Many thin films develop high residual stress during deposition. These stresses develop due to grain boundaries, dislocations, voids, and impurities within the film itself, or interfacial factors such as a lattice mismatch, difference in thermal expansion, or adsorption.[1–4] It is known that these intrinsic stresses can cause the spontaneous curving of substrates on which they are deposited.[5] If the substrate is much thicker than the stressed thin film, the substrate curves with a large radius of curvature. [6] In contrast, when the stressed thin film is deposited atop or below another thin film and the films are released from the substrate, it will spontaneously curve with a micro or nanoscale radii of curvature. [7–13] However, it is challenging to get the high intrinsic stress magnitudes needed to enable assembly with small nanoscale radii of curvature; typically, heteroepitaxial deposition at elevated temperatures is required, [11–13] which limits the types of devices and structures that can be assembled.

In addition to intrinsic stresses which build up during the deposition of thin films, stresses can also be induced following growth, post-deposition, by external factors. These extrinsic stresses can be generated by a variety of mechanisms such as a temperature change, chemical reactions, magnetic forces, or electric fields. [14–17] One advantage of using extrinsic stresses is that the self-assembly can be controlled to occur only when desired. In contrast, multilayer thin films with intrinsic stress assemble spontaneously on release from the substrate. [18]

In this communication, we describe the utilization of extrinsic stresses that develop due to grain coalescence in tin (Sn) films on heating, after deposition. The methodology required only thermal evaporation and low temperature processing; the layers could also easily be patterned with conventional electron-beam (e-beam) lithographic processing, and the self-assembly could be controlled to occur only when required.

After metal deposition, grain coalescence was triggered by plasma etching of the Si substrate with CF4 / O2; the chemical reactions which occur during etching are exothermic, [19–20] and the extent of grain coalescence increased with increasing plasma etching times (Fig. S1 in Supporting Information). This heating induced grain coalescence is accompanied by an increase in the stress within the Sn film (Fig. 1a). Hence, when grain coalescence was induced in Sn films, the edges curled up on release from the underlying Si substrate (Fig. 1b). This curving of Sn films can be rationalized by noting that a stress gradient develops in the coalescing thin film. Since the deposited Sn film was discontinuous (as a result of a Volmer-Weber growth[21]), however, the radius of curvature at the rolled-up edges was not uniform and was additionally difficult to control reproducibly. Moreover, it was challenging to pattern and create functional nanostructures with these discontinuous, single-layer Sn films.

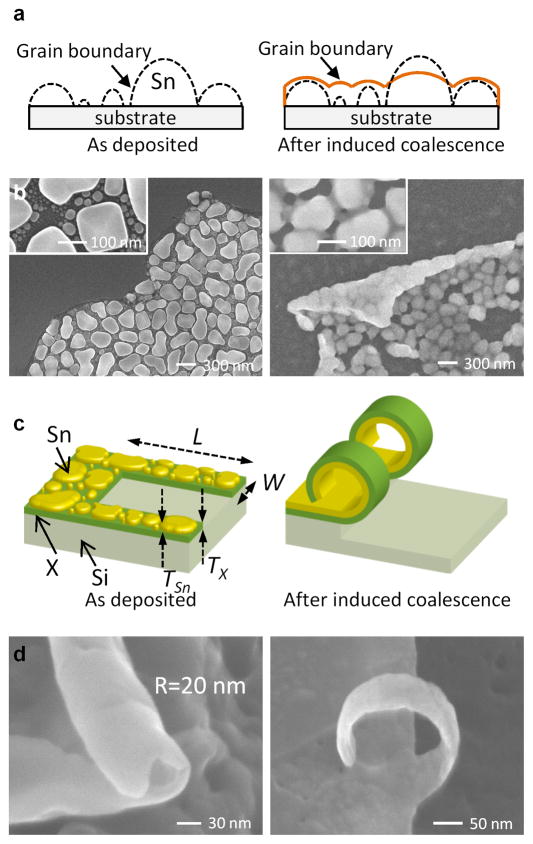

Figure 1.

Conceptual sketches and scanning electron microscopy (SEM) images showing the origin of the high extrinsic stress observed within the Sn film that caused Ni / Sn bilayers to curl up with nanoscale radii of curvature. a) The induction of grain coalescence in Sn films during plasma processing causes a large extrinsic stress. b) SEM images of Sn thin films deposited on bare Si before and after grain coalescence. Grain coalescence resulted in spontaneous curving of the released edges of the film due to the stress gradient generated. c) When deposited atop a Ni film, the stress generated within the Sn thin film due to grain coalescence was large enough to cause the Sn / Ni bilayer to curl up. d) SEM image of Ni / Sn bilayer curving into a nanoscale tubular structure with 20 nm radii of curvature. Also shown is a nanoscale ring.

Hence, in order to utilize this extrinsic stress to reproducibly curve patterned nanostructures, we investigated the insertion of a continuous film (denoted as X), in between the Si substrate and the Sn film to form a Si / X / Sn multilayer stack. Since the constituent X in the bilayer was continuous, it could be patterned on the nanoscale using e-beam lithography. To retain the induction of grain coalescence observed on bare Si (Figure 1a–b), it was necessary that the interfacial energy of the material X was such that the deposited Sn film also showed a Volmer-Weber or grain growth (similar to the morphology observed when Sn was deposited on bare Si; Fig. 1a–b). Then grain coalescence and the associated extrinsic stress could then be induced after deposition and during plasma etching of the underlying Si (Fig. 1c). We observed that nickel (Ni), silica (SiO2), and alumina (Al2O3) satisfy this criterion. E-beam patterned Ni / Sn bilayer films (Fig. 1d) did indeed curve on heating during the exothermic Si etching process. The smallest radii R = 20 nm (Fig. 1d), measured from electron microscopy images, was achieved with a thickness of 5 nm Ni and 5 nm Sn.

Several control experiments were carried out to confirm that the curving of the bilayers was induced by grain coalescence in the Sn film (Fig. 2 and Fig. S2 in Supporting Information). We decoupled the release of the bilayers from the Si substrate and the induced grain coalescence by introducing a polymeric (polyvinyl alcohol, PVA) sacrificial release layer between the Si substrate and Ni / Sn patterned bilayers (Fig. 2a). When this PVA layer was dissolved in water, and the patterned Ni / Sn bilayers were released from the underlying substrate, no discernible curvature was observed (Fig. 2b). This experiment indicates that the intrinsic stresses in these metals were not significant enough to curve them. Subsequently, curvature of these released flat patterned bilayers could be induced by grain coalescence (Fig. 2c), confirming that the extrinsic stresses were responsible for the curvature observed and also that the assembly can be triggered post-deposition, when required. In the absence of the Sn film, curvature could not be induced in single layer Ni films indicating that no significant extrinsic stress were generated within these films during plasma etching of Si. It should also be noted that these small nanoscale radii cannot arise from the small differences in thermal expansion coefficients on Sn (22.0 μm • m−1 • °C−1) and Ni (13.4 μm • m−1 • °C−1).[22] Finally, the direction of bilayer curving was always the same and was consistent with the direction that would be expected with a coalescing Sn film atop a relatively neutral stressed Ni film.

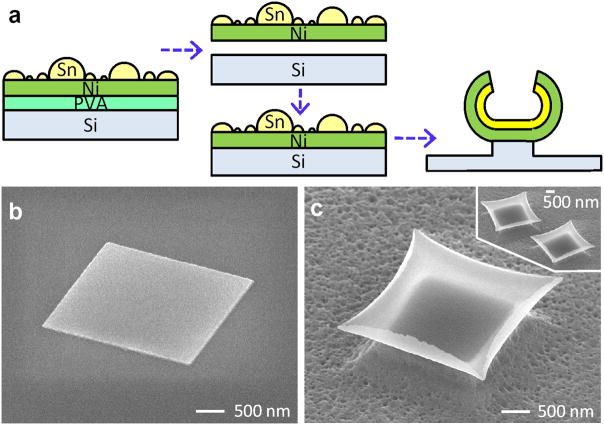

Figure 2.

Control experiment with a polymeric sacrificial layer demonstrating that the release of the structure from the underlying substrate and the self-assembly steps can be decoupled. a) Schematic showing the deposition of a Ni / Sn bilayer atop a polyvinyl alcohol (PVA) sacrificial layer. On dissolution of this sacrificial layer no curvature was observed in the released structure. Curvature was triggered only by inducing grain coalescence which could be achieved in a subsequent step. SEM images of a square patterned Ni 5 nm / Sn 5 nm film b) after release from the Si substrate showing no curvature and c) after Sn grain coalescence was induced.

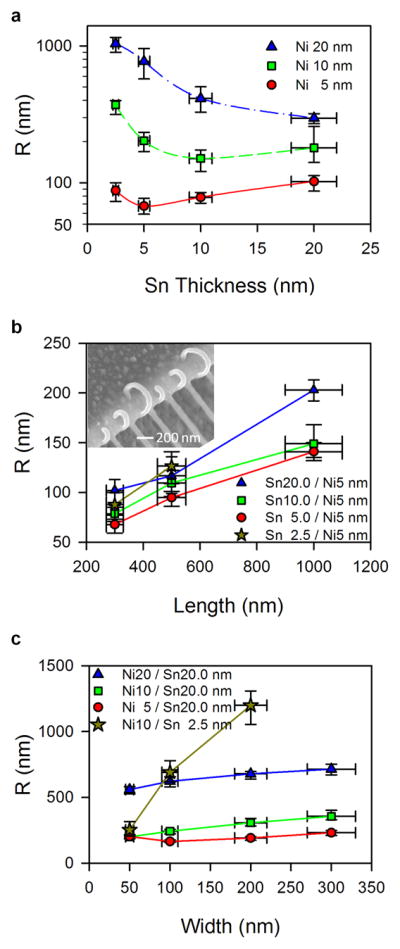

In order to study the geometric factors affecting curvature, we designed 2D cantilever shaped Ni / Sn bilayers with varying thickness (T), length (L), and width (W) using e-beam lithography and lift-off metallization. We observed that the radii of curvature (R) varied considerably when T, L and W were varied (Fig. 3). For the same deposition thickness of Sn, bilayer cantilevers composed of thinner Ni films showed tighter radii of curvature (i.e. smaller R, Fig. 3a [W= 50nm and L= 300nm]). In this cantilever geometry, we observed average R values as low as 70 nm (at a 5 nm Sn and 5 nm Ni thickness). Longer and wider cantilevers both curved with larger R values (Fig. 3b–c). We do not have an explanation for the observed increase in radius with increasing length however, this observation was reproducible.

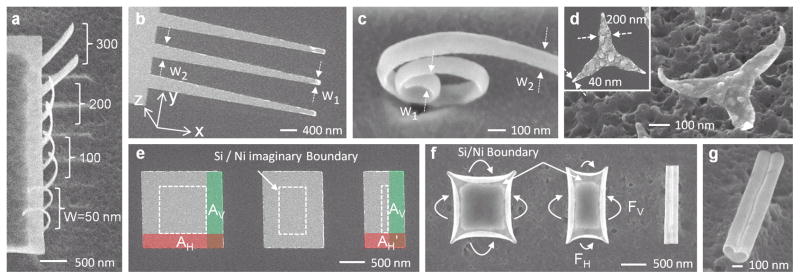

Figure 3.

Experimental results showing the variation of the radii of curvature with the cantilever geometry. a) Variation in thickness (L=300 and W= 50 nm). b) Variation in length (W=50 nm). c) Variation in width (L=1000 nm).

The observation of increasing R with increasing W (Fig. 3c and 4a) can be explained by considering an area moment of inertia (the second moment of area) argument (Fig. 4 and Fig. S3 in Supporting Information). It is known that the resistance of a beam to bending increases with increasing area moment of inertia. [23] Since the beams show simultaneous bending along orthogonal axes, when we increase W, the rolled cross-sectional area (along yz plane) increases, thus increasing the area moment of inertia in wider portion of the beam (Fig. S3 b in Supporting Information). For the same thicknesses of Sn and Ni on cantilevers with varying width, we observed tighter curving (or smaller R values) for the narrower regions. Therefore, by varying the width of the 2D structures we could construct nanostructures with homogeneous radii of curvature (tubes rings and scrolls) as well as those with varying radii (spirals and talons) (Fig. 4). Detailed explanations of the area moment of inertia vs. R are included in the Supplementary Information (Fig. S3).

Figure 4.

SEM images of the variation of curvature with varying widths showing that nanostructures with both homogeneous and varying radii of curvature can be self-assembled. a) SEM image of the curving of cantilevers with different widths (50, 100, 200, and 300 nm). All cantilevers have the same L= 1 μm and thickness (Ni 10 / Sn 2.5 nm). Cantilevers with the same width show the same radii of curvature, while those of larger widths have larger radii of curvature. This result highlights the reproducibility of the self-assembly process. b) SEM image of cantilevers with varying width along the length of the cantilever (i.e. W1<W2). c) A cantilever with such varying width curves with a varying radii of curvature due to a varying area moment of inertia, resulting in the formation of a nanospiral. d) Nanoscale three-fingered talon shaped structures before and after coalescence. e)-f) Square and rectangular patterns (Sn 5 nm / Ni 5 nm) before and after coalescence developing bending forces FV and FH of different magnitudes and directions. g) Tilted zoomed-in image of the nanoscroll shown in Figure 4f).

The etching geometry of the underlying substrate can also be used to control the structure formed. We observed that square shaped panels curved equally on all four sides, while rectangular shaped panels curved predominantly along the direction of least resistance i.e. along the axis with the smallest area moment of inertia (Fig. 4e–g). The shaded region in the Fig. 4e refers to the region that will be released from the substrate assuming an isotropic etch rate within the plane.

Since this assembly process was compatible with conventional e-beam processing, curved structures could be created with any desired patterns (Fig. 5). Structures were first defined in 2D using e-beam lithography with line widths as small as 20 nm (Fig. S4 in Supporting Information). To demonstrate patterning versatility, we defined structures with pores and the letters JHU and NANOJHU on them. When grain coalescence was induced, these structures curved spontaneously to form porous nanotubes and lithographically patterned scrolls, rings, and hooks. We also created structures composed of Al2O3 / Sn (Fig. 5f); the viability of curving nanostructures composed of both metallic or dielectric (insulating) materials are important for electronic and photonic applications. [24] The fact that Al2O3 / Sn structures curved also strengthens our proposed mechanism of grain coalescence driving curvature (as opposed to for example Sn/Ni intermetallic formation or other such thermally diffusive or chemically reactive processes).

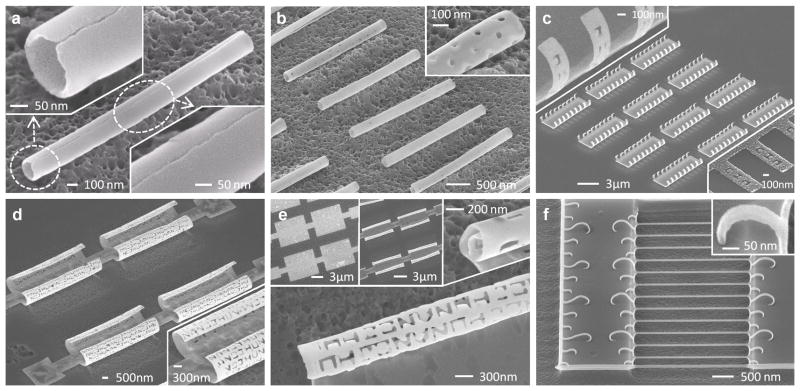

Figure 5.

Demonstration of surface patterning a)-e), materials versatility f) and parallel nature of the assembly process. SEM images of single rolled nanotubes without a) patterning and b) with patterning of pores. c)-e) Nanostructures such as rings and scrolls with the letters JHU and NANOJHU patterns on them. f) Curving nanostructures composed of a dielectric material namely alumina (Al2O3 6 nm / Sn 5 nm).

We envision widespread utility of the 3D curved and simultaneously patterned structures in optics, electronics, microfluidics, and medicine. Additionally, since in addition to temperature, extrinsic stresses can also be induced by chemical reactions, adsorption, and electromagnetic fields this concept can be utilized to create smart nanostructures and materials that can be reconfigured on-demand. The process is also versatile, requires only simple processing steps and is compatible with conventional microelectronic fabrication.

Experimental

Fabrication of 2D patterns on a silicon wafer

On an n-type <100> bare silicon wafer, 100 nm of an electron-beam (e-beam) resist, polymethylmethacraylate (PMMA, MW 950K 2A) was spun and the wafer was baked at 185 °C for 3 minutes. An electron beam controlled by a RAITH system (v 4.0) was used to pattern the resist. The resist was developed using an MIBK developer (1 to 3 parts IPA) for 35 seconds. Then, 0.2 nm chromium (Cr) and the respective thickness of Ni or Al2O3 were deposited using a thermal evaporator (for Ni) or an electron beam evaporator (for Al2O3). On the top of the sample, the required thickness of Sn was thermally evaporated. After evaporation, the resist was dissolved in acetone for lift-off metallization.

Fabrication of 2D patterns on PVA

This process required inserting a PVA sacrificial layer between the silicon wafer and PMMA. On an n-type <100> bare silicon wafer, 500 nm thick PVA was spun and the wafer was baked at 115°C for 12 hours. On top of the PVA layer, PMMA was spun and baked. After e-beam lithography and metal deposition, the sample was dissolved in acetone for lift-off metallization. Acetone will dissolve the e-beam resist; however, it does not attack PVA, because PVA is a water-soluble polymer. In order to dissolve PVA, the samples were rinsed a couple of times in deionized water.

Induction of grain coalescence

The samples were loaded in a planar etcher (Technics PEII-A) at a base pressure of 0.15 Torr. Carbon tetrafluoride (CF4) and oxygen (O2) were flowed into the etcher for 3 minutes and 25W RF power was applied for 3 minutes. Significant grain coalescence occurred during this time period, after which the power was turned off, and the pressure in the etcher was slowly increased to 1 atm over a period of 5 minutes.

Supplementary Material

Acknowledgments

This research was supported by the NIH Director’s New Innovator Award Program, part of the NIH Roadmap for Medical Research, Grant No. 1-DP2-OD004346–01 and by the National Science Foundation (NSF) Grant No. 0854881. Supporting Information is available online from Wiley InterScience or from the author.

References

- 1.Stoney GG. Pro R Soc London A. 1909;82:172. [Google Scholar]

- 2.Nix WD. Metall Mater Trans A. 1989;20:2217. [Google Scholar]

- 3.Freund LB, Suresh S. Thin film materials: stress, defect formation and surface evolution. Cambridge University Press; New York: 2009. [Google Scholar]

- 4.Koch R. J Phys Condens Matter. 1994;6:9519. [Google Scholar]

- 5.Hoffman RW. Thin Solid Films. 1976;34:185. [Google Scholar]

- 6.Ohring M. Materials Science of Thin Films. Academic Press; San Diego: 2002. pp. 711–781. [Google Scholar]

- 7.Chua CL, Fork DK, Schuylenbergh KV, Lu JP. J Microelectromech S. 2003;12:989. [Google Scholar]

- 8.Nastaushev YV, Prinz VY, Svitasheva SN. Nanotechnology. 2005;16:908. [Google Scholar]

- 9.Schmidt OG, Schmarje N, Deneke C, Muller C, Jin-Phillipp NY. Adv Mater. 2001;13:756. [Google Scholar]

- 10.Huang M, Boone C, Roberts M, Savage DE, Lagally MG, Shaji N, Qin H, Blick R, Nairn JA, Liu F. Adv Mater. 2005;17:2860. [Google Scholar]

- 11.Prinz VY, Seleznev VA, Gutakovsky AK, Chehovskiy AV, Preobrazhenskii VV, Putyato MA, Gavrilova TA. Phys E. 2000;6:828. [Google Scholar]

- 12.Schmidt OG, Eberl K. Nat. 2001;410:168. doi: 10.1038/35065525. [DOI] [PubMed] [Google Scholar]

- 13.Mei Y, Thurmer DJ, Deneke C, Kiravittaya S, Chen YF, Dadgar A, Bertram F, Bastek B, Krost A, Christen J, Reindl T, Stoffel M, Coric E, Schmidt OG. Acs Nano. 2009;3:1663. doi: 10.1021/nn900580j. [DOI] [PubMed] [Google Scholar]

- 14.Berger R, Delamarche E, Lang HP, Gerber C, Gimzewski JK, Meyer E, Güntherodt H-J. Science. 1997;276:2021. [Google Scholar]

- 15.Fritz J, Baller MK, Lang HP, Rothuizen H, Vettiger P, Meyer E, Güntherodt H-J, Gerber Ch, Gimzewski JK. Science. 2000;288:316. doi: 10.1126/science.288.5464.316. [DOI] [PubMed] [Google Scholar]

- 16.Liu C, Tsao T, Lee GB, Leu JTS, Yi YW, Tai Y-C, Ho C-M. Sens Actuators, A. 1999;78:190. [Google Scholar]

- 17.Weissmüller J, Viswanath RN, Kramer D, Zimmer P, Würschum R, Gleiter H. Science. 2003;300:312. doi: 10.1126/science.1081024. [DOI] [PubMed] [Google Scholar]

- 18.Bassik N, Stern GM, Gracias DH. Appl Phys Lett. 2009;95:091901. doi: 10.1063/1.3212896. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Cho JH, Gracias DH. Nano Lett. 2009;9:4049. doi: 10.1021/nl9022176. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Magunov AN. Instrum Exp Tech. 2000;43:706. [Google Scholar]

- 21.Hishita S, Stryhal Z, Sakaguchi I, Ohashi N, Saito N, Haneda H. Thin Solid Films. 2004;464–465:146. [Google Scholar]

- 22.Lide DR. CRC Handbook of Chemistry and Physics. Sec 12. CRC Press; Boca Raton: 2009. [Google Scholar]

- 23.Pilkey WD. Analysis and Design of Elastic Beams. John Wiley & Sons; New York: 2002. [Google Scholar]

- 24.Smith EJ, Liu Z, Mei Y, Schmidt OG. Nano Lett. 2010;10:1. doi: 10.1021/nl900550j. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.