Abstract

We developed quantitative estimates of historical exposures to respirable elemental carbon (REC) for an epidemiologic study of mortality, including lung cancer, among diesel-exposed miners at eight non-metal mining facilities [the Diesel Exhaust in Miners Study (DEMS)]. Because there were no historical measurements of diesel exhaust (DE), historical REC (a component of DE) levels were estimated based on REC data from monitoring surveys conducted in 1998–2001 as part of the DEMS investigation. These values were adjusted for underground workers by carbon monoxide (CO) concentration trends in the mines derived from models of historical CO (another DE component) measurements and DE determinants such as engine horsepower (HP; 1 HP = 0.746 kW) and mine ventilation. CO was chosen to estimate historical changes because it was the most frequently measured DE component in our study facilities and it was found to correlate with REC exposure. Databases were constructed by facility and year with air sampling data and with information on the total rate of airflow exhausted from the underground operations in cubic feet per minute (CFM) (1 CFM = 0.0283 m3 min−1), HP of the diesel equipment in use (ADJ HP), and other possible determinants. The ADJ HP purchased after 1990 (ADJ HP1990+) was also included to account for lower emissions from newer, cleaner engines. Facility-specific CO levels, relative to those in the DEMS survey year for each year back to the start of dieselization (1947–1967 depending on facility), were predicted based on models of observed CO concentrations and log-transformed (Ln) ADJ HP/CFM and Ln(ADJ HP1990+). The resulting temporal trends in relative CO levels were then multiplied by facility/department/job-specific REC estimates derived from the DEMS surveys personal measurements to obtain historical facility/department/job/year-specific REC exposure estimates. The facility-specific temporal trends of CO levels (and thus the REC estimates) generated from these models indicated that CO concentrations had been generally greater in the past than during the 1998–2001 DEMS surveys, with the highest levels ranging from 100 to 685% greater (median: 300%). These levels generally occurred between 1970 and the early 1980s. A comparison of the CO facility-specific model predictions with CO air concentration measurements from a 1976–1977 survey external to the modeling showed that our model predictions were slightly lower than those observed (median relative difference of 29%; range across facilities: 49 to –25%). In summary, we successfully modeled past CO concentration levels using selected determinants of DE exposure to derive retrospective estimates of REC exposure. The results suggested large variations in REC exposure levels both between and within the underground operations of the facilities and over time. These REC exposure estimates were in a plausible range and were used in the investigation of exposure–response relationships in epidemiologic analyses.

Keywords: elemental carbon, miners, exposure assessment, carbon monoxide, diesel exhaust

INTRODUCTION

In response to concerns about potential health effects associated with long-term exposure to diesel exhaust (DE), in particular lung cancer, the US National Cancer Institute (NCI) and the US National Institute for Occupational Safety and Health (NIOSH) initiated an epidemiologic study of DE among non-metal miners, known as the Diesel Exhaust in Miners Study (DEMS). One of the principal aims of the study was to develop retrospective estimates of workers’ exposure to respirable elemental carbon (REC), a constituent of DE, for all years in which diesel-powered equipment was used in the eight mining facilities. The resulting quantitative exposure assessment for REC for underground workers from the first year of underground diesel usage (1947–1967, depending on the facility) to the study end of follow-up (31 December 1997) was based on data from monitoring surveys conducted as part of the DEMS combined with time trend prediction models using historical carbon monoxide (CO, another component of DE) data and DE determinants. The exposure assessment for surface workers is described elsewhere (Coble et al., 2010; Stewart et al., 2010).

Personal REC exposure measurements from the DEMS surveys, each of which took place during a four to five consecutive day period between 1998 and 2001 depending on the facility, provided the basis for estimating average facility/department/job-specific REC exposure levels for the reference period of 1998–2001 (Coble et al., 2010). Analysis of the area measurements from the DEMS surveys found that REC concentrations correlated with CO levels and that CO concentrations increased approximately linearly in log-log space with REC concentrations (Vermeulen et al., 2010). These findings supported the use of past CO measurements to estimate historical REC exposure levels. Additional justification came from the fact that there were more detectable CO data historically than for any other DE component and that EC and CO are both produced by incomplete combustion of diesel fuel.

In this paper, we describe the development of the quantitative estimates of historical exposures to REC for underground workers in the DEMS. First, information on measurements and on possible DE determinants was collected and summarized by year. Subsequently, facility-specific time trend prediction models were developed using historical CO measurements and important exposure determinants (e.g. power of diesel engines and rates of airflow exhausted from the underground operations). These time trend prediction models were then linked with the facility/department/job-specific REC averages from the DEMS surveys to estimate annual historical facility/department/job REC exposure levels from 1998 to 2001 to the date of dieselization in each facility. Estimates were compared with external measurement data not used in the exposure modeling.

METHODS

The mining facilities

The mining facilities included three potash operations in New Mexico (B, D, and J), one rock salt facility in Ohio (E), one limestone facility in Missouri (A), and three trona (trisodium hydrogen dicarbonate dihydrate) operations in Wyoming (G, H, and I). Characteristics of the underground operations of these facilities can be found elsewhere (Coble et al., 2010; Stewart et al., 2010).

Data collection

A detailed description of the data collection efforts can be found in Stewart et al. (2010). In brief, three rounds of visits were made to the seven operating mining facilities to collect: DE-related measurements [including REC, CO, carbon dioxide (CO2), and nitrogen dioxide (NO2)] in 1998–2001 (i.e. the DEMS surveys) (Coble et al., 2010; Vermeulen et al., 2010), information on past exposure levels, and information on diesel equipment, job tasks, and locations. This and other production-related information was obtained from records and from interviews with long-term workers, including union or worker representatives and the management staff, who had held a broad spectrum of jobs. Because one facility (J) had closed before 1998, we were unable to conduct a monitoring survey. However, we were able to obtain extensive stored records on production parameters from the facility. In addition, we interviewed former employees from that facility concerning relevant aspects of the mining environment. Measurement data on all facilities were also acquired from other sources (see Description of the Measurement Database).

Description of the measurement database

An overview of the measurement database can be found in Stewart et al. (2010). The database contained underground and surface measurements taken in the eight study facilities from: the Mine Safety and Health Administration (MSHA) Mine Information Data System (MIDAS), a computerized database composed primarily of area measurements generated from compliance visits (years covered 1976–2001) (MSHA, 2006); the DEMS surveys of the seven operating facilities in the study (1998–2001) (Coble et al., 2010; Vermeulen et al., 2010); and a monitoring survey of Facility B (1994) conducted as part of a feasibility study for this project (Stanevich et al., 1997). In addition, measurement data were extracted from hard-copy reports from several monitoring surveys by the Mine Enforcement and Safety Administration/Bureau of Mines (MESA/BoM) (1976–1977) (Sutton et al., 1979) and from reports predominantly evaluating compliance that were available from MSHA, the mining facilities, and the State of New Mexico for the three facilities located there (1954–1996). Accompanying documentation for these monitoring data [the mining facility, duration, date, time, type of measurement (area, personal), agent, job or location description, and the sampling and analytic method] was entered into the database. The personal measurements were coded using the same job coding system as used for the work histories (Stewart et al., 2010). The area measurements were coded using the location codes in the MIDAS database (Watts and Parker, 1995). All coding was done without reference to the measurement results.

Description of the determinants database

Information on possible determinants of DE concentrations was assembled into a database by year and facility (Stewart et al., 2010). The determinant information covered the years from the date of dieselization in the underground operations to the reference year (1998–2001). Two of the major a priori determinants of DE were HP of the diesel-powered equipment used in each facility and the total airflow rates exhausted from the underground operation. HP was deemed the critical characteristic of diesel equipment in that, together with emissions rates (gram per horsepower-hour), it determines exhaust emissions. HP of the diesel-powered equipment was available on inventories of diesel-powered equipment used underground, extending back as far as the early 1970s from the facilities. Inventories generally were available for a few years in the 1970s and the 1990s but rarely in the 1980s. The lack of inventories was compensated by a careful scrutiny of each facility's production characteristics, trends over time in the number of diesel pieces used (for all the facilities, there was generally little change in equipment from year to year), and the number of years equipment was used, as well as being supplemented by information from the interviews. The specific section of the mine where the equipment was used was usually not identified. HP was directly available for 80% of the diesel equipment. For the other 20%, HP was estimated based on the same or similar equipment purchased about the same time in the same or in other facilities. From this information, the annual sum of the HP of all diesel-powered equipment in each facility was calculated based on all diesel engines used in a particular year.

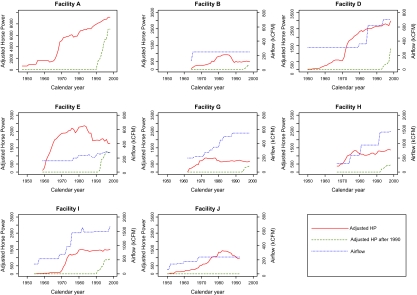

Diesel equipment was not, however, operated continuously over a full work shift. For example, diesel-powered mantrips, after transporting the work crews to the production face, were often turned off. To account for actual use, the average percentage of a work shift that each type and model of diesel equipment was used (%USEi) was estimated, based on interviews, to derive the adjusted HP (ADJ HPi), for year i for each facility (Fig. 1).

where HPij = HP estimate for a specific piece of diesel equipment j in year i and %USEij = average percentage of use for a specific piece of diesel equipment j in year i.

Fig. 1.

Overview of the primary model variables [i.e. adjusted HP (ADJ HP; solid line), total airflow exhaust rates (in CFM; dotted line), and adjusted HP after 1990 (ADJ HP1990+; dashed line)] from date of dieselization of the underground operation to 1998 by facility. Facility A relied primarily on natural ventilation, and therefore, no estimates of the airflow exhaust rates were available.

We used purchase dates to assign adjusted HP of equipment acquired after 1990 to account for possible lower emissions from newer (e.g. cleaner) direct injection engines (ADJ HP1990+) (Haney and Saseen, 2000).

Annual facility-specific estimates of total airflow rates exhausted from all operations within each underground mine, in cubic feet per minute (CFM) (1 CFM = 0.0283 m3 min−1), also were compiled. Records were available identifying the average total airflow rates exhausted from the underground operations when each exhaust shaft was installed since the beginning of diesel use and occasionally for other years. Information was not, however, available for sections of the underground mine. We also included year-specific information (if available) on fuel use (either in gallons or dollars); ore production (tonnage); mining methods [conventional, continuous (bore, drum), long wall]; ore haulage methods (conveyors, diesel shuttle cars, or electric shuttle cars), use of ammonium nitrate/fuel oil as the explosive; and various engineering controls and work practices (e.g. installation of scrubbers or catalytic converters on the diesel equipment, existence of a preventive maintenance program, and sealing of side passages from the main haulage ways) and other work place characteristics.

Building predictive models to estimate levels of DE exposure over time

Most of the collected measurements in our study were area measurements (n = 29 211; 78% of total) (Stewart et al., 2010). Of these, CO (n = 11 124; 38% of the area measurements), CO2 (n = 9651; 33%), and NO2 (n = 5045; 17%) were the most frequently measured agents, and as they are all components of DE, they were considered as the primary candidates for empirical modeling. CO area measurements were available for all facilities, with substantial proportions of the measurements above the limit of detection (LOD) (median of the CO measurements >LOD 61%; range 40–80% by facility). These historical CO concentration measurements, almost exclusively covering the years 1976 to the reference year, were used to develop the primary facility-specific time trend prediction models. Prediction models using NO2 concentration measurements were developed for three facilities (A, D, and E), but the model fit was poor and the models were not used. Most NO2 measurements from the other four facilities were below the LOD (up to 90%), which precluded model development. A model for facility J was not developed because there were no monitoring data from the DEMS surveys. Historical CO2 area measurements were not used due to uncertainty regarding data quality, i.e. >70% of the measurement data were below typical background CO2 levels of 375 parts per million (ppm) (Tans, 2009).

Natural log (Ln) transformation of the measurement data was used in the regression analyses, as the measurements were approximately log-normally distributed. We conducted a multiple imputation approach based on maximum-likelihood estimation to assign values that were below the LOD (Helsel, 1990; Helsel, 2005). This procedure was done separately for the historical data (i.e. MIDAS, MESA/BoM survey, State of New Mexico compliance data, and MSHA and facility hard-copy reports) and the feasibility (Stanevich et al., 1997) and DEMS surveys to account for differences in LODs (LOD CO: historical data = 1 ppm; feasibility/DEMS surveys = 0.3 ppm). This imputation procedure was repeated 100 times to obtain plausible values to represent the uncertainty of the LOD values, rendering 100 data sets consisting of the same (measured) values for CO measurements above the LOD and different (imputed) values for measurements below the LOD. Each of these data sets was used in the modeling procedure (see below).

The area CO measurements taken for compliance purposes were primarily short-term samples using a reusable specialized vacuum sampler (i.e. bistable) analyzed by gas chromatography (MSHA, 2006) or a direct-reading detector tube. CO measurements taken as part of the DEMS surveys and feasibility study were long-term direct-reading detector tubes (NCI/NIOSH, 1997; Stanevich, 1997). Only area measurements collected in the production face area were used for the modeling since these were more directly related to routine activities. All face area CO measurements were used in the modeling from all sources except for those from the MESA/BoM survey data, which were set aside to serve as an evaluation data set (see below Evaluation of Predictive Models).

A multiple linear regression model (PROC GLM; SAS) for CO was initially constructed for each facility incorporating that facility's estimates of ADJ HP, total exhaust airflow rates (CFM), and ADJ HP1990+. Due to the relatively high correlation of HP and airflow rates in some of the underground operations (n = 3; Pearson r: Facility D = 0.86; Facility G = −0.54; Facility H = 0.53) and for model consistency in the other facilities, we computed the ratio of the adjusted HP and the airflow rate (ADJ HP/CFM). Facility A relied primarily on natural airflow to ventilate the underground operations, so we could not estimate the airflow rate. Therefore, we used only the ADJ HP (Coble et al., 2010). ADJ HP/CFM and ADJ HP1990+ were log transformed in all the models to ease interpretability of the model by assuming proportional changes between these factors and CO concentrations. Because ADJ HP1990+ by default was zero before 1990, we added 1 to the ADJ HP1990+ estimate for all years to allow Ln transformation of the data. Additional work place characteristics, as well as measurement methods (bistable versus detector tube) were added in a forward stepwise manner to the facility-specific models, beginning with the variable having the smallest P value in the univariate analysis. Newly added variables were kept in the models if they were statistically significant (P < 0.05) and if alterations in the regression coefficients for the other variables appeared to be interpretable. The source of the measurement data (survey) and the season [winter (October to March) versus summer (April to September)] were forced in the models based on a priori decisions to adjust the models. Survey was included to correct for differences in measurement methods and strategies. Season was included to account for possible differences in ventilation efficiency and/or seasonal production rates.

The general structure of the CO regression models, therefore, was:

|

Multiple linear regression analyses were run on the 100 generated data sets from the LOD imputation procedure, and the results were combined to derive the parameter estimates, standard errors, 95% confidence limits, and associated P values (PROC MIANALYZE; SAS). These were considered our primary prediction models used in the epidemiologic analyses.

Application of the models to predict CO concentrations over time

The facility-specific models were employed to predict annual CO concentrations from the date of dieselization to the reference year (i.e. the year of each facility's DEMS survey) by inputting into the models the determinant information for these years. Then, the facility-specific predicted CO concentration for the reference year was set at 100% and all the prior predicted annual CO concentration estimates were scaled relative to the reference. For Facility J, because the underground operations had closed in 1993 and therefore was not in the DEMS survey, it had no 1998–2001 CO reference measurements. Therefore, we applied the model coefficients of Facility B to the determinant information of Facility J [e.g. Ln(ADJ HP/CFM)] to derive annual CO estimates. Facility B was selected because of similarities in geographic location, type of mining, the amount of ADJ HP present, and the airflow rates.

Predicting job-specific historical respirable elemental carbon exposure levels over time

REC estimates had been developed for the reference year for each mining facility/department/job based on the arithmetic means of the REC full-shift personal measurements (Coble et al., 2010; Stewart et al., 2010). As part of that process, the percentage of time worked in each of four major areas of the underground operations (face, haulage or travel ways, shop/office area, and crusher area) had been estimated for each underground job in the study. To estimate historical concentrations, these time allocations were used to derive estimates of the total percentage of time subjects worked in areas that received air that had already traveled through some portion of the mine, herein called ‘Mine air’, and for areas, such as the shop/office or, in some facilities, the crusher area that received intake air directly from the surface, herein called ‘Intake air’. Differentiation was made because changes in HP or CFM, and thus, DE concentrations were expected in the areas receiving mine air. In contrast, because few diesel pieces were run in the areas receiving fresh air, changes in HP or CFM should have had little or no effect in these areas. Thus, the relative historical trends were assumed to be applicable to the percentage of time in ‘Mine air’ but not for the percentage of time in ‘Intake air’.

To estimate the REC concentrations we used:

|

where RECik = REC exposure estimate for year i and job k; RECkR = reference REC exposure estimate assigned to job k, i.e. the 1998–2001 REC estimate; RELtrendi .= CO concentration estimate for year i relative to the reference CO concentration of 1998–2001, where the reference = 100%; % TMine air = total percentage of time of an average work shift job spent in underground areas receiving mine air (ranging from 0 to 100%); and %TIntake air = total percentage of time of an average work shift job spent in underground areas receiving intake air (ranging from 0 to 100%).

For example, if a job spent 100% of an average work shift in areas receiving mine air, the equation reduces to RECik=RECkR×RELtrendi. For a job that was located 100% in areas ventilated by intake air, the equation is RECik=RECkR. For workers who worked in areas ventilated by both mine and intake air, the RECkR values were adjusted according to the percentages of the time of a work shift ventilated by each source of air.

For Facility J, the 1993 department/job-specific REC estimates for Facility B were used as the reference department/job-specific REC estimates (RECkR). These estimates were subsequently multiplied with Facility J's relative time trend predictions where 1993 was set to 100%.

To prevent the estimated underground REC exposure levels from being lower than surface bystander exposure levels, the underground levels were bounded by the facility's REC estimate for surface bystander exposure to DE (exposure group B, see Coble et al., 2010). This procedure was followed because the use of diesel equipment in the relatively enclosed spaces in the underground operations would generally result in higher DE exposure levels than would be expected from outside surface operations involving diesel equipment. This occurred only for a few jobs and years in Facility D (four jobs, years 1950–1957) and Facility E (five jobs, year 1959).

Evaluation of predictive models

We had set aside two data sets when developing the models for use in evaluation of the modeling. In 1976–1977, short-term CO area measurements were taken by MESA/BoM to obtain a representative sample of air concentrations in six of our study facilities (B, D, E, H, I, and J) (Sutton et al., 1979). We compared average CO concentrations measured at the production face during these surveys with the estimated CO concentrations derived from our prediction models for 1976–1977. In a separate comparison, we contrasted the average of the personal REC measurements collected in Facility B in 1994 (Stanevich et al., 1997) with the 1994 REC estimates we derived from the model for this facility for two primary jobs (i.e. the continuous miner and the foreman). The 1994 survey was conducted as part of the feasibility study of the DEMS. REC measurements were collected according to NIOSH analytical method 5040 (Schlecht and O'Connor, 2003) over three days on miners working at two representative production sections. For both sets of comparisons (1976–1977 CO and 1994 REC), facility- or job-specific differences and relative differences were calculated, where the difference was defined as the difference between the mean of the observed measurements minus the predicted value and the relative difference as the difference divided by the observed mean.

Alternative models of DE exposure estimates over time

Our primary facility-specific trend models used in the epidemiologic analysis were based on CO concentration measurements and selected determinants of DE exposure as described. We also, however, explored two alternative sets of time trend models. The first set of models was based on actual 5-year average CO concentration levels (5-year average CO models) in each of the facilities without any modification by determinants after 1975 when measurement data were available. The CO averages for these time trends after 1975 were based only on the MIDAS measurements collected in the production face area as the MIDAS data were the only data that were truly longitudinal (∼1976–2001). Because there were only four CO concentration measurements before 1976, we extrapolated the 1976 CO mean concentration level in each facility by year back to the date of dieselization using the facility-specific annual changes in ADJ HP/CFM relative to the 1976 ADJ HP/CFM values. Relative changes in the CO concentrations were applied to the job-specific reference REC exposure levels, as done with the CO concentrations from the primary models.

In our primary time trend models, we assumed that a relative change in historical CO levels was directly translated to an identical change in REC levels over all the years of the study. Results from Yanowitz et al. (2000) suggest that indeed the CO-REC relationship probably changed little from 1976 to 1997. However, in the cross-sectional DEMS surveys, we observed that the relation between CO and REC in 1998 to 2001 might not be strictly proportional. The regression of Ln(REC) on Ln(CO) rendered a parameter estimate of 0.58, indicating that REC concentrations would increase with CO concentration to the power of 0.58 (Vermeulen et al., 2010). In our second set of alternative time trend models, therefore, we explored the influence of using the 0.58 power estimate by modifying the facility-specific relative time trends based on CO concentrations to estimate a different set of relative time trends in REC exposure levels (herein called the CO Model0.58).

All work was done blind to the epidemiologic results. Analyses were done using SAS version 9.0 software (SAS Institute, Cary, North Carolina, USA) and R version 2.9.0 (The R foundation for Statistical Computing).

RESULTS

Table 1 shows the summary statistics of CO area concentrations by 5-year time periods and major surveys in the production face area of the eight study facilities. The geometric means (GMs) of CO measurements from the MIDAS database were highest in 1980–1984 (1.2–3.6 ppm) in most facilities and declined thereafter to <1 ppm in most facilities in the 1990s. An exception was Facility A, where the GMs increased over time. Large differences were observed between the CO concentrations from the three major surveys. The GMs for the MESA/BoM surveys in 1976–1977 were ∼4-fold higher than those from the MIDAS survey in the same time period (range of differences across the facilities: 3.5–7.8). The GMs from the DEMS surveys were ∼2-fold higher than the GMs from the MIDAS 1995–1999 data and displayed a wider range of differences by facility (0.9–5.0) than seen in 1976–1977.

Table 1.

Summary statistics of measured CO (ppm) area concentrations by 5-year time period and surveya in the production face of the eight study facilitiesb

| Time period | Survey | Facility |

|||||||||||||||||||||||

| A |

B |

D |

E |

G |

H |

I |

J c |

||||||||||||||||||

| n | GM | GSD | n | GM | GSD | n | GM | GSD | n | GM | GSD | n | GM | GSD | n | GM | GSD | n | GM | GSD | n | GM | GSD | ||

| 1976–1977 | MESA/BoM | 90 | 4.9 | 2.6 | 136 | 7.1 | 3.0 | 148 | 6.8 | 2.1 | 100 | 4.7 | 3.0 | 122 | 5.6 | 2.6 | 217 | 5.1 | 2.8 | ||||||

| 1976–1979 | MIDAS | 37 | 1.7 | 3.4 | 53 | 1.4 | 2.8 | 66 | 1.6 | 3.7 | 24 | 1.4 | 2.6 | 16 | 1.6 | 6.4 | 242 | 0.6 | 3.3 | 111 | 1.2 | 3.1 | 35 | 1.2 | 3.0 |

| 1980–1984 | MIDAS | 95 | 2.4 | 3.0 | 265 | 2.1 | 2.4 | 116 | 1.7 | 3.2 | 95 | 3.1 | 2.6 | 71 | 2.1 | 4.1 | 1010 | 1.4 | 4.8 | 806 | 3.6 | 3.4 | 109 | 1.2 | 3.0 |

| 1985–1989 | MIDAS | 72 | 2.4 | 3.5 | 62 | 1.2 | 2.4 | 83 | 1.1 | 3.2 | 38 | 1.8 | 2.7 | 110 | 1.3 | 4.5 | 400 | 0.6 | 3.2 | 411 | 2.3 | 4.4 | 34 | 0.9 | 2.4 |

| 1990–1994 | MIDAS | 31 | 4.3 | 2.5 | 8 | 1.0 | 2.0 | 3 | 0.4 | 1.0 | 23 | 0.8 | 1.8 | 41 | 0.3 | 1.7 | 409 | 0.4 | 1.8 | 417 | 0.5 | 1.9 | |||

| 1995–1999 | MIDAS | 2 | 5.0 | 1.0 | 41 | 0.8 | 2.0 | 38 | 0.5 | 1.3 | 1 | 2.5 | — | 21 | 0.4 | 2.4 | 277 | 0.4 | 1.7 | 234 | 0.5 | 2.1 | |||

| 1998–2001 | DEMS surveys | 11 | 4.5 | 3.7 | 15 | 3.5 | 1.7 | 17 | 1.9 | 2.3 | 21 | 3.1 | 1.6 | 13 | 0.4 | 2.6 | 23 | 0.8 | 4.6 | 21 | 2.5 | 3.0 | |||

n, Number of measurements; GSD, geometric standard deviation.

MESA/BoM surveys were conducted in 1976–1977; DEMS surveys were conducted in 1998–1999 except for Facility B which was conducted in 2001; MIDAS comprises compliance measurements collected between 1976 and 2001.

In addition to the CO measurements presented here, 12 CO measurements from other sources were used in the statistical modeling.

Facility J closed in 1993.

Figure 1 shows that generally there was a very rapid increase in the estimated amount of ADJ HP in the facilities starting in 1960s to 1980. After 1980, ADJ HP continued to increase in two facilities (A and D) but leveled off (G, H, and I) or declined in others (B, E, and J). The proportion of ADJ HP from diesel engines introduced after 1990, as compared to the total ADJ HP, varied by facility, with a minimum of 32% for Facility H to a maximum of 77% for Facility A at the time of the DEMS surveys. The rates of total airflow exhausted from the underground operations generally increased with increasing ADJ HP.

The parameter estimates for Ln(ADJ HP/CFM) varied from 0.68 to 2.72 and were statistically significant (P < 0.05) for all facilities except Facility G (P = 0.31) (Table 2). The Ln(ADJ HP1990+) parameter estimates were all negative, indicating that the increase in CO concentrations relative to HP was lower for the newer engines compared to older engines. This factor achieved statistical significance (P < 0.05) only for Facilities D, G, and I. It was not possible to estimate the coefficients for Ln(ADJ HP1990+) for Facilities A and H due to collinearity with Ln(ADJ HP/CFM) after 1990 (Fig. 1). Most other facility-specific determinants considered did not improve model fit. The use of the long wall mining method for Facilities H and I, which were the only facilities where this mining technique was used (Coble et al., 2010; Stewart et al., 2010), was found to be significant. The long wall operation was associated with about three times higher CO levels than other mining operations in Facility I, while in Facility H the CO measurements associated with long wall operations were ∼40% lower. In addition, for Facility H, there were unusually high CO concentrations in 1981 and 1982 (about five times the concentrations in adjacent years). We corrected for these two types of unexplained phenomena by including indicator variables to improve overall model fit.

Table 2.

Facility-specific parameter estimates and 95% CIs of the primary facility-specific models based on CO area concentrations and exposure determinantsa

| Mining facility | n (% <LOD) | Ln(ADJ HP/CFM)b (95% CI) | Ln(ADJ HP1990+)c (95% CI) | Long wall mining techniqued (95% CI) | High periode (95% CI) |

| A | 248 (45) | 1.90 (0.27 to 3.53) | NCf | NAg | NA |

| B | 447 (39) | 1.05 (0.52 to 1.58) | −0.04 (−0.13 to 0.04) | NA | NA |

| D | 323 (38) | 0.74 (0.02 to 1.46) | −0.13 (−0.22 to −0.04) | NA | NA |

| E | 207 (20) | 1.29 (0.08 to 2.51) | −0.03 (−0.14 to 0.09) | NA | NA |

| G | 276 (30) | 0.68 (−0.64 to 2.01) | −0.20 (−0.36 to −0.05) | NA | NA |

| H | 2361 (60) | 0.75 (0.45 to 1.05) | NC | −0.55 (−0.77 to −0.32) | 1.65 (1.47 to 1.84) |

| I | 2000 (46) | 2.72 (1.38 to 4.05) | −0.07 (−0.11 to −0.04) | 1.08 (0.95 to 1.02) | NA |

| Jh | NA | 1.05 (0.52 to 1.58) | −0.04 (−0.13 to 0.04) | NA | NA |

CI, confidence interval; n, number of measurements; Ln, log transformed; ADJ HP, adjusted HP for percentage of a work shift used; ADJ HP1990+, adjusted HP after 1990.

All models were corrected for season and survey. Additionally, the primary models for Facilities A, B, E, and I were corrected for measurement technique (detector tube versus bistable).

Ln(Adj HP/CFM) was statistically significant (P < 0.05) for all facilities except Facility G.

Ln(ADJ HP1990+) was statistically significant (P < 0.05) for Facilities D, G, and I.

An indicator variable was used to improve model fit but it was not used in the prediction models because there were few subjects in the epidemiologic study who worked at the long wall.

The variable for high period, which occurred in 1981–1982, was not included in the prediction models as it could not be explained by any of the known determinants.

Not calculated: Ln(ADJ HP1990+) could not be fitted due to collinearity with Ln(ADJ HP/CFM).

Not applicable: The variable was not included in the particular facility-specific model.

Parameter estimates of Facility B are displayed as these were used in the prediction of the CO concentrations for Facility J because no facility-specific model was developed for Facility J.

Temporal analyses of the facility-specific CO models to evaluate model fit over time indicated that, in general, there was no association between the model residuals and the 5-year time periods [Fig. 2: the shaded 5-year average periods denote those periods when there was a significant difference (P < 0.05) between the mean of the CO area concentration measurements and the primary estimates from the facility-specific models for the same time period (i.e. mean of residuals differed significantly from zero)]. The exception was for Facility H for the three periods of 1980–1984, 1990–1994, and 1995–1998, where the model significantly underestimated and overestimated (for two periods) the Ln(CO) concentrations, respectively. In addition, the CO model significantly overestimated the Ln(CO) concentrations for the two periods of 1975–1984 of Facility E and the periods of 1980–1984 and 1990–1994 of Facility G.

Fig. 2.

Changes in CO concentrations (from date of dieselization to 1998–2001) relative to 1998–2001 (1998–2001 = 100%) predicted by the primary facility-specific models used in the epidemiologic analyses (CO Model; solid line) and the two alternative set of models: one based on a less than proportional increase in REC relative to CO (CO Model0.58; dashed line) and one based on 5-year average CO measurements (5-year CO average Model; dotted line). The estimates prior to 1976 from the 5-year average CO models were not based on actual measurements but were extrapolated from the 1976 CO values based on relative changes in ADJ HP/CFM. The shaded 5-year average periods denote those periods when there was a significant difference (P < 0.05) between the mean of the CO area concentration measurements and the primary estimates from the facility-specific models for the same time period (i.e. mean of residuals differ significantly from zero). Note, due to the relative scaling of the time trends, absolute differences in predicted CO concentrations cannot be read from figure 2.

The parameter estimates indicated in Table 2 were used to predict annual CO concentrations. For Facilities H and I, the CO concentrations were estimated for non-long wall operations, as the work histories indicated relatively few subjects at the long wall. In addition, the parameter estimate for the observed high period in Facility H was not included in the prediction model because the high concentrations could not be explained and only occurred for 2 years. The maximum predicted CO levels relative to the reference 1998–2001 CO means ranged from 100% for Facility A (i.e. all earlier years had lower levels than the reference period because of lower estimates of ADJ HP from smaller haulage trucks) to 685% in 1971 for Facility G (Fig. 2), with the median of the maximum relative increases among the operations being ∼300%. According to the models, the highest exposure levels occurred between 1970 and the early 1980s for most facilities.

The alternative set of facility-specific time trend models based on the 5-year average CO concentration levels were independent of any determinant data after 1975. These models revealed very similar trends as our primary facility-specific CO models based on exposure determinants except for most of the periods just indicated in the temporal analysis of the residuals and for the years 1980–1990 in Facility I, which, although diverging from the primary model, were not statistically significant (Fig. 2). The second set of facility-specific alternative time trends, which assumed that REC increased to the power 0.58 instead of a proportional 1:1 increase as assumed in the primary CO models, also are depicted in Figure 2 (CO Model0.58). Again, the time trends were similar, although, as expected, they resulted in lower historical relative levels (e.g. the maximum increase relative to 1998–2001 was 305% in Facility G, based on the 0.58 power parameter model, in contrast to 685% based on the primary model.

The estimated REC exposure levels derived by applying the relative CO time trends from our primary models to the reference REC estimates are shown in Figure 3 for the mine operator, a representative face job (as Facility A did not have a mine operator the loader operator is depicted). REC exposure levels for the mine operator ranged across the operations between 100 and 600 μg m−3 in the 1970–1980s. In addition, as can be seen, there was substantial variability in the REC estimates over time.

Fig. 3.

REC historical predictions (μg/m3) for the mine operator are shown, based on the primary facility-specific CO models, by mining facility. Footnote (*) Facility A had no mine operator and therefore the loader operator is depicted.

A comparison of the predicted CO concentrations for 1976–1977 with the average observed CO face concentrations from the MESA/BoM survey data of 1976–1977 showed that the facility-specific CO models underestimated the CO-measured concentrations in 1976–1977 by 24–49% (Table 3), except in Facility E, where the CO concentrations were overestimated (25%). Only two of four jobs previously measured in the feasibility study in Facility B could be exactly matched with the coded job titles in the DEMS survey. A small difference was observed between the predicted and observed REC levels, i.e. −10% for the continuous miner and −6% for the foreman (Table 4).

Table 3.

Assessment of differences and relative differences between the primary facility-specific CO prediction model estimates and the arithmetic means of the CO measurement data for 1976–1977

| Mining facility | MESA/BoM (1976–1977) |

Facility-specific CO models |

|||

| n | Measured CO concentration AM (ppm) | Estimated CO concentration in 1976–1977 (ppm) | Difference (ppm)a | Relative difference (%)b | |

| B | 90 | 7.23 | 5.15 | 2.08 | 29 |

| D | 136 | 10.50 | 7.98 | 2.52 | 24 |

| E | 148 | 8.50 | 10.60 | −2.10 | −25 |

| H | 100 | 7.68 | 3.90 | 3.78 | 49 |

| I | 122 | 7.73 | 4.85 | 2.88 | 37 |

| J | 217 | 8.09 | 4.36 | 3.73 | 46 |

| Overall median difference | 29 | ||||

n, Number of measurements; AM, arithmetic mean of the CO area measurements at the production face.

Difference between the AM of the measured CO concentrations in the MESA/BoM surveys and the estimated CO concentration.

Relative difference is the difference divided by the AM of the measured CO concentrations in the MESA/BoM surveys.

Table 4.

Assessment of differences and relative differences between the primary facility-specific predicted personal REC estimates in Facility B in 1994 and the arithmetic means of the REC personal measurements collected in 1994 (Stanevich et al., 1997)

| Job | Feasibility study (1994) |

Estimated REC AM (μg m−3) | |||

| n | REC AM (μg m−3) | Difference (μg m−3)a | Relative difference (%)b | ||

| Continuous miner | 26 | 248.4 | 272.7 | −24.3 | −10 |

| Foreman | 6 | 166.3 | 175.9 | −9.6 | −6 |

n, Number of measurements; AM, arithmetic mean of the personal REC measurements.

Difference between the AM of the measured REC exposure levels in the 1994 feasibility study and the estimated REC exposure level.

Relative difference is the difference divided by the AM of the measured REC exposure levels in the 1994 feasibility study.

DISCUSSION

In our study, job-specific exposure levels to DE were estimated from personal REC measurements collected in 1998–2001 during the DEMS surveys (Coble et al., 2010; Stewart et al., 2010). However, almost no REC or other EC monitoring data were available prior to these surveys, prohibiting us from estimating past DE levels based on EC measurements. As a consequence, the historical estimation of REC for underground jobs relied on back-extrapolation of the REC estimates from the DEMS data using predictive time trend models. CO was chosen to estimate relative changes in historical REC levels because of its frequent use in the past as a proxy of DE exposure (Pronk et al., 2009) and because it was the most frequently measured DE component in our study facilities EC and CO are both produced by incomplete combustion of diesel fuel. This decision was supported by our finding that CO area concentrations were correlated with REC, that CO increased approximately linearly in log-log space with REC area concentrations in the DEMS surveys, and that it loaded on the same factor as EC and DE gases (Vermeulen et al., 2010).

There were, however, several limitations to the use of CO to predict historical DE levels. First, except for four measurements from 1972 for one mine (G), CO measurements were only available after 1975 while we needed to predict exposures from the date of dieselization, which varied by facility from 1947 to 1967, to the reference year, which varied from 1998 to 2001. The prediction for all years, including prior to 1976, was achieved by applying the derived model parameter estimates for Ln(ADJ HP/CFM), Ln(ADJ HP1990+), and the other variables to the determinant data available for all years. This procedure, because the model was developed from measurement data after 1975, assumed that the parameter estimate for Ln(ADJ HP/CFM) was applicable to the time period prior to 1976. This assumption seemed reasonable since engine and ventilation technology did not differ substantially from the 1960s to the 1990s and there was little diesel equipment prior to the 1960s (ADJ HP ranged from <1 to 10% of the maximum ADJ HP in the five facilities that were in existence before 1960).

A second possible limitation was that CO might have arisen from sources in underground mining other than diesel engines. Another source of CO was likely from the explosives used to blast the face (Douglas and Beaulieu, 1983; Jacobsen et al., 1988). This source, however, was unlikely to have influenced our results as we only used CO face measurements, of which ∼95% were from inspection data. MSHA inspectors did not routinely monitor at the face immediately after a blasting because of the possible high exposures to the blasting fumes. Thus, the inspectors would not have entered the face areas until the blasting fumes were exhausted and diluted. This assumption was further supported by additional statistical analyses of the MIDAS data that did not find any indication of higher CO air concentrations shortly after the time of blasting compared to other times during the day (data not shown). Therefore, these data suggest that CO was a specific proxy for DE in underground mining operations in our study facilities.

We acquired CO measurement data from several data sources. Of these sources, MIDAS was the only source with truly longitudinal data, and it contributed >95% of the CO data that were used in the modeling. MIDAS measurements taken at the production face found average CO concentrations generally ranging from 1.2 to 1.6 ppm in 1975–1979, 0.9–3.1 ppm in the 1980s, and <1 ppm in the 1990s. The major exception was Facility A where concentrations increased over time. The difference for this facility was consistent with the increasing size (and therefore HP) and number of diesel equipment, particularly haulage trucks, used in the underground operations over time (Coble et al., 2010; Stewart et al., 2010). Although the year of introduction of the first diesel equipment varied considerably between the underground operations of the facilities (1947–1967), in general, the largest increase in diesel equipment usage occurred between 1960 and 1980 in all facilities (when the facilities rapidly dieselized their underground mining equipment) and use peaked in the early 1980s (Facility A being the exception). After the mid-1980s, diesel usage generally changed little or decreased slightly. Increases in exhausted airflow rates followed the increase in HP in almost all operations to control gaseous contaminant levels and rose or remained unchanged as HP remained the same or decreased, thus resulting in lower exposure levels. We also estimated the amount of HP that was introduced after 1990, the period which corresponded to the introduction of cleaner direct injection engines and cleaner fuels (Haney and Saseen, 2000). At the time of the DEMS surveys, the ADJ HP of the newer engines ranged between 32 and 77% of the total ADJ HP, per facility, suggesting that for most of the mines this additional parameter was important.

Our facility-specific CO models used ADJ HP, total exhaust airflow rates (CFM) and ADJ HP1990+ as predictors and CO concentration measurements as the dependent variable. These a priori selected predictors were similar to the main parameters of the deterministic model developed by MSHA to estimate diesel particulate matter (DPM) exposure at the faces of underground operations (Haney and Saseen, 2000). The MSHA model had basically three components: the quantity of exhaust emissions (i.e. estimated based on engine HP, engine DPM emission rates, the number of engines, and the length of the work shift), efficiency of exhaust control emissions (i.e. fuel properties and the efficiency of applied control technology), and the quantity of air exhausted from the face. A difference between the MSHA deterministic model and our predictive models is that we lacked airflow rate or ADJ HP data at each operating face of our facilities. For each face, however, a minimal set of equipment was generally necessary, so that the types and amount of equipment used for the production operations were not likely to differ substantially between faces within a facility at a given point in time. Support for this assumption was also found in the fact that the REC measurements on the jobs, which were taken in different areas, were relatively homogeneous within each facility, as were the area measurements, which also were taken in different places (Coble et al., 2010). It seemed reasonable, therefore, to use mine-wide ADJ HP estimates and total exhaust airflow rates to model area-specific CO concentrations.

Ln(ADJ HP/CFM) was significantly associated with area CO concentrations in six of the seven facility-specific models. The median parameter estimate of Ln(ADJ HP/CFM) in the seven facilities was ∼1 (range: 0.74–2.72). Except for Facility I, the 95% confidence intervals of the parameter estimates for all facilities included 1. The global P value for the test of homogeneity of the Ln(ADJ HP/CFM) parameter estimates for all facilities was 0.03, while if Facility I was excluded, the P value was 0.64, indicating that the coefficient was indeed similar across the facilities except for Facility I. A parameter estimate of 1 indicates that the change for CO and ADJ HP/CFM are directly proportional and equal, i.e. that a doubling in the ratio ADJ HP/CFM corresponds to a doubling of the CO concentration. This is consistent with the MSHA model where direct proportionality is assumed for HP and an inverse proportionality is assumed for airflow rate (Haney and Saseen, 2000). The explanation for the large parameter estimate for Ln(ADJ HP/CFM) in Facility I is unclear and might indicate incorrect data for HP or airflow rate in 1980–1990.

The negative estimates for Ln(ADJ HP1990+) in all facility-specific models where this parameter could be fitted indicates that the increase in CO concentrations relative to HP was lower for the newer engines compared to older engines. The global P value for the test of homogeneity of the Ln(ADJ HP1990+) parameter estimates for all facilities was 0.08, suggesting that this parameter estimate was not statistically different across the facilities. The observed reduced emission of newer engines in combination with cleaner fuels is in agreement with other reports (Haney and Saseen, 2000), which indicated that engines introduced after 1990 resulted in lower DE emissions (including CO) per unit of HP.

Because we found such similar results for the main model parameters [i.e. Ln(ADJ HP/CFM) and Ln(ADJ HP1990+)] in the various facilities, it can be assumed that the widely varying HP, loads, efficiency of the engines, and other characteristics tended to cancel those characteristics that affect the emission characteristics of an individual engine.

Since the CO models were developed to predict REC levels over time, the absence of temporal variations in the residuals was an important confirmation of internal model validity. We observed significant deviations in residuals for seven 5-year time periods in 35 facility/5-year time period combinations. In two instances, the models predicted higher levels than the measurements, and in five instances, the models predicted lower levels than the measurements. Thus, we found that the CO predictions were free of any marked temporal bias.

This finding was further corroborated by our alternative set of models using the 5-year average CO concentration time trends that showed temporal patterns similar to our primary CO models, indicating the good temporal fit of our models. We also used the CO models to extrapolate the DEMS average CO concentrations back to 1976–1977 to compare with average face concentrations measured during the MESA/BoM 1976–1977 survey. This comparison showed a median relative difference of 29%, which varied between 49 and -25% by facility. These differences were close to what would be expected if side-by-side measurements were taken (Zey et al., 2002). Noteworthy is the difference estimate of Facility J (46%). This facility was closed in 1993 and could not be measured in the DEMS surveys, so the model parameter estimates of Facility B were used. The relative difference seen for this facility was within the range for the other facilities, indicating that this approach for exposure estimation in Facility J was satisfactory.

Few industry-based studies of chemical agents have been able to evaluate historical quantitative exposure estimates in comparison to external measurement data. Investigators of a study of ethylene oxide workers found a relative difference of 24% when comparing predictions with measurements over a 6-year period (Hornung et al., 1994). In an acrylonitrile study, the relative difference for two estimation methods was −17% and −66% when compared to measurement data over an 11-year period (Stewart et al., 2003). A relative difference of −2% was found in a study of textile workers between the estimates and the measurements over a 15-year period (Astrakianakis et al., 2006). Investigators of an asphalt paving study found relative differences of −70 and −51% for bitumen fume and benzo(a)pyrene, respectively, when comparing measurements to estimates for up to 12 years back in time (Burstyn et al., 2002). The difference seen in our evaluation (median of 29%) is comparable to these earlier studies, even though our comparison covered over 20 years, whereas the other studies covered 15 years or less.

The main variables in our models were Ln(ADJ HP/CFM) and Ln(ADJ HP1990+), where the effect estimate of ADJ HP was conditioned on CFM. We therefore explored alternative model specifications in which Ln(ADJ HP), Ln(ADJ HP1990+), and Ln(CFM) were introduced as separate variables in the regression models. As previously indicated, the inclusion of CFM and ADJ HP as separate determinants in the models proved to be difficult for some of our facility-specific models (D, G, and H), due to collinearity between these two variables, resulting in implausible estimates of the parameters (i.e. increasing exposure levels with increasing airflow rates). However, for the models where collinearity was not a problem, the results were quite similar to the results based on the primary model specifications (data not shown). In addition, we explored models in which we modeled Ln(ADJ HP1990−/CFM) and Ln(ADJ HP1990+/CFM) separately (where ADJ HP1990− designates ADJ HP of equipment acquired before 1990). These models resulted in very similar fits and predictions as our primary models (data not shown). Based on these results, we concluded that our facility-specific models are reasonably robust toward differences in model specification.

The model coefficients were subsequently used to predict the relative CO concentrations from the reference year to the date of dieselization. These relative trends were used to back-extrapolate 1998–2001 personal exposure estimates by assuming that a relative change in historical CO levels could be directly translated to an identical change in REC over all the years of the study. A study by Yanowitz et al. (2000) suggests that indeed the CO-REC relationship probably changed little from 1976 to 1997. In that study, emission data based on laboratory tests of various engines with varying model years (1976–1997) were analyzed using regression analyses on emissions per mile of grams of CO and of grams of DPM. The authors found that CO and DPM emissions increased back through time at only slightly different rates [parameter estimate difference = −0.003, i.e. DPM increased slightly less than CO (US EPA, 2002)]. A comparable relationship was also likely to hold true for EC, given that it is a significant proportion of DPM (Birch and Noll, 2004).

However, in our cross-sectional DEMS surveys we observed that the relation between CO and REC might not be strictly proportional because the regression of Ln(REC) on Ln(CO) rendered a parameter estimate of 0.58, indicating that REC concentrations increased with CO concentration to the power of 0.58 (Vermeulen et al., 2010). We previously noted that, given the cross-sectional nature of this survey, it is possible that the observed parameter estimate might not apply longitudinally to past conditions (Vermeulen and Kromhout, 2005; Vermeulen et al., 2010). However, to assess the sensitivity of the epidemiologic findings to our decision of making the REC changes over time directly proportional to temporal changes in CO, we developed an alternative set of facility-specific models using the 0.58 power parameter to modify the relative CO concentrations. As expected, this change resulted in lower historical REC levels but had little effect on the ranking of the subjects’ cumulative exposure (Pearson correlation > 0.9) (Stewart et al., 2010).

To estimate mining facility/department/job/year-specific REC exposure levels, the facility-specific relative changes in CO were subsequently multiplied with the reference REC exposure estimates of the underground jobs. In Stewart et al. (2010), we showed that the hierarchical grouping strategy was successful in explaining the between-job variability of the REC measurements. Of course, this approach assumes that these grouping remained valid historically, which is reasonable as long as job locations did not differ significantly over time. For illustrative purposes, we presented the predicted REC levels for the mine operator. REC exposure levels for this job, one of the highest exposed jobs in the DEMS surveys, ranged between 100 and 600 μg m−3 in the 1970–1980s. There are few previously published data with which to compare the results of our study. However, recent studies have reported personal EC measurement levels between 20 and >500 μg m−3 (Ramachandran and Watts, 2003; Backe et al., 2004; Birch and Noll, 2004; Adelroth et al., 2006; Burgess et al., 2007; Dahmann et al., 2007; Noll et al., 2007). The wide range among these studies is likely due to different types and amounts of diesel equipment, airflow rates, and work practices, just as these differences influenced exposure levels in our facilities. The levels reported in the literature suggest that our historical REC estimates of up to ∼600 μg m−3 20 years ago are within plausible ranges of REC exposure levels.

In summary, the facility-specific models were developed based on the regression of diesel use, total exhaust airflow rates, and engine technology on historical CO area concentration measurements to predict relative changes in DE exposure levels. The models indicate substantial changes over time, with the highest DE exposure levels for most underground operations between 1970 and the early 1980s. Comparisons of the CO estimates from our time trend models with external CO measurement data showed that the estimates had a median relative difference of 29% in 1976–1977, a difference that is comparable to what other epidemiologic studies have found. We concluded that the predictions derived from the time trend models were plausible, resulting in time-varying REC exposure estimates that were in a range observed in other published monitoring studies. The subsequently derived time-varying REC job-specific exposure estimates were used in the investigation of exposure–response relationships in the epidemiologic evaluation.

FUNDING

Intramural Research Program of the National Institutes of Health, National Cancer Institute, Division of Cancer Epidemiology and Genetics, and the National Institute for Occupational Safety and Health, Division of Respiratory Disease Studies.

Acknowledgments

We thank the management, the representatives of the labor unions, and the employees of the facilities who participated in this study. We also thank Dr Noah Seixas at University of Washington for his valuable comments, and Rebecca Stanevich and Daniel Yereb formerly of NIOSH and Dr Mustafa Dosemeci formerly of NCI for their work on the DEMS surveys.

Disclaimer—The findings and conclusions in this report/presentation have not been formally disseminated by the National Institute for Occupational Safety and Health and should not be construed to represent any agency determination or policy.

References

- Adelroth E, Hedlund U, Blomberg A, et al. Airway inflammation in iron ore miners exposed to dust and diesel exhaust. Eur Respir J. 2006;27:714–9. doi: 10.1183/09031936.06.00034705. [DOI] [PubMed] [Google Scholar]

- Astrakianakis G, Seixas NS, Camp JE, et al. Modeling, estimation and validation of cotton dust and endotoxin exposures in Chinese textile operations. Ann Occup Hyg. 2006;50:573–82. doi: 10.1093/annhyg/mel018. [DOI] [PubMed] [Google Scholar]

- Backe E, Lotz G, Tittelbach U, et al. Immunological biomarkers in salt miners exposed to salt dust, diesel exhaust and nitrogen oxides. Int Arch Occup Environ Health. 2004;77:319–27. doi: 10.1007/s00420-004-0521-6. [DOI] [PubMed] [Google Scholar]

- Birch ME, Noll JD. Submicrometer elemental carbon as a selective measure of diesel particulate matter in coal mines. J Environ Monit. 2004;6:799–806. doi: 10.1039/b407507b. [DOI] [PubMed] [Google Scholar]

- Burgess JL, Fleming JE, Mulenga EM, et al. Acute changes in sputum IL-10 following underground exposure to diesel exhaust. Clin Toxicol. 2007;45:255–60. doi: 10.1080/15563650601072142. [DOI] [PubMed] [Google Scholar]

- Burstyn I, Boffetta P, Burr GA, et al. Validity of empirical models of exposure in asphalt paving. Occup Environ Med. 2002;59:620–4. doi: 10.1136/oem.59.9.620. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Coble JB, Stewart PA, Vermeulen R, et al. The Diesel Exhaust in Miners Study: II. Exposure monitoring surveys and development of exposure groups. Ann Occup Hyg. 2010;54:759–73. doi: 10.1093/annhyg/meq024. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dahmann D, Monz C, Sonksen H. Exposure assessment in German potash mining. Int Arch Occup Environ Health. 2007;81:95–107. doi: 10.1007/s00420-007-0194-z. [DOI] [PubMed] [Google Scholar]

- Douglas KE, Beaulieu HJ. Field validation study of NO2 personal passive samplers in a "diesel" haulage underground mine. Am Ind Hyg Assoc J. 1983;44:774–8. doi: 10.1080/15298668391405724. [DOI] [PubMed] [Google Scholar]

- Haney RA, Saseen GP. Estimation of diesel particulate concentrations in underground mines. Mining Engineer. 2000;52:60–4. [Google Scholar]

- Helsel DR. Less than obvious: statistical treatment of data below the detection limit. Environ Sci Tech. 1990;24:1766–74. [Google Scholar]

- Helsel DR. More than obvious: better methods for interpreting nondetect data. Environ Sci Tech. 2005;39:419A–23A. doi: 10.1021/es053368a. [DOI] [PubMed] [Google Scholar]

- Hornung RW, Greife AL, Stayner LT, et al. Statistical model for prediction of retrospective exposure to ethylene oxide in an occupational mortality study. Am J Ind Med. 1994;25:825–36. doi: 10.1002/ajim.4700250607. [DOI] [PubMed] [Google Scholar]

- Jacobsen M, Smith TA, Hurley JF, et al. Respiratory infections in coal miners exposed to nitrogen oxides. Res Rep Health Eff Inst. 1988;18:1–56. [PubMed] [Google Scholar]

- MSHA. Handbook series metal and nonmetal health inspection procedures. Mine Safety and Health Administration Handbook Number PH06-IV-1(1) Washington, DC: Mine Safety and Health Administration. 2006:3–40. [Google Scholar]

- NCI/NIOSH. A cohort mortality study with a nested case-control study of lung cancer and diesel exhaust among non-metal miners. Washington, DC: U.S. Department of Health and Human Resources; 1997. [Google Scholar]

- Noll JD, Bugarski AD, Patts LD, et al. Relationship between elemental carbon, total carbon, and diesel particulate matter in several underground metal/non-metal mines. Environ Sci Tech. 2007;41:710–6. doi: 10.1021/es061556a. [DOI] [PubMed] [Google Scholar]

- Pronk A, Coble J, Stewart P. Occupational exposure to diesel engine exhaust: A literature review. J Exp Sci Environ Epidemiol. 2009;19:443–57. doi: 10.1038/jes.2009.21. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ramachandran G, Watts WF., Jr Statistical comparison of diesel particulate matter measurement methods. Am Ind Hyg Assoc J. 2003;64:329–37. doi: 10.1080/15428110308984824. [DOI] [PubMed] [Google Scholar]

- Schlecht PC, O'Connor PF. NIOSH manual of analytical methods. 2003. DHHS Publication no. 94–113; 96–135; 98–119; 2003–154. Washington, DC: Department of Health and Human Services. [DOI] [PubMed] [Google Scholar]

- Stanevich R. Industrial hygiene—current exposure assessment operation manual. Morgantown, WVA: NIOSH; 1997. [Google Scholar]

- Stanevich RS, Hintz P, Yereb D, et al. Elemental carbon levels at a potash mine. Appl Occup Environ Hyg. 1997;12:1009–12. [Google Scholar]

- Stewart PA, Coble JB, Vermeulen R, et al. The Diesel Exhaust in Miners Study: I. Overview of the exposure assessment process. Ann Occup Hyg. 2010;54:728–46. doi: 10.1093/annhyg/meq022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stewart PA, Lees PS, Correa A, et al. Evaluation of three retrospective exposure assessment methods. Ann Occup Hyg. 2003;47:399–411. doi: 10.1093/annhyg/meg060. [DOI] [PubMed] [Google Scholar]

- Sutton GW, Weems GW, Schutz LA, et al. In: Industrial Hygiene for Mining and Tunneling: Proceedings of a Topical Symposium, November 6 and 7, 1978 Denver, Colorado. Cincinnati, OH: American Conference of Governmental Industrial Hygienists; 1979. Summary report of the environmental results of the MSHA and NIOSH silica/diesel exhaust study. [Google Scholar]

- Tans P. Trends in atmospheric carbon dioxide. 2009 [Earth System Research Laboratory]. Available at http://www.esrl.noaa.gov/gmd/ccgg/trends/. Accessed 14 October 2010. [Google Scholar]

- US EPA. Health assessment document for diesel engine exhaust. Prepared by the National Center for Environmental Assessment Washington DC, for the Office of Transportation and Air Quality. 2002. EPA/600/8-90/057F. Washington, DC: US Environmental Protection Agency. [Google Scholar]

- Vermeulen R, Coble JB, Yereb D, et al. The Diesel Exhaust in Miners Study: III. Interrelations between respirable elemental carbon and gaseous and particulate components of diesel exhaust derived from area sampling in underground non-metal mining facilities. Ann Occup Hyg. 2010;54:747–58. doi: 10.1093/annhyg/meq023. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vermeulen R, Kromhout H. Historical limitations of determinant based exposure groupings in the rubber manufacturing industry. Occup Environ Med. 2005;62:793–9. doi: 10.1136/oem.2004.016329. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Watts WF, Parker DR. Mine inspection data analysis system. Appl Occup Environ Hyg. 1995;10:323–30. [Google Scholar]

- Yanowitz J, McCormick RL, Graboski MS. In-use emissions from heavy-duty vehicle emissions. Environ Sci Technol. 2000;34:729–40. doi: 10.1021/es015559t. [DOI] [PubMed] [Google Scholar]

- Zey JN, Stewart PA, Hornung R, et al. Evaluation of concurrent personal measurements of acrylonitrile using different sampling techniques. Appl Occup Environ Hyg. 2002;17:88–95. doi: 10.1080/104732202317201320. [DOI] [PubMed] [Google Scholar]