Abstract

Laccases are blue multicopper oxidases, catalyzing the oxidation of an array of aromatic substrates concomitantly with the reduction of molecular oxygen to water. These enzymes are implicated in a variety of biological activities. Most of the laccases studied thus far are of fungal origin. The large range of substrates oxidized by laccases has raised interest in using them within different industrial fields, such as pulp delignification, textile dye bleaching and bioremediation. Laccases secreted from native sources are usually not suitable for large-scale purposes, mainly due to low production yields and high cost of preparation/purification procedures. Heterologous expression may provide higher enzyme yields and may permit to produce laccases with desired properties (such as different substrate specificities, or improved stabilities) for industrial applications. This review surveys researches on heterologous laccase expression focusing on the pivotal role played by recombinant systems towards the development of robust tools for greening modern industry.

Key words: laccase, yeasts, filamentous fungi, heterologous expression, directed evolution, industrial application

Introduction

Laccase (benzenediol:oxygen oxidoreductase; p-diphenol oxidase EC 1.10.3.2), a blue multi copper oxidase (MCO), was first discovered by Yoshida (1883)1 in the latex of the Chinese or Japanese lacquer trees (Rhus sp.). In plant these enzymes seem to be involved in lignification, in wound healing as part of an herbivore or pathogen defense response, and in iron metabolism.2 Fungal laccases were discovered during the 19th century.3 Laccases are thought to be nearly ubiquitous among fungi, and their presence has been documented in virtually every fungus examined so far.4 In fungi, laccases carry out a variety of physiological roles including morphogenesis, fungal plant-pathogen/host interaction, stress defence and lignin degradation.4 In general, fungal laccases are monomeric globular proteins of approximately 60–70 kDa with acidic isoelectric point (pI) around pH 4.0, although several exceptions exist. The majority of fungal laccases are extracellular enzymes generally glycosylated, with an extent of glycosylation usually ranging between 10 and 25% and only in few cases higher than 30%. Multiplicity of laccase genes is a common feature in fungi and plants, and the production of several laccase isoenzymes has been observed in many species. Some phenoloxidases showing “laccase properties” have been purified from larval and adult cuticles of several insects, probably associated with the sclerotization process.5 Now, there is increasing evidence for the existence of proteins with typical features of the multi-copper oxidase enzyme family also in prokaryotes.6 Laccase encoding genes have been found in gram-negative and gram-positive bacteria, including species living in extreme habitats. Early reports of laccases in actinomycetes were based on rather non-specific substrate reactions, but have been verified for some bacteria of genera Streptomyces.7 Role attributes to bacterial laccases include copper homeostasis, sporulation, or pigmentation of spores to confer resistance to stress factors such as UV radiation or hydrogen peroxide.8

Laccases couple the four single electron oxidations of a reducing substrate to the four electron reductive cleavage of the dioxygen bond, using four Cu atoms distributed into three sites, defined according to their spectroscopic properties.4 Typical metal content of laccases includes one type-1 copper (T1), one type-2 (T2) and two type-3 copper (T3) ions, with T2 and T3 arranged in a trinuclear cluster (TNC). The type 1 site contains the blue copper, whose tight coordination to a cysteine is responsible for an intense SCys → Cu(II) charge transfer transition at around 600 nm, giving the typical blue color to the enzyme. The T2 shows a characteristic electron paramagnetic resonance (EPR) spectrum, clearly distinct from that of T1, whereas T3 coppers are anti-ferromagnetically coupled and EPR-silent ions.

T1 exhibits a planar triangular coordination with the sulfur atom of a cysteine and with the Nδ1 nitrogen of two histidines. The three T2/T3 ions are arranged in a triangular fashion and coordinated to a strongly conserved pattern of four His-X-His motifs.9 Six of such histidine residues coordinate the T3 copper pair, whereas the T2 is coordinated by the remaining two histidine residues. Electrons from the reducing substrate are extracted from the T1, the primary electron acceptor, and then transferred to the TNC through a highly conserved His-Cys-His tripeptide, where the four electron reduction of dioxygen to water takes place.

A number of 3D structures of laccases have been solved. All the fungal laccases exhibit a similar molecular architecture organized in three sequentially arranged cupredoxin-like domains.4 The T1 is located in domain 3, whilst the TNC cluster is embedded between domains 1 and 3 with both domains providing residues for coppers coordination.

Laccases exhibit an extraordinary range of natural substrates (phenols, polyphenols, anilines, aryl diamines, methoxy-substituted phenols, hydroxyindols, benzenethiols, inorganic/organic metal compounds and many others) which is the major reason of their attractiveness for dozens of biotechnological applications.10 The repertory of laccase catalyzed oxidative reactions can be enlarged by the means of the so-called mediators. Suitable redox mediators are good laccase substrates, whose oxidized forms have a half-life long enough to permit their diffusion towards otherwise non-oxidable laccase substrates (non-phenolic substrates or large molecules), and possess high oxidation potential to allow laccases to indirectly oxidize them.11

A number of applications for laccases have been proposed in several industrial sectors, such as textile, food, paper and pulp, pharmaceutical, chemistry, nano-biotech, cosmetic, along with their application in bioremediation. As a fact, laccases can be adopted (1) to bleach textiles;12 (2) to eliminate undesirable phenolics responsible for the browning, haze formation and turbidity development in clear fruit juice, beer and wine;13 (3) to bleach wood pulp;14 (4) to synthesize various functional organic compounds such as drug, dyes;15,16 (5) to produce various polymers;17 (6) to detect molecules in biosensor devices;18 (7) to produce power in biofuel cells;19 (8) and to dye hair.20 As far as bioremediation is concerning, laccases may be applied to decolorize textile effluents;21 to degrade plastic waste having olefin units;20 to eliminate odor emitted from places such as garbage disposal sites, livestock farms, or pulp mills;20 to remove phenolic compounds from olive oil mills20,22 and pulp mills wastewaters;20 and to decontaminate soils from polycyclic aromatic hydrocarbon (PAH).20

Laccase Recombinant Expression

Laccase production from native sources cannot meet the increasing market demand due to low yields incompatibility of the standard industrial fermentation processes with the conditions required for the growth of many microorganisms. Recombinant protein expression in easily cultivable and handling hosts can allow higher productivity in shorter time and reduces the costs of production. The versatility and scaling-up possibilities of the recombinant protein production opened up new commercial opportunities for their industrial uses.23 Enzyme productivity can be increased by the use of multiple gene copies, strong promoters and efficient signal sequences, properly designed to address proteins to the extracellular medium, thus simplifying downstream processing. Moreover, protein production from pathogenic or toxin-producing species can take advantage of safer or even GRAS (generally recognized as safe) microbial hosts. In addition, protein engineering can be employed to improve the stability, activity and/or specificity of an enzyme, thus tailor made enzymes can be produced to suit the requirement of the users or of the process. Enzymes of superior quality have been obtained by site-directed or random mutagenesis, where single changes in aminoacidic sequences yield improvement in biochemical (pH optimum, thermostability, substrate specificity) and catalytic parameters (vmax, KM and Ki). Also, pooling and recombining parts of similar genes from different species or strains by “DNA shuffling” methods, yields remarkable improvements in enzymes in a very short amount of time.24

Since the beginning of nineties, recombinant expression of laccases has been field of research and matter of debate of many researcher groups. Heterologous expression of laccases in bacteria, yeasts, filamentous fungi and plants has been reported, along with examples of homologous expression.25–30

Laccase heterologous expression in Escherichia coli has been often used as a strategy to get around the problem of obtaining laccases not easily producible in natural hosts. The recombinant expression of Bacillus subtilis CotA in E. coli has allowed its deep characterization, structure solving, and functional evolution.8,31,32 However, very often the production yield is low, and recombinant enzymes form aggregates difficult to purify.33 On the other hand, recombinant production of Streptomyces coelicolor laccase (SLAC) in Streptomyces lividans has yielded considerable large amount of laccase (350 mg l−1) with high purity.34

The laccase from the ligninolytic fungus Cyathus bulleri has been just recently expressed in E. coli making it the first fungal laccase to be expressed in a bacterial host.35 A collection of references on recombinant expression of laccases in bacterial hosts is available in Table 1.36–46

Table 1.

List of heterologously expressed laccases in bacteria References regarding laccase engineering are in red.

| Laccase | Source | Bacteria | Reference |

| PpoA | Marinomonas mediterranea | 36 | |

| 8 | |||

| 31 | |||

| CotA | Bacillus subtilis | 37 | |

| 38 | |||

| 39 | |||

| 32 | |||

| EpoA | Streptomyces griseus | 40 | |

| STSL | Streptomyces lavendulae REN-7 | Escherichia coli | 33 |

| Lbh1 | Bacillus halodurans | 41 | |

| SLAC | Streptomyces coelicolor | 42 | |

| Tth-laccase | Thermus thermophilus HB27 | 43 | |

| McoA | Aquifex aeolicus | 44 | |

| CotA | Bacillus licheniformis | 45 | |

| 46 | |||

| SilA | Streptomyces ipomea | 7 | |

| Cbu-laccase | Cyathus bulleri | 35 | |

| SLAC | Streptomyces coelicolor | Streptomyces lividans | 34 |

References regarding laccase engineering are in red.

Plants have been successfully used as hosts for the recombinant expression of fungal and plant laccases. Expression of secreted recombinant laccases can result, for example, in phytoremediation systems.47,48 Furthermore, the overexpression of a potato laccase (PPO) in tomato conferred to the transgenic plant an enhanced resistance against a bacterial pathogen.49 A collection of references on laccase recombinant expression in plants is available in Table 2.50–54

Laccase recombinant expression has also been accomplished in insect Sf9 cells, via a baculovirus expression system, leading to a deep characterization of the insect laccase from tobacco hornworm, Manduca sexta.55

A deeply review of the available literature data on recombinant expression and engineering of laccases in yeasts and filamentous fungi is given in the following paragraphs.

Yeast Recombinant Systems

Yeasts offer the quickness of microbial growth and ease of microbial and gene manipulation of bacteria along with the ability to perform eukaryote-specific post-translational modifications, such as proteolytic processing, disulfide bridge formation, and glycosylation. Yeast growths are economical, usually give high yields, and are low demanding in terms of time and effort.56 Furthermore, yeasts are organisms suitable for creating new enzymes with desirable characteristics. Saccharmoyces cerevisiae and Pichia pastoris have often been the yeasts of choice for laccase recombinant expression. Also plant laccases were produced in these two yeasts.47,57 As a fact, P. pastoris is always a better producer of recombinant laccases with respect to S. cerevisiae, giving yields from 858 to 17 mg l−1.59 Hyper-glycosylated laccases are often produced in such conventional yeasts. First results of heterologous expression of fungal laccases in the non-conventional yeasts Kluyveromyces lactis,60 Yarrowia lipolytica,61 and Pichia methanolica62 have become available in 2005, with yields comparable to those obtained using other yeasts and a limited extent of glycosylation. A complete list of heterologously expressed laccases in yeasts is reported in Table 3.63–117

Table 3.

List of heterologously expressed laccases in yeasts

| Laccase | Source | Yeast | Reference |

| PO1 | Coriolus hirsutus | 63 | |

| PO2 | Coriolus hirsutus | 63 | |

| LCC1 | Trametes versicolor | 64 | |

| LCC2 | Trametes versicolor | 64 | |

| 65 | |||

| LAC2 | Pinus taeda | 57 | |

| LCC1 | Trametes sanguinea M85-2 | 66 | |

| 67 | |||

| 68 | |||

| MtL | Myceliophthora thermophyla | 69 | |

| 70 | |||

| 71 | |||

| 72 | |||

| LACIII | Trametes versicolor | 73 | |

| LAC1 | Melanocarpus albomyces | 74 | |

| 75 | |||

| LAC1 | Trametes sp. strain C30 | 76 | |

| LAC2 | Trametes sp. strain C30 | Saccharomyces cerevisiae | 76 |

| LAC3 | 76 | ||

| 77 | |||

| LAC3/LAC1 | Trametes sp. strain C30 | 78 | |

| LAC3/LAC2 | 78 | ||

| LAC3/LAC5 | 78 | ||

| POXC | Pleurotus ostreatus | 60 | |

| 60 | |||

| 79 | |||

| POXA1b | Pleurotus ostreatus | 80 | |

| 81 | |||

| 82 | |||

| LCC1 | Pycnoporus coccineus | 83 | |

| LCCα | Trametes versicolor UAMH8272 | 84 | |

| LAC2 | Coprinellus congregatus | 85 | |

| Ery3 | Pleurotus eryngii | 86 | |

| POX3 | Pleurotus ostreatus | 87 | |

| POX4 | Pleurotus ostreatus | 87 | |

| 88 | |||

| LCC1 | Trametes versicolor | 89 | |

| 90 | |||

| LAC1 | Cryptococcus neoformans | 91 | |

| LCCI | Trametes versicolor | 92 | |

| LAC1 | Pycnoporus cinnabarinus | 58 | |

| LCC1 | Trametes sanguinea M85-2 | 66 | |

| LCCIV | Trametes versicolor | 93 | |

| LAC4 | Pleurotus sajor-caju | 94 | |

| LCCT | Panus ridis | 95 | |

| LCC | Fome lignosus | 96 | |

| 97 | |||

| LAC1 | Gossypium arboreum | Pichia pastoris | 47 |

| LAC1 | Flammulina velutipes | 98 | |

| LCCPol | Pleurotus ostreatus | 99 | |

| LCC1 | Trametes versicolor | 100 | |

| LCC2 | Trametes versicolor | 100 | |

| LCC1 | Trametes trogii | 59 | |

| LAC a | Trametes sp. AH28-2 | 101 | |

| LACB | Trametes sp. AH28-2 | 102 | |

| 103 | |||

| LACD | Trametes sp. 420 | 104 | |

| 105 | |||

| 106 | |||

| LACC | Trametes sp. 420 | 107 | |

| GLlac1 | Ganoderma lucidum | 108 | |

| LAC | Pycnoporus sanguineus | 109 | |

| LCC2 | Trametes trogii | 110 | |

| POXC | Pleurotus ostreatus | ||

| POXA1b | Pleurotus ostreatus | 60 | |

| LCC1 | Trametes trogii | Kluyveromyces lactis | 111 |

| 112 | |||

| POXA3b | Pleurotus ostreatus | 113 | |

| POX3 | Pleurotus ostreatus | 87 | |

| POX4 | Pleurotus ostreatus | 87 | |

| LACIIIb | Trametes versicolor | Yarrowia lipolytica | 61 |

| 114 | |||

| LAC1 | Pycnoporus cinnabarinus | 115 | |

| LCC1 | Trametes versicolor | Pichia methalonica | 62 |

| 116 | |||

| 117 |

References regarding laccase engineering are in red.

It is worth to note the considerable variability of production yields with respect both to cDNAs expressed and to the host used for the heterologous expression. As a fact, LCC1 laccase from Trametes versicolor is actively expressed in P. pastoris88 and not in S. cerevisiae.64 Also POXC and POXA1b laccases form Pleurotus ostreatus have been expressed at higher level in K. lactis than in S. cerevisiae,60 whereas POX3 from the same source displayed the opposite behavior.87 Moreover, when K. lactis has been used as host, it is possible to note different level of expression between cDNAs originating from the same organism.60 Codon preferences between the host and the fungal source seem not to explain such differences. The inability of yeasts to process different laccases post-translationally with the same efficiency may influence the observed “selectivity” in expression.76

Laccase expression in yeasts has been investigated taking into account an array of different parameters with controversial results. For instance, both native laccase or yeast signal peptides (S. cerevisiae α-factor or invertase; K. lactis killer toxin; Y. lipolytica XPR2) have been used with different results for various expressed enzymes. Therefore, the best performing signal peptide to drive the secretion of recombinant laccases in yeasts seems not to be a priori predictable. The effect of pH, temperature, media composition, inducers, and copper has also been evaluated. High copper concentration is required for the production of active laccase at a post-translational step in a heterologous host.83 All together, these variable yields hinder forecast of the most suitable host, or the most promising laccase to express.

The availability of recombinant yeast systems has allowed to address some targets. For instance, the production of fuel ethanol from renewable raw materials has been obtained using laccase-expressing S. cerevisiae with an increased resistance of the yeast to phenolic inhibitors due to lignocellulose hydrolysates.65 Experiments to ascribe a pathogenic function to laccase from Criptococcus neoformans have been conducted using recombinant enzymes.91 Moreover, the availability of the recombinant expression system of the P. ostreatus heterodimeric laccase POXA3 in K. lactis allowed inferring a role to the quaternary structure in stabilizing laccase.113 Furthermore, heterologous expression has been often used as a strategy to get around the problem of obtaining laccase isoforms not easily producible in natural hosts.66,76,84,86,87,93

Some other authors have reported the production of recombinant laccases as a model (1) to better understand copper trafficking and the hierarchy of copper distribution in the cell;73 (2) to examine the protein quality control mechanism;83 (3) to study the induction of its own promoter by oxidative stress;85 (4) to explore the possible use of hypoxic induction of the KlPDC1 promoter to direct heterologous gene expression in yeasts.111

Development of applications of recombinant laccases from yeasts is discussed in a next section.

Filamentous Fungi Recombinant Systems

The attraction of filamentous fungi as production hosts is based on their natural ability to secrete large amounts of proteins into the growth medium.118 Until now, only a limited number of fungal host species has been explored for recombinant protein production. Filamentous fungi that dominate the markets as production hosts are the asexually reproducing Aspergillus niger, Aspergillus oryzae and Trichoderma reesei. Consequently, most reports on heterologous laccase expression concern studies on these fungi, and few examples in the genetically well-characterized Aspergillus nidulans, and in the patented expression system of Aspergillus sojae. A complete list of heterologously expressed laccases in filamentous fungi is reported in Table 4.119–158 The yields of heterologous laccases obtained in filamentous fungi are considerably higher than those obtained in yeasts, generally in the range of hundreds of milligrams per litre. The production levels reported for the expression of Melanocarpus albomyces laccase in T. reesei are the highest heterologous laccase expression levels reported so far, allowing the obtainment of 230 mg l−1 in shake-flask cultures, 290 mg l−1 in batch fermentations, and 920 mg l−1 in fed-batch fermentation.121 Actually, a series of investigations on laccases has been accomplished through heterologous production in fungi. The conclusions inferred by Xu and co-workers128 regarding redox potential, substrate specificity and stability of recombinant laccases expressed in A. oryzae well illustrate this point. Likewise, the recombinant laccase of Trametes villosa in A. oryzae was investigated to elucidate the reaction mechanism of the reduction of dioxygen to water by stopped-flow experiments and under steady-state conditions.134 Moreover, the availability of high yields of recombinant proteins has allowed solving 3D structures of the laccase from Coprinus cinereus139 and bacterial laccase from S. coelicolor expressed in A. oryzae,144 and that from M. albomyces expressed in T. reesei.123,126

Table 4.

List of heterologously expressed laccases in filamentous fungi. References regarding laccase engineering are in red.

| Laccase | Source | Filamentous fungus | Reference |

| PrL | Phlebia radiata | 119 | |

| Gene IV | Trametes versicolor | 120 | |

| 121 | |||

| 122 | |||

| Trichoderma reesei | 123 | ||

| LAC1 | Melanocarpus albomyces | 124 | |

| 125 | |||

| 126 | |||

| 75 | |||

| Laccase | Stachybotrys chartarum | 29 | |

| LCC1 | Rhizoctonia solani | 127 | |

| LCC2 | Rhizoctonia solani | 127 | |

| 127 | |||

| LCC4 | Rhizoctonia solani | 128 | |

| 129 | |||

| 130 | |||

| 131 | |||

| 128 | |||

| 132 | |||

| LCC1 | Trametes villosa (Polyporus pinsitus or Coriolus pinsitus) | 133 | |

| 18 | |||

| 130 | |||

| 134 | |||

| 135 | |||

| 136 | |||

| 128 | |||

| 129 | |||

| MtL | Myceliophthora thermophyla | Aspergillus oryzae | 18 |

| 130 | |||

| 137 | |||

| 135 | |||

| 138 | |||

| LCC1 | Coprinus cinereus | 139 | |

| 130 | |||

| 135 | |||

| Scytalidium thermophilum | 140 | ||

| 128 | |||

| LAC1 | Pycnoporus cinnabarinus | 141 | |

| LCC1 | Pycnoporus coccineus | 83 | |

| LAC1 | Trametes versicolor UAMH 8272 | 142 | |

| LAC4 | Trametes versicolor UAMH 8272 | 142 | |

| LCC1 | Lentinula edodes | 143 | |

| LCC4 | Lentinula edodes | 143 | |

| SLAC | Streptomyces coelicolor | 144 | |

| LAC | Schizophyllum commune | Aspergillus sojae | 145 |

| 146 | |||

| LAC1 | Pycnoporus cinnabarinus | 147 | |

| 148 | |||

| Oxidase B | Stachybotrys chartarum | 149 | |

| 150 | |||

| 151 | |||

| LCS-1 | Ceriporiopsis subvermispora | 152 | |

| LCC1 | Trametes versicolor | Aspergillus niger | 153 |

| 154 | |||

| Gene IV | Trametes versicolor | 155 | |

| pox2 | Pleurotus ostreatus | 156 | |

| Laccase | Stachybotrys chartarum | 29 | |

| Pel3 | Pleurotus eryngii | 157 | |

| LCC1 | Trametes versicolor | ||

| LCC2 | Trametes versicolor | 100 | |

| 158 | |||

| LCS-1 | Ceriporiopsis subvermispora | Aspergillus nidulans | 152 |

| Laccase | Stachybotrys chartarum | 29 |

References regarding laccase engineering are in red.

Laccase heterologous expression systems have also been employed as model to measure the effectiveness of different promoters,29 besides other more specific aims, such as (i) to study the effect of constitutive activation of the Unfolded-protein response (UPR) pathway on the production of heterologous protein in A. niger;153 (ii) to examine the protein quality control mechanism;83 (iii) to select strains with higher production levels of heterologous proteins;156 (iv) to evaluate the physiological state of an organism in biotechnical processes;124,125 (v) to establish the effects of reduced protease activity on the stabilities of secreted recombinant proteins.154

Development of applications of recombinant laccases from filamentous fungi is discussed in a next section.

Laccase Engineering

The availability of established recombinant expression systems for laccase isoenzymes has allowed their engineering with the aim of deepening knowledge of structure function relationships and of improving several enzymatic features for specific industrial needs. As a fact, (rational or random) mutagenesis has often been used to generate laccase variants, either in yeasts and in filamentous fungi. In their pioneering work, Xu and co-workers129,132 reported significant changes in pH optimum, KM and kcat for mutated fungal laccases. New insights into the binding of the reducing substrate into the active T1 site of a laccase produced by T. versicolor have been provided by site directed mutagenesis along with induced modifications in catalytic properties of the enzyme.114

The role of the C-terminus in basidiomycetous and ascomycetous laccases has been evaluated using site directed and random mutagenesis. Gelo-Pujic and co-workers92 found that the barrier to heterogeneous electron transfer is reduced when the C-terminus of LCCI from T. versicolor is truncated. An additional consequence of truncating the C-terminus of LCCI is a shift in the reduction potential of the active site to a lower value. When Kiiskinen and Saloheimo74 studied the expression of M. albomyces in S. cerevisiae, they found that the introduction of a stop codon after the native processing site at the C-terminus gives rise to a sixfold increase of laccase activity. A role for the C-terminal tail of P. ostreatus POXA1b in affecting both catalytic performance and stability properties of the enzyme has been inferred by Autore and colleagues.82 More recently, results obtained with M. albomyces laccase clearly confirmed the critical role of the last amino acids in its C-terminus.75 The deletion of the last four amino acids dramatically affected the activity of the enzyme. Moreover, the crystal structure of the mutant expressed in S. cerevisiae showed that the C-terminal mutation had clearly affected the TNC geometry. Further insights in the significance of the laccase C-terminal tail have also been provided through random mutagenesis. Functional expression of a laccase from Myceliophthora thermophila by directed evolution has been first reported by Bulter and co-workers67 giving a 170-fold increase of total activity, thus leading to the highest production yet reported for a laccase in a yeast (18 mg l−1). A 22-fold increase in kcat has also been observed. The most effective mutation (10-fold increase in total activity) adjusts the protein sequence to the different protease specificities of the heterologous host, thus confirming the role played by C-terminus processing in acquiring functional structures. A P. ostreatus POXA1b has undergone directed evolution through random mutagenesis, and one of the selected mutant has been found mutated in a variable and mobile loop at the C-terminus.79 Molecular dynamic simulations on 3D model structure of this mutant have shown the mutation affects flexibility of some regions of the protein, thus leading to an improved stability and activity of the enzyme.

Other techniques to randomly mutate laccases have been employed. Directed evolution followed by saturation mutagenesis rendered laccases able to tolerate high concentration of organic cosolvents.68–72 A higher laccase production and an increased thermal stability have been obtained in P. pastoris through mutagenesis with low-energy nitrogen ion implantation.101 Random mutagenesis through ethyl methane sulfonate-based (EMS) technique has improved laccase production up to 144 mg l−1 in P. pastoris.97

Taking inspiration from evolutionary pathways within the blue copper binding domain (BCBD) protein family, laccase chimeras through yeast mediated homologous recombination of Trametes sp. strain C30 laccase cDNAs have been constructed.78 The catalytic efficiency of the best-performing hybrid (LAC131) is 12-fold higher than that of the parental enzyme (LAC3). Compared to studies involving mutagenesis, this increase is one of the highest ever observed in a single mutational step, thus confirming how homologous recombination constitute a valuable tool set to study the plasticity of the enzyme.

Recombinant Laccases as Tools for Greening Industry

Laccases have shown a great potential within a variety of industrial applications, where they represent an attractive route for “greening” chemical processes. Owing to the heterogeneous properties observed among laccases from various sources,159 an ever-increasing suite of native laccases has been applied to different biotechnological processes, with the aim to find the most suitable enzyme for a specific application.160,161 However, only few examples of industrial uses of laccases currently exist. The major obstacle to their practical use is the large amount of enzymes required to meet industrial targets. Important breakthroughs towards an industrial use of laccases have been made by their recombinant expression in optimized hosts and production of genetically modified tailored biocatalysts.162 It is worth noting that the first industrial laccase preparation (DeniLite®), launched by Novozyme in 1996 for denim finishing, is based on a recombinant and thermostable M. thermophila laccase expressed in A. oryzae.136

Most of biotechnological applications with recombinant laccases are based on the same commercial preparation. DeniLite® has been applied to assemble amine-derivatized platinum electrodes for phenol detection. This sensor has shown a very fast response and a remarkable long-term stability towards p-phenylenediamine,163 catechol and catecholamines, with submicromolar detection limits.164 The same laccase preparation has been employed in the construction of stable and high-sensitive ionic liquids-based biosensors, for the detection of rosmarinic acid in plant extracts,165 rutin166 and luteolin,167 resulting in a low cost, reproducible and stable analytical method. Similarly, Kulys and co-workers18 developed graphite- or printed graphite-electrode based biosensors for environmental surveillance of phenolic compounds, by covalent immobilization of two recombinant fungal laccases from Polyporus pinsitus (T. villosa, Coriolus pinsitus) and M. thermophila, commercially available from Novozymes. Since the balance between optimal pHs for laccase function and substrate reversibility has been shown to be responsible for pH profile of catechol and catecholamines biosensors,164 it can be expected that modifications of enzyme properties by recombinant expression of mutated variants may result in fine-tuning of biosensor performances.

Recombinant laccases have been widely applied in bioremediation purposes, especially for the treatment of synthetic dyes59,80,109 and, more recently, of toxic polychlorinated biphenyls (PCBs),142 and PAHs.161 The purified recombinant Lcc1 from Trametes trogii, expressed in P. pastoris differently decolorizes several synthetic textile dyes, depending on their chemical structures. The extent of decolorisation is enhanced by the addition of synthetic mediators. Moreover, this enzyme has proved to be stable and active in the presence of moderate amounts of organic solvents.59 A potential use of a recombinant Pycnoporus sanguineus laccase expressed in P. pastoris for the treatment of dye-containing effluents has also been suggested by Lu and co-workers in light of its remarkable ability to degrade, at different extents, four synthetic dyes belonging to different classes (azo, anthraquinone, triphenylmethane and indigo).109 Finally, a POXA1b laccase mutant, selected for its improved stability in a wider pH range, has been successfully applied to dye decolorisation. This variant shows a further enlargement of dye degradation ability with respect to the wild-type, being also able to decolorize a recalcitrant dye with a complex stilbene type structure.80

In view of an application to real colored wastewaters, laccase treatment of a synthetic dye house effluent, containing various reactive dyestuffs and auxiliary chemicals, has been studied in a batch reactor using the commercial preparation DeniLite®. Significant correction of some water quality parameters (color, BOD, TOC, COD and toxicity) has been achieved and a reliable kinetic model has been developed to simulate the decolorisation process.168

As far as PCBs degradation is concerned, two laccase isoenzymes from T. versicolor produced in A. oryzae are effective towards all tested hydroxyl-PCBs, with higher chlorinated hydroxy-PCBs (HO-PCB) being less susceptible to laccase treatment than lower chlorinated HO-PCBs. Interestingly, these isoforms show different specificities in oxidation of HO-PCB congeners.142 In a similar report, four T. versicolor laccase isoenzymes, expressed in P. pastoris, exhibit different efficiencies towards PAHs oxidation.161

Laccases have also found interesting applications in biopulping and biobleaching of lignocellulosic materials for paper manufacturing.141,148 Sigoillot and co-workers investigated the pulp bleaching efficiency of P. cinnabarinus laccase expressed in two distinct Aspergilli hosts, in comparison with the native enzyme. The results obtained, together with the observed differences in redox potentials of the recombinant laccases, have been ascribed to the host-specific processing.141 In order to improve laccase treatments of pulp, Ravalson and co-workers synthesized a chimeric laccase by fusing P. cinnabarinus laccase lac1 to the carbohydrate binding module (CBM) of A. niger cellobiohydrolase B.148 The chimeric protein was investigated for its softwood kraft pulp biobleaching potential in comparison with the native counterpart. By conferring to the chimeric protein the ability to bind to a cellulosic substrate, CBM addition greatly improves laccase delignification properties. In a similar approach, laccases for bleaching carotenoid-containing stains on fabrics, have been engineered. Peptide sequences, selected for their ability to specifically bind to carotenoid stains, have been linked to C-terminus of Stachybotrys chartarum laccase. The targeted peptide-laccase fusion demonstrated enhanced catalytic properties on stained fabrics.151

Fungal laccases are ideal green catalysts for many transformations in organic synthesis, spanning from oxidation of functional groups and coupling of phenols and steroids, to construction of carbon-nitrogen bonds and synthesis of complex polymers.10 In an interesting example, a recombinant laccase from M. thermophyla, supplied by Novozymes A/S, has been applied to the synthesis of a resveratrol dimer, a compound exhibiting promising antioxidant activity. The reaction has been carried out on a preparative scale, in very mild conditions resulting in improved yields in comparison with the analogous chemically catalyzed reaction.15

Improved tolerance to high concentrations of organic solvents is an enviable quality for laccase application in organic chemistry, since most of the transformations are carried out at high concentrations of organic solvents in which laccases may undergo unfolding, thereby losing their activity.10 Zumarraga et al. addressed this target by selecting an enzyme able to tolerate high concentrations of cosolvents70 after five rounds of directed evolution of a laccase from M. thermophila. Regarding immobilization, the recombinant expression of an histidine-tagged Trametes sp.strain C30 laccase has allowed the oriented binding of a fully active monolayer of laccases on a chemically modified gold electrode. Such an immobilization strategy may be useful to modulate the electrical communication between an electrode and a redox protein site bond on its surface, as well as to improve ligand detection in solution.77

Biocatalytical production of elemental iodine (I2)—an attractive antimicrobial molecule—by oxidation of iodide, has been investigated using the recombinant laccases from P. pinsitus (rPpL), M. thermophila (rMtL), C. cinereus (rCcL), and Rhizoctonia solani (rRsL) in presence of methyl syringate as mediator. Tested enzymes show different kinetic behavior during the reaction. As a fact, the fitting kinetic data have revealed that the reversibility of the reaction increases for laccases with lower redox potential copper type I.130

Recombinant laccases have also been employed as important bio-control measures to safe-guard or improve the quality and acceptability of food and beverages. For example, a T. versicolor UAMH 8272 laccase, has been successfully used for eliminating the highly toxic and mutagenic toxin AflatoxinB (AFB1) in food sources. The degradation has also shown to coincide with a significant and typical dose response loss of mutagenicity of the AFB1 molecule.158 In another interesting report, a spectrophotometric method has been developed for antioxidant activity determination in “rich with antioxidant” food samples, by using P. pinsitus and M. thermophila laccases expressed in A. oryzae. The method, based on simultaneous oxidation of the antioxidant and an highly reactive laccase substrate producing chromophoric radical cation, allows the detection of submicromolar concentration of an antioxidant.135

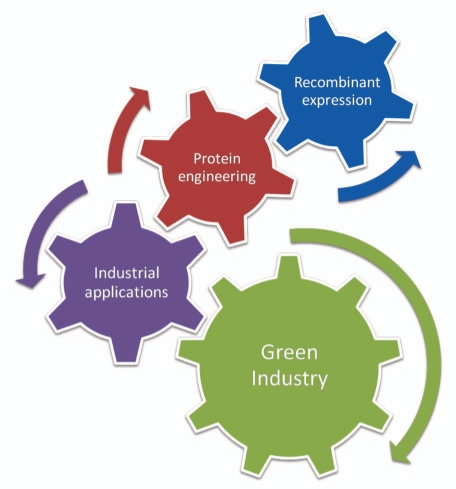

This review surveys the recent research on heterologous laccase expression focusing on the pivotal role played by recombinant systems towards the development of robust tools for greening modern industry (Fig. 1). Enhanced protein production, and genetic tailoring of the enzyme profiles have been carried out successfully to construct novel recombinant enzymes for industry.

Figure 1.

Schematic representation of the steps towards “greening” chemical industry.

When producing recombinant biocatalyst to address a specific industrial need, the choice of expression host strain cannot be made solely on the basis of production yields. Other aspects, such as regulatory issues, play a very important role in this choice. Moreover, patents and intellectual property rights call for searching for expression hosts other than the species traditionally used.

Note

Dedicated to the memory of our missed friend and colleague Sophie Vanhulle who died suddenly and tragically.

Table 2.

List of heterologously expressed laccases in plants

| Laccase | Source | Plant | Reference |

| LCC1 | Trametes versicolor | Zea Mays | 50 |

| Ltlacc2.1-4 | Liriodendron tulipifera | 51 | |

| Ltlacc2.2 | Nicotiana tabacum L. Cv. BY2 cells | 2 | |

| LCC1 | Lentinula edodes | 52 | |

| LCC1/LCC4 | 53 | ||

| LacIII | Coriolus versicolor | Nicotiana tabacum | 48 |

| MalL | Melanocarpus albomyces | Oryza sativa | 54 |

| PPO | Solanum tuberosum | Lycopersicon esculentum | 49 |

| LAC1 | Gossypium arboretum | Arabidopsis thaliana | 47 |

References regarding laccase engineering are in red.

Acknowledgements

This work is supported by grants from the Ministero dell'Università e della Ricerca Scientifica (Progetti di Rilevante Interesse Nazionale, PRIN), from the Ministero Degli Affari Esteri di Intesa con il Ministero dell'Università e della Ricerca (Progetti di ricerca di base e tecnologica approvati nei protocolli di cooperazione scientifica e tecnologica bilaterale come previsto dal protocollo bilaterale tra Italia e Turchia), from Compagnia di San Paolo, Turin-Italy, project “Sviluppo di procedure di biorisanamento di reflui industriali (BIOFORM),” and from COST Action FP0602 “Biotechnology for lignocellulose biorefineries (BIOBIO).”

Footnotes

Previously published online: www.landesbioscience.com/journals/biobugs/article/11438

References

- 1.Yoshida H. Chemistry of Lacquer (Urishi) part 1. J Chem Soc. 1883;43:472–486. [Google Scholar]

- 2.Hoopes JT, Dean JF. Ferroxidase activity in a laccase-like multicopper oxidase from Liriodendron tulipifera. Plant Physiol Biochem. 2004;42:27–33. doi: 10.1016/j.plaphy.2003.10.011. [DOI] [PubMed] [Google Scholar]

- 3.Laborde J. Sur la casse des vins. C R Hebd Seances Acad Sci. 1896;123:1074–1075. (Fre). [Google Scholar]

- 4.Giardina P, Faraco V, Pezzella C, Piscitelli A, Vanhulle S, Sannia G. Laccases: a never-ending story. Cell Mol Life Sci. 2010;67:369–385. doi: 10.1007/s00018-009-0169-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Dittmer NT, Suderman RJ, Jiang H, Zhu YC, Gorman MJ, Kramer KJ, et al. Characterization of cDNAs encoding putative laccase-like multicopper oxidases and developmental expression in the tobacco hornworm, Manduca sexta, and the malaria mosquito, Anopheles gambiae. Insect Biochem Mol Biol. 2004;34:29–41. doi: 10.1016/j.ibmb.2003.08.003. [DOI] [PubMed] [Google Scholar]

- 6.Sharma P, Goel R, Capalash N. Bacterial laccases. World J Microbiol Biotechnol. 2007;23:823–832. [Google Scholar]

- 7.Molina-Guijarro JM, Pérez J, Muñoz-Dorado J, Guillén F, Moya R, Hernández M, Arias ME. Detoxification of azo dyes by a novel pH-versatile, salt-resistant laccase from Streptomyces ipomoea. Int Microbiol. 2009;12:13–21. [PubMed] [Google Scholar]

- 8.Martins LO, Soares CM, Pereira MM, Teixeira M, Costa T, Jones GH, et al. Molecular and biochemical characterization of a highly stable bacterial laccase that occurs as a structural component of the Bacillus subtilis endospore coat. J Biol Chem. 2002;277:18849–18859. doi: 10.1074/jbc.M200827200. [DOI] [PubMed] [Google Scholar]

- 9.Messerschmidt A. Multi-Copper Oxidases. Singapore: World Scientific; 1997. [Google Scholar]

- 10.Kunamneni A, Camarero S, García-Burgos C, Plou FJ, Ballesteros A, Alcalde M. Engineering and applications of fungal laccases for organic synthesis. Microb cell fact. 2008;7:32–49. doi: 10.1186/1475-2859-7-32. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Bourbonnais R, Leech D, Paice MG. Electrochemical analysis of the interactions of laccase mediators with lignin model compounds. Biochim Biophys Acta. 1998;1379:381–390. doi: 10.1016/s0304-4165(97)00117-7. [DOI] [PubMed] [Google Scholar]

- 12.Vinod S. Enzymatic decolourisation of denims: a novel approach. Colourage. 2001;48:25–26. [Google Scholar]

- 13.Minussi R, Pastore GM, Duran N. Potential applications of laccase in the food industry. Trends Food Sci Technol. 2002;13:205–216. [Google Scholar]

- 14.Widsten P, Kandelbauer A. Laccase applications in the forest products industry: a review. Enzyme Microb Technol. 2008;42:293–307. [Google Scholar]

- 15.Nicotra S, Cramarossa MR, Mucci A, Pagnoni UM, Riva S, Forti L. Biotransformation of resveratrol: synthesis of trans-dehydrodimers catalyzed by laccases from Myceliophtora thermophyla and from Trametes pubescens. Tetrahedron. 2004;60:595–600. [Google Scholar]

- 16.Bruyneel F, Enaud E, Billottet L, Vanhulle S, Marchand-Brynaert J. Regioselective synthesis of 3-hydroxyorthanilic acid and its biotransformation with laccase into a novel phenoxazinone dye. Eur J Org Chem. 2008;1:72–79. [Google Scholar]

- 17.Gübitz GM, Cavaco Paulo A. New substrates for reliable enzymes: enzymatic modification of polymers. Curr Opin Biotechnol. 2003;14:577–582. doi: 10.1016/j.copbio.2003.09.010. [DOI] [PubMed] [Google Scholar]

- 18.Kulys J, Vidziunaite R. Amperometric biosensors based on recombinant laccases for phenols determination. Biosens Bioelectron. 2003;18:319–325. doi: 10.1016/s0956-5663(02)00172-0. [DOI] [PubMed] [Google Scholar]

- 19.Amir L, Tam TK, Pita M, Meijler MM, Alfonta L, Katz E. Biofuel cell controlled by enzyme logic systems. J Am Chem Soc. 2009;131:826–832. doi: 10.1021/ja8076704. [DOI] [PubMed] [Google Scholar]

- 20.Kunamneni A, Plou FJ, Ballesteros A, Alcalde M. Laccases and their applications: a patent review. Recent Pat Biotechnol. 2008;2:10–24. doi: 10.2174/187220808783330965. [DOI] [PubMed] [Google Scholar]

- 21.Faraco V, Pezzella C, Miele A, Giardina P, Sannia G. Bio-remediation of colored industrial wastewaters by the white-rot fungi Phanerochaete chrysosporium and Pleurotus ostreatus and their enzymes. Biodegradation. 2009;20:209–220. doi: 10.1007/s10532-008-9214-2. [DOI] [PubMed] [Google Scholar]

- 22.Olivieri G, Marzocchella A, Salatino P, Giardina P, Cennamo G, Sannia G. Olive mill wastewater remediation by means of Pleurotus ostreatus. Biochem Eng J. 2006;31:180–187. [Google Scholar]

- 23.Ferrer-Miralles N, Domingo-Espín J, Corchero JL, Vázquez E, Villaverde A. Microbial factories for recombinant pharmaceuticals. Microb Cell Fact. 2009;24:8–17. doi: 10.1186/1475-2859-8-17. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Demain AL, Vaishnav P. Production of recombinant proteins by microbes and higher organisms. Biotechnol Adv. 2009;27:297–306. doi: 10.1016/j.biotechadv.2009.01.008. [DOI] [PubMed] [Google Scholar]

- 25.Schilling B, Linden RM, Kupper U, Lerch K. Expression of Neurospora crassa laccase under the control of the copper-inducible metallothionein-promoter. Curr Genet. 1992;22:197–203. doi: 10.1007/BF00351726. [DOI] [PubMed] [Google Scholar]

- 26.Alves AM, Record E, Lomascolo A, Scholtmeijer K, Asther M, Wessels JG, et al. Highly efficient production of laccase by the basidiomycete Pycnoporus cinnabarinus. Appl Environ Microbiol. 2004;70:6379–6384. doi: 10.1128/AEM.70.11.6379-6384.2004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Kajita S, Sugawara S, Miyazaki Y, Nakamura M, Katayama Y, Shishido K, et al. Overproduction of recombinant laccase using a homologous expression system in Coriolus versicolor. Appl Microbiol Biotechnol. 2004;66:194–199. doi: 10.1007/s00253-004-1663-x. [DOI] [PubMed] [Google Scholar]

- 28.Waterman SR, Hacham M, Panepinto J, Hu G, Shin S, Williamson PR. Cell wall targeting of laccase of Cryptococcus neoformans during infection of mice. Infect Immun. 2007;75:714–722. doi: 10.1128/IAI.01351-06. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Mander GJ, Wang H, Bodie E, Wagner J, Vienken K, Vinuesa C, et al. Use of laccase as a novel, versatile reporter system in filamentous fungi. Appl Environ Microbiol. 2006;72:5020–5026. doi: 10.1128/AEM.00060-06. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Kataoka K, Komori H, Ueki Y, Konno Y, Kamitaka Y, Kurose S, et al. Structure and function of the engineered multicopper oxidase CueO from Escherichia coli-deletion of the methionine-rich helical region covering the substrate-binding site. J Mol Biol. 2007;373:141–152. doi: 10.1016/j.jmb.2007.07.041. [DOI] [PubMed] [Google Scholar]

- 31.Bento I, Martins LO, Gato Lopes G, Arménia Carrondo M, Lindley PF. Dioxygen reduction by multi-copper oxidases; a structural perspective. Dalton Trans. 2005;21:3507–3513. doi: 10.1039/b504806k. [DOI] [PubMed] [Google Scholar]

- 32.Brissos V, Pereira L, Munteanu FD, Cavaco-Paulo A, Martins LO. Expression system of CotA-laccase for directed evolution and high-throughput screenings for the oxidation of high-redox potential dyes. Biotechnol J. 2009;4:558–563. doi: 10.1002/biot.200800248. [DOI] [PubMed] [Google Scholar]

- 33.Suzuki T, Endo K, Ito M, Tsujibo H, Miyamoto K, Inamori Y. A thermostable laccase from Streptomyces lavendulae REN-7: purification, characterization, nucleotide sequence and expression. Biosci Biotechnol Biochem. 2003;67:2167–2175. doi: 10.1271/bbb.67.2167. [DOI] [PubMed] [Google Scholar]

- 34.Dubé E, Shareck F, Hurtubise Y, Daneault C, Beauregard M. Homologous cloning, expression, and characterisation of a laccase from Streptomyces coelicolor and enzymatic decolourisation of an indigo dye. Appl Microbiol Biotechnol. 2008;79:579–603. doi: 10.1007/s00253-008-1475-5. [DOI] [PubMed] [Google Scholar]

- 35.Salony, Garg N, Baranwal R, Chhabra M, Mishra S, Chaudhuri TK, et al. Laccase of Cyathus bulleri: structural, catalytic characterization and expression in Escherichia coli. Biochim Biophys Acta. 2008;1784:259–268. doi: 10.1016/j.bbapap.2007.11.006. [DOI] [PubMed] [Google Scholar]

- 36.Sanchez-Amat A, Lucas-Elío P, Fernández E, García-Borrón JC, Solano F. Molecular cloning and functional characterization of a unique multipotent polyphenol oxidase from Marinomonas mediterranea. Biochim Biophys Acta. 2001;157:104–116. doi: 10.1016/s0167-4838(01)00174-1. [DOI] [PubMed] [Google Scholar]

- 37.Durão P, Bento I, Fernandes AT, Melo EP, Lindley PF, Martins LO. Perturbations of the T1 copper site in the CotA laccase from Bacillus subtilis: structural, biochemical, enzymatic and stability studies. J Biol Inorg Chem. 2006;11:514–526. doi: 10.1007/s00775-006-0102-0. [DOI] [PubMed] [Google Scholar]

- 38.Durão P, Chen Z, Silva CS, Soares CM, Pereira MM, Todorovic S, et al. Proximal mutations at the type 1 copper site of CotA laccase: spectroscopic, redox, kinetic and structural characterization of I494A and L386A mutants. Biochem J. 2008;412:339–346. doi: 10.1042/BJ20080166. [DOI] [PubMed] [Google Scholar]

- 39.Pereira L, Coelho AV, Viegas CA, Santos MM, Robalo MP, Martins LO. Enzymatic biotransformation of the azo dye Sudan Orange G with bacterial CotA-laccase. J Biotechnol. 2009;139:68–77. doi: 10.1016/j.jbiotec.2008.09.001. [DOI] [PubMed] [Google Scholar]

- 40.Endo K, Hayashi Y, Hibi T, Hosono K, Beppu T, Ueda K. Enzymological characterization of EpoA, a laccase-like phenol oxidase produced by Streptomyces griseus. J Biochem. 2003;133:671–677. doi: 10.1093/jb/mvg086. [DOI] [PubMed] [Google Scholar]

- 41.Ruijssenaars HJ, Hartmans S. A cloned Bacillus halodurans multicopper oxidase exhibiting alkaline laccase activity. Appl Microbiol Biotechnol. 2004;65:177–182. doi: 10.1007/s00253-004-1571-0. [DOI] [PubMed] [Google Scholar]

- 42.Machczynski MC, Vijgenboom E, Samyn B, Canters GW. Characterization of SLAC: a small laccase from Streptomyces coelicolor with unprecedented activity. Protein Sci. 2004;13:2388–2397. doi: 10.1110/ps.04759104. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Miyazaki K. A hyperthermophilic laccase from Thermus thermophilus HB27. Extremophiles. 2005;9:415–425. doi: 10.1007/s00792-005-0458-z. [DOI] [PubMed] [Google Scholar]

- 44.Fernandes AT, Soares CM, Pereira MM, Huber R, Grass G, Martins LO. A robust metallo-oxidase from the hyperthermophilic bacterium Aquifex aeolicus. FEBS J. 2007;274:2683–2694. doi: 10.1111/j.1742-4658.2007.05803.x. [DOI] [PubMed] [Google Scholar]

- 45.Koschorreck K, Richter SM, Ene AB, Roduner E, Schmid RD, Urlacher VB. Cloning and characterization of a new laccase from Bacillus licheniformis catalyzing dimerization of phenolic acids. Appl Microbiol Biotechnol. 2008;79:217–224. doi: 10.1007/s00253-008-1417-2. [DOI] [PubMed] [Google Scholar]

- 46.Koschorreck K, Schmid RD, Urlacher VB. Improving the functional expression of a Bacillus licheniformis laccase by random and site-directed mutagenesis. BMC Biotechnol. 2009;23:9–12. doi: 10.1186/1472-6750-9-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Wang GD, Li QJ, Luo B, Chen XY. Ex planta phytoremedia-tion of trichlorophenol and phenolic allelo chemicals via an engineered secretory laccase. Nat Biotechnol. 2004;22:893–897. doi: 10.1038/nbt982. [DOI] [PubMed] [Google Scholar]

- 48.Sonoki T, Kajita S, Ikeda S, Uesugi M, Tatsumi K, Katayama Y, et al. Transgenic tobacco expressing fungal laccase promotes the detoxification of environmental pollutants. Appl Microbiol Biotechnol. 2005;67:138–142. doi: 10.1007/s00253-004-1770-8. [DOI] [PubMed] [Google Scholar]

- 49.Li L, Steffens JC. Overexpression of polyphenol oxidase in transgenic tomato plants results in enhanced bacterial disease resistance. Planta. 2002;215:239–247. doi: 10.1007/s00425-002-0750-4. [DOI] [PubMed] [Google Scholar]

- 50.Bailey MR, Woodard SL, Callaway E, Beifuss K, Magallanes-Lundback M, Lane JR, Horn ME, et al. Improved recovery of active recombinant laccase from maize seed. Appl Microbiol Biotechnol. 2004;63:390–397. doi: 10.1007/s00253-003-1362-z. [DOI] [PubMed] [Google Scholar]

- 51.LaFayette PR, Eriksson KE, Dean JF. Characterization and heterologous expression of laccase cDNAs from xylem tissues of yellow-poplar (Liriodendron tulipifera) Plant Mol Biol. 1999;40:23–35. doi: 10.1023/a:1026437406859. [DOI] [PubMed] [Google Scholar]

- 52.Sakamoto Y, Nakade K, Yano A, Nakagawa Y, Hirano T, Irie T, et al. Heterologous expression of lcc1 from Lentinula edodes in tobacco BY-2 cells results in the production an active, secreted form of fungal laccase. Appl Microbiol Biotechnol. 2008;79:971–980. doi: 10.1007/s00253-008-1507-1. [DOI] [PubMed] [Google Scholar]

- 53.Nakagawa Y, Sakamoto Y, Kikuchi S, Sato T, Yano A. A chimeric laccase with hybrid properties of the parental Lentinula edodes laccases. Microbiol Res. 2009 doi: 10.1016/j.micres.2009.08.006. [DOI] [PubMed] [Google Scholar]

- 54.de Wilde C, Uzan E, Zhou Z, Kruus K, Andberg M, Buchert J, et al. Transgenic rice as a novel production system for Melanocarpus and Pycnoporus laccases. Transgenic Res. 2008;17:515–527. doi: 10.1007/s11248-007-9124-9. [DOI] [PubMed] [Google Scholar]

- 55.Dittmer NT, Gorman MJ, Kanost MR. Characterization of endogenous and recombinant forms of laccase-2, a multicopper oxidase from the tobacco hornworm, Manduca sexta. Insect Biochem Mol Biol. 2009;39:596–606. doi: 10.1016/j.ibmb.2009.06.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Gellissen G, Hollenberg CP. Application of yeasts in gene expression studies: a comparison of Saccharomyces cerevisiae, Hansenula polymorpha and Kluyveromyces lactis: a review. Gene. 1997;190:87–97. doi: 10.1016/s0378-1119(97)00020-6. [DOI] [PubMed] [Google Scholar]

- 57.Sato Y, Wuli B, Sederoff R, Whetten R. Molecular cloning and expression of eight cDNAs in loblolly pine (Pinus taeda) J Plant Res. 2001;114:147–155. [Google Scholar]

- 58.Otterbein L, Record E, Longhi S, Asther M, Moukha S. Molecular cloning of the cDNA encoding laccase from Pycnoporus cinnabarinus I-937 and expression in Pichia pastoris. Eur J Biochem. 2000;267:1619–1625. doi: 10.1046/j.1432-1327.2000.01166.x. [DOI] [PubMed] [Google Scholar]

- 59.Colao MC, Lupino S, Garzillo AM, Buonocore V, Ruzzi M. Heterologous expression of lccl gene from Trametes trogii in Pichia pastoris and characterization of the recombinant enzyme. Microb Cell Fact. 2006;5:31–36. doi: 10.1186/1475-2859-5-31. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Piscitelli A, Giardina P, Mazzoni C, Sannia G. Recombinant expression of Pleurotus ostreatus laccases in Kluyveromyces lactis and Saccharomyces cerevisiae. Appl Microbiol Biotechnol. 2005;69:428–439. doi: 10.1007/s00253-005-0004-z. [DOI] [PubMed] [Google Scholar]

- 61.Jolivalt C, Madzak C, Brault A, Caminade E, Malosse C, Mougin C. Expression of laccase IIIb from the white-rot fungus Trametes versicolor in the yeast Yarrowia lipolytica for environmental applications. Appl Microbiol Biotechnol. 2005;66:450–456. doi: 10.1007/s00253-004-1717-0. [DOI] [PubMed] [Google Scholar]

- 62.Guo M, Lu FP, Pu J, Bai DQ, Du LX. Molecular cloning of the cDNA encoding laccase from Trametes versicolor and heterologous expression in Pichia methanolica. Appl Microbiol Biotechnol. 2005;69:178–183. doi: 10.1007/s00253-005-1985-3. [DOI] [PubMed] [Google Scholar]

- 63.Kojima Y, Tsukuda Y, Kawai Y, Tsukamoto A, Sugiura J, Sakaino M, et al. Cloning, sequence analysis, and expression of ligninolytic phenoloxidase genes of the white-rot basidiomycete Coriolus hirsutus. J Biol Chem. 1990;265:15224–30. [PubMed] [Google Scholar]

- 64.Cassland P, Jonsson LJ. Characterization of a gene encoding Trametes versicolor laccase A and improved heterologous expression in Saccharomyces cerevisiae by decreased cultivation temperature. Appl Microbiol Biotechnol. 1999;52:393–400. doi: 10.1007/s002530051537. [DOI] [PubMed] [Google Scholar]

- 65.Larsson S, Cassland P, Jonsson LJ. Development of a Saccharomyces cerevisiae strain with enhanced resistance to phenolic fermentation inhibitors in lignocellulose hydrolysates by heterologous expression of laccase. Appl Environ Microbiol. 2001;67:1163–1170. doi: 10.1128/AEM.67.3.1163-1170.2001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 66.Hoshida H, Nakao M, Kanazawa H, Kubo K, Hakukawa T, Morimasa K, et al. Isolation of five laccase gene sequences from the white-rot fungus Trametes sanguinea by PCR, and cloning, characterization and expression of the laccase cDNA in yeasts. J Biosci Bioeng. 2001;92:372–380. doi: 10.1263/jbb.92.372. [DOI] [PubMed] [Google Scholar]

- 67.Bulter T, Alcalde M, Sieber V, Meinhold P, Schlachtbauer C, Arnold FH. Functional expression of a fungal laccase in Saccharomyces cerevisiae by directed evolution. Appl Environ Microbiol. 2003;69:987–995. doi: 10.1128/AEM.69.2.987-995.2003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 68.Alcalde M, Bulter T, Zumárraga M, García-Arellano H, Mencía M, Plou FJ, et al. Screening mutant libraries of fungal laccases in the presence of organic solvents. J Biomol Screen. 2005;10:624–631. doi: 10.1177/1087057105277058. [DOI] [PubMed] [Google Scholar]

- 69.Alcalde M, Zumárraga M, Polaina J, Ballesteros A, Plou FJ. Combinatorial saturation mutagenesis by in vivo overlap extension for the engineering of fungal laccases. Comb Chem High T Scr. 2006;9:719–727. doi: 10.2174/138620706779026079. [DOI] [PubMed] [Google Scholar]

- 70.Zumárraga M, Bulter T, Shleev S, Polaina J, Martinez-Arias A, Plou FJ, et al. In vitro evolution of a fungal laccase in high concentrations of organic cosolvents. Chem Biol. 2007;14:1052–1064. doi: 10.1016/j.chembiol.2007.08.010. [DOI] [PubMed] [Google Scholar]

- 71.Zumárraga M, Vaz Domínguez C, Camarero S, Shleev S, Polaina J, Martínez-Arias A, et al. Combinatorial saturation mutagenesis of the Myceliophthora thermophila laccase T2 mutant: the connection between the C-terminal plug and the conserved 509VSG511tripeptide. Comb Chem High-Throughput Screen. 2008;11:807–816. doi: 10.2174/138620708786734235. [DOI] [PubMed] [Google Scholar]

- 72.Zumárraga M, Camarero S, Shleev S, Martínez-Arias A, Ballesteros A, Plou FJ, et al. Altering the laccase functionality by in vivo assembly of mutant libraries with different mutational spectra. Proteins. 2008;71:250–260. doi: 10.1002/prot.21699. [DOI] [PubMed] [Google Scholar]

- 73.Uldschmid A, Dombi R, Marbach K. Identification and functional expression of ctaA, a P-type ATPase gene involved in copper trafficking in Trametes versicolor. Microbiology. 2003;149:2039–2048. doi: 10.1099/mic.0.26177-0. [DOI] [PubMed] [Google Scholar]

- 74.Kiiskinen LL, Saloheimo M. Molecular cloning and expression in Saccharomyces cerevisiae of a laccase gene from the ascomycete Melanocarpus albomyces. Appl Environ Microbiol. 2004;70:137–144. doi: 10.1128/AEM.70.1.137-144.2004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 75.Andberg M, Hakulinen N, Auer S, Saloheimo M, Koivula A, Rouvinen J, et al. Essential role of the C-terminus in Melanocarpus albomyces laccase for enzyme production, catalytic properties and structure. FEBS J. 2009;276:6285–6300. doi: 10.1111/j.1742-4658.2009.07336.x. [DOI] [PubMed] [Google Scholar]

- 76.Klonowska A, Gaudin C, Asso M, Fournel A, Reglier M, Tron T. LAC3, a new low redox potential laccase from Trametes sp. strain C30 obtained as a recombinant protein in yeast. Enzyme Microb Technol. 2005;36:34–41. [Google Scholar]

- 77.Balland V, Hureau C, Cusano AM, Liu Y, Tron T, Limoges B. Oriented immobilization of a fully active monolayer of histidine-tagged recombinant laccase on modified gold electrodes. Chemistry. 2008;14:7186–7192. doi: 10.1002/chem.200800368. [DOI] [PubMed] [Google Scholar]

- 78.Cusano AM, Mekmouche Y, Meglecz E, Tron T. Plasticity of laccase generated by homeologous recombination in yeast. FEBS J. 2009;276:5471–5480. doi: 10.1111/j.1742-4658.2009.07231.x. [DOI] [PubMed] [Google Scholar]

- 79.Festa G, Autore F, Fraternali F, Giardina P, Sannia G. Development of new laccases by directed evolution: functional and computational analyses. Proteins. 2008;72:25–34. doi: 10.1002/prot.21889. [DOI] [PubMed] [Google Scholar]

- 80.Miele A, Giardina P, Sannia G, Faraco V. Random mutants of a Pleurotus ostreatus laccase as new biocatalysts for industrial effluents bioremediation. J Appl Microbiol. 2009;108:998–1006. doi: 10.1111/j.1365-2672.2009.04505.x. [DOI] [PubMed] [Google Scholar]

- 81.Miele A, Faraco V, Piscitelli A, Del Vecchio C, Giardina P, Sannia G. Selection of ‘better performing’ laccases through directed evolution. FEBS J. 2009;276:377–378. [Google Scholar]

- 82.Autore F, Del Vecchio C, Fraternali F, Giardina P, Sannia G, Faraco V. Molecular determinants of peculiar properties of a Pleurotus ostreatus laccase: analysis by site-directed mutagenesis. Enzyme Microb Technol. 2009;45:507–513. [Google Scholar]

- 83.Hoshida H, Fujita T, Murata K, Kubo K, Akada R. Copper-dependent production of a Pycnoporus coccineus extracellular laccase in Aspergillus oryzae and Saccharomyces cerevisiae. Biosci Biotechnol Biochem. 2005;69:1090–1097. doi: 10.1271/bbb.69.1090. [DOI] [PubMed] [Google Scholar]

- 84.Necochea R, Valderrama B, Díaz-Sandoval S, Folch-Mallol JL, Vázquez-Duhalt R, Iturriaga G. Phylogenetic and biochemical characterisation of a recombinant laccase from Trametes versicolor. FEMS Microbiol Lett. 2005;244:235–241. doi: 10.1016/j.femsle.2005.01.054. [DOI] [PubMed] [Google Scholar]

- 85.Kim D, Kwak E, Choi HT. Increase of yeast survival under oxidative stress by the expression of the laccase gene from Coprinellus congregatus. J Microbiol. 2006;44:617–621. [PubMed] [Google Scholar]

- 86.Bleve G, Lezzi C, Mita G, Rampino P, Perrotta C, Villanova L, et al. Molecular cloning and heterologous expression of a laccase gene from Pleurotus eryngii in free and immobilized Saccharomyces cerevisiae cells. Appl Microbiol Biotechnol. 2008;79:731–741. doi: 10.1007/s00253-008-1479-1. [DOI] [PubMed] [Google Scholar]

- 87.Pezzella C, Autore F, Giardina P, Piscitelli A, Sannia G, Faraco V. The Pleurotus ostreatus laccase multi-gene family: isolation and heterologous expression of new family members. Curr Genet. 2009;55:45–57. doi: 10.1007/s00294-008-0221-y. [DOI] [PubMed] [Google Scholar]

- 88.Jönsson LJ, Saloheimo M, Penttila M. Laccase from the white-rot fungus Trametes versicolor: cDNA cloning of lcc1 and expression in Pichia pastoris. Curr Genet. 1997;32:425–430. doi: 10.1007/s002940050298. [DOI] [PubMed] [Google Scholar]

- 89.O'Callaghan J, O'Brien MM, McClean K, Dobson ADW. Optimisation of the expression of a Trametes versicolor laccase gene in Pichia pastoris. J Ind Microbiol Biotechnol. 2002;29:55–59. doi: 10.1038/sj.jim.7000268. [DOI] [PubMed] [Google Scholar]

- 90.Hong F, Meinander NQ, Jönsson LJ. Fermentation strategies for improved heterologous expression of laccase in Pichia pastoris. Biotechnol Bioeng. 2002;79:438–449. doi: 10.1002/bit.10297. [DOI] [PubMed] [Google Scholar]

- 91.Williamson PR, Wakamatsu K, Ito S. Melanin biosynthesis in Cryptococcus neoformans. J Bacteriol. 1998;180:1570–1572. doi: 10.1128/jb.180.6.1570-1572.1998. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 92.Gelo-Pujic M, Kim HH, Butlin NG, Palmore GT. Electrochemical studies of a truncated laccase produced in Pichia pastoris. Appl Environ Microbiol. 1999;65:5515–5521. doi: 10.1128/aem.65.12.5515-5521.1999. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 93.Brown MA, Zhao Z, Mauk AG. Expression and characterization of a recombinant multi-copper oxidase: laccase IV from Trametes versicolor. Inorg Chim Acta. 2002;331:232–238. [Google Scholar]

- 94.Soden DM, O'Callaghan J, Dobson AD. Molecular cloning of a laccase isozyme gene from Pleurotus sajorcaju and expression in the heterologous Pichia pastoris host. Microbiology. 2002;148:4003–4014. doi: 10.1099/00221287-148-12-4003. [DOI] [PubMed] [Google Scholar]

- 95.Yang JQ, Tang GY, Dai HM, Liu G, Zhu HC. Expression and purification of the modified gene of laccase from Panus rudis in Pichia pastoris. Lett Biotechnol. 2003;16:255–258. [Google Scholar]

- 96.Liu W, Chao Y, Liu S, Bao H, Qian S. Molecular cloning and characterization of a laccase gene from the basidiomycete Fome lignosus and expression in Pichia pastoris. Appl Microbiol Biotechnol. 2003;63:174–181. doi: 10.1007/s00253-003-1398-0. [DOI] [PubMed] [Google Scholar]

- 97.Hu MR, Chao YP, Zhang GQ, Yang XQ, Xue ZQ, Qian SJ. Molecular evolution of Fome lignosus laccase by ethyl methane sulfonate-based random mutagenesis in vitro. Biomol Eng. 2007;24:619–624. doi: 10.1016/j.bioeng.2007.08.020. [DOI] [PubMed] [Google Scholar]

- 98.Zhang YB, Jiang Q, Jiang ML, Ma LX. Cloning of a laccase gene from Flammulina velutipes and study on its expression in Pichia pastoris. Acta microbiologica Sinica. 2004;44:775–779. [PubMed] [Google Scholar]

- 99.Zhang YB, Jiang ML, Hu XJ, Zhang GM, Ma LX. Expression of a laccase gene from Pleurotus ostreatus in Pichia pastoris and characterization of the recombinant enzyme. Acta microbiologica Sinica. 2005;45:625–629. [PubMed] [Google Scholar]

- 100.Bohlin C, Jönsson LJ, Roth R, van Zyl WH. Heterologous expression of Trametes versicolor laccase in Pichia pastoris and Aspergillus niger. Appl Biochem Biotechnol. 2006;129:195–214. [PubMed] [Google Scholar]

- 101.Hong Y, Xiao Y, Zhou H, Fang W, Zhang M, Wang J, et al. Expression of a laccase cDNA from Trametes sp. AH28-2 in Pichia pastoris and mutagenesis of transformants by nitrogen ion implantation. FEMS Microbiol Lett. 2006;258:96–101. doi: 10.1111/j.1574-6968.2006.00209.x. [DOI] [PubMed] [Google Scholar]

- 102.Li F, Hong YZ, Xiao YZ, Xu YH, Fang W. High production of laccase B from Trametes sp. in Pichia pastoris. World J Microbiol Biotechnol. 2007;23:741–745. [Google Scholar]

- 103.Hong YZ, Zhou HM, Tu XM, Li JF, Xiao YZ. Cloning of a laccase gene from a novel basidiomycete Trametes sp 420 and its heterologous expression in Pichia pastoris. Curr Microbiol. 2007;54:260–265. doi: 10.1007/s00284-006-0068-8. [DOI] [PubMed] [Google Scholar]

- 104.Cui TJ, Wang XT, Zhou HM, Hong YZ, Xiao YZ, Cui TJ, et al. High output of a Trametes laccase in Pichia pastoris and characterization of recombinant enzymes. Sheng Wu Gong Cheng Xue Bao. 2007;23:1055–1059. doi: 10.1016/s1872-2075(07)60063-6. [DOI] [PubMed] [Google Scholar]

- 105.Zhou HM, Hong YZ, Xiao YZ, Cui TJ, Wang XT, Pu CL. High output of a Trametes laccase in Pichia pastoris and characterization of recombinant enzymes. Chin J Biotech. 2007;23:1055–1059. doi: 10.1016/s1872-2075(07)60063-6. [DOI] [PubMed] [Google Scholar]

- 106.Xu Y, Hong Y, Xiao Y, Fang W. Preparation and application of polyclonal antibody against a recombinant laccase. Cell Mol Immunol. 2007;4:315–317. [PubMed] [Google Scholar]

- 107.Li JF, Hong YZ, Xiao YZ. Cloning and heterologous expression of the gene of laccase C from Trametes sp. 420 and potential of recombinant laccase in dye decolorization. Acta microbiologica Sinica. 2007;47:54–58. [PubMed] [Google Scholar]

- 108.Joo SS, Ryu IW, Park JK, Yoo YM, Lee DH, Hwang KW, et al. Molecular cloning and expression of a laccase from Ganoderma lucidum, and its antioxidative properties. Mol Cells. 2008;25:112–118. [PubMed] [Google Scholar]

- 109.Lu L, Zhao M, Liang SC, Zhao LY, Li DB, Zhang BB. Production and synthetic dyes decolourization capacity of a recombinant laccase from Pichia pastoris. J Appl Microbiol. 2009;107:1149–1156. doi: 10.1111/j.1365-2672.2009.04291.x. [DOI] [PubMed] [Google Scholar]

- 110.Colao MC, Caporale C, Silvestri F, Ruzzi M, Buonocore V. Modeling the 3-D structure of a recombinant laccase from Trametes trogii active at a pH close to neutrality. Protein J. 2009;28:375–383. doi: 10.1007/s10930-009-9204-1. [DOI] [PubMed] [Google Scholar]

- 111.Camattari A, Bianchi MM, Branduardi P, Porro D, Brambilla L. Induction by hypoxia of heterologous-protein production with the KlPDC1 promoter in yeasts. Appl Environ Microbiol. 2007;73:922–929. doi: 10.1128/AEM.01764-06. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 112.Ranieri D, Colao MC, Ruzzi M, Romagnoli G, Bianchi MM. Optimization of recombinant fungal laccase production with strains of the yeast Kluyveromyces lactis from the pyruvate decarboxylase promoter. FEMS Yeast Res. 2009;9:892–902. doi: 10.1111/j.1567-1364.2009.00532.x. [DOI] [PubMed] [Google Scholar]

- 113.Faraco V, Ercole C, Festa G, Giardina P, Piscitelli A, Sannia G. Heterologous expression of heterodimeric laccase from Pleurotus ostreatus in Kluyveromyces lactis. Appl Microbiol Biotechnol. 2008;77:1329–1335. doi: 10.1007/s00253-007-1265-5. [DOI] [PubMed] [Google Scholar]

- 114.Madzak C, Mimmi MC, Caminade E, Brault A, Baumberger S, Briozzo P, et al. Shifting the optimal pH of activity for a laccase from the fungus Trametes versicolor by structure-based mutagenesis. Protein Eng Des Sel. 2006;19:77–84. doi: 10.1093/protein/gzj004. [DOI] [PubMed] [Google Scholar]

- 115.Madzak C, Otterbein L, Chamkha M, Moukha S, Asther M, Gaillardin C, et al. Heterologous production of a laccase from the basidiomycete Pycnoporus cinnabarinus in the dimorphic yeast Yarrowia lipolytica. FEMS Yeast Res. 2005;5:635–646. doi: 10.1016/j.femsyr.2004.10.009. [DOI] [PubMed] [Google Scholar]

- 116.Guo M, Lu FP, Du LX, Pu J, Bai DQ. Optimization of the expression of a laccase gene from Trametes versicolor in Pichia methanolica. Appl Microbiol Biotechnol. 2006;71:848–852. doi: 10.1007/s00253-005-0210-8. [DOI] [PubMed] [Google Scholar]

- 117.Guo M, Lu F, Liu M, Li T, Pu J, Wang N, et al. Purification of recombinant laccase from Trametes versicolor in Pichia methanolica and its use for the decolorization of anthraquinone dye. Biotechnol Lett. 2008;30:2091–2096. doi: 10.1007/s10529-008-9817-z. [DOI] [PubMed] [Google Scholar]

- 118.Nevalainen KM, Te'o VS, Bergquist PL. Heterologous protein expression in filamentous fungi. Trends Biotechnol. 2005;23:468–474. doi: 10.1016/j.tibtech.2005.06.002. [DOI] [PubMed] [Google Scholar]

- 119.Saloheimo M, Niku-Paavola ML. Heterologous production of a ligninolytic enzyme: expression of the Phlebia radiata laccase gene in Trichoderma reesei. Bio Technology. 1991;9:987–990. [Google Scholar]

- 120.Baker CJO, White TC. Expression of the laccase IV gene from Trametes versicolor in Trichoderma reesei. Abst Papers Am Chem Soc. 2000;219:154. [Google Scholar]

- 121.Kiiskinen LL, Kruus K, Bailey M, Ylosmaki E, Siika-Aho M, Saloheimo M. Expression of Melanocarpus albomyces laccase in Trichoderma reesei and characterisation of the purified enzyme. Microbiol. 2004;150:3065–3074. doi: 10.1099/mic.0.27147-0. [DOI] [PubMed] [Google Scholar]

- 122.Kiiskinen LL, Palonen H, Linder M, Viikari L, Kruus K. Laccase from Melanocarpus albomyces binds effectively to cellulose. FEBS Lett. 2004;576:251–255. doi: 10.1016/j.febslet.2004.08.040. [DOI] [PubMed] [Google Scholar]

- 123.Hakulinen N, Kruus K, Koivula A, Rouvinen J. A crystallographic and spectroscopic study on the effect of X-ray radiation on the crystal structure of Melanocarpus albomyces laccase. Biochem Biophys Res Commun. 2006;350:929–934. doi: 10.1016/j.bbrc.2006.09.144. [DOI] [PubMed] [Google Scholar]

- 124.Rautio JJ, Smit BA, Wiebe M, Penttilä M, Saloheimo M. Transcriptional monitoring of steady state and effects of anaerobic phases in chemostat cultures of the filamentous fungus Trichoderma reesei. BMC Genomics. 2006;7:247. doi: 10.1186/1471-2164-7-247. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 125.Rautio JJ, Bailey M, Kivioja T, Söderlund H, Penttilä M, Saloheimo M. Physiological evaluation of the filamentous fungus Trichoderma reesei in production processes by marker gene expression analysis. BMC Biotechnol. 2007;7:28. doi: 10.1186/1472-6750-7-28. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 126.Hakulinen N, Andberg M, Kallio J, Koivula A, Kruus K, Rouvinen J. A near atomic resolution structure of a Melanocarpus albomyces laccase. J Struct Biol. 2008;162:29–39. doi: 10.1016/j.jsb.2007.12.003. [DOI] [PubMed] [Google Scholar]

- 127.Wahleithner JA, Xu F, Brown SH, Golightly EJ, Halkier T, Kauppinen S, et al. The identification and characterization of four laccases from the plant pathogenic fungus Rhizoctonia solani. Curr Genet. 1996;29:395–403. doi: 10.1007/BF02208621. [DOI] [PubMed] [Google Scholar]

- 128.Xu F, Shin W, Brown SH, Wahleithner JA, Sundaram UM, Solomon WI. A study of a series of recombinant fungal laccases and bilirubin oxidase that exhibit significant differences in redox potential, substrate specificity, and stability. Biochim Biophys Acta. 1996;1292:303–311. doi: 10.1016/0167-4838(95)00210-3. [DOI] [PubMed] [Google Scholar]

- 129.Xu F, Berka RM, Wahleithner JA, Nelson BA, Shuster JR, Brown SH, et al. Site-directed mutations in fungal laccase: effect on redox potential, activity and pH profile. Biochem J. 1998;334:63–70. doi: 10.1042/bj3340063. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 130.Kulys J, Bratkovskaja I, Vidziunaite R. Laccase-catalysed iodide oxidation in presence of methyl syringate. Biotechnol Bioeng. 2005;92:124–128. doi: 10.1002/bit.20610. [DOI] [PubMed] [Google Scholar]

- 131.Yaver DS, Xu F, Golightly EJ, Brown KM, Brown SH, Rey MW, et al. Purification, characterization, molecular cloning, and expression of two laccase genes from the white rot basidiomycete Trametes villosa. Appl Environ Microbiol. 1996;62:834–841. doi: 10.1128/aem.62.3.834-841.1996. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 132.Xu F, Palmer AE, Yaver DS, Berka RM, Gambetta GA, Brown SH, et al. Targeted mutations in a Trametes villosa laccase, axial perturbations of the T1 copper. J Biol Chem. 1999;274:12372–12375. doi: 10.1074/jbc.274.18.12372. [DOI] [PubMed] [Google Scholar]

- 133.Kulys J, Krikstopaitis K, Ziemys A, Schneider PP. Laccase-catalysed oxidation of syringates in presence of albumins. J Mol Cat B Enzym. 2002;18:99–108. [Google Scholar]

- 134.Bukh C, Lund M, Bjerrum MJ. Kinetic studies on the reaction between Trametes villosa laccase and dioxygen. J Inorg Biochem. 2006;100:1547–1557. doi: 10.1016/j.jinorgbio.2006.05.007. [DOI] [PubMed] [Google Scholar]

- 135.Kulys J, Bratkovskaja I. Antioxidants determination with laccase. Talanta. 2007;72:526–531. doi: 10.1016/j.talanta.2006.11.011. [DOI] [PubMed] [Google Scholar]

- 136.Berka R, Schneider P, Golightly E, Brown S, Madden M, Brown K, et al. Characterization of the gene encoding an extracellular laccase of Myceliophthora thermophila and analysis of the recombinant enzyme expressed in Aspergillus oryzae. Appl Environ Microbiol. 1997;63:3151–3157. doi: 10.1128/aem.63.8.3151-3157.1997. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 137.López-Cruz JI, Viniegra-Gonzalez G, Hernández-Arana A. Thermostability of native and pegylated Myceliophthora thermophila laccase in aqueous and mixed solvents. Bioconjug Chem. 2006;17:1093–1098. doi: 10.1021/bc0503465. [DOI] [PubMed] [Google Scholar]

- 138.Yaver DS, Overjero MDC, Xu F, Nelson BA, Brown KM, Halkier T, et al. Molecular characterization of laccase genes from the basidiomycete Coprinus cinereus and heterologous expression of the laccase Lcc1. Appl Environ Microbiol. 1999;65:4943–4948. doi: 10.1128/aem.65.11.4943-4948.1999. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 139.Ducros V, Brzozowski AM, Wilson KS, Brown SH, Ostergaard P, Schneider P, et al. Crystal structure of the type-2 Cu depleted laccase from Coprinus cinereus at 2. angstrom resolution. Nat Struct Biol. 1998;5:310–316. doi: 10.1038/nsb0498-310. [DOI] [PubMed] [Google Scholar]

- 140.Berka RM, Xu F, Thompson SA. 1995. I P WO 9533837 A1.

- 141.Sigoillot C, Record E, Belle V, Robert JL, Levasseur A, Punt PJ, et al. Natural and recombinant fungal laccases for paper pulp bleaching. Appl Microbiol Biotechnol. 2004;64:346–352. doi: 10.1007/s00253-003-1468-3. [DOI] [PubMed] [Google Scholar]

- 142.Fujihiro S, Higuchi R, Hisamatsu S, Sonoki S. Metabolism of hydroxylated PCB congeners by cloned laccase isoforms. Appl Microbiol Biotechnol. 2009;82:853–860. doi: 10.1007/s00253-008-1798-2. [DOI] [PubMed] [Google Scholar]

- 143.Yano A, Kikuchi S, Nakagawa Y, Sakamoto Y, Sato T. Secretory expression of the non-secretory-type Lentinula edodes laccase by Aspergillus oryzae. Microbiol Res. 2009;164:642–649. doi: 10.1016/j.micres.2008.12.001. [DOI] [PubMed] [Google Scholar]

- 144.Skálová T, Dohnálek J, Østergaard LH, Østergaard PR, Kolenko P, Dusková J, et al. The structure of the small laccase from Streptomyces coelicolor reveals a link between laccases and nitrite reductases. J Mol Biol. 2009;385:1165–1178. doi: 10.1016/j.jmb.2008.11.024. [DOI] [PubMed] [Google Scholar]

- 145.Hatamoto O, Sekine H, Nakano E, Abe K. Cloning and expression of a cDNA encoding the laccase from Schizophyllum commune. Biosci Biotechnol Biochem. 1999;63:58–64. doi: 10.1271/bbb.63.58. [DOI] [PubMed] [Google Scholar]

- 146.Record E, Punt PJ, Chamkha M, Labat M, van Den Hondel CA, Asther M. Expression of the Pycnoporus cinnabarinus laccase gene in Aspergillus niger and characterization of the recombinant enzyme. Eur J Biochem. 2002;269:602–609. doi: 10.1046/j.0014-2956.2001.02690.x. [DOI] [PubMed] [Google Scholar]

- 147.Sigoillot C, Camarero S, Vidal T, Record E, Asther M, Pérez-Boada M, et al. Comparison of different fungal enzymes for bleaching high-quality paper pulps. J Biotechnol. 2005;115:333–343. doi: 10.1016/j.jbiotec.2004.09.006. [DOI] [PubMed] [Google Scholar]

- 148.Ravalason H, Herpoël-Gimbert I, Record E, Bertaud F, Grisel S, de Weert S, et al. Fusion of a family 1 carbohydrate binding module of Aspergillus niger to the Pycnoporus cinnabarinus laccase for efficient softwood kraft pulp biobleaching. J Biotechnol. 2009;142:220–226. doi: 10.1016/j.jbiotec.2009.04.013. [DOI] [PubMed] [Google Scholar]

- 149.Aehle W, Convents D, Doornink M, Van Gastel F, Rodriguez AM, Toppozada A, et al. Detergent compositions comprising novel phenol oxidizing enzymes. 2002. WO 0220711. [Google Scholar]

- 150.Aehle W, Baldwin TL, Janssen GG, Van Gastel FJC, Wang H, Winetzky DS. Selection and production of laccase and other phenol oxidizing-binding peptide complexes for detergents and carotenoid stain removal. 2003. WO 2003023067. [Google Scholar]

- 151.Janssen GG, Baldwin TM, Winetzky DS, Tierney LM, Wang H, Murray CJ. Selective targeting of a laccase from Stachybotrys chartarum covalently linked to a carotenoid-binding peptide. J Pept Res. 2004;64:10–24. doi: 10.1111/j.1399-3011.2004.00150.x. [DOI] [PubMed] [Google Scholar]

- 152.Larrondo LF, Avila M, Salas L, Cullen D, Vicuna R. Heterologous expression of laccase cDNA from Ceriporiopsis subvermispora yields copper-activated apoprotein and complex isoform patterns. Microbiology. 2003;149:1177–1182. doi: 10.1099/mic.0.26147-0. [DOI] [PubMed] [Google Scholar]