Abstract

The objective of the present work was to carry out a systematic evaluation of flow of pharmaceutical powders and granules using compendial and non-compendial methods. Angle of repose, bulk density, tapped density, Carr’s compressibility index, and Hausner ratios were evaluated. Additionally, flow was characterized using a powder rheometer in which a sensitive force transducer monitors the forces generated as a result of the sample displacement. The critical attributes such as cohesivity index, caking strength, and flow stability were determined for samples. The samples consisted of different grades of magnesium stearate powder including bovine, vegetable, and food grade, physical mixture powder blend consisting of a model formulation, granules prepared by various methods including slugging, high shear granulator, and fluid bed dryer. Lubricant efficiency was also determined for granules lubricated with various concentrations of magnesium stearate. It was observed that the compendial methods were often non-discriminating for minor variations in powder flow. The additional characterization such as cohesivity, and caking strength were helpful in understanding the flow characteristics of pharmaceutical systems. The flow stability test determined that the powders were not affected by the test conditions on the rheometer. The non-compendial tests were discriminating to even minor variations in powder flow.

Key words: caking strength, cohesivity, flow stability, powder flow, powder rheometer

INTRODUCTION

Powder flow is a key requirement for pharmaceutical manufacturing process. Tablets are often manufactured on a rotary multi-station tablet press by filling the tablet die with powders or granules based on volume. Thus, the flow of powder from the hopper into the dies often determines weight, hardness, and content uniformity of tablets. In case of capsules manufacturing, similar volume filling of powders or granules is widely used. Understanding of powder flow is also crucial during mixing, packaging, and transportation. And thus, it becomes essential to measure the flow properties of these materials prior to tabletting or capsule filling.

There are various methods available to measure the powder flow. The compendial methods include measurement of angle of repose (1), bulk density, tapped density (2) Carr’s compressibility index (3), or Hausner ratio (4). With technological advances, innovative methods of characterization of powder flow such as cohesivity determination (5), avalanching determination (6), shear cell (7,8), dielectric imaging (9), atomic force microscopy (10), and penetrometry (11). These methods suffer from various limitations including reproducibility, performance conditions, and predictability. For instance, powder flow measurement by angle of repose and avalanching has limitations for very cohesive powder which doesn’t flow through the funnel and vibrating the funnel introduces inherent variability in measurement technique. The other compendial methods of powder flow characterization which includes measurements of bulk and tap density which is semi-quantitative. Shear tests have widespread use in engineering and soil industries, however, is very time consuming and not very reproducible for elastic powders. Another powder flow measurement method includes use of photovoltaic array with patented technology named “Aero-Flow” (12). However, it suffers from a major limitation which includes narrowness of the disk which makes significant particle-wall friction and is not a true representation of pharmaceutical mixing or filling process. So far no single test has been accepted as a standard for measurement of powder flow.

Very recently powder rheometers are also being investigated to measure powder flow (13,14). The method is indicated to explain potential impact of processing factors on particulate systems. The principle of the instrument includes force-displacement measurement through the powder bed. In this work, we build on the proposed technology offered by Texture technologies (Scarsdale, NY) to determine the flow behavior of powders and granules and compare with compendial methods of characterizing powder flow by measuring angle of repose, Carr’s compressibility index, Hausner ratio, bulk and true density measurements.

In the manuscript, flow behavior of powders is measured. Cohesivity of powders influences the flow of powders and sometimes causes difficulties in powder flow. However, static charges during filling operations cause very fine powders to flow off and therefore moderate cohesivity is sometimes desirable, especially if the fines contain an active pharmaceutical ingredient. The quick and easy measurement of cohesivity of powders will thus be very useful which can be done on the powder rheometer. In addition, the tendency of the powder to agglomerate or form lumps is measured using caking test. This test simulates the caking behavior of powders during storage or transportation. The effect of test speeds and angles on powders is measured using powder flow speed dependence test. It also measures the flow stability during various testing.

MATERIALS AND METHODS

Chemicals

Ibuprofen (IBU, Albemarle, Orangeburg, SC, USA), microcrystalline (MCC, Emcocel®, JRS Rettenmaier & Soehne, Rosenburg, Germany), lactose monohydrate (LMH, Foremost, Rothschild, WI, USA), and hypromellose (HPMC, E15 MethocelTM LV, Dow Chemical, Midland, MI, USA) were purchased. Vegetable-based magnesium stearate (code 2257), bovine-based magnesium stearate (MgSt-B, code 2256), and food grade magnesium stearate (MgSt-F, code 5716) were obtained from Mallinckrodt Inc. (Hazelwood, MO, USA). All materials were used “as received” after passing through standard US no. 20 mesh sieves.

Preparation of Powder Blends

Product intermediates for tablet preparation were obtained by four different methods: physical mixture and granules obtained by slugging, dry granulated methods; granules prepared by fluid bed and high-shear mixer, wet granulated methods. The model formulations consisted of IBU (25%), MCC (25%), LMH (50%), and HPMC (2.4%). The physical mixtures were prepared by mixing the ingredients in a v-blender in 6,000 g batches (2L Miniblend, GlobePharma, New Brunswick, NJ). In case of slugging, the slugs in a batch size of 6,000 g were compressed to 12 mm diameter (1 g, hardness 3 to 4 kP) by adding only half of MCC initially on MiniPress-I (GlobePharma) tablet press and subsequently, milling in a Comil (U3, Quadro Inc., Milburn, NJ) followed by sieving and blending with the remaining MCC. The wet granulated formulations were prepared by spraying water to physical blends and subsequently wet screening, drying and dry screening through standard US mesh No. 20 sieve in 750 g batches. High-shear mixer (KG5, Key International Inc, Englishtown, NJ), and fluid bed dryer (GEA Niro, Soeborg, Denmark) were used. The batch size was 1,000 g per run.

The above formulations (500 g) were lubricated with the MgSt-B or MgSt-V powders at 0.5% in a v-blender at 30 RPM for 5 min. The fluid bed granules were lubricated at 0.25, 1, and 1.5% MgSt-B to determine lubricant efficiency.

Flow Measurements

Flow properties were measured on MgSt-B, MgSt-V, and MgSt-F grades and powder blends. Table I presents some of the physical characteristics of various grades of MgSt.

Table I.

Particle Size, Specific Surface Area, and Moisture Content of Various Grades of MgSt

| Code | Particle Size 50th % (μm)a | Particle Size 90th % (μm)a | Specific Surface Area (m2/g)a | Average Moisture Content % (Karl–Fisher methodb) |

|---|---|---|---|---|

| 2256 (MgSt-B) | 13.6 | 24.4 | 7.0 | 5.55 ± 0.11 |

| 2257 (MgSt-V) | 13.7 | 25.2 | 6.1 | 5.54 ± 0.07 |

| 5716 (MgSt-F) | 9.6 | 17.3 | 7.5 | 5.58 ± 0.14 |

aThe data was obtained from manufacturer’s certificate of analysis

bKarl–Fisher method (USP) was used to determine the moisture content

Angle of Repose

The angle of repose is the angle formed by the horizontal base of the bench surface and the edge of a cone-like pile of granules. Funnel used was a stainless steel funnel and the size of the orifice was 10 mm and the height from the beginning of funnel to end of orifice was 111 mm. The funnel was fixed in place, 4 cm above the bench surface. After the cone from 5 g of sample was built, height of the granules forming the cone (h) and the radius (r) of the base were measured. The angle of repose (θ) was calculated as follows:

|

1 |

Results were only considered valid when a symmetrical cone of powder was formed.

Bulk Density and Tapped Density

Bulk and tapped densities were determined using the methods outlined in the USP (2). Samples (9–13 g) of MgSt were passed through a no. 18 sieve into a pre-weighed 25 ml graduated cylinder with 0.5 ml markings. The bulk volume was measured after manually tapping the cylinder two times on a flat table top surface. The tapped volume was measured with the Electrolab ETD-1020 Tap Density Tester (GlobePharma) after tapping in increments of 500, 750 and 1250 taps with 250 drops per minute.

Compressibility Index and Hausner Ratio

The bulk and tapped densities were used to calculate the Carr’s compressibility index (3) (Eq. 2) and the Hausner ratio (4) (Eq. 3) to provide a measure of the flow properties and compressibility of MgSt powders.

|

2 |

|

3 |

where ρtap is the tap density and ρbulk is the bulk density.

Powder Rheometer from Texture Analyzer

Powder flow measurements were performed on texture analyzer with powder flow analyzer attachment (TAXT.Plus, Texture technologies, Scarsdale, NY). Approximately 10–15 g of material equivalent to 30 in 35 ml graduated cylinder was used. Samples consisted of unlubricated and lubricated material with 0.5% MgSt-B and MgSt-V. The sample was introduced into the sample holder by taking care not to lose any powder due to static charges or flying off. Fines were allowed to settle by resting the cylinders for 15 min. The test was done in triplicates. Change in person and day-to-day variations were evaluated as a preliminary study before beginning of this study. It was found to be user independent. Temperature and humidity of the room were within very narrow range.

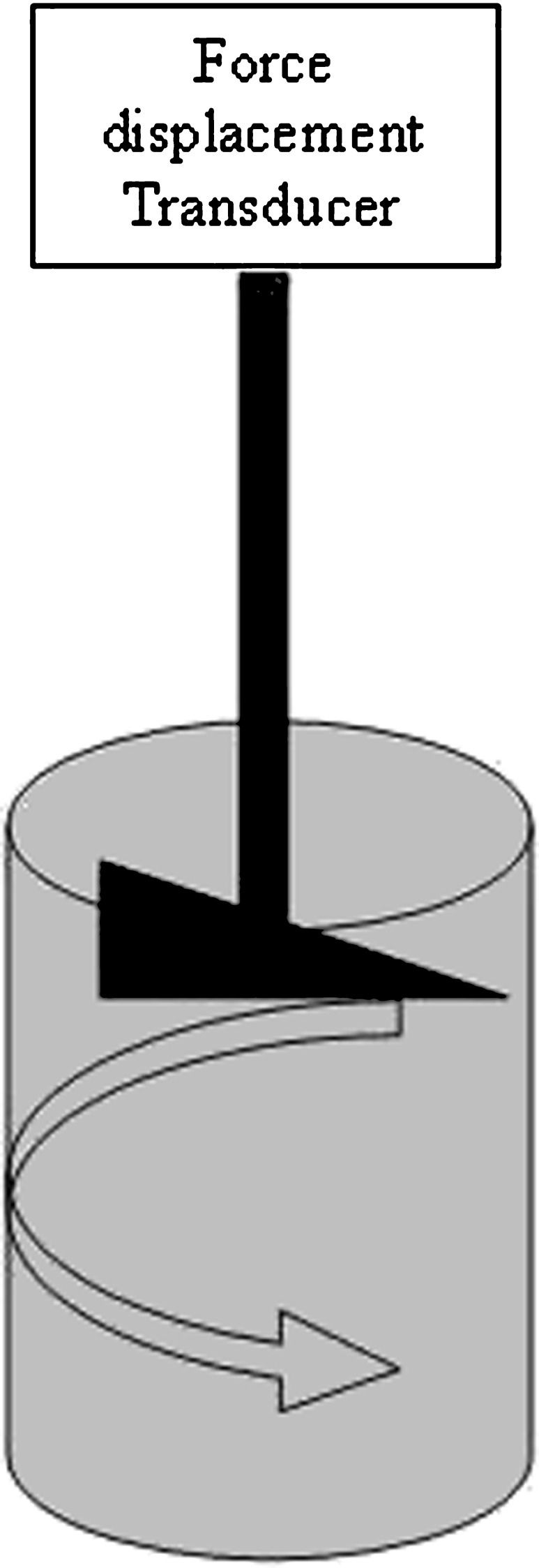

A sensitive force transducer monitors the reactive forces caused by the sample displacement due to a rotor rotating clockwise or anticlockwise while passing up or down through the sample. A rotor carrying a specific blade is passed through the sample, to prepare/condition and then assess the sample’s flow properties (Fig. 1). The twisted or helical shaped blade having two regions is mounted. The first region has an angle formed by its surface with respect to a plane perpendicular to the rotation axis achieved by extending the surface from first region parallel to the rotational axis. The second region spaced from the axis of rotation has a second angle which is also formed by its surface plane perpendicular to the axis of rotation. The blade is designed such that it can cut through the column of the powder bed reproducibly without an aid of torque systems. Conventional blade shapes with large flat central area give rise to undesirable powder compression below the blade. However, the effect is not seen with the helical design (15).

Fig. 1.

Schematic of powder flow analyzer demonstrating helical path of the blade

Work done (mJ) by the rheometer as it moves up and down the powder bed is measured which is the area under the curve in a force vs distance plot. The positioning of anchor points is important in determining the relevance and accuracy of the calculated work done. The first step is to condition the powder so as to remove any variability due to filling of the samples in the cylinder.

Conditioning of the powder

During the conditioning cycles, the rotor is moved down through the powder column twice at a tip speed of 50 mm/s and an angle of 175°, and then back up through the powder at 50 mm/s and 178°.

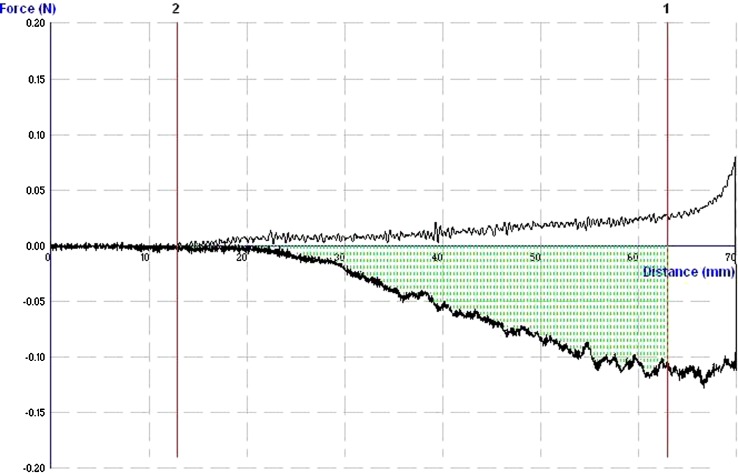

Cohesion test

The test is made up of downward movement of probe at 20 mm/s at 175° and then upward movement at 75 mm/s. The Cohesion (as the rotor moves up and lifts and separates the powder) is recorded from the first two cycles and averaged. The area under the force vs distance curve is calculated and is divided by the weight of the sample to obtain cohesivity index value.

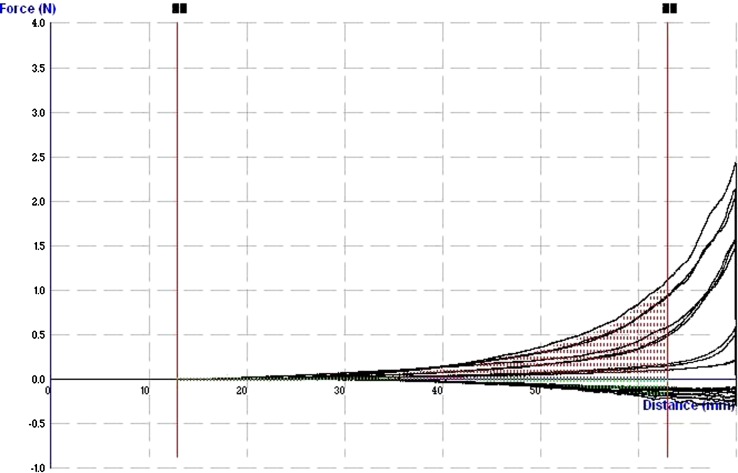

Caking test

The rotor moves to a force of 5 g at 20 mm/s and 2°. This step levels off the powder and allows to record the rate at which the column height reduces during the caking process. Once target force is reached, the data is recorded as it moves down through the powder column at 20 mm/s and 20° until it reaches a force of 500 g. Then the rotor moves upwards at 10 mm/s and 45° subjecting powder column to minimum displacement. This is repeated for five compactions. At the end, the rotor slices through the compacted cake recording hardness of the cake, i.e. the force required to get the compacted powder flowing freely. Finally the rotor moves back to the top. The data analysis is done using the data on column height at the start of each compaction cycle, the distance at the point the final 500 g force is reached (the cake height) for each cycle, and finally the mean force and work required (g.mm) to slice through the caked area. Cake height ratios (ratio of the initial column height) and also the cake strength (both as the mean force and also the work required—the area under the curve) are calculated.

Powder Speed Flow Dependence (PFSD) test

The rotor moves down through the powder column at 10 mm/s and 5°. The data is recorded to measure the resistance of the powder to being pushed at a controlled flow, i.e. the interparticle friction of the powder. At the bottom of the powder column, the rotor slices through the powder to avoid hard compact. The rotor then moves up through the powder at 20 mm/s twice followed by two cycles of 50 mm/s, two cycles at 100 m/s, and two cycles at 10 mm/s. The analysis is performed on both the positive (force vs distance) and negative areas. The average is taken for the two areas for the compaction (as the rotor moves down through the powder column) at each flow rate. These are recorded as the compaction coefficient at 10, 20, 50 and 100 mm/s. The compaction coefficient for the final two cycles at 10 mm/s is averaged and ratio with that from the initial two cycles at 10 mm/s to assess whether the powder has broken down during the testing to get a value of PFSD. A value close to 1 means it has not changed at all during the testing. If the figure is >1 means the product has changed during testing (giving a higher compaction coefficient) if <1 means it has changed giving it a lower compaction coefficient.

Statistical Analysis

For all the data sets F test performed to test for homogeneity of variances. The variance for each sample set was calculated and the F test was carried out in Excel program with chosing variable 1 as the one with highest variance. Then F and Fcritical values were determined with level of significance of <0.05. If F > Fcritical, the variance between two sample sets was significantly different, whereas when F < Fcritical, the variance was equal. Statistical analysis was performed using a single factor ANOVA or unpaired Student’s t test for equal variance A p value of <0.05 was considered as statistically significant.

RESULTS AND DISCUSSION

The present work compared the compendial methods which are widely used in pharmaceutical field to measure the powder flow and was compared with the non-compendial novel methods.

Compendial Powder Flow Measurements

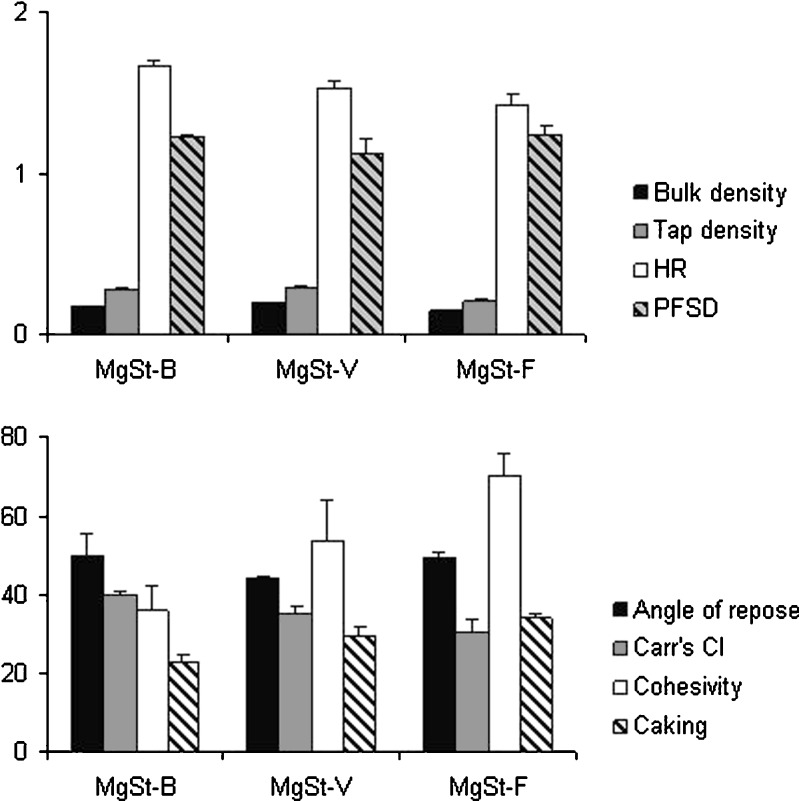

Bulk and tapped density of different grades of raw materials were measured and the results are presented in Fig. 2. It was found that food grade of MgSt had lower bulk and tap densities as compared to that of bovine or vegetable sources. Also it was found that the measurements were highly dependent on amount of sample and since the volumetric measurements are obtained visually, it is highly variable from analyst to analyst.

Fig. 2.

Powder flow analysis of different grades of MgSt. Units of measurements are bulk density (g/cc), tap density (g/cc), angle of repose (deg), caking strength (g.mm), cohesivity index (mm−1)

The Carr’s compressibility index (CI, %) and Hausner ratio (HR) were also calculated based on the equations presented in Eqs. 2 and 3 and are presented in Fig. 2 for MgSt powder. The CI and HR were found to be lower for MgSt-F grade as compared to MgSt-B and MgSt-V grades. This is in accordance with density measurements. CI is a measure of powder bridge strength and stability, and the Hausner ratio (HR) is a measure of the interparticulate friction. Flow character is rated based on compressibility index and Hausner ratio (3,4). Lower CI or lower Hausner ratios of a material indicate better flow properties than higher ones. A Carr’s CI of <10 or HR of <1.11 is considered ‘excellent’ flow where as CI > 38 or HR > 1.60 is considered ‘very very poor’ flow. There are intermediate scales for CI between 11–15 or HR between 1.12–1.18 is considered ‘good’ flow, CI between 16–20 or HR between 1.19–1.25 is considered ‘fair’ flow, CI between 21–25 or HR between 1.26–1.34 is considered passable flow, CI between 26–31 or HR between 1.35–1.45 is considered ‘poor’ flow, and CI between 32–37 or HR between 1.46–1.59 is considered ‘very poor’ flow (3,4). If powders are readily compressed by tapping, their flow energy requirement increases. Based on the results obtained, flow of MgSt-F was rated as ‘poor’, that of MgSt-V was rated as ‘very poor’, and MgSt-B was considered to be ‘very very poor’ in terms of its flow based on CI and HR values.

The angle of repose, a traditional characterization method for pharmaceutical powder flow, is also used in other branches of science (i.e. geology) to characterize solids. The height of the granules forming the cone, h and the radius, r of the base were measured. The angle of repose (θ) was calculated from Eq. 1 and are shown in Fig. 2 for different grades of MgSt. Flowability is indicated based on the angle of repose (1). A value of <30° indicates ‘excellent’ flow whereas >56° indicates ‘very poor’ flow. The intermediate scale indicates ‘good’ (θ between 31–35°), ‘fair’ (θ between 36–40°), ‘passable which may hang up’ (θ between 41–45°), and ‘poor which must be agitated or vibrated’ (θ between 46–55°). Based on this, the flow was rated as ‘poor, must agitate or vibrate’ for MgSt-B and MgSt-F grade whereas MgSt-V was rated as ‘passable, may hang up’. Thus flow for MgSt-F was better as compared to other two grades based on CI and HR. However, based on the angle of repose results, MgSt-V was better than other two grades. This discrepancy might be due to very qualitative nature of the scale of measurements and ratings for flow properties based on these compendial methods.

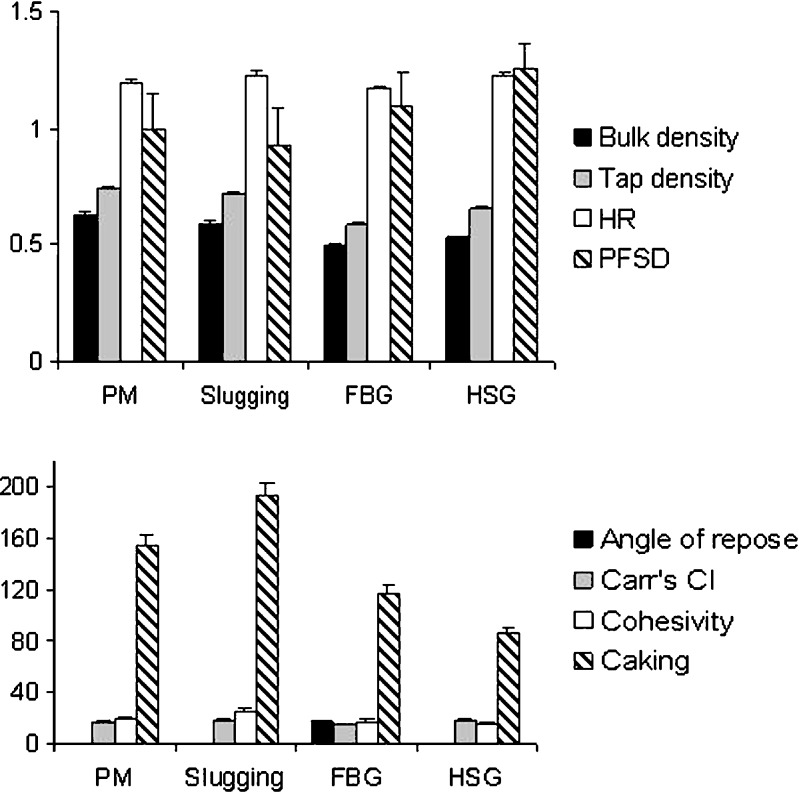

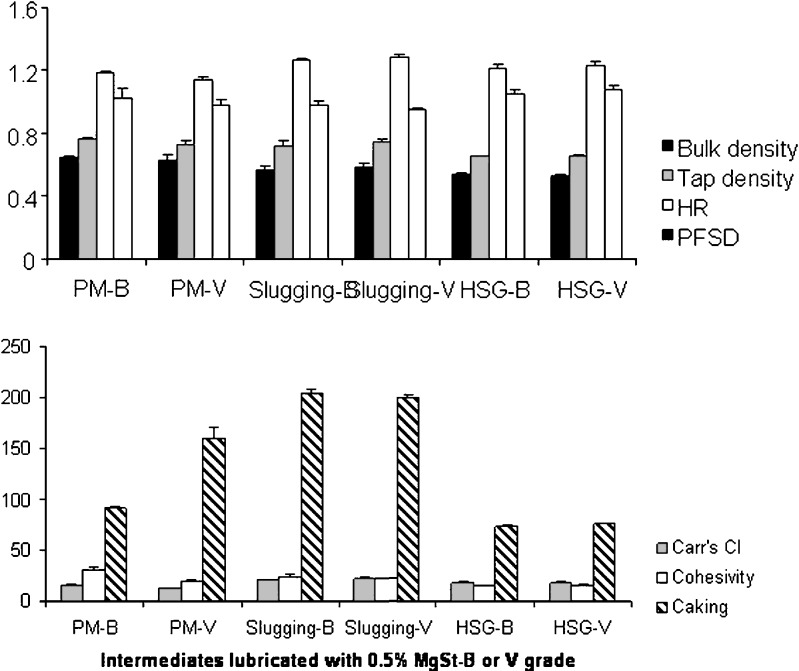

Model intermediates were also characterized for flow properties using the conventional methods. The results are presented in Fig. 3. Based on CI and HR values obtained, the flow was rated as ‘fair’ for physical mixture, slugged granules as well as granules prepared by high shear mixer. The flow was rated as ‘good’ only for granules prepared by fluid bed. However when comparing lubricant efficiency of 0.5% MgSt-B and MgSt-V grades for these intermediates, as depicted in Fig. 4, the flow became from ‘fair’ to ‘good’ only for physical mixture as compared to unlubricated material. There was no change in flow character for lubricated and unlubricated granules prepared by fluid bed or high shear. In case of slugged materials, addition of lubricant made the flow worse based on compendial test results as the rating went down to ‘passable’ from ‘fair’.

Fig. 3.

Powder flow analysis of unlubricated intermediates. Units of measurements are same as in Fig. 2

Fig. 4.

Comparison of lubricant efficiency of MgSt-B and MgSt-V for intermediates. Units of measurements are same as in Fig. 2

Magnesium stearate is a very widely used lubricant. It is a cohesive material and therefore helps to avoid powder dust during filling and thus improving the flow properties, when added in small quantities above which it might deteriorate the flow. Also it improves the wall friction. Since the tests outlined in the manuscript measures cohesiveness and caking tendency of powder blends, the lubricant was chosen to see the effect on these two parameters at various concentrations as well as from various sources.

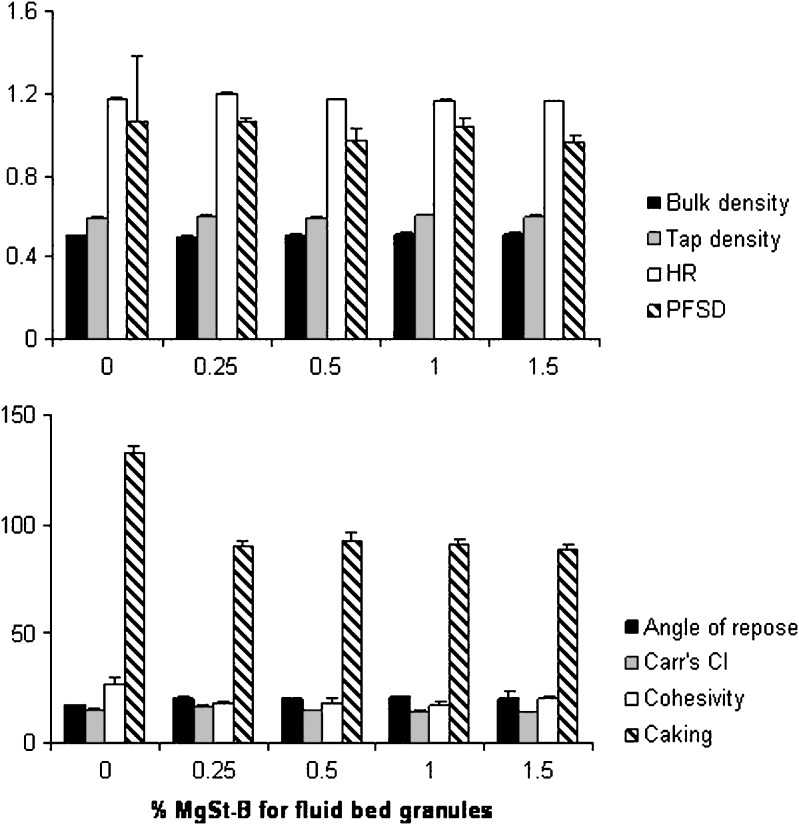

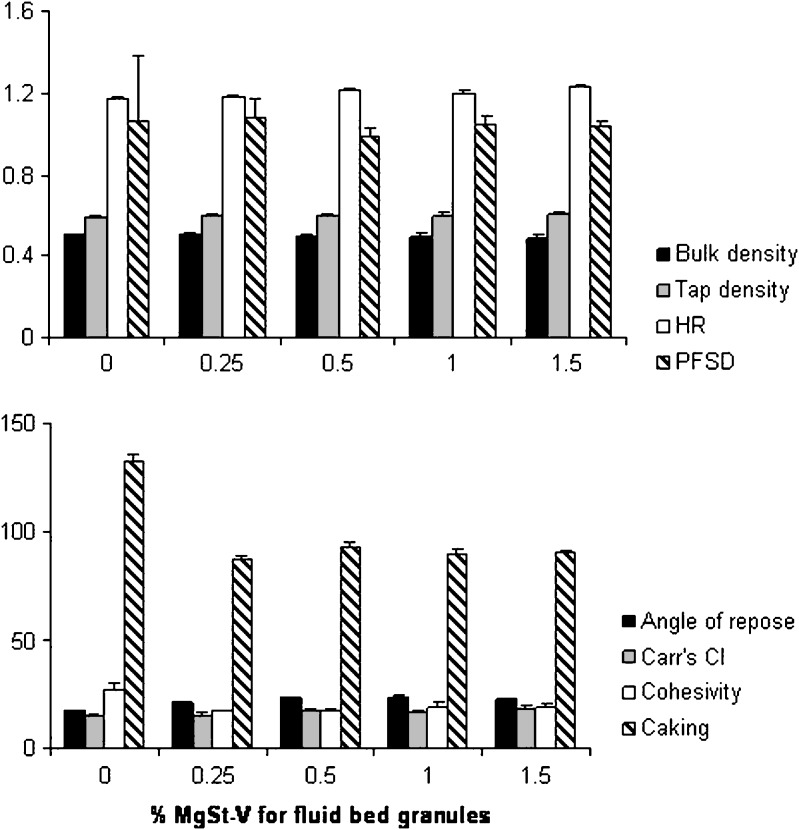

Lubricant efficiency in terms of flow enhancement was also determined for granules prepared by fluid bed method for MgSt-B and MgSt-V grades. The percent of MgSt evaluated was 0, 0.25, 0.5, 1, and 1.5% for both grades are results are presented in Figs. 5 and 6, respectively for bovine and vegetable grades. There was no statistically significant difference except for 0.25% concentration for MgSt-B grade in terms of CI and HR values (Fig. 5). Thus, 0.5, 1, and 1.5% of MgSt-B did not change the flow properties of the granules as determined by compendial methods. However, in case of granules lubricated with MgSt-V showed a different flow pattern with increasing concentrations of lubricant (Fig. 6). Unlubricated granules showed better flow based on CI and HR ratios as compared to any of the unlubricated granules. Whereas, angle of repose test showed that the θ value increased from 0 to 0.25% MgSt-V concentration but after that up to 1.5%, it remained constant implying that the flow improved with low amounts of lubricant after which there was no change.

Fig. 5.

Lubricant efficiency of MgSt-B for fluid bed granules. Units of measurements are same as in Fig. 2

Fig. 6.

Lubricant efficiency of MgSt-V for fluid bed granules. Units of measurements are same as in Fig. 2

Thus, it was observed that the compendial tests are sometimes non-discriminating while assessing the minor differences in granule flow with lubricant. Therefore, a novel method using powder rheometer was used to characterize the flow of these preparations.

Non-compendial Powder Flow Measurements

Powder rheometer with force-displacement transducer was used for measuring the cohesivity, caking ability and strength, and flow stability of powders and granules as described in earlier sections (Fig. 1).

Cohesivity of powders causes difficulties in powder flow. Cohesivity index measurement is the quick analysis which allows rapid and repeatable quantification of the cohesiveness of the bulk solid. Cohesion-controlled flow determines whether the large majority of technologically important powders will fluidize, cake, flow out of hoppers and blenders, fill small cavities in compression and encapsulation systems, mix, or segregate. Based on the cohesivity index obtained, flow behavior can be rated as free flowing (<11), easy flowing (11–14), cohesive (14–16), very cohesive (16–19), and extremely cohesive (>19; Texture technologies). A typical force-displacement profile for cohesivity test is shown in Fig. 7. Two conditioning cycles were also performed at the beginning to remove any variation in the powder due to loading into the cylinder from the container. The effective area of interest is highlighted by dotted AUC within the zone of interest between 1 and 2. The program has in built macro to run the test and analyze the results at the end of the run. MgSt samples were analyzed for cohesivity and all the grades were found to be extremely cohesive (Fig. 2). The moisture content of all of the MgSt grades was about 5.4% as determined by Karl–Fisher titration as depicted in Table I (Mettler Toledo DL38, Columbus, OH). Thus the extreme cohesive nature of MgSt causes the difficulty in powder flow. For intermediates, it was seen that physical mixture and slugged granules were extremely cohesive also. Whereas granules prepared by fluid bed or high shear methods were cohesive and easy flowing, respectively (Fig. 3). Addition of lubricant, 0.5% MgSt-B or MgSt-V did not affect the cohesivity of the granules except those for fluid bed (Fig. 4). For FBG, there was statistically significant difference for lubricated versus unlubricated material. The cohesivity index went down from unlubricated granules to lubricated with 0.25% of MgSt-B or MgSt-V (Figs. 5 and 6). However after that concentration, the cohesivity index remained constant.

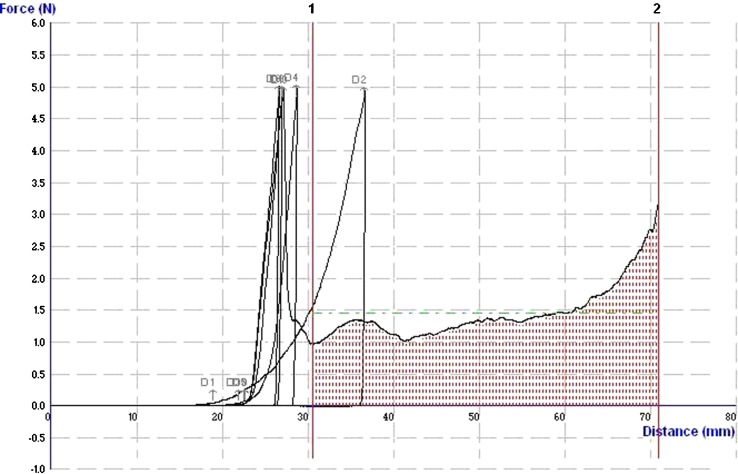

Fig. 7.

Typical force-displacement profile for a cohesion test on powder rheometer

Powder flow stability distribution (PFSD) was analyzed to quantify the dependence of flow characteristics on flow rate for powders. It also measured flow stability or how the powder breaks down during testing. A typical force-displacement profile for PFSD test is shown in Fig. 8. The effective area of interest is highlighted by dotted AUC within the zone of interest between 1 and 2. For all the materials tested, PFSD remained at around 1 exhibiting stable powder flow (Figs. 2, 3, 4, 5, and 6). This implied that the powders will not break down during testing. The granules also exhibited greater stability implying that they did not break down into smaller fragments with the movement of the blade through the powder. This was important to determine as in case of other compendial tests such as tapped density, due to frictional and abrasive forces, granules might break down during the test, and hence, might not be a true measure of the granule flow. Whereas powder rheometer does not impart such forces, and thus are considerably ‘gentle’ for the samples and can give reliable results.

Fig. 8.

Typical force-displacement profile for a powder flow stability test on powder rheometer

Caking strength was measured to evaluate potential of above samples to form a cake and the forces required to cut through the cake formed which would determine the strength of the cake. Greater is the strength, more will be a tendency to form a hard cake which is not easy to redisperse. This also explains the segregation potential of the powders where transportation of powder or granule blends might cake and thus ultimately result in variability in tablets or capsules. Also cohesive nature of powders determines the caking tendency. A typical force-displacement profile for caking strength test is shown in Fig. 9. The powder is first compacted five times using 500 g force and then the blade slices through the powder cake formed. The compression cycle is depicted as the downward movement of the probe and lifting is depicted as the upward movement of the probe. The area under the curve is integrated in the force displacement profile which will represent the work done by the blade to overcome the resistance to its movement through the cake which is considered as caking strength. The effective area of interest is highlighted by dotted AUC within the zone of interest between 1 and 2. As consistent with cohesivity results, for MgSt-F, the cake strength was highest as compared to other grades of MgSt raw materials (Fig. 2). Also for intermediates, physical mixture and slugged granules had higher cake strength as compared to fluid bed or high shear granules (Fig. 3). In all cases, lubrication reduced the cake strength (Figs. 4, 5, and 6) implying better redispersibility with addition of lubricant. It was also observed that for fluid bed granules, addition of 0.25% MgSt-B or MgSt-V grades reduced the cake strength significantly after which there was no change even up to 1.5% concentration (Figs. 5 and 6). Thus 0.25% concentration seems to be optimum to improve the redispersibility of the cake.

Fig. 9.

Typical force-displacement profile for a caking strength test on powder rheometer

Reproducibility of the test was evident from the triplicate run results. The particle size, shape, and moisture content of each of the ingredient was variable and this might contribute to a small deviations in the reading which was observed. The instrument factors were not responsible, which was confirmed during preliminary experiments where the same sample which once was filled in the cylinder was subjected to the tests three times. The same sample showed results which were within 0.1% of each other. However, this does not represent true sampling, authors used three different samples coming out of the same blend, which might have contributed to some variability in the results. However, all the readings were found to fall within 5%.

Moisture content, shape, surface area, and particle size along with palmitate content and other fatty acids present in the magnesium stearate might have an important role in determining the lubricity of a powder batch (16). From Table I it is clear that there was no significant difference in terms of particle size, area or moisture content. Therefore, one possible explanation seen might be due to differences in fatty acid contents, surface tension, and charge. Since the purpose of this manuscript was not to find out the causes for differences between various grades of MgSt but to evaluate the ability of rheometer to discern the subtle differences in terms of lubricity, only the later was evaluated in the study.

CONCLUSIONS

Determination of powder flow was aided by using powder rheometers to understand the cohesivity and caking tendency of powders which gives a fundamental understanding of the characteristics of powder flow. In addition to compendial methods which included angle of repose, densities of powders, compressibility index, and Hausner ratio, non-compendial methods were determined which are important quality attributes in terms of powder flow.

Acknowledgements

The authors wish to thank Mazen Hamad, Abhay Gupta, and Christopher Ellison from the division for their assistance.

Footnotes

The opinions expressed in this work are only of authors, and do not necessarily reflect the policy and statements of the FDA.

References

- 1.USP. <1174> Powder flow. USP30 NF 25 (2007).

- 2.USP. <616> Bulk density and tapped density. USP30 NF 25 (2007).

- 3.Carr R. L. Evaluating flow properties of solids. Chem. Eng. 1965;72:69–72. [Google Scholar]

- 4.Hausner H. H. Friction conditions in a mass of metal powder. Int. J. Powder Metall. 1967;3:7–13. [Google Scholar]

- 5.Faqih A., Chaudhuri B., Alexander A. W., Davies C., Muzzio F. J., Silvina T. M. An experimental/computational approach for examining unconfined cohesive powder flow. Int. J. Pharm. 2006;324:116–127. doi: 10.1016/j.ijpharm.2006.05.067. [DOI] [PubMed] [Google Scholar]

- 6.Hancock B. C., Vukovinsky K. E., Brolley B., Grimsey I., Hedden D., Olsofsky A., Doherty R. A. Development of a robust procedure for assessing powder flow using a commercial avalanche testing instrument. J. Pharm. Biomed. Anal. 2004;35:979–990. doi: 10.1016/j.jpba.2004.02.035. [DOI] [PubMed] [Google Scholar]

- 7.Jenike A. W. Storage and flow of solids. Utah Eng. Exp. Stn. Bull. 1964;123:1–194. [Google Scholar]

- 8.Ramachandruni H., Hoag S. W. Design and validation of an annular shear cell for pharmaceutical powder testing. J. Pharm. Sci. 2001;90:531–540. doi: 10.1002/1520-6017(200105)90:5<531::AID-JPS1010>3.0.CO;2-U. [DOI] [PubMed] [Google Scholar]

- 9.Dyakowski T., Luke S. P., Ostrowski K. L., Williams R. A. On-line monitoring of dense phase flow using real time dielectric imaging. Powder Technol. 1999;104:287–295. doi: 10.1016/S0032-5910(99)00106-0. [DOI] [Google Scholar]

- 10.Weth M., Hoffman M., Kuhn J., Frick J. Measurement of attractive forces between single aerogel powder particles and the correlation with powder flow. J. Non-Cryst. Solids. 2001;285:236–243. doi: 10.1016/S0022-3093(01)00460-4. [DOI] [Google Scholar]

- 11.Zatloukal Z., Sklubalova Z. Penetrometry and estimation of the flow rate of powder excipients. Pharmazie. 2007;62:185–189. [PubMed] [Google Scholar]

- 12.Kaye B. H., Gratton-Limatainen J., Lloyd J. The effect of flow agents on the rheology of a plastic powder. Part Syst. Charact. 1995;12:194–197. doi: 10.1002/ppsc.19950120406. [DOI] [Google Scholar]

- 13.Lindberg N. O., Palsson M., Pihl A. C., Freeman T., Zetzener H., Enstad G. Flowability measurements of pharmaceutical powder mixtures with poor flow using five different techniques. Drug Dev. Ind. Pharm. 2004;30:785–791. doi: 10.1081/DDC-120040343. [DOI] [PubMed] [Google Scholar]

- 14.Navaneethan C. V., Missaghi S., Fassihi R. Application of powder rheometer to determine powder flow properties and lubrication efficiency of pharmaceutical particulate systems. AAPS PharmSciTech. 2005;6:E398–E404. doi: 10.1208/pt060349. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.C. M. Iles, I. D. Bateson, and J. A. Walker. Rheometer. US Patent 6,481,267B1. Stable Microsystems Ltd (2002).

- 16.Miller T. A., York P. Physical and chemical characteristics of some high purity magnesium sterate and palmitate powders. Int. J. Pharm. 1985;23:55–67. doi: 10.1016/0378-5173(85)90222-4. [DOI] [Google Scholar]