Abstract

We describe the use of a microwave reaction for the conversion of various bromides to sodium sulfonates that have been further elaborated to sulfonyl chlorides. This new approach leads to much improved yields and shorter reaction times. Representative sulfonyl chlorides serve as precursors for the respective sulfonyl fluorides that are potent inhibitors of the fatty acid amide hydrolase.

Keywords: Sodium sulfonates, Microwave, Sulfonyl chlorides, Sulfonyl fluorides

Introduction

Sulfonyl chlorides are important intermediates for the synthesis of a range of organic compounds including industrial and agricultural chemicals. For example, these are used in the preparation of sulfonic acid amides and esters as well as in the production of herbicides, detergents, dyes, elastomers, ion exchange resins and pharmaceuticals.1–10

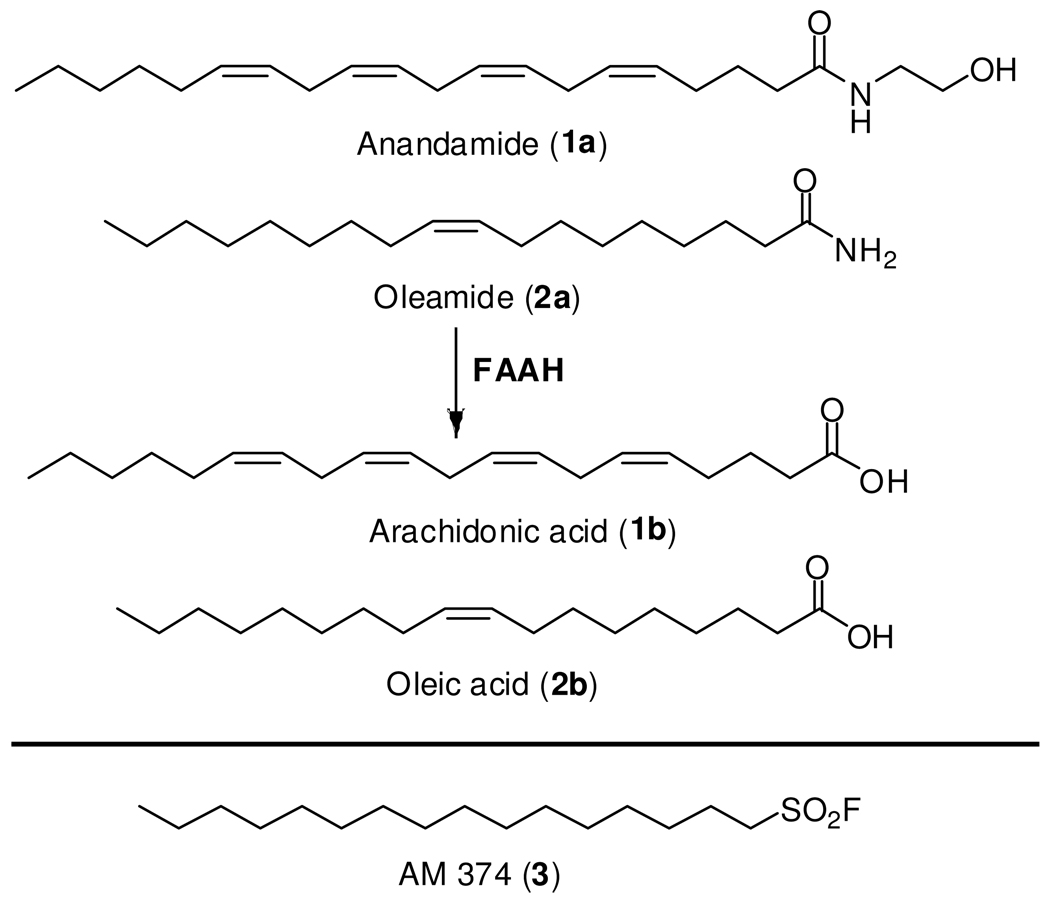

In the course of our program aiming at developing potent and selective inhibitors for the endocannabinoid deactivating enzymes,11–17 we were faced with the synthesis of substituted and unsubstituted phenylalkyl and phenoxyalkyl sulfonyl chlorides (Scheme 1) that serve as precursors for the respective sulfonyl fluorides. In general, sulfonyl fluorides (e.g. AM 37414, 3, Figure 1) are capable of inhibiting12–14,18 fatty acid amide hydrolase (FAAH),19–21 an intracellular membrane-bound enzyme that degrades and inactivates bioactive lipid amides including the endocannabinoid anandamide22 (1a, Figure 1) and the sleep inducing agent oleamide23 (2a, Figure 1). Some sulfonyl fluorides act as FAAH inhibitors and exhibit therapeutic potential for the treatment of pain, inflammation, cancer, anxiety, and sleep disorders.24–26

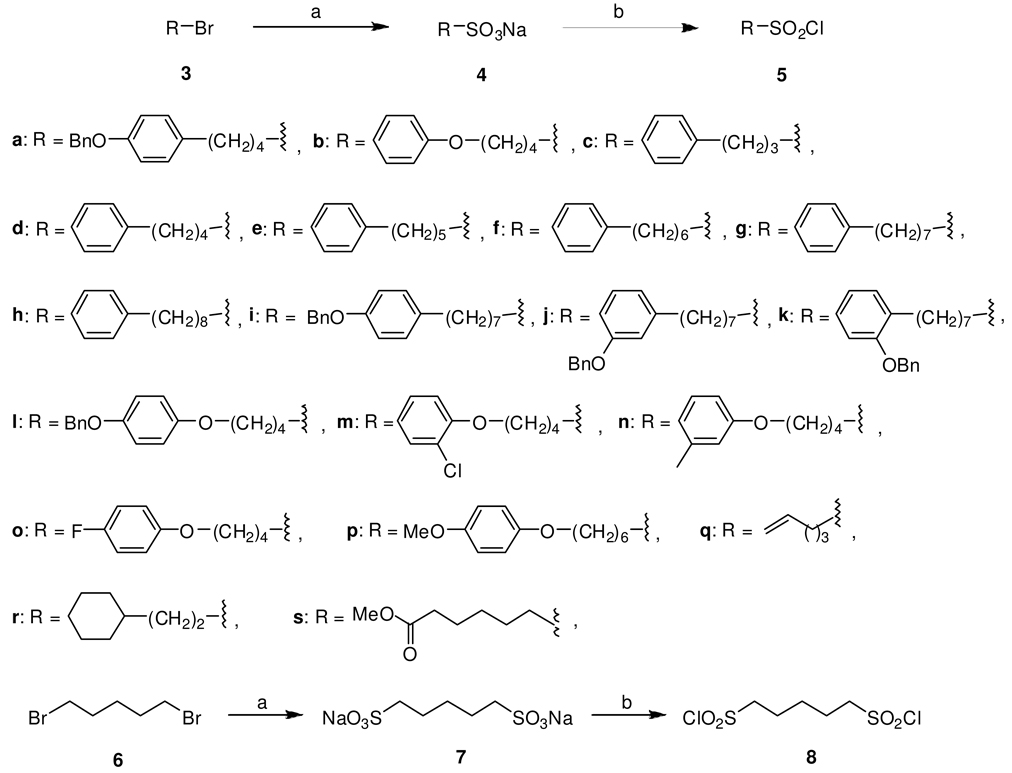

Scheme 1.

Reagents and conditions: (a) Na2SO3, THF:EtOH:H2O (1:2:2), MW, 160°C, 15 min; (b) SOCl2, benzene/DMF, 50°C, 3 h, 44–65% from 3.

Figure 1.

Substrates (1a, 2a) and inhibitor (3) of Fatty Acid Amide Hydrolase (FAAH).

A general approach for the preparation of sulfonyl chlorides involves oxidative chlorination of the precursor sulfur derivatives9, 27–38 (e.g. thiols, sulfides, thiocyanates, thiocarbamates, thioacetates, isothioureas etc.). However, many of these procedures involve stepwise oxidation followed by chlorination leading to low yields, and are not convenient and safe due to the use of hazardous and noxious reagents. Recently developed oxidizing agents such as N-chlorosuccinimide,39,40 as well as the iodosobenzene/HCl41 and the chloro-trimethysilane/KNO3 42 systems are more effective when used with aryl and benzyl thiols and thiol derivatives.

Non oxidative approaches for the synthesis of alkyl sulfonyl chlorides involve: (a) formation of Grignard or organolithium reagents from alkyl halides and subsequent addition to sulfuryl chloride;18,43,44 and (b) refluxing of bromides with sodium or ammonium sulfite in water45–49 to give the corresponding sulfonates that upon treatment with a chlorinating agent45–51 (e.g. SOCl2/DMF, POCl3, PCl5, cyanuric chloride etc.) lead to sulfonyl chlorides. However, use of organometalic reagents involves tedious procedures and results in poor and at best moderate yields, while conversion of bromides to sulfonates requires refluxing for many hours.

While seeking to improve the method which employs sodium sulfite in refluxing water,45–47,49 we found that use of microwave irradiation remarkably decreases the time required for the conversion of bromides to sodium sulfonates and enhances the yield of the respective sulfonyl chlorides. Optimal conditions involve microwave heating (160°C) of bromide and sodium sulfite in a mixture of THF:EtOH:H2O for 15 min. We report here details of this work and include the synthesis of the hitherto unknown sulfonyl fluorides 9b, 9m and 9n (Scheme 2). A full structure activity relationship (SAR) study for all sulfonyl fluorides synthesized11,12 as FAAH inhibitors will be reported elsewhere.

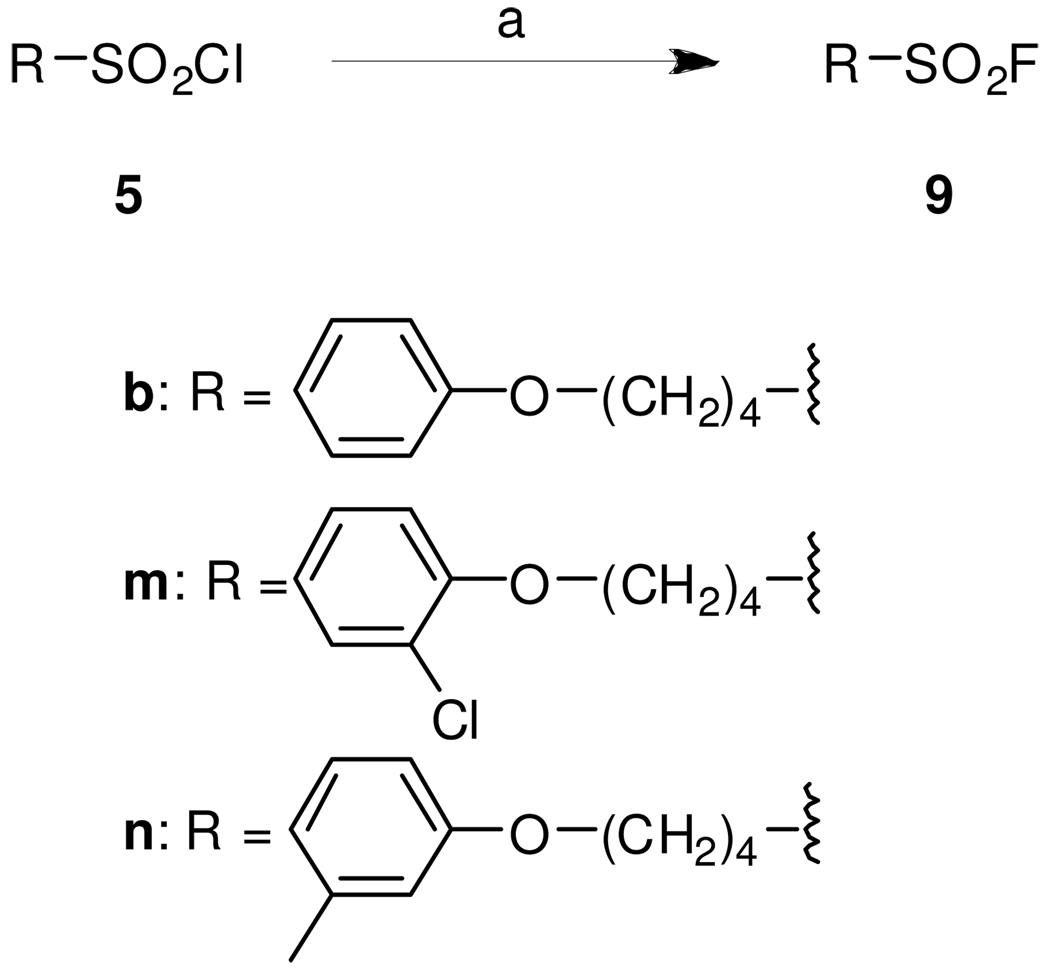

Scheme 2.

Reagents and conditions: (a) NH4F, acetone, reflux, 2 h, 90–92%.

Results and Discussion

In order to identify optimal reaction conditions for the conversion of substituted and unsubstituted phenylalkyl and phenoxyalkyl bromides 3a–3p to the respective sodium sulfonates 4a–4p (Scheme 1) we have chosen 3a and 3b as representative starting materials for a screening process where a number of reaction conditions were explored (Table 1). The required 4-phenoxybutyl bromide (3b) was commercially available while 4-bromo-1-(4-benzyloxyphenyl)butane (3a) was synthesized in five steps from 4-phenoxybutyl bromide and 4-anisaldehyde following our disclosed procedures.12 Bromides 3a and 3b were heated with sodium sulfite using reaction conditions shown in Table 1, and the crude sodium sulfonates 4a and 4b were treated with thionyl chloride in the presence of catalytic amounts of DMF, under standard conditions,12,46,49 to give the respective sulfonyl chlorides 5a and 5b. As seen in Table 1, heating of 3a and sodium sulfite in refluxing water for 36 hours led to sulfonyl chloride 5a in 18% isolated yield (entry 1). The yield of this conversion was improved significantly (37%) and the heating time was reduced to 24 hours when the solvent was changed to a mixture of EtOH:H2O (2:1 ratio, entry 2). Replacement of the conventional heating method with microwave irradiation resulted in improved yield for sulfonyl chloride 5a (41%) while the reaction time was remarkably reduced to 10 min (entry 3). Further improvement in the yield of 5a (47–50%) was accomplished by microwave heating at 160°C for 15 min using a mixture of THF:EtOH:H2O (1:2:2 ratio) as the reaction solvent (entries 4–6).

Table 1.

Reaction conditions for the conversion of bromides 3a and 3b to sodium sulfonates 4a and 4b and yields of the final products sulfonyl chloridesa 5a and 5b respectively.

| Entry | Bromide | Product Sulfonyl chloride |

Solvent (equiv. of Na2SO3) |

Heating (temp.) |

Time of heating for the conversion of bromides to sodium sulfonates |

Yieldbof sulfonyl chloride |

|---|---|---|---|---|---|---|

| 1 | 3a | 5a | H2O (1.4) |

CHc (reflux) |

36 h | 18% |

| 2 | 3a | 5a | EtOH:H2O= 2:1 (1.4) |

CHc (reflux) |

24 h | 37% |

| 3 | 3a | 5a | EtOH:H2O= 2:1 (1.4) |

MWd (120°C) |

10 min | 41% |

| 4 | 3a | 5a | THF:EtOH:H2O = 1:2:2 (1.4) |

MWd (120°C) |

10 min | 47% |

| 5 | 3a | 5a | THF:EtOH:H2O =1:2:2 (1.4) |

MWd (160°C) |

15 min | 50% |

| 6 | 3a | 5a | THF:EtOH:H2O = 1:2:2 (1.4) |

MWd (160°C) |

20 min | 48% |

| 7 | 3b | 5b | EtOH:H2O= 2:1 (1.4) |

CHc (reflux) |

24 h | 58% |

| 8 | 3b | 5b | EtOH:H2O= 2:1 (1.4) |

MWd (150°C) |

10 min | 61% |

| 9 | 3b | 5b | EtOH:H2O = 2:1 (1.6) |

MWd (160°C) |

15 min | 62% |

| 10 | 3b | 5b | THF:EtOH:H2O = 1:2:2 (1.6) |

MWd (160°C) |

15 min | 65% |

Sulfonyl chlorides were produced from the intermediate sodium sulfonates 4a and 4b using standard conditions (Scheme 1).12

Isolated yields of spectroscopically pure compounds.

CH = Conventional heating inside a thermostated oil bath under magnetic stirring.

MW = Microwave irradiation using a CEM Discover microwave devise in closed vessels and under magnetic stirring.

Similar trends were observed in the conversion of 4-phenoxybutyl bromide (3b) to the respective sulfonyl chloride 5b (Table 1). Conventional heating for 24 hours is required to produce 5b in 58% yield, while microwave irradiation for 15 min using 1.6 equivalents of sodium sulfite, led to 62% yield for 5b (entries 7–9). Again, use of a mixture of THF:EtOH:H2O (1:2:2 ratio) as the reaction solvent, enhances the yield of the two step procedure (entry 10). In summary, optimal reaction conditions for the conversion of bromides 3a and 3b to the respective sodium sulfonates 4a and 4b (Scheme 1) involve microwave irradiation (160°C) of 3a or 3b and 1.6 equivalents of sodium sulfite in a mixture of THF:EtOH:H2O (1:2:2 ratio).

With these results in hand, the scope of our microwave approach was explored with a variety of substituted and unsubstituted phenylalkyl and phenoxyalkyl bromides as well as with alkyl, alkenyl and substituted alkyl bromides52 (Scheme 1 and Table 2). The required starting materials 3c–3h, 3m–3s, and 6 were commercially available while bromides 3i, 3j and 3k were synthesized in five steps from 6-phenoxyhexyl bromide and 4- or 3- or 2-anisaldehyde following our previously disclosed procedures.12 Starting bromide 3l was prepared by etherification12 of commercially available 4-hydroxyphenol with 1,4-dibromobutane.

Table 2.

Examples of synthesized sulfonyl chlorides using the microwave assisted approach.a

| Entry | Bromide | Sulfonyl chloride |

Yieldb |

|---|---|---|---|

| 1 | 3a | 5a | 50% |

| 2 | 3b | 5b | 65% |

| 3 | 3c | 5c | 61% |

| 4 | 3d | 5d | 65% |

| 5 | 3e | 5e | 65% |

| 6 | 3f | 5f | 63% |

| 7 | 3g | 5g | 60% |

| 8 | 3h | 5h | 61% |

| 9 | 3i | 5i | 52% |

| 10 | 3j | 5j | 51% |

| 11 | 3k | 5k | 50% |

| 12 | 3l | 5l | 51% |

| 13 | 3m | 5m | 63% |

| 14 | 3n | 5n | 65% |

| 15 | 3o | 5o | 52% |

| 16 | 3p | 5p | 53% |

| 17 | 3q | 5q | 55% |

| 18 | 3r | 5r | 57% |

| 19 | 3s | 5s | 51% |

| 20 | 6 | 8 | 44% |

Reagents and conditions: (a) Na2SO3, THF:EtOH:H2O (1:2:2), MW, 160°C, 15 min; (b) SOCl2, benzene/DMF, 50°C, 3 h.

Isolated yields of spectroscopically pure compounds.

We have previously synthesized phenylalkyl sulfonyl chlorides 5c–5h (Scheme 1) from the respective iodides using a low temperature lithium-iodine exchange53 and treatment of the resulting organolithium reagent with sulfuryl chloride.12 This approach gave 5c–5h in only 19–23% yields12 while following our optimized microwave assisted method the yield was increased to 60–65% (Table 2, entries 3–8). In addition, the benzyloxy substituted phenylheptyl sulfonyl chlorides 5i–5k (Scheme 1) were previously synthesized by us in 38–40% yields using conventional heating for 24 hours,12 whereas microwave irradiation for 15 min increased the yields to 50–52% (Table 2, entries 9–11). In a similar fashion, sulfonyl chlorides 5l–5s and the 1,5-disulfonyl chloride 8 were synthesized in 44–65% yield (Table 2, entries 12–20). Treatment of 5b, 5m and 5n with ammonium fluoride in refluxing acetone gave the respective sulfonyl fluorides 9b, 9m and 9n in 90–92% yield54 (Scheme 2).

Conclusion

In summary, we found that use of microwave irradiation remarkably decreases the time required for the conversion of bromides to sodium sulfonates and enhances the yield of the respective sulfonyl chlorides. Representatives of the latter serve as precursors for the corresponding sulfonyl fluorides that are potent inhibitors of the fatty acid amide hydrolase.

Acknowledgments

This work was supported by grants from the National Institute on Drug Abuse, PO1-DA009158, R37-DA003801, and RO1-DA007215.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References and notes

- 1.Green TW, Wuts PGM. Protective groups in organic Chemistry. 3rd ed. New York: Wiley-Interscience; 1999. [Google Scholar]

- 2.Kociensky PJ. Protecting Groups. New York: Thieme; 1994. [Google Scholar]

- 3.Levitt G. In: Synthesis and Chemistry of Agrochemicals II. Baker DR, Fenyes JG, Moberg WK, editors. Washington, D. C: American Chemical Society; 1991. pp. 16–31. [Google Scholar]

- 4.Theodoridis G. Tetrahedron. 2000;56:2339. [Google Scholar]

- 5.Moore JD, Herpel RH, Lichtsinn JR, Flynn DL, Hanson PR. Org. Lett. 2003;5:105. doi: 10.1021/ol0270273. [DOI] [PubMed] [Google Scholar]

- 6.Blotny G, Biernat JF, Taschner E. Liebigs Ann. Chem. 1963;663:195. [Google Scholar]

- 7.Dubbaka SR, Vogel P. J. Am. Chem. Soc. 2003;125:15292. doi: 10.1021/ja038328q. [DOI] [PubMed] [Google Scholar]

- 8.Brewster JH, Ciotti CJ. J. Am. Chem. Soc. 1955;77:6214. [Google Scholar]

- 9.Kvrn L, Werder M, Hauser H, Carreira EM. Org. Lett. 2005;7:1145. doi: 10.1021/ol0502127. [DOI] [PubMed] [Google Scholar]

- 10.Lassalle G, Galtier D, Galli F. Application: EU 643047 A1. 1995:12. [Google Scholar]

- 11.Makriyannis A, Nikas SP, Alapafuja SO, Shukla VG. Application: WO 2009052319 A1. USA: Northeastern University; 2009. p. 209. [Google Scholar]

- 12.Makriyannis A, Nikas SP, Alapafuja SO, Shukla VG. Application: WO 2008013963 A2. USA: University of Connecticut; 2008. p. 123. [Google Scholar]

- 13.Makriyannis A, Lin S, Hill WA. Application: WO 97/45407. USA: University of Connecticut; 1997. p. 34. [Google Scholar]

- 14.Deutsch DG, Lin S, Hill WAG, Morse KL, Salehani D, Arreaza G, Omeir RL, Makriyannis A. Biochem. Biophys. Res. Commun. 1997;231:217. doi: 10.1006/bbrc.1997.6072. [DOI] [PubMed] [Google Scholar]

- 15.Gifford AN, Magalie B, Lin S, Goutopoulos A, Makriyannis A, Volkow ND, Gatley JS. Eur. J. Pharmacol. 1999;383:9. doi: 10.1016/s0014-2999(99)00609-3. [DOI] [PubMed] [Google Scholar]

- 16.Zvonok N, Pandarinathan L, Williams J, Johnston M, Karageorgos I, Janero DR, Krishnan SC, Makriyannis A. Chemistry & Biology. Cambridge, MA: United States; 2008. pp. 15–854. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Karanian DA, Karim SL, Wood J-AT, Williams JS, Lin S, Makriyannis A, Bahr BA. J. Pharmacol. Exp. Ther. 2007;322:1059. doi: 10.1124/jpet.107.120147. [DOI] [PubMed] [Google Scholar]

- 18.Segall Y, Quistad GB, Nomura DK, Casida JE. Bioorg. Med. Chem. Lett. 2003;13:3301. doi: 10.1016/s0960-894x(03)00721-2. [DOI] [PubMed] [Google Scholar]

- 19.Cravatt BF, Giang DK, Mayfield SP, Boger DL, Lerner RA, Gilula NB. Nature. 1996;384:83. doi: 10.1038/384083a0. [DOI] [PubMed] [Google Scholar]

- 20.Giang DK, Cravatt BF. Proc. Natl. Acad. Sci. U.S.A. 1997;94:2238. doi: 10.1073/pnas.94.6.2238. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Bracey MH, Hanson MA, Masuda KR, Stevens RC, Cravatt BF. Science. 2002;298:1793. doi: 10.1126/science.1076535. [DOI] [PubMed] [Google Scholar]

- 22.Devane WA, Hanus L, Breuer A, Pertwee RG, Stevenson LA, Griffin G, Gibson D, Mandelbaum A, Etinger A, Mechoulam R. Science. 1992;258:1946. doi: 10.1126/science.1470919. [DOI] [PubMed] [Google Scholar]

- 23.Boger DL, Henriksen SJ, Cravatt BF. Curr. Pharm. Des. 1998;4:303–314. [PubMed] [Google Scholar]

- 24.Cravatt BF, Lichtman AH. Curr. Opin. Chem. Biol. 2003;7:469. doi: 10.1016/s1367-5931(03)00079-6. [DOI] [PubMed] [Google Scholar]

- 25.Lambert DM, Fowler CJ. J. Med. Chem. 2005;48:5059. doi: 10.1021/jm058183t. [DOI] [PubMed] [Google Scholar]

- 26.Di Marzo V. Nature Rev. Drug Discov. 2008;7:438. doi: 10.1038/nrd2553. [DOI] [PubMed] [Google Scholar]

- 27.Sandler SR, Karo W. Organic Functional group Preparations. Vol.I. New York: Academic Press; 1983. p. 630. [Google Scholar]

- 28.Sprague JM, Johnson TB. J. Am. Chem. Soc. 1937;59:1837. [Google Scholar]

- 29.Johnson TB. Proc. Natl. Acad. Sci. U.S.A. 1939;25:448. doi: 10.1073/pnas.25.9.448. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Meinzer A, Breckel A, Thaher BA, Manicone N, Otto H-H. Helv. Chim. Acta. 2004;87:90. [Google Scholar]

- 31.Piatek A, Chapuis C, Jurczak J. Helv. Chim. Acta. 2002;85:1973. [Google Scholar]

- 32.Humljan J, Gobec S. Tetrahedron Lett. 2005;46:4069. [Google Scholar]

- 33.Monnee MC, Marijne MF, Brouwer AJ, Liskamp RM. Tetrahedron Lett. 2000;41:7991. [Google Scholar]

- 34.Schindler W. Helv.Chim. Acta. 1957;40:2148. [Google Scholar]

- 35.Park YJ, Shin HH, Kim YH. Chem. Lett. 1992:1483. [Google Scholar]

- 36.Langler RF. Can. J. Chem. 1976;54:498. [Google Scholar]

- 37.Langler RF, Marini ZA, Spalding ES. Can. J. Chem. 1979;57:3193. [Google Scholar]

- 38.Douglass IB. J. Org. Chem. 1974;39:563. [Google Scholar]

- 39.Kim DW, Ko YK, Kim SH. Synthesis. 1992:1203. [Google Scholar]

- 40.Nishiguchi A, Maeda K, Miki S. Synthesis. 2006:4131. [Google Scholar]

- 41.Sohmiya H, Kimura T, Fujita M, Ando T. Tetrahedron. 1998;54:13737. [Google Scholar]

- 42.Prakash GKS, Mathew T, Panja C, Olah GA. J. Org. Chem., 2007;72:5847. doi: 10.1021/jo070907g. [DOI] [PubMed] [Google Scholar]

- 43.Gilbert EE. Synthesis. 1969:3. [Google Scholar]

- 44.Quast H, Kees F. Synthesis. 1974:489. [Google Scholar]

- 45.King JF, Harding DRK. J. Am. Chem. Soc. 1976;98:3312. [Google Scholar]

- 46.Castang S, Chantegrel B, Deshayes C, Dolmazon R, Gouet P, Haser R, Reverchon S, Nasser W, Hugouvieux-Cotte-Pattat N, Doutheau A. Bioorg. Med. Chem. Lett. 2004;14:5145. doi: 10.1016/j.bmcl.2004.07.088. [DOI] [PubMed] [Google Scholar]

- 47.Johnston TP, Kussner CL, Holum LB. J. Org. Chem. 1960;25:399. [Google Scholar]

- 48.Markgraf HJ, Hess AB, Jr, Nichols CW, King RW. J. Org. Chem. 1964;29:1499. [Google Scholar]

- 49.Abramovitch RA, Holcomb WD, Thompson WM, Wake S. J. Org. Chem. 1984;49:5124. [Google Scholar]

- 50.Erman WF, Kretschmar HC. J. Org. Chem. 1961;26:4841. [Google Scholar]

- 51.Blotny G. Tetrahedron Lett. 2003;44:1499. [Google Scholar]

- 52.Typical procedure for the conversion of bromides 3 to sulfonyl chlorides 5 via sodium sulfonates 4.Sulfonic acid sodium salts (4). A mixture of bromide 3 (1 mmol) and Na2SO3 (1.6 mmol) in THF/EtOH/H2O (1:2:2 mixture, 5 mL) was heated for 15 minutes at 160°C under microwave irradiation (300 W) using a CEM Discover system. The reaction mixture was cooled to room temperature and volatiles were removed under reduced pressure. The residue was scrupulously dried under high vacuo and the crude product 4, (a pale yellow solid) was used in the next step without further purification.Sulfonyl chlorides (5). To a stirred suspension of sulfonate 4 in anhydrous benzene (7 mL)/DMF (0.1 ml), was added thionyl chloride (2.6 mmol) and the mixture was heated at 50°C for 3 hours under argon. The reaction mixture was quenched by dropwise addition of water at room temperature and extracted with diethyl ether. The organic layer was washed with brine dried (MgSO4), and the solvent was evaporated under reduced pressure. Purification by flash column chromatography on silica gel (diethyl ether in hexane) gave 5 in yields shown on Table 2. Selected data of synthesized sulfonyl chlorides:4-Phenoxybutanesulfonyl chloride (5b). IR (neat) 2935, 1513, 1371 (s), 1164 (s); 1H NMR (500 MHz, CDCl3) δ 7.29 (t, J = 8.2 Hz, 2H, 3-H, 5-H, -OPh), 6.97 (t, J = 8.2 Hz, 1H, 4-H, -OPh), 6.89 (d, J = 8.2 Hz, 2H, 2-H, 6-H, -OPh), 4.04 (t, J = 5.7 Hz, 2H, -CH2-OPh), 3.80 (m as t, J = 8.0 Hz, half of an AA'XX' system, 2H, -CH2SO2Cl), 2.29 (m as qt, J = 7.0 Hz, 2H, -CH2CH2SO2Cl), 2.01 (qt, J = 6.0 Hz, 2H, -CH2CH2CH2SO2Cl); mass spectrum m/z (relative intensity) 250 (M++2, 7), 248 (M+, 21), 155 (16), 107 (22), 94 (100), 77 (21), 65 (15); Exact mass calculated for C10H13ClO3S, 248.0274; found, 248.0276.4-(2-Chlorophenoxy)butanesulfonyl chloride (5m). IR (neat) 2927, 1512, 1371 (s), 1163 (s); 1H NMR (500 MHz, CDCl3) δ 7.39 (dd, J = 8.0 Hz, J = 1.5 Hz, 1H, 3-H, -O-Ph-Cl), 7.24 (td, J = 8.0 Hz, J = 1.5 Hz, 1H, 5-H, -O-Ph-Cl), 6.94 (td, J = 8.0 Hz, J = 1.5 Hz, 1H, 4-H, -O-Ph-Cl), 6.93 (dd, J = 8.0 Hz, J = 1.5 Hz, 1H, 6-H, -O-Ph-Cl), 4.13 (t, J = 5.8 Hz, 2H, -CH2-O-Ph-Cl), 3.95 (m as t, J = 7.3 Hz, half of an AA'XX' system, 2H, -CH2SO2Cl), 2.35 (m as qt, J = 7.5 Hz, 2H, - CH2CH2SO2Cl), 2.10 (qt, J = 6.0 Hz, 2H, -CH2CH2CH2SO2Cl); mass spectrum m/z (relative intensity) 286 (M++4, 2), 284 (M++2, 13), 282 (M+, 19), 183 (5), 155 (31), 141 (15), 128 (100), 111 (6), 99 (7), 83 (8); Exact mass calculated for C10H12Cl2O3S, 281.9884; found, 281.9887.4-(3-Methylphenoxy)butanesulfonyl chloride (5n). IR (neat) 2943, 1513, 1372 (s), 1164 (s); 1H NMR (500 MHz, CDCl3) δ 7.19 (t, J = 7.5 Hz, 1H, 5-H, -O-Ph-Me), 6.81 (d, J = 7.5 Hz, 1H, 4-H, - O-Ph-Me), 6.73 (s, 1H, 2-H, -O-Ph-Me), 6.71 (d, J = 7.5 Hz, 1H, 6-H, -O-Ph-Me), 4.04 (t, J = 5.5 Hz, 2H, -CH2-O-Ph-Me), 3.81 (m as t, J = 7.3 Hz, half of an AA'XX' system, 2H, -CH2SO2Cl), 2.35 (s, 3H, -Me), 2.29 (m as qt, J = 7.1 Hz, 2H, -CH2CH2SO2Cl), 2.02 (qt, J = 6.9 Hz, 2H, - CH2CH2CH2SO2Cl); mass spectrum m/z (relative intensity) 264 (M++2, 3), 262 (M+, 9), 162 (21), 147 (12), 131 (19), 119 (42), 108 (100), 91 (95), 77 (22), 64 (43); Exact mass calculated for C11H15ClO3S, 262.0430; found, 262.0429.

- 53.Bailey WF, Punzalan ER. J. Org. Chem. 1990;55:5404. [Google Scholar]

- 54.Typical procedure for the conversion of sulfonyl chlorides 5b, 5m and 5n to fluorides 9b, 9m and 9n.To a stirred solution of sulfonyl chloride 5 (1 equiv.) in dry acetone, was added anhydrous NH4F (2.3 equiv.) and the mixture refluxed for 2 hours under argon. The solvent was evaporated under reduced pressure and the residue was dissolved in diethyl ether. The ethereal solution was washed with water and brine, dried (MgSO4), and evaporated in vacuo. Purification by flash column chromatography on silica gel (diethyl ether in hexane) gave sulfonyl fluoride 9 as a white solid in 90–92% yield.4-Phenoxybutanesulfonyl fluoride (9b). IR (neat) 2940, 1513, 1398 (s), 1194 (s); 1H NMR (500 MHz, CDCl3) δ 7.30 (td, J = 8.5 Hz, J = 1.0 Hz, 2H, 3-H, 5-H, -OPh), 6.97 (td, J = 8.5 Hz, J = 1.0 Hz, 1H, 4-H, -OPh), 6.89 (dd, J = 8.5 Hz, J = 1.0 Hz, 2H, 2-H, 6-H, -OPh), 4.03 (t, J = 5.6 Hz, 2H, -CH2-OPh), 3.50 (m as dt, J = 11.0 Hz, J = 4.5 Hz, 2H, -CH2SO2F), 2.20 (m as qt, J = 7.5 Hz, 2H, - CH2CH2SO2F), 2.00 (qt, J = 7.0 Hz, 2H, -CH2CH2CH2SO2F); 13C NMR (100 MHz, CDCl3) δ 158.48, 129.58, 121.11, 114.41, 66.52, 50.65 (d, J = 16.4 Hz, -CH2SO2F), 27.43, 20.91; mass spectrum m/z (relative intensity) 232 (M+, 25), 139 (9), 107 (6), 94 (100), 77 (13); Exact mass calculated for C10H13FO3S, 232.0569; found, 232.0572. Anal. Calc. (C10H13FO3S): C, 51.71; H, 5,64. Found: C, 52.09; H, 5.75.4-(2-Chlorophenoxy)butanesulfonyl fluoride (9m). IR (neat) 2929, 1511, 1394 (s), 1197 (s); 1H NMR (500 MHz, CDCl3) δ 7.40 (dd, J = 8.0 Hz, J = 1.5 Hz, 1H, 3-H, -O-Ph-Cl), 7.24 (td, J = 8.0 Hz, J = 1.5 Hz, 1H, 5-H, -O-Ph-Cl), 6.94 (td, J = 8.0 Hz, J = 1.5 Hz, 1H, 4-H, -O-Ph-Cl), 6.93 (dd, J = 8.0 Hz, J = 1.5 Hz, 1H, 6-H, -O-Ph-Cl), 4.12 (t, J = 6.0 Hz, 2H, -CH2-O-Ph-Cl), 3.64 (m as dt, J = 11.0 Hz, J = 3.5 Hz, 2H, -CH2SO2F), 2.26 (m as qt, J = 8.0 Hz, 2H, -CH2CH2SO2F), 2.08 (q, J = 6.0 Hz, 2H, -CH2CH2CH2SO2F); mass spectrum m/z (relative intensity) 268 (M++2, 7), 266 (M+, 21), 238 (9), 196 (10), 149 (12), 139 (14), 128 (100), 99 (6); Exact mass calculated for C10H12FClO3S, 266.0180; found, 266.0178.4-(3-Methylphenoxy)butanesulfonyl fluoride (9n). IR (neat) 2954, 1515, 1398 (s), 1192 (s); 1H NMR (500 MHz, CDCl3) δ 7.19 (t, J = 7.5 Hz, 1H, 5-H, -O-Ph-Me), 6.81 (d, J = 7.5 Hz, 1H, 4-H, - O-Ph-Me), 6.73 (s, 1H, 2-H, -O-Ph-Me), 6.71 (d, J = 7.5 Hz, 1H, 6-H, -O-Ph-Me), 4.04 (t, J = 6.0 Hz, 2H, -CH2-O-Ph-Me), 3.52 (m as dt, J = 11.0 Hz, J = 3.5 Hz, 2H, -CH2SO2F), 2.36 (s, 3H, -Me), 2.21 (m as qt, J = 7.6 Hz, 2H, -CH2CH2SO2F), 2.00 (qt, J = 6.7 Hz, 2H, -CH2CH2CH2SO2F); mass spectrum m/z (relative intensity) 246 (M+, 31), 139 (8), 128 (9), 108 (100), 91 (12), 77 (6); Exact mass calculated for C11H15FO3S, 246.0726; found, 246.0729.