Abstract

tert-Butylsulfinamides are unstable above room temperature, and in chlorinated solvents they undergo rearrangement to form the more stable N-(tert-butylthio)-tert-butylsulfonamide.

Keywords: chlorinated solvents, N-(tert-butylthio)-tert-butylsulfonamide, tert-butylsulfinamide, thermal rearrangement

Introduction

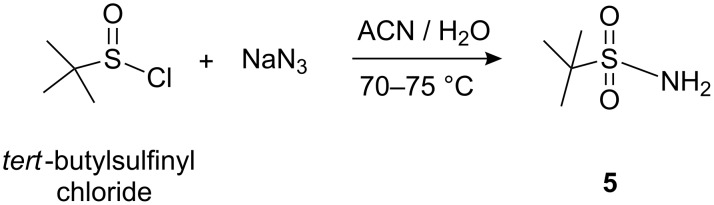

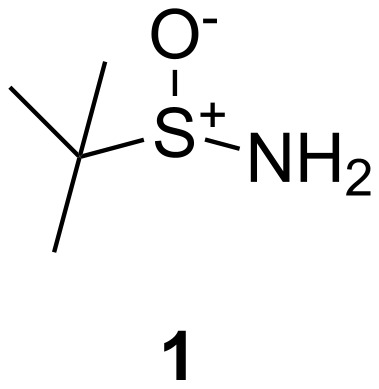

Over the past decade, an ever increasing number of methods based upon the chiral amine reagent tert-butylsulfinamide (1) (Figure 1) has become one of the most extensively used synthetic approaches for both the production and discovery of drug candidates [1]. In particular, the tert-butylsulfinyl group showed high levels of asymmetric induction in many processes. The importance of these reagents (R and S) is evident by the number of manufacturers (>75) and by the number of publications (>400).

Figure 1.

tert-Butylsulfinamide.

Results and Discussion

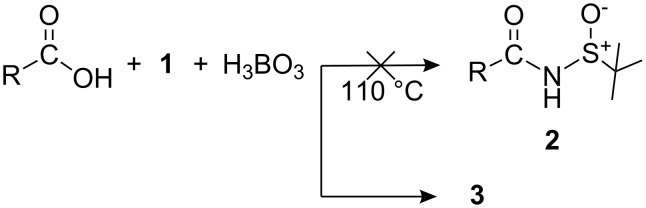

During our studies [2] on the industrial utilization of these two reagents (R and S), we found an interesting observation, i.e., when sulfinamide 1 was reacted with an organic acid in the presence of boric acid [3] to obtain an amide 2 (Scheme 1), no amide was obtained, which was confirmed by IR and NMR data, and the product was also devoid of an acid residue. The product appeared to be derived only from the reagent 1.

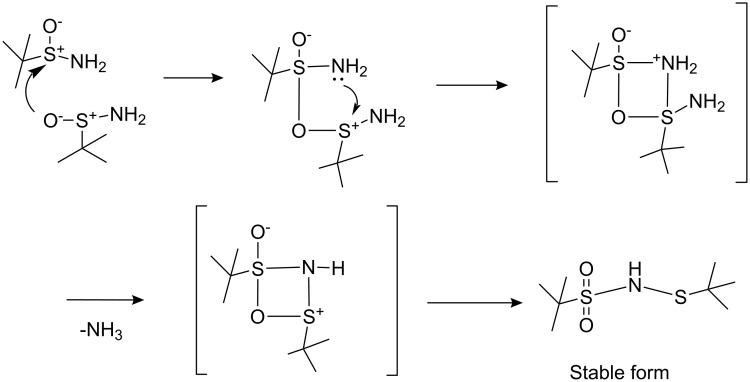

Scheme 1.

Synthesis of acid amide.

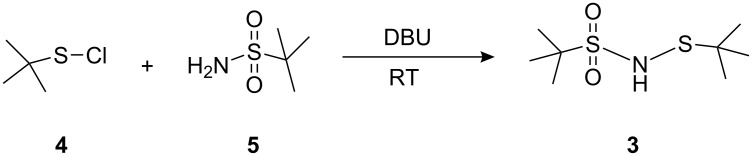

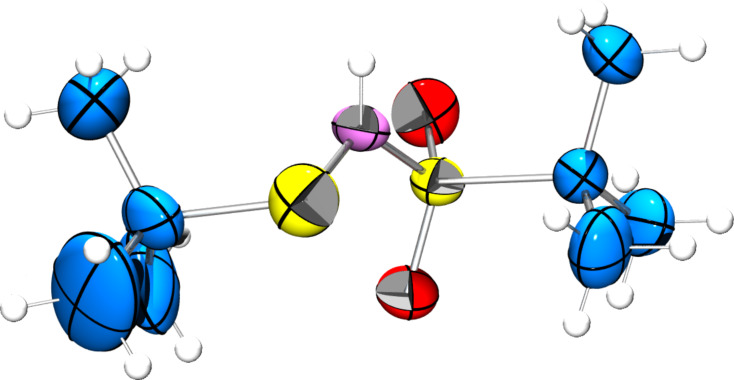

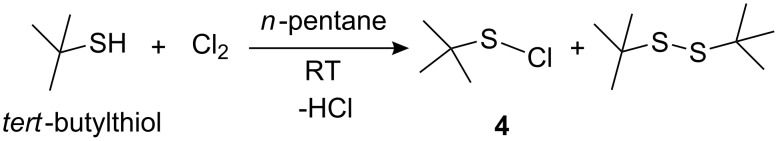

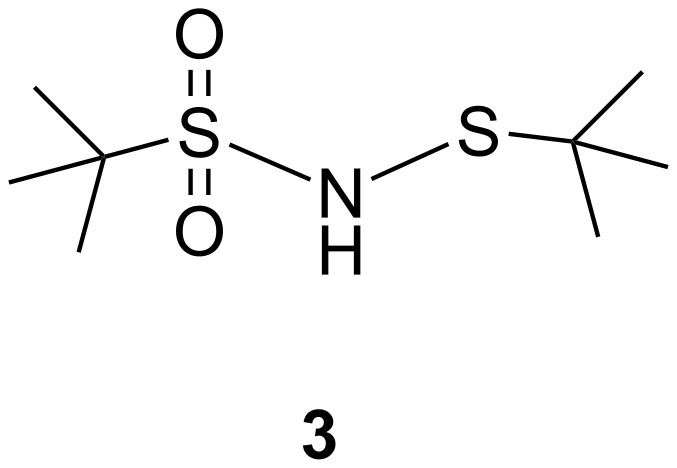

From the spectral data, structure 3 was assigned to the product shown in Figure 2. The structure of 3 was confirmed by chemical synthesis (Scheme 2) and finally by XRD [4] (Figure 3). Both tert-butylsulfanyl chloride 4 (Scheme 3) and tert-butylsulfonamide 5 (Scheme 4) were prepared by known procedures [5–6].

Figure 2.

N-(tert-butylthio)-tert-butylsulfonamide.

Scheme 2.

Chemical synthesis of 3.

Figure 3.

ORTEP diagram of 3.

Scheme 3.

Synthesis of tert-butylsulfanyl chloride.

Scheme 4.

Synthesis of tert-butylsulfonamide.

A possible mechanism for the proposed rearrangement is shown in Scheme 5.

Scheme 5.

Proposed mechanism for rearrangement.

First it is assumed that the product is formed only by the degradation of reagent 1. Further experiments, in the presence of acids (entries 7 to 13, Table 1) or the absence of acids (entries 1 to 6, Table 1), under sonication (entries 14 to 18) and with microwave irradiation (entry 26), confirmed the assumption that the reagent is thermally unstable. Also the rearrangement is likely not to proceed by a homolytic fission (radical) mechanism, because the rate of reaction is not affected either by benzoyl peroxide, by TEMPO a radical initiator (entries 22 and 23) or by a radical inhibitor 2,6-di-tert-butylphenol (entry 24).

Table 1.

Screening of rearrangement conditions.

| Entry | Reaction conditions | Yield (%)a | ||||

| Starting material |

Reagent / condition type |

Solvent | T (°C) | Time (h) | ||

| 1 | (R)-isomer | - | - | 110 | 3 | 27 |

| 2 | (R)-isomer | - | toluene | 110 | 48 | 70 |

| 3 | (R)-isomer | - | o-xylene | 140 | 48 | 64 |

| 4 | (R)-isomer | - | ethylene dichloride | 80 | 72 | 40 + 20c |

| 5 | (R)-isomer | - | CHCl3 | 65 | 72 | 25 |

| 6 | (R)-isomer | - | toluene | 110 | 48 | 70 |

| 7 | (R)-isomer | boric acid (1.0 equiv) | toluene (u/N2) | 110 | 24 | 65 |

| 8 | (R)-isomer | boric acid (1.0 equiv) | toluene | 110 | 24 | 65 |

| 9 | (R)-isomer | boric acid (0.5 equiv) | toluene | 110 | 48 | 60 |

| 10 | (R)-isomer | MeSO3H | toluene | 110 | 1 | 27 |

| 11 | (R)-isomer | tartaric acid | toluene | 110 | 24 | 38 |

| 12 | (R)-isomer | citric acid | toluene | 110 | 24 | 16 |

| 13 | (R)-isomer | p-TSA | toluene | 110 | 24 | 38 |

| 14 | (R)-isomer | sonication | CHCl3 | RT | 2 | 34b |

| 15 | (R)-isomer | sonication | DMF | RT | 1 | 2b |

| 16 | (R)-isomer | sonication | ethyl acetate | RT | 1 | 5b |

| 17 | (R)-isomer | sonication + boric acid | CHCl3 | RT | 1 | 16b |

| 18 | (R)-isomer | sonication + p-TSA | CHCl3 | RT | 0.5 | 23b |

| 19 | (R)-isomer | - | toluene | RT | 144 | 3 |

| 20 | (R)-isomer | - | CHCl3 | RT | 144 | 21b |

| 21 | (R)-isomer | - | MeOH | RT | 144 | 3b |

| 22 | (R)-isomer | benzoyl peroxide | toluene | 110 | 48 | 60 |

| 23 | (R)-isomer | TEMPO | toluene | RT - 110 | 40 | 9b |

| 24 | (R)-isomer | 2,6-di-tert-butylphenol | toluene | 110 | 24 | 75 |

| 25 | (S)-isomer | - | toluene | 110 | 48 | 70 |

| 26 | (R)-isomer | MW 150 Watt | DMF | 150 | 0.5 | 70 |

aIsolated yield, b% conversion in HPLC, crecovered starting material with SOR +5°

When the reagent 1 alone was subjected to thermal rearrangement (entry 1), complete consumption of starting material was observed. Only 27% product was isolated and 73% of the material was lost by vaporitation. When the reaction was carried out in the presence of solvents such as toluene (entries 2, 6 and 24), o-xylene (entry 3), or solvents with reagents such as boric acid (entries 7, 8 and 9), methanesulphonic acid (entry 10), p-TSA (entry 13), benzoyl peroxide (entry 22), 2,6-di-tert-butylphenol (entry 23) or with microwave irradiation (entry 25), complete consumption of starting material was observed. In other cases (entries 4, 5, 11 and 12), 10 to 30% of the starting material was recovered without racemization.

Conclusion

We found that both (R and S) tert-butanesulfinamides are unstable above room temperature and in chlorinated solvents.

Experimental

See Supporting Information File 1 for full experimental data.

Supporting Information

Full experimental data.

Acknowledgments

We wish to thank Prof. A. Srikrishna of IISc. (Bangalore) for the X-ray analysis and the management of Suven for providing excellent facilities.

Contributor Information

Veera Reddy Arava, Email: reddyvenis@rediffmail.com.

Laxminarasimhulu Gorentla, Email: laxman164@rediffmail.com.

Pramod Kumar Dubey, Email: pkdubeyjntu@yahoo.co.in.

References

- 1.Robak M T, Herbage M A, Ellman J A. Chem Rev. 2010;110:3600–3740. doi: 10.1021/cr900382t. [DOI] [PubMed] [Google Scholar]

- 2.Reddy A V, Rao S U B, Narasimha G L, Dubey P K. Synth Commun. 2009;39:1451–1456. doi: 10.1080/00397910802519216. [DOI] [Google Scholar]

- 3.Mylavarapu R K, Kondaiah G C M, Kolla N, Veeramalla R, Koilkonda P, Bhattacharya A, Bandichhor R. Org Process Res Dev. 2007;11:1065–1068. doi: 10.1021/op700098w. [DOI] [Google Scholar]

- 4.Deposited as CCDC 773082 (2010).

- 5.Himel C M, Park M, inventors. Production of tertiary alkyl thio sulfenyl chlorides. 2,934,563. U.S. Patent. 1960 Apr 26;

- 6.Sharpless K B, Gontcharov A V, Liu H, inventors. Aminohydroxylation of olefins with tert-alkyl sulfonamides. 6,008,376. U.S. Patent. 1999 Aug 21;

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Full experimental data.