Abstract

A core-sheath of multi-walled carbon nanotube (MWNT)-cellulose fibers of diameters from several hundreds nm to several µm were prepared by co-axial electrospinning from a non-valatile, non-flammable ionic liquid (IL) solvent, 1-methyl-3-methylimidazolium acetate ([EMIM][Ac]). MWNTs were dispersed in IL to form a gel solution. This gel core solution was electrospun surrounded by a sheath solution of cellulose disolved in the same IL. Electrospun fibers were collected in a coagulation bath containing ethanol-water to completely remove the IL and dried to form a core-sheath MWNT-cellulose fibers having a cable structure with a conductive core and insulating sheath. Enzymatic treatment of a portion of a mat of these fibers with cellulase selectively removed the cellulose sheath exposing the MWNT core for connection to an electrode. These MWNT-cellulose fiber mats demonstrated excellent conductivity due to a conductive pathway of bundleled MWNTs. Fiber mat conductivity increased with increasing ratio of MWNT in the fibers with a maximum conductivity of 10.7 S/m obtained at 45 wt% MWNT loading.

1. Introduction

Carbon nanotubes (CNTs) have attracted significant interest for a wide variety of potential applications due to their high strength, flexibility, and high electrical and thermal conductivities.1–4 The electrical properties of a polymer matrix have been enhanced by using shear mixing to introduce a very low loading of CNTs.5 However, the strong van der Waals interactions between CNTs make it difficult to achieve high CNT loadings, good dispersion and alignment within polymer matrices. Thus, the preparation of structured CNT nanocomposites with desirable electrical, thermal, and strength properties remains challenging. A mixture of single wall carbon nanotubes (SWNTs) and imidazolium-based room temperature ionic liquids (RTILs) have been reported to form ordered, viscoelastic gels after being ground together.6 These heavily entangled SWNT bundles were found to untangle within the gels, forming much finer bundles and resulting in having suitable flow properties for several standard processing methods, such as painting, injection, and extrusion.

Electrospinning, a method to extrude fibers at high speed from a solution using electrostatic charging, was first reported in 1934, and has been used to prepare continuous quasi-one-dimensional, ultra-fine fibers with diameters ranging from nanometers to micrometers.7 Several types of hybrid nanofibers have been fabricated using electrospinning by incorporating nanomaterials into polymer solutions.8 Recently, a new electrospinning method has been described by our laboratory relying on non-volatile ionic liquid (IL) solvents.9 Electrospun polymer fibers are collected in a coagulation bath containing an IL co-solvent and a polymer anti-solvent.9,10 ILs can dissolve many biopolymers, such as cellulose, silk, and chitosan that are insoluble in solvents such as water or alcohol. The electrospinning of these biopolymers has several advantages compared to conventional electrospinning that relies on volatile and often flammable solvents. ILs are non-volatile and non-flammable, reducing the risk of ignition and explosion, providing a safer electrospinning process. Owing to exceptionally low vapor pressure of ILs, loss of solvent is small, allowing for simplified scaling to commercial and industrial processes. Additionally, it is possible to recycle the ILs from the coagulation bath by simple distillation of the latter, which reduces waste and lowers processing costs. In this way, electrospinning with ILs can be viewed as an economically attractive, environmentally friendly alternative to conventional electrospinning processes.

Sun et al.11 demonstrated that materials that cannot normally be electrospun could be fabricated into fibers through co-electrospinning, using a co-axial double needle spinneret. In this process, two different solutions are spun into a core-sheath type fiber, one through an inner needle and one through an outer needle. For example, poly(dodecylthiophene), a polymer that normally cannot be electrospun, is placed in the core (inner needle) and poly(ethylene oxide), which can be easily electrospun, is placed in the sheath (outer needle) to obtain a core-sheath nanofiber of poly(dodecylthiophene)-poly(ethylene oxide).

In the work presented here, co-axial, core-sheath nanofibers with multi-wall carbon nanotubes (MWNTs) in the core and a cellulose sheath were produced through a dry jet wet electrospinning process using RTILs as solvents. MWNT/1-methyl-3-methylimidazolium acetate ([EMIM][Ac]) IL gel, which cannot be electrospun by itself, is surrounded by easily electrospun cellulose in [EMIM][Ac], affording core-sheath nanofibers. After spinning into a coagulation bath containing water and/or alcohol, the IL was quickly removed from core and sheath, yielding core-sheath MWNT-cellulose nanofibers. The structure of these nanofibers was characterized. These nanofibers were designed to have electrically conductive MWNT cores with an insulating cellulose sheath. The cellulose sheath could be selectively removed from these nanofibers through an enzymatic reaction catalyzed by cellulase to enable connection of the nanofiber core to an electrode. The conductivities of electrospun MWNT-cellulose nanofiber mats could then be determined.

2. Experimental

Preparation of Electrospinning Solution

MWNTs, purchased from Cheap-Tubes (Brattleboro, Vermont, USA), were produced by catalytic chemical vapor dispersion (CCVD). The average diameters and lengths were 20–30 nm and 10–30 µm, respectively, with 95% purity according to the manufacturer’s specifications. 1-Ethyl-3-methylimidazolium acetate ([EMIM][Ac]) and 5-wt% cellulose (degree of cellulose polymerization 1100) in [EMIM][Ac] (Cellionic™) were obtained from Sigma-Aldrich (St. Louis, Missouri, USA. Core solutions were prepared by mixing MWNTs with [EMIM][Ac] using a mortar and pestle until the mixture becomes a homogeneous gel (approximately 30 min of hand grinding). The MWNT loading in the gel solution was varied from 1.2- to 7.0-wt%. The sheath solution was prepared by diluting the 5-wt% cellulose [EMIM][Ac] solution to 1.5 wt% with neat [EMIM][Ac]. The mixture was then mechanically stirred using a magnetic stirrer (Fisher Scientific, Pittsburgh, Pennsylvania, USA) at 80 °C to form a homogeneous solution.

Electrospinning Method

Core-sheath fibers were fabricated using a co-electrospinning process with a co-axial spinneret (MECC, Ogori, Fukuoka, Japan). The diameter of the inner needle and outer needle were 0.94 mm and 2.50 mm, respectively. The distance between the spinneret tip and aluminum collector electrode was fixed at 9 cm. Flow rate and applied voltage were optimized to obtain good electrospinnability, with typical values of 280–320 µL/min and 18–22 kV respectively. Electrospun fibers were collected into a coagulation bath, which was filled with a water/ethanol mixture to remove IL, thereby solidifying the fibers. The fibers form an entangled web (fiber mat) in the coagulation bath, and were subsequently removed and washed with ethanol and dried under vacuum to remove residual water and ethanol.

Enzymatic Selective Sheath Removal

Cellulase aqueous enzyme solution (700 U/g) from Sigma-Aldrich was used for cellulose digestion. Two sides of an electrospun fiber mat (15 mm long × 5 mm wide × 50–80 µm thick) were covered with rectangles (2 mm long ×5 mm wide × 0.45 µm thick) cut from hydrophilic poly(tetrafluoroethylene) filters (Millipore, Billerica, Massachusetts, USA), which had been impregnated with an aqueous cellulase solution (10 µL/cm2). After two days of enzymatic reaction the fiber mats were washed with deionized water to remove the digested cellulose and the cellulose sheath-off fiber mats were dried under vacuum.

Morphological Characterization

Field emission - scanning electron microscopy (FE-SEM) was performed to study the surface morphology of fibers with a JEOL JSM-6332 FE-SEM (Tachikawa, Tokyo, Japan) equipped with a secondary electron detector at an accelerating voltage of 5 kV. Prior to performing the FE-SEM analysis, fibers were coated with gold by sputtering to form a conductive film. Transmission electron microscopy (TEM) was performed with a Philips CM12 (Eindhoven, Amsterdam, Netherlands) at an accelerating voltage of 120 kV. Fibers on 400 mesh TEM grids were obtained by scooping electrospun fibers in coagulation bath with grid and drying in vacuum oven for overnight. Confocal Raman microscopy was performed using a Witec alpha 300 confocal Raman microscope (Maryville, Tennessee, USA). For excitation, 5 mW, 532 nm Nd:Yag laser was used. For the lateral CRM mappings of both pure cellulose fiber and MWNTs/cellulose fiber, areas with the sizes of 30 × 30 µm at 150 ×150 pixels (22500 spectra) were scanned using a l00× dry-objective (NA = 0.90). The acquisition time for each spectrum was 50 ms.

Mechanical Characterization

Tensile strength measurements were performed using an Instron Materials Testing Machine (Model 5543, Norwood, Massachusetts, USA) equipped with a 10 N static load cell and hydraulic grips (Instron 2712-001). Specimens were tested at 0.25-mm/min tension speed, with a 5 mm gauge length. Both load and grip-to-grip distance were measured. Tensile strength was calculated by dividing the peak load by the initial cross-sectional area of the sample.

Thermal Characterization

Thermogravimetric analysis (TGA) was performed using a computer controlled TA Instruments TGA Q50 (New Castle, Delaware, USA). The temperature was ramped up at 20 °C per min up to 700 °C with the furnace open to allow airflow along with nitrogen purge gas.

Conductivity Measurements

A fiber mat with two sheath-off areas on either side prepared by enzymatic selective sheath removal were sandwiched by aluminum foil (20 µm thick) current collectors and then compressed by clamp at 0.7 MPa. The distance between both sheath-off areas was 1 cm and the thickness of the fiber mat was 50–80 µm. Characteristic I–V curves were obtained from a partially sheath-off fiber mat at room temperature by a two-probe method using an electropotentiostat (Princeton Applied Research, Model 273A, Oak Ridge, Tennessee, USA) with an applied voltage up to 1 V at a scan rate of 100 mV/sec. The electrical conductivity of sheath-off fiber mat was calculated using Eq. 1.

| (1) |

Where the electrical conductivity σ is defined as the length L (distance between sheath-off areas) divided by the product of resistance R multiplied by the cross-sectional area A of the fiber mat, and is given in units of Siemens per meter (S/m).

3. Results and Discussion

Electrospinning of core-sheath fibers of MWNTs-cellulose

The ILs, 1-butyl-3-methylimidazolium chloride ([BMIM][Cl]) and 1-allyl-3-methylimidazolium chloride ([AMIM][Cl]), have been previously reported as solvents for electrospinning unmodified cellulose.9,10 In this study, [EMIM][Ac], having a lower viscosity and higher conductivity than either [BMIM][Cl] or AMIM][Cl], was used as a solvent for cellulose and MWNTs. These improved properties allow smaller diameter fibers to be obtained. The cellulose/[EMIM][Ac] solution was prepared at concentration of 1.5 wt%, which can be electrospun to produce solid cellulose nanofibers. MWNT/[EMIM][Ac] gel solution was prepared by grinding at concentrations of 1.2, 2.5, 4.5 and 7.0 wt%. Grinding the mixture of MWNTs and [EMIM][Ac] was employed to afford a well dispersed MWNT gel solution to obtain desirable fiber morphology without significant chemical or physical alteration of the MWNTs, and without the addition of other chemicals. Alternative approaches, such as the addition of surfactant12,13 and the surface treatment of CNTs,14,15,16 have reportedly afforded acceptable CNT dispersions in ILs. However, desirable electrical, thermal, and structural properties of CNTs may be diminished by such approaches. This gel solution exhibited good MWNT dispersion possibly due to an interaction between the π-electron cloud covering the surface of MWNTs and the delocalized electrons of the IL’s imidazolium ring.6 Attempts were made to electrospin this gel solution alone; however, only droplets were obtained and no continuous fibers were observed. The viscoelastic properties arising from the entanglement of the MWNTs were apparently insufficient to form continuous fibers. As a result, the MWNT gel solution was broken into small droplets during the elongation process of electrospinning.

Next, the MWNT gel solution was electrospun in combination with electrospinnable cellulose using a co-axial double needle spinneret. The MWNT gel solution was fed into the inner needle and the cellulose solution was fed into the outer needle, resulting in a core-sheath type fiber. Electrospun MWNT-cellulose core-sheath fibers were collected into a 50/50 vol% ethanol-water coagulation bath. [EMIM][Ac] has higher solubility in ethanol than in water, but taking into consideration the high voltage employed, the increased risk of ignition makes the use of pure ethanol unadvisable. Using a co-solvent of ethanol/water provided for a safer process with low risk of ignition combined with an adequate solidification rate. Ethanol and water can completely dissolve [EMIM][Ac] used in the dissolution, but cellulose and MWNTs are insoluble in both ethanol and water. Hence, as the fibers were formed, the ethanol/water removed the [EMIM][Ac], affording pure MWNTs-cellulose core-sheath fibers. These fibers were then subjected to further washing with ethanol until there was no residual [EMIM][Ac] within these fibers. The fibers were then dried under vacuum to remove residual ethanol and water. Complete removal of the residual [EMIM][Ac] in fiber was confirmed by FTIR (Perkin Elmer Spectrum One Spectrometer, Waltham, Massachusetts, USA).

Morphological characterization

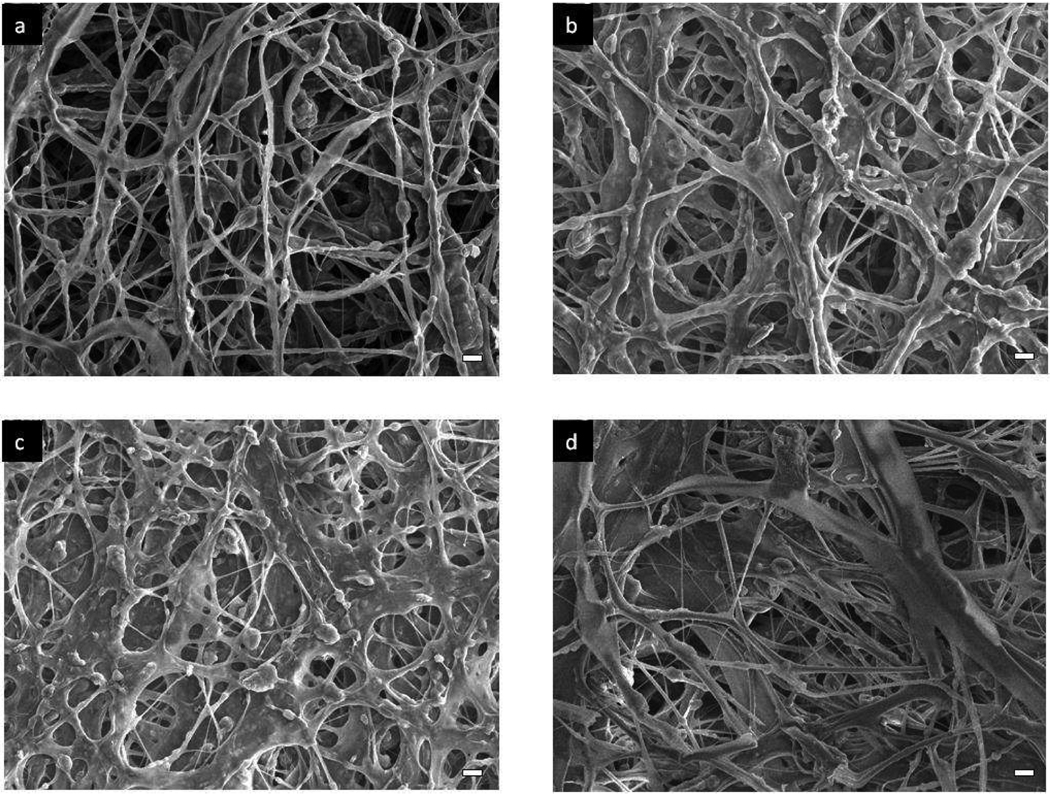

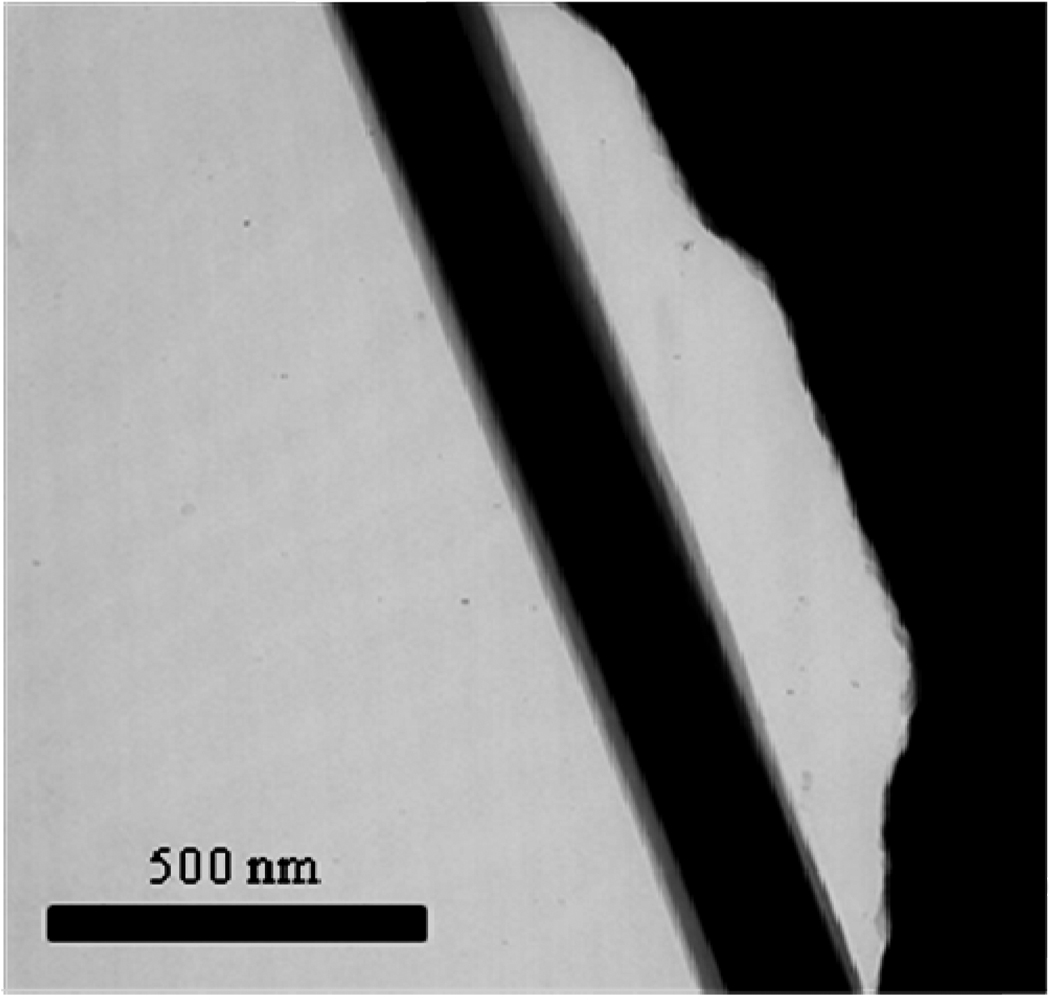

The dried fiber mats were morphologically characterized using field emission scanning microscopy (FESEM) and transmission electron microscopy (TEM). The SEM images show smooth fiber surfaces with no MWNTs protruding out of the fibers, as shown in Figure 1. Fiber diameters ranged from several hundred nanometers to micrometers. The fibers produced were not of a uniform diameter, and this is due to less than optimal spinning conditions, which can be corrected by fine tuning of the spinning solution with additives such as viscosity modifiers (e.g., DMF, DMSO) and salts to increase the conductivity of the solution. Increasing the cellulose ratio in the fibers resulted in slightly increased fiber diameters and a pronounced film-like structure over the collected fibers. This film-like structure was ascribed to slow fiber solidification within the coagulation bath causing the fibers to coalesce. TEM images in Figure 2 clearly show that these nanofibers have discernible MWNT cores and cellulose sheaths with a clear boundary between the core and sheath. This distinct boundary suggests that an exchange of materials between core and sheath did not take place during electrospinning and subsequent coagulation process.

Figure 1.

SEM images of core-sheath of MWNT-cellulose fiber mats: (a) MWNT-cellulose = 45/55 wt%; (b) 40/60 wt%; (c) 30/70 wt%; (d) 20/80 wt%. Scale bars are 10 µm in all images.

Figure 2.

TEM image of core-sheath of MWNTs-cellulose nanofiber, with a MWNT-cellulose = 40/60 wt%.

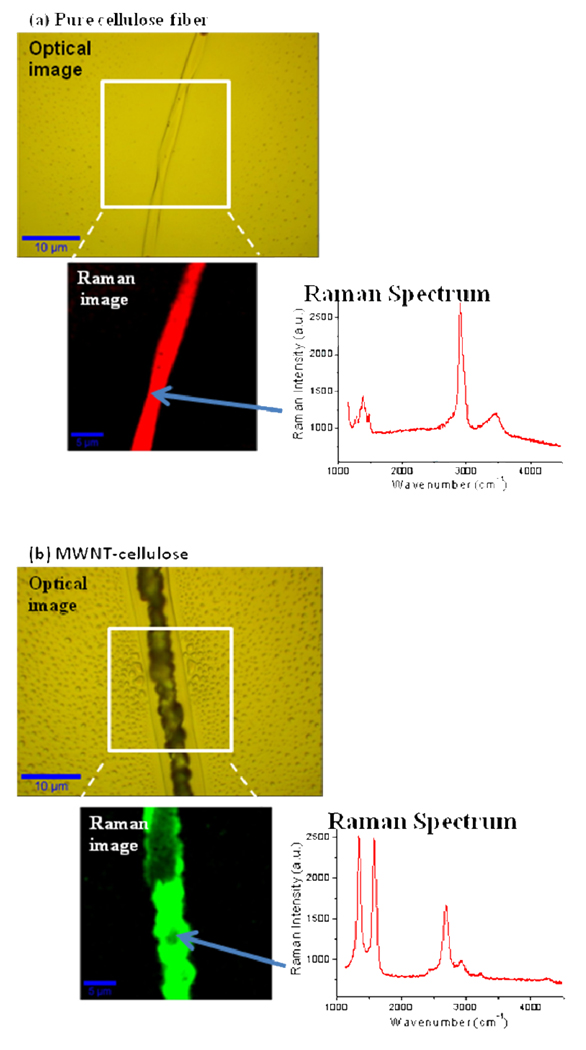

Confocal Raman Microscopy (CRM) mapping was also performed to observe core-sheath structure of one of the thicker electrospun core-sheath fibers, approximately 7-µm diameter. This larger fiber was selected due to difficulties in obtaining high contrast of core and sheath by TEM and the resolution restrictions of the CRM mapping. The MWNTs do not appear to be substantially aligned, and show a random arrangement in the core as confirmed by selected area electron diffraction (SAED) (data not shown). Core-sheath images could not be obtained because of carbonization of cellulose during CRM mapping of MWNT-cellulose fiber. For CRM mapping of pure cellulose fiber, maximum laser power was used to obtain sufficient Raman scattering signal intensity for Raman imaging. The clear CRM image of pure cellulose was obtained as shown in Figure 3(a). However, in case of CRM mapping of MWNT/cellulose fiber, the laser power was reduced to approximately 10% of the original power to avoid burning of the fiber and generating heat by MWNTs. While this lower laser power could not generate sufficient Raman scattering signal intensity to image the cellulose fraction of the fibers, we were able to image the continuous MWNT core in MWNT/cellulose fibers (Figure 3-(b)).

Figure 3.

Optical and Confocal Raman Microscope images: (a) pure cellulose fiber; (b) MWNT/cellulose fiber with a MWNT:cellulose ratio of 40%:60%.

The fibers that failed to form a core-sheath structure were more prevalent at high core solution feed rates and at high core solution concentrations. Yu et al.17 described similar results in the electrospinning of core-sheath fibers of poly(aniline)-poly(vinyl alcohol) and suggested that this was caused because the polyaniline solution had a higher charge density than the poly(vinyl alcohol) solution. According to their work, the polyaniline solution would be pulled too quickly from the spinneret by the electric field at higher solution feed rates, resulting in a discontinuous stream of polyaniline solution. Our results are consistent with these observations, as the MWNT solution similarly has a higher charge density than that of the cellulose solution. Such discontinuous streams might be minimized by combining high feed rates with larger quantities of core solution at higher concentrations (i.e., high MWNTs concentration in the core solution). By such optimization of solution properties, we were able to produce a core-sheath structure the majority of fibers. However, further work is needed to obtain absolute core continuity in all of the fibers together with a narrow fiber diameter distribution.

Mechanical and thermal characterization

Tensile strength measurements and thermogravimetric analysis (TGA) were performed to determine the impact of combining MWNTs with cellulose on the mechanical and thermal properties, respectively, of these fibers (Table 1). A pure cellulose fiber mat (15 mm ×5 mm×50–80 µm) had the highest tensile strength measured at 6.22 MPa. The tensile strength of the fiber mats was related to the cellulose (sheath) ratio in the fiber, since the individual MWNTs are not strongly connected to one another in these fibers. Despite this lack of connectivity, the fiber mat (15 mm ×5 mm × 50–80 µm) with the highest MWNT loading (45 wt%) still exhibited reasonable tensile strength at 2.54 MPa. When MWNTs are used to form a polymer composite they can reinforce the material and yield higher tensile strengths. In this work, the MWNTs are concentrated in the core and therefore do not reinforce the material like they would if dispersed throughout a polymer matrix as they are in composites. In fact, the MWNT core reduces the tensile strength of the fiber by forcing a hollow polymer fiber morphology (sheath) and having a poor mechanical interface with the polymer. The aim of this work is to form novel core-shell conductive materials, not to create a mechanically reinforced cellulose composite, and so the reduced tensile strength is acceptable considering the gains in electrically conductivity.

Table 1.

Mechanical and thermal properties of MWNTs-cellulose fiber mat

| MWNTs/Cellulose (wt%) | Tensile Strength (MPa) | Elongation (%) | Weight Loss (%) |

|---|---|---|---|

| 0/100 | 6.22 ± 0.06 | 7.5 ± 0.8 | 81 |

| 20/80 | 5.14 ± 0.41 | 5.5 ± 0.4 | 63 |

| 30/70 | 4.23 ± 0.53 | 7.6 ± 0.8 | 52 |

| 40/60 | 2.79 ± 0.18 | 8.9 ± 1.9 | 44 |

| 45/55 | 2.54 ± 0.28 | 7.5 ± 0.8 | 44 |

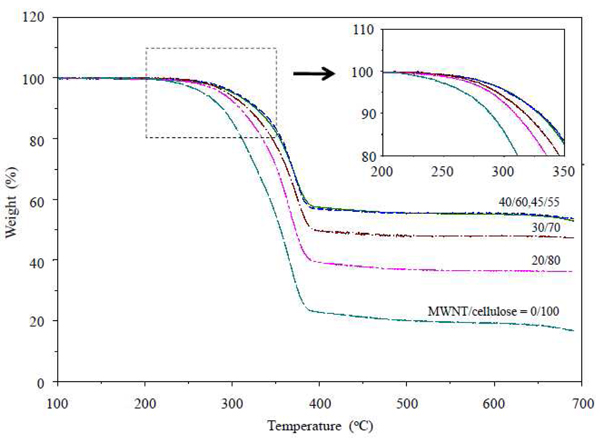

The weight loss percentage by TGA also depends on cellulose (sheath) ratio in the fiber. It is interesting to note that the onset of degradation temperature increased with increasing MWNT ratio in fiber (Figure 4). These data suggest that the thermal stability of the cellulose sheath was improved by increasing the MWNT core. El-Wakil et al.18 have reported that the temperature of the onset of cellulose degradation of cellulose regenerated from several solvents is related its crystallinity. We speculate that either the cellulose crystallinity of cellulose-MWNT fiber is increased by MWNT loading due to enhanced electrospinning speed resulting from increased MWNT conductivity or MWNTs may act as a heat sink or an anti-oxidant protecting the cellulose from thermal degradation. The cellulose crystallinity of cellulose-MWNT fiber was further studied by FT-IR from which the calculated crystallinity index is theoretically agree with XRD measurement.19–21 The absorption ratio between 1372 and 2900 cm−1 is best fit to XRD measurement. As we see from supporting materials, the absorption ratios for MWNT-cellulose fiber with MWNT loading of 0, 20, 30, and 40 % are 1.08, 1.35, 1.40, and 1.44. The crystallinity index gradually increases as increasing of MWNT loading, which indicated that increased crystallinity of cellulose could afford high thermal stability of MWNT-cellulose fibers. It is important to note that the core component consists almost completely of MWNTs. In the case composites formed by blending MWNTs into a polymer matrix, the MWNTs must form a network structure to conduct current.12,16 We observed that such conductivities become saturated at relatively low MWNT loading. These results support the concept that a continuous MWNT core forms a superior conductive pathway due to the high MWNT density as compared to a CNT-polymer composite.22 The cellulose sheath component serves as an insulating coating as well as a key structural component. The MWNT-cellulose ratio can be controlled by both the solution concentrations and feed rates during electrospinning, as long as both the concentration of the core solution and the feed rate of core solution are high enough to achieve high core continuity. In the current study, we observed that the MWNT loading could be increased to up to 45-wt% in fibers while maintaining stable electrospinning conditions.

Figure 4.

TGA curves of MWNTs-cellulose fiber mats. Enlarged figure of onset region is shown in inset.

Enzymatic cellulase removal of cellulose sheath

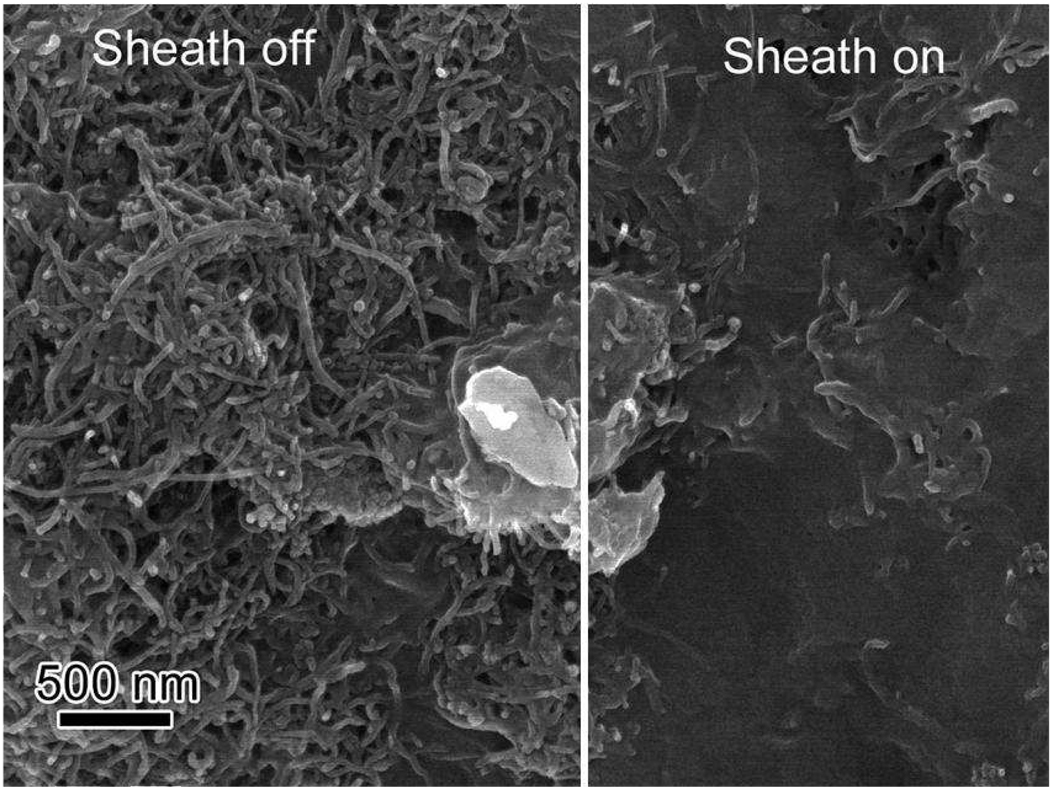

Core-sheath MWNT-cellulose fibers, having a conductive core and insulating sheath, had structures similar to insulated nanocables or nanowires. In order to apply voltage to the conducting MWNT core (or wire), some of the cellulose sheaths (or insulation) needed to be removed. Although cellulose can be dissolved with ILs, solutions of cellulose in ILs are highly viscous and, in trial experiments, were difficult to apply and remove without destroying the isolated core components. However, an advantage of a cellulose sheath is that it serves as a biodegradable surface that can be hydrolyzed by common cellulases, thereby exposing the inner core; controlling the cellulase location and concentration would provide control over the degree of exposure. To achieve selective cellulose removal on the fibers, both ends of an electrospun fiber mat were covered with a Teflon filter that was soaked with aqueous cellulase solution. After two days at room temperature, the fiber mats were gently washed with water to remove hydrolyzed cellulose and expose the core structure. This fiber mats were dried under vacuum to obtain partially sheath-off fiber mats. In the sheath-off areas, MWNTs were exposed on the surfaces of these mats, while in the sheath-on areas, the MWNT cores were still surrounded by insulating cellulose (Figure 5).

Figure 5.

SEM image of sheath-off and sheath-on fiber mat.

Conductivities of MWNTs-cellulose fiber mats

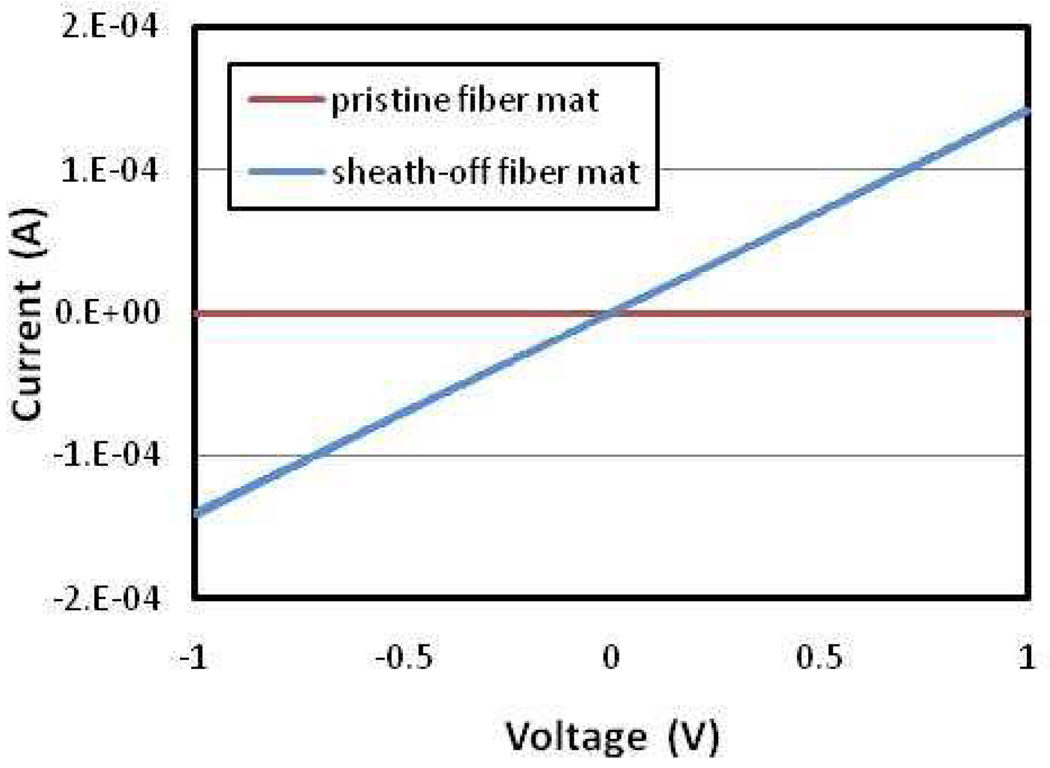

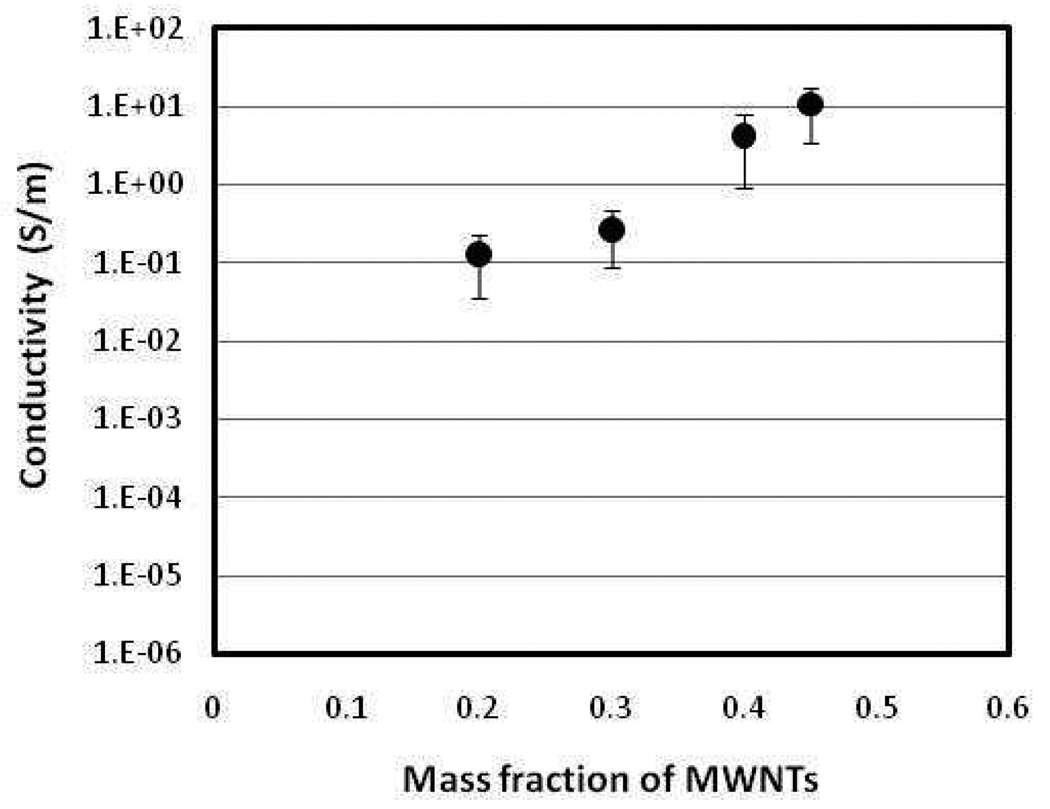

The conductivities of the MWNT-cellulose fiber mats, which were subjected to selective sheath removal, were evaluated with various MWNT concentrations. A pristine core-sheath MWNT-cellulose fiber mat showed non-conductive properties due to the substantially insulating effects of cellulose sheaths. In contrast, the partially sheath-off fiber mats showed significant conductive properties, which followed Ohm’s law (Figure 6). This results from the exposed MWNTs, in the sheath-off areas, connecting a circuit between the two collector electrodes on either side of the fiber mat, with the MWNT core functioning as the conductive pathway. The distance between the two sheath-off areas on the fiber mat was 1 cm. These data suggest that continuous cores of at least 1 cm in length had been obtained in the co-axial electrospinning of the fiber mat. Furthermore, these conductivities increased with higher MWNT loading with nearly a 2-order of magnitude increase in conductivity by simply doubling the mass fraction of MWNTs in the fiber mats (Figure 7). One possible explanation for these results is that the continuity of the core structures improves at higher MWNT loading and that the MWNTs in the core structures form denser cores similar to a 1-D wire or 2-D bundle, rather than an extended 3-D network structure. Such dense wire or cable-like structures are very important to achieve maximum conductivity. The maximum conductivity, observed in the fiber mats produced in the current study, was 10.7 S/m at 45-wt% MWNTs. The conductivity of electrospun fiber mats will always be lower than bulk sample, such as film or single fiber, due to its inherently porous structure. Additionally, some of the fibers in the sheath-off fiber mats will not function as conductive pathways due to discontinuities.

Figure 6.

I–V characteristic curves of MWNTs-cellulose fiber mat.

Figure 7.

Conductivities of sheath-off fiber mats at various mass fractions of MWNTs.

The technique used in this work to evaluate the conductive properties of the fiber mats requires the connection of both ends of individual fibers having exposed cores (i.e., with selectively removed cellulose sheath) to both the positive and negative electrodes. A uniaxially aligned fiber mat would afford improved fiber mat conductivity, but significant advances in process engineering are required to achieve such fiber alignment. Nevertheless, the conductivities observed in these randomly aligned fiber mats are much higher than previously reported values of CNT containing polymer fiber mats, including 3.7 × 10−2 S/m in a poly(styrene)/SWNT fiber material and 4.05 × 10−6 S/m in a poly(ethylene terephthalate)/MWNTs fiber material.23,24 These results were for electrospun fiber mats fabricated by blending CNTs into matrix polymer. Because the conductivity of a blended system has limited electrical percolation, the system becomes conductive only when a critical concentration is reached, known as the percolation threshold, and high conductivities are difficult to achieve in such systems. The formation of a percolative CNT network allows the electrons to transport charge through the network by tunneling from one CNT to another wherever they are within physical proximity. In contrast, the core of the MWNT-cellulose fibers produced in the present work consist of pure MWNTs free of a polymer matrix allowing for a dense MWNT network to be formed in fiber core that is able to more effectively conduct electrical current.

4. Conclusions

We have successfully fabricated core-sheath of MWNTs-cellulose fiber using co-axial electrospinning from a non-valatile, non-flammable [EMIM][Ac] IL solvent. MWNTs were well dispersed in a MWNTs/[EMIM][Ac] gel solution. MWNTs/[EMIM][Ac] gel core solution could be electrospun by surrounding it with cellulose/[EMIM][Ac] sheath solution having good spinnability. Electrospun fibers were collected into a coagulation bath containing ethanol-water to completely remove [EMIM][Ac] to form a core-sheath structure. After drying, MWNT-cellulose fibers having a cable structure with a conductive core and insulating sheath were obtained. Upon reaction with cellulase, the cellulose sheath was selectivily removed and the exposed MWNT core was connected to a collector electrode to conduct current. MWNT-cellulose fiber mats demonstrated excellent conductivity due to a highly conductive pathway, which consist of bundleled MWNTs. The conductivity of fiber mats were increased with increasing MWNT/cellulose ratio in the fiber due to improved core continuity with a maximum conductivity of 10.7 S/m obtained at 45-wt% MWNT loading.

CNTs are a promising candidate for future on-chip interconnects and electro-thermal applications due to their superior electrical and thermal properties.25 Highly aligned CNTs structures may outperform copper in terms of failure current density, power dissipation, and on-chip signal transfer delay. However, fabrication of such highly aligned and dense CNTs structures is extremely crucial and has, up to now, not been fully realized. The co-axial electrospinning presented in this work could be employed as a top-down cost efficient approach for forming high density bundled CNT structures. The thin surrounding sheath layer serves as an effective nanoscale insulating layer, which could have several potential benefits. For example, two parallel core-sheath MWNT-cellulose fibers can be used in electrical double layer supercapacitor devices. The distance between two electrodes would be double the sheath thickness, or on the scale of hundreds of nanometers. Since capacitance is inversely related to the distance between two electrodes (CNT cores), very high specific capacitance can be obtained in such devices. Another possible application of the nanoscale insulating layer of MWNTs-cellulose nanofiber might be as the separator of a bimorph actuator, based on the formation of electrical double layer.26 Such a thin and flexible separator might provide improved response properties, which is a critical issue of actuator design.

Supplementary Material

Acknowledgements

This work was supported by the U.S. National Science Foundation funded Rensselaer Nanotechnology Center as well as Chisso Corporation.

Footnotes

Supporting Information Available: FT-IR spectra and Crystallinity Index calculated from FT-IR spectra for MWNT-cellulose fibers. This material is available free of charge via the internet at http://pubs.acs.org.

References and Notes

- 1.Iijima S. Nature. 1991;354:56–58. [Google Scholar]

- 2.Baughman RH, Zakhidov AA, de Heer WA. Science. 2002;297:787–792. doi: 10.1126/science.1060928. [DOI] [PubMed] [Google Scholar]

- 3.Collins PC, Arnold MS, Avouris P. Science. 2001;297:706–709. doi: 10.1126/science.1058782. [DOI] [PubMed] [Google Scholar]

- 4.Yu MF, Lourie O, Dyer MJ, Moloni K, Kelly TF, Ruoff RS. Science. 2000;287:637–640. doi: 10.1126/science.287.5453.637. [DOI] [PubMed] [Google Scholar]

- 5.Sandler JKW, Kirk JE, Kinloch IA, Shaffer MSP, Windle AH. Polymer. 2003;44:5893–5899. [Google Scholar]

- 6.Fukushima T, Kosaka A, Ishimura Y, Yamamoto T, Takigawa T, Ishii N, Aida T. Science. 2003;300:2072–2074. doi: 10.1126/science.1082289. [DOI] [PubMed] [Google Scholar]

- 7.Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S. Compos. Sci. Technol. 2003;63:2223–2253. [Google Scholar]

- 8.Li D, Xia YN. Adv. Mater. 2004;16:1151–1170. [Google Scholar]

- 9.Viswanathan G, Murugesan S, Pushparaj V, Nalamasu O, Ajayan PM, Linhardt RJ. Biomacromolecules. 2006;7:415–418. doi: 10.1021/bm050837s. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Xu SS, Zhang J, He AH, Li JX, Zhang H, Han CC. Polymer. 2008;49:2911–2917. [Google Scholar]

- 11.Sun ZC, Zussman E, Yarin AL, Wendorff JH, Greiner A. Adv. Mater. 2003;15:1929–1932. [Google Scholar]

- 12.Ojha SS, Stevens DR, Stano K, Hoffman T, Clarke LI, Gorga RE. Macromolecules. 2008;41:2509–2513. [Google Scholar]

- 13.McCullen SD, Stano KL, Stevens DR, Roberts WA, Monterio-Riviere NA, Clarke LI, Gorga RE. J. Appl. Poly,. Sci. 2007;105:1668–1678. [Google Scholar]

- 14.Zhang QH, Chang ZJ, Zhu MF, Mo XM, Chen DJ. Nanotechnology. 2007;18:115611. [Google Scholar]

- 15.Feng W, Wu ZG, Li Y, Feng YY, Yuan XY. Nanotechnology. 2008;19:105707. doi: 10.1088/0957-4484/19/10/105707. [DOI] [PubMed] [Google Scholar]

- 16.Wang G, Tan ZK, Liu XQ, Chawda S, Koo JS, Samuilov V, Dudley M. Nanotechnology. 2006;17:5829–5835. [Google Scholar]

- 17.Yu JH, Fridrikh SV, Rutledge GC. Adv. Mater. 2004;16:1562–1566. [Google Scholar]

- 18.El-Wakil NA, Hassn ML. J. Appl. Polym. Sci. 2008;109:2862–2871. [Google Scholar]

- 19.Magalhaes WLE, Cao XD, Lucia LA. Langmuir. 2009;25:13250–13257. doi: 10.1021/la901928j. [DOI] [PubMed] [Google Scholar]

- 20.Wan JQ, Wang Y, Xiao Q. Bioresour. Technol. 2010;101:4577–4583. doi: 10.1016/j.biortech.2010.01.026. [DOI] [PubMed] [Google Scholar]

- 21.Wistara N, Zhang X, Young RA. Cellulose. 1999;6:325–348. [Google Scholar]

- 22.Miao J, Miyauchi M, Simmons TJ, Dordick JS, Linhardt RJ. J. Nanosci. Nanotechnol. 2010;10:1–13. doi: 10.1166/jnn.2010.3073. [DOI] [PubMed] [Google Scholar]

- 23.Mazinani S, Ajji A, Dubois C. Polymer. 2009;50:3329–3342. [Google Scholar]

- 24.Ahn BW, Chi YS, Kang TJ. J. Appl. Polym. Sci. 2008;110:4055–4063. [Google Scholar]

- 25.Kaushik Bk, Goel S, Rauthan G. Microelectron.s Int. 2007;24:53–63. [Google Scholar]

- 26.Madden JD. Science. 2007;318:1094–1097. doi: 10.1126/science.1146351. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.