Abstract

Nine cross-linked UHMWPE acetabular liners were retrieved at revision surgery. Eight of the liners were fully intact and functional at retrieval. Six cases contained shallow initiated cracks at the root of rim notches; one crack had propagated several millimeters. Optical and electron microscopic inspection of the crack surfaces revealed clam shell markings, which are characteristic of fatigue crack initiation. Crack initiation at notches has been identified in reports of catastrophic cross-linked liner failures, with cracks initiation sites exhibiting similar morphology and clam shell markings. Thus, we believe the shallow cracks identified in this case series are precursors to catastrophic rim fracture. The results of this study recommend further investigations to clarify the etiology and prevalence of crack initiation in cross-linked acetabular liners.

Keywords: Acetabular liner, total hip arthroplasty, fracture, UHMWPE, crosslinked UHMWPE, crack initiation

Introduction

Highly cross-linked ultrahigh molecular weight polyethylene (UHMWPE) is used in total joint replacements as a wear resistant, polymeric bearing material. Cross-linking via ionizing radiation has been found to reduce the volume of wear debris generated during frictional contact with a metallic counterface in a dose-dependent manner [1]. Clinical evidence has shown this increased wear resistance to reduce the wear rate in vivo and consequently the potential for wear-induced osteolysis [2]. However, it is also established that cross-linking reduces the fracture and fatigue crack propagation resistance of this material [3,4]. Thus, improvements in wear performance may be offset by reductions in the ability of a component to tolerate flaws or cracks [5].

There have been recent reports of the catastrophic fracture of highly cross-linked acetabular liners of four different designs [6-8]. Halley et al. presented a rim fractured highly cross-linked liner, which was attributed to a combination of malpositioning and a large femoral head diameter (40 mm) [6]. The case series investigated by Tower et al. included four highly cross-linked liners from two bilateral revisions, all of the same design [7]. All of the implants in that series were vertically malpositioned in abduction, and the authors also cautioned against combining cross-linked UHMWPE with large diameter liners in malpositioned components. Furmanski et al. investigated four cross-linked acetabular liners that had sustained rim fractures, each of a different design [8]. Those components were generally well placed, though one case was excessively anteverted (45°), and only one case had a large diameter head (36 mm). Scanning electron microscopy (SEM) revealed that these rim fractures initiated at a stress concentration in the unsupported rim of each design. The two former case reports support the importance of large diameter heads and malpositioning for rim fracture, while the work of Furmanski et al. questioned whether material and design factors were more indicative of fracture risk than femoral head diameter or surgical placement.

A study of acetabular liner retrievals by Shon et al. [9] revealed that a majority of 162 randomly selected retrieved implants showed permanent wear scarring resulting from rim loading events. Based on this prevalence of substantial rim loading in acetabular components, Furmanski et al. proposed that direct rim loading events could have been the underlying etiology in their series of rim fractures [8]. They conducted finite element simulations to predict the stress states that would develop in the retrieved component designs during direct rim loading events. Their results predicted that a 500 N distributed load applied to the rim in each design would be sufficient to propagate cracks from the observed fracture initiation sites. The simulations also predicted that the maximal tensile stress would diminish substantially a short distance from the initiation site. Consequently, Furmanski et al. proposed that shallow cracks might be commonly found at the root of rim notches in intact cross-linked acetabular liners with unsupported rims [8].

The purpose of this work was to quantify the incidence of initiated cracks in clinically retrieved cross-linked UHMWPE acetabular liners with unsupported rims. We hypothesized that short initiated cracks would be found in intact retrieved cross-linked UHMWPE acetabular liners with unsupported and notched rim designs.

Materials and methods

Nine highly cross-linked UHMWPE acetabular liners were retrieved during revision surgery at University Hospitals Case Medical Center between February 2007 and May 2008 under an IRB approved protocol. The nine liners represented all the cross-linked unsupported rim components available for inspection in the authors’ retrieval laboratory at the time this work was performed. All nine liners were of the Trilogy™ design (Zimmer, Warsaw, IN) with head diameters ranging from 28-40 mm and unsupported rims containing notches (Figure 1). Between November 1999 and December 2009, the authors’ institution implanted approximately 2,800 Trilogy™ liners using highly cross-linked UHMWPE, and 59 revisions were performed on liners of that design and material. 12 of the retrievals were obtained after this investigation was conducted, 32 were not available for inspection (had been previously allocated to another retrieval study), and 5 did not meet the inclusion criteria (highly cross-linked UHMWPE and unsupported rim). All acetabular components used cementless fixation. Liners in cases A, B, C, and F were implanted during primary arthroplasty, while those in cases E, G, and H were inserted during a first revision surgery. Finally, the liner in case D was inserted during a second revision. (Table 1). Retrieved components were cleaned and documented, and the surgical positioning of the acetabular components was evaluated radiographically for anteversion angle and for abduction angle [10]. Implant positioning was compared to the placement guidelines of Lewinnek [11] and Kleuss et al. [12]: Lewinnek recommended 5-25° of anteversion and 35-55° of abduction to mitigate dislocation, while Kleuss et al. recommended 15-30° of anteversion and 45° of abduction (without articulating a tolerance beyond these values) to mitigate femoral neck impingement and dislocation.

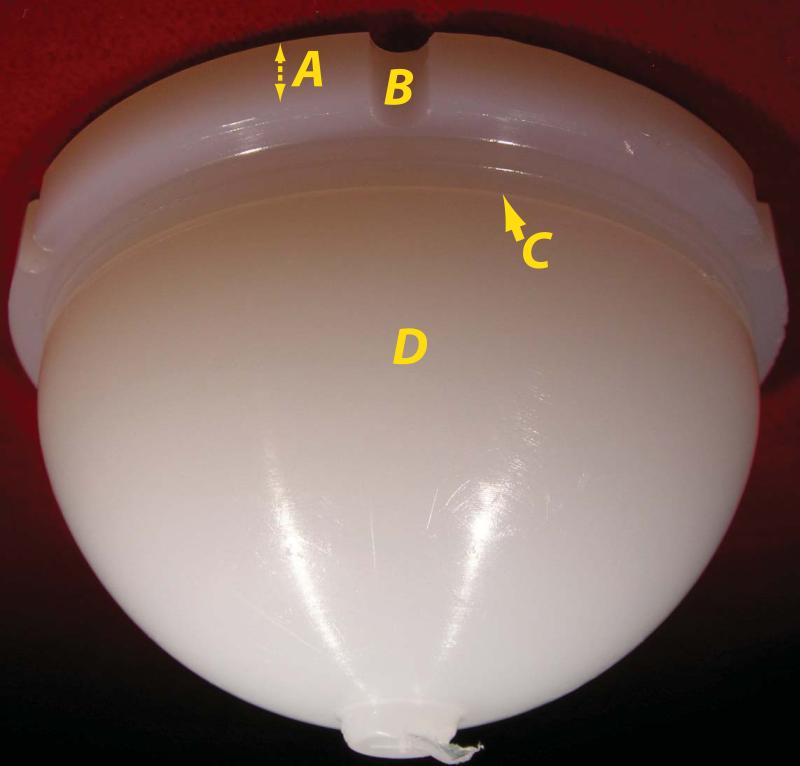

Fig 1.

External view of case E liner. The elevated rim (A) is unsupported by the metal shell. Six notches (B) are cut into the exterior of rim. A locking groove (C) accepts an external clip to prevent dissociation from the metal backing. The external liner surface below the rim (D) contacts the metal shell.

Table 1.

Case data and inspection results

| Case | #Cr | TIV(y) | G | Age (y) | W (kg) | Revision Diag. | AnA (°) | AbA (°) | Dia (mm) | Rev. Hist. |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 4 | 0.08 | F | 74 | 68 | Infection | 9 | 52.6 | 36 | Primary |

| B | 2 | 0.07 | M | 60 | 101 | Instability | 11 | 41.4 | 36 | Primary |

| C | 1 | 4.11 | F | 69 | 82 | Infection | 14 | 46 | 28 | Primary |

| D | 1 | 2.09 | F | 52 | 63 | Subluxation/Acet. Loose | 31 | 48.6 | 36 | 2nd Rev. |

| E | 2 | 0.01 | M | 51 | 125 | Infection | 16 | 49.8 | 40 | 1st Rev. |

| F | 5 | 1.00 | F | 72 | 82 | Pain | 9 | 45.2 | 36 | Primary |

| G | 0 | 6.26 | F | 46 | 79 | Fem. Loose | 20 | 41.6 | 28 | 1st Rev. |

| H | 0 | 0.80 | F | 62 | 85 | Dislocation | 11 | 46.6 | 32 | 1st Rev. |

| I | 0 | 0.03 | F | 83 | 110 | Dislocation | 33 | 55.2 | 32 | Primary |

Num. cracks (#Cr). Time In Vivo (TIV), Anteversion (AnA), Abduction (AbA)

All implants are Zimmer Trilogy™ with Longevity™ highly cross-linked UHMWPE with elevated rim

UHMWPE liners were inspected for cracks using indirect illumination with a fiber optic illuminator (Dolan-Jenner, Boxborough, MA) and optical magnification (0.63-4x) in a stereo dissection microscope (Leica, Bannockburn, IL). Illumination adjacent to the region of interest results in general diffuse lighting of the material, while crack surfaces reflect the light and appear either brighter or darker than the background when properly oriented. Deep scratches and tool cuts on the surface exhibit plastic deformation near the opening of an observed flaw, and such surface features were differentiated from cracks and excluded from the results.

The results of the optical inspection were reinforced by direct observation of the exposed surface of a documented shallow crack with a scanning electron microscope (SEM) in secondary electron mode (Hitachi, Pleasanton, CA). To reveal the crack surface, the rim was first separated from the liner with a band saw, with care taken to avoid damaging the rim. A cut was then made through the intact material in the plane of the identified initiated crack with a razor blade without touching the crack itself. The rim was then cooled in liquid nitrogen to promote a brittle fracture process and the crack surface exposed for observation by rupturing the remaining ligament of material in the crack plane. The crack surface was then sputter coated with a gold-palladium alloy for SEM inspection.

Results

The patients’ ages ranged from 46-83 (Table 1), and their weights ranged from 63-125 kg (one N/A). The diagnoses for revision were infection (A, D, E), instability or dislocation (B, H, I), component loosening (D, G), and pain (F). The implants in this series were well positioned in abduction, according to the positioning guidelines of Lewinnek [11], though most cases were slightly in excess of the recommended 45° of abduction of Kleuss et al. [12]. However, cases D and I were marginally over-anteverted beyond the positioning recommendations of Lewinnek and Kleuss et al. , and cases A, B, C, F, and H were mildly (1-6°) under-anteverted, according to Kleuss et al. The time in-vivo for each component varied widely from 3 days to 4.11 years (Table 1).

Six of the nine UHMWPE acetabular liners in this series exhibited shallow cracks (cases A-F, Table 1), all of which were identified at the root of a notch machined in the unsupported rim of the component (Figure 1). One liner had sustained a partial fracture secondary to a failure of a metallicacetabular augment (case D) and the rest were intact and fully functional at the time of revision surgery. Four liners exhibited multiple cracks, with as many as five cracks in case F. Each crack was found in a separate notch, and the reported shallow crack identified in case D occurred in a different notch than the fracture.

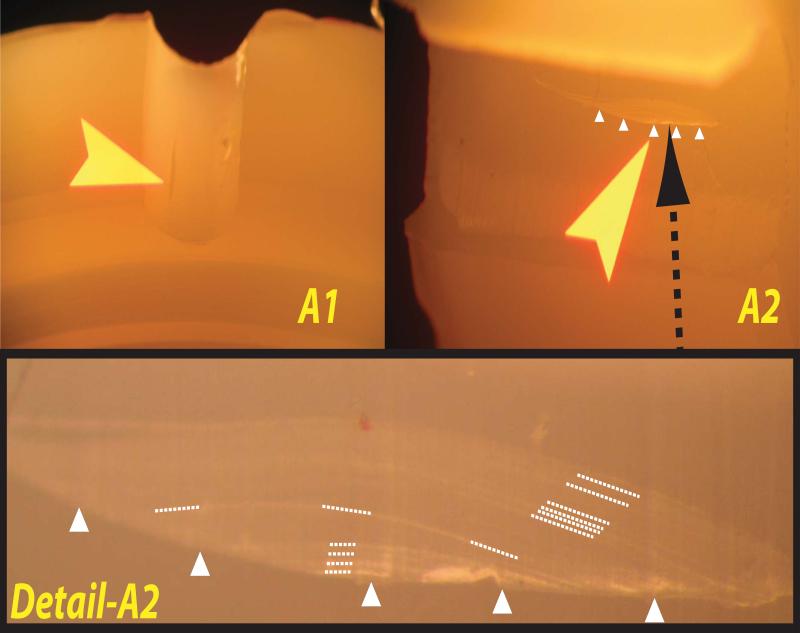

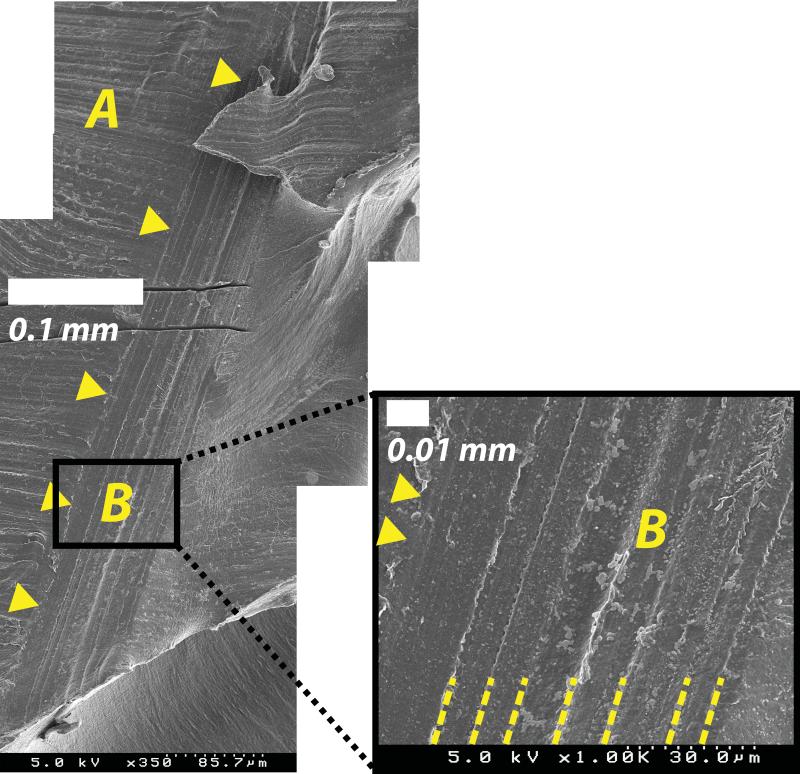

The initiated cracks were all approximately 1-3 mm long and 0.1 mm deep, extending from the surface of the notch in a radial direction (Figure 2). Additionally, many of the initiated crack surfaces exhibited clearly identifiable clam shell markings (Figures 2b-3), which are characteristic of fatigue crack initiation and intermittent growth and have been observed at the initiation sites of previously documented catastrophic liner fractures[8]. SEM observation of an exposed crack surface in case E (Figure 3) verified the existence of clam shell markings, in agreement with the optical inspection findings (Figure 2).

Fig 2.

Representative optical microscopy images from case A showing two initiated cracks in two separate rim notches (denoted A1 and A2). A1 shows a crack that is in dark contrast with the liner, and clam shell markings were difficult to resolve for this crack. A2 shows a crack in light contrast with the background, where the crack surface is nearly in the plane of the image. Detail-A2 shows the thumbnail shaped crack at the root of the notch, with the crack opening at the implant surface indicated by triangular markers. Clam shell markings indicative of intermittent crack growth are visible, and those that are most clear are marked by dashed lines.

Fig 3.

Scanning electron micrographs of the exposed surface of an initiated crack from case E, oriented approximately vertically as in Fig 1. The external surface of the liner notch (A) features horizontal machining lines. The intersection of the crack with the surface is delineated with triangular markers. The surface of the crack (B) exhibits distinct vertically oriented and parallel clam shell markings (highlighted with dashed lines), verifying the observations made with visible microscopy. The parallel cuts in upper left are artificial marks for locating the fracture surface.

Discussion

Our observations of clinically retrieved cross-linked UHMWPE acetabular liners support the hypothesis of this retrieval case study, i.e., cracks may exist in early retrievals near notches in the unsupported rim of such components. However, only one crack observed in this series had developed into a fracture prior to revision.

The discovery of initiated cracks in intact cross-linked UHMWPE acetabular liners provides insight to the potential susceptibility of these components to fracture. As described by Furmanski et al., finite element modeling predicted that the conditions for crack propagation during rim loading would be focused near the surface, potentially resulting in initiated cracks without sufficient driving force to grow beyond the notch affected region [8]. The size and location of the initiated cracks in this series agree with those predictions. The clam shell markings on the initiated crack surfaces in this work also correspond with those observed at the crack initiation sites in a case series of fractured cross-linked liners [8]. The agreement of the morphology and location of the observed cracks in this series with the initiation sites of documented liner fractures implies that these initiated cracks may serve as precursors to fracture.

Based on our observations, and previous analyses of acetabular liner rim fracture [8], we propose the following chronology of crack progression: 1) Rim loading generates excessive tensile stress at the root of a stress concentration in the unsupported rim. 2) UHMWPE fails locally at the peak tensile stress location, and a crack initiates. 3) The initiated crack grows under excessive stress due to rim loading near the stress concentration, i.e., the notch-affected region. Crack growth may be intermittent, driven by uncommon rim loading events. 4) Crack growth slows as the crack exits the notch affected region. 5) The crack grows to a sufficient length that propagation requires relatively low stress, and fracture occurs. The fracture may propagate through to another surface and liberate a fragment of the rim [6-8].

It should be noted that three of the six cracked liners were removed within a month of implantation (A, B, E). This is an important observation, as patients typically experience limited weight bearing and activity for 6 weeks or more, and so are unlikely to substantially load their implants during this early post-operative period. This suggests that the development of these cracks may occur early and is not necessarily driven by the accumulation of damage under sustained loading during activities of daily living (i.e., fatigue loading). Thus, the observed shallow cracks cannot be generally attributed to prolonged exposure to typical clinical conditions. Rather, the observation of initiated cracks in components of durations less than 1 month suggests that some of the observed cracks could have initiated during manufacture, surgical insertion, or during initial physiological loading. Regarding surgical insertion, impact forces on the rim could potentially be sufficiently severe to initiate cracks, particularly if the liner is positioned eccentric to the metal shell during insertion. Future investigations are planned to assess the prevalence of crack initiation both prior to and secondary to surgical insertion.

Five of the six cases containing initiated cracks had a femoral head diameter of 36 mm or 40 mm, suggesting that increased head size could be a contributing factor for crack initiation. The reports of highly cross-linked fractured liners of Halley et al. and Tower et al. both indicated that larger liner diameters contributed to the etiology of the fractures [7-8], and our observations are consistent with their findings. However, in the case report of Furmanski et al., three of four fractured cases had a head diameter of 32 mm or above [8]. Thus, larger head diameters may be an exacerbating factor for rim crack initiation and fracture, but do not appear to be necessary to cause fracture. In order to maintain the minimum UHMWPE thickness at the pole of the liner, the Trilogy™ design 36 mm head diameter liners are lateralized 3.5 mm, which decreases the liner thickness at the rim by 4.6 mm. For the smaller acetabular sizes (50-54 mm) this results in a minimum liner thickness of 2.2 mm at the rim. Thus larger head diameters are directly linked to reduced liner thickness in this design, which in turn may be an exacerbating factor for fracture.

The surgical placement of the acetabular components was generally satisfactory, according to recommended tolerances of Lewinnek and Kleuss et al., though nearly all cases were marginally anteverted or abducted 1-8° beyond one of the two sets of positioning guidelines referenced in this study. The fractured liners reported of Halley et al. and Tower et al. were all linked to extreme malpositioning of the acetabular components [6-7], but in the study of Furmanski et al. only one was substantially malpositioned [8]. Thus, the relative contribution of malpositioning to liner fracture is uncertain. The results of this study indicate that rim cracks can develop in well-positioned implants.

The cohort in this case series is limited, comprising nine implants of only one design from one institution. However, the prevalence of initiated cracks in cross-linked components of other designs remains to be established. Nevertheless, these findings suggest that intact and functional acetabular components may harbor initiated cracks for much or all of their lifetime. We postulate that other centers and implant designs will have a similar prevalence of crack initiation. As other retrieval collections are inspected for cracks, the prevalence of crack initiation may be assessed across multiple centers and with a more representative collection of designs and based on a greater sample size.

The fact that all of the components reported in this study are of the Trilogy™ design should not be over-interpreted. The majority of implants used at our institution and received for analysis by our laboratory are manufactured by Zimmer. We postulate the etiology of these cracks to be related primarily to direct loading of the unsupported and notched rim. This and similar geometric features are prominent among a number of designs currently in clinical use, and previous stress analyses of four different unsupported rim designs concluded that all were at risk of crack propagation from rim notches [8]. Thus, we anticipate that inspection of other liners designs will yield similar results to those of this study.

The clinical impact of the observed initiated cracks reported here is not yet fully understood. Crack initiation in commercial acetabular liners under controlled laboratory conditions has not been reported, and the mechanism of crack initiation and failure remains unclear. A future study combining in-vitro rim loading of acetabular components and finite element analyses are planned to investigate the potential for fatigue crack initiation, growth, and fracture in cross-linked UHMWPE total hip replacements.

Acknowledgments

Source of Funding This study was supported in part by a grant from the Sulzer Settlement and by NIH/NIAMS T32 AR007505.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Muratoglu OK, Bragdon CR, O'Connor DO, Jasty M, Harris WH. A novel method of cross-linking ultra-high-molecular-weight polyethylene to improve wear, reduce oxidation, and retain mechanical properties - Recipient of the 1999 HAP Paul Award. J of Arthroplasty. 2001;16:149–60. doi: 10.1054/arth.2001.20540. [DOI] [PubMed] [Google Scholar]

- 2.Marshall AM, Ries MD, Paprosky W. How prevalent are implant wear and osteolysis, and how has the scope of osteolysis changes since 2000? JAAOS. 2008;16(S1):S1–S6. doi: 10.5435/00124635-200800001-00003. [DOI] [PubMed] [Google Scholar]

- 3.Gencur SJ, Rimnac CM, Kurtz SM. Fatigue crack propagation resistance of virgin and highly crosslinked, thermally treated ultra-high molecular weight polyethylene. Biomaterials. 2006;27:1550–7. doi: 10.1016/j.biomaterials.2005.09.010. [DOI] [PubMed] [Google Scholar]

- 4.Pruitt LA. Deformation, yielding, fracture and fatigue behavior of conventional and highly cross-linked ultra high molecular weight polyethylene. Biomaterials. 2005;26:905–15. doi: 10.1016/j.biomaterials.2004.03.022. [DOI] [PubMed] [Google Scholar]

- 5.Rimnac CM, Pruitt LA. How do material properties influence wear and fracture mechanisms? JAAOS. 2008;16(S1):S94–S100. doi: 10.5435/00124635-200800001-00019. [DOI] [PubMed] [Google Scholar]

- 6.Halley D, Glassman A, Crowninshield RD. Recurrent dislocation after revision total hip replacement with a large prosthetic femoral head. A case report. J Bone Joint Surg Am. 2004;86-A:827–30. doi: 10.2106/00004623-200404000-00025. [DOI] [PubMed] [Google Scholar]

- 7.Tower SS, Currier JH, Currier BH, Lyford KA, Van Citters DW, Mayor MB. Rim cracking of the cross-linked longevity polyethylene acetabular liner after total hip arthroplasty. J Bone Joint Surg Am. 2007;10:2212–7. doi: 10.2106/JBJS.F.00758. [DOI] [PubMed] [Google Scholar]

- 8.Furmanski J, Bal BS, Anderson MR, Penenberg BL, Halley DK, Greenwald AS, Ries MD, Pruitt LA. Clinical fracture of cross-linked UHMWPE acetabular liners. Biomaterials. 2009 doi: 10.1016/j.biomaterials.2009.07.013. In press. doi:10:1016/j.biomaterials.2009.07.013. [DOI] [PubMed] [Google Scholar]

- 9.Shon WY, Baldini T, Peterson MG, Wright TM, Salvati EA. Impingement in total hip arthroplasty a study of retrieved acetabular components. J Arthroplasty. 2005;4:427–35. doi: 10.1016/j.arth.2004.09.058. [DOI] [PubMed] [Google Scholar]

- 10.Ackland MK, Bourne WB, Uhthoff HK. Anteversion of the acetabular cup. Measurement of angle after total hip replacement. J Bone Joint Surg Br. 1986;3:409–13. doi: 10.1302/0301-620X.68B3.3733807. [DOI] [PubMed] [Google Scholar]

- 11.Lewinnek GE, Lewis JL, Tarr R, Compere CL, Zimmerman JR. Dislocations after total hip-replacement arthroplasties. J Bone Joint Surg Am. 1978;2:217–20. [PubMed] [Google Scholar]

- 12.Kleuss D, Martin H, Mittelmeier W, Schmitz K, Bader R. Influence of femoral head size on impingement, dislocation and stress distribution in total hip replacement. Med Eng and Phys. 2007;29:465–71. doi: 10.1016/j.medengphy.2006.07.001. [DOI] [PubMed] [Google Scholar]