Abstract

STATEMENT OF PROBLEM

Recently Yttrium-stabilized tetragonal zirconia polycrystal (Y-TZP) has been introduced due to superior flexural strength and fracture toughness compared to other dental ceramic systems. Although zirconia has outstanding mechanical properties, the phenomenon of decrease in the life-time of zirconia resulted from degradation in flexural strength after low temperature aging has been reported.

PURPOSE

The objective of this study was to investigate degradation of flexural strength of Y-TZP ceramics after various low temperature aging treatments and to evaluate the phase stability and micro-structural change after aging by using X-ray diffraction analysis and a scanning electron microscope (SEM).

MATERIAL AND METHODS

Y-TZP blocks of Vita In-Ceram YZ (Vita Zahnfabrik, Bad Säckingen, Germany) were prepared in 40 mm (length) × 4 mm (width) × 3 mm (height) samples. Specimens were artificially aged in distilled water by heat-treatment at a temperature of 75, 100, 125, 150, 175, 200, and 225℃ for 10 hours, in order to induce the phase transformation at the surface. To measure the mechanical property, the specimens were subjected to a four-point bending test using a universal testing machine (Instron model 3365; Instron, Canton, Mass, USA). In addition, X-ray diffraction analysis (DMAX 2500; Rigaku, Tokyo, Japan) and SEM (Hitachi s4700; Jeol Ltd, Tokyo, Japan) were performed to estimate the phase transformation. The statistical analysis was done using SAS 9.1.3 (SAS institute, USA). The flexural strength data of the experimental groups were analyzed by one-way analysis of variance and to detect statistically significant differences (α= .05).

RESULTS

The mean flexural strength of sintered Vita In-Ceram YZ without autoclaving was 798 MPa. When applied aging temperature at below 125℃ for 10 hours, the flexural strength of Vita In-Ceram YZ increased up to 1,161 MPa. However, at above 150℃, the flexural strength started to decrease. Although low temperature aging caused the tetragonal-to-monoclinic phase transformation related to temperature, the minimum flexural strength was above 700 MPa.

CONCLUSION

The monoclinic phase started to appear after aging treatment above 100℃. With the higher aging temperature, the fraction of monoclinic phase increased. The ratio of monoclinic/tetragonal + monoclinic phase reached a plateau value, circa 75% above 175℃. The point of monoclinic concentration at which the flexural strength begins to decrease was between 12% and 54%.

Keywords: Low temperature aging, Y-TZP ceramic, Phase transformation, Mechanical property

INTRODUCTION

Recently, all ceramic restorations are widely used not only for anterior and posterior single crowns, but also for anterior three or four-unit fixed partial dentures. Among several dental ceramics, Yittrium-stabilized tetragonal zirconia polycrystal (Y-TZP) was accepted by dentists and patients due to its superior flexural strength and fracture toughness compared to other dental ceramic systems.1

Zirconia has three different crystal phases at different temperatures: monoclinic, tetragonal and cubic. At room temperature zirconia exists in monoclinic phase.2 Above 1070℃, the monoclinic phase transforms into a tetragonal phase, which is stable between 1170℃ and 2370℃.2 The cubic phase is stable only at very high temperature. Zirconia can maintain the tetragonal phase at room temperature by adding the stabilizers such as yttria, magnesia and ceria etc. The martensitic tetragonal-to-monoclinic phase transformation may be initiated by stress (such as wear, machining, etc) and/or water. The phase transformation from tetragonal to monoclinic exhibits a volume expansion of 3 - 4%.3 The crack propagation is inhibited by the volume expansion at the crack tip. This phase transformation toughening phenomenon results in high strength and fracture toughness of the zirconia.

Although zirconia has outstanding mechanical properties, the phenomenon that decreases the life-time of zirconia has been reported for more than twenty years. Kobayashi et al. were the first to observe the degradation concerning the aging phenomenon at 150 - 400℃.4 Since then, numerous studies have focused on the low temperature aging phenomenon associated with the mechanical properties.5-9

The objectives of this study were i) to investigate the degradation of flexural strength of Y-TZP ceramics after various low temperatures aging treatment and ii) to evaluate the phase stability and micro-structural change after aging by using a scanning electron microscope and X-ray diffraction analysis.

MATERIAL AND METHODS

Preparation of specimens

Y-TZP blocks of Vita In-Ceram YZ (Vita Zahnfabrik, Bad Säckingen, Germany) were fully sintered according to manufacturer's recommendations. The fully sintered blocks were cut into the size of 41 (length) × 5 (width) × 4 mm (height) approximately. Then the blocks were divided into 8 groups, 10 specimens for each. All specimens were polished with 6 µm diamond paste, followed by 1 µm for 10 minutes at 3 kg load, then annealed in a porcelain furnace at a temperature of 1200℃. The purposes of the polishing were to remove all surface residual stresses, to round chipped corners of the specimens, and to eliminate any cracks from inherent material defects. The annealing process can remove any monoclinic phase on the surface of specimens during specimen preparation procedures. Final size of the specimens was 40 ± 0.2 (length) × 4 ± 0.1 (width) × 3 ± 0.1 mm (height).

Low temperature aging

For a constant boiling of the specimens, the Autoclave reactor (ECO solution, Seoul, Korea) was used. Specimens were artificially aged in distilled water by heat-treatment at a temperature of 75, 100, 125, 150, 175, 200, and 225℃ for 10 hours in order to induce the phase transformation at the surface.

Flexural strength

To measure the mechanical property, the specimens were subjected to a four-point bending test using a universal testing machine (Instron model 3365, Instron, Canton, Mass, USA) at a crosshead speed of 0.5 mm/min. The load to failure of the specimens was recorded in Newton (N), and the flexural strength was calculated in mega Pascal (MPa). To estimate the reliability and variability of strength, the Weibull modulus (m) was calculated. It was obtained from the slope of the curve generated by plotting ln[ln 1/(1-Pf)] against lnσ.

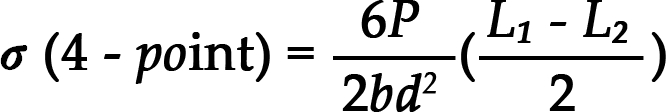

The following equation was used to calculate the flexural strength.10

Where P is the load at failure, L1 and L2 are the outer and inner span length respectively. b is the specimen's breadth, and d is the specimen's height. In this study, L1: 30 mm, L2: 10 mm, b: 4 mm, and d: 3 mm.

X-ray diffraction analysis

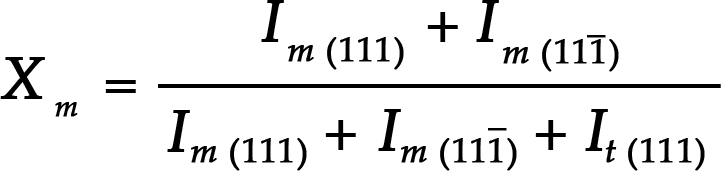

To measure the crystalline phase fraction, X-ray diffraction (DMAX 2500; Rigaku, Tokyo, Japan) was carried out. The specimens were placed in the holder of a diffractometer and scanned by using Cu-Kα radiation (λ= 1.54056Å) at a diffraction angle change from 25° to 40°. Step size of 0.02° and scan speed of 1 degree per minute were used to determine the peak position and composition. Peaks from the XRD output were compared with library data and the monoclinic/tetragonal phase ratio Xm was calculated using the following equation, as described by Garvie and Nicholson.11

Where Ij{h k l} is the area of the {h k l} peak of the phase j measured by XRD. The X-ray penetration depth is around 5 µm.12

Scanning electron microscopy

The image of surface grains of each subgroup was analyzed by a scanning electron microscope (Hitachi s4700, JEOL, Tokyo, Japan). Photographs were taken at magnifications of × 15.0 k, × 30.0 k. The specimens were coated with a 15 nm gold layer prior to observation in order to make their surface conductive.

Statistics

The statistical analysis was done using SAS 9.1.3 (SAS institute, Cary, USA). The flexural strength data of the experimental groups were analyzed by one-way analysis of variance to detect statistically significant differences (α= .05).

RESULTS

Flexural strength

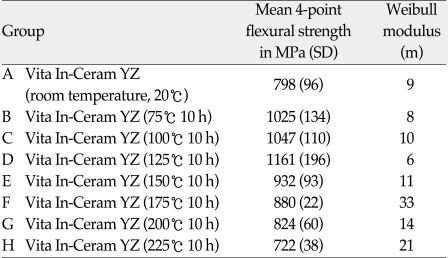

Mean 4-point flexural strength value, standard deviation, and Weibull modulus (m) of Vita In-Ceram YZ are listed in Table I. The mean flexural strength of sintered Vita In-Ceram YZ without autoclaving was 798 MPa. The specimens autoclaved at 125℃ for 10 hours had the highest flexural strength of 1161 MPa.

Table I.

Flexural strength and Weibull modulus (m) of Vita In-Ceram YZ

Scanning electron microscopy (SEM) analysis

Weibull statistics indicated that the Weibull modulus (m) was ranged from 6 to 33 (Table I).

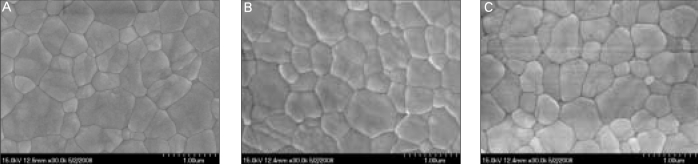

Fig. 1. showed the porous microstructure and grain size of Vita In-Ceram YZ. The average grain size of 0.5 µm was measured using the linear intercept method. The gap among the grains became definite in the groups autoclaved at 150 and 225℃ for 10 hours, compared to the specimen without autoclaving.

Fig. 1.

The images taken by scanning electron microscope.

(A) Vita In-Ceram YZ without autoclave aging, original magnification × 30.0 k (B) Vita In-Ceram YZ with autoclave aging at 150℃ for 10 hours, original magnification × 30.0 k (C) Vita In-Ceram YZ with autoclave aging at 225℃ for 10 hours, original magnification × 30.0 k

X-ray diffraction analysis

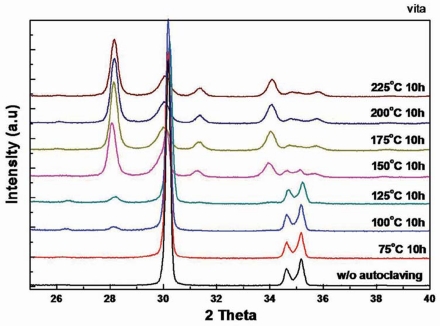

The peaks from the X-ray diffraction analysis were compared with the library data, which is the X-ray diffraction standards file (17-0923) on zirconium oxide. The results from X-ray diffraction analysis of the specimens without autoclaving revealed only the tetragonal phase. However, the X-ray diffraction analysis for the other groups indicated that they had various ratio of tetragonal and monoclinic phase related to the temperature applied. The major peaks of the tetragonal phase of Vita In-Ceram YZ in the range from 25 degree to 40 degree 2θ were 30.18, 34.62, and 35.18 degree. Also, those of the monoclinic phase were detected at 28.16 and 31.4 degree. The dominant peak was the tetragonal phase at 30.18 degree. The relative intensities of the tetragonal and monoclinic phase changed with various materials and autoclaving temperature. The monoclinic phase concentration (by % weight) was calculated from the relative intensity of the tetragonal and monoclinic peaks using the equation proposed by Garvie and Nicholson.

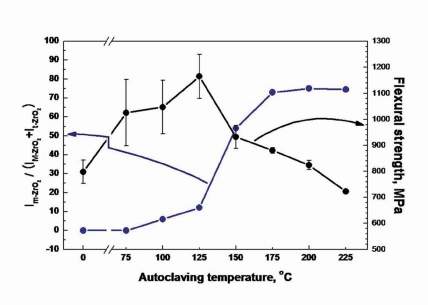

Fig. 2. shows the relationship between the ratio of monoclinic/tetragonal + monoclinic phase and various temperatures. And, Fig. 3. reveals the relationship between the flexural strength and monoclinic phase concentration of Vita In-Ceram YZ. The monoclinic phase started to appear after aging treatment above 100℃. The fraction of monoclinic phase increased as the aging temperature became higher. The ratio of monoclinic/tetragonal + monoclinic phase reached a plateau value, circa 75% above 175℃.

Fig. 2.

X-ray diffraction pattern of Vita In-Ceram YZ after aging process at different temperatures.

Fig. 3.

Graph of the flexural strength and monoclinic phase concentration of Vita In-Ceram YZ.

DISCUSSION

The data of flexural strength, monoclinic/tetragonal + monoclinic ratio, and microstructure of fractured surface indicated that the mechanical property of Y-TZP ceramic varied after low temperature aging.

Flexural strength increased from room temperature to 125℃, and at a temperature of 125℃, the flexural strength was the highest. After that, it started to decrease. This result was different from that of the previous studies. In the previous studies, low temperature aging did not reduce the flexural strength of zirconia or the degradation of strength was dependent on the aging temperature and time.5-9,13,14 The temperature applied to low temperature aging varied with the studies. Cales et al.13 applied 37℃, and Shimizu et al.14 used above 100℃ for aging temperature. In the study that low temperature aging treatment did not reduce the flexural strength, the temperature applied to the aging treatment was relatively low. In fact, 37℃ is a lower temperature than that applied in the other studies and can not cause degradation of Y-TZP in a short time.15

Chevalier et al.16 investigated the time-dependent aging changes on Y-TZP. The authors reported that the higher the temperature and dwell duration, the higher the transformation rate and it could be related to the overall grain size. As the size of tetragonal grain increased, the stability began to diminish. In this study, the specimens were aged at various temperatures for 10 hours. Aging at 134℃ for 1 hour is theoretically similar to 3 - 4 years in vivo.5,17,18 So, the experimental condition may approximately correspond to a long period of time. Chevalier et al.5 found that aging at 130℃ after 7 hours, for a monoclinic content higher than 30%, the nucleation rate reached a saturation level. In the present study, the flexural strength was higher in the group autoclaved at 125℃ for 10 hours than the group without aging. These results revealed that monoclinic concentration to some extent provides the increase of flexural strength. At first, the tetragonal-to-monoclinic phase transformation is initiated at the surface of Y-TZP. And, when the amount of monoclinic phase was small, the change of grain size and physical property was insignificant.15 On the contrary, the residual stress diminishes and the volume expansion by the phase transformation inhibits the crack propagation.2 This phenomenon may be related to the increase of flexural strength. However, when the saturation in monoclinic phase is reached at the surface, the phase transformation then proceeds into the bulk of the Y-TZP ceramic.9 Under this condition, internal flaws can be critical, and the degradation of the flexural strength occurs. Nevertheless, further reduction of the flexural strength was not observed below 700 MPa. The strengths were still higher than those of other dental ceramic systems, and those were above the value of occlusal force reported by the previous studies.19 Therefore, the strengths of Vita In-Ceram may be sufficient for allowing reliable use for crown and fixed partial denture in the posterior region.

Ceramics have a wide variability of strength due to the flaws and micro cracks inside. The Weibull modulus (m) is related to the flaw-size distribution.20 In order to get the reliability of experimental data, it is important to investigate the mean flexural strength and to estimate the Weibull modulus (m). Thus, in the study concerning ceramics, the Weibull modulus was calculated. While low m value corresponds to a wide flaw-size distribution and large error range, high m value corresponds to a narrow flaw-size distribution and outstanding reliability.20,21 Most ceramics are reported to have 'm' values in the range of 5 to 15.22 In the present study, Vita In-Ceram has'm' values in the range of 6 to 33. These facts indicate that they have great structural reliability.

Three-point bending test is the standard method for estimating the flexural strength of dental ceramics. However, in this study, 4-point bending test was performed to reflect the flaws and defects in specimens thoroughly. The 4-point bending test develops lower level of shear force in the specimen compared to the 3-point bending test.23

X-ray diffraction analysis indicated that the flexural strength was increased until up to 12% of monoclinic concentration. The flexural strength decreases remarkably above 125℃ aging temperature, At the same time, monoclinic concentration increases sharply from 12% to 75%. Further study is needed to determine the critical amount of monoclinic phase at which the flexural strength begins to fall.

It was reported that the tetragonal-to-monoclinic transformation proceeds from the external to the internal of Y-TZP ceramic.9 Therefore, it can be assumed that tetragonal-to-monoclinic phase transformation begins to proceed from the external to the internal when the amount of monoclinic increases sharply. Images taken by SEM showed that the transformation from tetragonal to monoclinic phase during low temperature aging procedure begins to make rapid progress between at 125℃ and at 150℃. Low temperature aging caused the fractured surface of Vita In-Ceram YZ to reveal an" orange peel"like texture.24 This means that each grain was pushed out of the surface and the roughness of surface increased due to low temperature aging. This change of surface may lead to the degradation of mechanical property of Y-TZP ceramics. Previous low temperature aging studies have also attributed decreased strength to phase transformation in Y-TZP ceramics.5,6,8 Due to the difficulty of performing the X-ray diffraction analysis on depth deeper than the first 5 µm, another method such as AFM is necessary for more precise analysis.5

In clinical situations, fractures of veneer and/or interface between veneer and core happen more frequently than those of including core generally.25 Therefore, flexural strength exceeds 700 MPa even after low temperature aging may not guarantee that this result would be effective in the clinical situation. In order to make the condition similar to clinical situation, it is strongly recommended to design an improved experimental model loaded repeatedly vertical and lateral with the force applied to the veneer/core specimens after low temperature aging.

CONCLUSION

1. Low temperature aging produced the positive and negative effects on the mechanical properties of Y-TZP ceramics depending on the temperature applied.

2. When applied aging temperature at below 125℃ for 10 hours, the flexural strength of Y-TZP ceramics increased. However, at above 150℃, the flexural strength started to decrease.

3. Low temperature aging caused the tetragonal-to-monoclinic phase transformation related to temperature. The monoclinic phase started to appear after aging treatment above 100℃. The fraction of monoclinic phase increased with the higher aging temperature. The ratio of monoclinic/tetragonal + monoclinic phase reached a plateau value, circa 75% above 175℃.

4. The point of monoclinic concentration at which the flexural strength begins to decrease is between 12% and 54%.

5. After aging process of various temperatures, minimum flexural strength of 700 MPa and minimum Weibull modulus of 6 was maintained.

Footnotes

This work was supported by the Korea Science and Engineering Foundation (KOSEF) grant funded by the Korea government(MOST) (No. R01-2007-000-10977-0).

References

- 1.Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999;15:426–433. doi: 10.1016/s0109-5641(99)00070-6. [DOI] [PubMed] [Google Scholar]

- 2.Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999;20:1–25. doi: 10.1016/s0142-9612(98)00010-6. [DOI] [PubMed] [Google Scholar]

- 3.Subbarao EC, Maiti HS, Srivastava KK. Martensitic transformation in zirconia. Phys Status Solidi Series A. 1974;21:9–40. [Google Scholar]

- 4.Kobayashi K, Kuwajima H, Masaki T. Phase change and mechanical properties of ZrO2-Y2O3 solid electrolyte after ageing. Solid State Ionics. 1981;3/4:489–493. [Google Scholar]

- 5.Chevalier J, Cales B, Drouin JM. Low-temperature aging of Y-TZP ceramics. J Am Ceram Soc. 1999;82:2150–2204. [Google Scholar]

- 6.Lilley E. Review of low temperature degradation in Y-TZPs. In: Tressler RE, McNallan M, editors. Ceramic transaction: corrosion and corrosive degradation of ceramics. Westerville: American Ceramics Society; 1990. pp. 387–407. [Google Scholar]

- 7.Lawson S. Environmental degradation of zirconia ceramics. J Eur Ceram Soc. 1995;15:485–502. [Google Scholar]

- 8.Deville S, Chevalier J, Fantozzi G, Bartolome JF, Requena J, Moya JS. Low-temperature ageing of zirconia-toughened alumina ceramics and its implication in biomedical implants. J Eur Ceram Soc. 2003;23:2975–2982. [Google Scholar]

- 9.Yoshimura M. Phase stability of zirconia. Am Ceram Sot Bull. 1988;67:1950–1955. [Google Scholar]

- 10.Lube T, Manner M, Danzer R. The miniaturization of the 4-point bend test. Fatigue Fract. Engng Mater Struct. 1997;20:1605–1616. [Google Scholar]

- 11.Garvie RC, Nicholson PS. Phase analysis in zirconia systems. J Am Ceram Soc. 1972;55:303–305. [Google Scholar]

- 12.Emsley J. The Elements. 2nd ed. Oxford, UK: Oxford University Press; 1991. [Google Scholar]

- 13.Cales B, Stefani Y, Lilley E. Long-term in vivo and in vitro aging of a zirconia ceramic used in orthopaedy. J Biomed Mater Res. 1994;28:619–624. doi: 10.1002/jbm.820280512. [DOI] [PubMed] [Google Scholar]

- 14.Shimizu K, Oka M, Kumar P, Kotoura Y, Yamamuro T, Makinouchi K, Nakamura T. Time-dependent changes in the mechanical properties of zirconia ceramic. J Biomed Mater Res. 1993;27:729–734. doi: 10.1002/jbm.820270605. [DOI] [PubMed] [Google Scholar]

- 15.Pittayachawan P, McDonald A, Petrie A, Knowles JC. The biaxial flexural strength and fatigue property of Lava Y-TZP dental ceramic. Dent Mater. 2007;23:1018–1029. doi: 10.1016/j.dental.2006.09.003. [DOI] [PubMed] [Google Scholar]

- 16.Chevalier J, Deville S, Münch E, Jullian R, Lair F. Critical effect of cubic phase on aging in 3mol% yttria-stabilized zirconia ceramics for hip replacement prosthesis. Biomaterials. 2004;25:5539–5545. doi: 10.1016/j.biomaterials.2004.01.002. [DOI] [PubMed] [Google Scholar]

- 17.Cales B. Zirconia as a sliding material: histologic, laboratory, and clinical data. Clin Orthop Relat Res. 2000;379:94–112. [PubMed] [Google Scholar]

- 18.Deville S, Gremillard L, Chevalier J, Fantozzi G. A critical comparison of methods for the determination of the aging sensitivity in biomedical grade yttria-stabilized zirconia. J Biomed Mater Res B Appl Biomater. 2005;72:239–245. doi: 10.1002/jbm.b.30123. [DOI] [PubMed] [Google Scholar]

- 19.Suárez MJ, Lozano JF, Paz Salido M, Martínez F. Three-year clinical evaluation of In-Ceram Zirconia posterior FPDs. Int J Prosthodont. 2004;17:35–38. [PubMed] [Google Scholar]

- 20.Oblak C, Jevnikar P, Kosmac T, Funduk N, Marion L. Fracture resistance and reliability of new zirconia posts. J Prosthet Dent. 2004;91:342–348. doi: 10.1016/j.prosdent.2004.01.009. [DOI] [PubMed] [Google Scholar]

- 21.Roebben G, Basu B, Vleugels J, Van der Biest O. Transformation-induced damping behaviour of Y-TZP zirconia ceramics. J Eur Ceram Soc. 2003;23:481–489. [Google Scholar]

- 22.Guazzato M, Quach L, Albakry M, Swain MV. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J Dent. 2005;33:9–18. doi: 10.1016/j.jdent.2004.07.001. [DOI] [PubMed] [Google Scholar]

- 23.Wen MY, Mueller HJ, Chai J, Wozniak WT. Comparative mechanical property characterization of 3 all-ceramic core materials. Int J Prosthodont. 1999;12:534–541. [PubMed] [Google Scholar]

- 24.Ardlin BI. Transformation-toughened zirconia for dental inlays, crowns and bridges: chemical stability and effect of low-temperature aging on flexural strength and surface structure. Dent Mater. 2002;18:590–595. doi: 10.1016/s0109-5641(01)00095-1. [DOI] [PubMed] [Google Scholar]

- 25.Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005;21:984–991. doi: 10.1016/j.dental.2005.03.013. [DOI] [PubMed] [Google Scholar]