Abstract

PURPOSE

Marginal fit is a very important factor considering the restoration's long-term success. However, adding porcelain to copings can cause distortion and lead to an inadequate fit which exposes more luting material to the oral environment and causes secondary caries. The purpose of this study was to compare the marginal fit of 2 different all-ceramic crown systems before and after porcelain veneering. This study was also intended to verify the marginal fit of crowns originated from green machining of partially sintered blocks of zirconia (Lava CAD/CAM system) and that of crowns obtained through machining of fully sintered blocks of zirconia (Digident CAD/CAM system).

MATERIALS AND METHODS

20 crowns were made per each system and the marginal fit was evaluated through a light microscope with image processing (Accura 2000) at 50 points that were randomly selected. Each crown was measured twice: the first measurement was done after obtaining a 0.5 mm coping and the second measurement was done after porcelain veneering. The means and standard deviations were calculated and statistical inferences among the 2 groups were made using independent t-test and within the same group through paired t-test.

RESULTS

The means and standard deviations of the marginal fit were 61.52 ± 2.88 µm for the Digident CAD/CAM zirconia ceramic crowns before porcelain veneering and 83.15 ± 3.51 µm after porcelain veneering. Lava CAD/CAM zirconia ceramic crowns showed means and standard deviations of 62.22 ± 1.78 µm before porcelain veneering and 82.03 ± 1.85 µm after porcelain veneering. Both groups showed significant differences when analyzing the marginal gaps before and after porcelain veneering within each group. However, no significant differences were found when comparing the marginal gaps of each group before porcelain veneering and after porcelain veneering as well.

CONCLUSION

The 2 all-ceramic crown systems showed marginal gaps that were within a reported clinically acceptable range of marginal discrepancy.

Keywords: Marginal fit, Digident CAD/CAM Zirconia Ceramic Crown, Lava CAD/CAM Ceramic Crown, Porcelain veneering

INTRODUCTION

The final aim of restorative dentistry is to fabricate restorations which are indistinguishable from natural teeth and ceramics are the material of choice when aesthetic restorations that mimic natural dentition are demanded.

Not only esthetic but strength and accuracy of fit are also required in an all-ceramic crown. Despite all-ceramic crowns are regarded as being theoretically strong, they tend to be relatively weak in practice, particularly under tensile strength. Their accuracy of fit has also been variable when constructed by existing methods.1

Accuracy of fit is considered a very important factor when fabricating a crown. An inadequate fit creates a potential space between the restoration and the prepared tooth. As this space increases, more luting material is exposed to the oral environment. Because most dental cements are soluble, bacterial plaque can easily accumulate in this defective area, which in turn can result in gingival inflammation, caries and pulpal lesions. In addition to that, variations in the fit can create stress concentrations which may reduce the strength of the restoration and consequently cause its fracture.2

Variations exist regarding what constitutes a clinically acceptable margin and several authors have attempted to determine margins that are imperceptible to the naked eye and undetectable with a sharp explorer. It has been reported that the all ceramic crowns show a mean marginal discrepancy that ranges from 19 to 160 µm.1-6 McLean and von Fraunhofer proposed that a restoration would be successful if marginal gaps and cement thickness of less than 120 µm could be achieved.7

Advances in dental ceramic materials and processing techniques have helped increasing the strength and improving the fit of ceramic restorations. Among them, CAD (computer-aided design)/CAM (computer-aided manufacturing) and milling technology have facilitated the development and application of superior dental ceramics.8

In the Digident CAD/CAM system, the digitization of the models of prepared teeth is performed without contact by a white light stripe projection technique in the optical high precision scanner DigiScan L. The fabrication of copings is done through a construction software and the calculated numerical control files are transferred to the 4-axis milling machine DigiCut. The DigiCut milling device works motion-free and without vibrations to machine the final desired framework shape from a fully sintered block of partially stabilized dense zirconia (HIP: hot isostatic pressing).9

On the other side, Lava CAD/CAM system includes an optical scanner (Lava Scan), a computerized milling machine (Lava Form) and a sintering oven (Lava Therm). A partially sintered block of yttrium tetragonal zirconia polycrystal (Y-TZP) is milled producing an enlarged framework structure to compensate for shrinkage during the sintering process.10

These copings are subsequently veneered with their respective ceramic material to produce the final restoration. During the porcelain veneering, the crown undergoes multiple firing procedures and they can be distorted causing misfit.2

Therefore, the purpose of this study was to investigate and compare the marginal fit of 2 different CAD/CAM all-ceramic crown systems before and after porcelain veneering. This study was also intended to verify the marginal fit of crowns originated from green machining of partially sintered blocks of yttrium tetragonal zirconia polycrystal followed by a sintering process (Lava CAD/CAM system) and crowns obtained through machining of fully sintered blocks of HIP zirconia (Digident CAD/CAM system).

MATERIALS AND METHODS

One extracted maxillary central incisor without caries was cleaned and its root was embedded in an autopolymerizing resinmanufactured block (Orthodontic resin; Dentsply International Inc, Milford, Del). The long axis of the tooth was set perpendicular to the surface of the block.

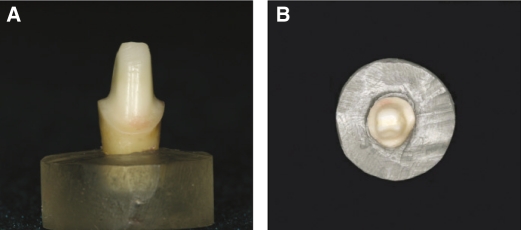

The tooth was prepared for all-ceramic crown fabrication. Using a high-speed handpiece, incisal reduction of 2-3 mm and axial reduction of approximately 1 mm were done. The tooth was finished by milling (F2; Degussa, Hanau, Germany), which resulted in about a 1 mm shoulder margin with 6° tapered angles and an approximate height of 7 mm (Fig. 1).

Fig. 1.

The prepared maxillary central incisor embedded in a self-curing resin block. A: labial view, B: incisal view.

A preliminary impression was made using irreversible hydrocolloid impression material (Aroma fine; GC Corp, Tokyo, Japan), and a plaster (Samwoo plaster; Samwoo Corp, Seoul, Korea) cast was made.

After obtaining the relief of 2 sheets of baseplate wax (Modeling wax; Pemaco Inc, St. Louis, MO) on the plaster cast, 40 custom-made trays were fabricated using acrylic resin (Quicky; Nissan Dental Products Inc, Kyoto, Japan). Final impressions were made with polyvinyl siloxane (Examixfine; GC America Inc, Alsip, IL) using custom trays and 40 master stone dies were fabricated (Rhombrock; Mitsubishi, Tokyo, Japan).

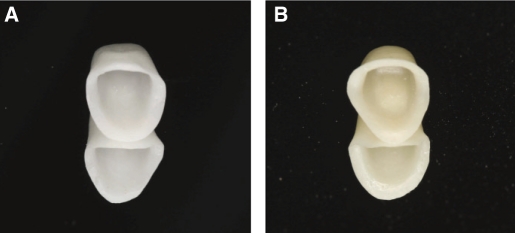

Initially, forty copings (20 copings per group) of 0.5 mm were fabricated: 20 Digident CAD/CAM zirconia copings (Girrbach Dental, Pforzheim, Germany) and 20 Lava CAD/CAM zirconia copings (3M ESPE Dental Products, Seefeld, Germany) (Fig. 2).

Fig. 2.

A: Digident CAD/CAM zirconia coping, B: Lava CAD/CAM zirconia coping.

In order to verify the influence of porcelain veneering on the marginal fit of the crown, each one had its marginal fit measured in 2 different stages of the crown fabrication: the first measurement was done after obtaining the coping and the second measurement was done after the veneering process. The first measurement of each group served as the baseline, and the changes in the marginal fit of copings after the firing cycles were evaluated.

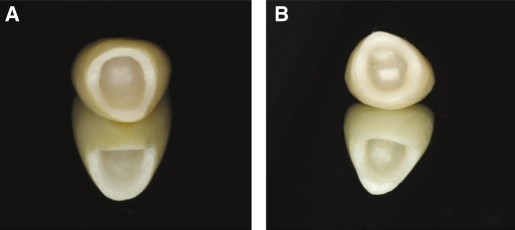

Following the first measurement, specific porcelain of the Lava CAD/CAM system (Lava Ceram; 3M ESPE Dental Products, Seefeld, Germany) and Digident CAD/CAM system (Creation CP ZI; Creation Willi Geller International AG, Baar, Switzerland) were veneered on the correspondent coping by one experienced dental technician who was accustomed to both systems. These crowns underwent 3 firing cycles which was considered a typical number for a clinical case. After the veneering process, the second measurement of the marginal fit was achieved (Fig. 3).

Fig. 3.

A: Digident CAD/CAM zirconia ceramic crown, B: Lava CAD/CAM zirconia ceramic crown.

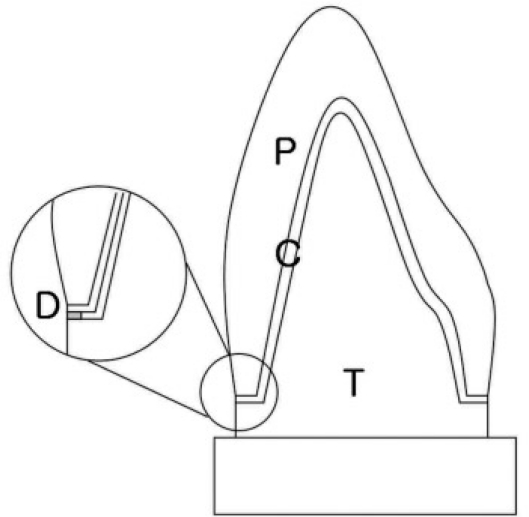

The marginal fit was evaluated by measuring the gap between the edge of the coping/crown and the prepared tooth margin in a light microscope with image processing (Accura 2000, INTEK PLUS, Daejon, Korea) at × 240 magnification (Fig. 4).

Fig. 4.

The light microscope with image processing (Accura 2000).

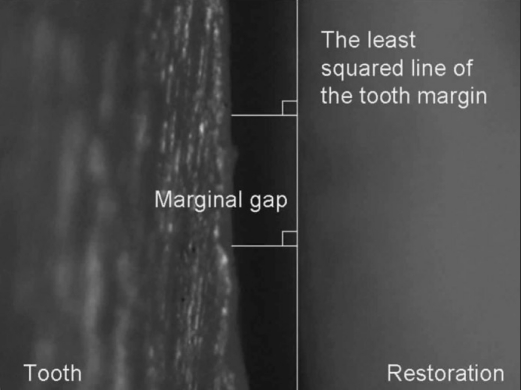

The accuracy of this light microscope was ± 0.1 µm. The gap was measured as the minimum distance from one point of the coping/crown edge to a line determined by least squares of points at the tooth margin (Fig. 5 and 6). All measurements and the least squared lines were computed by the programmed macro provided by Accura 2000 software system. Measurements were made without cementation. The marginal gap of one coping/crown was measured at 50 points along the margin that were randomly selected in distances of about 400 µm. The marginal fit of one coping/crown was defined as a mean value of these 50 measurements.

Fig. 5.

Drawing shows sites in which measurements were done. (D), minimum distance from one point of the coping/crown edge to the tooth margin; (C) coping; (P) porcelain; (T) tooth.

Fig. 6.

Captured image of tooth/restoration interface.

The means and standard deviations per group were calculated and statistical inferences among the 2 groups were made using t-test at 0.05 level of significance. Paired t-test was performed at 0.01 level of significance to compare marginal fit before and after the veneering of porcelain within the same group. It was possible to obtain a more definite statistical inference and analysis by enough sample size, sufficient measurements and proper variable control.

RESULTS

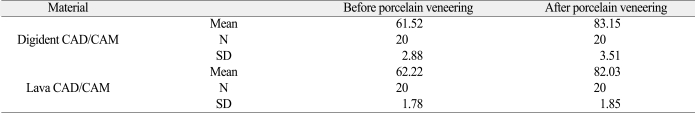

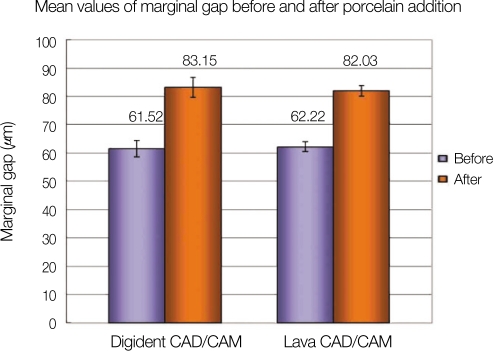

Table 1 and Fig. 7 show the means and the standard deviations of marginal fit in each of the groups.

Table 1.

The means and standard deviations of marginal fit in each of the groups (unit µm)

Fig. 7.

Captured image of tooth/restoration interface.

The means and standard deviations of the marginal fit were 61.52 ± 2.88 µm for the Digident CAD/CAM zirconia ceramic crowns before porcelain veneering and 83.15 ± 3.51 µm after porcelain veneering. Lava CAD/CAM zirconia ceramic crowns showed means and standard deviations of 62.22 ± 1.78 µm before porcelain veneering and 82.03 ± 1.85 µm after porcelain veneering.

The absolute amount of change of the marginal fit of Digident CAD/CAM zirconia ceramic crowns and Lava CAD/CAM zirconia ceramic crowns were analyzed through t-test. Significant differences were not found between groups.

Marginal gaps of Digident CAD/CAM zirconia ceramic crowns and Lava CAD/CAM zirconia ceramic crowns before porcelain veneering were compared as well as their marginal gaps after porcelain veneering. No significant differences were found between groups.

Paired t-test was performed to analyze the marginal gaps before and after porcelain veneering within each group. Both groups showed significant differences (P = .00).

DISCUSSION

Along with several factors, marginal accuracy is an important criterion of quality of fixed prosthodontics.11 Beschnidt and Strub stated that the evaluation of the marginal discrepancy of crowns depends on factors such as: measurements of cemented or not-cemented crowns, storage time and treatment (such as aging procedures) after cementation, kind of abutment used for measurements, kind of microscope and enlargement factor used for measurements, location and quantity of single measurements.12

When measuring the marginal gap after cementation, the same number of teeth or steel dies as that of restoration sample is needed because of the control of variables. On the other hand, only one tooth or steel die is needed if the measurement is done without a luting agent. Some investigators4,12,13 found a significant increase in the marginal discrepancy after cementation. These results, however, varied according to the luting agent. The marginal fit was, therefore, measured without cementation for a more sophisticated variable control in this study.

There are no definite standards for the proper sample size and number of measurements for each sample size. In many articles, nonparametric statistical analysis was used in evaluating the marginal gap because it was very difficult to obtain normal distribution of the data. When the sample size was 10, non-parametric analysis was chose in marginal gap measurement because standard deviations were relatively large compared with mean values, resulting in failure when acquiring normality. However the parametric analysis is more reliable in evaluating the original population than the non-parametric one. On the statistical side, parametric tests are advocated if normality of the data of the samples can be obtained. When the sample size is high (at least 20), the distribution of data is usually normal.14 The number of measurement points per crown used in previous studies has varied considerably. Groten et al suggested that 50 measurements along the margin of a crown yield clinically relevant information and a consistent estimate for the gap size and it was of minor importance whether 50 measurements along the margin were randomly selected or recorded in distances of about 400 µm (strategic 50 measurements).15 Conversely, Gassino et al. reported that minimum number of measurements required to ensure relevant results for gap analysis was 18 for experimental crowns.16 In the present study, unlike many studies that had sample sizes varying from 5 to 10, 20 specimens for each test group and 50 measurements per sample in random manner were selected for a more accurate result.

In order to get the complete crown form, porcelain was veneered on the milled coping. Balkaya et al., when analyzing the influence of firing cycles on the marginal fit of all-ceramic crowns, did not apply porcelain to an area approximately 0.5 to 1 mm wide at the coping margin for precision of measurement.2 In this study, the conventional method of porcelain veneering used in clinical situations was conducted to obtain more clinical results.

It should be noted that there are varieties among the zirconia material used by different systems. The Lava CAD/CAM system utilizes a presintered block of zirconia that undergoes a green machining approach while Digident CAD/CAM system utilizes a HIP zirconia block which is milled from its fully sintered state. Although all of these materials have the same chemical composition, there are differences in strength and translucency based on the chosen powder type and the production conditions.17

It is said that during milling of dense sintered HIP zirconia blocks, there is the danger of provoking unwanted surface and structural defects on the ceramic. Caused by diamond burs, these can negatively affect the marginal fit of the crowns.17 However, in this experiment no statistically significant differences were found among the marginal openings of the Lava CAD/CAM system that utilizes partially sintered zirconia and Digident CAD/CAM system that utilizes fully sintered zirconia.

In vitro studies have revealed mean marginal gaps of 64 - 83 µm in CAD/CAM- generated all-ceramic single tooth restorations.18 Hertlein et al. investigated the marginal fit of the Lava All Ceramic System for anterior and posterior teeth with a chamfered preparation margin under a stereomicroscope and the marginal adaptation was reported to vary between 40 µm and 70 µm.19 Reich et al. reported the clinical fit of CAD/CAM fabricated all-ceramic three-unit fixed partial dentures. The investigated systems were Digident, Cerec InLab and Lava CAD/CAM system. The reported marginal gaps were 75 µm for Digident, 65 µm for Lava and Cerec InLab18. Opposed to that, the marginal gaps recorded in the present study were 82 µm for Lava CAD/CAM system and 83 µm for Digident CAD/CAM system.

A clinical study of 1000 restorations over a 5 year-period concluded that 120 µm is the maximum clinically acceptable marginal misfit. It indicated that 50 µm opening might be difficult to achieve clinically.7 Therefore, the marginal gaps recorded in the present study were all within this clinically acceptable standard.

Regarding the effect that porcelain veneering has on the marginal fit, several authors reported various results on the matter. Balkaya et al., in their study, compared the marginal fit of 3 all-ceramic systems: conventional In-Ceram, copy-milled In Ceram and copy-milled feldspathic crowns. The results showed that the porcelain firing significantly altered the marginal fit of these crowns. They concluded that the copings were not completely stable during the porcelain firing cycle and that the distortion that occurred might have been due to nonuniform porcelain mass. These crowns however, exhibited no significant differences during the glaze firing.2 Gemalmaz and Alkumru obtained results that showed a small increase in the metal-ceramic crown's gap size after firing body porcelain and this distortion was most evident during the first firing cycle.20 Castellani et al. compared gaps of all-ceramic crowns with those of porcelain-fused-to-metal (PFM) crowns and concluded that the firing cycles had significantly different effects on the vertical discrepancy. They also concluded that allceramic crowns were more sensitive to repeated porcelain firing cycles than were PFM restorations.21 Hung et al., in their study, concluded that thermocycling changed the marginal discrepancies of all three crown types they tested.4

On the contrary, Shearer et al. proved the copings to be stable through multiple firing cycles and that the method of porcelain build-up was acceptable. They conducted paired comparisons within groups showing that porcelain addition did not materially alter the fit of copings.1 Song et al. also concluded that the reduction in marginal precision was not significantly different in Auro Galvano crowns after the baking procedure.24 In the present study however, marginal gaps of the Digident CAD/CAM system and Lava CAD/CAM system showed to be significantly different after the porcelain veneering on their copings.

This difference may be explained by the fact that during the porcelain veneering procedure, particles of porcelains melt and gather to fill up voids and the resulting contraction of the porcelain mass causes a compressive force on the coping.22 The deformation of the coping under the stress of contracting porcelain is spread around the whole circumference of the margin. Nevertheless, it must be noted that the marginal openings of these crowns after the porcelain veneering are within clinically acceptable standards and that the amount of distortion suggests no inferences to the detriment of clinical application.

The differences between the results of the present study and those of other studies may be related to the different methods of measurements, different types of microscope and magnification, different location23 and number of measurements, and the use of different luting agents12.

There were some limitations in this study. Despite marginal gaps were measurable through this experimental design, internal gaps were not, since cementation and sectioning of specimens are required for such measurement. The specimens were also not submitted to an aging process which simulates oral conditions.4 Further investigations are needed to measure both the marginal and internal fits and to evaluate the influence of the aging process on the margin distortion.

CONCLUSION

Within the limitations of this study, the following conclusions could be drawn:

There were no significant differences in the marginal discrepancy among the 2 all-ceramic crown systems.

Porcelain veneering showed to have a statistically significant influence on the marginal fit of the 2 all-ceramic crown systems, however it suggests no inferences to the detriment of clinical application.

The 2 all-ceramic crown systems showed marginal gaps that were within a reported clinically acceptable range of marginal discrepancy.

References

- 1.Shearer B, Gough MB, Setchell DJ. Influence of marginal configuration and porcelain addition on the fit of In-Ceram crowns. Biomaterials. 1996;17:1891–1895. doi: 10.1016/0142-9612(95)00302-9. [DOI] [PubMed] [Google Scholar]

- 2.Balkaya MC, Cinar A, Pamuk S. Influence of firing cycles on the margin distortion of 3 all-ceramic crown systems. J Prosthet Dent. 2005;93:346–355. doi: 10.1016/j.prosdent.2005.02.003. [DOI] [PubMed] [Google Scholar]

- 3.Davis DR. Comparison of fit of two types of all-ceramic crowns. J Prosthet Dent. 1988;59:12–16. doi: 10.1016/0022-3913(88)90098-4. [DOI] [PubMed] [Google Scholar]

- 4.Hung SH, Hung KS, Eick JD, Chappell RP. Marginal fit of porcelain-fused-to-metal and two types of ceramic crown. J Prosthet Dent. 1990;63:26–31. doi: 10.1016/0022-3913(90)90260-j. [DOI] [PubMed] [Google Scholar]

- 5.Vahidi F, Egloff ET, Panno FV. Evaluation of marginal adaptation of all-ceramic crowns and metal ceramic crowns. J Prosthet Dent. 1991;66:426–431. doi: 10.1016/0022-3913(91)90499-m. [DOI] [PubMed] [Google Scholar]

- 6.Pera P, Gilodi S, Bassi F, Carossa S. In vitro marginal adaptation of alumina porcelain ceramic crowns. J Prosthet Dent. 1994;72:585–590. doi: 10.1016/0022-3913(94)90289-5. [DOI] [PubMed] [Google Scholar]

- 7.McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971;131:107–111. doi: 10.1038/sj.bdj.4802708. [DOI] [PubMed] [Google Scholar]

- 8.McLaren EA, Terry DA. CAD/CAM systems, materials, and clinical guidelines for all-ceramic crowns and fixed partial dentures. Compend Contin Educ Dent. 2002;23:637–641. [PubMed] [Google Scholar]

- 9.Steger T. Digident CAD/CAM production-growing with the possibilities. Int J Comput Dent. 2004;7:77–84. [PubMed] [Google Scholar]

- 10.Piwowarczyk A, Ottl P, Lauer HC, Kuretzky T. A clinical report and overview of scientific studies and clinical procedures conducted on the 3M ESPE Lava All-Ceramic System. J Prosthodont. 2005;14:39–45. doi: 10.1111/j.1532-849X.2005.00003.x. [DOI] [PubMed] [Google Scholar]

- 11.Gardner FM. Margins of complete crowns-literature review. J Prosthet Dent. 1982;48:396–400. doi: 10.1016/0022-3913(82)90072-5. [DOI] [PubMed] [Google Scholar]

- 12.Beschnidt SM, Strub JR. Evaluation of the marginal accuracy of different all-ceramic crown systems after simulation in the artificial mouth. J Oral Rehabil. 1999;26:582–593. doi: 10.1046/j.1365-2842.1999.00449.x. [DOI] [PubMed] [Google Scholar]

- 13.Kern M, Schaller HG, Strub JR. Marginal fit of restorations before and after cementation in vivo. Int J Prosthodont. 1993;6:585–591. [PubMed] [Google Scholar]

- 14.Yeo IS, Yang JH, Lee JB. In vitro marginal fit of three all-ceramic crown systems. J Prosthet Dent. 2003;90:459–464. doi: 10.1016/j.prosdent.2003.08.005. [DOI] [PubMed] [Google Scholar]

- 15.Groten M, Axmann D, Pröbster L, Weber H. Determination of the minimum number of marginal gap measurements required for practical in-vitro testing. J Prosthet Dent. 2000;83:40–49. doi: 10.1016/s0022-3913(00)70087-4. [DOI] [PubMed] [Google Scholar]

- 16.Gassino G, Barone Monfrin S, Scanu M, Spina G, Preti G. Marginal adaptation of fixed prosthodontics: a new in vitro 360-degree external examination procedure. Int J Prosthodont. 2004;17:218–223. [PubMed] [Google Scholar]

- 17.Reich S, Wichmann M, Nkenke E, Proeschel P. Clinical fit of all-ceramic three-unit fixed partial dentures, generated with three different CAD/CAM systems. Eur J Oral Sci. 2005;113:174–179. doi: 10.1111/j.1600-0722.2004.00197.x. [DOI] [PubMed] [Google Scholar]

- 18.Hertlein G, Hoscheler S, Frank S, Suttor D. Marginal fit of CAD/CAM manufactured all ceramic prosthesis. J Dent Res. 2001;80:42–44. [Google Scholar]

- 19.Gemalmaz D, Alkumru HN. Marginal fit changes during porcelain firing cycles. J Prosthet Dent. 1995;73:49–54. doi: 10.1016/s0022-3913(05)80272-0. [DOI] [PubMed] [Google Scholar]

- 20.Castellani D, Baccetti T, Clauser C, Bernardini UD. Thermal distortion of different materials in crown construction. J Prosthet Dent. 1994;72:360–366. doi: 10.1016/0022-3913(94)90554-1. [DOI] [PubMed] [Google Scholar]

- 21.Lui JL. The effect of firing shrinkage on the marginal fit of porcelain jacket crowns. Br Dent J. 1980;149:43–45. doi: 10.1038/sj.bdj.4804453. [DOI] [PubMed] [Google Scholar]

- 22.Weaver JD, Johnson GH, Bales DJ. Marginal adaptation of castable ceramic crowns. J Prosthet Dent. 1991;66:747–753. doi: 10.1016/0022-3913(91)90408-o. [DOI] [PubMed] [Google Scholar]

- 23.Song TJ. Marginal fit of the auro galvano crown system made using the electroforming technique. Seoul, Korea: Seoul National University; 2004. Master thesis. [Google Scholar]