Abstract

This report provides an overview of the exposure assessment process for an epidemiologic study that investigated mortality, with a special focus on lung cancer, associated with diesel exhaust (DE) exposure among miners. Details of several components are provided in four other reports. A major challenge for this study was the development of quantitative estimates of historical exposures to DE. There is no single standard method for assessing the totality of DE, so respirable elemental carbon (REC), a component of DE, was selected as the primary surrogate in this study. Air monitoring surveys at seven of the eight study mining facilities were conducted between 1998 and 2001 and provided reference personal REC exposure levels and measurements for other agents and DE components in the mining environment. (The eighth facility had closed permanently prior to the surveys.) Exposure estimates were developed for mining facility/department/job/year combinations. A hierarchical grouping strategy was developed for assigning exposure levels to underground jobs [based on job titles, on the amount of time spent in various areas of the underground mine, and on similar carbon monoxide (CO, another DE component) concentrations] and to surface jobs (based on the use of, or proximity to, diesel-powered equipment). Time trends in air concentrations for underground jobs were estimated from mining facility-specific prediction models using diesel equipment horsepower, total air flow rates exhausted from the underground mines, and, because there were no historical REC measurements, historical measurements of CO. Exposures to potentially confounding agents, i.e. respirable dust, silica, radon, asbestos, and non-diesel sources of polycyclic aromatic hydrocarbons, also were assessed. Accuracy and reliability of the estimated REC exposures levels were evaluated by comparison with several smaller datasets and by development of alternative time trend models. During 1998–2001, the average measured REC exposure level by facility ranged from 40 to 384 μg m−3 for the underground workers and from 2 to 6 μg m−3 for the surface workers. For one prevalent underground job, ‘miner operator’, the maximum annual REC exposure estimate by facility ranged up to 685% greater than the corresponding 1998–2001 value. A comparison of the historical CO estimates from the time trend models with 1976–1977 CO measurements not used in the modeling found an overall median relative difference of 29%. Other comparisons showed similar levels of agreement. The assessment process indicated large differences in REC exposure levels over time and across the underground operations. Method evaluations indicated that the final estimates were consistent with those from alternative time trend models and demonstrated moderate to high agreement with external data.

Keywords: diesel exhaust, elemental carbon, exposure assessment, miners

INTRODUCTION

Epidemiologic studies have found that long-term employment in occupations involving diesel exhaust (DE) exposure was associated with an increase in the risk of mortality from lung cancer, but very few of those studies had quantitative estimates of DE exposure (Silverman, 1998). In 1992, the US National Cancer Institute (NCI) and the US National Institute for Occupational Safety and Health (NIOSH) initiated an epidemiologic study of DE exposure among non-metal miners [the Diesel Exhaust in Miners Study (DEMS)] to investigate the association between quantitative estimates of DE exposure and mortality from lung cancer and other causes of death (NCI/NIOSH, 1997). The DEMS included a cohort study and a nested case–control study of lung cancer, both based upon an extensive retrospective exposure assessment effort.

This report describes the process used to develop quantitative estimates of historical DE exposure levels over all years of the study subjects' employment from the start of diesel-powered equipment use through 1997 by using respirable elemental carbon (REC) as a surrogate for DE in the evaluation of exposure–response relationships. REC was selected because there is no standard method for assessing the totality of DE exposure, it is a major component of DE, and it is currently considered the best surrogate of diesel particulate matter (DPM) in underground mines because of its specificity, sensitivity, and reliability (Birch and Cary, 1996; Bunn et al., 2002; Birch and Noll, 2004).

This report provides an overview of the exposure assessment process. One set of estimates was developed as the primary estimates for both the cohort and the case–control studies. Details of specific components of the process are described in other reports, i.e. a description of the personal (Coble et al., 2010) and area (Vermeulen et al., 2010b) measurements from the 1998–2001 monitoring surveys conducted for the DEMS, the development of exposure groups with similar exposure levels (Coble et al., 2010), and the process of estimating historical REC exposure levels for underground workers (Vermeulen et al., 2010a). An evaluation of the assessment methods will be provided in a future report. All of the data collection, data processing, and exposure estimation activities were undertaken without knowledge (i.e. blinded) of the mortality data and analytic results.

METHODS

The mining industry was selected for study because monitoring reports indicated this industry has higher levels and a wider range of DE exposure levels than other industries (Pronk et al., 2009). After an extensive feasibility effort, 10 mining facilities in the USA [four potash in New Mexico, three trona (trisodium hydrogen dicarbonate dihydrate) in Wyoming, two rock salt (in Ohio and in Louisiana), and one limestone in Missouri] were selected for study. These particular facilities were chosen in large part because they were likely to have had low air concentrations of potential lung cancer confounders, such as silica, radon, and asbestos (NCI/NIOSH, 1997). Two of the 10 facilities, a potash and the salt facility in Louisiana, were later excluded from the DEMS due to incomplete personnel records.

Exposure estimates were developed by year, back to the start of diesel equipment use (1947–1967, depending on the facility) through 31 December 1997, the end of the study follow-up. The estimates employed both exposure measurements from recent air monitoring surveys and historical compliance measurements and determinant data. The estimates were developed following six basic steps:

Collection of exposure information, i.e. air measurements collected in 1998–2001 at the study facilities for the DEMS, measurement results from other sources [including the US Mine Safety and Health Administration (MSHA) and the US Mine Enforcement and Safety Administration/Bureau of Mines (MESA/BoM), and other work place information (Table 1);

Work history collection and processing, including inference of missing information (Table 1);

Assignment of REC exposure estimates, including compilation of air measurements and possible exposure determinants, development of exposure groups, and derivation of 1998–2001 and historical exposure levels (Table 1);

Estimation of potential confounding exposures within the facilities;

Quality control procedures; and

Evaluation of the exposure assessment methods.

Table 1.

Types, sources, and use of data in the estimation of REC exposure levelsa

| Types of data (years covered) | Source | Use |

| Monitoring data | ||

| DEMS surveys (1998–2001) | NIOSH/NCI | Estimate 1998–2001 REC levels for underground and surface jobs |

| MIDAS (1976–2003) | MSHA | Develop models for predicting 1976–2001 CO levels for underground jobs |

| Miscellaneous (1954–1996) | State of New Mexico, MSHA, mining facilities | Develop models for predicting 1976–2001 CO levels for underground jobs (with MIDAS data) |

| Work histories (1947–1998) | Mining facilities | Identify underground and surface jobs requiring estimates |

| Job descriptions, organizational charts, and interview data (1947–2001) | Mining facilities | Develop job groups for underground and surface jobs |

| Underground determinant information from diesel equipment inventories, other records, and interview data, specifically: Diesel equipment (types, models, numbers, HP, and ADJ HP) (1947–2001); total exhaust air flow rates (1947–2001); and miscellaneous other work place characteristics (mining method, haulage method, etc.) (1947--2001) | Mining facilities | Develop models for predicting 1976–2001 CO levels for underground jobs |

| Predict 1947–2001 CO levels of underground jobs from models | ||

| Interview data and equipment inventories on surface equipment (1947–2001) | Mining facilities | Predict 1947–2001 REC levels of surface jobs |

Another source of monitoring data was from 1976–1977 MESA/BoM surveys (Sutton et al., 1979). These data were not used in the estimation process but were used to evaluate the estimates (Vermeulen et al., 2010a).

Collection of exposure information

From 1998 to 1999, the first of three rounds of visits occurred at six facilities (A, D, E, G–I) during which monitoring was conducted (herein called the DEMS surveys). A seventh facility (B), which had had a limited monitoring survey in 1994 for a feasibility study (Stanevich et al., 1997), was surveyed again in 2001. All data were assigned the year of measurement, but for purposes of simplicity, the period is referred to as 1998–2001. The eighth facility (J) had ceased operations in 1993 and thus was not available for monitoring.

Details of the personal and area measurements taken during the DEMS surveys are provided elsewhere (Coble et al., 2010; Vermeulen et al., 2010b). In addition to DE components, area measurements were taken for agents that could potentially confound the epidemiologic results, i.e. respirable dust (RD), silica, radon, asbestos, polycyclic aromatic hydrocarbons (PAHs), nickel, arsenic, and cadmium. A second purpose of the DEMS surveys was to gather ancillary information needed for the retrospective exposure assessment process, including industrial hygiene monitoring reports, job descriptions, diesel equipment inventories, ventilation reports, and other work place documents covering the period of diesel use at the facilities (Table 1).

Between 2001 and 2005, additional site visits were made to supplement the information collected earlier on the jobs and to discuss the investigators' understanding of the underground and surface jobs, diesel equipment used, and exposure conditions with facility staff and workers. The study investigators interviewed long-term workers (including management and union or worker representatives) who had held jobs representing a spectrum of the predominant jobs at various locations within each facility over the study period. These jobs included production, maintenance, and support functions, and both supervisory and non-supervisory (i.e. hourly or blue collar) positions. 6–10 surface workers and 6–10 underground workers typically were interviewed at each facility per visit. Former employees of Facility J were contacted and interviewed using the same format as followed at the other facilities.

Work history collection and processing

Work histories were abstracted from the mining facility personnel records for all workers who ever held a non-supervisory non-administrative job and who had worked at least 1 year at the study facilities within the period from the first use of diesel equipment at the facility up through 1997. Job title, department name, start and end dates, and work history-related comments, e.g. military service and labor strikes, were recorded.

Large differences in REC exposure levels were observed between jobs located underground compared to jobs on the surface (Coble et al., 2010); therefore, accurate determination of each study subject's location was essential. The records for several subjects failed to identify whether their jobs were worked on the surface or underground. The work histories of these subjects who held a job with an unknown location for at least 2 years were reviewed with facility employees during the site visits. Jobs for which there was a consensus on the location were assigned that location; otherwise, for jobs with no consensus and jobs held <2 years, the location assigned was the predominant location of the subject or of the job in that facility.

As is typical in industry-based cohort studies, the job entries from the work histories contained multiple abbreviations, spellings, and synonyms for the same job. The department and job titles were coded to standardized titles, keeping the associated task information as precise as possible by assigning the same title only to those with variations in spelling or word order or to those that facility personnel had identified as having performed the same job tasks. Each of the standardized job titles was assigned a unique code.

Assignment of REC exposure estimates

Strategy.

In addition to the differences between the surface and underground REC exposure levels, there were large differences in the average measured REC exposure levels of underground workers between the facilities (Coble et al., 2010). Within many of the facilities, there also were substantial differences between the measured REC exposure levels of underground workers with different jobs. The goal of the assessment process, therefore, was to develop a REC exposure estimate for each mining facility/department/standardized job title (hereafter called job) for underground and for surface workers for every year of the study. The estimation process was done separately for the two types of jobs. First, for both types, groups of jobs (herein called exposure groups) were developed that were considered to have similar exposure levels based on descriptive information on the jobs, tasks, and locations obtained from records and the site visit interviews. The assignment was made without reference to the air measurement data because, as is typical in most epidemiologic studies, not all jobs had been monitored in the DEMS surveys. Second, an exposure estimate reflecting 1998–2001 exposure levels was assigned to each job using the DEMS REC monitoring data. For each unmonitored job, the mean of the pooled measurement data on other jobs included in its exposure group was assigned. The arithmetic mean (AM) of the REC measurements was chosen as the indicator statistic because it is considered the best summary statistic for estimating cumulative exposure in the investigation of chronic disease (Seixas et al., 1988). Finally, the 1998–2001 REC estimates were back extrapolated to the start of dieselization. The estimates for both underground and for surface jobs were combined with the work histories to derive personal cumulative and other exposure estimates. No modification of the estimates was made for respirator use.

Databases of air measurements and possible exposure determinants.

A database of air measurements taken at the study facilities was compiled from various sources (Table 1). Measurements were available for carbon monoxide (CO), nitrogen dioxide (NO2), carbon dioxide (CO2), nitric oxide (NO), dust, and other DE components and co-exposures in the mining facilities.

All personal measurements were coded with the same standardized job title codes used in the work histories, and all area measurements were coded using MSHA location codes (Watts and Parker, 1995). Coding was done without reference to the measurement results. Other databases were compiled of possible underground exposure determinants, such as power of the diesel equipment [in horsepower (HP)], HP adjusted for the average proportion of time the equipment was used over a work shift (ADJ HP), total air flow rates exhausted from the underground operations, mining and ore haulage methods, and work practices (Vermeulen et al., 2010a) (Table 1). (One HP = 0.746 kW.)

Underground exposure groups.

Because the number of jobs monitored in the DEMS surveys was necessarily limited, exposure groups of underground jobs that were considered as having similar exposure levels were developed to allow assignment of exposure levels to all jobs. Grouping was based on three criteria, each of which resulted in a set of underground job exposure groups in each facility. These criteria, in decreasing specificity, were: (i) jobs from the work histories assigned the same standardized job title (U1 groups); (ii) jobs with differing standardized job titles that spent similar proportions of time in the major areas of the underground mine (i.e. the production face, haulage and travel ways, maintenance shop and office area, and crusher) (U2 groups); and (iii) jobs that spent time in areas with similar CO air concentrations, as estimated from area CO measurements (U3 groups). CO measurements were used to combine U2 groups into broader U3 groups because there were no historical REC measurements prior to the 1990s and CO is the DE component that had the greatest number of historical measurements available in these facilities (Table 2) (Vermeulen et al., 2010a). CO also has been used historically as a surrogate for DE (Pronk et al., 2009). More detail is provided in Coble et al., 2010.

1998–2001 and historical REC exposure estimates for underground jobs.

Assignment of the REC AMs was a hierarchical process based on each job's most specific exposure group having at least five measurements (U1>U2>U3). A minimum of five samples was required to provide reasonable assurance that the AM of the measurements reflected the average exposure level of workers with that job. Any job without an estimate from a U1 to U3 group was assigned the AM of all DEMS underground personal REC measurements at its facility (designated as U4 groups). The assignment of jobs to the U1–U4 groups was made without reference to the REC measurement levels. After the assignment, all estimates were reviewed to determine if the estimates were appropriate relative to the other jobs, based on the locations and tasks of the jobs. The exposure levels of a few jobs were identified as having been potentially overestimated because the job descriptions indicated that the workers with these jobs were located in underground areas that were supplied with fresh air coming directly from the intake shaft and that these workers generally did not perform DE-related tasks. These jobs, called overrides and designated as U5 groups, were assigned the AM of the measurements of all the jobs in the fresh air in the corresponding underground facility, although they were based on fewer than five measurements. More detail is provided in Coble et al., 2010. Because there were no REC measurements taken in Facility J, the 1993 (i.e. the last year of Facility J's underground operations) estimates from Facility B were applied to Facility J's U3–U5 groups because of the similarity of geographic location, the type of mining, the amount of HP present, and the air flow rates in the two facilities (Vermeulen et al., 2010a).

No REC measurements were available at the facilities prior to the early 1990s. Therefore, the 1998–2001 exposure REC levels were back extrapolated to derive historical REC levels for underground jobs, by year, to the date of dieselization at each facility (Vermeulen et al., 2010a). This was done by modeling the historical CO measurements taken at the face against exposure determinants (Table 1) to derive facility-specific parameter estimates reflecting the relationship of CO and the exposure determinants for every year between 1976 and 1998–2001. A modeling approach using determinants was used because CO measurements were available only back to 1976, whereas information on the determinants was available back to the start of dieselization. CO was selected as the agent for modeling for the reasons described above (‘Underground Exposure Groups’). In addition, the proportion of CO measurements above the limit of detection (LOD) was substantially larger than for other DE components, such as NO2. Facility-specific prediction trends of annual CO concentrations were estimated by application of the historical determinants to the derived models' parameter estimates. Each facility's modeled trend of CO concentrations, relative to 1998–2001, was applied to each underground job's 1998–2001 REC estimate to predict an historical REC exposure level for every year of the study. This set of estimates was considered the primary exposure estimates, and the set of associated models, the primary models (other models and estimates were developed for method evaluation, see Discussion).

Surface exposure groups.

The number of surface jobs with exposure measurements and the number of measurements on the surface were more limited than those available for underground jobs. REC exposure levels, however, were much lower on the surface compared to underground and generally had much less absolute variability (Coble et al., 2010). Each standardized job title on the surface was categorized into one of three exposure groups depending on the expected relative exposure intensity: jobs in which workers had no or very limited contact with diesel equipment (exposure group A); jobs in which workers drove a diesel forklift indoors or operated heavy diesel equipment (>75 HP) <4 h per shift on average, drove light diesel equipment (≤75 HP), or worked in close proximity to diesel-powered equipment on a regular basis (exposure group B); and jobs in which workers operated heavy diesel equipment or drove a diesel forklift truck indoors for ≥4 h per shift on average and mechanics or maintenance workers who repaired diesel equipment (exposure group C).

1998–2001 and historical REC exposure estimates for surface jobs.

Because the majority of REC measurements taken on the surface was below the LOD (Coble et al., 2010), to derive the AMs, the concentrations for the nondetectable measurements were imputed based on a distributional maximum likelihood estimation procedure (Helsel, 2005; Vermeulen et al., 2010a). If a surface exposure group within a facility comprised jobs that had at least five pooled measurements, the AM of those measurements was assigned to each job in the group (S1 estimation groups). If there were fewer than five samples for the group, assignment of the AM was based on the pooled measurements of all jobs assigned to the same surface exposure group for the same type of facility (e.g. potash) (S2 estimation groups); if not, the AM was calculated from the pooled measurements of the same surface exposure group across all facilities (S3 estimation groups).

DE exposure of surface jobs was considered constant over time because of the very low exposure levels of workers on the surface compared to underground workers, the less specific information on diesel equipment, and the large number of jobs that were worked out of doors. Accordingly, the 1998–2001 estimates were assigned to surface jobs for each year of the study back either to the first year the particular type of diesel equipment was used by the job (which was reported on facility records or was estimated from information collected during the interviews) or to the year when diesel equipment was first introduced in the area where the job was located. Information on locomotives and on-the-road trucks that hauled raw materials onto and product off of the facility property was not available to us because this equipment was owned by other companies. The use of diesel for these types of equipment only became prevalent in the USA in the 1950s (Woskie et al., 1988; Steenland et al., 1990). Therefore, any job held prior to 1955 where the source of DE exposure was locomotives or on-the-road trucks was assigned to exposure group A, but the estimate associated with this group was overridden by a zero. (Note: some of the mines started operations after this time, so their start of dieselization was later than the 1950s.)

A total of 1112 workers held at least one job where they performed tasks both underground and on the surface within a shift. These workers and jobs were characterized as ‘mixed’. REC estimates for both the underground and the surface job components of each mixed job were developed, weighted, respectively, in proportion to the time spent underground and on the surface, and summed.

Estimation of potential confounding exposures

Workers may have been exposed to other agents that may be potential confounders in the DEMS. For RD, jobs were assigned to one of three underground groups (production and crushing; haulage and travel ways; and shop and office jobs) or to one of three surface groups (crushing and screening; other production and loading; and maintenance and support jobs) based on job descriptions. All available personal measurements were then assigned to one of the same six groups. Both steps were done without regard to the measurement results. Each job was assigned the facility-group-decade-specific AM of these data.

For silica, radon, asbestos, and PAHs, there were many fewer measurements than RD and so no changes over time were considered. For silica, many of the measurements were below the LOD and there were no measurements for the job with the expected highest exposure level, i.e. sandblaster. Scores of 0, 1, or 2 were assigned in each facility to all underground jobs and to all surface jobs likely exposed to the ore based on the average of the measurements. Jobs that sandblasted were assigned a score of 3.

Radon levels in the mines monitored during the DEMS surveys were all below the detection limit of 0.07 working level (WL). Some radon measurements found in MSHA's Mine Information Data System (MIDAS) taken from the 1970s to the 1990s were detectable, but low (<0.1 WL). The facility-specific AM of all underground measurements [using  (Hornung and Reed, 1990) for nondetectable results] was assigned to jobs that spent time underground. Surface jobs were considered not exposed.

(Hornung and Reed, 1990) for nondetectable results] was assigned to jobs that spent time underground. Surface jobs were considered not exposed.

Ordinal estimates were developed for asbestos because the number of measurements was small (n = 26). Based on the possible sources of asbestos, the dryer operators, kiln operators, maintenance workers, and mechanics were assigned a score of 1; auto and diesel mechanics, boiler operators, power operators, and bricklayers, a score of 2; and pipe fitters, a score of 3. All other jobs were considered not exposed to asbestos.

PAHs were generated from both diesel and non-diesel equipment in these facilities. A job was considered exposed to PAHs only if non-diesel PAH-emitting equipment was in the area of the job. Because all available measurements appeared to have been taken near diesel equipment, the jobs were assessed based on an evaluation of possible sources. Mechanics, powerhouse operators, blacksmiths, boiler operators, welders, kiln operators, dryer operators, firemen, maintenance workers, ironworkers, pipe fitters, and steelworkers were assigned a score of 1. All other jobs were considered not exposed. Estimates of arsenic, cadmium, and nickel were not developed because there were few measurement results (total across all mines <155) and no other information was available that could provide guidance to the estimation process.

Quality control procedures

Several checks were implemented to ensure data of the highest quality. First, the work history records, copies of which were provided to the study investigators by the facilities, were double keyed and a 10% check made on the keyed data. Second, a sample of 10% of the records was re-abstracted and re-coded for comparison with the original coding. Third, the work history records of two facilities were particularly complex and so were re-abstracted. Fourth, because of the complexity of the record keeping data provided by all the facilities, only work history records had been abstracted originally. For subjects whose work history was missing the location where the job was worked (surface or underground), the entire set of records of each subject, including supplemental records not originally used for the abstraction, was reviewed. Fifth, final coding of all departments and jobs was reviewed by the study industrial hygienists to ensure that the tasks of all jobs assigned the same code were similar.

A 10% random sample of the DEMS sampling measurements was compared against the original laboratory reports. Over half of all other measurement data on paper copy were checked against the original documents to ensure that the sample result, the date, and the location had been correctly entered. All measurements were reviewed for duplicate records, which were deleted. Final coding of the measurement data to the appropriate job or location code was checked for accuracy by the study industrial hygienists.

RESULTS

Collection of exposure information

A total of 1156 personal REC measurements were taken during the DEMS surveys at the seven mining facilities (Table 2). The average REC exposure level measured underground ranged from 40 μg m−3 at Facility G to 384 μg m−3 at Facility A, an ∼10-fold range across the facilities (Coble et al., 2010). The average REC exposure level measured for surface workers ranged from 2 μg m−3 at Facilities G and H to 6 μg m−3 at Facility A.

Table 2.

Number of area and personal DE-related measurements by agent for the eight mining facilities

| Agent | Surveya |

All surveys |

Total | ||||||||||

| MIDAS 1976–2001 |

DEMS 1998–2001 |

MESA/BoM 1976–1977 |

Feasibility study 1994 |

Other 1954–1996 |

|||||||||

| Areab | Personalb | Area | Personal | Area | Personal | Area | Personal | Area | Personal | Area | Personal | ||

| CO | 9746 | 46 | 208 | 0 | 1099 | 0 | 25 | 0 | 46 | 0 | 11 124 | 46 | 11 170 |

| CO2 | 8234 | 15 | 390 | 0 | 961 | 0 | 17 | 0 | 49 | 0 | 9651 | 15 | 9666 |

| NO | 45 | 0 | 381 | 995 | 24 | 0 | 42 | 69 | 9 | 0 | 501 | 1064 | 1565 |

| NO2 | 4288 | 38 | 387 | 1031 | 252 | 646 | 42 | 69 | 76 | 11 | 5045 | 1795 | 6840 |

| TD | 1 | 782 | 215 | 0 | 161 | 667 | 32 | 0 | 69 | 703 | 478 | 2152 | 2630 |

| RD | 0 | 324 | 209 | 2 | 99 | 0 | 31 | 0 | 158 | 178 | 497 | 504 | 1001 |

| SD | 0 | 0 | 121 | 0 | 0 | 0 | 69 | 0 | 20 | 0 | 210 | 0 | 210 |

| TEC | 0 | 0 | 224 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 224 | 0 | 224 |

| REC | 0 | 0 | 216 | 1156 | 0 | 0 | 0 | 69 | 12 | 4 | 228 | 1229 | 1457 |

| SEC | 0 | 0 | 209 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 209 | 0 | 209 |

| TOC | 0 | 0 | 224 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 224 | 0 | 224 |

| ROC | 0 | 0 | 221 | 1151 | 0 | 0 | 0 | 0 | 0 | 0 | 221 | 1151 | 1372 |

| SOC | 0 | 0 | 207 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 207 | 0 | 207 |

| DPM/SCD | 0 | 0 | 212 | 0 | 0 | 0 | 0 | 0 | 180 | 102 | 392 | 102 | 494 |

| Total | 22 314 | 1205 | 3424 | 4335 | 2596 | 1313 | 258 | 207 | 619 | 998 | 29 211 | 8058 | 37 269 |

DPM, diesel particulate matter; RD, respirable dust; ROC, respirable organic carbon; SCD, submicron combustible dust; SD, submicron dust; SEC, Submicron elemental carbon; SOC, submicron organic carbon; TD, total dust; TEC, total elemental carbon; TOC, total organic carbon.

Surveys: the MSHA MIDAS (1976–2001); the DEMS (1998–2001) (Coble et al., 2010; Vermeulen et al., 2010b); the MESA/BoM (1976–1977) (Sutton et al., 1979); the feasibility study for the DEMS in Facility B (1994) (Stanevich et al., 1997); compliance visits by the State of New Mexico, MSHA hard copy reports, and the mining facilities (1954–1996).

Area measurements; personal measurements. The number includes both full-shift and short-term measurements.

Work history collection and processing

The cohort consisted of 12 382 study subjects in the eight facilities. (A further 67 subjects were excluded from the cohort on the basis of invalid birth dates and other criteria so that the final cohort comprised 12 315 subjects.) The work histories were coded to 1164 unique facility/department/standardized job title combinations: 333 were underground jobs, 703 were surface jobs, and 128 were mixed jobs [the latter contributed ∼4000 exposure-years (3%)]. About 8% of the exposure-years had unspecified locations, and of these, ∼75% were assigned a location based on the on-site interviews of where the specific subject worked.

Assignment of REC exposure estimates

Databases of air measurements and possible exposure determinants.

Three sources of measurement data accounted for almost 95% of all DE-related measurement data, with MIDAS contributing 63%; the DEMS surveys contributing 21%; and the 1976–1977 MESA/BoM surveys contributing 10% of the measurements (Table 2). There were >11 000 measurements available on CO. The >6000 CO area measurements taken in the face area, which were used to develop the underground prediction models, had geometric mean air concentrations typically ranging from 1 to 2 parts per million (ppm) in 1975–1979, 1 to 3 ppm in the 1980s, and ≤1 ppm in the 1990s (Vermeulen et al., 2010a).

The characteristics of the mining facilities varied considerably across time and across the facilities (Table 3). Means of decade-specific underground ADJ HP ranged from 24 in the 1950s, when diesel-powered equipment was first introduced underground in Facility I, to 8559 in the 1990s (Facility A). The decade average total airflow rate exhausted from the underground operations ranged from 132 thousand cubic feet per minute (kcfm) (Facility J in the 1950s) to 1519 kcfm (Facility I in the 1990s). (1 kcfm = 28.3 m3 min−1.) The underground operations for Facility A depended mostly on natural ventilation through the use of air holes drilled from the surface. Although some holes were equipped with exhaust fans, others were not, so the total airflow rate could not be estimated. The three trona facilities (G, H, and I) had parallel ventilation systems underground (i.e. each face received fresh air), whereas the salt and potash facilities (B, D, E, and J) were ventilated in series (i.e. air moved from one face to the next). The mining methods consisted of conventional (with truck or conveyor haulage), continuous, and longwall mining. More details of the facilities' underground operations are in Coble et al., 2010.

Table 3.

Characteristics of the mining facilities

| Mining facility—ore type (year of first diesel use) | Workersa (n) | Decade | Mining method | Decade mean of ADJ HP underground (min and max) | Decade mean of total exhaust airflow rate undergroundb (kcfm) (min–max) |

| A—limestone (1947) | 1684 | 1940s | Cv/H | 647 (644–649) | NA |

| 1950s | Cv/H | 1158 (649–1615) | NA | ||

| 1960s | Cv/H | 2119 (1273–4829) | NA | ||

| 1970s | Cv/H | 5738 (5016–6096) | NA | ||

| 1980s | Cv/H | 7082 (6471–7789) | NA | ||

| 1990s | Cv/H | 8559 (7995–9105) | NA | ||

| B—potash (1964) | 899 | 1960s | Cv/Con | 202 (75–268) | 229 (125–250) |

| 1970s | Cv/Con, Ct | 425 (263–761) | 250 (250–250) | ||

| 1980s | Ct | 795 (433–907) | 250 (250–250) | ||

| 1990s | Ct | 488 (461–527) | 250 (250–250) | ||

| D—potash (1950) | 2105 | 1950s | Cv/H | 76 (26–191) | 310 (310–310) |

| 1960s | Cv/Con | 462 (246–598) | 310 (310–310) | ||

| 1970s | Cv/Con | 1598 (557–2313) | 310 (310–310) | ||

| 1980s | Cv/Con | 2549 (2360–2741) | 490 (310–620) | ||

| 1990s | Cv/Con, Ct | 2865 (2754–3402) | 664 (600–700) | ||

| E—salt (1959) | 548 | 1959 | Cv/H | 125 | 160 |

| 1960s | Cv/H | 1503 (227–2296) | 160 (160–160) | ||

| 1970s | Cv/H | 2509 (2370–2705) | 172 (160–200) | ||

| 1980s | Cv/H | 2527 (1928–2846) | 228 (208–247) | ||

| 1990s | Cv/H | 1936 (1752–2058) | 266 (236–286) | ||

| G—trona (1962) | 1167 | 1960s | Cv/Con | 350 (39–64) | 212 (200–235) |

| 1970s | Cv/Con | 813 (694–871) | 293 (212–350) | ||

| 1980s | Cv/Con, Ct | 674 (646–727) | 481 (314–570) | ||

| 1990s | Cv/Con, Ct | 681 (632–734) | 544 (530–552) | ||

| H—trona (1967) | 1937 | 1960s | Cv/Con | 423 (385–499) | 300 (300–300) |

| 1970s | Cv/Con, Ct, LW | 1021 (509–1329 | 450 (300–600) | ||

| 1980s | Cv/Con, Ct, LW | 1103 (1034–1173) | 915 (600–950) | ||

| 1990s | Ct | 1303 (1174–1384) | 1309 (950–1429) | ||

| I—trona (1956) | 2453 | 1950s | Cv/H, Con, Ct | 24 (9–35) | 440 (350–530) |

| 1960s | Cv/Con, Ct | 81 (42–104) | 547 (530–700) | ||

| 1970s | Cv/Con, Ct | 940 (210–1270) | 1079 (700–1450) | ||

| 1980s | Cv/Con, Ct, LW | 1454 (1398–1505 | 1482 (1450–1630) | ||

| 1990s | Ct, LW | 1465 (1383–1514) | 1519 (1500–1670) | ||

| J—potash (1952) | 1589 | 1950s | Cv/H | 84 (0–155) | 132 (60–143) |

| 1960s | Cv/H & Con, Ct | 289 (160–501) | 187 (176–230) | ||

| 1970s | Cv/Con, Ct | 834 (520–1085) | 238 (228–240) | ||

| 1980s | Cv/Con, Ct | 1317 (1139–1421) | 239 (228–240) | ||

| 1990s | Ct | 983 (950–1035) | 240 (240–240) |

Mining method: Cv/Con, conventional with conveyor belts; Cv/H, conventional with truck haulage; Ct, continuous (with conveyor belts); LW, longwall (with conveyor belts); min, minimum; max, maximum; NA, not applicable (see Table footnoteb).

n, Number of workers from year of dieselization (1947–1967, depending on the facility) to 31 December 1997. Subjects are only counted once based on the mining facility in which they worked the longest. A total of 1007 subjects worked in more than one facility. The numbers reflect the cohort before exclusions due to invalid birth dates and other criteria. See Results.

Exhaust ventilation for the underground operations in Facility A consisted of holes drilled from the surface; some holes provided natural ventilation, while others had fans. Facilities B, D, E, and J had serial ventilation. Facilities G, H, and I had parallel ventilation.

Underground exposure groups.

Of the 333 unique, underground standardized job titles, 49 had been measured for REC five or more times in 1998–2001, and so each was assigned the AM of its measurements (U1 groups). These 49 job titles provided 1998–2001 reference levels for 40% of the underground exposure-years (Table 4). Six to 14 U2 groups were developed per facility and were used to assign estimates to 155 unique standardized job titles. The AMs of these groups were the reference for another 40% of the underground exposure-years. There were three to four U3 groups per facility; these groups were the reference levels for 49 standardized job titles and 6% of the exposure-years. Estimates based on the facility-specific pooled measurements of all underground jobs (U4 groups) were assigned to 44 standardized job titles (12% of the exposure-years), and estimates assigned to overrides (U5 groups) were applied to 36 standardized job titles (1%).

Table 4.

Distribution of underground standardized job titles and exposure-years by underground exposure groupa and by mining facility

| Mining facility | Standardized job titlesb (n) | Total E-Yc (n) | Underground exposure group E-Ys (%)d |

||||

| U1 | U2 | U3 | U4 | U5 | |||

| A | 40 | 8142 | 47 | 49 | 0 | 3 | 1 |

| B | 25 | 5530 | 51 | 43 | <1 | 3 | 2 |

| D | 58 | 11 103 | 28 | 63 | 1 | 8 | 1 |

| E | 36 | 3708 | 46 | 45 | 9 | 0 | <1 |

| G | 38 | 5240 | 68 | 32 | <1 | 0 | <1 |

| H | 43 | 9190 | 40 | 53 | 4 | <1 | 2 |

| I | 55 | 13 236 | 57 | 36 | 4 | 1 | 1 |

| J | 38 | 9072 | 0 | 0 | 27 | 71 | 2 |

| Total | 333 | 65 220 | 40 | 40 | 6 | 12 | 1 |

E-Y, exposure-years; n, number.

Does not include mixed workers, i.e. workers who worked both underground and on the surface on the same job. For underground jobs, the exposure groups were used only to group the jobs for assigning exposure estimates, in contrast to the surface jobs that had two types of exposure groups.

Standardized job titles are the study titles of groups of job entries from the facility's personnel records that differed only in spelling or word order or were synonyms but performed the same tasks.

E-Ys is defined as end date minus start date of a job plus 1, divided by 365.2425, and summed across all jobs. E-Ys may not sum to 100% due to rounding.

U1 groups were based on the standardized job title; U2 groups comprised groups of standardized job titles that spent similar proportions of time in four major areas of the underground operation; U3 groups were groupings of U2 groups defined by similarity of CO air concentrations; U4 groups were the default, i.e. all underground jobs; and U5 groups were exceptions or overrides. A minimum of five REC measurements from the DEMS surveys was required for assigning the groups, except U5. Assignment was hierarchical from U1 to U5. E-Ys (%), the percentage of E-Ys assigned an exposure estimate based on the identified exposure group.

1998–2001 and historical REC exposure estimates for underground jobs.

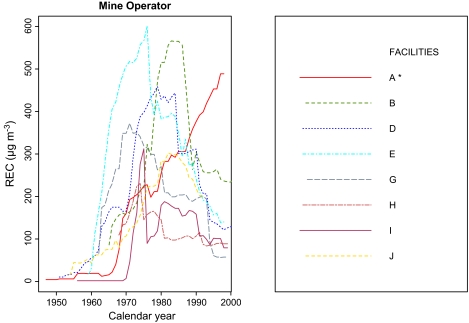

The models developed to estimate historical changes in CO concentrations varied slightly across underground operations at the facilities, but the primary variables were the ADJ HP, total airflow rate exhausted from the underground operations, the source of the CO measurements (e.g. MIDAS), and the season of the measurement. The relationships, i.e. the parameter estimates for ADJ HP, total exhaust airflow rate, and CO were generally consistent among the facilities (Vermeulen et al., 2010a) but because of the large differences in HP and exhaust airflow rates among the underground operations, substantial differences were predicted in the CO levels and, consequently, in the derived REC estimates over time and across operations. Fig. 1 presents the time trends for the miner operator for the eight mining facilities. The temporal pattern of the exposure estimates for most underground operations exhibited an inverted U-shaped curve, with the highest estimates typically being in the mid-1970s to early 1980s. In Facility A, however, estimates of underground REC levels continued to rise throughout the study period due to the use of increasingly larger haulage trucks with increasingly larger HP over time. The ratio of the maximum estimate to the 1998–2001 REC reference levels ranged from 100% (Facility A) to 685% (Facility G).

Fig. 1.

Estimated historical REC trends for the miner operator, by facility. The symbol asterisk indicates there was no job title of miner operator in Facility A. The loader operator, who worked at the face, is presented.

Surface exposure groups

Of the 1164 standardized job titles, 703 were surface titles (Table 5). Of these, 606 were assigned to surface exposure group A (no or limited contact with diesel equipment). These provided the 1998–2001 reference exposure levels for 69% of the surface exposure-years. Only 79 standardized job titles were assigned to group B (bystander or incidental contact), and these provided reference levels for 23% of the surface exposure-years. A total of 18 standardized job titles assigned to group C (operation of large pieces of diesel equipment) provided reference levels for 4% of the exposure-years.

Table 5.

Distribution of surface standardized job titles, exposure-years, estimation strategy, and assigned REC levels by surface exposure groupa and by mining facility

| Mining facility | Standardized job titlesb (n) | Total E-Y (n) | Surface exposure groupc |

|||||||||||

| A |

B |

C |

||||||||||||

| E-Yd (%) | ne | Surface estimation groupf | REC estimateg (μg m−3) | E-Y (%) | n | Surface estimation group | REC estimate (μg m−3) | E-Y (%) | n | Surface estimation group | REC estimate (μg m−3) | |||

| Ah | 101 | 21 872 | 57 | 96 | S3 | 2 | 27 | 11 | S1 | 4 | 5 | 6 | S1 | 11 |

| B | 65 | 3194 | 64 | 9 | S1 | 1 | 36 | 50 | S1 | 3 | 0 | NA | S3 | NA |

| Dh | 151 | 12 165 | 87 | 20 | S1 | 1 | 4 | 12 | S1 | 2 | <1 | 34 | S3 | 5 |

| E | 32 | 1469 | 36 | 6 | S1 | 1 | 42 | 11 | S1 | 4 | 21 | 8 | S1 | 4 |

| G | 62 | 8040 | 57 | 12 | S1 | 2 | 43 | 17 | S1 | 2 | <1 | 17 | S2 | 4 |

| H | 80 | 9129 | 48 | 8 | S1 | 1 | 46 | 22 | S1 | 2 | 5 | 17 | S2 | 4 |

| I | 142 | 17 570 | 85 | 25 | S1 | 1 | 11 | 10 | S1 | 2 | 4 | 12 | S1 | 5 |

| Jh | 70 | 4788 | 90 | 29 | S2 | 1 | 4 | 62 | S2 | 3 | 2 | 34 | S3 | 5 |

| Totalhi | 703 | 78 228 | 69 | 96 | 1 | 23 | 133 | 3 | 4 | 34 | 5 | |||

E-Y, exposure-years, defined as end date minus start date of a job plus 1, divided by 365.2425, and summed across all jobs; n, number.

Does not include mixed jobs, i.e. jobs that worked both underground and on the surface. In contrast to underground jobs, for surface jobs, two types of groups were developed: surface exposure groups (A–C; equivalent to the standardized job titles for underground jobs) and surface estimation groups (S1–S3; equivalent to groups U1–U5).

Standardized job titles are the study titles of groups of job entries from the facility's personnel records that differed only in spelling or word order or were synonyms but performed the same tasks.

Surface exposure group: A, jobs in which workers had no or very limited contact with diesel equipment; B, jobs in which workers drove a diesel forklift indoors or operated heavy diesel equipment (>75 HP) <4 h per shift on average, drove light diesel equipment (≤75 HP), or worked in close proximity to diesel-powered equipment on a regular basis; and C, jobs in which workers operated heavy diesel equipment or drove a diesel forklift truck indoors for ≥4 h per shift on average, and mechanics or maintenance workers who repaired diesel equipment.

E-Ys(%), the percentage of E-Ys assigned an exposure estimate based on the identified exposure group.

n, Number of measurements used to determine the estimation group and the REC estimate.

Surface estimation group: S1, ≥5 measurements pooled from all jobs assigned to the surface exposure group within the same facility; S2, ≥5 measurements pooled from all jobs assigned to the same surface exposure group across facilities of the same ore type; S3, ≥5 measurements pooled from all jobs assigned to the same surface exposure group across all facilities.

REC estimate derived from all REC measurements for that exposure group and estimation group. The total value represents the mean of all measurements for that category; not the mean of the facility estimates.

The percentage of E-Y does not equal 100 across the exposure groups because E-Ys were not included that were assigned a zero prior to the introduction of diesel equipment at the surface of the facility: n = 2264 E-Y for Facility A; n = 1118 E-Y for Facility D; and n = 203 E-Y for Facility J.

Total n measurements does not equal the sum of n because the measurements for estimation groups S2 and S3 were derived from pooling measurements from multiple jobs that also may have been contributed to S1 estimation groups.

1998–2001 and historical REC exposure estimates for surface jobs.

The REC estimate range was 1–2 μg m−3 for surface group A (mean = 1 μg m−3 across all facilities); 2–4 μg m−3 (mean = 3 μg m−3) for group B; and 4–11 μg m−3 (mean = 5 μg m−3) for group C (Table 5). These represent the 1998–2001 and, for most jobs, the historical estimated REC levels. Generally the estimates increased as the contact with diesel equipment increased within each facility, i.e. from group A to group C. Most of the surface exposure-years (75%) were assigned an estimate based on the facility-specific measurements (estimation group S1) (data not shown).

Estimation of potential confounding exposures

Estimated RD levels for underground production and crusher workers ranged from 1.2–3.8 mg m−3 among the facilities across the decades; 0.9–5.1 mg m−3 for workers who spent most of their time in the haulage and travel ways; and 0.4–0.5 mg m−3 for workers who spent most of their time in the shop or office areas (Table 6). Surface workers in the crushing and screening areas were assigned levels of 0.9–3.4 mg m−3; other production workers and loading workers, 0.5–1.1 mg m−3; and maintenance and support workers, 0.3–0.6 mg m−3. All workers were estimated to have been exposed to RD. The means of the silica measurements were ≤0.02 mg m−3, and 80% of the subjects were assigned exposure to negligible but detectable levels of silica. Mean radon levels were assigned by facility and ranged from 0.01 to 0.02 WL, which is at or below the LOD for at least one of the sampling data sources for each of the eight facilities. About two-thirds of the cohort (i.e. all subjects who ever worked underground) was potentially exposed to these negligible levels of radon. The estimates for asbestos and PAHs exposures were ordinal. About 40% of the cohort was identified as potentially being exposed to each of these substances. The average measurement levels for radon, asbestos, and PAHs were <5% of the MSHA standards (MSHA, 2006).

Table 6.

Estimation of RD and potential confounding exposures

| Agenta | Location | Measurementsb [type: n; range of AMs by facility (years)] | Description of estimates and levels assigned | % of cohort potentially exposed to detectable levels |

| Respirable dust | UG | Pc: n = 273; 1.2–6.1 mg m−3 (1970s–1990s) | Facility and decade specific. Three categories based on where workers spent most of their time underground. Range is for the eight facilities across all decades: production and crusher, 1.2–3.8 mg m−3; haulage and travel ways, 0.9–5.1 mg m−3; and shop and office, 0.4–0.5 mg m−3 | 100 |

| S | P: n = 169; <0.1–1.4 mg m−3 (1970s–1990s) | Facility and decade specific. Three categories based on the type of surface worker. Range is for the eight facilities across all decades: Crushing and screening, 0.9–3.4 mg m−3; other production and loading, 0.5–1.1 mg m−3; and maintenance and support, 0.3–0.6 mg m−3 | ||

| Silica | UG and S | A: n = 217; <0.01–0.02 mg m−3 (95% NDd) (1998–2001) | Categorical score, based on the AMs of area silica measurements, by facility: 3—sandblasters (all facilities): not based on measurements; 2—all UG jobs and all surface production jobs likely exposed to the ore at Facilities G, H, and I: 0.02 mg m−3; 1—all UG jobs and all surface production jobs likely exposed to the ore at Facilities B, D, and J: 0.01 mg m−3; and 0—all jobs at Facilities A and E and remaining surface jobs at Facilities B, D, G–J: <0.01 mg m−3 | 80 |

| P: n = 441; 0.01–0.02 mg m−3 (85% NDd) (1970s–1990s) | ||||

| Radon | UG | A: n = 28; (100% ND)e (1998–2001) | Based on the AMs of the radon measurements: UG workers at Facilities A, B, D, E, and G: 0.02 WL; UG workers at Facilities H–J: 0.01 WL; | 67 |

| A: n = 251; 0.01–0.02 WL (54% ND) (1970s–1990s) | ||||

| S | No measurements | 0—All surface jobs | ||

| Asbestosf | UG and S | P: n = 11; all <0.1 fiber per cc (1980s) | Categorical scores, based on an evaluation of sources: 3—pipe fitters; 2—auto and diesel mechanics, boiler ops, power ops, and bricklayers; 1—dryer ops, kiln ops, maintenance workers, and mechanics; and 0—all other jobs | 40 |

| Bulk samples: n = 15; (100% ND) (1998–2001) | ||||

| PAHs, as benzo(a)pyreneg | UG and S | No PAH measurements on non-diesel sources | Categorical scores, based on an evaluation of the job's potential contact with PAH sources other than diesel equipment: 1—mechanics, powerhouse ops, blacksmiths, boiler ops, welders, kiln ops, dryer ops, firemen, maintenance workers, ironworkers, pipe fitters, and steelworkers; 0—all other jobs | 41 |

A, area measurement; n, Number of measurements; ND, not detected; Ops, operators; P, personal measurement; S, surface; UG, underground; WL, working level.

Agent: few measurements were available for arsenic, cadmium, and nickel and therefore they were not assessed. Measurements were generally nondetectable in 1998–2001 (97, 87, and 88%, respectively) and 1970s–1990s (80, 92, and 51%, respectively).

1998–2001 indicates measurement results from the DEMS surveys.

No personal RD measurements taken in the DEMS surveys.

The LOD for the DEMS silica data was 0.005 mg m−3. The LOD used for the MIDAS silica data was the lowest detectable value (0.01 mg m−3). All values <LOD were imputed by  (Hornung and Reed, 1990).

(Hornung and Reed, 1990).

The LOD for the DEMS radon data ranged from <0.01–0.07 WL across the facilities. The LOD used for the MIDAS radon data was the lowest detectable value (0.01 WL). All values <LOD were imputed by  (Hornung and Reed, 1990).

(Hornung and Reed, 1990).

The LOD for asbestos bulk samples is <1% asbestos (http://www.cdc.gov/niosh/nmam/pdfs/9002.pdf). Asbestos measurements are presented for information purposes only, as they were not used to categorize workers' exposure.

PAHs were evaluated for sources other than diesel equipment.

DISCUSSION

The process of estimating retrospective exposure levels for this study was complex and time consuming, but quantitative levels of exposure were crucial to the epidemiologic study to allow investigation of exposure–response relationships between DE exposure and mortality outcomes. Given the large differences in exposure levels between the facilities' underground operations (Coble et al., 2010) and the existence of pronounced trends in the estimated REC exposure levels over time (Vermeulen et al., 2010a), quantifying exposures minimizes misclassification of exposure that would otherwise occur using cruder estimates of exposure levels. In this study, the types and amount of data available for estimation of past exposure levels varied across facilities, across jobs within the facilities, and over time. To maximize the usefulness of the data to accurately estimate REC exposure levels, we developed methods for integrating the disparate types of data, identified the assumptions being made, and instituted numerous quality control checks.

Wherever possible, supplemental data were used to evaluate the exposure assessment methods. Some investigators have described this type of effort as validation. That term, however, implies the availability of a gold standard, a standard that is rarely found in epidemiologic studies. We did not have a gold standard; however, we did have several different types of information that could be used for comparisons. Thus, we made a series of comparisons of the estimates or components of the estimates with sources of measurement data or exposure surrogate information not used in the estimation process, and we conducted several sensitivity analyses to understand the effect of different assumptions (Table 7). These evaluations were made to estimate the accuracy and the reliability of the exposure estimates and will be presented elsewhere.

Table 7.

Summary of the method evaluations

| Step in exposure assessment process | Evaluation | Comments | Results |

| Identification of agents used for estimation (REC and CO) | Compared REC measurements with measurements of TEC and SEC, NO, NO2, CO, and CO2 | Used area measurements from DEMS surveys | rP = 0.92 for TEC, 0.94 for SEC, 0.72 for NO, 0.52 for NO2, 0.41 for CO and 0.66 for CO2; EC components and gases loaded on same component in factor analysis; CO and REC approximately linear in log-log space |

| Compared REC measurements with REC measurements collected by Cohen et al., (2002) | Used personal REC measurements from DEMS surveys | No statistical difference for nine comparisons except for the surface group in one facility | |

| Development of underground exposure groups | Compared 8-h time-weighted REC averages calculated from area measurements and estimates of time in areas to full-shift personal REC AMs | Used estimates of time for U2 and, indirectly, U3 groups. Used area and personal data from DEMS surveys | Median relative difference = −19% (−48 to +20% by facility); rP = 0.83 (0.21–0.95 by facility) |

| Estimated between- and within-group variability of REC measurements by analysis of variance | Evaluated U1–U3 groups based on REC data from DEMS surveys | U1 groups explained more variability than U2 and U3 groups in three facilities (B, E, and G). Little between job variability in Facilities A, H, and I. | |

| Modeling of historical trends | Compared 1976–1977 underground CO estimates to 1976–1977 CO underground measurements in six facilities | CO historical trends were relative to 1998–2001 CO data and derived from facility-specific models using primarily ADJ HP, total exhaust airflow rates, and CO measurements. CO data from Sutton et al., 1979 | Median relative difference = 29% (−25 to +49% by facility) |

| Compared 1994 REC estimates to 1994 personal REC measurements for two underground jobs in Facility B | Used REC data from Stanevich et al., 1997 | Relative difference = −6 and −10% | |

| Sensitivity analyses: compared estimated REC cumulative exposures from primary estimates to estimated REC cumulative exposure from two alternative models | One model used the ratio of REC = CO0.58 calculated from the DEMS survey data; one model used 5-year averages of CO MIDAS measurements | REC = CO0.58 models: rP = 0.88 (0.96–0.99 by facility); 5-year average CO models: rP = 0.87 (0.95–0.99 by facility) | |

| Development of surface exposure groups | Calculated REC AMs and %NDs for surface categories | Development of surface exposure groups used a hierarchy based on the job's relationship to diesel equipment and the number of measurements. Used REC data from DEMS surveys | With increased contact with diesel equipment, REC AMs increased overall (1, 3, and 5 μg m−3) and in five of seven facilities and %NDs decreased overall (65, 55, and 47%) and in four of seven facilities |

| Selection of the AM as the exposure metric | Sensitivity analyses: compared estimated REC cumulative exposures using the AM to estimated REC cumulative exposures using the median for underground workers | Used personal REC measurement data from the DEMS surveys for the AM and the median and the same historical prediction models as used in primary models | rP = 0.98 (0.98 to >0.99 by facility) |

| Processing of the work histories | Compared reported locations (underground and surface), as identified in interviews, of subjects' jobs that had missing location with locations indicated in the facility personnel records | Filled in missing data with personnel record information where available after review by interviewees | 93% agreement (overall, for jobs identified as surface in the personnel records, and for jobs identified as underground in the personnel records) |

| Relationship of REC to CO over time | Calculated the average year of study diesel engines by year and adjusted underground REC exposure levels using Yanowitz et al., 2000 data. Compared these REC estimates with the primary REC exposure estimates | Yanowitz et al., 2000 studied 1976–1997 diesel engines and found DPM, which is almost entirely REC, increased slightly less than CO (−0.003) per year back to 1976 | 1976 REC estimates would have been 10% lower |

ND, nondetectable measurements; SEC, submicron elemental carbon; TEC, total elemental carbon; DPM, diesel particulate matter; rP = Pearson correlation coefficient.

The goal of the exposure assessment effort was to develop quantitative estimates of historical exposure levels to DE. DE is a complex mixture of gases and particulates. Of all the DE constituents, REC currently is considered the best surrogate of DPM (Bunn et al., 2002) because it can be measured easily and has acceptable measurement variability (Birch and Cary 1996; Birch and Noll, 2004). It is not known if REC is the best surrogate for determining the possible carcinogenicity of DE, but REC correlated moderately to strongly with most other components of DE in the DEMS surveys (Vermeulen et al., 2010b). REC could not be used, however, to estimate historical exposure levels because there were no measurements before the 1990s. NO2 and CO, two other components of DE, have often been used historically as surrogates for DE (Pronk et al., 2009). There were many fewer NO2 measurements than CO (∼7000 versus 11 000), and for three of the facilities, the percentage of nondetectable NO2 measurements was very high (i.e. up to 90%). For these reasons, CO was selected to estimate relative differences in DE concentrations over time. The fact that CO measurements correlated moderately with REC measurements, they were associated with elemental carbon, NO, CO2, and NO2 measurements in a factor analysis and they were approximately linear in log-log space with REC measurements supported our decision (Vermeulen et al., 2010b) (Table 7).

The DEMS survey data were very comparable to measurements taken concurrently in some of the facilities by different investigators (Cohen et al., 2002) (Table 7). A statistical difference between the means of three types of jobs (production, maintenance, and surface) in these two studies was found for only one of nine comparisons and there, only at the surface which may have been an artifact of how the jobs were defined in the facility. Comparability of the two data sets suggests that the DEMS data used to estimate 1998–2001 exposure levels were reliable.

Within any given facility, the underground operating sections or faces were at different distances from the intake and exhaust shafts, and the faces may have had different types of equipment being used and differing exhaust airflow rates. The DE air concentrations at the production faces, therefore, may have varied. The work histories, however, did not indicate at which face the study subjects worked, so we assigned the same facility-specific exposure estimate to all underground subjects with the same job in the same year. Examination of the measurement data suggests that this approach is not likely to have had a substantial impact on the estimates. The average REC levels of both the underground personal and the area measurements typically were characterized by geometric standard deviations (GSDs) of <3 within each facility (Coble et al., 2010), even though these measurements were taken at different sections of the underground operations. Furthermore, for any given year within a facility, operating faces generally used similar types and numbers of equipment to extract the ore, so that the HP, and therefore the DE level, was not likely to have differed substantially between different operating faces of a facility. The homogeneity in the REC measurements between mine faces and in the equipment likely used at the faces suggests that exposure levels to DE were likely to have been similar across faces. The approach taken here has been used by others studying underground miners (e.g. Seixas et al., 1991).

Exposure assessment in epidemiologic studies typically requires a strategy for developing exposure groups for the purpose of estimating exposure levels for jobs lacking measurements for all or part of the study time period. The goal of grouping is to reduce within-group variability and maximize between-group variability. The first set of underground job groups (U1) was highly specific and generally associated with low variability in the REC measurements (Coble et al., 2010). U2 groups were based on the proportion of time jobs were worked in four particular areas of the underground operation. This approach was taken because the DEMS REC area measurements suggested that air concentrations in these four areas differed systematically (Coble et al., 2010). Within each area of the operation, however, exposure levels were relatively homogeneous. About 70% of the underground area means had GSDs <3 and about half had GSDs <2. Both U2 and, indirectly, U3 groups used estimates of time spent in each of these areas based on data collected from the interviews. To determine the validity of the time estimates, we used these estimates with the DEMS area measurements to calculate 8-h time-weighted REC averages for various jobs and compared these to the corresponding jobs' means of the DEMS full-shift personal REC measurements. We found a low overall median difference of −19% and a high correlation of 0.83 between the two types of estimates (Table 7). Thus, the time estimates we used appeared to be representative of the true percentages of time spent by workers in these areas when monitored.

Pooling of measurements from different jobs into a single group provides more reliable estimates than keeping the measurements of individual job titles separate because the number of samples is increased, but this advantage is at the potential cost of greater (nondifferential) misclassification among the jobs, resulting in a reduction in the range of exposure levels between jobs. Our preference was to assign the most specific mean with a minimum of five measurements, which maximized the reliability of the job-specific estimates. We were unable to evaluate between and within worker variability because personal identifying information was not collected on the measured workers. After assigning the estimates, however, we conducted an analysis of variance of the DEMS REC measurements in the seven facilities to determine how well the underground grouping strategy performed. We found that the standardized job title approach (U1) explained more variability than the other two types of groups (U2 or U3) in three facilities (B, E, and G) (Table 7), and for these facilities, more of the underground exposure-years were based on the U1 groups than the other groups (although for Facility E there was little difference between U1 and U2 groups). In addition, there was little between job variance for Facilities A, H, and I. For these facilities, >90% of the actual underground exposure-years were based on U1–U3 groups. Thus, it appears that the adopted grouping strategy was successful in explaining the variability of the measurements. This approach assumed that the estimates of time remained valid historically, as did the calculation of exposure levels of mixed workers who worked both underground and on the surface within a work shift. The U2 and, indirectly, U3 groups were based on broad estimates of time (<30, 30–59, and >59%), which was likely to minimize misclassification. In addition, the primary jobs that spent time on the surface and underground were management and technical (e.g. engineers), but the number of exposure-years contributed by these jobs and the generally substantially lower exposure levels assigned to these jobs suggested that small variations in the time spent underground would have had minor effects on the overall study results. In all cases, when discussing jobs or diesel equipment use, the interviewers were asked to focus on historical conditions, not current conditions, which also should have minimized errors.

The facility-specific prediction models were based primarily on ADJ HP and the total airflow rates exhausted from the underground operations. The parameter estimates observed for these exposure variables varied slightly between facilities (Vermeulen et al., 2010a), in spite of the operations having different physical configurations, levels of HP and exhaust airflow rates, and mining methods, suggesting that these factors were robust and valid predictors of exposure levels. In addition, several evaluations were made of the estimation process. First and foremost, in 1976–1977, the MESA/BoM surveys designed to obtain representative exposure levels for an epidemiologic study were conducted in six of the facilities in the study (Sutton et al., 1979). Among the agents monitored was CO. We compared the underground CO estimates developed from the primary prediction models for 1976–1977 to the measured underground CO levels from those surveys. There was an overall median relative difference of only 29% (−25 to +49% across facilities) (Table 7) (Vermeulen et al., 2010a). We also had REC measurements from our feasibility study conducted in Facility B in 1994 (Table 7) (Stanevich et al., 1997). We were able to compare, for two of the four underground jobs monitored during this survey, the average measured REC levels with the 1994 REC estimates and found differences of only −6% and −10% for the two jobs.

We also developed two alternative sets of historical prediction models to evaluate the sensitivity of the primary models to the assumptions used in the models. One set of models used a power relationship of REC = CO0.58 for all facilities, based on the relationship between REC and CO in the cross-sectional DEMS surveys in 1998–2001, rather than the 1:1 ratio used in the primary models (Table 7) (Vermeulen et al., 2010b). The second set used 5-year averages of the MIDAS CO measurements. These two sets of relative trends were applied in sensitivity analyses to the underground jobs' 1998–2001 REC estimates, as had been done for the primary set of estimates, to develop historical estimates of REC levels. Cumulative exposure was calculated for each underground study subject using the three sets of estimates. Overall correlations between the subjects' cumulative exposure estimates based on the primary set of models and their cumulative exposure estimates derived from the two alternative set of models were ∼0.9 for both models (0.95–0.99 for both the REC = CO0.58 and the 5-year average CO models across the facilities) (Vermeulen et al., 2010a). These results support the robustness of the primary estimates.

No adjustment to the REC estimates was made to account for respirator use for several reasons. First, when respirators are used, there are substantial requirements of a respiratory protection program to ensure that wearers are adequately protected (US CFR 30, Part 57, 2001). Second, as of 2005 no air purifying filter respirator had been certified by NIOSH for protection against DPM (US CFR 70, Part 57, 2005). Third, respiratory use was optional in the study mines. Thus, for these reasons, it is unlikely that historical use of respirators was effective for protection against the higher levels of DE seen historically in this study. Fourth, no information was available as to which cohort members used respiratory protection. Information was available on subjects from the case–control study, with 45% of the controls reporting ever using a respirator or other respiratory protective equipment, such as a mask, at the study facilities. Reports of use of such protective equipment did not, however, impact the findings of the case–control study.

Estimation of exposure levels for surface jobs used a strategy similar to that used for underground jobs, i.e. we preferred increased specificity, based on at least five REC measurements from the DEMS surveys, over greater reliability of the estimates. Comparison of the AMs of the categories within each facility typically found increasing trends from the expected low to the expected high surface category, and there was generally an inverse monotonic trend for the percentage of nondetectable measurements (Table 7). Surface REC exposure levels were estimated to be 4–11 μg m−3 when operating heavy diesel equipment, driving a forklift indoors, or repairing diesel equipment; 2–4 μg m−3 when working near heavy equipment or operating light equipment; and 1–2 μg m−3 for the remaining, generally unexposed, workers. In other studies, measured REC exposure levels of construction workers operating heavy equipment were 8–15 μg m−3 (Blute et al., 1999; Woskie et al., 2002; Lewne et al., 2007) and two studies of dockworkers found mean exposure levels of 1 and 24 μg m−3 (Zaebst et al., 1991; Davis et al., 2007). Mechanics repairing diesel equipment have been reported as having mean REC exposure levels of 1–36 μg m−3 (Zaebst et al., 1991; Sauvain et al., 2003; Seshagiri and Burton, 2003; Davis et al., 2007; Lewne et al., 2007). Outdoor workers near diesel-powered equipment had a geometric mean exposure level of 4 μg m−3 (Lewne et al., 2007), and the average background level near highways was 3 μg m−3 (Zaebst et al., 1991). Finally, residential and industrial background air levels have been reported to be 1–2 μg m−3 (Zaebst et al., 1991; Davis et al., 2007). Thus, the study estimates for the surface REC exposure levels are reasonably consistent with the published literature.

Several of the comparisons conducted with independent data to evaluate the study estimates were described above. We conducted several other evaluations as well (Table 7). Each of these exercises has its limitations but overall, the results showed moderate to high agreement. Moreover, the most important comparison, that of the 29% difference between the 1976–1977 CO observed measurement means to the predicted 1976–1977 CO estimates, is in the range that investigators of other studies have found who have been able to evaluate their exposure assessment methods (Hornung et al., 1994; Burstyn et al., 2002; Stewart et al., 2003; Astrakianakis et al., 2006) and is similar to differences seen in two studies of side-by-side measurements of acrylonitrile (Zey et al., 2002) and of REC (Cohen et al., 2002). These findings, with those of other evaluations, indicate that the estimates were likely to have been accurate. This is not to say that we believe that the estimated exposure levels are without error; bias and imprecision in the estimates is inherent in any estimation procedure.

In conclusion, the goal of the study was to develop quantitative estimates of DE. We accomplished this for all 1164 facility/department/job combinations for every year from 1997 back to the first year of dieselization in each of the eight facilities by using REC as the surrogate for DE. The process was done first by calculating REC means of underground and of surface jobs or groups of jobs using the 1998–2001 REC measurement data and then back extrapolating these means using prediction models. Exposures to RD, silica, radon, asbestos, and PAHs also were assessed. The exposure assessment process was complex because the data available typically varied across facilities, across jobs within the facilities, and over time. We integrated these differing sources of information, explicitly defining the assumptions made, and performed a substantial number of quality control checks. We compared the estimates to several different types of independent data using various approaches. The cumulative evidence of the many evaluations indicated moderate to high agreement. In particular, the comparison with the 1976–1977 CO air concentrations found differences close to what others have found in epidemiologic and monitoring studies. For these reasons, we believe that the estimates are credible and can be used in the epidemiologic analysis with confidence.

FUNDING

Intramural Research Program of the National Institutes of Health, National Cancer Institute, Division of Cancer Epidemiology and Genetics, and the National Institute for Occupational Safety and Health, Division of Respiratory Disease Studies.

Acknowledgments

We thank the management and employees of the facilities and representatives of the labor unions who participated in this study. Without their help and the extra efforts they made to provide us with historical reports, this study would not have been possible. We also thank Dr Noah Seixas at University of Washington for his valuable comments, Rebecca Stanevich and Daniel Yereb formerly of NIOSH and Dr Mustafa Dosemeci formerly of NCI for their work on the DEMS surveys, Nathan Appel of IMS, Inc. for programming support, and Lützen Portengen, Utrecht University for statistical support.

Disclaimer—The findings and conclusions in this report/presentation have not been formally disseminated by the NIOSH and should not be construed to represent any agency determination or policy.

References

- Astrakianakis G, Seixas NS, Camp JE, et al. Modeling, estimation and validation of cotton dust and endotoxin exposures in Chinese textile operations. Ann Occup Hyg. 2006;50:573–82. doi: 10.1093/annhyg/mel018. [DOI] [PubMed] [Google Scholar]

- Birch M, Cary R. Elemental carbon-based method for occupational monitoring of particulate diesel exhaust: methodology and exposure issues. Analyst. 1996;121:1183–90. doi: 10.1039/an9962101183. [DOI] [PubMed] [Google Scholar]

- Birch ME, Noll JD. Submicrometer elemental carbon as a selective measure of diesel particulate matter in coal mines. J Environ Monit. 2004;6:799–806. doi: 10.1039/b407507b. [DOI] [PubMed] [Google Scholar]

- Blute NA, Woskie SR, Greenspan CA. Exposure characterization for highway construction. Part I: cut and cover and tunnel finish stages. Appl Occup Environ Hyg. 1999;14:632–41. doi: 10.1080/104732299302440. [DOI] [PubMed] [Google Scholar]

- Bunn WB, III, Valberg P, Slavin TJ, et al. What is new in diesel. Int Arch Occup Environ Health. 2002;75:S122–32. doi: 10.1007/s00420-002-0342-4. [DOI] [PubMed] [Google Scholar]

- Burstyn I, Boffetta P, Burr GA, et al. Validity of empirical models of exposure in asphalt paving. Occup Environ Med. 2002;59:620–4. doi: 10.1136/oem.59.9.620. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Coble JB, Stewart PA, Vermeulen R, et al. The Diesel Exhaust in Miners Study: II. Exposure monitoring surveys and development of exposure groups. Ann Occup Hyg. 2010;54:759–73. doi: 10.1093/annhyg/meq024. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cohen HJ, Borak J, Hall T, et al. Exposure of miners to diesel exhaust particulates in underground nonmetal mines. Am Ind Hyg Assoc J. 2002;63:651–8. doi: 10.1080/15428110208984753. [DOI] [PubMed] [Google Scholar]

- Davis ME, Blicharz AP, Hart JE, et al. Occupational exposure to volatile organic compounds and aldehydes in the U.S. trucking industry. Environ Sci Technol. 2007;41:7152–8. doi: 10.1021/es071041z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Helsel DR. More than obvious: better methods for interpreting nondetect data. Environ Sci Tech. 2005;39:419A–23A. doi: 10.1021/es053368a. [DOI] [PubMed] [Google Scholar]

- Hornung RW, Greife AL, Stayner LT, et al. Statistical model for prediction of retrospective exposure to ethylene oxide in an occupational mortality study. Am J Ind Med. 1994;25:825–36. doi: 10.1002/ajim.4700250607. [DOI] [PubMed] [Google Scholar]

- Hornung R, Reed LD. Estimation of average concentration in the presence of nondetectable values. Appl Occup Environ Hyg. 1990;5:46–51. [Google Scholar]

- Lewne M, Plato N, Gustavsson P. Exposure to particles, elemental carbon and nitrogen dioxide in workers exposed to motor exhaust. Ann Occup Hyg. 2007;51:693–701. doi: 10.1093/annhyg/mem046. [DOI] [PubMed] [Google Scholar]

- MSHA. Handbook series metal and nonmetal health inspection procedures. Mine Safety and Health Administration; 2006. Handbook Number PH06-IV-1(1), Washington, DC: Mine Safety and Health Administration. pp. 3-52, 3-60, 10–3. [Google Scholar]