Abstract

Macroporous hydrogels may have direct applications in regenerative medicine as scaffolds to support tissue formation. Hydrogel microspheres may be used as drug delivery vehicles or as building blocks to assemble modular scaffolds. A variety of techniques exist to produce macroporous hydrogels and hydrogel microspheres. A subset of these relies on liquid-liquid two phase systems. Within this subset, vastly different types of polymerization processes are found. In this review, the history, terminology and classification of liquid-liquid two phase polymerization and crosslinking are described. Instructive examples of hydrogel microsphere and macroporous scaffold formation by precipitation/dispersion, emulsion and suspension polymerizations are used to illustrate the nature of these processes. The role of the kinetics of phase separation in determining the morphology of scaffolds and microspheres is also delineated. Brief descriptions of miniemulsion, microemulsion polymerization and ionotropic gelation are also included.

Keywords: review, thermally induced phase separation, aqueous two phase systems, suspension polymerization, emulsion polymerization, dispersion polymerization, precipitation polymerization, microemulsion, miniemulsion, phase inversion, porogen, colloid, coacervate, coacervation, PEG, NIPAAm, HEMA, gelatin, LCST, coarsening, coalescence, Ostwald ripening, pinning, syneresis, microsyneresis, scaffold, tissue engineering, regenerative medicine

I. Introduction

Porous scaffolds are useful in tissue engineering to enhance nutrient or waste transport, to allow vascularization, or to promote rapid ingrowth of cells. The production of porous scaffolds generally relies on the use of two phase systems, with one phase consisting of the scaffold material and the other phase serving as a porogen. The porogen may be a gas, liquid or solid. While the use of solid or gaseous porogens is not absolutely incompatible with cell survival, this has proven to be so in the vast majority of systems. For cell transplantation, this requires that the cells must be introduced into the scaffold after formation of the pores, which may result in a non-uniform distribution of cells. At the other end of the spectrum, non-macroporous bulk hydrogels may be readily formed in the presence of cells, but the lack of porosity may be a limitation. Liquid-liquid phase separated systems may bridge the gap between macroporous scaffolds formed apart from cells and non-macroporous hydrogels formed in the presence of cells.

Liquid-liquid phase separations present a number of opportunities to precisely engineer the structure of hydrogel scaffolds. A phase-separated solution may be directly crosslinked to form a porous scaffold (‘top-down’ scaffold assembly). Alternatively, hydrogel microparticles may be produced in a liquid-liquid two phase system and then assembled into scaffolds (‘bottom-up’ scaffold assembly). Manipulation of the thermodynamics and kinetics of phase separations leads to a wide variety of morphologies of the phase-separated domains, which greatly impacts the architecture of macroporous scaffolds, or the size and porosity of microspheres. This review will highlight how different types of heterogeneous polymerizations produce distinct classes of hydrogel biomaterials.

Several excellent reviews on related topics are available in the literature. Methods to form macroporous scaffolds from non-hydrogel materials have been previously reviewed [1–3]. Microparticle production by mechanical means (e.g. photolithography, micromolding, droplet generators and microfluidics) has been reviewed [4, 5]. Methods to produce nanogels, which are particularly useful for drug delivery applications, have been recently reviewed [6, 7]. Self-assembling molecules to produce biomimetic materials have been considered elsewhere [8]. Reviews are available concerning “microgels” that form prior to gelation of crosslinking systems [9, 10]. Additionally, reviews on hydrogel microparticle synthesis by Saunders et al. are highly recommended [11, 12].

Liquid-liquid two phase systems are currently being exploited in a wide variety of intriguing ways in the fields of biomaterials and tissue engineering. In this review, the focus will be on selected examples of that particularly highlight the historical development or the benefits and limitations of the different polymerization strategies. It is hoped that clarification of the history and nature of liquid-liquid two-phase microgel/scaffold production methods will ignite further innovations in the production of novel macroporous biomaterials.

II. Polymerization schemes for the production of microspheres, microcapsules and porous materials via liquid-liquid two phase systems

Background

Four major types of two-phase systems are used for the production of microspheres and microcapsules: emulsion polymerization, suspension polymerization, dispersion polymerization and precipitation polymerization. The definitions of each polymerization type have not been codified by IUPAC. However, several sources are in general agreement. Arshady produced excellent review articles that delineate the differences between these four types of polymerization [13, 14]. The definitions largely recapitulate those of Barrett in the monograph, Dispersion Polymerization in Organic Media [13, 14]. Arshady and Barrett in turn relied on the definitions of Schildknecht in the book he edited from 1956, Polymer Processes [15]. The characteristics of the different polymerization types are summarized in Table 1 for chain growth (e.g. free radical) polymerizations and in Table 2 for step growth (i.e. polycondensation or polyaddition) polymerizations.

Table 1.

Different types of heterogeneous polymerizations are distinguished by the solubility of the monomer, initiator and resulting polymer. Rigorous classification also requires study of the kinetics of polymerization.

| Polymerization type |

Monomer solubility in continuous phase |

Initiator solubility in continuous phase |

Polymer solubility in continuous phase |

Product | Representative Examples |

|---|---|---|---|---|---|

| Suspension | Insoluble | Insoluble | Insoluble | Generally >10 µm particles |

153–156, 185, 187–203 |

| Emulsion | Insoluble | Soluble | Insoluble | Sub-micron particles |

225–226 |

| Microsuspension/ Microemulsion/ Miniemulsion |

Classification depends on location of initiation and kinetics of polymerization (i.e. number of radicals per polymerization locus) |

239–243 | |||

| Precipitation | Soluble | Soluble | Insoluble | Irregular particles, > 1 µm, may produce a porous bulk gel under some conditions |

109–114 |

| Dispersion | Soluble | Soluble | Insoluble | Generally 1- 10 µm particles |

109–114 |

Table 2.

Condensation (step growth) polymerization in two phase systems.

| Polymerization type |

Monomer A solubility in continuous phase |

Monomer B solubility in continuou s phase |

Polymer solubility in continuou s phase |

Product | Representative Examples |

|---|---|---|---|---|---|

| Suspension | Insoluble | Insoluble, but soluble in same phase as A |

Insoluble | Generally >10 µm particles |

163–175, 182– 184 |

| Emulsion | See Interfacial | ||||

| Interfacial | Soluble | Insoluble | Varies | In emulsified systems, may produce microcapsule s if polymer insoluble in both phases. |

231–235 |

| Precipitation/Di spersion |

Soluble | Soluble | Insoluble | Generally 1– 10 µm particles |

|

Solution, suspension and emulsion polymerizations

Solution polymerization is a single phase (homogenous) polymerization in which all constituents (monomers, initiators, etc.) are soluble in the polymerization medium. Many hydrogels used for biomedical applications are produced by solution polymerization, yielding relatively homogenous materials. Examples include the photopolymerization of PEG-diacrylate [16], addition reactions of PEG-vinylsulfone with dithiol peptides [17], and cycloadditions of PEG-azide with peptide alkynes [18]. Cell viability is minimally affected by these chemistries. Unfortunately, introduction of macroporosity in the presence of living cells is less straightforward.

Polymerizations may also be conducted in heterogeneous, two phase or multiphase systems, with a monomer-rich phase suspended in a solvent-rich phase. The solvent-rich phase is typically called the continuous phase, since its volume is usually large compared to the monomer-rich phase. It remains topologically connected (percolated) throughout the volume. If the solvent-rich phase were present as the minority phase, a porous material would be directly produced upon polymerization of the percolated monomer-rich phase, with the pores formed by the solvent-rich phase. In the discussion below, it will be assumed that the monomer-rich phase exists as discrete droplets and the solvent-rich phase is the continuous phase.

Suspension polymerization is also called pearl, bead or granular polymerization [15]. In suspension polymerization, the monomer is ‘insoluble’ in the continuous phase, but in practice may have slight solubility (e.g. styrene in water) [15]. In suspension polymerization, initiation occurs within the monomer-rich droplets and with greater than one radical per droplet at any time [19]. The presence of multiple radicals per droplet results in termination kinetics that are similar to those observed in solution polymerization. Essentially, a solution polymerization occurs in each suspended monomer-rich droplet, although with better heat transfer due to the large total surface area.

Emulsion polymerization is also characterized by poor solubility of the monomer in the continuous phase, but with initiation occurring outside of the monomer droplets [15]. The initiator causes chain growth of the monomer dissolved in the majority phase or monomer contained in micelles if surfactants are present [15]. Large monomer droplets provide a source of monomer for the reaction, but polymerization does not occur within the monomer droplets. The relatively small surface area of the monomer droplets and the short lifetime of the radicals ensure that initiation occurs within the continuous phase or within micelles. As such, the size of particles produced does not depend on the dimensions of the monomer-rich droplets. The size of the monomer-rich droplets depends on the stirring rate, but stirring rate does not affect the size of the product. Since initiation in emulsion polymerization occurs apart from the large monomer droplets, the sizes of formed microparticles are dictated primarily by the number of polymerization loci generated outside the monomer droplets [19]. The size of formed microparticles is typically quite small, in the range of 100 nm, and often with low polydispersity in size [20]. To produce larger microspheres by emulsion polymerization, sub-micron microspheres formed by emulsion polymerization may be ‘seeded’, i.e. swollen in monomer, and polymerized a second time [21]. An emulsion/seeded polymerization process was used on the space shuttle to produce micron-sized polystyrene microspheres for use as calibration standards, which was the first commercial product made in space [22].

Distinguishing suspension polymerizations from emulsion polymerizations

Suspension polymerization may be distinguished from emulsion polymerization at first glance by the size of the particles formed. The monomer droplets that are polymerized in a suspension polymerization are typically much larger than 10 µm in diameter [20]. The size of the monomer droplets is determined by two major factors, the rate at which droplets are broken up by the input of mechanical energy (e.g. stirring rate) and the rate at which monomer droplets grow in size by merging with other droplets (coalescence) [23]. In a suspension polymerization, the large particles that form tend to aggregate and settle out, while a stable latex of particles may result from an emulsion polymerization [20].

Simplistically, suspension polymerization and emulsion polymerization may also be distinguished by the location of the initiator. The initiator and monomer are in the same phase in suspension polymerizations, while they are in separate phases in emulsion polymerization. More rigorously, the distinction relies on the kinetics of polymerization as delineated by Smith and Ewart in 1948 [24]. The rate of polymerization and the degree of polymerization of the product are influenced by the number of radicals per droplet. In suspension polymerizations, the number of radicals per droplet is typically much larger than one, with molecular weights limited by termination between macroradicals (Smith and Ewart case III). In an ideal emulsion polymerization, the number of free radicals per polymerization locus is one half. Termination of polymerization occurs rapidly when a second radical enters the polymerization locus, but otherwise either zero or one radical exist per polymerization locus. The rate is maximal when half of the loci contain no radical and half contain one radical. Thus, in the ideal case, a single free radical in a polymerization locus reacts with monomer unhindered, resulting in high molecular weights and rapid rates of polymerization (Smith and Ewart case II). Slower polymerizations result if the average number of radicals per polymerization locus is much less than one (Smith and Ewart case I).

“Emulsion polymerization” is a misnomer when applied to step growth (polycondensation or polyaddition) reactions (see Table 2). If the two condensing species are in different phases, the reaction is an interfacial polymerization. If the condensing species are in the same phase, the reaction is a suspension polymerization [14]. Smith & Ewalt kinetics are not relevant to step growth polymerizations.

Microemulsion/microsuspension/miniemulsion polymerizations

Thermodynamically unstable emulsions (i.e. ‘macroemulsions’) are used in conventional emulsion polymerizations and suspension polymerizations, both of which take place in the presence of large monomer droplets. With sufficient concentrations of emulsifier, thermodynamically stable emulsions (‘microemulsions’) may result. Microemulsions require surfactant concentrations much higher than the critical micelle concentration. Large monomer droplets are not present in microemulsions, as sufficient stabilizer exists such that monomer is present either within micelles or dissolved in the continuous phase [20]. The large surface area of the micelles results in efficient capture of radicals even if the initiator is in the continuous phase. This may result in kinetics that resemble suspension polymerization. If the initiator is in the monomer-rich phase, the size of the micelles may be so small that the average number of radicals is less than one. Thus, ‘microemulsion’ polymerization may have kinetics characteristic of a suspension polymerization, and ‘microsuspension’ polymerization may have kinetics characteristic of emulsion polymerization. It has been proposed that if either of the criteria (initiator location or kinetics) point to an emulsion polymerization, it should be characterized as a microemulsion polymerization [20]. Difficulty results when the polymerization kinetics are not characterized. Absent knowledge of the kinetics, the more general term ‘water-in-oil’ or ‘heterogeneous’ polymerization has been suggested but rarely applied [20].

An intermediate case exists when thermodynamically unstable but kinetically stable monomer droplets are generated. These are called ‘miniemulsions’ and require much less surfactant than microemulsions. Miniemulsions are produced by inputting large amounts of mechanical energy (e.g. sonication) resulting in submicron domains with relatively narrow size distributions [20]. Miniemulsion polymerizations take place within the small monomer droplets because of their large total surface area. Even if the initiator is in the continuous phase, capture of radicals by the monomer droplets is efficient and thus initiation occurs within droplets. The polymerization kinetics may approach those of a suspension polymerization regardless of the initial location of the initiator. Ideally, each monomer droplet will become a particle, typical of suspension polymerization. However, some monomer droplets do not polymerize but contribute monomer to the growing particles. Thus, formed particles tend to be larger than the droplets [25].

While microemulsion polymerizations may occur even if the monomer and initiator are in the same phase, this is not true with macroemulsions. Suspension polymerization is the correct term in that case. This is because the average number of radicals per polymerization locus is almost certainly greater than one for these large phase separated domains. The size of the produced particles is an indication of the type of polymerization. Microemulsion polymerizations yield ≈ 100 nm particles, microsuspension polymerizations yields 1–10 µm particles, while suspension polymerizations yields particles typically much greater than 10 µm [20]. Confusion also results from the fact that suspension polymerizations and emulsion polymerizations both occur in macroemulsions [20]. Said another way, suspension polymerizations occurs in (macro)emulsions, but are not emulsion polymerizations.

“Inverse” systems

If the continuous phase is a water-immiscible solvent, then ‘inverse’ is often added to the classification (“direct” = oil-in-water polymerization, “inverse” = water-in-oil polymerization). Typically, the distinction between ‘direct’ and ‘inverse’ systems is clear from the context and is sometimes omitted. Great difficulties are encountered in classifying free-radical polymerizations in inverse systems compared to direct systems [26]. It is believed that partial solubility of the initiator in the aqueous phase or termination of polymerization by reaction of the radical with the emulsifier hinder true inverse emulsion polymerizations. In direct emulsion polymerization, the use of a charged initiator in the aqueous phase ensures extremely low solubility of the initiator in the organic/monomer phase. For inverse emulsion polymerizations, although the monomer may be predominantly dissolved in the organic phase, the initiator may have some limited solubility in the aqueous phase, particularly when large amounts of monomer are dissolved in the aqueous phase. This may result in kinetics that resemble an inverse suspension polymerization. Similar to direct microemulsions, the physical location of the initiator in an inverse microemulsion does not determine the kinetics of crosslinking. The term ‘inverse microemulsion’ is used if either the initiator location or the kinetics point to an emulsion polymerization [27].

Precipitation and dispersion polymerizations

Precipitation polymerization exploits differences in the solubility of monomer and polymer to produce microparticles. Larger polymer chains have lower solubility than smaller ones [28]. Above a specific molecular weight, phase separation may be favored. Precipitation polymerization initially begins as solution polymerizations in a single phase, homogenous system. Shortly after the start of the polymerization, a relatively high concentration of polymer chains is present, favoring phase separation by nucleation. Later in the polymerization, the concentration of polymer chains is low and existing particles capture the chains before nucleation of new particles can occur [29]. Thus, nucleation of particles occurs only for a brief period of time shortly after the start of the reaction. This often results in a narrow size distribution of particles. In a precipitation polymerization, surfactants are not included, so particle coarsening by coalescence is prevalent, leading in many cases to the formation of irregularly shaped particles with larger size distributions [30].

If surfactants or other stabilizers are used to prevent coalescence of particles, the precipitation polymerization is then called a dispersion polymerization [13, 30]. Dispersion polymerizations originally referred to the polymerization of vinyl acetate in water in the presence of high concentrations of water soluble polymer [15]. However, vinyl acetate is only sparingly soluble in water, so this was either an emulsion or suspension polymerization, and not a type of precipitation polymerization. Later, Barrett used dispersion polymerization to describe a precipitation polymerization in organic solvent in the presence of large amounts of stabilizer to prevent coalescence of particles [30]. Many monomers of commercial interest are soluble in organic solvents, favoring the use of precipitation or dispersion polymerization in organic media. Dispersion polymerization now refers simply to a stabilized precipitation polymerization. Some authors prefer to use precipitation polymerization even when stabilizers are used and when spherical, nearly monodisperse particles are produced. The terms will be used essentially interchangeably herein, with preference given to precipitation polymerization.

Definitions and conventions

Originally, microgel was defined by IUPAC as a “network of microscopic dimensions” [31]. In 2007, IUPAC changed the definition to a: “Particle of gel of any shape with an equivalent diameter of approximately 0.1 to 100 µm” [32]. A nanogel was also then defined as a: “Particle of gel of any shape with an equivalent diameter of approximately 1 to 100 nm”. Microgel has also been used since 1949 to describe the highly crosslinked, high molecular weight polymer molecules that form during typical crosslinking reactions prior to gelation [33]. Such species are not predicted by the Flory-Stockmayer gelation theory [34, 35], but are found experimentally, particularly in solution polymerizations conducted at low concentrations of monomer, which favors intramolecular crosslinking [33]. The sizes of such ‘microgels’ are typically hundreds of thousands or millions of Daltons and thus are submicron in diameter [10]. Microgels are typically only a small percentage of the mass of the polymerizing medium but are readily detected by light scattering. A broad range of molecular weights is present, including large amounts of unreacted monomer. The polydispersity of the mixture is much higher than the typical size distribution of ‘microgels’ produced by suspension, emulsion, precipitation or dispersion polymerization, micromolding, droplet generators, microfludics, etc.

Definitions of the pore sizes of materials have also evolved over time. IUPAC defined ‘macroporous polymers’ as having pore diameters between 50 nm - 1 µm, while ‘mesoporous polymers’ have pore diameters from 2 – 50 nm [36]. According to definitions proposed by Peppas and Langer and in common use in the biomaterials field, ‘microporous’ membranes have pore diameters between 10 – 50 nm and ‘macroporous’ membranes have pore diameters in the range of 50 nm – 1 µm. ‘Non-porous’ membranes have pores at the molecular level, e.g. between swollen macromolecular chains [37]. Consistent with these definitions, materials with pore diameters larger than 1 µm have been termed ‘superporous’ [38]. Given the trends of definitions in numerous fields (e.g. see nanogel and microgel above), it is proposed that ‘nanoporous’ be used for pore diameters up to 100 nm, ‘microporous’ for pore diameters between 100 nm and 1 µm, and ‘macroporous’ for pore diameters larger than 1 µm. This convention will be used herein.

The mean sizes of water-swollen nanogels, microgels and pores in macroporous scaffolds may be challenging to measure. Transmission electron microscopy and scanning electron microscopy are typically performed on dried samples, which may not reflect the swollen state of a hydrogel. In particular, porosity may be observed in non-macroporous hydrogels upon drying. The collapse of polymer chains during drying may result in the development of structures that are not present in the wet state. Including a non-macroporous hydrogel as a control is advisable when characterizing porosity in the dry state. It is also advisable to supplement studies in the dry state (electron microscopy, mercury intrusion porosimetry, etc.) with scanning confocal microscopy in the swollen state. Dynamic light scattering (DLS) is also useful to obtain not only an average hydrodynamic radius of microparticles but also a size distribution. However, the mean size obtained is a z-average, which is highly skewed towards large particles [39]. Additionally, obtaining size distributions from DLS requires solution of an inverse problem that must make some assumptions about the nature of the underlying particle size distribution, which may not be accurate for a given sample [40]. For broad size distributions, fractionation, e.g. by gel permeation chromatography, is required to obtain reliable light scattering measurements.

Thermodynamics of phase separations

Phase separation of a polymer may occur due to changes in polymer molecular weight, solvent composition or temperature. Phase separation occurs when the composition dependence of the free energy of mixing (ΔFmix), has at least two minima (see Figure 1A). For polymer blends, the free energy of mixing per monomer is:

| [1] |

where k is Boltzman’s constant, T is temperature, φ is the volume fraction of polymer A, χ is the Flory interaction parameter, NA is the degree of polymerization of polymer A, and NB is the degree of polymerization of polymer B. For polymer A dissolved in a solvent B, NB is equal to 1. For further discussion, excellent introductory texts on the topic are available [41, 42].

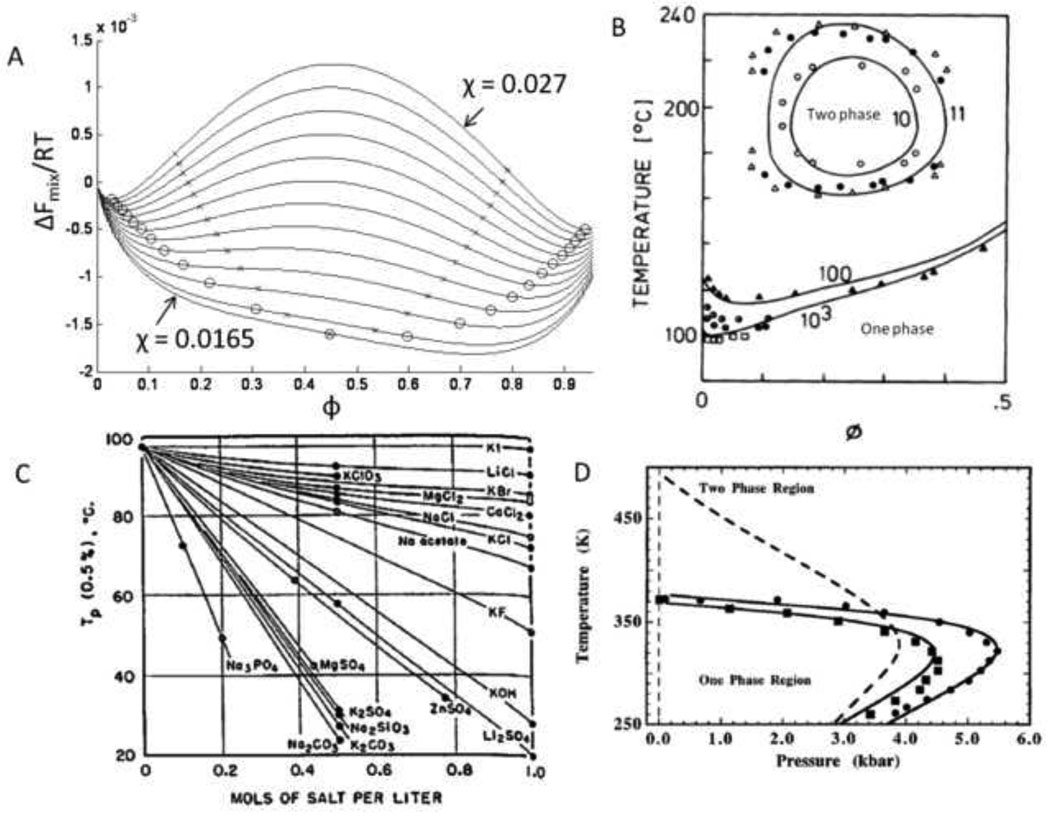

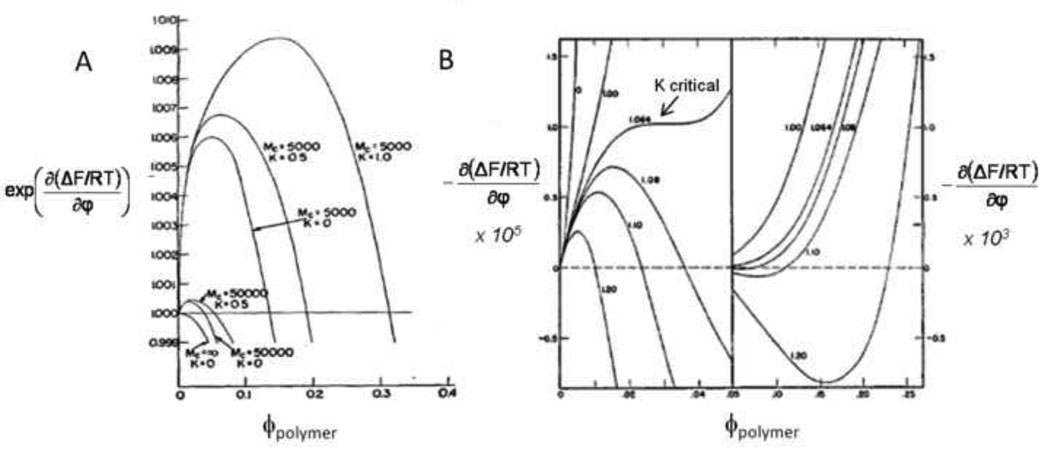

Figure 1. Thermodynamics of phase separation.

(A) The Flory-Huggins equation (Equation [1]) describes the free energy of mixing as a function of composition (ϕ). The free energy of mixing is shown for a mixture of two polymers (degrees of polymerization of 150 and 100) and different values of the Flory interaction parameter (χ). Binodal points are shown as open circles and spinodal points are shown as x’s. The dependence of the Flory interaction parameter on temperature determines if a lower or upper critical solution temperature exists. The critical point occurs at χ = 0.0165. (B) Phase diagram of PEG in water. The degree of polymerization of PEG is listed next to each binodal line. A one phase solution exists below the binodal lines, with the minima of the lines at the critical temperature (lower critical solution temperature, LCST). For low molecular weight PEG, closed loop behavior is observed, with an upper critical solution temperature (UCST) above the LCST. Adapted from Matsuyama & Tanaka, Physical Review Letters, 65, 341–344, 1990. (C) Salts greatly affect the LCST of PEG in water. Kosmotropic (water-structuring) salts are most effective at reducing the LCST. From Bailey & Callard, J. Appl. Polym. Sci., 1, 56–62, 1959. (D) Pressure also affects the phase behavior. Phase separation occurs at room temperature for PEG mol. wt. 21,000 (circles), PEG mol. wt. 1360 (squares) and PVP (dotted line) in water at elevated pressures. Adapted with permission from Sun & King, Macromolecules, 31, 6383–6386, Copyright 1998 American Chemical Society.

Two phases may coexist at compositions that have the same chemical potential (∂ΔFmix/∂ φ) and minimize the net free energy of mixing. These compositions define the binodal points at a particular temperature/solvent combination. With changes in temperature or solvent, the composition dependence of ΔFmix changes due to changes in the Flory interaction parameter, resulting in new binodal points (χ-induced phase separation). Given multiple sets of binodal points, binodal lines may be drawn that not only reveal the composition of incipient phase separation, but also display the composition of the two phases. Due to the scattering of light during phase separation, the binodal is also called the cloud point. At compositions between the binodal points where ∂2ΔFmix/∂ φ2 < 0, the solution is unstable and spontaneously phase separates by spinodal decomposition. The inflection points, where ∂2ΔFmix/∂ φ2 = 0, are the spinodal points. Connected spinodal points form a spinodal line. At solution compositions between the two binodal points, but where ∂2ΔFmix/∂ φ2 > 0, the solution is metastable. Thermal fluctuations in composition are suppressed and phase separation occurs only by nucleation and growth.

At a critical value of the Flory interaction parameter, which is a function of temperature, the binodal and spinodal points collapse to a single point. If χ decreases with increasing temperature, the temperature of the critical point defines an upper critical solution temperature (UCST). Above this temperature, the polymer and solvent are stable at all compositions. If χ increases with increasing temperature, the temperature of the critical point defines a lower critical solution temperature (LCST) [42]. Note that at off critical compositions, the polymer solution may be outside the binodal points and thus stable even though beyond the critical temperature. Equation [1] also shows that increases in the degree of polymerization of the polymer, NA, will affect the binodal and spinodal points (reaction-induced phase separation [43]) [28].

Water soluble polymers exhibit LCST behavior in water, for example poly(N-isopropylacrylamide) (poly(NIPAAm); LCST ≈ 31°C) [44] and poly(ethylene glycol) (PEG; LCST ≈ 95°C) [45]. Using PEG as an example, the nature of LCST behavior can be further explored. The origin of LCST behavior of PEG in water is the destabilization of hydrogen bonding at elevated temperatures that disrupts the hydration shell surrounding the polymers [46]. A phase diagram for PEG in water is shown in Figure 1B [47]. PEG of low molecular weight has a UCST greater than its LCST, leading to closed loop phase diagrams [48]. As the molecular weight of PEG increases, the LCST decreases. Thus, a precipitation polymerization of PEG macromonomers could be conducted in pure water at temperatures between about 100–150°C. Salts, particularly “water-structure breaking” salts of the Hofmeister series (kosmotropes), can greatly decrease its LCST (Figure 1C) [49, 50]. Increased pressure also lowers the LCST of PEG (Figure 1D) [51, 52]. Aqueous mixtures of water-soluble polymers may also undergo phase separations, such as dextran and PEG in water [53]. The phase behavior of other water soluble polymers is similar and has been catalogued in great detail [54].

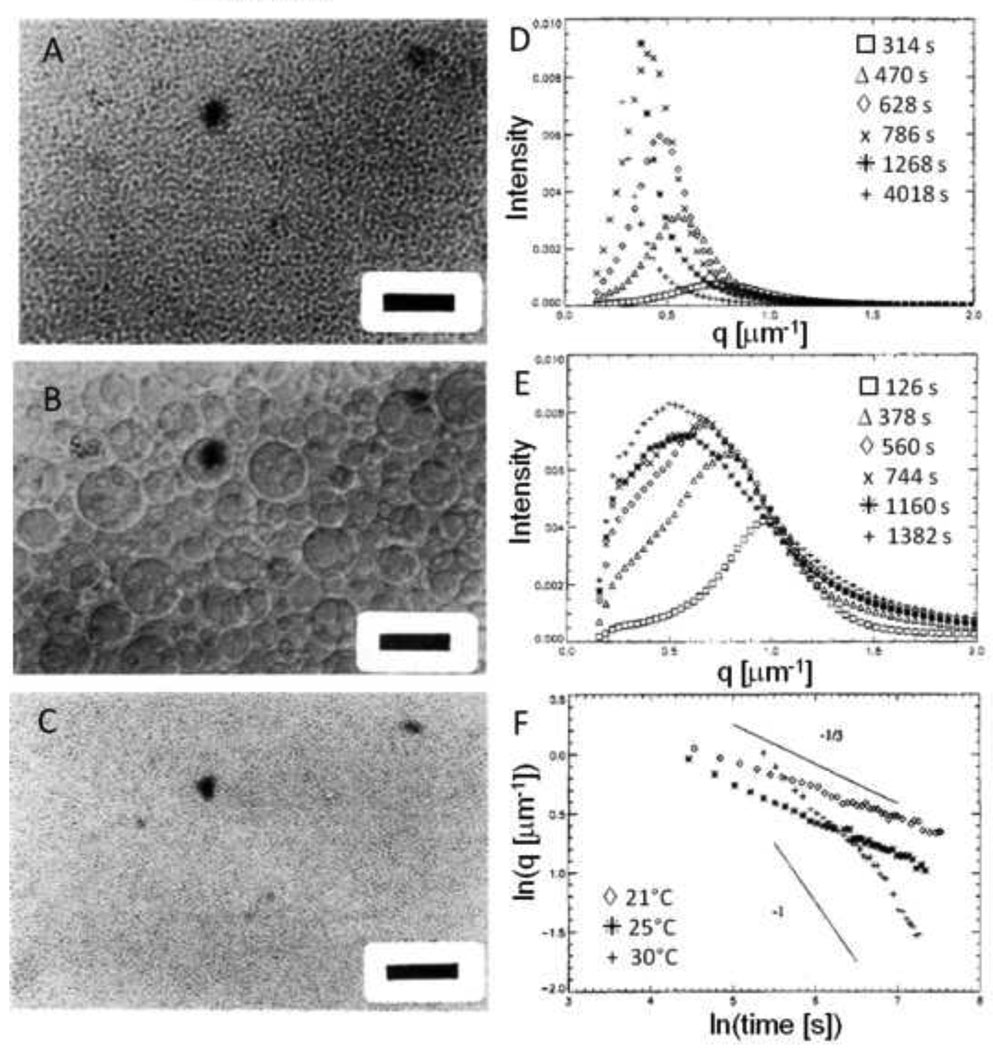

Phase separation may occur without mixing by solvent evaporation in thin films or by a simple change in temperature (a thermally induced phase separation; Figure 2). The spinodal points are often quickly surpassed, ensuring that phase separation occurs by spinodal decomposition instead of nucleation and growth. In the early stages of spinodal decomposition, phase domains exist as rapidly growing concentration fluctuations on molecular length scales. The concentration fluctuations rapidly evolve into a bicontinuous (doubly percolated) network if the volume fractions of the two formed phases are similar. Due to surface tension, the characteristic size of the percolated domains grows as the liquid phases flow to become more spherical [55]. During this hydrodynamic process, the average size of the phase domains grows linearly with time. Once spherical domains form, the domains are physically separated and grow in size by mass transfer rather than by fluid flow, causing a change in the growth law that defines the percolation-to-cluster transition (Figure 3) [56]. ‘Coarsening’ or ‘ripening’ of the spherical domains occurs by coalescence (direct merger of droplets) or Ostwald ripening (diffusion of molecules from smaller, less stable droplets to larger, more stable droplets). In both coalescence and Ostwald ripening, average domain sizes grow with the cube root of time [56]. Due to the slower growth during the latter phase, the mean size of the domains is said to be ‘pinned’ at the percolation-to-cluster transition [57]. The sizes of the domains are not truly pinned to a certain value, but simply grow at a much slower rate [56]. The evolution of phase morphology towards the equilibrium state may be observed by light and neutron scattering, or directly by scanning confocal microscopy (Figure 4A) [57, 58]. At long times, the two phases generally form two distinct macroscopic layers due to density differences between the phases. The coarsening process may be ‘pinned’ by vitrification, crystallization or gelation [57]. The morphology of the pinned phase domains will influence the mechanical properties of a material [59].

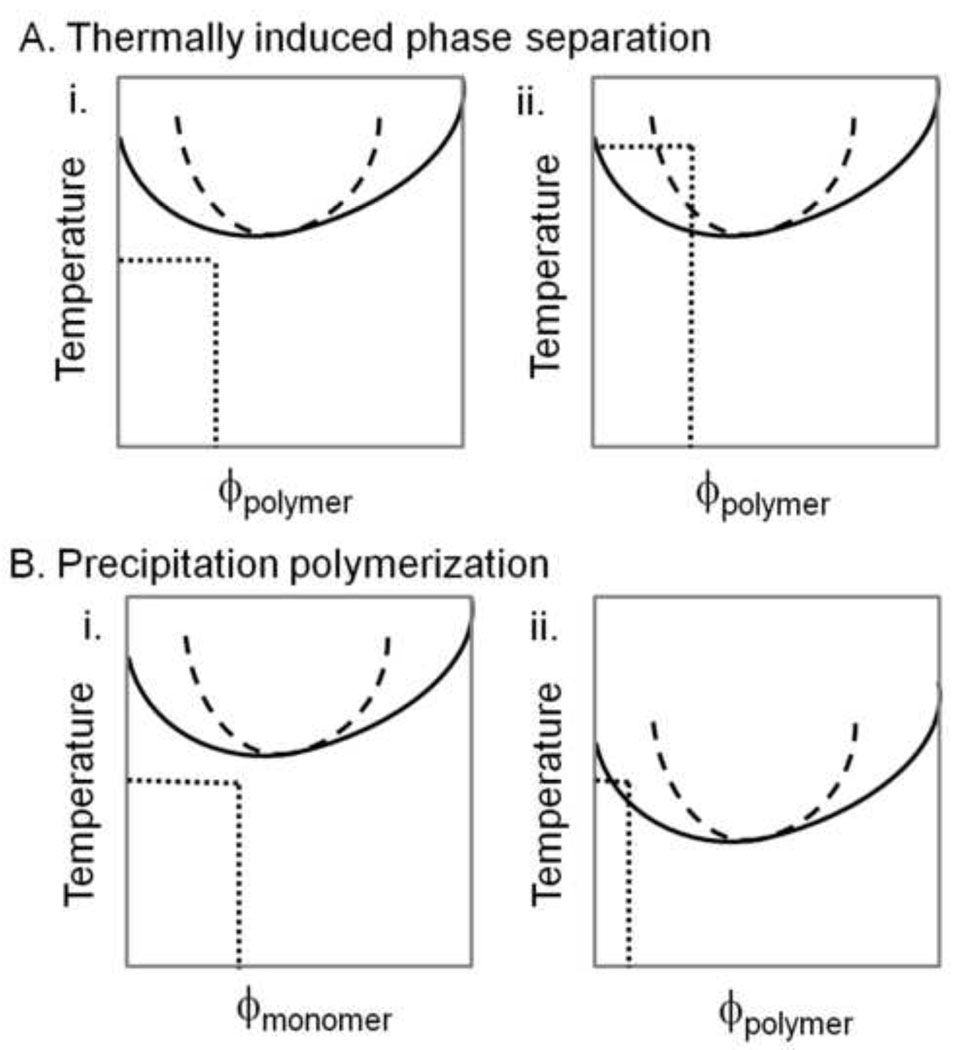

Figure 2. Hypothetical phase diagrams for a polymer exhibiting LCST phase behavior.

(A) In a thermally induced phase separation, the solution is initially a single phase (i). The temperature is raised until the two phase region is entered (ii). The binodal line is solid and the spinodal line is dashed. If the solution is ‘quenched’ deeply so as to cross the spinodal line, phase separation is by spinodal decomposition. (B) In a precipitation polymerization, the temperature remains constant. The monomer is soluble throughout the polymerization (i). The polymer that forms has a different phase diagram from the monomer (ii). Polymer chains with different degrees of polymerization have distinct phase diagrams, as evident from the Flory-Huggins equation (Equation [1]). At the polymerization temperature, polymer chains above a certain degree of polymerization and concentration may phase separate. As shown in (ii), phase separation would be by nucleation and growth because only the binodal line is surpassed, while phase separation by spinodal decomposition will occur in (i).

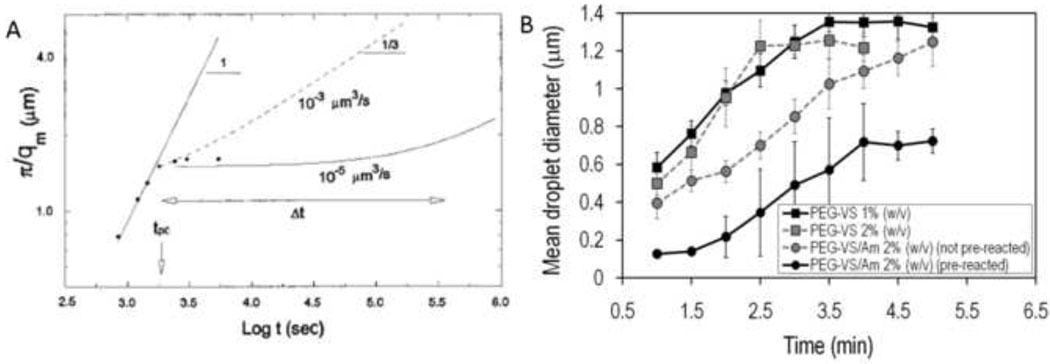

Figure 3. ‘Pinning’ of phase separation during spinodal decomposition.

(A) The inverse of the wave vector with peak intensity, qm, reveals the characteristic dimension of the phase separated domains. This is measured over time following a deep quench beyond the spinodal point of a poly(butadiene)/poly(isoprene) blend. The log-log plot reveals the power law nature of the process. Initially, the slope of one indicates a linear relationship between the characteristic size of the phase separated domain and time. Eventually, the power law exponent changes and growth appears to halt (i.e. ‘pinned’). In fact, the growth law has simply changed, with an exponent at longer times of 1/3. The change in growth law occurs at the percolation-to-cluster transition. Reprinted with permission from Crist, B., Macromolecules, 29, 7276–7279, Copyright 1996 American Chemical Society. (B) The same phenomenon can be observed with PEG in PBS + 0.6 M sodium sulfate. When the temperature is raised to 37°C, dynamic light scattering showed a linear growth in the mean diameter, followed by pinning. This occurred with PEG alone at 1% or 2% (w/w), or with solutions of reactive PEGs. The reactive PEGs were either mixed immediately prior to phase separation or allowed to react for about 6 h prior to phase separation (‘pre-reacted’). Reprinted from Biomaterials, 30, Nichols et al., “Factors affecting size and swelling of poly(ethylene glycol) microspheres formed in aqueous sodium sulfate solutions without surfactants”, 5283–5291, Copyright 2009 with permission from Elsevier.

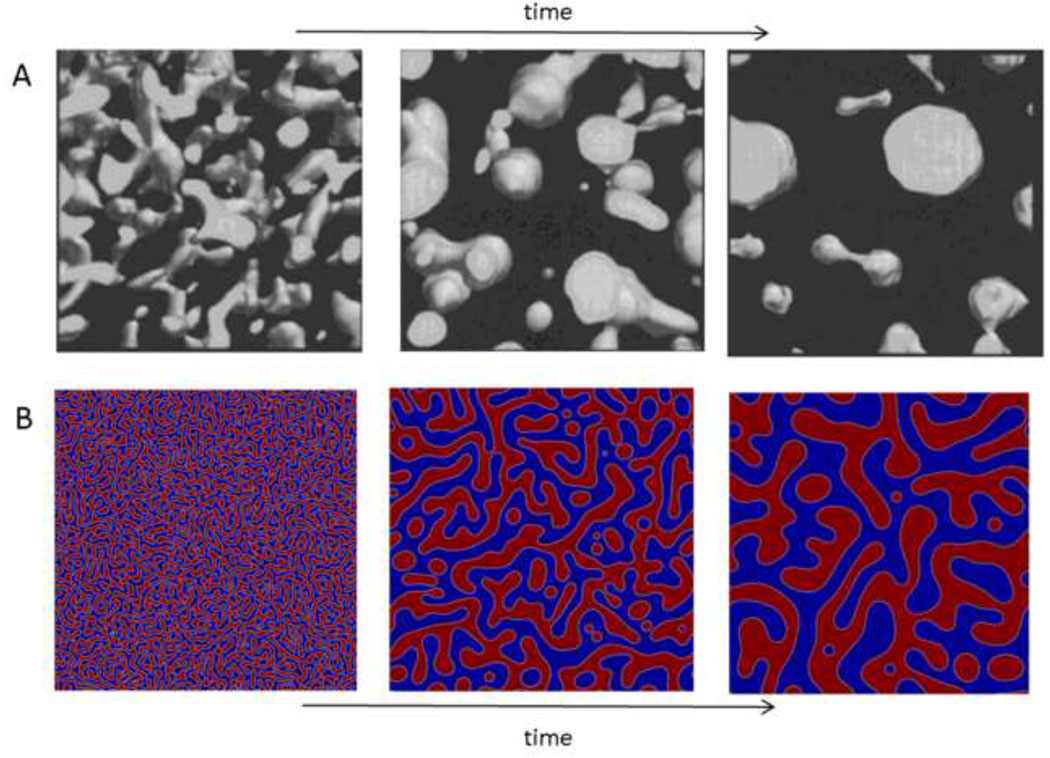

Figure 4. Spinodal decomposition and the percolation-to-cluster transition.

(A) Direct visualization of the percolation-to-cluster transition by scanning confocal microscopy (the ‘clusters’ are the spherical domains). Fluorescently labeled poly(butadiene) was phase separated from poly(styrene-ran-butadiene) by spinodal decomposition following a deep quench. Reprinted with permission from Takeno et al., Macromolecules, 33, 9657–9665, Copyright 2000 American Chemical Society. (B) Solution to the Cahn-Hilliard equation that describes phase separation by spinodal decomposition and coarsening by Ostwald ripening. At the first time point, both red and blue phases percolate the entire area and exist as a bicontinuous network. Over time, the larger domains grow by absorbing mass from the smaller domains, with surface area minimized by adopting more spherical morphologies.

Cahn and Hilliard developed a model of phase separation by spinodal decomposition and coarsening by Ostwald ripening (Figure 4B) [60, 61]. This model is particularly suited for phase separations in solids or viscous solutions, e.g. in polymer/polymer blends, in which diffusion of phase domains is hindered, slowing coalescence. In less viscous solutions, coalescence may dominate due to the ability of the phase separated domains to encounter each other by diffusion [56]. With mechanical stirring, droplets will encounter each other frequently and the kinetics of the phase separation process will be similar to those that govern droplet size in a stirred suspension polymerization [23].

Gelation is itself a form of phase separation. The free energy of mixing as calculated by equation [1] (with the degree of polymerization of the gel, NA, equal to infinity) is added to the elastic free energy change due to chain stretching within the swollen network. The elastic free energy is a function of the crosslink density, ν and the volume fraction of polymer, φ. The phase outside the gel is assumed to have no polymer and the chemical potential with respect to the polymer is thus equal to zero. The amount of solvent in the gel, and thus the equilibrium swelling of the gel, exist where the chemical potential in the gel phase is also zero (Figure 5) [62]. If more solvent is present during crosslinking than the equilibrium amount in the gel, the solvent will be exuded from the gel (syneresis, specifically, ν-induced syneresis). If further crosslinking traps solvent in the gel, solvent-rich pores may form within the gel (microsyneresis) [63]. Dusek also described a second type of syneresis, χ-induced syneresis, where a change in the Flory interaction parameter drives phase separation [63, 64]. Syneresis occurs within the gel phase, where NA is infinity, so it must be induced by changes in ν or χ. However, under conditions that promote precipitation polymerization, the formation of polymer particles may introduce heterogeneity prior to gelation, resulting in porosity by a mechanism that differs from ν-induced or χ-induced microsyneresis.

Figure 5. Gelation is a form of phase separation.

(A) The chemical potential of a gel as a function of the polymer volume fraction determines the degree of swelling in excess solvent. No polymer exists outside the gel, so the equilibrium volume fractions of the fully swelled gel must fall on the dotted line (where the chemical potential is zero). Mc is the molecular weight between crosslinks; as Mc decreases from 50,000 to 5000 at constant K, the number of crosslinks (ν) in the gel increases and the equilibrium amount of polymer in the gel (ϕ) increases (i.e. the gel deswells). Decreased swelling with decreasing Mc is ν-induced syneresis. K contains the Flory interaction parameter (χ); as K increases at constant Mc, the interaction between solvent and monomer subunits becomes less favorable. Decreased swelling with increasing K is χ-induced syneresis. Reprinted with permission and adapted from Flory, P.J. & Rehner, J., “Statistical Mechanics of Cross-Linked Polymer Networks II. Swelling”, J. Chem. Phys., 11, 521–526, Copyright 1943, American Institute of Physics. (B) For comparison, the chemical potential for a polymer in solution as described by the Flory-Huggins equation (first derivative of equation [1] with respect to composition). The composition of the first phase will be to the left of the maximum, while the composition of the second phase will be to the right of the minimum (note that the two sides of the plot are on different scales). The numbers next to each curve are values of K. The arrow points to the critical value of K for phase separation. The chemical potential of the phase separated solutions is not necessarily zero but will be some value between the maximum and minimum that minimizes the total free energy of the solution (which is not apparent from this diagram alone). The figure illustrates the basis of χ-induced phase separation, but does not show the effects of increasing the degree of polymerization (NA in equation [1]), which causes reaction-induced phase separation. Reprinted with permission and adapted from Flory, P.J., “Thermodynamics of High Polymer Solutions”, J. Chem. Phys., 10, 51–61, copyright 1942, American Institute of Physics.

Colloidal properties of phase separated systems

Proteins and polysaccharides dissolved in water undergo phase separation at certain temperatures and solvent compositions [65]. The nature of the phase separation of biomacromolecules is thermodynamically equivalent to those encountered with polymers. However, the study of the phase behavior of proteins and polysaccharides pre-dated the routine synthesis of polymers, and different terminology developed.

Colloids are defined by their size (1–1000 nm) [66]. Colloids must be stabilized in some manner to prevent aggregation. Two types of stabilization are common, electrostatic and steric. Electrostatic stabilization results from the presence of like charges on all of the colloidal particles, which causes repulsion due to overlap of the electric double layers that surround the particles. Steric stabilization relies on the presence of solvent-soluble polymers attached to the surface of the colloidal particles. Overlap of polymer chains upon close approach of two particles is unfavorable. In both steric and electrostatic stabilization, long range repulsion prevents the close contact required for aggregation by van der Waals forces. Electrostatic stabilization is ineffective in high salt solutions and in organic solvents with low dielectric constants, due to the decrease in thickness of the electric double layer to the point that shorter-range attractive forces may overcome electrostatic repulsion. Steric stabilization is required in these cases [67].

Phase separation of polymers, proteins or polysaccharides may lead to the formation of solid precipitates or flocs that retain extremely low amounts of solvent. However, if more solvent is retained in the polymer-rich phase, two liquid phases result. In the colloid literature, a liquid-liquid two-phase solution is a coacervate [65]. Phase separation to form liquid-liquid two phase systems also occurs following the interaction of oppositely charged macromolecules, such as gelatin and gum arabic or poly(lysine) and alginate. This is termed complex coacervation, contrasted with a one component simple coacervate [65]. The difference between coacervation and precipitation is simply the amount of solvent retained in the polymer-rich phase [68].

III. Instructive examples of liquid-liquid two phase systems for the production of microspheres and macroporous hydrogels

Precipitation polymerization for the formation of hydrogel scaffolds

Wichterle and Lim introduced hydrogels to the biomedical community in 1960 [69]. In the original manuscript in Nature, the authors state, “Gels based on glycolmethacrylates are also noteworthy for their transparency (in the case of polyglycolmonomethacrylate with a water content less than 30 percent and with the higher glycols at all concentrations)”. Glycolmonomethacrylate is now known as 2-hydroxylethylmethacrylate (HEMA), which is typically crosslinked with a small amount of ethylene glycol dimethacrylate. The ‘higher glycols’ referred to are oligoethylene glycols, which were produced by reacting ethylene oxide gas with methacrylic acid. The “transparent gels at all water contents” were thus formed from a mixture of poly(ethylene glycol)-monomethacrylate and poly(ethylene glycol)-dimethacrylate [70, 71]. This is not to be confused with poly(ethylene glycol methacrylate) or polyglycolmonomethacrylate, which are simply poly(HEMA) [72]. Unlike PEG-based hydrogels, the poly(HEMA) hydrogels were cloudy at high water contents. This was due to the propensity of poly(HEMA) to phase separate from water. Above a degree of polymerization of 30, the cloud point of HEMA in water is less than 40°C, while the monomer and smaller oligomers are completely miscible [73].

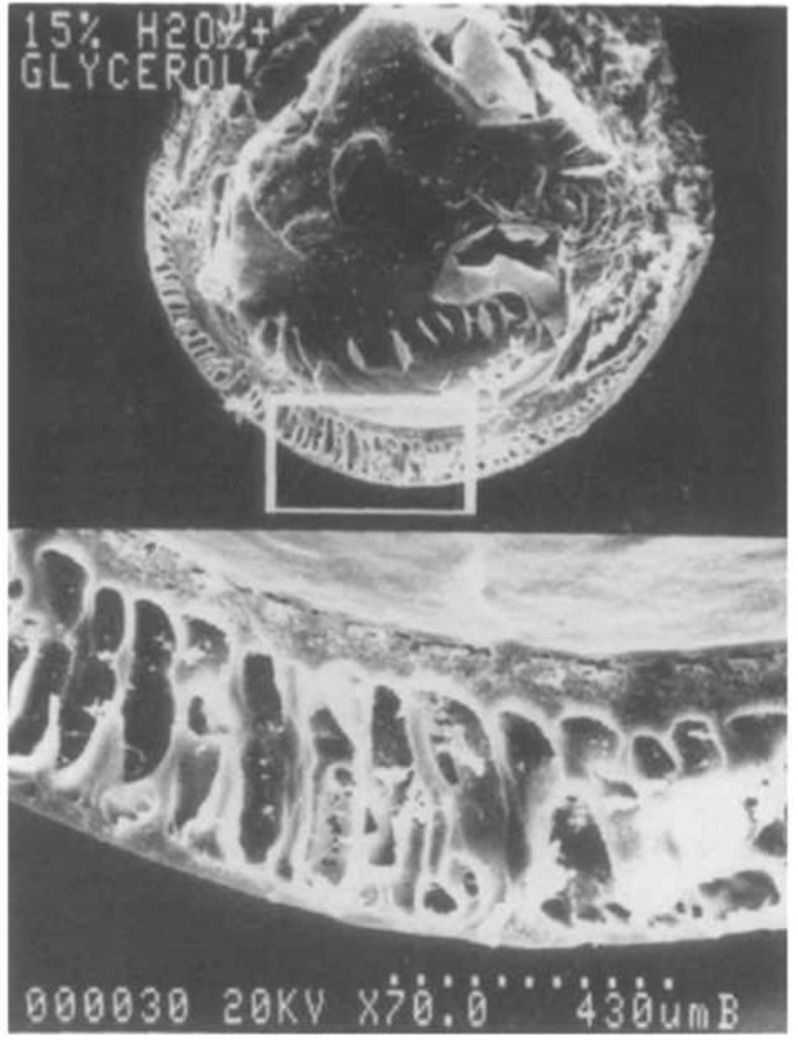

Non-macroporous poly(HEMA) materials are typically produced neat or in alcohols with only a small amount of water present. Polymerization of HEMA in 60–90 wt% water resulted in the formation of a porous hydrogel sponge (Figure 6A). As described by the authors, “The initially excellent solubility of the monomers in water decreases sharply with increasing conversion and phase separation takes place” [74]. The sponges consisted of what appeared to be aggregated microspheres, less than about 10 µm in diameter and with low size dispersity. This suggests a precipitation polymerization with aggregation and crosslinking of the formed particles. Wichterle and Lim originally described the result of the polymerization of HEMA in water as follows: “With a water content greater than corresponds to the equilibrium capacity of the gel, a porous structure will arise by coalescing of the water-phase droplets into interconnected channels” [69]. This implies that the authors believed the cloudiness was caused by ν-induced microsyneresis, which is a different mechanism from precipitation polymerization. Evidence that precipitation polymerization is the dominant mechanism is that poly(HEMA) microspheres may be formed if the HEMA concentration in water is decreased (described in detail in the next section). Thus, porosity of hydrogels may not always be readily explained in terms of microsyneresis.

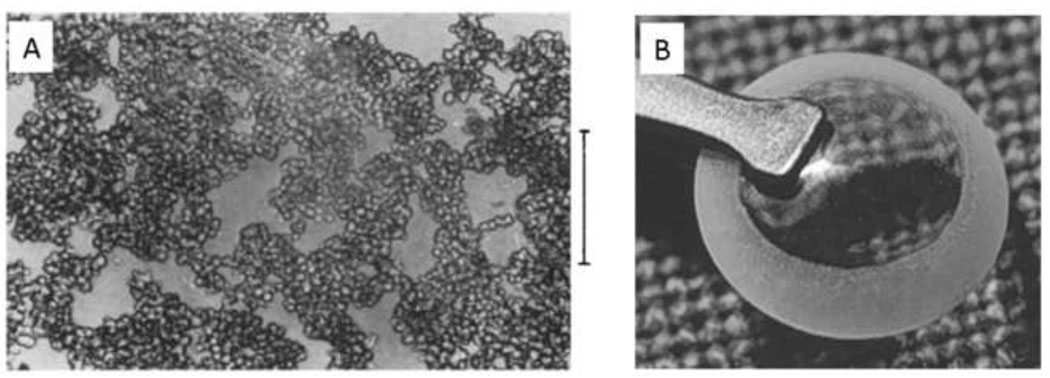

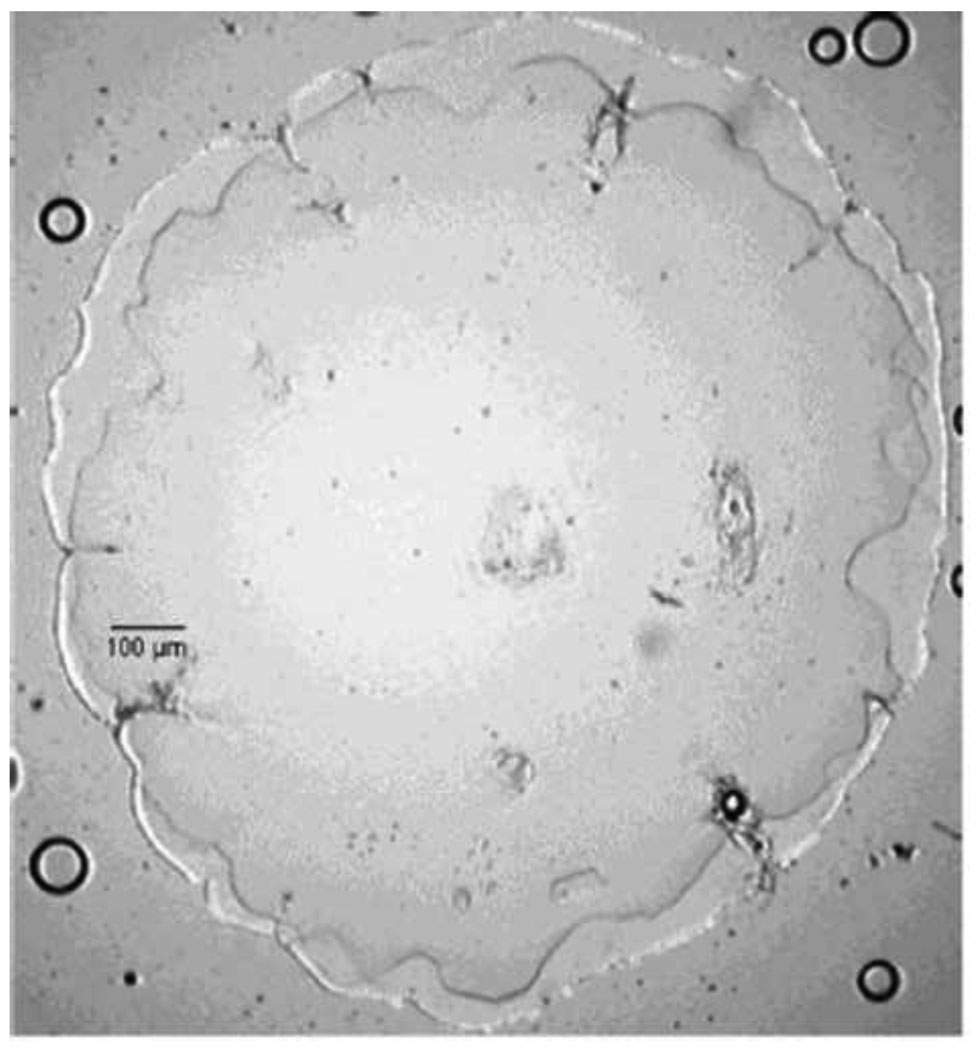

Figure 6. Porous HEMA hydrogels formed under conditions that promote precipitation polymerization.

(A) Sponge-like poly(HEMA) gel formed in the presence of high concentrations of water. Note that the gel consists of microparticles with a narrow size distribution. This appears to be the result of coalescence of microparticles that formed by precipitation polymerization. Scale bar is 100 µm. Reprinted from Barvic et al., J. Biomed. Mater. Res., 1, 313–323, 1967. (B) A poly(HEMA) corneal replacement device. An optically clear center region is formed using a low concentration of water and a macroporous skirt is formed using a high concentration of water. The macroporous region is designed to allow tissue ingrowth for better integration of the device. Reprinted by permission from Macmillan Publishers Ltd: Eye, 17, Hicks et al., 385–392, copyright 2003.

Sponges formed in 50–60% water that were implanted in animals became surrounded by a fibrous capsule similar to non-macroporous HEMA hydrogels. Higher water content during polymerization produced pores large enough for the ingrowth of cells into the sponge. Increased porosity resulted in smaller fibrous capsules and better vascularization [75]. It was observed that the microarchitecture of materials (pore size), rather than surface chemistry, enhanced the integration of the material with the host’s vascular system [76]. Enhanced vascularization may promote survival of transplanted cells, enhance endothelialization of vascular grafts or reduce diffusion limitations of biosensors [77].

In 1983, macroporous HEMA membranes were used to form containers for the transplantation of pancreas tissue [78]. The goal was to enhance the transport of insulin while preventing ingrowth of leucocytes. As such, the membranes were not porous enough to vascularize, but were surrounded by a thin, vascularized fibrous capsule [79]. The enhanced transport properties of macroporous HEMA membranes led to their use in a glucose sensor that also released insulin [80]. Spongy HEMA hydrogels have been used for breast augmentation and as replacements for articular cartilage [81, 82]. However, the propensity of HEMA hydrogels to calcify and in some cases cause tumors has been noted [83, 84]. Furthermore, calcification may be enhanced by macroporosity [85].

Interest in macroporous HEMA hydrogels was later revived due to their potential to promote tissue ingrowth. Chirila and colleagues produced a homogenous poly(HEMA) hydrogel surrounded by a macroporous poly(HEMA) skirt, which has been used for clinical corneal replacement (Figure 6B) [86]. Lowman and colleagues used HEMA to form porous sponges, finding that sonication aided in developing uniform pores. The authors speculated that non-uniformity may have resulted from the formation of nitrogen gas bubbles as the initiator, 2,2-azobis(2-azobis(2-methyl-proprionitrile) (AIBN), decomposed [87]. Phase separation was tolerant to small amounts of poly(ethylene glycol) monomethylether monomethacrylate mol. wt. 200 included in the reaction mixture. The grafted PEG chains enhanced the interconnectivity of the pores, perhaps by delaying phase separation. Greater pore interconnectivity allowed endothelial cells to enter the sponges and form tubules [88]. Such endothelial tubules are significant because rapid vascularization of scaffolds may require the presence of preformed tubules that join to the host’s vasculature [89].

Shoichet and colleagues polymerized HEMA and methyl methacrylate in water to make macroporous nerve guidance conduits. The polymerization reaction began as a homogenous solution that was placed in a sealed tube and spun at 2500 rpm on a drill. The denser polymer migrated to the outer edge of the tube, forming a hollow fiber membrane. Polymerization of pure HEMA in water resulted in highly porous membranes. At higher water contents, a beaded morphology was observed, consistent with the coalescence of microparticles formed by precipitation polymerization (Figure 7A). At slightly lower water contents, a microporous membrane formed. The water concentration was above the equilibrium water concentration of the gels, so the micropores likely resulted from ν-induced microsyneresis (Figure 7B). Addition of methyl methacrylate to the reaction resulted in a highly porous inner layer and a more continuous outer layer with large, unconnected pores (Figure 7C). The inner layer was likely the result of a precipitation polymerization. The outer layer may have been enriched in methyl methacrylate and phase separated early in the reaction. The phase separation reached an advanced stage before gelation, producing a nearly homogenous network. The large pores in the outer layer were most likely the result of ν-induced microsyneresis [90–92]. These materials clearly illustrate that subtle changes in polymerization conditions may lead to vastly different modes of polymerization and pore formation.

Figure 7. The mode of polymerization depends on subtle differences in reaction conditions.

(A) A ‘macroporous’ poly(HEMA) hydrogel crosslinked with greater than 80% water showed the beaded morphology consistent with the coalescence of microparticles formed under precipitation polymerization conditions. (B) A ‘microporous’ poly(HEMA) hydrogel crosslinked with a lower water concentration than (A) but with more water than the equilibrium water concentration of the fully swollen hydrogel. The micropores may have formed by ν-induced microsyneresis. (C) Tube of hydrogel formed by spinning the polymerizing solution. HEMA was mixed with methyl methacrylate, water and a crosslinker. The inner region had a beaded morphology. The outer region was a nearly homogenous gel surrounding large pores. The outer region may have completely phase separated prior to gelation, while the inner layer resulted from a precipitation polymerization. Reprinted from Biomaterials, 23, Dalton et al., “Manufacture of poly(2-hydroxyethyl methacrylate-co-methyl methacrylate) hydrogel tubes for use as nerve guidance channels”, 3843–3851, Copyright 2002, with permission from Elsevier.

Other water soluble polymers also undergo phase separation in water and this may be exploited to produce macroporous hydrogels. Poly(vinylmethylether), which has a cloud point of around 37°C, was crosslinked by gamma radiation from a 60Co source, resulting in a porous gel. The hydrogels exhibited rapid swelling and deswelling near the LCST of poly(vinylmethylether), attributed to the porous nature of the hydrogel. The hydrogel may have been porous due to a rise in temperature during crosslinking leading to phase separation of the polymer [93]. However, radiation crosslinking may generate hydrogen gas, so the role of gas bubbles in generating porosity was difficult to discern [94]. To avoid radiation crosslinking, the more reactive acrylamide group on N-isopropylacrylamide (NIPAAm) was used in a precipitation polymerization with a heat-initiated free radical polymerization. NIPAAm is water soluble at high temperatures, while poly(NIPAAm has an LCST of about 31°C [44]. NIPAAm thus forms macroporous hydrogels if polymerized at elevated temperatures [95]. Hoffman and colleagues further increased the porosity of poly(NIPAAm) hydrogels by adding hydroxypropyl cellulose to the monomer solution, which has an LCST of about 42°C. The hydroxypropyl cellulose precipitated at the polymerization temperature of 50°C along with the newly formed poly(NIPAAm). The cellulose particles were then extracted in water following polymerization, producing a highly porous scaffold with rapid swelling and deswelling kinetics [96, 97]. Gotoh et al. compared the swelling and strength of poly(N,N’-diethylacrylamide) hydrogels and poly(NIPAAm) hydrogels, both crosslinked with N-N’-methylenebis(acrylamide) (BIS). Both polymers showed LCST behavior and both types of hydrogels formed porous ‘aggregated bead’ structures at temperatures above the LCST of the polymer. However, the poly(N,N’-diethylacrylamide) hydrogels did not form the porous structures unless formed well above the LCST, while poly(NIPAAm) hydrogels were porous even when polymerized at the LCST [98]. Such temperature sensitive gels undergo macrosyneresis as the temperature is raised above the LCST of the polymer, an example of χ-induced syneresis.

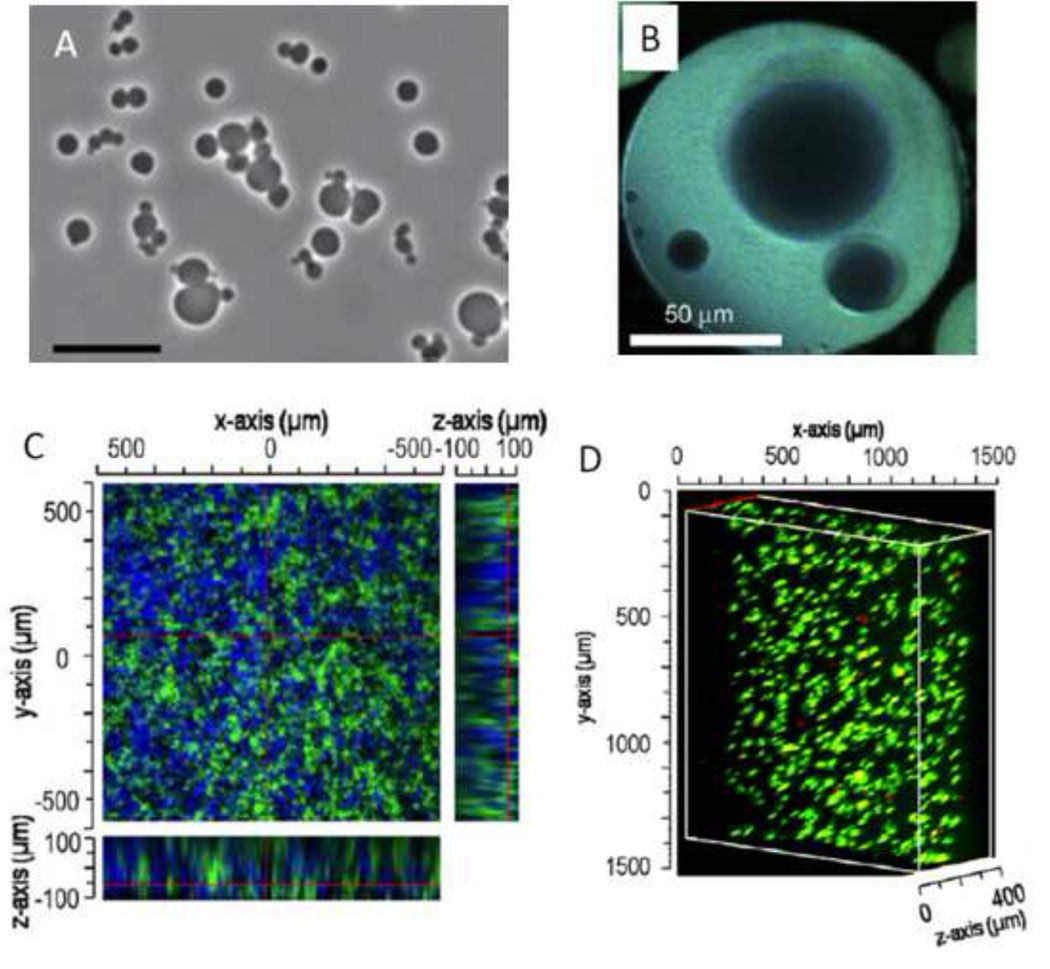

Shoichet and colleagues exploited the phase separation properties of PEG and dextran to produce macroporous scaffolds. Dextran-methacrylate that was crosslinked within a narrow range of PEG concentrations yielded architectures that by SEM appeared to be coalesced beads in the micron-size range (Figure 8A). Lower PEG concentrations produced non-macroporous dextran hydrogels, while higher PEG concentrations produced heterogeneous suspensions. The results suggested that the macromonomer (dextran-methacrylate) was soluble below a threshold concentration of PEG and precipitated only during the polymerization. Increasing the amount of dextran-methacrylate macromonomer resulted in structures that appeared to be continuous hydrogel containing large pores filled with beaded hydrogel (Figure 8B) [99]. The continuous portion of the hydrogel may have resulted from a phase separation of the dextran-methacrylate macromonomer and PEG prior to gelation. The solutions were mixed, perhaps resulting in suspended PEG-rich droplets that became trapped in the hydrogel. The beaded structure that formed within the pores in Fig. 8B suggests a precipitation polymerization. Phase diagrams for PEG and dextran-methacrylate reveal that at the polymerization conditions shown in Figure 8B, the PEG-rich phase may contain up to about 7.5% dextran-methacrylate [100]. The dextran-methacrylate dissolved in the PEG-rich phase may have polymerized and then precipitated to yield the beaded structures within the large pores.

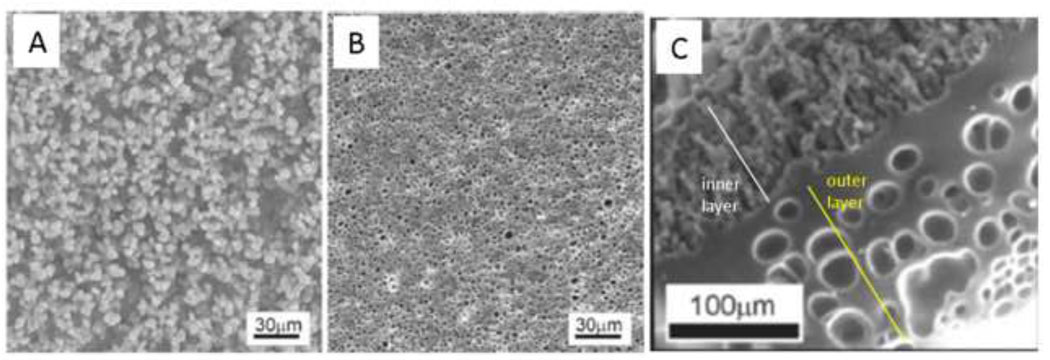

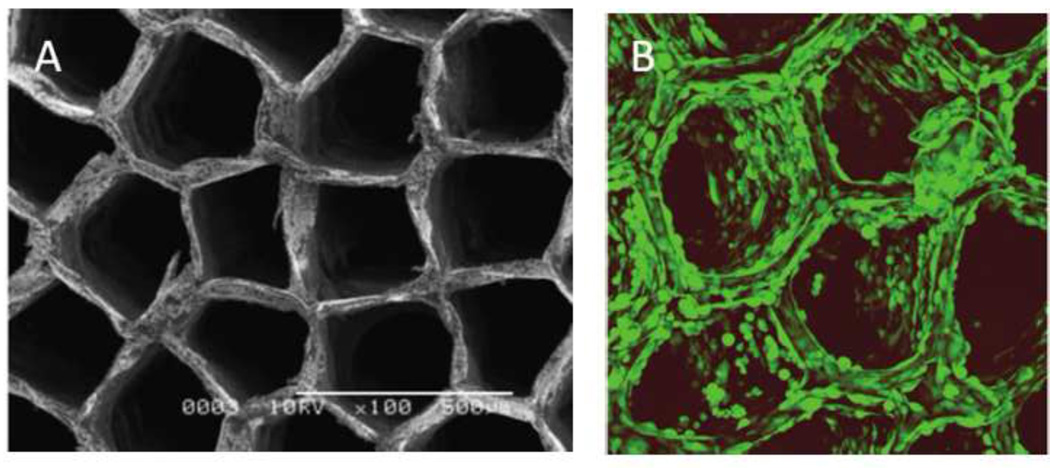

Figure 8. The mode of polymerization depends on subtle differences in reaction conditions.

(A) Dextran-methacrylate (dextran-MA) was crosslinked in the presence of PEG. Within a narrow range of PEG concentrations, the dextran-MA was soluble, but became insoluble upon polymerization. A precipitation polymerization thus may have produced the beaded morphology. (B) At higher concentrations of dextran-MA, the PEG and dextran-MA may have phase separated before polymerization. The dextran-MA-rich phase produced a continuous hydrogel containing large pores. Inside the large pores, a precipitation polymerization may have occurred in the PEG-rich phase. This was likely due to the presence of some amount of dextran-MA within the PEG-rich phase at equilibrium. Reprinted and adapted from Biomaterials, 26, Levesque et al., “Macroporous interconnected dextran scaffolds of controlled porosity for tissue-engineering applications”, 7436–7446, Copyright 2005, with permission from Elsevier.

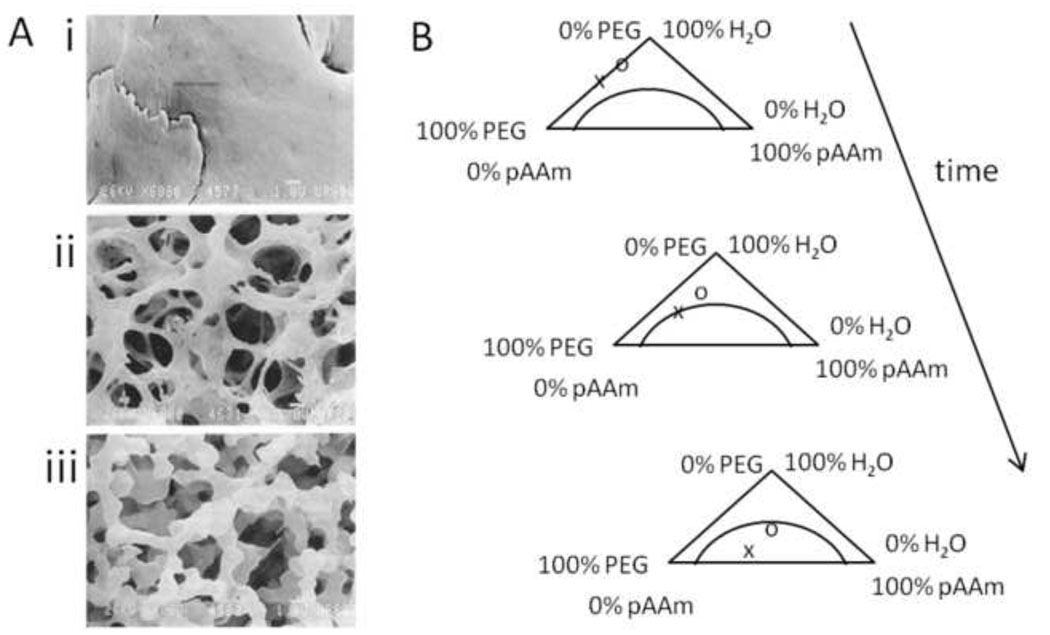

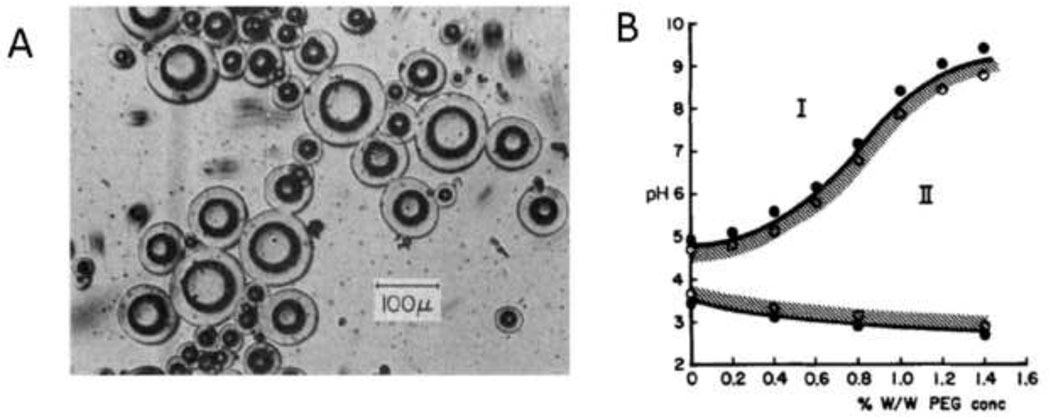

Righetti et al. found that poly(acrylamide) gels crosslinked with BIS undergo phase separation in the presence of non-crosslinkable water-soluble polymers, resulting in pore formation [101]. Acrylamide was completely soluble in PEG solutions, but poly(acrylamide) underwent phase separation during polymerization, even in the absence of the BIS crosslinker [102]. Scanning electron microscopy suggested that the poly(acrylamide) formed fibers around spherical pores (Figure 9A) [101, 103]. As the PEG concentration increased, the sizes of the pores also increased. This may be explained by referring to the hypothetical ternary phase diagram in Figure 9B. Initially, the concentration of poly(acrylamide) is zero. During polymerization, the concentration of poly(acrylamide) increases until the binodal of the two phase region is reached. If the binodal is reached earlier in the crosslinking process, i.e. at a high PEG concentration, the phase-separated solution had more time to coarsen before the process is halted by gelation, resulting in larger pores [102]. Macroporous gels were also generated by crosslinking poly(acrylamide) in the presence of hydroxymethylcellulose or poly(vinyl pyrrolidone) [101]. Initially, the authors believed that crystallization of poly(acrylamide) chains caused defects in crosslinking of the network that resulted in pore formation [104]. Only later did light scattering reveal that phase separation by spinodal decomposition occurred, with coarsening over time that was halted by gelation [102]. Kwok et al. have catalogued the conditions for precipitation polymerization of poly(acrylamide) and other water soluble polymers in a variety of solvents [105–108]. More recent examples of precipitation polymerizations to produce macroporous gels have been reviewed [64].

Figure 9. Polyacrylamide gels are macroporous if polymerized in the presence of PEG.

(A) Poly(acrylamide) gel polymerized with (i) 0% PEG, (ii) 2.5% PEG, (iii) 5% PEG. Reprinted from Charlionet et al, “Eliciting macroporosity in polyacrylamide and agarose gels with polyethylene glycol”, Electrophoresis, 1996, 17, 58–66. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission. (B) A hypothetical ternary phase diagram for poly(acrylamide) (pAAm), PEG and water to explain the increase in pore size with higher PEG concentrations. At the start of the reaction, no poly(acrylamide) is present. PEG is present at a higher (x) or lower concentration (o). As the poly(acrylamide) concentration increases, the higher concentration PEG solution phase separates first. This results in larger pores due to increased time for phase separation. Redrawn based on Asnaghi et al., J. Chem. Phys. 102, 9736–9742, 1995.

Precipitation/dispersion polymerization for the formation of hydrogel microspheres

Early method development

While radiation crosslinking of HEMA in the presence of BIS usually resulted in the formation of a macroporous scaffold, discrete microspheres could also be produced by precipitation polymerization (Figure 10A). In 1976, Rembaum et al. used less than 5% w/w monomer to produce crosslinked HEMA microspheres (90% HEMA/10% BIS). Higher concentrations of monomer could be used if 0.4% PEG was included. Microspheres formed in the presence of PEG were more resistant to sodium chloride-induced aggregation, which suggested that the PEG became grafted to the microspheres. Bound PEG may sterically stabilize the growing particles, hindering coalescence and aggregation [109].

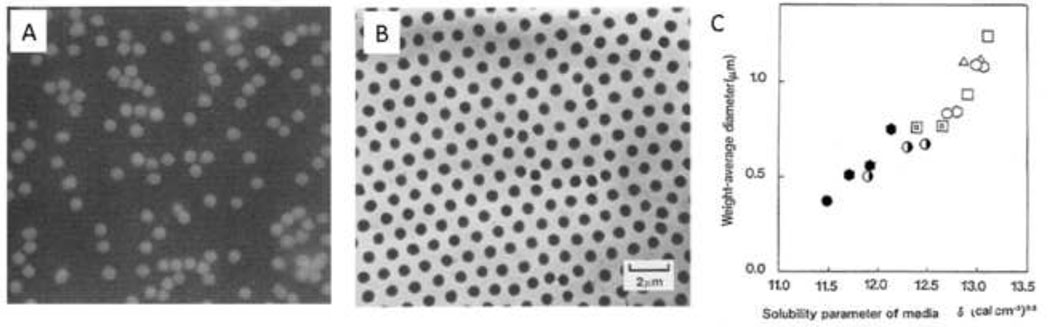

Figure 10. Near monodisperse microspheres by precipitation polymerization.

(A) Poly(HEMA) microspheres formed by gamma-irradiation of HEMA and BIS at a monomer concentration of 5% in water. Reprinted with permission from Macromolecules, 9, Rembaum et al., “Functional Polymeric Microspheres Based on 2-Hydroxyethyl Methacrylate for Immunochemical Studies”, 328–336, Copyright 1976 American Chemical Society. (B) Poly(NIPAAm) microspheres. Reprinted from Colloids and Surfaces, 20, Pelton & Chibante, “Preparation of aqueous latices with N-isopropylacrylamide”, 247–256, Copyright 1986, with permission from Elsevier. (C) Variation in the mean size of poly(acrylamide) microspheres due to subtle changes in the solvent composition. From Kawaguchi et al., Polymer International, 30, 225–231, 1993.

The LCST properties of poly(NIPAAm) may also be exploited to produce microspheres by precipitation/dispersion polymerization. In 1986, Pelton and Chibante published a method to produce monodisperse particles of NIPAAm or NIPAAm/acrylamide crosslinked with BIS (Figure 10B). Potassium persulfate or 2,2’-azobis(2-amidinopropane)·HCl were used as initiators to impart a negative or positive charge, respectively, at one terminus of the growing chain. Deionized water was the solvent and the polymerizations were performed at 60°C and higher. Lower temperatures did not result in microsphere formation. Concentrations of monomers above 2.5% resulted in the formation of precipitates. Increasing the concentration of acrylamide relative to NIPAAm also resulted in the formation of precipitates, although at very high ratios of acrylamide to NIPAAm, the formed polymer chains did not precipitate at all [110]. Formation of a monodisperse product thus occurred only over only a small range of experimental conditions. Kawaguchi et al. used this method to produce monodisperse poly(NIPAAm) microspheres and demonstrated that protein adsorption was higher on the poly(NIPAAm) microspheres above the LCST than below. The microspheres deswelled thirteen fold as the temperature was raised above the LCST and the less swollen state promoted about a three-fold increase in protein adsorption [111]. Peppas and colleagues later demonstrated that polyethylene glycol-monomethacrylate could be co-polymerized with NIPAAm monomer to produce poly(NIPAAm-co-PEG) microspheres by dispersion polymerization [112].

Kawaguchi et al. adapted the Pelton and Chibante method to produce temperature sensitive microspheres with other acrylamide monomers - acryloyl pyrrolidine and acryloyl piperidine. Poly(acryloyl pyrrolidine) had an LCST of 50°C and poly(acryloyl piperidine) had an LCST of 5°C. Polymerization with BIS in water at 70°C produced about 1 µm diameter monodisperse microspheres. Adding up to 5% ethanol, a good solvent for the polymers, delayed precipitation and produced slightly larger particles. The formed particles could also be used as ‘seeds’ in subsequent polymerization, slightly increasing the particle size [113]. Attempts to produce microspheres with only acrylamide and BIS were undertaken by carrying out the polymerization in water/alcohol mixtures. The alcohols were needed as non-solvents for the poly(acrylamide), due to the high water-solubility of this polymer. Microspheres with low polydispersity in size were produced, but these aggregated into ≈ 100 µm clusters. Including only a fraction of a percent of methacyrlic acid prevented aggregation and produced ≈ 1 µm diameter monodisperse poly(acrylamide) microspheres (Figure 10C) [114].

A few examples follow of microspheres formed by precipitation polymerization that were used to produce macroporous materials, drug delivery vehicles and surface coatings.

Scaffold assembly from microspheres

Colloids of equal size pack into ordered structures (colloidal crystals) that are iridescent due to the nature of light scattering from the regularly spaced particles [115]. Asher and colleagues produced poly(NIPAAm-co-2-acrylamido-2-methyl-1-propanesulfonic acid) microgels based on the Pelton and Chibante protocol. The microgels self assembled into colloidal crystals that scattered light due to the ordered structure of the material [116]. The size of the poly(NIPAAm) microspheres produced by precipitation polymerization was controllable by the concentration of BIS in the reaction. Changes in microsphere size affected the light scattering of self-assembled scaffolds [117]. Lyon and colleagues demonstrated that poly(NIPAAm-co-acrylic acid) microgels assemble into iridescent colloidal crystals that persist for some period of time without chemical crosslinking [118, 119]. If the scaffolds of poly(NIPAAm-co-acrylic acid) microgels were assembled in the presence of colloidal gold, exposure to a narrow beam of laser light caused contraction of the colloidal crystal within the beam, leading to the formation of a lens-like structure [120, 121]. The unusual phase behavior of these non-crosslinked thermosensitive colloidal crystals has been reviewed [122].

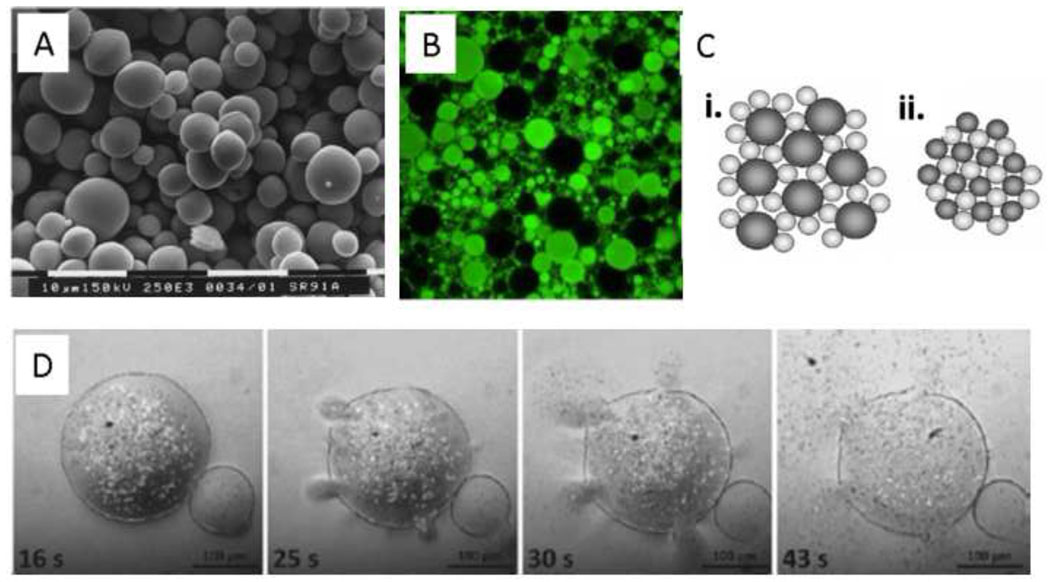

Hu et al. produced crosslinked scaffolds from poly(NIPAAm) microspheres by precipitation polymerization (mischaracterized as an emulsion polymerization) [123]. The microspheres were crosslinked with epichlorohydrin or divinylsulfone to form scaffolds that exhibited opalescence (iridescence; Figure 11A) [124]. Similarly, copolymerization of NIPAAm with allylamine in a precipitation polymerization produced microspheres that could be crosslinked with glutaraldehyde in the presence of dextran, serving as a model for a drug delivery system [125]. The precipitation polymerization technique was also adapted to produce microspheres of 2-(2-methoxyethoxy)ethyl methacrylate and oligoethylene glycol-methacrylate, taking advantage of the temperature-sensitive properties of the first component [126]. A related patent application describes the non-covalent self assembly of microparticles of poly(HEMA) produced by precipitation polymerization [127]. Cai & Gupta demonstrated that packed poly(NIPAAm) microgels could be crosslinked into scaffolds by adding NIPAAm and BIS and initiating polymerization. The monomers may have reacted with residual acrylamide groups in the microgels or may have simply diffused into the microgels to form an interpenetrating network [128].

Figure 11. Materials formed by assembling microspheres produced by precipitation polymerization.

(A) Self-assembled and covalently crosslinked monodisperse poly(NIPAAm) microspheres exhibit iridescence. The concentration of the microspheres in solution during crosslinking increases from left to right. From Hu et al., “Hydrogel Opals”, Advanced Materials, 2001, 13, 1708–1712. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission. (B) Poly(NIPAAm-co-PEG) microgels crosslinked to a poly(ethylene terephthalate) surface. Reprinted with permission from Biomacromolecules, 8, Singh et al., “Covalent Tethering of Functional Microgel Films onto Poly(ethylene terephthalate) Surfaces”, 3271–3275. Copyright 2007 American Chemical Society.

Weitz and colleagues also assembled poly(NIPAAm) microspheres into three dimensional materials. Copolymerization of NIPAAm and allylamine by precipitation polymerization produced microgels. In the presence of poly(acrylic acid) and above the LCST of NIPAAm, the microgels aggregated and were crosslinked by glutaraldehyde. Due to the presence of pores resulting from packing defects, scaffolds assembled from microgels exhibited about two orders of magnitude more rapid swelling than bulk gels. The microgels were conjugated to antibodies to add bioactivity, or mixed with silica particles, polystyrene microspheres or magnetic nanoparticles to add different properties to the scaffolds [129, 130]. The microgels segregated to silicone oil/water interfaces due to the hydrophilic amide and the hydrophobic isopropyl groups. Crosslinking of amine groups in the microgels resulted in stable shells of microgel, referred to as ‘colloidosomes’. Uniform sized colloidosomes were also produced using a microfluidics device [131].

Wu and Shen used dispersion polymerization of polyacrylamide to produce micron sized microspheres that could be crosslinked to form an injectable sealant. Some microspheres were copolymers of acrylamide with aminoethyl methacrylate, while others contained acetoacetoxyethyl methacrylate, which contains an ester that may be aminolysed. Upon mixing, the two types of microspheres reacted, forming a crosslinked gel within 90 seconds [132].

Kawaguchi and colleagues produced poly(NIPAAm) microgels by precipitation polymerization and used these to produce Janus particles. Janus particles have different chemistries on opposite halves of the particles. Carboxyl-containing poly(NIPAAm) microgels were used to stabilize an emulsion of hexadecane in water, with the microgels in essence serving as a surfactant. Activation of the carboxylic acids with a water-soluble carbodiimide and ethylenediamine promoted functionalization of the water-facing side of the microgels. The resulting microparticles were shown to stack into chains of microgels at pH 4 [133]. This suggests an ability to direct the self-assembly of microspheres into scaffolds with complex architectures.

Selected drug delivery applications

Thermally responsive microspheres have been used extensively for drug delivery applications and only a few examples will be described. Kiser et al. produced monodisperse microgels from methacrylic acid crosslinked with BIS by the precipitation polymerization methods of Kawaguchi. The anionic microgels were loaded with the cationic drug doxorubicin. The microspheres were deswelled in acidic solutions and coated with a phospholipid bilayer. Upon return to physiological pH, the microgels stayed at the dehydrated size until the lipid bilayer was broken by electroporation. The pH equilibrated rapidly after rupture of the membrane, the microgels swelled and the drug was released [134–136]. Positively charged, infrared absorbing gold nanorods have been attached to negatively charged poly(NIPAAm-co-acrylic acid) microgels, producing materials that underwent photothermally triggered swelling and drug release [137, 138]. Hoare and Pelton added an acrylated phenylboronic acid to poly(NIPPAAm) microgels produced by precipitation polymerization. The microgels were loaded with insulin and binding of glucose to the phenylboronic acid resulted in gel swelling that promoted insulin release [139].

Surface coatings from microspheres

Griffith and colleagues used a dispersion polymerization of methyl methacrylate in 1:1 ethanol:water to produce microspheres non-covalently coated with a PEG/methyl methacrylate copolymer surfactant. The surfactant was of high molecular weight and water-insoluble, and thus bound strongly to poly(methyl methacrylate) microspheres. The microspheres were then spin coated onto substrates and melted to form films. The films retained the PEG-containing stabilizer and thus had hydrophilic surfaces. The films resisted cell adhesion, unless a cell-adhesive RGD peptide was coupled to the stabilizer prior to the dispersion polymerization. The stabilizer itself could also be dissolved in ethanol/water and spin coated onto substrates, producing films that resisted non-specific cell adhesion. Microspheres containing RGD were embedded in continuous films of stabilizer that did not contain RGD, presenting cell adhesion peptide to cells at discrete locations [140].

Poly(NIPAAm-co-acrylic acid) microspheres were electrostatically coated on aminosilanated glass and assembled into polyelectrolyte multilayer structures with a polycation by Lyon and colleagues. The films were loaded with drug (doxorubicin or insulin) below the LCST, which was released rapidly by raising the temperature above the LCST to deswell the film [141, 142]. To reduce protein adsorption at physiological temperatures, PEG was added to the microgels. A two stage polymerization was used, with poly(NIPAAm) cores formed first and then ‘seeded’ with PEG macromonomer. However, protein adsorption to the microspheres was substantial unless high amounts of PEG were included in the core, without addition of a shell [143, 144]. The PEG/NIPAAm microgels were covalently coupled to poly(ethylene terephthalate) (PET) substrates (Figure 11B). The PET was modified in an argon plasma to introduce groups that produce free radicals to initiate polymerization of acrylic acid. The poly(acrylic acid) on the surface was activated with ethyl-3-[3-dimethyl amino] propyl carbodiimide (EDC) and N-hydroxysuccinimide (NHS) and coupled to an amine-containing benzophenone photoinitiator. Microgels were deposited on the surface by spin coating and coupled to the surface by exposure to UV light. The microgels were detected on the surface by AFM and resisted cell adhesion [145]. Following implantation in mice, fewer leukocytes adhered to the microgel-coated materials compared to uncoated PET [146]. Additional surface coatings based on responsive microgels have been reviewed [147].

Suspension polymerization with organic continuous phase

Suspension polymerization was first described in a German patent from 1931 [15]. The main advantage of suspension polymerization is better heat transfer, important due to high heats of polymerization, and the direct formation of a granular product that can be easily processed [15]. An early example of inverse suspension polymerization to produce hydrogel microspheres was the polymerization of dextran to produce a product now known as Sephadex [148, 149]. Aqueous solutions of dextran were suspended in toluene with poly(vinyl acetate) as a stabilizer and crosslinked with epichlorohydrin [150]. In another early study, dextran microspheres were produced by acrylating dextran and performing a free radical polymerization in water suspended in chloroform. Enzymes were trapped within the microspheres and retained about 50% of their activity. The enzymes were released in a controlled manner over a few months. The enzymes also demonstrated greater heat stability when trapped in the microspheres [151]. Since that time, water-in-oil suspension polymerizations have been so commonly practiced that the focus will be on a few biomaterials-related examples of the formation of poly(NIPAAm), poly(ethylene glycol), hyaluronic acid and gelatin microspheres. Alginate microsphere formation by suspension polymerization has recently been reviewed [152].

Although poly(NIPAAm) hydrogel microspheres are typically formed by precipitation polymerization, inverse suspension polymerization below the LCST is also possible. In 1985, Tanaka and colleagues found that polymerization of NIPAAm suspended in paraffin oil resulted in microspheres with diameters in the range 0.1–1.5 mm (note the large size compared to precipitation polymerization) [153]. Later, they also copolymerized NIPAAM and N-(acryloxy)succinimide, with hexane as the suspending medium, SPAN 20 as the emulsifier, and ammonium persulfate (APS) as the initiator. Swollen microspheres in the submicron range were found by dynamic light scattering after passage through a 5 µm filter. However, optical microscopy revealed the presence of microspheres with diameters of up to 240 µm in diameter. This illustrates the high polydispersity in size found with suspension polymerizations, which the authors mischaracterized as an inverse emulsion polymerization [154]. In 1988, Park & Hoffman produced poly(NIPAAm-co-acrylamide) microspheres by inverse suspension polymerization at room temperature. The suspending medium was paraffin oil, Pluronic L-81 was the emulsifier, and APS was the initiator, producing microspheres 200–400 µm in diameter. The microspheres entrapped the enzyme β-galactosidase, which was found to be active below the LCST of poly(NIPAAm) but inactive above the LCST [155].

Peppas and colleagues produced microspheres that were 50% by weight poly(ethylene glycol) by inverse suspension polymerization. Monomethoxypoly(ethylene glycol) monomethacrylate 1000 was copolymerized with methacrylic acid in water that was suspended in silicone oil. Tetraethyleneglycol dimethacrylate was used as a crosslinker, AIBN was the initiator and poly(dimethylsiloxane-b-ethylene oxide) was the surfactant. The surfactant had little effect on mean microsphere size (about 25 µm) but did reduce the size distribution [156]. Although AIBN is soluble in organic solvents, the sizes of the microspheres suggested an inverse suspension polymerization rather than an emulsion polymerization, perhaps due to partial solubility of the AIBN in water.

Inverse suspension polymerization is also commonly used to produce PEG-based peptide synthesis resins [157, 158]. Ulijn and colleagues started with these resins and synthesized peptides with balanced positive and negative charges at neutral pH. Under acidic conditions, the particles became positively charged and swelled. The swollen microspheres were incubated with protein solutions, trapping the proteins by returning to neutral pH. Upon enzymatic cleavage of the peptide with thermolysin, the particles again became charged, swelled, and released the loaded protein [159–161]. Degradable PEG-diacrylate has also been free-radical crosslinked after suspension in mineral oil. This produced PEG microspheres with average sizes in the range of ≈ 100–350 µm, which were used as porogens in poly(epsilon-caprolactone)-based scaffolds (Figure 12A) [162].

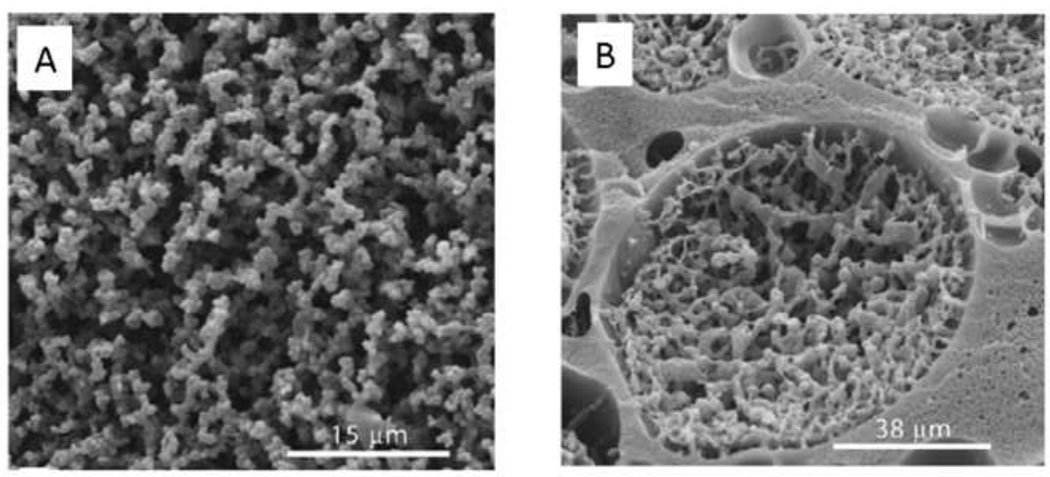

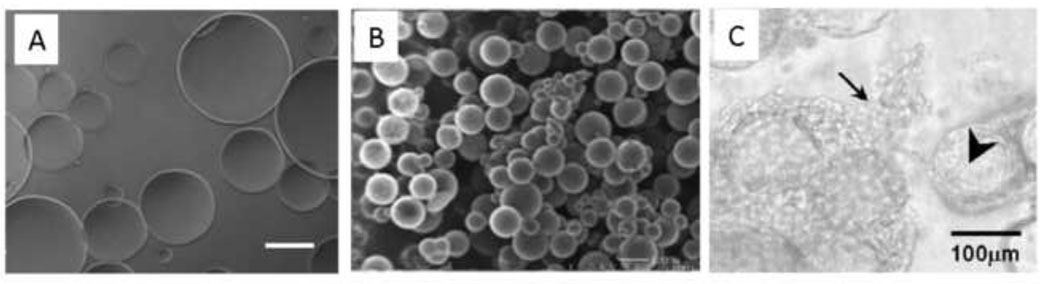

Figure 12. Microspheres formed by inverse (water-in-oil) suspension polymerization.

(A) PEG-sebacic acid-diacrylate microspheres free radical crosslinked in water suspended in mineral oil. Scale bar is 200 µm. From Kim et al., Tissue Engineering C, 15, 583, 2009. (B) Hyaluronic acid microspheres crosslinked in water suspended in mineral oil. Reprinted from Biomacromolecules, 7, Jia et al., “Hyaluronic Acid-Based Microgels and Microgel Networks for Vocal Fold Regeneration”, 3336–3344, Copyright 2006, with permission from Elsevier. (C) TGF-β1-loaded gelatin microspheres formed by suspension polymerization in olive oil (large arrow) and chondrocytes (small arrows), both polymerized in an oligo(poly(ethylene glycol)-fumarate) hydrogel. Reprinted from Biomaterials, 26, Park et al., “Delivery of TGF-β1 and chondrocytes via injectable, biodegradable hydrogels for cartilage tissue engineering applications”, 7095–7103, Copyright 2005, with permission from Elsevier.