Abstract

We describe a platform technology, called metal-assisted and microwave-assisted evaporative crystallization (MA-MAEC), based on the combined use of silver nanoparticles and microwave heating for selective and rapid crystallization of small molecules. In this regard, the crystallization of a model small molecule (glycine) was achieved in several seconds. Glycine crystals grown on silver nanostructures with and without microwave heating were found to be larger than those grown on blank glass slides. The MA-MAEC technique has the potential to selectively grow the desired polymorphs of small molecules “on-demand” in a fraction of the time as compared to the conventional evaporative crystallization.

There has been increased interest in the area of controlled crystal formation in the pharmaceutical industry, particularly in the area of crystal polymorphism and solid form purity.1 Typically, synthesized drugs are crystallized in the purest form possible and marketed in the forms of pills, tablets, etc. In addition, crystallization is also used for understanding of molecular structures and interactions of proteins to develop new drug treatments that target specific human, animal, and plant diseases.2

One can find numerous studies related to crystallization of small molecules in the literature. For example, Myerson and co-workers have been employing polarized laser light irradiation for the crystallization of different polymorphs of glycine.3 The same group has also demonstrated the use of self-assembled monolayers (SAMs) of alkane thiols on patterned gold thin films for size-controlled crystallization of glycine molecules through solvent evaporation.4 Ward and co-workers have employed nanoscale cylindrical pores to control the orientation of crystals formed by stereochemical inhibition.5 Zukoski and co-workers have demonstrated the selective growth of γ-glycine crystals via concentrating microdroplets of aqueous glycine solutions through a slow evaporation-based crystallization platform.6 In these reports, it was shown that the rapid evaporation of solvent produces the unstable β-form of glycine, while slowing the evaporation of solvent produced the kinetically stable α-form. Moreover, the generation of very slow supersaturation from water results in the stable γ-form.6 It was also shown that the distribution of glycine crystals can be affected by the surface (SAMs, polymers, etc.) as well as by the solution pH.6 However, no techniques exist for the rapid (in a matter of seconds) and selective formation of the stable α- and γ-forms without using additives, SAMs of alkanethiols, or other engineered surfaces.

In this communication, we present a platform technology, called metal-assisted and microwave-accelerated evaporative crystallization (MA-MAEC), which is based on the combined use of metal nanostructures and microwave heating, for selective and rapid crystallization of small molecules. The proof-of-principle of our new technique was demonstrated with a model amino acid, i.e., glycine. Glycine has three distinct polymorphs at ambient conditions: α, β,and γ.4 The formation of glycine crystals mainly depends on the type of solvent, pH, and concentration. In the MA-MAEC technique, metal nanostructures serve as (1) selective nucleation sites for the crystallization of glycine due to the interactions of primary amine (of glycine) and silver nanostructures and as (2) a microwave-transparent medium for the creation of a thermal gradient between the warmer solution and the silver nanostructures that remain at room temperature after microwave heating.7 The microwave heating affords for the significant reduction in the time of the crystallization process.

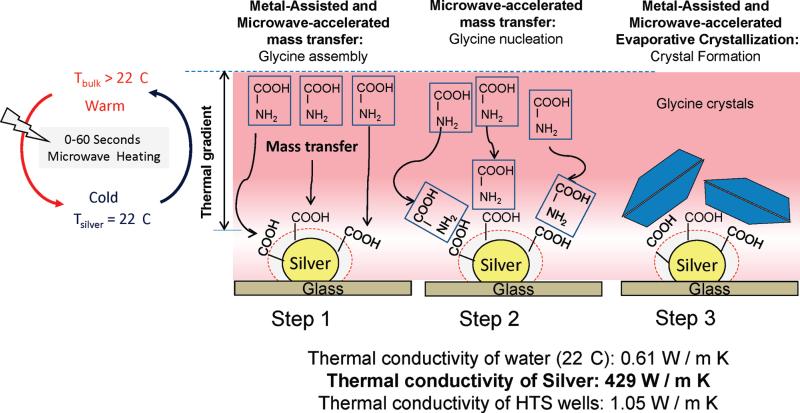

Figure 1 depicts the proposed mechanism for the MA-MAEC technique. In MA-MAEC, upon exposure to microwave heating, a thermal gradient is created between the solution and the silver nanoparticles due to the ~620-fold difference in the thermal conductivity of silver (429 W/mK) and water (0.61 W/mK). This thermal gradient affords for the mass transfer of glycine molecules from the warmer solution to the cooler nanoparticles in an effort to thermally equilibrate the system. Subsequently, glycine molecules assemble either directly (or by other functional groups on silver) onto the silver nanoparticles (Figure 1, step 1). With continued microwave heating, mass transfer of glycine continues and the glycine molecules assemble onto the ones on the surface of silver nanoparticles in a process called nucleation (Figure 1, step 2). Crystal growth takes place as the solution evaporates and subsequent glycine molecules assemble onto one another until all glycine molecules crystallize (Figure 1, step 3).

Figure 1.

Schematic depiction of metal-assisted and microwave-accelerated evaporative crystallization.

Silver island films (SIFs) were deposited onto glass microscope slides by allowing them to soak in a heated silver nitrate/d-glucose solution as previously described.7 Freshly prepared SIFs (Supporting Information 1, Figure S1) were used in all the experiments. The effect of concentration and pH on the crystallization of glycine in deionized water (no other solvent was used) at constant solution volume was studied. In this regard, aqueous solutions of glycine (>99.5%, Sigma-Aldrich, USA) with three different concentrations were prepared: 1.60, 3.20, and 4.0 M. The pH of the glycine solutions was adjusted to 4 (acidic), 6 (neutral), and 9 (basic) using 6 M HCl or 6 M NaOH. In the MA-MAEC experiments, a fixed volume (20 μL) of freshly prepared glycine solution was pipetted onto SIFs-coated glass slides and was either heated in a conventional microwave oven (100% power level) or incubated at room temperature. The time taken for the solution to completely evaporate was recorded. In two control samples, the crystallization of glycine was carried out on blank glass slides with microwave heating and on blank glass slides at room temperature.

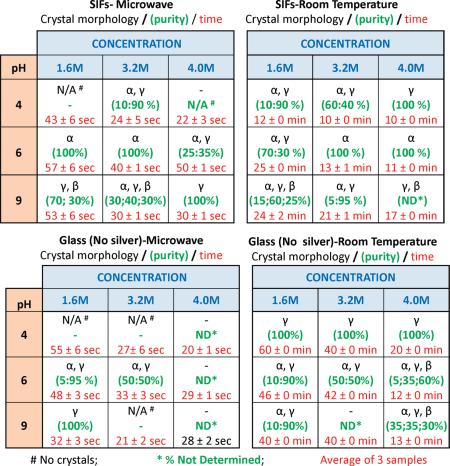

Glycine crystals formed on SIFs and glass slides were characterized by microscopy (optical microscope and scanning electron microscope, Supporting Information 1, Figures S2–S9) and powder X-ray diffraction (XRD).8 The crystal polymorph distribution was calculated using the microscope images of three different samples. Table 1 summarizes the results for the crystallization of glycine using the MA-MAEC technique and control experiments. In this regard, the crystal morphology, the crystal polymorph distribution (i.e., purity), and the total time to evaporate different glycine solutions are listed.

Table 1.

Summary of Results for the Crystallization of Glycine Using the MA-MAEC Technique and Control Experiments

|

For a fixed volume of glycine solution, the total evaporation time on blank glass slides at room temperature (a control sample, evaporative crystallization) was recorded to be between 12 (for 4M, pH = 6) and 60 min (for 1.6 M, pH = 4). As the concentration of glycine solution is increased, the total time of crystallization was decreased up to 4-fold, which is due to the presence of more glycine molecules in solution, driving the crystallization process more rapidly. Under acidic and basic conditions, the γ-form of glycine was dominant. The α-form of glycine was observed mostly at pH = 6, as confirmed by XRD. Figures 2-Top and S2 (Supporting Information 1) show the optical microscope and SEM images of the glycine crystals formed on blank glass slides at room temperature. As expected, γ-glycine is formed as needles (3250–5000 μm in length) and α-glycine (125–1000 μm in length) is formed as bipyramids, which can be explained by a kinetically controlled process involving the presence of cyclic dimers.9

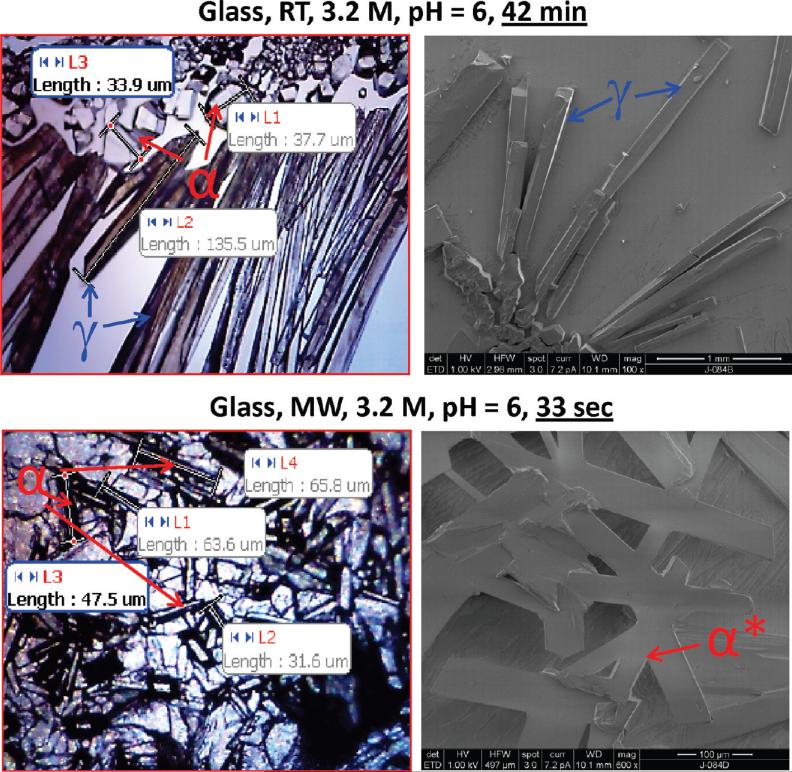

Figure 2.

Optical and SEM images for glycine crystals grown on blank glass slides from 3.2 M solution, pH = 6 (Top) at room temperature and (Bottom) using microwave heating (MW). * indicates platelike α-glycine. Actual length of glycine crystals are ×25 of the lengths shown here.

When identical glycine solutions on blank glass slides were exposed to microwave heating, glycine solution completely evaporated in 20–55 s. However, glycine crystals were grown only for three out of nine solutions and the crystals were not well organized as compared to those grown at room temperature. That is, microwave heating of glycine solution on blank glass slides did not yield better crystals (Figure 2-Bottom, Figure S3 (Supporting Information 1), and Figure S10B (Supporting Information 2)).

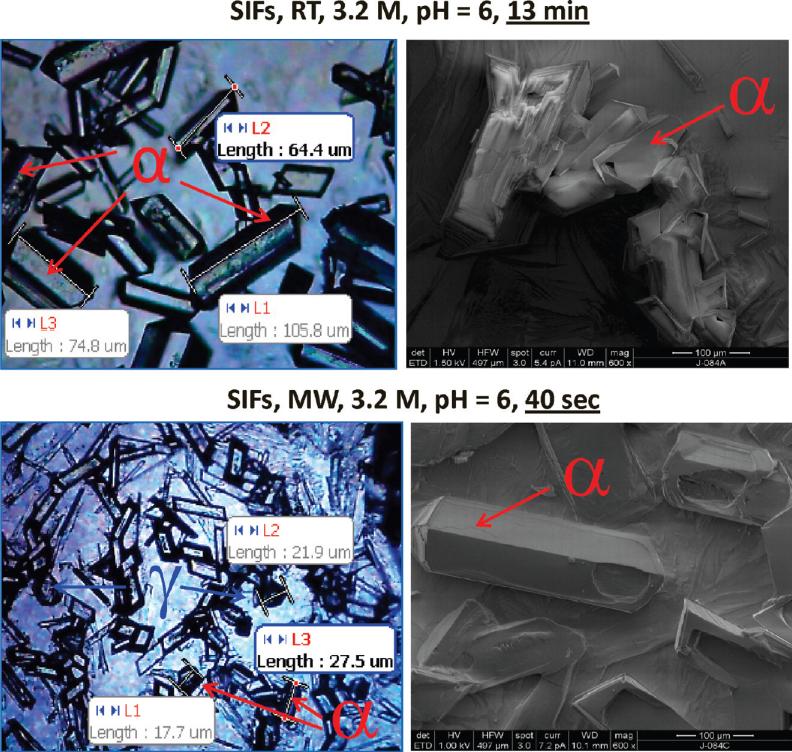

Since primary amine (and thiol) groups have affinity toward silver nanostructures, glycine molecules are expected to assemble onto silver nanostructures through amine groups facing the silver surface. That is, silver nanostructures serve as selective nucleation sites for the crystallization of glycine, which increases the rate of crystallization and potentially results in selective polymorphism. Subsequently, the growth of glycine crystals at room temperature was carried out on SIFs. For a fixed volume of glycine solution, the total evaporation time on SIFs at room temperature was reduced by up to 5-fold (for 1.6 M, pH = 4) as compared to those on blank glass slides at room temperature. Moreover, glycine crystals were grown on SIFs for all nine conditions, and these crystals are well organized and larger (Figure 3-Top and Figures S4-S6) as compared to those grown on blank glass slides. In this regard, the size of α-glycine grown on SIFs (up to ~2500 μm in size) is ~2-fold larger than those grown on blank glass slides. This is thought to be due to the presence of multiple silver nanostructures within close proximity to one another (Figure S1), which affords for multiple crystal nucleation/growth processes to occur simultaneously.

Figure 3.

Optical and SEM images for glycine crystals grown on SIFs from 3.2 M solution, pH = 6 (Top) at room temperature and (Bottom) using microwave heating. Actual length of glycine crystals are ×25 of the lengths shown here.

It is also important to note that γ-glycine grown on SIFs reach lengths > 10 mm (Figure S5), which makes them a very promising candidate for nonlinear optical applications.10 In addition, a superior distribution of crystal polymorphs was observed on SIFs, where the desired type of polymorph can be grown in a relatively short time. These observations prove that the use of silver nanostructures (metal-assisted crystallization, MAC) can significantly improve the crystallization process.

Despite the notable improvements afforded by MAC, the crystallization process (for complete evaporation of a 20 μL solution) still requires up to 25 min to be completed. Subsequently, the effect of microwave heating on the crystallization process on SIFs was investigated (i.e, MA-MAEC). When identical glycine solutions on SIFs were exposed to microwave heating, glycine solution completely evaporated in 22–57 s (up to ~60-fold decrease as compared to glass at RT). Seven (out of 9) of the glycine solutions yielded well organized glycine crystals (Figure 3-Bottom and Figures S7–S9 (Supporting Information 1). In MA-MAEC the heating of glycine solutions to higher temperatures (water is completely evaporated) resulted in the transformation of the γ-form into the α-and β-forms. This is due to the fact that α-and γ-glycine are enantiotropically related and such a transformation occurs at high temperatures.4 The existence of the high energy β-form can be explained by the high supersaturation process resulting from rapid evaporation of water.4

It is important to note that glycine crystals started to appear on SIFs before the complete evaporation (< 1 min) of the aqueous glycine solution. That is, one can use the MA-MAEC technique without complete evaporation of the solvent, especially for the separation of impurities from the desired crystals.

In summary, the proof-of-principle of a platform technology, which involves the use of silver nanostructures with and without microwave heating to significantly improve the crystallization of organic small molecules, was demonstrated. In this regard, the crystallization of a model organic molecule (glycine) from a small volume aqueous solution using microwave heating was achieved in seconds. Glycine crystals grown on silver nanostructures with and without microwave heating were found to be larger than those grown on blank glass slides. The MA-MAEC technique has the potential to selectively grow the desired polymorphs of small organic and biological molecules “on-demand” in a fraction of the time as compared to the conventional evaporative crystallization.

Supplementary Material

Acknowledgment

The project described was supported by Award Number 5-K25EB007565-04 from the National Institute of Biomedical Imaging and Bioengineering. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institute of Biomedical Imaging and Bioengineering or the National Institutes of Health.

Footnotes

Supporting Information Available: Additional images of glycine crystals (Supporting Information 1), powder XRD data (Supporting Information 2), and CIF files. This material is available free of charge via the Internet at http://pubs.acs.org.

References

- 1.Brittain HG. Effects of mechanical processing on phase composition. J. Pharm. Sci. 2002;91(7):1573–1580. doi: 10.1002/jps.10115. [DOI] [PubMed] [Google Scholar]

- 2.Roberts MM, Heng JYY, Williams DR. Protein Crystallization by Forced Flow through Glass Capillaries: Enhanced Lysozyme Crystal Growth. Cryst. Growth Des. 2010;10(3):1074–1083. [Google Scholar]

- 3.Garetz BA, Matic J, Myerson AS. Polarization switching of crystal structure in the nonphotochemical light-induced nucleation of supersaturated aqueous glycine solutions. Phys. Rev. Lett. 2002;89(17):175501. doi: 10.1103/PhysRevLett.89.175501. [DOI] [PubMed] [Google Scholar]

- 4.Lee AY, Lee IS, Dettet SS, Boerner J, Myerson AS. Crystallization on confined engineered surfaces: A method to control crystal size and generate different polymorphs. J. Am. Chem. Soc. 2005;127(43):14982–14983. doi: 10.1021/ja055416x. [DOI] [PubMed] [Google Scholar]

- 5.Hamilton BD, Weissbuch I, Lahav M, Hillmyer MA, Ward MD. Manipulating Crystal Orientation in Nanoscale Cylindrical Pores by Stereochemical Inhibition. J. Am. Chem. Soc. 2009;131(7):2588–2596. doi: 10.1021/ja807193s. [DOI] [PubMed] [Google Scholar]

- 6.He GW, Bhamidi V, Wilson SR, Tan RBH, Kenis PJA, Zukoski CF. Direct growth of gamma-glycine from neutral aqueous solutions by slow, evaporation-driven crystallization. Cryst. Growth Des. 2006;6(8):1746–1749. [Google Scholar]

- 7.Aslan K, Geddes CD. Microwave-accelerated metal-enhanced fluorescence: Platform technology for ultrafast and ultrabright assays. Anal. Chem. 2005;77(24):8057–8067. doi: 10.1021/ac0516077. [DOI] [PubMed] [Google Scholar]

- 8.Please see Supporting Information for the discussion of X-ray crystallography data.

- 9.Weissbuch I, Lahav M, Leiserowitz L. Toward stereochentical control, monitoring, and understanding of crystal nucleation. Cryst. Growth Des. 2003;3(2):125–150. [Google Scholar]

- 10.Bhat MN, Dharmaprakash SM. Effect of solvents on the growth morphology and physical characteristics of nonlinear optical gamma-glycine crystals. J. Cryst. Growth. 2002;242(1-2):245–252. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.