Abstract

A novel matrix-free LDI MS platform using a thin film of patterned nanostructured gold, capped with methyl- and carboxy- terminated self assembled monolayers (SAM) is presented. Calibration on the matrix-free LDI surface was performed using a peptide standard mixture available for MALDI analysis. MS analysis for limit of detection was performed using angiotensin I peptide. Peptide fragments from standard protein digests of bovine serum albumin, bovine catalase and bovine lactoperoxidase were used to carry out peptide mass fingerprinting analysis. Sequence coverage of each protein digest and the number of detected peptide fragments were compared with conventional MALDI MS on a standard MALDI plate. Versatility of the nanostructured gold LDI substrate is illustrated by performing MS analysis on a protein digest using different enzymes and by small molecule MS analysis.

Keywords: Nanostructured gold, porous gold, matrix-free LDI, SALDI, MALDI

Introduction

Matrix-assisted laser desorption/ionization time-of-flight mass spectrometry (MALDI-TOF-MS) is a well-established rapid, selective, and sensitive analytical tool for characterization of biomolecules. However, limitations of using organic matrix in conventional MALDI mass spectrometry in terms of low mass interference and inhomogeneous co-crystallization have encouraged investigation of inorganic materials (mostly metals) as surface assisted laser desorption ionization (SALDI) substrates. SALDI was first demonstrated by Tanaka et al. using 30 nm cobalt particles mixed with glycerol.1 This pioneering innovation was shown to be functional for desorption/ionization of proteins having masses up to 26 kDa using Co nanopaticles having high surface area and high photo-absorption at a nitrogen laser wavelength. A few years later, with further improvement in the technique, Sunner et al. demonstrated SALDI MS using larger size (2–150 µm) graphite particles mixed with glycerol as a matrix.2 In fact, the term SALDI for surface-assisted laser desorption/ionization was introduced by Sunner et al. for this technique. The authors could observe at optimum conditions, mass spectrum signal intensities as good as that in conventional MALDI with very few background peaks, even at low mass. Since then, several efforts have been made in demonstrating enhanced SALDI activity using nanoparticles of Mn, Mo, Al, Sn, SnO2, Zn, ZnO, TiO2, Si, W, WO3, ZnS, Pt, Ag, Fe3O4, HgTe, oxidized graphitized carbon, diamond, and barium strontium titanate.3–11

Recently, SALDI MS on gold nanoparticles (AuNP) has attracted a great deal of interest due to its high surface areas and simplicity of fabrication.6, 12–25 The first usage of gold nanoparticles (size 2–10 nm) for SALDI MS of peptides and proteins was reported by McLean et al.12 Molar-to-analyte ratio of AuNP compared to conventional organic matrix suggested a highly efficient ionization process using AuNPs possessing the capacity for ionization of more than one analyte per laser pulse.12 AuNPs with different functionalizations have been demonstrated to act as a selective probe with preferential ionization for specific biomolecules.12–14, 16, 21 Besides peptide and protein identification, AuNP SALDI MS has also been shown to be highly sensitive for detection of neutral compounds like carbohydrates.17 This paper reports the advantages of AuNP as a SALDI matrix: easy sample preparation, high ionization efficiency, and high shot-to-shot reproducibility. Another advantage of AuNP was demonstrated as its high-salt tolerance ability for analysis of biomolecules by SALDI MS.22 High salt tolerance of AuNP towards detection of biomolecules indicated utility of AuNP-SALDI MS without any desalting step.

In spite of advantages and promising results with AuNP-SALDI MS, using AuNPs as a SALDI matrix often prduces many Au cluster peaks in the mass spectrum that tend to suppress the actual sample ion peak; and, moreover, the gold colloids may get inhomogeneously distributed after getting dried on the target plate thus leading to poor reproducibility. Use of nanoparticles in SALDI MS can also be limited by the risk of particles flying off inside the MS instrument during laser ablation.

As an alternate approach, matrix-free LDI surfaces which utilize the functional surface of a sample substrate have been used as an ionization platform; thus, presenting better sensitivity and robustness. Some of the successful matrix-free LDI surfaces 26 include, porous silicon,27 silicon nanowire,28, 29 porous alumina,30, 31 nanocrystalline titania,32, 33 carbon nanotubes array, 34 porous silicon dioxide,35 porous polymer monolith,36 etc.

Utilizing similar concept of matrix-free LDI surface, Arakawa et al. used polymer films to immobilize gold nanoparticles, so as to overcome the problems associated with AuNP SALDI MS.18, 20 They used two approaches: one employed ammonium citrate capped AuNP on a Si substrate with block copolymer micelles; the second used a layer-by-layer approach to assemble negatively charged AuNPs with a positively charged polyallylamine hydrochloride polymer on a SiO2 substrate. In the first approach, extensive Au clusters were detected in the mass spectrum to a large extent using a non-aggregated distribution of AuNPs on the polymer films with one hour dipping time in the gold solution. Good mass spectra were obtained only when AuNPs were deposited for 24 hours. Data were presented on only a single peptide and a single protein with 5 pmol concentration. In the secondapproach, at least 5 polymer/AuNP layers were needed to get a good SALDI active substrate and the optimum duration of AuNP dipping time was 68 hours where the AuNP were present in aggregated form with higher surface coverage. Signal reproducibility in this layer-by-layer technique was strongly dependent on the washing step in between deposition of each layer. The detection limit for angiotensin I was as low as 10 fmol but at the expense of a lengthy preparation time for an optimum SALDI substrate (~ 68×5 hours of gold deposition; 30×5 mins of polymer film deposition time) along with critical washing steps that may significantly degrade MS signal intensity.

In this study we present a simple and highly efficient matrix-free LDI MS platform using thin film of patterned nanostructured gold, capped with methyl- and carboxy- terminated self assembled monolayers (SAM) and report its sensitivity for analysis of peptide mixtures in proteomic analysis. We electrochemically prepared nanostructured gold on indium tin oxide (ITO) coated glass substrates. There are several other methods for fabricating porous/nanostructured gold. The most commonly used method is by de-alloying,37, 38 where two metals (one of which is gold) form a composite film, and then one of the metal is removed by selective etching, leaving behind pores on the gold surface. Other methods include a template method, self assembly of gold particles into porous structures, etc.39, 40 Most of these methods used to fabricate porous/nanostructured gold require multiple steps. Methods like self assembling are comparatively simpler. In the present work we followed another simple and highly reproducible method of depositing nanostructured gold by electrochemically reducing HAuCl4 in presence of H2SO4 as previously reported by Cotter et al.41 Cotter et al. reported the use of nanostructured gold for increased surface area for covalent attachment of proteins in MALDI analysis using an organic UV absorbing matrix. Their study suggested that patterned porous gold substrate can be a well-suited as platform for printing microarrays for detection with MALDI MS. Patterning the substrate with hydrophilic spots and superhydrophobic background not only created a strong wettability contrast between the spots and the background and also prevented biofouling of the hydrophobic/hydrophilic pattern. Here we show that the gold nanostructured surface with similar patterning can be used as a matrix-free LDI surface. Our system is benefited by the hydrophobic/hydrophilic patterning in two ways- one by providing a visibility contrast between the analyte spots; second by preventing cross-contamination of sample solution from one spot to another.

Materials and Methods

Standards and Chemicals

Peptides (angiotensin I), protein standards (bovine serum albumin (BSA), bovine catalase, bovine lactoperoxidase), iodoacetamide, dithiothreitol (DTT), dodecanethiol, mercaptoundecanoic acid, ornithine, tetrachloroauric acid-III (HAuCl4), α-cyano-4-hydroxycinnaminic acid (CHCA), proteomic grade trypsin and Glu-C were purchased from Sigma Aldrich (St. Louis, MO). Ammonium bicarbonate (NH4HCO3), trifluoroacetic acid (TFA), ammonium citrate, citric acid, and sulfuric acid were purchased from Thermo-Fisher Scientific (Pittsburgh, PA). Peptide calibration mixture-1 from Applied Biosystems (Foster City, CA) was used to calibrate MALDI and LDI MS data.

Protein Digest Preparation

Protein sample (0.84–0.87 mg) was dissolved in 90 µl of 100 mM NH4HCO3 solution. DTT (10 µl of 100 mM) was added to the protein solution, and incubated at 37 °C for 2 h. Iodoacetamide (200 mM) was added to a final concentration of 55 mM and allowed to react 30 min in darkness. to alkylate cysteine residues. Trypsin (10 µg) in 200 µl of 100 mM NH4HCO3 was added and the solution incubated at 37 °C overnight. The reaction was quenched by adding 10 µl of 10% TFA. The resulting digested protein solutions were diluted to working concentrations of 0.2 µg/µl.

Gold thin film deposition

ITO glass slides were purchased from Bruker Daltonics Inc. to fit the MTP II slide adapter (Bruker Daltonics) for LDI analysis. Slides were degreased in isopropanol and acetone in an ultrasonic bath, rinsed in deionized water and dried under a stream of nitrogen and then transferred to the sputtering chamber. Gold thin film was deposited using a custom made dc magnetron sputtering system inside a DV-502A (Denton Vacuum, Moorestown, NJ) vacuum system which had been modified by addition of a stainless steel vacuum chamber and turbomolecular pump. Thickness of the deposited gold film was 200 nm. as measured with a Denton DTM-100 Thickness Monitor. Growth parameters were: base pressure- 2 × 10−6 Torr; partial pressure of Ar gas-20 mTorr; Target−Substrate distance-6 cm,; applied voltage- 400 V with 25 mA current.

Nanostructured gold pattern synthesis

A PDMS mask was fabricated by spin coating a mixture of polydimethylsiloxane (PDMS), 1:10 curing agent to base, (SYLGARD 184 silicone elastomer base and curing agent, Dow Corning, Midland, MI) and then curing it at 60° C for 6 hours. The obtained PDMS mask (160 µm thick) was punched with holes of 1.5 mm diameter using a custom designed metal punching tool. The patterned PDMS mask was placed on the gold substrate for formation of nanostructured gold spots in the bare gold region using an electrochemical etching process. Regions on the gold surface which were in contact with the PDMS membrane made a leak proof contact thus preventing etching in those areas. A PWR-3 power module/potentiostat (Bioanalytical systems Inc, West Lafayette, IN) was used for electrochemical modification of the gold surface. Under constant stirring, the gold substrate was etched at −0.44 V potential in presence of 2 mg/ml HAuCl4 in 0.3 M H2SO4 solution using a custom designed three electrode electrochemical cell. A Pt mesh was used as an auxiliary electrode with a Ag/AgCl (CH Instruments, Austin, TX) reference electrode and the gold substrate as the working electrode. The Pt mesh area was larger than the surface area of the gold substrate to ensure a uniform etching of gold. Films were etched until 35 C of charge had accumulated (total area of exposed gold surface [spots + ends] was ca. 10 cm2). A fixed charge deposition at a constant potential was used instead of a fixed time because with reuse of the gold solution, ion depletion from the solution reduced the steady-state current with time. After the etching process, substrates were removed from the cell, cleaned thoroughly with water and blown dry under a stream of nitrogen.

Coating hydrophobic/hydrophilic self assembled monlayers (SAM)

First the etched gold substrate along with the PDMS mask was dipped in a 10mM mercaptoundecanoic acid solution in ethanol for 30s, resulting in a carboxy- terminated SAM coating on the nanostructured gold spots which were hydrophilic in nature. Then, the substrate was rinsed in ethanol and the PDMS mask was peeled off from the substrate. The glass slide was then dipped in 10 mM ethanolic dodecanethiol for 1 min to get a methyl- terminated SAM coating (hydrophobic background) on the bare gold surface surrounding the hydrophilic spots. Later the slide was cleaned with ethanol and water and blow dried under nitrogen stream.

MALDI and LDI analysis

MALDI and LDI MS analysis were performed on a Bruker Autoflex III TOF mass spectrometer under linear mode of operation. MALDI analysis was performed by spotting 0.2 µl of each protein digest (dissolved in 50% acetonitrile, 0.1% TFA) and an equal volume of CHCA matrix (7 mg/ml) on a standard SS MALDI plate. LDI analysis was performed with the SAM patterned nanostructured gold substrates positioned on a MTP slide adapter. Protein digests were dissolved in 80% ACN and 20% citrate buffer solution (3:1 50 mM ammonium citrate/100 mM citric acid) and 0.2 µl of each digest were spotted on the hydrophilic etched gold spots. Both MALDI and LDI mass spectra were generated from an average of 1000 laser shots. Three sets of sample spots were analyzed, and the best spectrum was selected for each method (LDI/MALDI). Safety note: TFA, mercaptoundecanoic acid and dodecanethiol should be used in a fume hood.

MS-Fit database search program (UCSF Protein Prospector, http://prospector.ucsf.edu) was used to match the peptide fragment masses to a specific protein sequence (allowing 1 missed cleavage and a mass tolerance of ±0.8 Da; with constant “Carbamidomethylation” modification).

Results and Discussion

Initially gold thin film was deposited directly on a glass substrate using an in-situ plasma cleaning step. However, adhesion of gold was poor as indicated while peeling off the PDMS mask from the gold coated slide. Coating a thin intermediate layer of Cr is a widely accepted choice for ensuring good adhesion of gold with glass.42 ITO is also a good choice for adhesion of gold on glass.43 In the present work, ITO coated glass slides were used for promoting adhesion of gold on glass due its ready availability.

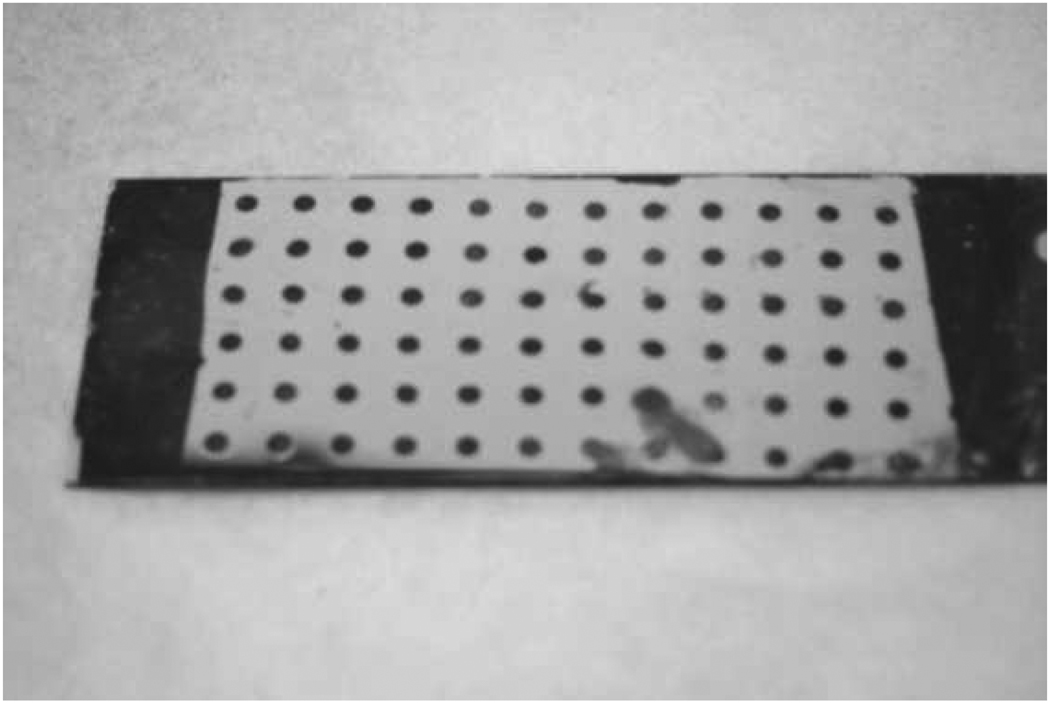

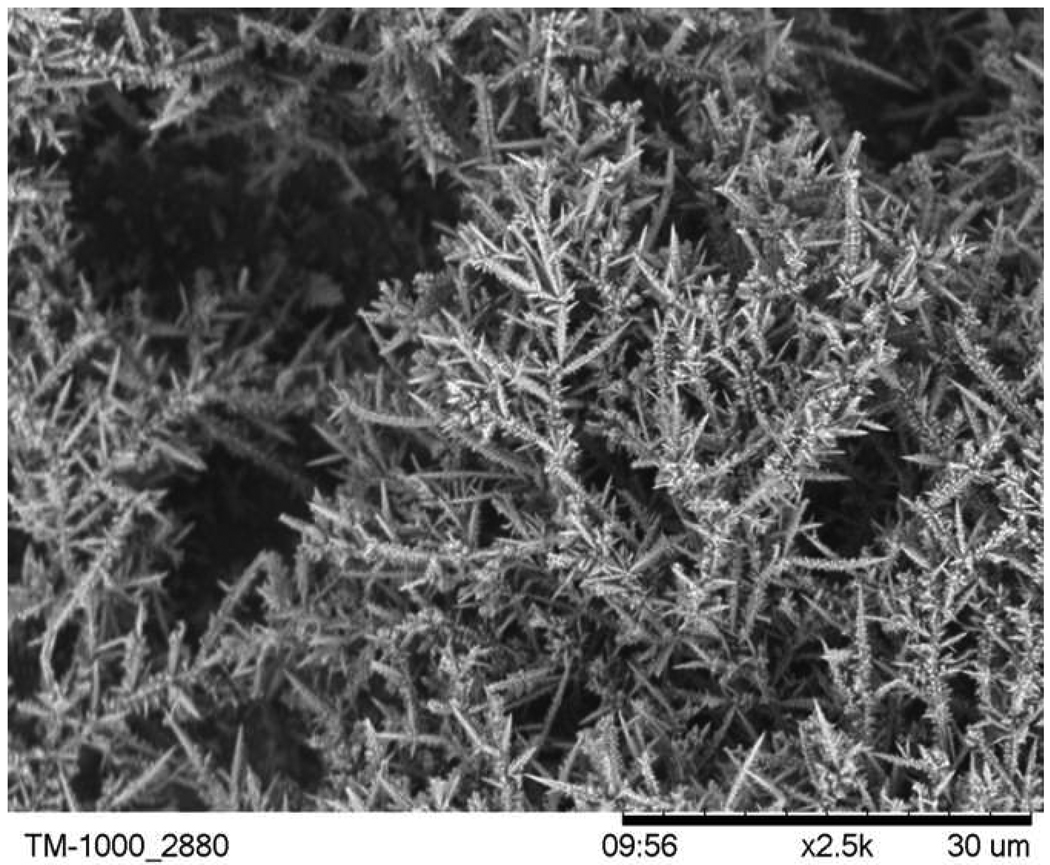

PDMS is known to make a conformal contact with a flat and also a moderately uneven surface. In our experiments, however, it was found that the PDMS mask on the gold film would peel off when the cell was subjected to ultrasonic vibrations during the electrochemical process (run time ~ 12 mins). Vibration was needed to remove bubbles that were formed initially on the gold spots and would prevent further deposition on those regions. As a solution to this problem, ultrasonication was carried out only for 45 s to remove the initially formed bubbles and the cell was kept under constant magnetic stirring during the process. This ensured a clean patterned nanostructured gold formation as spots on a gold coated slide, as can be seen from Figure 1. Magnetic stirring was also an essential step in the process to remove bubbles formed on the Pt mesh as well as on the gold substrate due to hydrogen evolution. The thickness of the resulting nanostructured gold was not determined in this study. The charge deposited was used as an indicator of the thickness, and the amount of charge deposition was kept constant in order to maintain a constant thickness of the nanostructured gold layer for the experiments. Formation of the nanostructured gold was visibly confirmed when color of the gold coated spots altered from bright yellow to tan color. The morphology of the nanostructured gold surface, shown in Figure 2, resembles branches of a tree with a highly enhanced surface area of the gold, which is a primary requirement for a substrate to be utilized for SALDI/ matrix-free LDI MS. This structure can be compared with the aggregated AuNPs as reported by Arakawa et al. 18, 20 The gold nanostructure used here has even greater surface area. Moreover, the short time needed to fabricate this nanostructured gold surface is an added advantage over the previously reported AuNP SALDI surfaces.

Figure 1.

Photograph of hydrophilic/hydrophobic SAM patterned nanostructured gold surface.

Figure 2.

SEM image of nanostructured gold surface.

An approach reported by Cotter et al.41 was attempted to pattern the nanostructured gold surface. In this approach, initially gold film was etched completely without a PDMS mask. Spots of mercaptoundecanoic acid were printed on the substrate and then the slide was immersed in a selective gold etchant solution to dissolve the nanostructured gold from the unprinted region. Using this method, the gold film beneath the nanostructured gold also dissolved giving a bare ITO surface. It was difficult to make the ITO surface hydrophobic even with neat dodecanethiol. Thus, a different approach was followed to pattern the gold nanostructure using a PDMS mask as mentioned in Materials and Methods section. Self assembled monolayers with hydrophilic spots and hydrophobic background were formed rapidly. While the substrate was immersed in mercaptoundecanoic acid, the PDMS mask on the gold coated slide protected the underlying gold in contact with the mask. Only the nanostructured gold spots were covered with a hydrophilic layer. Once the PDMS mask was peeled off and the complete substrate was immersed in dodecanethiol, the bare gold region previously in contact with PDMS mask was covered with a hydrophobic coating leaving the carboxy- terminated hydrophilic nanostructured gold spots unaffected. Patterning was used in this study primarily to facilitate spotting low concentrations of analyte. Analyte solution spotted on a completely etched gold surface (without patterning) could not be distinguished from the unspotted region, even after patterning with hydrophilic and hydrophobic SAM on the etched surface. A visual difference was needed to position the laser on the analyte spots. Thus, the current approach of patterning using PDMS mask was followed. Moreover, this type of patterning also prevented any cross-contamination between adjacent analyte spots.

Patterned gold nanostructured substrates were further utilized for LDI MS analysis. Citrate buffer was used to dissolve the analytes. Citrate buffer was found to enhance the LDI MS analysis of complex mixture of peptides, similar to a previously published report.32 Citrate buffer with pH ~ 4 to 5 is considered to play the role of a proton source and also an alkali metal-cation-chelating reagent that may prevent or reduce the alkali metal ion adducts. However, MALDI performance was found to be better with 50% ACN, 0.1% TFA buffer solution. For MALDI analysis, CHCA matrix was spotted on dried analyte spots.

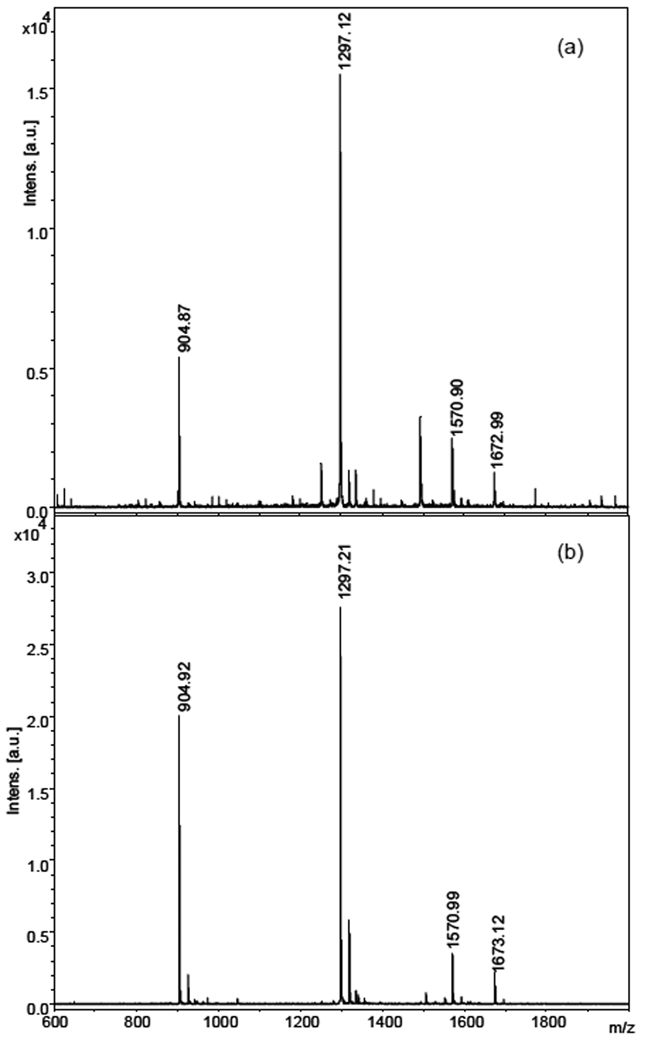

Intense protonated molecular ion peaks for the components of a standard peptide MALDI-MS calibration mixture 1 (from Applied Biosystems) containing des-arg1 –bradykinin, angiotensin I, glu1 -fibrinopeptide B, and neurotensin were observed at m/z 904.87, 1297.12, 1570.90, 1672.99 respectively for LDI analysis as shown in Figure 3a. The observed signal intensities and resolution of the mass spectrum was comparable to conventional MALDI (Figure 3b). This standard peptide mixture was also used as a calibrant for all other mass spectra acquired using LDI and MALDI. LDI experiments on the nanostructured gold surface required ~ 1.1 times higher laser fluence than conventional MALDI to obtain a comparable signal count from the same sample. The laser fluence in all the LDI MS experiments was kept constant. Similarly, MALDI experiments were also done at constant laser fluence. Resolution of the peaks observed with LDI and MALDI were comparable.

Figure 3.

(a) Matrix-free LDI MS and (b) MALDI MS analysis of standard peptide calibration mixtures containing 1.6 pmol of des-Arg1-Bradykinin (calc. MH+ 904.47); 2.1 pmol of Angiotensin I (calc. MH+ 1296.69); 2.1 pmol of Glu1-Fibrinopeptide B (calc. MH+ 1570.68); and 80 fmol of Neurotensin (calc. MH+ 1672.92).

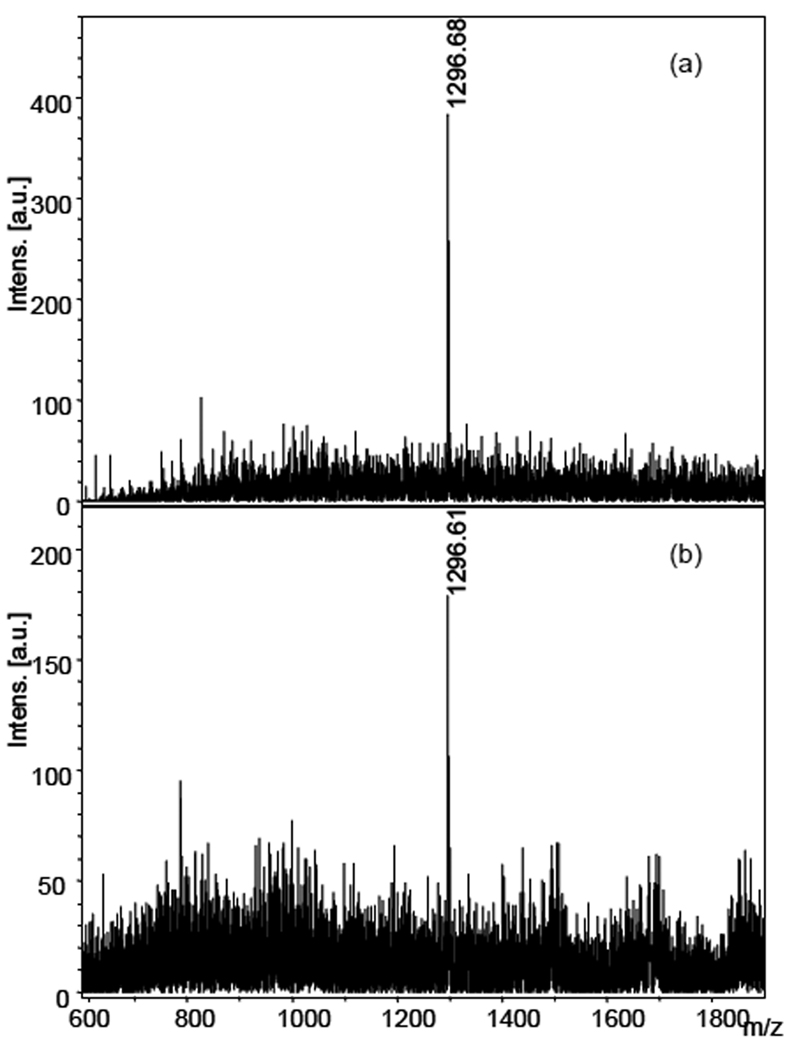

The sensitivity of the nanostructured gold substrate LDI was observed by analyzing the limit of detection on a single peptide (angiotensin I) as shown in Figure 4. A S/N of 10.2 was observed at 16 fmol total deposited amount of analyte (Fig 4a); reducing the amount to half at 8 fmol yielded an observed S/N of 5.3 (Fig 4b).

Figure 4.

Estimation of detection limit on nanostructured gold surface. Mass spectra of angiotensin I using LDI MS (a) at 16 fmol (S/N 10.2) and (b) 8 fmol (S/N 5.3) total deposited amount.

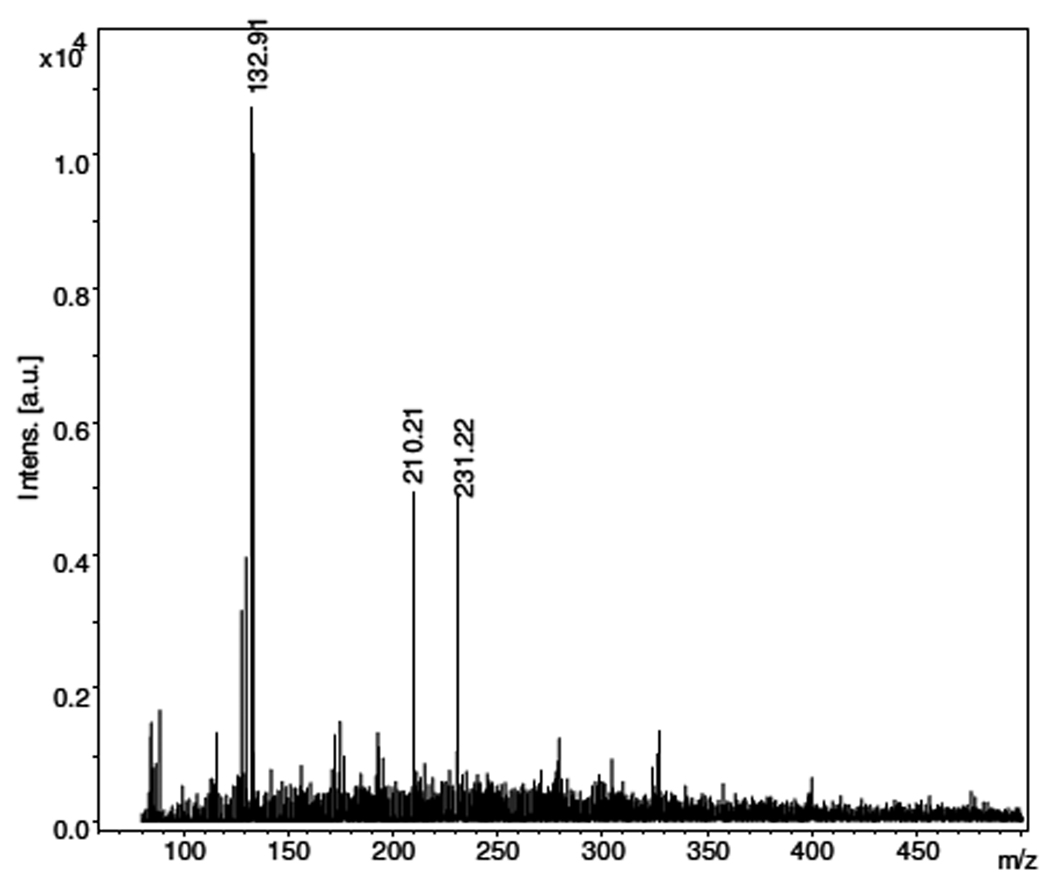

Matrix-free LDI substrates are more commonly utilized for small molecule analysis because of less background interference in low mass range. As an example, small molecule analysis of ornithine was performed on the nanostructured gold substrate. The protonated molecular ion peak of ornithine at 1.5 pmol concentration was detected at m/z 132.9 (calculated MH+ 133.2) as observed in Figure 5. The other peaks observed in the mass spectrum are background peaks from the substrate and citrate buffer (m/z 193; 210; 215; 231). A general comparison with MALDI mass spectra definitely shows a cleaner mass spectrum in low mass range with very few background interferences for the nanostructured gold LDI substrate.

Figure 5.

Small molecule analysis using nanostructured gold LDI substrate. Mass spectrum of ornithine (calc. MH+ 133.2) at 1.5 pmol concentration. Citrate buffer background peaks observed at m/z 210.21 and 231.22.

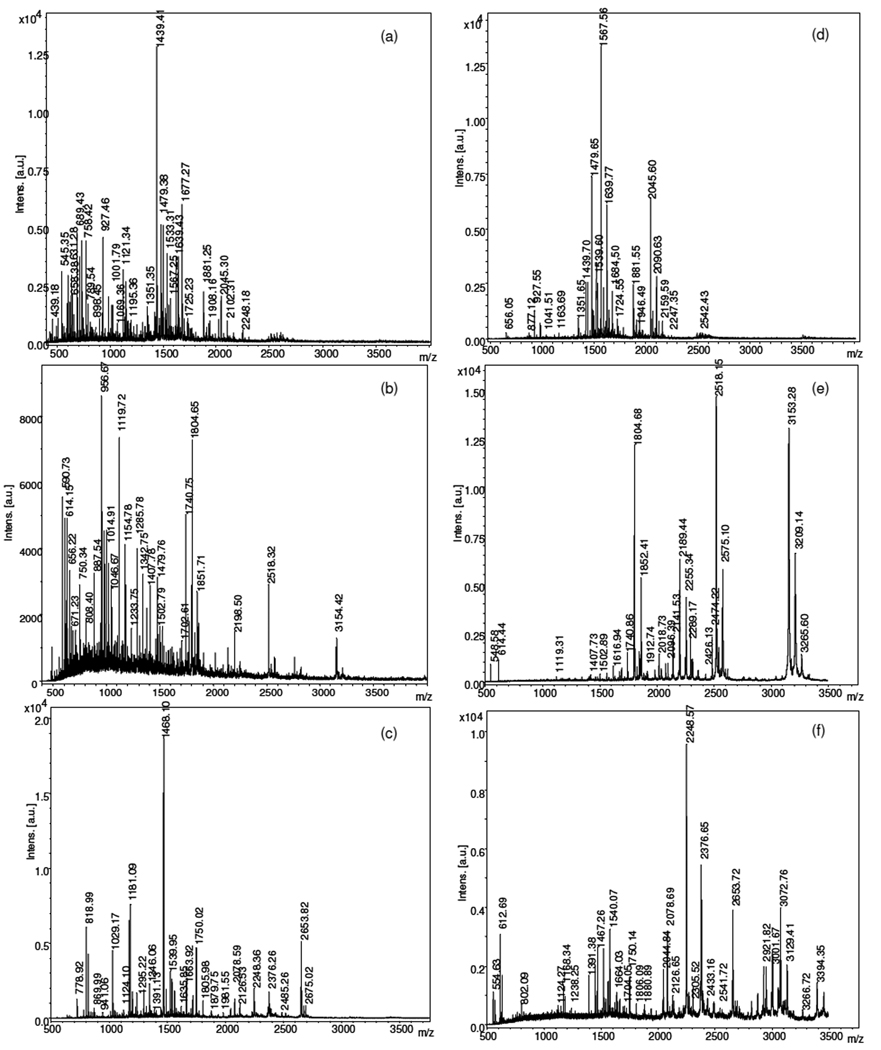

MS analysis using fragments of peptides obtained from trypsin digestion of three different standard proteins (BSA, catalase, lactoperoxidase) was also performed on the nanostructured gold LDI substrate and the mass spectra were compared with MALDI. Figure 6a, 6b, and 6c represents the LDI mass spectra of BSA, catalase, and lactoperoxidase digests at 0.62 pmol, 0.76 pmol, and 0.55 pmol respectively. Figure 6d, 6e, 6f show the MALDI mass spectra of BSA, catalase, and lactoperoxidase digest respectively at same concentrations as in LDI.

Figure 6.

LDI MS and MALDI MS analysis of trypsin digested proteins. (6a) BSA LDI; (6d) BSA MALDI; (6b) Catalase LDI; (6e) Catalase MALDI; (6c) Lactoperoxidase LDI; (6f) Lactoperoxidase MALDI.

A summary of the observed peptide fragment peaks from the trypsin digested proteins using the LDI and MALDI analysis is shown in Table 1. Further data on the matched peaks are shown in the Supporting Information. Overall the data in Table 1 and Figure 6 indicate that LDI MS on nanostructured gold detects significantly larger number of peptide fragment peaks than observed with MALDI. Some of the peptide fragment peaks observed in these experiments are common to both LDI and MALDI MS, as expected. Larger number of peptides fragments were observed using LDI MS compared to MALDI, however the protein sequence coverage shows a varying trend in both the methods. A greater coverage is observed for BSA and lactoperoxidase digest with LDI whereas MALDI provides greater coverage for catalase digest.

Table 1.

Peptide mass fingerprinting analysis using trypsin digested proteins

| Protein | Sample Size (pmol) |

Number of peptides | Sequence coverage | ||

|---|---|---|---|---|---|

| MALDI | LDI | MALDI | LDI | ||

| Serum albumin | 0.62 | 29 | 42 | 55.7% | 60.1% |

| Catalase | 0.76 | 19 | 27 | 50.1% | 48.0% |

| Lactoperoxidase | 0.55 | 20 | 31 | 43.4% | 48.0% |

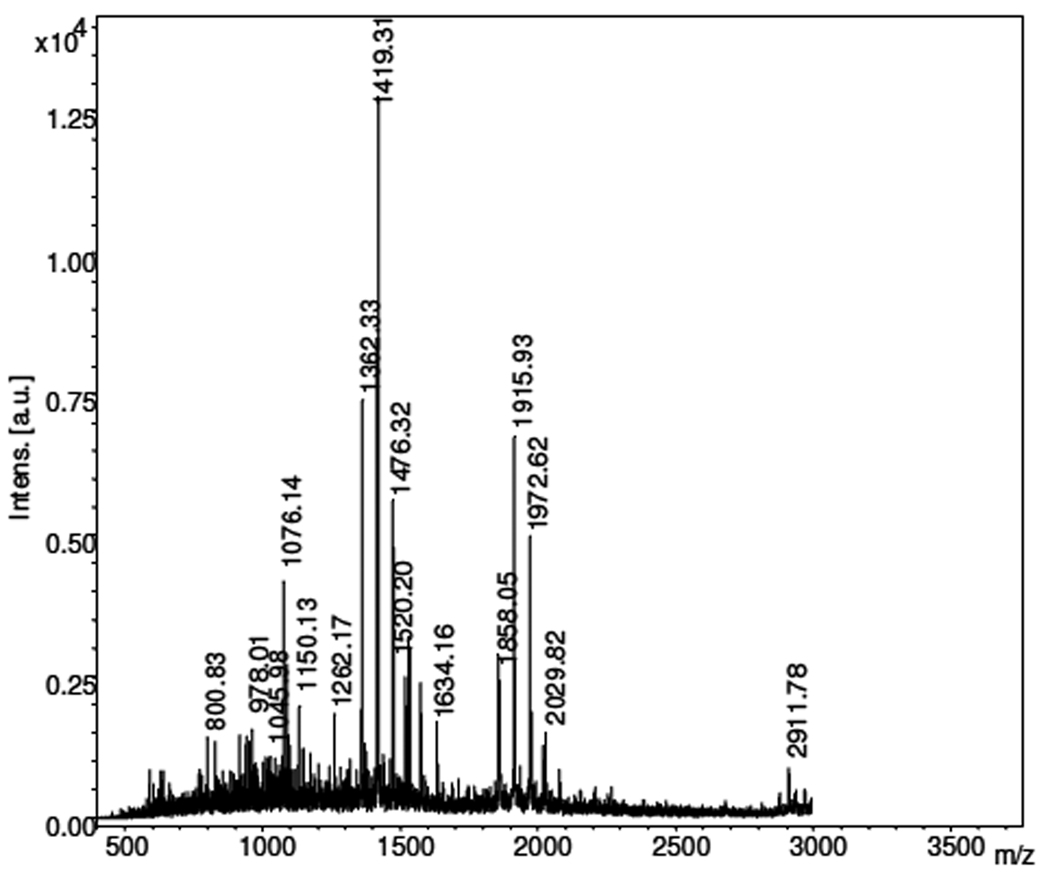

It is known that for effective protein characterization and identification by mass spectrometry protein digestion is a basic step to generate peptide fragments. Trypsin is the most commonly used protein digestion enzyme.44 However, digestion with other proteases, such as Glu-C, Lys-C, Asp-N or chymotrypsin, which cleave at different sites, can improve sequence coverage and number of unique peptides observed. In this study, Glu-C was used as an alternative protease to digest BSA protein. MS analysis of Glu-C digested BSA resulted in 18 peptide fragments with 31.6% sequence coverage (Figure 7). Glu-C digestion combined with trypsin digestion of BSA increased the protein sequence coverage from 60.1% to 68.5%. Benefits of using multiple proteases in mass spectrometric-based protein analysis is illustrated by this experiment; it also demonstrates the flexibility of the nanostructured gold LDI substrate being sensitive to detection of peptides produced using different proteases.

Figure 7.

Mass spectrum of Glu-C digested BSA protein (0.62 pmol) using LDI MS.

High sensitivity and versatility of the proposed nanostructured gold LDI substrate is demonstrated using MS analysis of single peptide as well as a mixture of peptide fragments from proteolytic digestion. Although the mechanism of LDI MS is not clear, but it is suggested that energy transfer from the nanoparticles to the analyte apparently occurs by means of a thermal phenomenon.1 Assuming this mechanism, the LDI performance observed in this work is likely a result of the enhanced surface area of the nanostructured gold. Enhanced surface area in turn helps to trap more analytes in a smaller region and nanostructures being rapidly heated promote effective and faster energy transfer to the analyte when irradiated with a laser. Arakawa et al.18, 20 observed that aggregated AuNP offered enhanced desorption/ionization efficiency of peptides than the non-aggregated (dispersed) AuNPs. They suggest that clustering in the aggregated AuNP causes rapid heating, thus raising a high local temperature that causes more efficient desorption/ionization of the peptides. In the present study the nanostructured gold represents a surface equivalent of clustered gold nanoparticles. The results indicate that the nanostructured gold surface has further enhanced surface area that promote a highly efficient desorption/ionization process without the need of a matrix.

Conclusion

Nanostructured gold substrates provide a versatile platform for performing matrix-free LDI MS. The limit of detection of a single peptide was observed to be as low as 8 fmol. Peptide mass fingerprinting analysis of trypsin digested proteins using nanostructured gold surface presents a comparable or greater number of peptide fragments and sequence coverage as observed with MALDI. Analysis of ornithine illustrated possible utility as a small molecule MS analysis platform. Added flexibility of this substrate is demonstrated by its feasibility to detect peptides digested using different proteases. Protein digestion using multiple proteases (trypsin and Glu-C) improved the sequence coverage thus boosting the protein identification probability.

Supplementary Material

Acknowledgement

Funding of this work was supported in part by the NHLBI Proteomics Initiative via contract N01-HV28181 and by NIH grant R21-RR02795. The authors thank Robert J. Cotter and Kenyon Evans-Nguyen for their advice in setting up the electrochemical cell for nanostructured gold preparation.

References

- 1.Tanaka K, Waki H, Ido Y, Akita S, Yoshida Y, Yoshida T, Matsuo T. Rapid Commun Mass Spectrom. 1988;2:151–153. [Google Scholar]

- 2.Sunner J, Dratz E, Chen Y-C. Anal Chem. 1995;67:4335–4342. doi: 10.1021/ac00119a021. [DOI] [PubMed] [Google Scholar]

- 3.Kinumi T, Saisu T, Takayama M, Niwa H. J Mass Spectrom. 2000;35:417–422. doi: 10.1002/(SICI)1096-9888(200003)35:3<417::AID-JMS952>3.0.CO;2-#. [DOI] [PubMed] [Google Scholar]

- 4.Chiang C-K, Yang Z, Lin Y-W, Chen W-T, Lin H-J, Chang H-T. Anal Chem. 2010;82:4543–4550. doi: 10.1021/ac100550c. [DOI] [PubMed] [Google Scholar]

- 5.Chen C-T, Chen Y-C. Anal Chem. 2005;77:5912–5919. doi: 10.1021/ac050831t. [DOI] [PubMed] [Google Scholar]

- 6.Chiang C-K, Chiang N-C, Lin Z-H, Lan G-Y, Lin Y-W, Chang H-T. J Am Soc Mass Spectrom. 2010;21:1204–1207. doi: 10.1016/j.jasms.2010.02.028. [DOI] [PubMed] [Google Scholar]

- 7.Chiu T-C, Chang L-C, Chiang C-K, Chang H-T. J Am Soc Mass Spectrom. 2008;19:1343–1346. doi: 10.1016/j.jasms.2008.06.006. [DOI] [PubMed] [Google Scholar]

- 8.Yonezawa T, Kawasaki H, Tarui A, Watanabe T, Arakawa R, Shimada T, Mafune F. Anal Sci. 2009;25:339–346. doi: 10.2116/analsci.25.339. [DOI] [PubMed] [Google Scholar]

- 9.Amini N, Shariatgorji M, Thorsen G. J Am Soc Mass Spectrom. 2009;20:1207–1213. doi: 10.1016/j.jasms.2009.02.017. [DOI] [PubMed] [Google Scholar]

- 10.Kailasa SK, Kiran K, Wu H-F. Anal Chem. 2008;80:9681–9688. doi: 10.1021/ac8015664. [DOI] [PubMed] [Google Scholar]

- 11.Gholipour Y, Giudicessi SL, Nonami H, Erra-Balsells R. Anal Chem. 2010;82:5518–5526. doi: 10.1021/ac1003129. [DOI] [PubMed] [Google Scholar]

- 12.McLean JA, Stumpo KA, Russell DH. J Am Chem Soc. 2005;127:5304–5305. doi: 10.1021/ja043907w. [DOI] [PubMed] [Google Scholar]

- 13.Huang Y-F, Chang H-T. Anal Chem. 2006;78:1485–1493. doi: 10.1021/ac0517646. [DOI] [PubMed] [Google Scholar]

- 14.Vanderpuije BNY, Han G, Rotello VM, Vachet RW. Anal Chem. 2006;78:5491–5496. doi: 10.1021/ac0604181. [DOI] [PubMed] [Google Scholar]

- 15.Chiu T-C, Huang L-S, Lin P-C, Chen Y-C, Chen Y-J, Lin C-C, Chang H-T. Recent Pat Nanotechnol. 2007;1:99–111. doi: 10.2174/187221007780859618. [DOI] [PubMed] [Google Scholar]

- 16.Huang Y-F, Chang H-T. Anal Chem. 2007;79:4852–4859. doi: 10.1021/ac070023x. [DOI] [PubMed] [Google Scholar]

- 17.Su C-L, Tseng W-L. Anal Chem. 2007;79:1626–1633. doi: 10.1021/ac061747w. [DOI] [PubMed] [Google Scholar]

- 18.Kawasaki H, Sugitani T, Watanabe T, Yonezawa T, Moriwaki H, Arakawa R. Anal Chem. 2008;80:7524–7533. doi: 10.1021/ac800789t. [DOI] [PubMed] [Google Scholar]

- 19.Chiang N-C, Chiang C-K, Lin Z-H, Chiu T-C, Chang H-T. Rapid Commun Mass Spectrom. 2009;23:3063–3068. doi: 10.1002/rcm.4221. [DOI] [PubMed] [Google Scholar]

- 20.Tarui A, Kawasaki H, Taiko T, Watanabe T, Yonezawa T, Arakawa R. J Nanosci Nanotechnol. 2009;9:159–164. doi: 10.1166/jnn.2009.j046. [DOI] [PubMed] [Google Scholar]

- 21.Wang M-T, Liu M-H, Wang C-R, Chang S-Y. J Am Soc Mass Spectrom. 2009;20:1925–1932. doi: 10.1016/j.jasms.2009.06.018. [DOI] [PubMed] [Google Scholar]

- 22.Wu H-P, Yu C-J, Lin C-Y, Lin Y-H, Tseng W-L. J Am Soc Mass Spectrom. 2009;20:875–882. doi: 10.1016/j.jasms.2009.01.002. [DOI] [PubMed] [Google Scholar]

- 23.Lin Y-W, Chen W-T, Chang H-T. Rapid Commun Mass Spectrom. 2010;24:933–938. doi: 10.1002/rcm.4473. [DOI] [PubMed] [Google Scholar]

- 24.Chen W-T, Chiang C-K, Lin Y-W, Chang H-T. J Am Soc Mass Spectrom. 2010;21:864–867. doi: 10.1016/j.jasms.2010.01.023. [DOI] [PubMed] [Google Scholar]

- 25.Chiang C-K, Lin Y-W, Chen W-T, Chang H-T. Nanomedicine. 2010 [Google Scholar]

- 26.Peterson DS. Mass Spectrom Rev. 2007;26:19–34. doi: 10.1002/mas.20104. [DOI] [PubMed] [Google Scholar]

- 27.Wei J, Buriak JM, Siuzdak G. Nature. 1999;399:243–246. doi: 10.1038/20400. [DOI] [PubMed] [Google Scholar]

- 28.Go EP, Apon JV, Luo G, Saghatelian A, Daniels RH, Sahi V, Dubrow R, Cravatt BF, Vertes A, Siuzdak G. Anal Chem. 2005;77:1641–1646. doi: 10.1021/ac048460o. [DOI] [PubMed] [Google Scholar]

- 29.Luo G, Chen Y, Daniels H, Dubrow R, Vertes A. J Phys Chem B. 2006;110:13381–13386. doi: 10.1021/jp0609582. [DOI] [PubMed] [Google Scholar]

- 30.Nayak R, Knapp DR. Anal Chem. 2007;79:4950–4956. doi: 10.1021/ac062289u. [DOI] [PubMed] [Google Scholar]

- 31.Wada Y, Yanagishita T, Masuda H. Anal Chem. 2007;79:9122–9127. doi: 10.1021/ac071414e. [DOI] [PubMed] [Google Scholar]

- 32.Chen C-T, Chen T-C. Rapid Commun Mass Spectrom. 2004;18:1956–1964. doi: 10.1002/rcm.1572. [DOI] [PubMed] [Google Scholar]

- 33.Lo C-Y, Lin J-Y, Chen W-Y, Chen C-T, Chen Y-C. J Am Soc Mass Spectrom. 2008;19:1014–1020. doi: 10.1016/j.jasms.2008.04.025. [DOI] [PubMed] [Google Scholar]

- 34.Shin SJ, Choi D-W, Kwak H-S, Lim GI, Choi YS. Bull Korean Chem Soc. 2006;27:581–583. [Google Scholar]

- 35.Górecka-Drzazga A, Bargiel S, Walczak R, Dziuban JA, Kraj A, Dylag T, Silberring J. Sens Act B: Chem. 2004;103:206–212. [Google Scholar]

- 36.Peterson DS, Luo Q, Hilder EF, Svec F, Frechet JM. J. Rapid Commun Mass Spectrom. 2004;18:1504–1512. doi: 10.1002/rcm.1515. [DOI] [PubMed] [Google Scholar]

- 37.Zhang J, Liu P, Ma H, Ding Y. The Journal of Physical Chemistry C. 2007;111:10382–10388. [Google Scholar]

- 38.Jia F, Yu C, Ai Z, Zhang L. Chemistry of Materials. 2007;19:3648–3653. [Google Scholar]

- 39.Bartlett PN, Baumberg JJ, Birkin PR, Ghanem MA, Netti MC. Chemistry of Materials. 2002;14:2199–2208. [Google Scholar]

- 40.Zhang R, Hummelgård M, Olin H. Journal of Colloid and Interface Science. 2009;340:58–61. doi: 10.1016/j.jcis.2009.08.006. [DOI] [PubMed] [Google Scholar]

- 41.Evans-Nguyen KM, Tao S-C, Zhu H, Cotter RJ. Anal Chem. 2008;80:1448–1458. doi: 10.1021/ac701800h. [DOI] [PubMed] [Google Scholar]

- 42.Moody NR, Adams DP, Medlin D, Headley T, Yang N, Volinsky A. International Journal of Fracture. 2003;120:407–419. [Google Scholar]

- 43.Szunerits S, Praig VG, Manesse M, Boukherroub R. Nanotechnology. 2008;19:195712. doi: 10.1088/0957-4484/19/19/195712. [DOI] [PubMed] [Google Scholar]

- 44.Getie-Kebtie M, Franke P, Aksamit R, Alterman MA. Journal of Proteome Research. 2008;7:3697–3707. doi: 10.1021/pr800258k. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.