Abstract

Our laboratory tested water samples used for cooling low-acid canned foods at a canning facility under investigation by the U.S. Food and Drug Administration. We used an enzyme-linked immunosorbent assay with digoxigenin-labeled antibodies (DIG-ELISA) and real-time PCR as screening methods and confirmed the presence of neurotoxin-producing Clostridium botulinum in the samples by mouse bioassay.

Clostridium botulinum, an anaerobic spore-forming bacterium, produces a family of botulinum neurotoxins (BoNTs) consisting of seven serotypes, A to G, which are the most potent natural food poisoning agents known. The neurotoxins are resistant to the acidic and protease-rich environment of the gastrointestinal tract (3, 4, 9-12), and their mechanism causes paralysis of the host. Serotypes A, B, and E are most commonly associated with illness in humans, whereas serotype F is implicated less often and serotypes C and D are rarely associated with human botulism (7). Serotype G has never been linked to human botulism (14). C. botulinum is the pathogen of concern for low-acid canned foods (LACF). The organism may be found in LACF if the cans are underprocessed or if the organism enters the can as a result of leakage after processing.

Recently, the U.S. Food and Drug Administration initiated an inspection at a Michigan company that manufactures a variety of LACF, including green beans and other vegetables. During the inspection, swollen and flat cans were collected and tested and viable neurotoxin-producing C. botulinum was found in flat cans of green beans. After this discovery, an expanded investigation began with a focus on can processing and can cooling. Ultimately, the investigation revealed several serious violations of LACF regulations as well as a finding of C. botulinum spores in the cooling water system.

During the course of the investigation, our laboratory received six water samples collected from the can-cooling water system and supply wells to test for C. botulinum spores. Our test protocol used three different methods for confirmation of the presence of C. botulinum organisms and/or neurotoxins. After spore concentration and enrichment culture, samples were screened by amplified enzyme-linked immunosorbent assay with digoxigenin-labeled antibodies (DIG-ELISA) to detect BoNTs of serotypes A, B, E, and F (8). After initial screening by DIG-ELISA, we confirmed the presence of C. botulinum in the water samples using the mouse bioassay, a sensitive method that detects both the presence and biological activity of the neurotoxin (13).

We also employed a real-time TaqMan PCR assay using previously published primers and probes specific for genes encoding type A, B and E neurotoxins and a newly developed primer and probe set specific for the type F neurotoxin gene. We compared the results of the PCR assay with those of DIG-ELISA and mouse bioassay.

Sample preparation and cultures.

Six 1-liter water samples (samples 4, 8, 10, 12, 14, and 16) were filtered using a 0.2-μm-pore-size nylon membrane. The filter from each sample was then transferred to a 50-ml conical tube containing 20 ml of distilled water and heat-shocked for 5 min at 80°C to induce spore germination. For culturing of bacteria, half of the filter and 10 ml of the distilled water were transferred into 100 ml each of Trypticase-peptone-glucose-yeast extract (TPGY) and cooked meat medium (CMM) and incubated anaerobically at 37°C for 72 h. Following incubation, the cultures were centrifuged at 13,840 × g for 10 min at 4°C. The resultant pellet was used for DNA extraction and subsequent real-time PCR, while the supernatant was used for screening by DIG-ELISA and for confirmation by the mouse bioassay.

Selective isolation of C. botulinum on botulinum selective medium (BSM).

CMM cultures from each water sample were inoculated by evenly spreading 100 μl on solid botulinum selective medium (BSM) prepared as described with the following exception: 50 U thymidine phosphorylase (Sigma) was added instead of 100 IU (5). Single colonies (four total, except for sample 16, which had only two colonies) were reinoculated into CMM and incubated anaerobically at 37°C for 72 h. As with the original cultures, these cultures were centrifuged and the resulting pellet and supernatant were used for DNA extraction and DIG-ELISAs.

DIG-ELISA and mouse bioassays.

Following centrifugation, the supernatant from the CMM and/or TPGY cultures was used for testing toxin production by DIG-ELISA. Toxicity of the supernatants was confirmed using the mouse bioassay. These methods were followed as described in the Bacteriological Analytical Manual (BAM) (13).

The remaining supernatant from the original CMM and TPGY cultures was mixed with an equal volume of gelatin phosphate buffer. The mixtures were then filtered through a 0.22-μm-pore-size syringe filter. For each mouse (two total), 0.5 ml of the sample was injected intraperitoneally. Mice were observed for symptoms of botulism and death over a 48-hour period (8, 13).

DNA extractions and quantification by real-time PCR.

DNA was extracted from the cell pellets harvested by centrifugation as described above using the MasterPure Gram-positive DNA purification kit (Epicentre Biotechnologies), and the purified genomic DNA was quantified by spectrophotometry. Real-time PCRs were carried out using the Platinum quantitative PCR supermix-UDG (Invitrogen) and a Smartcycler II real-time PCR system (Cepheid). Each reaction mixture was 25 μl and contained 1× Platinum quantitative PCR supermix-UDG, 300 nM primer, 100 nM probe, and ∼10 ng of purified genomic DNA. Thermal cycling parameters were set at 50°C for 2 min, 95°C for 2 min, and 45 cycles of 95°C for 15 s and 60°C for 30 s. For detection of type A, B, and E neurotoxin genes, we used primers and probe sets as previously described (1). For serotype F, we used a unique primer and probe set designed in our laboratory. The primer sequences for detection of the C. botulinum serotype F gene were as follows: forward, 5′-CCATCCAGTTACTAGAACTACAAG-3′; reverse, 5′-TCTAACGGGGTAAGAAGAATTTTC-3′; TaqMan probe, 5′-Cy5- AGGTCCTGCTCCCAATACAA-IowaBlackRQ-3′, where underlined nucleotides are locked nucleic acids.

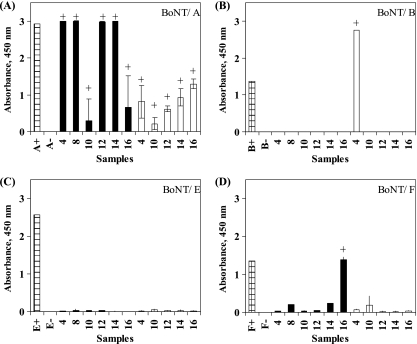

The initial screening of the enriched cultures by DIG-ELISA gave positive results for C. botulinum serotype A toxin in all six water samples (Fig. 1). In addition, sample 4 was positive for serotype B toxin from TPGY growth medium and sample 16 was positive for serotype F toxin from CMM growth medium. The mouse bioassay confirmed the presence of botulinum toxin in all CMM samples except for sample 10, and all samples were positive when grown in TPGY (Table 1). For the CMM enrichment of sample 10, the mice survived >48 h, indicating a negative result. However, the mice showed weak symptoms of botulinal neurointoxication, so perhaps the neurotoxin was present in amounts less than 1 mouse lethal dose. The real-time PCR analysis (Table 2) gave positive results for the gene encoding type A toxin from all water samples tested. Similarly to the ELISA results, no samples were positive for type E by real-time PCR analysis, and only one sample, sample 16, was positive for type F. In contrast to our ELISA results, all samples were positive for type B. It is possible that nonproteolytic type E bacteria were excluded from growth by incubation at 37°C. We chose to incubate at 37°C in order to maximize the serotypes captured by the assays, especially since type E bacteria are not likely to be associated with these types of samples due to their aquatic sediment-based ecology.

FIG. 1.

DIG-ELISA detection of C. botulinum serotypes A, B, E, and F. Water samples 4, 8, 10, 12, 14, and 16 were enriched in CMM (black bars) or TPGY (white bars), and the culture supernatant was analyzed by DIG-ELISA for neurotoxin serotype A (A), serotype B (B), serotype E (C), and serotype F (D). An A450 of >0.2 was considered positive (+) after the background and negative-control absorbance were subtracted from each sample.

TABLE 1.

Comparison of results from three methods for screening and confirmation of C. botulinum serotypes A, B, E, and Fa

| Sample | Original enriched cultures |

Selectively enriched cultures |

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mouse bioassay result | ELISA results |

Real-time PCR results |

ELISA results |

Real-time PCR results |

|||||||||||||

| A | B | E | F | A | B | E | F | A | B | E | F | A | B | E | F | ||

| Positive control | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + |

| Negative control | − | − | − | − | − | − | − | − | − | − | − | − | − | − | − | − | − |

| CMM samples | |||||||||||||||||

| Sample 4 | + | + | − | − | − | + | + | − | − | − | − | − | − | + | + | − | − |

| Sample 8 | + | + | − | − | − | + | + | − | − | + | − | − | + | + | + | − | − |

| Sample 10 | − | + | − | − | − | + | + | − | − | − | − | − | − | + | + | − | − |

| Sample 12 | + | + | − | − | − | + | + | − | − | + | − | − | − | + | + | − | − |

| Sample 14 | + | + | − | − | − | + | + | − | − | + | − | − | + | + | + | − | − |

| Sample 16 | + | + | − | − | + | + | + | − | + | + | − | − | + | + | + | − | − |

| TPGY samples | |||||||||||||||||

| Sample 4 | + | + | + | − | − | + | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND |

| Sample 8 | + | ND | ND | ND | ND | + | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND |

| Sample 10 | + | + | − | − | − | + | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND |

| Sample 12 | + | + | − | − | − | + | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND |

| Sample 14 | + | + | − | − | − | + | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND |

| Sample 16 | + | + | − | − | − | + | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND | ND |

Original enriched cultures used water samples enriched in CMM or TPGY; selectively enriched cultures were enriched on BSM solid medium. +, positive; −, negative; ND, data not determined for these samples.

TABLE 2.

Real-time PCR detection of C. botulinum serotypes A, B, E, and Fa

| Sample | Real-time PCR result (CT ± SD) |

|||||||

|---|---|---|---|---|---|---|---|---|

| Original enriched cultures |

Selectively enriched cultures |

|||||||

| A | B | E | Fb | A | B | E | F | |

| CMM samples | ||||||||

| Positive control | 20.87 ± 0.47 | 20.04 ± 0.33 | 16.34 ± 0.30 | 29.81 | 20.50 ± 0.49 | 21.29 ± 0.17 | 16.17 ± 0.14 | 27.89 ± 0.88 |

| No template | − | − | − | − | − | − | − | − |

| Sample 4 | 23.88 ± 0.21 | 38.19 ± 1.22 | − | − | 35.83 ± 0.06 | 38.85 ± 0.64 | − | − |

| Sample 8 | 23.30 ± 0.18 | 20.80 ± 0.19 | − | − | 21.80 ± 0.11 | 21.10 ± 0.06 | − | − |

| Sample 10 | 38.00 ± 0.71 | 37.95 ± 0.25 | − | − | 35.56 ± 0.01 | 39.42 ± 0.93 | − | − |

| Sample 12 | 23.38 ± 0.16 | 36.67 ± 0.08 | − | − | 20.16 ± 0.13 | 37.83 ± 0.45 | − | − |

| Sample 14 | 22.90 ± 0.36 | 20.12 ± 0.13 | − | − | 22.60 ± 0.13 | 22.73 ± 0.54 | − | − |

| Sample 16 | 38.80 ± 0.45 | 37.34 ± 0.01 | − | 29.94 ± 0.71 | 21.39 ± 0.16 | 38.98 ± 0.56 | − | − |

| TPGY samples | ||||||||

| Positive control | 19.31 ± 0.26 | ND | ND | ND | ND | ND | ND | ND |

| No template | − | ND | ND | ND | ND | ND | ND | ND |

| Sample 4 | 30.32 ± 0.06 | ND | ND | ND | ND | ND | ND | ND |

| Sample 8 | 34.90 ± 0.17 | ND | ND | ND | ND | ND | ND | ND |

| Sample 10 | 36.42 ± 1.59 | ND | ND | ND | ND | ND | ND | ND |

| Sample 12 | 35.57 ± 0.28 | ND | ND | ND | ND | ND | ND | ND |

| Sample 14 | 38.11 ± 0.93 | ND | ND | ND | ND | ND | ND | ND |

| Sample 16 | 24.10 ± 0.49 | ND | ND | ND | ND | ND | ND | ND |

Water samples 4, 8, 10, 12, 14, and 16 were analyzed by real-time PCR for genes encoding neurotoxin serotype A, serotype B, serotype E, and serotype F. See Table 1 for explanation of enrichments. Threshold cycle (CT) values are an average of results for two replicates and represent the cycle number at which the sample crossed the threshold of 8 fluorescence units. −, no CT value (i.e., no positive signal by real-time PCR); ND, data not determined for these samples.

Only one replicate was run for the positive control for this assay.

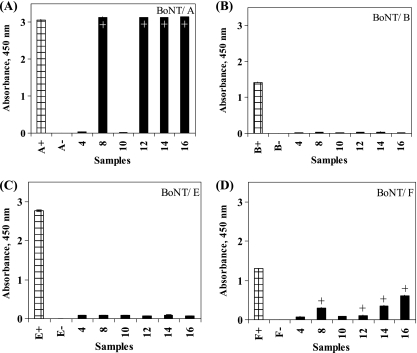

The colonies picked from BSM and subcultured in CMM for samples 8, 12, 14, and 16 were all positive for serotype A toxin when screened by DIG-ELISA (Fig. 2), and real-time PCR confirmed the presence of the serotype A toxin gene in these samples as well as in samples 4 and 10, which were not positive by DIG-ELISA. For samples 8, 14, and 16, DIG-ELISA also indicated the presence of serotype F toxin in the CMM subcultures. However, no positive results were observed for the serotype F toxin gene by real-time PCR on these samples. Real-time PCR did indicate the presence of the serotype B toxin gene in all of the CMM subcultures tested, despite no detection of the serotype B toxin in the DIG-ELISA for those subcultured samples.

FIG. 2.

DIG-ELISA detection of C. botulinum serotype A, B, E, and F neurotoxins from water samples selectively enriched in BSM medium. DIG-ELISA results for detection of neurotoxin serotype A (A), serotype B (B), serotype E (C), and serotype F (D). Each sample represents the average of results for two to four different colonies. Each bar representing an A450 of >0.2 was considered positive (+) after the background and negative-control signal were subtracted from each sample.

Our results clearly indicate that the water samples were contaminated by either a mixed culture of bacteria harboring different botulinum serotypes (A, B, and/or F) or possibly a single strain with the ability to produce multiple toxins (A/B- and/or A/F-producing strains). Indeed, the ability of certain C. botulinum strains to produce multiple toxin types is not unprecedented (2, 6). Toxin type can be identified and classified by using a toxin neutralization assay with homologous type-specific monovalent antitoxin. Additional experiments such as sequencing of the neurotoxin gene and the mouse neutralization assay are under way to characterize these strains.

Conclusions.

Detection of C. botulinum using the mouse bioassay is the only definitive and accepted method for regulatory samples that confirms both the presence and the biological functionality of BoNTs in contaminated samples. A more rapid method that can be used for screening of samples suspected of harboring C. botulinum is needed to ensure a prompt and accurate response in the event of an outbreak. The DIG-ELISA and real-time PCR assays can be completed more rapidly than the mouse bioassay and can be used to reduce the number of samples that require testing by the mouse bioassay.

The data from this study verify the presence of C. botulinum in the cooling water supply of a Michigan cannery using three distinct analytical methods. Clearly, the cooling water was a likely source of C. botulinum contamination for the LACF products. It is not unreasonable to expect that some very low number of C. botulinum spores might be present in well water, since this organism is known to be associated with soil. However, in this particular case, there was a rupture in an underground water line connecting the supply from two of the deep wells. This rupture went undetected for an unknown period of time and allowed the introduction of soil into the cannery's cooling water supply. The cooling water was not chlorinated. It is our belief that this caused the water to become contaminated with spores of C. botulinum in much greater numbers than would ordinarily be expected in water from a deep well. It is important to ensure the microbiological quality of can cooling water, to periodically monitor water quality, and to control the quality of can seams and to handle cans in a manner that protects the integrity of the double seam. If these measures are not taken, LACF may become contaminated with C. botulinum spores and result in a hazard to public health.

Acknowledgments

The views and opinions expressed by the authors are solely their own and do not necessarily represent the views or opinions of the Food and Drug Administration.

Footnotes

Published ahead of print on 1 October 2010.

REFERENCES

- 1.Akbulut, D., K. A. Grant, and J. McLauchlin. 2004. Development and application of real-time PCR assays to detect fragments of the Clostridium botulinum types A, B, and E neurotoxin genes for investigation of human foodborne and infant botulism. Foodborne Pathog. Dis. 1:247-257. [DOI] [PubMed] [Google Scholar]

- 2.Barash, J. R., and S. S. Arnon. 2004. Dual toxin-producing strain of Clostridium botulinum type Bf isolated from a California patient with infant botulism. J. Clin. Microbiol. 42:1713-1715. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Fu, F. N., S. K. Sharma, and B. R. Singh. 1998. A protease-resistant novel hemagglutinin purified from type A Clostridium botulinum. J. Protein Chem. 17:53-60. [DOI] [PubMed] [Google Scholar]

- 4.Li, L., T. Binz, H. Niemann, and B. R. Singh. 2000. Probing the mechanistic role of glutamate residue in the zinc-binding motif of type A botulinum neurotoxin light chain. Biochemistry 39:2399-2405. [DOI] [PubMed] [Google Scholar]

- 5.Mills, D. C., T. F. Midura, and S. S. Arnon. 1985. Improved selective medium for the isolation of lipase-positive Clostridium botulinum from feces of human infants. J. Clin. Microbiol. 21:947-950. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Santos-Buelga, J. A., M. D. Collins, and A. K. East. 1998. Characterization of the genes encoding the botulinum neurotoxin complex in a strain of Clostridium botulinum producing type B and F neurotoxins. Curr. Microbiol. 37:312-318. [DOI] [PubMed] [Google Scholar]

- 7.Shapiro, R. L., C. Hatheway, and D. L. Swerdlow. 1998. Botulism in the United States: a clinical and epidemiologic review. Ann. Intern. Med. 129:221-228. [DOI] [PubMed] [Google Scholar]

- 8.Sharma, S. K., J. L. Ferreira, B. S. Eblen, and R. C. Whiting. 2006. Detection of type A, B, E, and F Clostridium botulinum neurotoxins in foods by using an amplified enzyme-linked immunosorbent assay with digoxigenin-labeled antibodies. Appl. Environ. Microbiol. 72:1231-1238. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Sharma, S. K., F. N. Fu, and B. R. Singh. 1999. Molecular properties of a hemagglutinin purified from type A Clostridium botulinum. J. Protein Chem. 18:29-38. [DOI] [PubMed] [Google Scholar]

- 10.Sharma, S. K., and B. R. Singh. 2000. Immunological properties of Hn-33 purified from type A Clostridium botulinum. J. Nat. Toxins 9:357-362. [PubMed] [Google Scholar]

- 11.Singh, B. R., J. Foley, and C. Lafontaine. 1995. Physicochemical and immunological characterization of the type E botulinum neurotoxin binding protein purified from Clostridium botulinum. J. Protein Chem. 14:7-18. [DOI] [PubMed] [Google Scholar]

- 12.Singh, B. R., B. Li, and D. Read. 1995. Botulinum versus tetanus neurotoxins: why is botulinum neurotoxin but not tetanus neurotoxin a food poison? Toxicon 33:1541-1547. [DOI] [PubMed] [Google Scholar]

- 13.Solomon, H. M., and T. Lilly, Jr. Accession date: 18 June 2009. Clostridium botulinum, chapter 17. In G. J. Jackson, R. I. Merker, and R. Bandler (ed.), Bacteriological analytical manual, 8th ed. U.S. Food and Drug Administration, Center for Food Safety and Applied Nutrition, College Park, MD. http://www.fda.gov/Food/ScienceResearch/LaboratoryMethods/BacteriologicalAnalyticalManualBAM/UCM070879.

- 14.Sonnabend, O., W. Sonnabend, R. Heinzle, T. Sigrist, R. Dirnhofer, and U. Krech. 1981. Isolation of Clostridium botulinum type G and identification of type G botulinal toxin in humans: report of five sudden unexpected deaths. J. Infect. Dis. 143:22-27. [DOI] [PubMed] [Google Scholar]