Abstract

Zirconia-based ceramics with high strength have been identified as a material of choice for sliding components in a variety of biomedical and engineering applications. Despite the high flexural strength, zirconia prostheses are still vulnerable to wear and surface damage. We hypothesize that such tribological damage may be substantially mitigated by an engineered grading of elastic modulus at the ceramic surface. In this study, graded structures were fabricated by infiltrating glass into the top and bottom surfaces of zirconia plates, with resulting diminished modulus in the outer surfaces. The plates were then subjected to frictional sliding tests using a hard spherical indenter. Compared to non-infiltrated controls, infiltrated specimens showed a significant increase in the fracture loads, by over a factor of 3. The increase in the sliding contact resistance is attributed to the diminishing tensile stresses at the graded lower-modulus surface. The results confirm that suitably graded structures can be highly beneficial in the design of next-generation orthopedic and dental prostheses.

Keywords: Zirconia (Y-TZP), Functionally graded materials, Sliding contact, Wear, Elastic modulus gradients

INTRODUCTION

Yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) is an attractive material for biomechanical and other engineering applications due to its excellent biocompatibility, flexural strength, and chemical durability.1,2 Ceramic-on-ceramic total joint replacements are a special case in point.3-5 All-ceramic dental restorations are another case in point.6,7 Despite a continuous effort to improve the properties of biomedical ceramics, ceramic prostheses are still vulnerable to wear and fracture. Wear characteristic and catastrophic failure of ceramic-on-ceramic articulations continue to be a concern.8,9 Fracture and chipping resulting from sliding contact (occlusion) continue to be a dominant failure mode in zirconia-based all-ceramic dental prostheses.10-12 Therefore, it is highly desirable to develop a material that has better wear resistance and higher flexural strength than Y-TZP.

One way to engineer this material is by grading the elastic properties.13-16 Suresh, Padture and collaborators17,18 have demonstrated that when the contact surface of alumina or silicon nitride was infiltrated with aluminosilicate or oxynitride glass, respectively, which have similar coefficients of thermal expansion (CTE) and Poisson’s ratios but lower moduli to the infiltrating surfaces, an increase in elastic modulus from surface glass to a strong ceramic interior can be engineered without introducing significant residual stresses. The graded glass/ceramic (G/C) surfaces produced in this manner offered much better resistance to contact damage with and without a sliding action17-19 than either constituent ceramic or glass. We extended the G/C system to a graded G/C/G structure by infiltrating the top and bottom ceramic surfaces with glass, and infiltrated a strong class of ceramic—Y-TZP—to create a graded glass/zirconia/glass (G/Z/G) structure.14,15

Our previous studies have shown that G/Z/G plates exhibit increased resistance to flexural fracture relative to monolithic Y-TZP.14-16 This is because the graded structure spreads the maximum tensile stresses from the surface into the interior. Such a strengthening effect becomes more pronounced in relatively thin thickness range (d = 0.4 – 1.5 mm), which is most pertinent to dental restorations. Our findings suggest that all-ceramic dental restorations made from graded G/Z/G can possess close to twice the load-bearing capacity compared to the current Y-TZP-based restorations.14,16 This study is sought to elucidate the resistance to sliding contact of G/Z/G relative to monolithic Y-TZP. Sliding wear resistance, alluded to in the preceding paragraph, is a crucial property for dental and orthopedic components.

Controlled abrasive wear tests, such as a rigid ball sliding against a flat surface, provide characteristic wear patterns for fundamental understanding of the tribological behavior of ceramics. It is well established that when a spherical indenter is moved across the brittle surface at constant velocity, a composite wear track of herringbone cracks (approximately evenly spaced “partial” cone cracks) is formed at a critical load.20-27 The term “partial” cone describes the incomplete arcuate trace of each individual crack on the specimen surface.22 In this study, we characterize the resistance of an elastically graded G/Z/G surface to frictional sliding contact using a hard sphere. A homogeneous Y-TZP is used as control. The mechanism of partial cone formation under sliding contact is considered. Fracture characteristics of elastically graded surfaces are discussed. We focus here on the critical conditions for crack initiation in ceramics. This is because biomechanical prostheses must withstand intense body-weight or biting forces under hostile in vivo environmental and cyclic conditions. The onset of any damage initiation could be potentially fatal to the intended function, particularly to fatigue life.28

MATERIALS AND METHODS

Material Preparation

Graded G/Z/G sandwich structures were fabricated using a glass-ceramic infiltration technique. To infiltrate Y-TZP, a new family of glass system has been developed.14,15,29 The main composition (i.e. >1 wt.%) of the infiltrating glass consisted of SiO2 (65.5 wt.%), Al2O3 (11.7 wt.%), K2O (10.0 wt.%), Na2O (7.3 wt.%), CaO (3.0 wt.%), and Tb4O7 (1.9 wt.%).14,29 This composition was selected so that the final product had a high melting point coupled with an excellent resistance to crystallization during the cooling from the elevated temperatures. The CTE of the selected glass composition was around 10.4 × 10−6 °C−1 (from 25 to 450 °C), similar to that of Y-TZP (10.4 × 10−6 °C−1, from 25 to 450 °C).

Y-TZP green compacts were formed from a fine-grain (mean particle size ~28 nm) yttria-stabilized zirconia powder (TZ-3Y-E, Tosoh, Japan) using a cold isostatic press at 200 MPa. The green compacts were divided into two groups. To produce monolithic Y-TZP, one group was sintered at 1450 °C for 2 h inside a high temperature box air furnace (ST-1700C-6612, Sentro Tech Corp., Berea, Ohio). To produce functionally graded sandwich structures, another group was heat treated at 1350 °C for 1 h in air, creating a somewhat porous template for glass infiltration. The top and bottom surfaces of the heat-treated Y-TZP were then coated with powdered glass slurry (solid loading approximately ~15 vol.%). Glass infiltration was carried out at 1450 °C for 2 h in a high temperature box air furnace. The density of Y-TZP heat-treated at 1350 °C for 1 h was ρ = 6.01 g/cm3, which was slightly lower than that (ρ = 6.06 g/cm3) of the 1450 °C 2 h sintered Y-TZP and the core portion of the graded material. A heating and cooling rate of 900 °C per hour was employed. The final dimension of G/Z/G and homogeneous Y-TZP was 12 × 12 × 2.5 mm. In order to prevent flexural fracture at high loads, specimens with relatively large thickness were used in the current study.

Microstructures of graded G/Z/G and monolithic Y-TZP were examined using scanning electron microscopy (SEM). Ceramic plates were bisected in the direction normal to the lateral surfaces using a precision diamond saw (Isomet 2000, Buehler Ltd., Lake Bluff, USA). The cross-sections of the plates were polished with successive grits to 1 μm finish, ultrasonically cleaned in ethanol, and carbon coated to prevent charge accumulation. Backscattered electron (BSE) images as well as analysis on the elemental composition were performed on a Hitach S-3500N SEM equipped with an energy dispersive X-ray (EDX) spectrometer operating at 20 kV. The glass content in the graded zirconia-glass layer was estimated based on phase contrast from BSE images using an imaging analysis program (Image J).

One concern of the glass-infiltration process is the tetragonal to monoclinic phase transformation of Y-TZP and the crystallization of the infiltrating glass. Both phase transformation of Y-TZP and crystallization of glass could introduce compressive stresses at the surface, affecting the wear behavior of ceramics. In order to determine whether phase transformation and crystallization have occurred upon cooling from the infiltrating temperature, X-ray diffraction (XRD) measurements were made on surfaces of polished G/Z/G, hydrofluoric acid (HF) etched G/Z/G, and Y-TZP control. The analyses were performed on a Philips X’Pert x-ray diffractometer (Philips Analytical Inc., MA, USA) with nickel filtered CuKα radiation (weighted average wavelength 0.1541838 nm). XRD spectra were collected over a 2θ range between 15° and 70° at a scan speed of 1°/min and a step size of 0.02°.

Sliding Tests

Frictional sliding tests were performed on the polished surfaces of both graded G/Z/G and monolithic Y-TZP with a spherical tungsten carbide (WC) indenter of radius r = 1.5 mm in a biaxial mouth-motion simulator (Elf 3300, EnduraTEC Division of Bose, Minnetonka, MN) in water (Figs. 1a and 1b). The WC indenter had an elastic modulus E = 640 GPa and a Poisson’s ratio ν = 0.26. The contact surfaces of the ceramic plates were polished to 1 μm finish. For G/Z/G, residual glass on the surfaces was carefully removed by polishing using 6 μm diamond abrasives, followed by 1 μm finish. The polished plates were then embedded in a two-part epoxy (Leco, St. Joseph, MI) using a cylindrical polyvinyl chloride mould with an inner diameter of 25.4 mm.

Figure 1.

Schematic illustration of sliding test of (a) Y-TZP and (b) functionally graded glass/zirconia/glass (G/Z/G) composites. Backscattered electron (BSE) images showing the microstructure of (c) monolithic Y-TZP and (d) graded G/Z/G, respectively.

The current sliding tests were designed to determine the critical normal load, Pn, for the onset of surface cracking in the wake of the contact track. The range of normal contact load investigated were 600, 1000, 1800, 2000 N for G/Z/G and 500, 600, 800, 1000 N for monolithic Y-TZP. Tests were run in a biaxial mode: indenter contacts the specimen surface, load to the prescribed maximum load while the specimen holder translates horizontally for 4 mm at a constant velocity v = 2 mm/s. The loading rate was 2000 N/s. Therefore, depending on the magnitude of the prescribed normal load, it took 0.25 to 1 seconds to reach the prescribed load. Once the prescribed load was attained, the frictional sliding reached a steady-state. The normal load Pn and the tangential force Q were monitored continuously using vertical and horizontal load cells. The steady-state coefficient of friction μ was calculated: μ = Q/Pn. Four specimens were tested for each prescribed load per specimen type. This yields a total n = 16 specimens for each specimen group.

Specimens after each sliding test were subjected to damage examination using combined optical microscopy (3D polarized specular reflection microscope, Edge R400, Micro Science Technologies, Marina Del Rey, CA) and a sectioning technique.21,30

RESULTS

A cross-sectional view of a glass-infiltrated Y-TZP specimen in BSE microscopy revealed the graded structure (Fig. 1d). Regional variations in the weighted mean gray levels from Fig. 1d indicate relative differences in mean atomic number; the dark phase in this image indicates glass, the lighter phase indicates zirconia. For the glass infiltration condition used, the thickness of the graded layer was h = 120 ± 10 μm (mean and standard deviation, 6 specimens). Image analysis of this structure has shown that the glass content varied from 45 – 50 vol.% at the residual glass and graded layer interface to 0% at h = 120 μm, resulting in an increase in elastic modulus from surface to interior. Monolithic Y-TZP plates were prepared as controls (Fig. 1c).

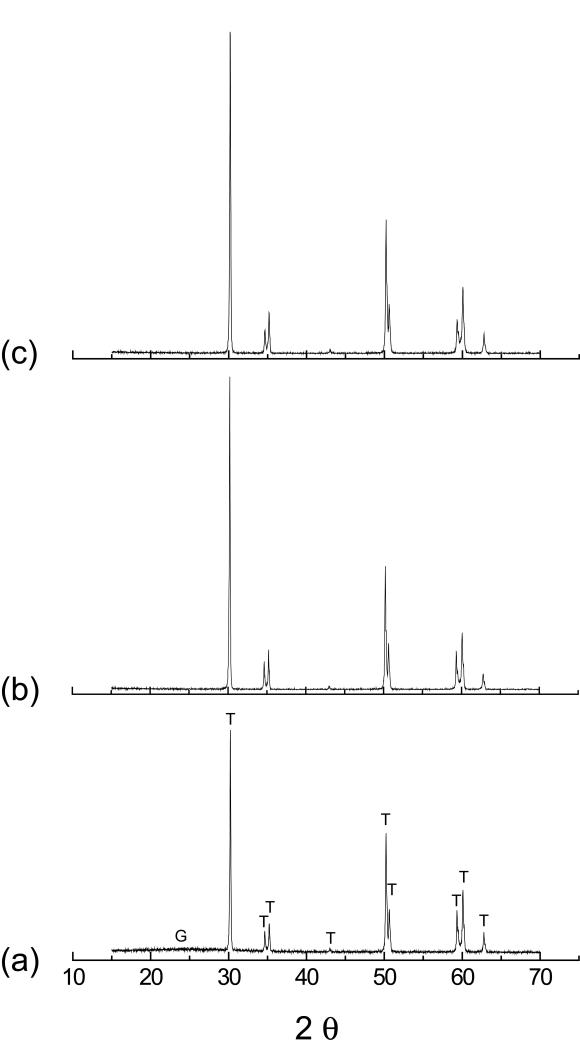

XRD analysis of glass-infiltrated G/Z/G surfaces revealed a small amount of glass phase on the surface (Fig. 2a). There was no detectable secondary crystalline phase present in addition to the metastable tetragonal phase, suggesting that there was no significant crystallization of the infiltrating glass as well as phase transformation of the tetragonal Y-TZP. XRD spectrum of the HF etched G/Z/G surfaces revealed a reduced amount of glass phase on the surface of G/Z/G, again no traces of the presence of the secondary phases (Fig. 2b). It is important to note that despite a slight difference in the heat treatment temperatures (i.e. 1350 °C in the current study vs. 1400°C in previous studies), the crystalline phase present in graded G/Z/G was identical to our previous findings. For reference, an XRD spectrum of a sintered (1450 °C for 2 h) monolithic Y-TZP is shown in Fig. 2c, revealing a tetragonal Y-TZP phase.

Figure 2.

XRD spectra of (a) glass infiltrated surface of G/Z/G; (b) HF acid (10%, 10 min) etched surface of G/Z/G; and (c) sintered surface of homogeneous Y-TZP control. Note: no secondary crystalline phases exist in G/Z/G. Spectra acquired using CuKα radiation with a scan rate of 1°/min and a step size of 0.02°. T and G in (a) denote the tetragonal zirconia phase and the amorphous glass phase, respectively.

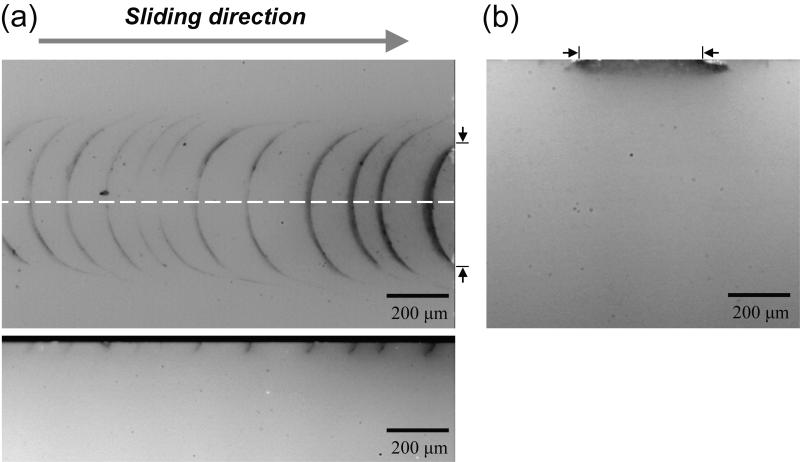

For monolithic Y-TZP, the critical normal load to cause surface cracking when sliding was Pn = 600 N. The pertinent features of the sliding contact damage in Y-TZP are illustrated by the optical micrographs of Fig. 3. The sliding direction is from left to right of micrographs (Fig. 3a). The surface view (top, Fig. 3a) revealed a sequence of herringbone cracks which formed during frictional sliding using a WC sphere (r = 1.5 mm) under normal load Pn = 1000 N. The side view along the wear track (Fig. 3a, bottom image) showed that, unlike the classical cone cracks, the herringbone cracks propagated down to form partial cones (i.e. only the crack arm at the trailing edge of the sliding indenter extended downward, and the angle of the partial crack was much steeper than that of the classical cone crack, typically 22°). The front-on view in the direction against the sliding direction revealed a truncated cone with crack angles ~22°. The coefficient of friction during steady-state sliding was found to be μ = 0.083 ± 0.004 (n = 12) for normal load ranging from 600 to 1000 N (i.e. Pn = 600, 800, 1000 N).

Figure 3.

Optical micrographs showing (a) surface (top) and side (bottom) views, and (b) front-on view of sliding wear track on Y-TZP surface caused by WC sphere of radius r = 1.5 mm under normal load Pn = 1000 N. Sliding direction is from left to right of (a). Note: the side view (bottom) was produced by truncating the specimen along the white dashed line in (a).

Analogous to Fig. 3, representative features of graded G/Z/G composites following frictional sliding under normal load Pn = 2000 N are shown in Fig. 4. The sliding direction is from left to right of images (Fig. 4a). No significant fractures were observed on the sliding wear track (top image of Fig. 4a) or beneath the surface (bottom image of Fig. 4a and Fig. 4b). The graded G/Z/G composite exhibited a far superior resistance to sliding contact damage than the monolithic Y-TZP. The critical normal load for the onset of the herringbone cracks in G/Z/Gwas 2000 N, which was over a factor of three higher than that (Pn = 600 N) for monolithic Y-TZP. The coefficient of friction, μ, in graded surface was 0.092 ± 0.005 (n = 12) for normal loads varying from 1000 – 2000 N (i.e. Pn = 1000, 1800, 2000 N).

Figure 4.

Optical micrographs showing (a) surface (top) and side (bottom) views, and (b) front-on view of sliding wear track on G/Z/G surface caused by WC sphere of radius r = 1.5 mm under normal load Pn = 2000 N. Sliding direction is from left to right of (a). Note: the side view (bottom) was produced by truncating the specimen along the white dashed line in (a).

DISCUSSION

Tribological damage of ceramics raises considerable concerns regarding the performance of biomechanical components. Hertzian testing using a translating spherical indenter pressed against a flat surface provides direct information on wear processes in real applications. We have investigated the influence of frictional sliding contact on the critical normal load for the onset of partial cone cracks on a planar surface of graded G/Z/G and monolithic Y-TZP. The critical normal load for the onset of partial cone fracture is Pn = 2000 N for the graded G/Z/G, which is over three times higher than that (Pn = 600 N) for monolithic Y-TZP. In addition, our findings show that frictional sliding is highly deleterious for Y-TZP-based ceramics, reducing the critical normal load for the onset of fracture by almost an order of magnitude compared to normal loading without a sliding action. The enhanced sliding contact damage resistance of graded G/Z/G relative to homogeneous Y-TZP is due to the elastic gradients in the surface. Previous studies have shown that when glass infiltrated into a heat-treated (1400 °C for 1 h) Y-TZP surface, the Young’s modulus variation from surface to interior is best described by a power-law relation E = Es + (Eb – Es)(z/h)m, with z the distance from the outer surface, m = 0.56 the power-law exponent, and Es = 125 GPa and Eb = 240 GPa the modulus at the outer surface and in the bulk zirconia respectively.14,15 Such elastic variation effectively transfers the maximum contact stresses into the interior, resulting in significantly improved resistance to cone fracture at the contact surface.13,17,24,31

It may be argued that the improved resistance to sliding contact damage of graded G/Z/G is due to the surface residual compressive stresses developed from the glass-ceramic infiltration at the elevated temperature. Surface residual stresses may develop from the tetragonal to monoclinic phase transformation of Y-TZP32 and/or from the crystallization of the surface glass. However, XRD analysis revealed no monoclinic phase and other crystalline phases in either glass infiltrated, infiltrated and then etched, or monolithic Y-TZP specimens, at least within the detection limit of XRD (i.e. ~3 vol.%), suggesting that the possible compressive stresses associated with the tetragonal to monoclinic phase transformation of Y-TZP and/or crystallization of the infiltrating glass are unlikely.

The large discrepancy in critical loads between normal (frictionless) and sliding (frictional) contact of WC sphere against Y-TZP plates warrants further elaboration. When a hard ball is pressed normally against a flat (frictionless contact), the maximum tensile stress lies just outside the circle of contact. If a tangential force is applied to the ball, the stress field in the flat body is altered. Hamilton and Goodman33 show that the tensile stress is enhanced at the trailing edge of the moving indenter to a value σ

| (1) |

where Pn is the applied normal load, v is Poisson’s ratio, μ is the coefficient of friction and a is the radius of the circle of contact. If cracks form at the same tensile stress under normal loading as when sliding and since a3 ∝ P (i.e. the cube of the contact radius is proportional to the applied load),34 the critical load P for the onset of Hertzian cone cracks under normal frictionless loading can be related to the critical normal load Pn for the formation of herringbone cracks in sliding20

| (2) |

Using the experimental results of the friction coefficient μ = 0.083 and Poisson’s ratio ν = 0.315 (measured using the sonic resonance method), equation 2 predicts that the critical normal load for the onset of partial cone cracks from sliding in monolithic Y-TZP is almost an order of magnitude smaller than that required for the onset of Hertzian cone cracks under normalfrictionless loading: Pn = P/9.8. The large reduction in the critical load even at a low friction coefficient μ = 0.083 is due to a relatively high Poisson’s ratio ν = 0.315 for Y-TZP compared to alumina (ν = 0.23) and other ceramics. Our previous experiments have shown that under normal frictionless loading using a WC indenter of r = 1.5 mm, a massive 4000 N load does not generate any cone cracks on a polished Y-TZP surface. However, such a high contact damage resistance quickly diminishes when subject to sliding. The critical normal load for the onset of partial cone cracks in sliding is reduced to 600 N for μ = 0.083. Our findings suggest that Y-TZP is susceptible to sliding contact damage, which is consistent with clinical reports.8 To improve the performance of Y-TZP-based biomechanical components, improvement in resistance to sliding contact damage is necessary.

In this study, Hertzian contact frictional sliding was used to evaluate the damage resistance of functionally graded G/Z/G material. The present glass infiltrated G/Z/G sandwich structure exhibited enhanced resistance to sliding contact and flexural damage compared to its monolithic Y-TZP counterpart. This glass-infiltration technique can be readily extended to other ceramic materials such as alumina, alumina-zirconia composites, etc. The results of this study indicate the beneficial influence of graded structures in the design of ceramic-on-ceramic bearings for total joint replacements, as well as all-ceramic crowns, bridges, inlays, onlays, partial crowns, endodontic posts, and implant abutments and posts for dental applications.

ACKNOWLEDGEMENTS

This investigation was supported by Research Grant 1R01 DE017925 (PI. Zhang) from the United States National Institute of Dental & Craniofacial Research, National Institutes of Health and Research Grant CMMI-0758530 (PI. Zhang) from the Division of Civil, Mechanical & Manufacturing Innovation, the United States National Science Foundation.

REFERENCES

- 1.Mehmood S, Jinnah RH, Pandit H. Review on ceramic-on-ceramic total hip arthroplasty. J Surg Orthop Adv. 2008;17(1):45–50. [PubMed] [Google Scholar]

- 2.Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999;20(1):1–25. doi: 10.1016/s0142-9612(98)00010-6. [DOI] [PubMed] [Google Scholar]

- 3.Jarrett CA, Ranawat AS, Bruzzone M, Blum YC, Rodriguez JA, Ranawat CS. The squeaking hip: a phenomenon of ceramic-on-ceramic total hip arthroplasty. J Bone Joint Surg Am. 2009;91(6):1344–9. doi: 10.2106/JBJS.F.00970. [DOI] [PubMed] [Google Scholar]

- 4.Jazrawi LM, Kummer FJ, Di Cesare PE. Hard bearing surfaces in total hip arthroplasty. Am J Orthop. 1998;27(4):283–92. [PubMed] [Google Scholar]

- 5.Willmann G. Ceramics for total hip replacement--what a surgeon should know. Orthopedics. 1998;21(2):173–7. doi: 10.3928/0147-7447-19980201-11. [DOI] [PubMed] [Google Scholar]

- 6.Burke FJ, Fleming GJ, Nathanson D, Marquis PM. Are Adhesive Technologies Needed to Support Ceramics? An Assessment of the Current Evidence. J Adhes Dent. 2002;4(1):7–22. [PubMed] [Google Scholar]

- 7.Kelly JR, Denry I. Stabilized zirconia as a structural ceramic: An overview. Dental Materials. 2008;24(3):289–298. doi: 10.1016/j.dental.2007.05.005. [DOI] [PubMed] [Google Scholar]

- 8.Barrack RL, Burak C, Skinner HB. Concerns about ceramics in THA. Clinical Orthopaedics and Related Research. 2004;429:73–79. doi: 10.1097/01.blo.0000150132.11142.d2. [DOI] [PubMed] [Google Scholar]

- 9.Chevalier J. What Future for Zirconia as a Biomaterials? Biomaterials. 2006;27:534–43. doi: 10.1016/j.biomaterials.2005.07.034. [DOI] [PubMed] [Google Scholar]

- 10.Tinschert J, Schulze KA, Natt G, Latzke P, Heussen N, Spiekermann H. Clinical behavior of zirconia-based fixed partial dentures made of DC-Zirkon: 3-year results. Int J Prosthodont. 2008;21(3):217–22. [PubMed] [Google Scholar]

- 11.Sailer I, Pjetursson BE, Zwahlen M, Hämmerle CHF. A Systematic Review of the Survival and Complication Rates of All-Ceramic and Metal-Ceramic Reconstructions after an Observation Period of at Least 3 Years. Part II: Fixed Dental Prostheses. Clin. Oral Impl. Res. 2007;18(3):86–96. doi: 10.1111/j.1600-0501.2007.01468.x. [DOI] [PubMed] [Google Scholar]

- 12.Sailer I, Feher A, Filser F, Gauckler LJ, Luthy H, Hammerle CH. Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont. 2007;20(4):383–8. [PubMed] [Google Scholar]

- 13.Suresh S. Graded Materials for Resistance to Contact Deformation and Damage. Science. 2001;292:2447–51. doi: 10.1126/science.1059716. [DOI] [PubMed] [Google Scholar]

- 14.Zhang Y, Kim JW. Graded structures for damage resistant and aesthetic all-ceramic restorations. Dent Mater. 2009;25(6):781–790. doi: 10.1016/j.dental.2009.01.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Zhang Y, Ma L. Optimization of ceramic strength using elastic gradients. Acta Materialia. 2009;57:2721–2729. doi: 10.1016/j.actamat.2009.02.037. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Zhang Y, Chai H, Lawn BR. Graded Structures for All-Ceramic Restorations. Journal of Dental Research. doi: 10.1177/0022034510363245. in press. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Jitcharoen J, Padture NP, Giannakopoulos AE, Suresh S. Hertzian-Crack Suppression in Ceramics with Elastic-Modulus-Graded Surfaces. J. Am. Ceram. Soc. 1998;81(9):2301–8. [Google Scholar]

- 18.Pender DC, Padture NP, Giannakopoulos AE, Suresh S. Gradients in elastic modulus for improved contact-damage resistance. Part I: The silicon nitride–oxynitride glass system Acta Materialia. 2001;49(16):3255–3262. [Google Scholar]

- 19.Suresh S, Olsson M, Giannakopoulos AE, Padture NP, Jitcharoen J. Engineering the Resistance to Sliding-Contact Damage Through Controlled Gradients in Elastic Properties at Contact Surfaces. Acta Materialia. 1999;47(14):3915–3926. [Google Scholar]

- 20.Gilroy DR, Hirst W. Brittle fracture of glass under normal and sliding loads. J. Phys. D: Appl. Phys. 1969;2(12):1784. [Google Scholar]

- 21.Kim JW, Kim JH, Thompson VP, Zhang Y. Sliding contact fatigue damage in layered ceramic structures. J Dent Res. 2007;86(11):1046–50. doi: 10.1177/154405910708601105. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Lawn BR. Partial Cone Crack Formation in a Brittle Material Loaded with a Sliding Indenter. Proceedings of the Royal Society of London. 1967;A299:307–16. [Google Scholar]

- 23.Lawn BR, Wiederhorn SM, Roberts DE. Effect of Sliding Friction Forces on the Strength of Brittle Materials. Journal of Materials Science. 1984;19:2561–69. [Google Scholar]

- 24.Suresh S, Giannakopoulos AE, Olsson M, Thampuran R, Jorgensen O, Padture NP, Jitcharoen J. Functionally-Graded Materials and the Engineering of Tribological Resistance at Surfaces. Massachusetts Institute of Technology; University of Connecticut; Cambridge, MA: Farmington, CT: 6,641,893 B1. USA patent. 2003 Nov;:4. assignee.

- 25.Zhang Y, Kim JW, Kim JH, Lawn BR. Fatigue damage in ceramic coatings from cyclic contact loading with a tangential component. Journal of the American Ceramic Society. 2008;91(1):198–202. [Google Scholar]

- 26.Kim JH, Kim JW, Myoung SW, Pines M, Zhang Y. Damage maps for layered ceramics under simulated mastication. J Dent Res. 2008;87(7):671–5. doi: 10.1177/154405910808700706. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Kim JW, Kim JH, Janal MN, Zhang Y. Damage maps of veneered zirconia under simulated mastication. J Dent Res. 2008;87(12):1127–32. doi: 10.1177/154405910808701210. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Lawn BR, Deng Y, Miranda P, Pajares A, Chai H, Kim DK. Overview: Damage in Brittle Layer Structures From Concentrated Loads. Journal of Materials Research. 2002;17(12):3019–36. [Google Scholar]

- 29.Zhang Y, Kim JW. Graded glass/zirconia/glass structures for damage resistant ceramic dental and orthopedic prostheses. US Prov. Patent App. 2006

- 30.Kim B, Zhang Y, Pines M, Thompson VP. Fracture of porcelain-veneered structures in fatigue. J Dent Res. 2007;86(2):142–6. doi: 10.1177/154405910708600207. [DOI] [PubMed] [Google Scholar]

- 31.Giannakopoulos AE, Suresh S. Indentation of Solids with Gradients in Elastic Properties: Part I. Point Force. Int. J. Solids Struct. 1997;34(19):2357–92. [Google Scholar]

- 32.Garvie RC, Hannink RHJ, Pascoe RT. Ceramic Steel? Nature. 1975;258:703. [Google Scholar]

- 33.Hamilton GM, Goodman LE. The Stress Field Created by a Circular Sliding Contact. Journal of Applied Mechanics. 1966;33:371–76. [Google Scholar]

- 34.Hertz H. On the Contact of Elastic Solids. J. Reine und Angewandte Mathematik. 1882;92:156–171. [Google Scholar]