J. Am. Chem. Soc. 2007;129:11350–11351. doi: 10.1021/ja074301l. [DOI] [PubMed] [Google Scholar]

- 13.de Luzuriaga AR, Ormategui N, Grande HJ, Odriozola I, Pomposo JA, Loinaz I. Macromo. Rapid Commun. 2008;29:1156–1160. [Google Scholar]

- 14.Njikang G, Liu G, Curda SA. Macromolecules. 2008;41:5697–5702. [Google Scholar]

- 15.a Foster EJ, Berda EB, Meijer EW. J. Am. Chem. Soc. 2009;131:6964–6966. doi: 10.1021/ja901687d. [DOI] [PubMed] [Google Scholar]; b Seo M, Beck BJ, Paulusse JMJ, Hawker CJ, Kim SY. Macromolecules. 2008;41:6413–6418. [Google Scholar]

- 16.a Harth E, Van Horn B, Lee VY, Germack DS, Gonzales CP, Miller RD, Hawker CJ. J. Amer. Chem. Soc. 2002;124:8653. doi: 10.1021/ja026208x. [DOI] [PubMed] [Google Scholar]; b Pyun J, Tang CB, Kowalewski T, Frechet JMJ, Hawker CJ. Macromolecules. 2005;38:2674–2685. [Google Scholar]; c Kim Y, Pyun J, Fréchet JMJ, Hawker CJ, Frank CW. Langmuir. 2005;21:10444–10458. doi: 10.1021/la047122f. [DOI] [PubMed] [Google Scholar]; e Croce TA, Hamilton SK, Chen ML, Muchalski H, Harth E. Macromolecules. 2007;40:6028–6031. [Google Scholar]; f Hamilton SK, Harth E. ACS Nano. 2009;3:402–410. doi: 10.1021/nn800679z. [DOI] [PubMed] [Google Scholar]

- 17.Perrier S, Takolpuckdee P, Westwood J, Lewis DM. Macromolecules. 2004;37:2709. [Google Scholar]

- 18.Liu JW, Mackay ME, Duxbury PM. Europhys Letters. 2008;84:46001. [Google Scholar]

- 19.Botterhuis NE, van Beek DJM, van Gemert GML, Bosman AW, Sijbesma RP. J. Polym. Sci., Part A: Polym. Chem. 2008;46:3877–3885. [Google Scholar]

- 20.a Xu J, He J, Fan D, Wang X, Yang Y. Macromolecules. 2006;39:8616–8624. [Google Scholar]; b Deletre M, Levesque G. Macromolecules. 1990;23(22):4733–4741. [Google Scholar]; c Achilleos M, Legge TM, Perrier S, Patrickios CS. J. Polym. Sci., Part A: Polym. Chem. 2008;46:7556–7565. [Google Scholar]; d Barner-Kowollik C, Perrier S. J. Polym. Sci., Part A: Polym. Chem. 2008;46:5715–5723. [Google Scholar]

- 21.Jeong M, Mackay ME, Hawker CJ, Vestberg R. Macromolecules. 2001;34:4927–4936. [Google Scholar]

- 22.Mourey TH, Turner SR, Rubinstein M, Frechet JMJ, Hawker CJ, Wooley KL. Macromolecules. 1992;25:2401. [Google Scholar]

- 23.Chong YK, Moad G, Rizzardo E, Thang SH. Macromolecules. 2007;40:4446. [Google Scholar]