Abstract

This paper presents a standalone closed loop wireless power transmission system that is built around a commercial off-the-shelf (COTS) radio frequency identification (RFID) transceiver (MLX90121) operating at 13.56 MHz. It can be used for inductively powering implantable biomedical devices in a closed loop fashion. Any changes in the distance and misalignment between transmitter and receiver coils in near-field wireless power transmission can cause a significant change in the received power, which can cause either malfunction or excessive heat dissipation. RFID transceivers are often used open loop. However, their back telemetry capability can be utilized to stabilize the received voltage on the implant. Our measurements showed that the delivered power to the transponder was maintained at 1.48 mW over a range of 6 to 12 cm, while the transmitter power consumption changed from 0.3 W to 1.21 W. The closed loop system can also oppose voltage variations as a result of sudden changes in load current.

I. Introduction

Passive radio frequency identification (RFID) transponders and certain implantable microelectronic devices (IMD) do not include batteries due to cost, size, weight, safety, and lifetime limitations. Inductive power transmission provides these devices with the required power [1], [2]. In these systems, wireless power transmission takes place across a pair of loosely coupled coils, preceded by a power amplifier (PA) on the external unit, and followed by an efficient rectifier on the implanted unit to provide the IMD with an unregulated supply voltage [3].

Coupling factor, k, between transmitter and receiver coils is key in determining the amount of power which can be delivered to the IMD. Any changes in k can drastically change the received power. Misalignments and distance variations between the coils as a result of movements are the main causes of variations in k. Variations in the received power can cause large voltage variations across the secondary coil. Load changes can also cause variation in the secondary coil voltage [4]. In IMDs, such variations are highly undesired because too little power can cause malfunction, and extra power can increase heat dissipation within the implant and damage the surrounding tissue [5].

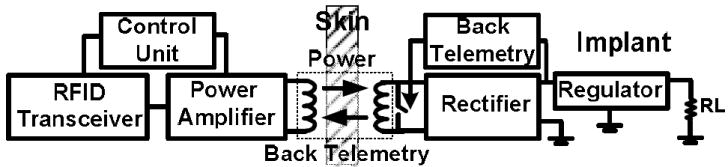

Therefore, stabilizing the IMD received power over a range of coupling and loading variations is imperative. One possible solution is to change the transmitted power in a closed loop in a way that the received power stays slightly above the minimum level that keeps the IMD operational [5]. Fig. 1 shows such a closed loop power transmission system. A back telemetry block based on load shift keying (LSK) has been used to send information about the received power to the external transmitter. In the external unit, a detection circuit receives the back telemetry data, and a control unit provides the necessary voltage for a class-E PA through a DC-DC converter [5]. A similar loop is utilized in [6], where an n-bit shift register is used to control the transmitter supply voltage. The information about the received power can also be sent actively along with other biological data from the IMD to the outside of the body. In [7], rectifier voltage inside IMD has been compared with a reference voltage, and a power bit is generated, which is interleaved with the recorded data bits, and transmitted to an external receiver. In [8], an analog to digital converter digitizes the rectifier voltage to provide the power bits for digital communication. In [9], a frequency control method is used to regulate the power transferred to the IMD. In this method any changes in the power transmitter frequency cause detuning in the secondary coil and change the secondary absorbed power. The power bits are interleaved with biological data and transmitted to the external unit.

Fig. 1.

Closed loop inductive wireless power transmission across the skin.

In this paper, instead of developing a custom application specific integrated circuit (ASIC) through a long and costly process, we have taken advantage of the built-in capabilities of a commercial off-the-shelf (COTS) RFID transceiver, MLX90121 (Melexis, Concord, NH), in the external unit to not only close the inductive power transmission loop through back telemetry but also drive the transmitter PA circuitry [10]. This is a novel application for a COTS RFID transceiver to be part of a standalone closed loop wireless power transmission system. Because up until now RFID systems have often been operated open loop for one way data or power transmission. Since motion artifacts occur at low frequencies, the bandwidth offered by the COTS RFID back telemetry link (~ 0.5 Mb/s) is much higher than what is required for regulating the received power. Therefore, the excess bandwidth can be used for sending recorded biological information to the external unit.

The closed loop power transmission system including RFID transponder and transmitter blocks are discussed in section II and measurement results are given in section III.

II. System Architecture

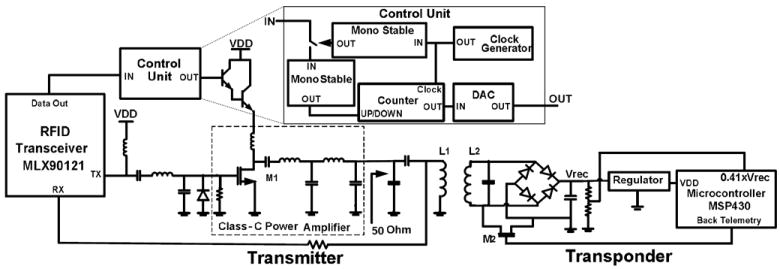

Fig. 2 shows the block diagram of the proposed closed loop power transmission system. This system is composed of two main blocks, power transmitter and transponder. Power is transferred from transmitter to transponder through L1 and L2. Transponder generates a supply voltage for the other blocks, and uses LSK to send information about received power back to the transmitter.

Fig. 2.

Block diagram of the RFID based closed loop power transmission system.

A. Standalone Transponder

Transponder block consists of a rectifier, regulator, LSK circuit, and an ultra low power MSP430 microcontroller (Texas Instruments, Dallas, TX) as a load. A wideband fullwave rectifier is used to provide a DC voltage, Vrec, from 13.56 MHz carrier. Vrec is divided (0.4125 × Vrec) and compared with an internal MSP430 reference voltage (Vref = 1.65 V). If the result is positive, i.e. Vrec > 4 V, then the LSK circuit sends short data bits back to the primary by closing M2 at a rate of 500 Hz. These pulses, which are short (30 μs) to prevent unnecessary power dissipation, indicate that the received power is more than enough. If the result of the comparison is negative, i.e. Vrec < 4 V, no data will be sent.

B. Power Transmitter

Transmitter block sends power to the transponder and detects the back telemetry data to adjust the transmitted power. An RFID transceiver is a logical candidate for this purpose. Because it can both drive a coil, and recover LSK back telemetry data. In order to increase the RFID output power and drive capability, a class-C power amplifier was added after the RFID transceiver chip (see Fig. 2). Supply voltage of the PA transistor, M1, was used to control its output power through a Darlington-connected BJT pair.

A control unit, which consists of a mono-stable circuit, clock generator, 8-bit counter, and 8-bit digital to analog converter (DAC), as shown in Fig. 2 inset, increases the transmitted power by default with an adjustable step size, until short data bits are received from the transponder. With back telemetry data present, the transmitted power is decreased until there is no more data bit coming from the transponder. In this case, control unit once again increases the PA output power. In steady state, without any external disturbance, the control unit continues this cycle to ensure that a constant amount of power is being delivered to the transponder and Vrec is maintained around 4 V.

In the presence of a disturbance, in the form of a change in the coils relative distance or transponder loading, Vrec deviates from its nominal value of 4 V, and the back telemetry data or lack of it indicates whether the PA supply voltage should be increased or decreased. This would return Vrec towards 4 V, and stabilize the power transmission cycle around a new steady state condition.

The control unit counter, driven by a 1 kHz clock, normally counts up and increases the DAC output voltage. The DAC can change the PA supply voltage from 2 V to 12 V in 256 steps. Back telemetry data bits, when present at 500 Hz, are detected by the RFID transceiver and sent to the control unit through Data Out pin. Since these bits are too short (10 μsec), a mono-stable circuit is used to convert them to 2 ms pulses. These pulses change the direction of the counter from up to down, decreasing the DAC output. The frequency of the back telemetry pulses (500 Hz) should always be smaller than the counter frequency (1 kHz) to ensure that there is a rising edge of clock at the counter when there is back telemetry data (2 ms pulses).

Since the reader RFID transceiver is very sensitive to variations in the primary coil voltage, L1, any change in this voltage, even from the control unit, can result in false data detection. Therefore, a switch has been used to disconnect the Data Out pin from the mono-stable whenever there is a change in supply voltage. These changes occur at the rising edge of the 1 kHz clock generator. One advantage of using counter as opposed to a shift register in the control unit is that with an n-bit counter, 2n different steps can be generated. Also the DAC voltage steps can be adjusted.

III. Measurement results

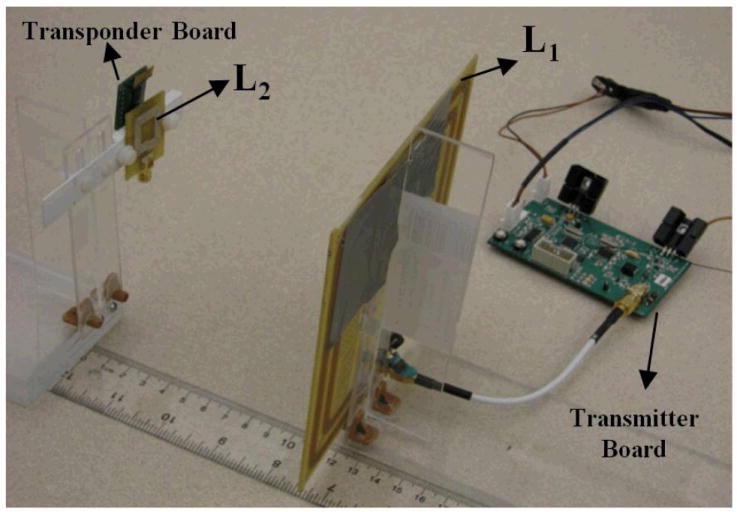

MLX90121 nominal output power is 200 mW, which is not sufficient for powering stimulating IMDs at large coil separation. Hence, we increased the output power to 1 W by adding a class-C PA with 7 dB gain. Two printed spiral coils (PSC) were designed with their geometries optimized for fP = 13.56 MHz and relative distance d = 10 cm, and fabricated on FR4 printed circuit boards (PCB) [11]. On the transponder, a 3.3 V regulator provides a constant supply voltage for the microcontroller, with 1.48 mW power consumption. Fig. 3 shows the RFID based closed loop power transmission test setup.

Fig. 3.

RFID based closed loop power transfer measurement setup.

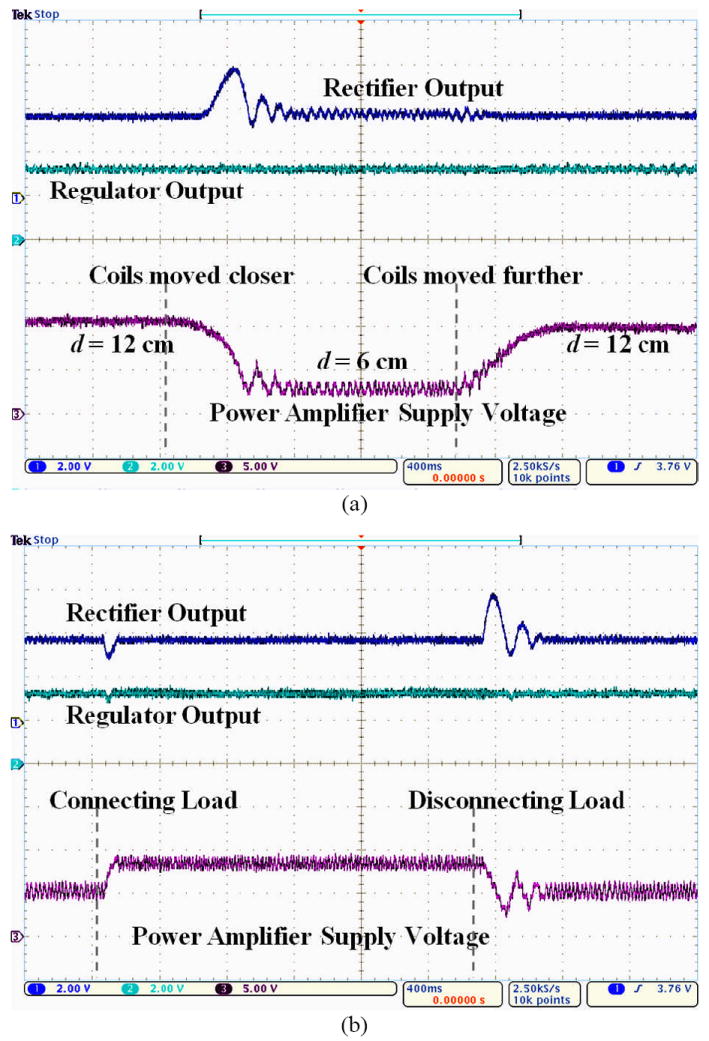

We used two methods to verify the functionality of the closed loop system. First, we looked at variations in k by changing d. Fig. 4a shows the Vrec and regulator outputs on the transponder and PA supply voltage on the transmitter. When d = 12 cm, PA supply voltage is 12 V, Vrec = 4 V and the regulator voltage is 3.3 V. In about 1 s after the beginning of the trace on the left side, d is suddenly changed to 6 cm by hand, while trying to maintain the coils alignment. As a result of this step change in k, it takes about 0.5 s for Vrec to return back to 4 V, and PA supply voltage to settle to its new value, slightly more than 3.5 V. It can be seen that, as a result of increased k, the transmitted power has been decreased. After ~1.5 s, coils have been returned back to their original position at d = 12 cm, and the PA supply voltage has also returned back to 12 V. Nevertheless, the regulator output is maintained constant at 3.3 V throughout these changes. It should also be noted that there was a 10 μF ripple rejection capacitor after the rectifier which helped in stabilizing Vrec.

Fig. 4.

Closed loop inductive power transmission system measured waveforms: (a) Changing coil distance and coupling coeficient. (b) Changing the transponder loading from 1.48 mW to 3.66 mW.

The second experiment was observing the effects of changes in the transponder loading on the closed loop system. This was done by connecting and disconnecting a 5 kΩ resistor across the regulator output. This resistance changes the transponder power consumption form 1.48 mW to 3.66 mW. The transient response is shown in Fig. 4b. The regulator and rectifier voltage decrease slightly by applying the load as the power consumption suddenly increases. It can be seen that the PA power supply increases to compensate for higher power demand on the transponder side. However, after disconnecting the additional load, PA voltage returns back to its original value. A limiting circuit is needed at the input of the rectifier to avoid damage as a result of large voltages across L2 when the coils move too close or when transponder power consumption reduces, increasing the loaded quality factor of the secondary coil.

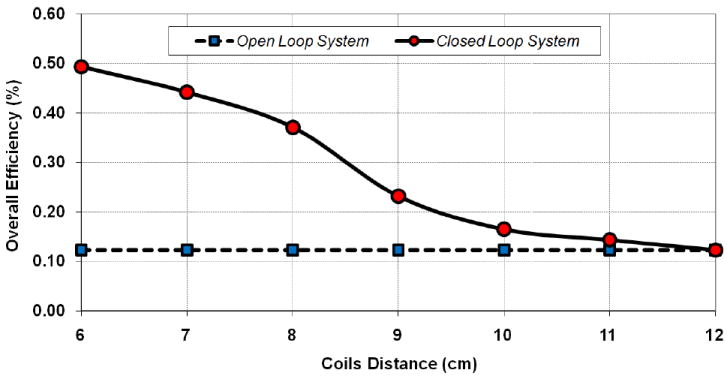

Improving the power efficiency is another advantage of the closed loop power transmission system. In an open loop system, the transmitter power is always constant and the receiver power can change with respect to variations in k and loading. To ensure the functionality of the system in all conditions, the transmitter power should be high enough to energize the IMD in the worst case scenario (largest possible d). This results in poor efficiency when k increases or load decreases, and the extra power is dissipated as heat both on the transmitter or receiver sides. On the other hand, in a closed loop system, the transmitter power is increased only as much as needed based on k and loading conditions.

Fig. 5 compares the measured overall efficiency (PA × inductive link × rectifier) of the open loop and closed loop systems. Even though the overall efficiency is low due to coils large relative distance, the closed loop power control has increased the efficiency significantly, particularly when the coils are closer to one another.

Fig. 5.

Open loop and closed loop overall efficencies vs. coil distance.

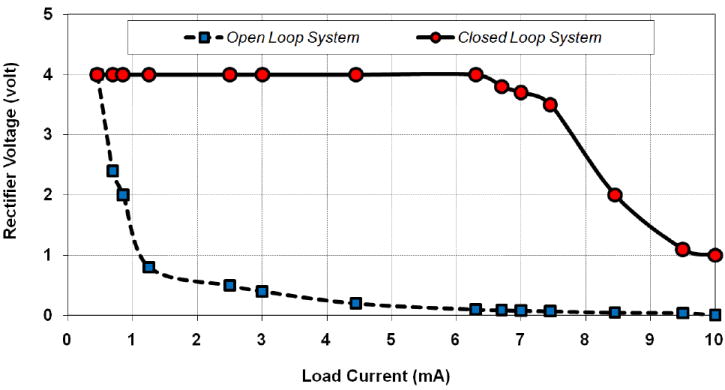

Load regulation capability of this closed loop wireless regulation mechanism is demonstrated in Fig. 6. The closed loop system increases the transmitted power to keep the rectifier voltage constant for loads up to 6 mA, which is the maximum power that the transmitter can provide in this system at d = 6 cm. In the open loop system, the rectifier voltage decreases when transponder load current increases because the transmitted power remains constant.

Fig. 6.

Open loop and closed loop load regulation.

Table I shows a summary of the RFID based closed loop power transmission system specifications and measured results.

Table I.

System Specifications and Measured Results

| Parameters | Measured Values |

|---|---|

| Transmitter coil (L1) | Inductance = 1 μH |

| Outer diameter = 13 cm | |

| Inner diameter = 8.3 cm | |

| Number of turns = 2 | |

| Receiver coil (L2) | Inductance = 0.4 μH |

| Outer diameter = 2 cm | |

| Inner diameter = 1 cm | |

| Number of turns = 4 | |

| Power transmission frequency | 13.56 MHz |

| Back telemetry frequency | 500 Hz |

| Counter clock frequency | 1 kHz |

| Overall efficiency of the closed loop system (d = 6 cm) | 0.5 % |

| Overall efficiency of open loop system (d = 12 cm) | 0.12 % |

IV. Conclusion

In this paper we presented a stand alone transponder which utilizes a closed loop power system to keep the delivered power constant over load or coils coupling variations. We have taken advantage of a 13.56MHz RFID reader to send power and also detect back telemetry data. The transponder has a microcontroller which is powered by the transmitter and communicates back to send data about the transponder power. The experiments by using discrete components show that the closed loop system works properly in all conditions (load and coils coupling change). We changed the distance between coils from 6 cm to 12 cm and also misaligned the coils and the loop controlled supply voltage of the power amplifier to keep the transponder supply constant. The closed loop system can increase the efficiency of the system by compensating load and coupling factor variation.

Acknowledgments

The authors would like to thank U.M. Jow and V. Sukumar from GT-Bionics Lab for their help with the coil designs and microcontroller programming.

This work was supported in part by the National Institutes of Health grant 1R01NS062031-01A1, and the National Science Foundation under award ECCS-824199.

References

- 1.Finkenzeller K. RFID-Handbook. 2. Hoboken, NJ: Wiley; 2003. [Google Scholar]

- 2.Catrysse M, Hermans B, Puers R. An inductive power system with integrated bidirectional data-transmission. Sens Actuators A. 2004;115:221–229. [Google Scholar]

- 3.Bawa G, Ghovanloo M. Active high power conversion efficiency rectifier with built-in dual-mode back telemetry in standard CMOS technology. IEEE Trans Biomed Circuits Syst. 2008 Sept;2(no. 3):184–192. doi: 10.1109/TBCAS.2008.924444. [DOI] [PubMed] [Google Scholar]

- 4.Baker MW, Sarpeshkar R. Feedback analysis and design of RF power links for low-power bionic systems. IEEE Trans Biomed Circuits Syst. 2007 Mar;1(no. 1):28–38. doi: 10.1109/TBCAS.2007.893180. [DOI] [PubMed] [Google Scholar]

- 5.Wang G, Liu W, Sivaprakasam M, Kendir GA. Design and analysis of an adaptive transcutaneous power telemetry for biomedical implants. IEEE Trans Circuits Syst I. 2005 Oct;52(no. 10):2109–2117. [Google Scholar]

- 6.Bashirullah R, Liu W, Ji Y, Kendir A, Sivaprakasam M, Wang G, Pundi B. A smart bi-directional telemetry unit for retinal prosthetic device. IEEE Intl Symp Circuits Syst. 2003 May;5:V5–V8. [Google Scholar]

- 7.Chaimanonart N, Zimmerman M, Young DJ. Adaptive RF power control for wireless implantable bio-sensing network to monitor untethered laboratory animal real-time biological signals. IEEE Sensors Conf. 2008 Oct;:1241–1244. [Google Scholar]

- 8.Si P, Hu AP, Chiang M, Wang Y, Malpas S, Budgett D. Wireless power supply for implantable biomedical device based on primary input voltage regulation. IEEE Conf Industrial Electronics Applications. 2007 May;:235–239. [Google Scholar]

- 9.Si P, Hu AP, Malpas S, Budgett D. A Frequency Control Method for Regulating Wireless Power to Implantable Devices. IEEE Trans Biomed Circuits Syst. 2008 March;2(no. 1):22–29. doi: 10.1109/TBCAS.2008.918284. [DOI] [PubMed] [Google Scholar]

- 10.MLX90121 13.56 MHz RFID Transceiver, [Online] Available: www.melexis.com.

- 11.Jow UM, Ghovanloo M. Design and optimization of printed spiral coils for efficient transcutaneous inductive power transmission. IEEE Trans Biomed Circuits Syst. 2007 Sept;1(no. 3):193–202. doi: 10.1109/TBCAS.2007.913130. [DOI] [PubMed] [Google Scholar]