1. Introduction

1.1. Overview and Historical Background of Nickel-Catalyzed Cross-Couplings

Synthetic organic chemists are Ångstrom-scale architects who take great pleasure in drafting the blueprints for the edification of intricate molecular topologies and architectures. In order to turn the molecular dreams into a reality, synthetic chemists must ultimately roll up their sleeves and become molecular construction workers building their structure brick by brick. From the dawn of the modern chemistry in the ages of Boyle, Dalton and Lavoisier to the present days the tools for molecular construction have evolved, progressing through notable paradigm shifts from the development of the atomistic theory to the rigorous application of the retrosynthetic method focusing on the enantioselective synthesis of medicinal natural products.1,2,3 More recently academic and industrial focus has moved toward efficient chemistry utilizing low-cost and green reagents in transformations designed with high atom-economy starting for bio-sourced feedstocks as well as beyond the small molecule in strategies to produce designed macromolecular materials4 and supramolecular ensembles.5,6 Numerous strategies have been explored for the synthesis of relatively large organic molecules and polymers, but typically the coupling of pre-fabricated units together is more expeditious.7,8,9,10,11,12,13,14,15

Early in the development of homocoupling, the joining of identical chemical fragments, and cross-coupling, early transition metals such as Ni, were identified as useful reagents and catalysts. However, in the intervening years more attention was invested in the development of later transition metal catalysis, particularly Pd-catalyzed Heck,16,17 Hiyama,18 Kumada,19 Negishi,20,21 Suzuki-Miyaura,22,23 Sonogashira,24 Stille25,26 coupling techniques due to some advantages in terms of the diversity and tenability of preparable catalysts, their oxidative and aqueous stability, and relatively facile isolation and structural analysis of their complexes which aided mechanistic and methodologic developments. These, typically Pd-catalyzed,27 coupling reactions employed a diversity of organometallic transmetalating reagents or unsaturated functionalities for coordination/insertion chemistry, but nearly uniformly required aryl, vinyl, allyl or sometimes alkyl halides as electrophiles. While this manuscript was under revision the pioneering work on Pd-catalyzed cross-coupling was recognized with the 2010 Nobel Prize in Chemistry for Professors Heck, Negishi, and Suzuki. However, there is growing interest in using more available, economical, and environmentally friendly phenol and enol-derived electrophiles.

1.2.The Value of Phenol- and Enol-Derived Electrophiles

Industrial chemists are now able to provide a wide array of aryl, polyaryl, vinyl, allyl, and alkyl halides to the hands of bench chemists. However, such species are far less available from natural sources and are certainly not used as coupling partners in biosynthetic pathways. A key benefit to phenol- and enol-derived electrophiles is the ready accessibility of these substrates. In the case of phenols, such compounds are naturally abundant or can be readily prepared from other easily accessed aromatic species.28 A Scifinder search reveals that over 50,000 phenol and aryl polyol derivatives are commercially available.29 Moreover, for certain heteroaromatic compounds, a phenol-type substituent can often be derived from a lactam precursor. The advantages are similar for enol-derived electrophiles, as cross-coupling partners of this class can be accessed by enolization and subsequent trapping of readily available carbonyl compounds.

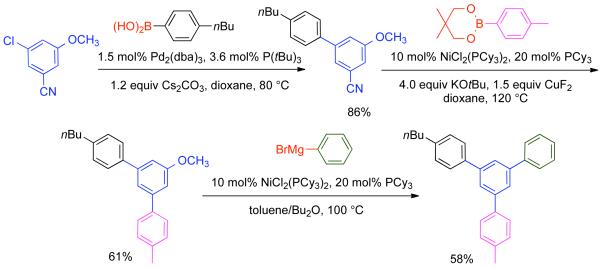

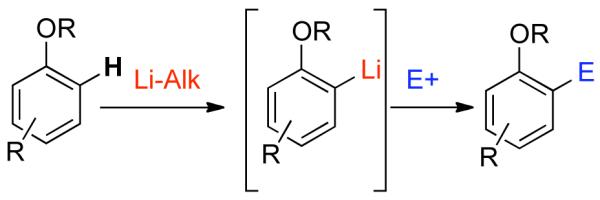

Other advantages to using phenol-derived electrophiles exist. Most notably, oxygenation on the aromatic ring can be used to introduce additional substituents via a number of pathways including electrophilic aromatic substitution.30 Depending on the nature of the O-substituent and the electrophile it is often possible to control the preferred formation of para or ortho substituted products. Ortho substitution of phenol derivatives can also be achieved using directed ortho-metallation (DoM).31 Using this methodology, numerous functional groups, such as phenols, ethers, carbamates, and sulfamates can direct ortho-lithiation (Scheme 1). Subsequent quenching of the resulting organolithium species with an electrophilic species E+ provides the ortho-substituted product, which could potentially be used as a cross-coupling substrate. Recently, aryl pivalates32 and aryl carbamates33,34 have been ortho-arylated directly using palladium-catalyzed functionalization methodologies.

Scheme 1.

The advantage of using phenol-derived electrophiles in coupling reactions is readily apparent. Nevertheless, the implementation of such a strategy is often not as simple as for aryl halides, largely due to a higher C-O bond strength relative to C-Cl, C-Br, and C-I. Often the energy of activation of the C-O bond rivals the energy for deleterious side-reactions and the selectivity of the coupling strategy is diminished. Typically, the C-O bond must be first activated, most often through conversion of the phenols to more reactive sulfonates, ideally through the use of inexpensive methanesulfonyl chloride. However, some recent examples utilizing alternative activation as esters or carbamates, or even directly employing ethers and phenols have been reported.

1.3. Ni, Not Just an Alternative to Pd and Pt

From the perspective of economics, Ni is clearly more desirable than the later elements in the d10 group. Ni is a commodity metal with a cost of roughly $1.20 per mol, whereas Pd and Pt are precious metals, which command a significantly higher price of $1,500 and $10,000 per mol, respectively.35 Thus, unless a process is viable with very low levels of Pd, or Pt can be used and recycled, or very high levels of Ni are required, a Ni-catalyzed approach would be preferred on a cost-basis. In addition to often advantageous economics, Pd-catalysis and Pt-catalysis is not as readily applied to coupling reactions involving phenol-derived electrophiles. Despite cohabitation of group 10, Pt ([Xe]4f145d96s1), is chemically dissimilar from its lower period cousin Pd ([Kr]4d10) and Ni ([Ar]4s23d8), more readily accessing higher oxidation states (+4) and participating in oxygenation and other chemistries outside the scope of this review. Pd is typically observed in the (0 and +2) oxidation states and is very efficient in coupling reactions involving C-X electrophiles. Recent advances in ligand design36,37 mostly from the laboratory of Buchwald have provided improved reactivity toward phenol-derived electrophiles. Nevertheless, the early transition metal Ni (found in 0, +2 as well as +1,+3 oxidation states), is more nucleophilic on account of its smaller size and can harness phenol derived as well as other less reactive electrophiles, employing typically less exotic ligands or even under ligand-free conditions. Therefore, we find Ni to be a privileged reagent for cross-coupling from the standpoints of economics and versatility.

1.4. Scope of the Review

This review will cover the historical development through the present state-of-the art in the Ni-catalyzed homocoupling, cross-coupling, and functionalization of C-O bonds. The functionalization of C-O bonds is not only critical for installing the ultimate functionality of the target molecule but also for providing reactive handles for subsequent cross-coupling reactions. The review is intended to be comprehensive for Ni-mediated chemistry up until late July 2010. Work utilizing other transition metals, notably Pd will be covered less comprehensively and typically for the purpose of historical context and comparison. In some cases extensive discussion of Ni-catalyzed transformations of organohalides was necessary in order to understand the development and the mechanism in the corresponding sulfonates, ethers, or esters.

The review is organized into sections according to the type of phenol-derived electrophile employed. These sections are further divided between homocoupling, cross-coupling, and functionalization and divided into subchapters according to either the transmetallating agent employed or the type of Ni-catalyst used.

2. Nickel-Catalyzed Reactions of Aryl and Vinyl Sulfonates and Sulfates

2.1. Homocoupling of Aryl and Vinyl Sulfonates and Sulfates

2.1.1. Homocoupling of Aryl Halides to Produce Biaryls

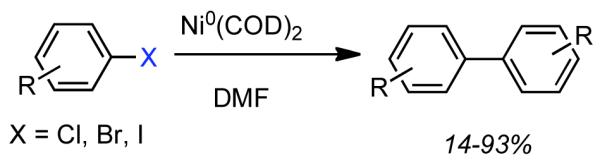

Ni0 complexes first attracted attention as reagents for organic coupling reactions through early work of Wilke on the cyclooligomerization of butadiene.38 A. Yamamoto and Saito elaborated Ni0 mediated reactions involving olefins and established that both linear oligomerization and cyclooligomerization proceeded through a coordination/insertion mechanism.39,40 Interest in the Ni0-catalyzed homocoupling of aryl halides and pseudohalides emerged in 1966, when Saito and A. Yamamoto prepared Et2NiII(bpy), and determined that upon heating it decomposed to butane or ethane and ethylene via free-radical coupling or disproportionation, respectively.41 1971 witnessed the pioneering disclosure by Semmelhack that stoichiometric Ni0(COD)2 could mediate homocoupling of aryl chlorides, bromides, and iodides in DMF at 25-45 °C (Scheme 2).42 This technique was immediately recognized as a very mild, robust and selective approach to the synthesis of biaryls and heterobiaryls. At the time state-of-the-art Ullmann coupling approaches frequently required temperatures exceeding 200 °C, while competitive aryllithium and Grignard techniques were intolerant toward electrophilic substrates. Semmelhack investigated alternative reagents such as Ni0(CO)4, but its use was complicated by competitive CO insertion. It was demonstrated that the rate of homocoupling depended strongly on the nature of the leaving group with -I > -Br > -Cl >> -OSO2R~0. A tentative three-step mechanism was invoked: (1) oxidative addition of Ar-X to Ni0(COD)2 to form NiIIArX(COD)2, (2) further oxidative addition of Ar-X to form NiIVAr2X2, followed by (3) reductive elimination to generate biaryl and NiIIX2. The involvement of a NiIV species was supported by faster consumption of Ar-X than Ni0(COD)2. While clearly a promising discovery, limitations to this early embodiment of Ni0-mediated homocoupling were evident, such as poor reactivity with ortho-substituted aryl halides, decomposition of the catalyst at elevated temperature, reduction of the C-X bond when protic substrates were employed, and limited solvent scope.

Scheme 2.

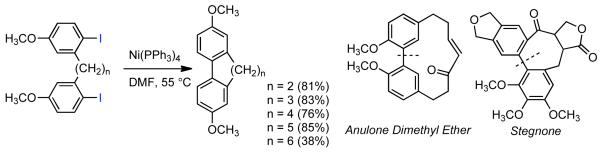

In subsequent studies, Semmelhack explored the utility of Ni0-mediated homocoupling in the synthesis of natural products, specifically the capability of Ni0 to facilitate the synthesis of cyclic biphenyls.43,44 Ni0(COD)2 alone, nor in conjunction with phosphine ligand additives, was able to produce any form of cyclic biphenyl synthesis. Nevertheless, precomplexed Ni0(PPh3)4 could afford cyclic biaryls of various size from acyclic bis(aryliodides) (Scheme 3). Ni0-mediated annulation was readily applied to the synthesis of dimethyl ether variant of plant derived natural product Anulsone, while the aforementioned incompatibility with ortho-substituents prohibited the elaboration of Stegnone and related compounds through this approach.

Scheme 3.

As first reported by Tolman, Ni0(PPh3)4 is expected to exhibit appreciable dissociation in solution into Ni0(PPh3)3 and free PPh3 ligand, due to the steric bulk of PPh3.45,46 Kende realized that this dissociation phenomenon meant that Ni0(PPh3)3 is likely the active catalyst in Ni0 -mediated homocoupling and sought to develop a convenient method to prepare this highly air sensitive reagent in situ.47 Ultimately, Kende determined that NiIICl2(PPh3)2 could be converted to Ni0(PPh3)3 using Zn0 powder in the presence of excess PPh3 in deoxygenated DMF as solvent. This in situ generation of active Ni0 was harnessed in the homocoupling of diversely substituted aryl bromides and other halides (42-85% yield). Electron deficient aryl halides exhibited higher homocoupling yields than electron-rich examples. Likewise, lower yields were observed for singly ortho-substituted aryl halides, while no conversion was documented for doubly ortho-substituted aryl halides. A similarly powerful steric inhibition by ortho-substituents was noted by Semmelhack in his seminal work.42

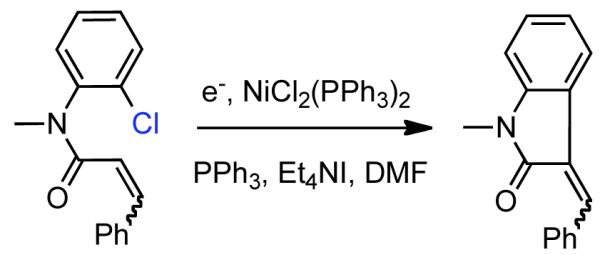

Using electrochemistry,48 Jennings provided early mechanistic insight into Ni0-catalyzed homocoupling of phenyl bromide.49 Here, Ni0 was generated from NiII(acac)2 in situ via electrochemical reduction in DMF in the presence or absence of PPh3 as a stabilizing ligand. In the absence of metal acetylacetonato (acac), no coupling product was formed, confirming the involvement of low-valent Ni complexes generated in situ. Alternatively, Ban reported the electrochemical generation of Ni0(PPh3)3 from NiCl2(PPh3)2, in DMF in the presence of additional PPh3 and Et4NI as an electrolyte.50 Ni0(PPh3)3 generated in this fashion was suitable for the homocoupling of some aryl halides. Of the substrates tested bromobenzene provided the highest yield in the shortest time (80% in 4h). Aryl chlorides or electron-rich aryl bromides reacted slower and often did not achieve complete conversion. Electron deficient aryl bromides seemed to exhibit phenyl transfer from triphenylphosphine ligand. Like Ni0 generated in situ from chemical reduction,51,52 electrochemically generated Ni0(PPh3)3 was synthetically useful and was able to mediate intramolecular Heck-addition to form indoles (Scheme 4). Generation of Ni0 from NiIIX2(PPh3)2 via electrochemical reduction in THF/HMPT and its ability to mediate the homocoupling of aryl bromides and chlorides was also demonstrated. 53

Scheme 4.

In 1977, Kumada realized that a major deficiency of the emerging Ni0 mediated homocoupling reactions was the stoichiometric levels of the Ni0 or NiII precursor employed,54 and demonstrated that the homocoupling reaction could be made catalytic in Ni if stoichiometric levels of Zn0 were used. Scouting experiments revealed that the homocoupling of bromobenzene to generate biphenyl could provide a high yield (89%) when the following ratio of the reactants was employed at 50 °C [PhBr]o:[Zn0]o:[PPh3]o:[NiIICl2(PPh3)2]o = 1 : 1 : 0.4 : 0.5. Lower levels of PPh3, NiIICl2(PPh3), or the use of other solvents than DMF such as MeCN, THF, or EtOH resulted in diminished yields. Under these catalytic conditions the homocoupling reaction was similarly successful for p-bromotoluene, p-bromoanisole, methyl p-bromobenzoate, and p-bromoacetophenone. Lower yields were achieved for ortho-substituted aryl bromides and heterocyclic thienyl bromide. At the time of this work, the prevailing assumption was that Zn0 served as a reducing agent, rather than as a precursor to organozinc intermediates.55 Kumada observed a rate-acceleration of the homocoupling when iodide anions were added. The iodide anions seemed to act as electron-transfer accelerants presumably vis-à-vis a bridging interaction between Ni and Zn. Through the use of stoichiometric KI, the homocoupling yield of bromobenzene after 24 h at room temperature was increased from 24% to 81%.

Simultaneously, Caubère elaborated chemistry to modulate the basicity of NaH through the formation of so-called “Complex Reducing Reagents” (CRA)s. CRAs were defined as a mixture of NaH, sodium alkoxides and other metal salts and their preparation typically involved the treatment of alcohols with NaH.56 In particular Caubère reported a 4:2:1 mixture of NaH, t-AmONa and NiIIOAc, NiCRA, which was effective at mediating the reduction of aryl iodides, bromides, chlorides, and somewhat surprisingly fluorides under relatively mild conditions.57 NiCRA, also effectively mediated the reduction of gem-dihalocyclopropanes58 as well as alkyl, allyl, benzyl, and vinyl halides.59,60 The stereochemical outcome of the reduction of 7,7-dibromonorcarane by NiCRA, for example, indicated the potential for a radical mechanism.58 Interestingly, treatment of 1-bromonaphthalene with NiCRA in the presence of PPh3 as ligand, afforded 70% 1,1′-binaphthalene and 25% naphthalene.59 The use of 2,2′-bipyridine (bpy) as coligand in conjunction with NiCRA helped to eliminate side reactions such as aryl exchange, allowing for the homocoupling of ortho-, meta-, and para-substituted aryl chlorides and bromides.61 NiCRA could also be employed for the synthesis of bipyridines.62 In the formation of the NiCRA more H2 is generated than would be expected for complete consumption of the t-AmOH in the presence of superstoichiometric NaH. The excess H2 generated was attributed to the hydridic reduction of NiII to Ni0.63 Therefore, it is likely that in the presence of ligand, Ni0(bpy) or Ni0(PPh3)n complexes are formed in solution and the mechanism of NiCRA mediated homocoupling is akin to that of other Ni0 reagents.

Supplementary to Zn0 or hydride mediated reduction of NiII, Rieke demonstrated that reduction of NiIII2 with potassium64 or lithium65 metal in the presence of PEt3 produced a highly active fine metal powder,66 “Rieke Nickel.” Treatment of this powder with bromopentafluorobenzene resulted in the formation of an isolable trans-haloaryl NiII complex, BrNiII(PEt3)2C6F5 in 60% yield.64 In subsequent work, a preliminary demonstration of the ability of Rieke Nickel to mediate the homocoupling of iodobenzene and bromobenzene was provided,67 followed by a full exploration of the scope of Rieke Nickel catalyzed homocoupling of aryl bromides and ioides.65 In the latter study, it was concluded that the nature of the progenitor NiII salt generally did not have a significant effect and that Rieke Nickel prepared from NiIICl2, NiIIBr2, and NiIII2 were similarly effective homocoupling reagents. Nevertheless, treatment of Rieke Nickel derived from NiIIBr2 with p-bromochlorobenzene resulted in the predominately reduction product, while Rieke Ni synthesized from NiIII2 efficiently produced 4,4′-dichlorobiphenyl. It is therefore possible that iodide generate from the preparation of the Rieke Ni affected a halogen exchange to generate a more selectively reactive p-chloroiodobenzene. Though not explicitly mentioned, it is also possible that the iodide could help accelerate electron transfer processes in this reaction. In general, the most significant effects to product outcome were derived from the structure of the aryl halide. Aryl iodides were more reactive than aryl bromides after the same amount of time at comparable temperatures, though good homocoupling yields for aryl bromides could be achieved after longer time at higher temperature. Electron-deficient aryl halides were more readily homocoupled than electron-rich aryl halides. As in other catalytic systems, ortho-substitution reduced homocoupling and favored reduction of the halide, while the presence of a nitro-group completely inhibited the reaction.

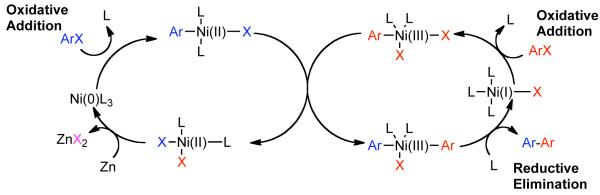

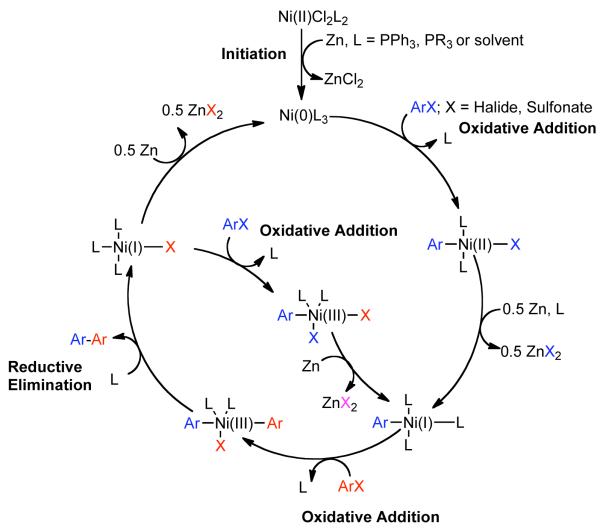

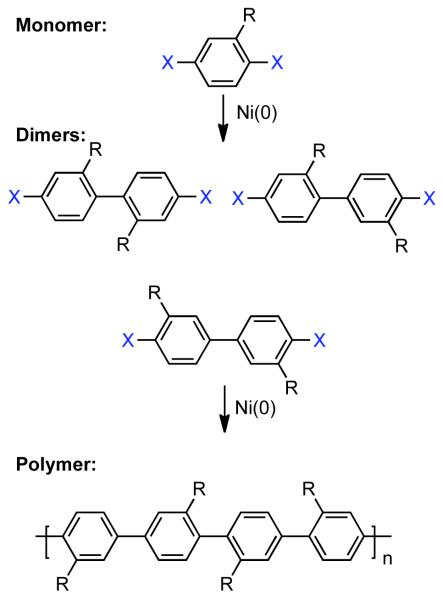

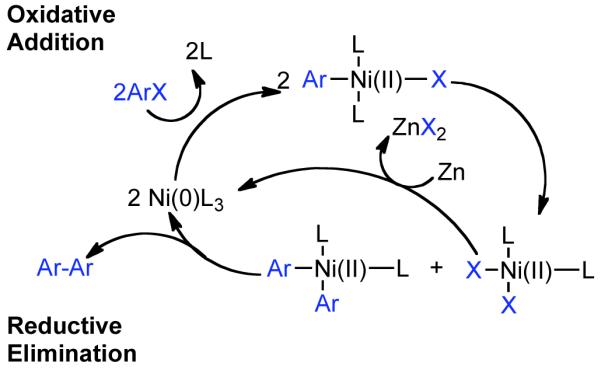

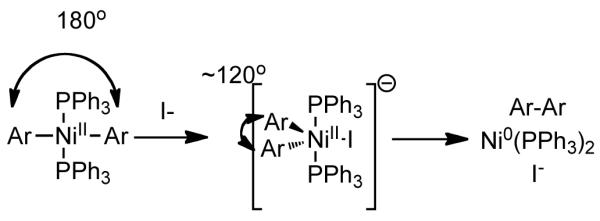

In earlier work Semmelhack had suggested that the Ni-mediated homocoupling in DMF solvent using stoichiometric Ni0 preceded via sequential oxidative additions involving three distinct oxidation states of Ni: 2ArX +Ni0 ➔ ArX + ArNiIIX ➔ Ar2NiIVX2.42 However, the only evidence for NiIV in this reaction was the observation that Ar-X may be consumed faster by Ni0. On the other hand Kochi suggested that a NiI/NiIII radical-chain pathway was more likely in nonpolar solvents (Scheme 5).68,69 In this mechanism, one equivalent of Ar-X oxidatively adds to Ni0L3 to form the ArNiIIXL2 complex, whilst the second equivalent of Ar-X oxidatively adds to NiIXL3 to form ArNiIIIX2L2. Exchange of the NiII bound aryl group for a NiIII bound halide provides Ar1Ar2NiIIIXL2 and the NiIIX2L2. Reductive elimination of Ar1Ar2NiIIIXL2 regenerates NiIXL3 and produces the homocoupled biaryls. The mechanism by which NiI or NiIII is generated from NiII or Ni0 progenitors is more complex and not as well understood. In fact, it has been suggested that treatment of NiII(PPh3)3 with Ar-I produces barely any biaryls product.70 If Zn0 is present, it is likely only once this catalytic cycle, to convert NiIIX2L2 to Ni0L3. In a much later report T. Yamamoto investigated the mechanism of the Ni0 mediated dehalogenative coupling that he adopted from Semmelhack to develop a robust polymerization technique for haloaryl and haloheteroaryl monomers.71 In Semmelhack’s original disclosure, Ni0(COD)2 was used without the presence of a co-ligand. Yamamoto demonstrated that species such as Ni0(COD)bpy are more active. Of most concern was the observation via kinetic studies that the homocoupling was second-order in the nickel-complex and therefore, that oxidative addition is not the rate-determining step. The observation that the rate of the reaction was independent of aryl halide concentration conflicted Kochi and Semmelhack’s mechanisms.

Scheme 5.

Based on his previous observation of an isolable trans-haloaryl Ni-complex, ArNiIIX(PEt3)264, Rieke concluded that Ar-X + Ni0 + PEt3 ➔ ArNiIIX(PEt3)265 must represent the first step of the reaction. An alternative mechanism to Semmelhack and Kochi was suggested (Scheme 6), wherein two equivalents of ArNiIIX(PEt3) undergo metathesis/disproportionation to provide Ar2NiII(PEt3)2 which produces the homocoupled product via reductive elimination. While more reasonable than the aforementioned mechanism involving a NiII/NiIV redox cycle, there is no substantial evidence that NiII metathesis can actually occur.

Scheme 6.

In addition to Rieke Nickel, Cheng reported an electrochemical method to produce Ni0 amalgam from NiIISO4.72 Cheng’s Nickel could mediate the homocoupling of aryl bromides and iodides including polybrominated compounds to generate useful polyaromatic structures. Somewhat surprising the addition of KI to the reaction mixture allowed for the rapid homocoupling of aryl chlorides as well.

In a 1981 patent73 and in the open literature in 1986, Colon reported other methods to generate the Ni0 complex in situ from simple NiII salts.74 He found that in the presence of PPh3 additive, NiIICl2 and NiIIBr2 could be reduced by other low-valent metals in situ to form Ni0 complexes that are capable to mediate the homocoupling of chlorobenzene in quantitative yield. NiIII2·6H2O, NiII(OAc)2·4H2O, and NiII(acac)2·2H2O were less effective as precatalysts, providing a mixture of homocoupling and hydrodehalogenation under these reaction conditions. On the other hand, NiII(NO3)2·6H2O, NiIIO and NiIIF2 did not generate useful Ni0 complexes via in situ reduction with metal, and were therefore, completely incompatible with the homocoupling methodology. Of the metals investigated by Colon, Zn provided the optimum balance of rate, product selectivity (i.e. homocoupling vs dehalogenation), and yield, with Mn and Mg as close seconds. Al, Ca, and Na were far less effective and Fe provided no reaction at all. It was intriguing to note that under Semmelhack’s conditions,42 which presumably would generate the same active catalyst as the one described by Colon, Ni0(PPh3)3, only 14% yield was achieved for the homocoupling of chlorobenzene, while in the case of Colon’s system 98+% was obtained. Alternatively, in the presence of stoichiometric Ni0(PPh3)4 prepared fresh in a separate flask, but in the absence of reducing metal, only 40% yield was obtained after 24 h. Treatment of this stalled reaction with Zn after this 24 h period restarted the reaction and provided quantitative yield, clearly demonstrating that it is the excess Zn in Colon’s system that allows for the greater catalytic turnover and higher yield. An investigation of precatalysts suggested that those bearing monodentate triarylphosphine ligands were superior to both those bearing bidendate bis(diarylphosphine) ligands and trialkylphospine ligands, as the latter two classes provided for more sluggish reactions.

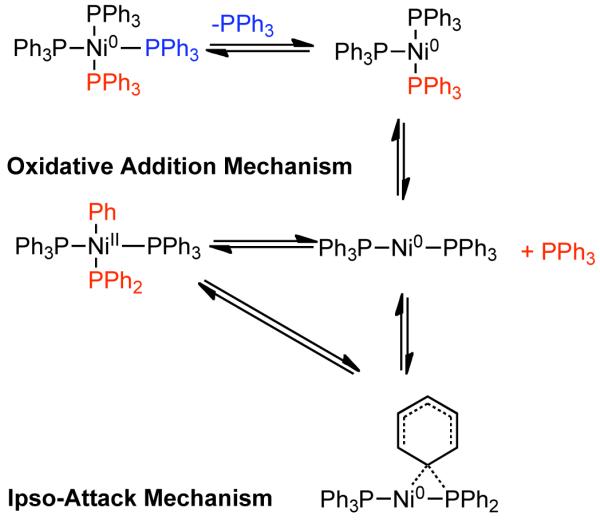

Colon noted similar reactivity trends to those documented previously by others for the various substituted chloroarenes investigated. Additionally, he observed that electron-withdrawing substituents on the arene were most effective for boosting the yield of biaryls, while electron-donating substituents provided more significant levels of monosubstituted biaryl impurities. The formation of the monosubstituted biphenyl adduct appears to be the result of aryl exchange75,76 from the phosphine ligand (Scheme 7). Experimental work demonstrated that the process of aryl-exchange was accelerated by higher reaction temperatures and suppressed by the presence of additional phosphine ligand. At room temperature Ni0(PPh3)3 is the most stable ligation state of Ni0 in solution, while at elevated temperature further ligand dissociation may occur. The resulting, Ni0(PPh3)2 might oxidatively add to PPh3 and provide PhNiIIPPh2(PPh3)2. This trans-phosphinoaryl Ni-complex might undergo subsequent cross-coupling of the Ni-bound phenyl with Ar-X (Scheme 7).76,77 Alternatively, phenyl-migration may occur directly via ipso-substitution on the phenyl ring, where the aryl carbon is transferred from P to Ni (Scheme 7).75,78 As expected, this aryl exchange process which results in monosubstituted biphenyl side products, could be diminished somewhat by the addition of bidentate ligands such as 2,2′-bipyridine, which do not dissociate as readily and provide for a more stable active catalyst. As noted by others, nitro-groups were completely incompatible due to either reductive side-reactions or potentially due to the formation of nitro-Ni0 complexes.93 Protic chlorobenzene derivatives were prone to direct reduction, for example p-chlorophenol to phenol. This reduction process can be exploited through the injection of additional H2O to provide a mild approach for aryl hydrodehalogenation.119 Reduction to the nonhalogenated arene was also more prevalent in aryl bromides and aryl iodides. The mechanism of this hydrodehalogenation may involve the formation of reductive nickel-hydrides in the presence of protic substrate or adventitious moisture. Alternatively, the trans-haloaryl Ni intermediate that results from the oxidative addition of Ni0(PPh3)3 to Ar-X may react with a proton source and decompose to the hydrodehalogenated arene.

Scheme 7.

Colon confirmed an earlier observation of Kumada54 that the addition of salts was shown to accelerate the rate of the homocoupling reaction, and specifically that this acceleration followed the trend F−<SO42−<Cl−<<Br−<I−. This rate enhancement is not thought to be due to halide substitution on the arene, as aryl iodides alone were less effective for homocoupling due to competitive reduction and the fact that no acceleration was observed in the absence of Zn.

Colon suggested that the great dissimilarity of reaction conditions and associated experimental findings, suggested that various mechanisms for Ni0 catalyzed homocoupling are plausible, but nevertheless that their system was most probably described by the mechanism of Bontempelli, where all electrochemical reductions are replaced with Zn0-mediated electron-transfer (Scheme 8).79 Here, Zn0 reduction of the NiIICl2L2 precatalyst to Ni0L3, where L is a generic phosphine, often monodentate phosphine ligand, PPh3, or solvent. An aryl halide can oxidatively add to Ni0L3 or as will be described later, an aryl sulfonate, to form a σ-bonded ArNiIIXL2 complex. Further reduction with ½ equivalent of Zn0 and ligand addition can provide ArNiIL3. Subsequent oxidative addition with a second equivalent of aryl halide or aryl sulfonate would result in Ar1Ar2NiIIIXL2. Reductive elimination of this complex, would generate the homocoupled biaryls and the NiIXL3 complex. Further, reduction with ½ equivalent of Zn0 would provide Ni0L3, thereby closing the catalytic cycle. Alternatively, oxidative addition of Ar-X to NiIXL3 could furnish the ArNiIIIX2L2 complex, which can productively re-enter the main catalytic cycle by reduction with an equivalent Zn0 to form ArNiIIL3. Amatore demonstrated that this mechanism has been substantiated for aryl halides through detailed electrochemical studies.80

Scheme 8.

In considering the mechanism of homocoupling, Colon noted the autocatalytic role of aryl halides in the absence of additional halide additives, and the pseudo-zero-order dependence of aryl chloride in the presence of sufficient external halide. The observation of autocatalysis strongly suggests that oxidative addition is not rate-limiting. However, reductive elimination is certainly a plausible rate-limiting step. If the reaction rates are compared under conditions of suppressed auto-catalysis, it was found that the rates increased according to I<Br<Cl for iodobenzene, bromobenzene, and chlorobenzene homocoupling, respectively. These observations are the inverse of those made by Semmelhack in regard to Ni0(PPh3)4 mediated homocoupling in the absence of Zn, and therefore provide some evidence that the Zn-mediated and Zn-free reactions follow different mechanisms. Colon proposed that the rate acceleration offered by halide ion, was due to its complexation with square planar Ar2NiL2 which generates a trigonal bypyramidal structure that would enhance reductive elimination by bringing the aryl substituents closer together (Scheme 9). The only observation that contradicts reductive elimination as being the rate-determining step was that the reaction rate was dependant on the level of Zn provided, which suggests that one of the electron transfer steps may be rate determining. In this case, the role of the halide additive may be as a bridging ligand54 or to enhance the dielectric properties of the solvent, either of which should accelerate the electron transfer. From electrochemical data and other observations Colon speculated that the reduction of ArNiIICl(PPh3)2 to ArNiIL3 by Zn was the least favored and the slowest step. The role of additive halide in accelerating this step, may once again be due to the formation of a penta-coordinated nickel intermediate that could allow for more facile bridging with the Zn surface for subsequent reduction. However, the rate-determining step in any homocoupling reaction will be dependent upon the substrate and progress of the reaction. For example, arenes bearing electron-withdrawing groups or high conversion may cause oxidative addition to become rate determining.

Scheme 9.

In the same report, Colon also disclosed preliminary investigations of Ni0–catalyzed cross-coupling. While, addition of two aryl halides to the reaction mixture provided a random mixture of homocoupling and cross-coupling adducts, significant residual trans-haloaryl Ni complex remained upon termination of the reaction, particularly in the case of electron-rich aryl halides. Treatment of this complex with a second dissimilar aryl halide produced exclusively the cross-coupled product.

In search of thermally stable active catalysts, Takagi investigated the use of Ni0 generated in situ from complexes of NiIICl2 and trialkylphosphates or bidendate 1,2-bis(diethylphosphino)ethane (dppe).81,82,-83 Investigations, with iodobenzene, bromobenzene, chlorobenzene, as well as a few substituted derivatives thereof, revealed that NiIICl2(PEt3)2 in HMPA as solvent to be the most effective trialkylphosphate-based pre-catalyst. In all cases additional ligand and KI electrolyte were present in the reaction mixture. The Ni0(PEt3)n catalyst prepared in situ from the Zn-mediated reduction of NiCl2(PEt3)2 also mediated the homocoupling of heteroaromatic halides such as 3-bromoform (80%), methyl 2-bromo-5-furancarboxylate (90%), and iodothiophene (83-87%) in very high yield. However, neither 2-bromothiophene nor iodopyridines could be coupled in appreciable yield. A similar mechanistic proposal was advanced, with the one difference that a Ni0(PR3)2 rather than a Ni0(PR3)3, active complex was proposed. Given the decreased lability of trialkylphosphates vs triarylphosphates from Ni, it is not apparent why fewer ligands per metal center would be expected.

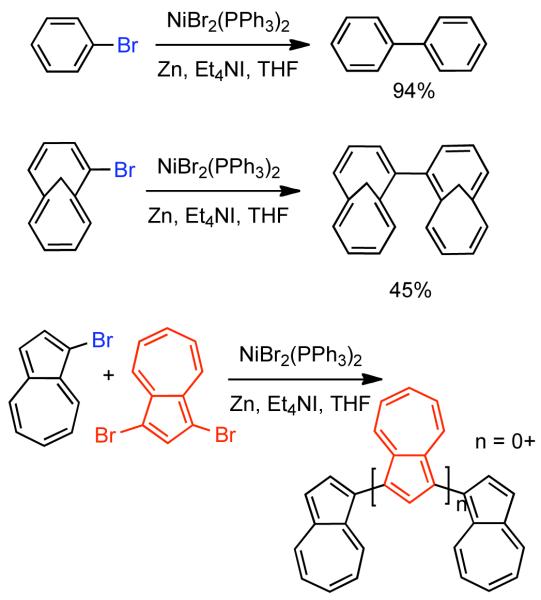

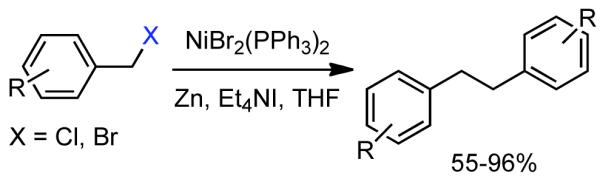

The final step-forward in Ni0-based homocoupling aryl halides was the employment of broadly soluble iodide sources, particularly Et4NI. In 1985, Iyoda reported that Ni0 generated in situ from NiIIBr2(PPh3)2 in the presence of Zn0 could mediate the rapid homocoupling of benzylchlorides and benzyl bromides at room temperature in less polar organic solvents such as THF or benzene if Et4NI was used as the iodide source (Scheme 10).84 A diversity of substituents was tolerated without any definitive reactivity trends, except to say that nitro groups were not tolerated. The relative insensitivity toward aromatic substitutions highlights the key difference between homocoupling at the aryl site vs the benzyl site, where electronic and steric effects are reduced. This technique was utilized in the synthesis of Ricardin B, a metabolite of liverwort Riccardia multifida that possesses a macrocyclic structure containing a bibenzyl linkage. In his synthesis, Iyoda, utilized the aforementioned catalytic conditions to achieve the intramolecular macrocyclization of benzylchloride.85

Scheme 10.

In conjunction with his disclosure of Et4NI as an iodide source in benzyl halide homocoupling, Iyoda also began to explore the homocoupling of aryl halides.86 NiIIBr2(PPh3)2 was determined to be the optimal catalyst for the homocoupling of bromobenzene in the presence of Zn0 and Et4NI in THF as solvent. Using these optimized conditions, bi-1,6-methano[10]annulenes were prepared from 7-bromobicyclo[4.4.1]undeca-1,3,5,7,9-pentaene and oligo- and poly(azulene)s were prepared from 1-bromoazulene and 1,3-dibromo azulene (Scheme 11). Iyoda also reported the synthesis of other interesting polycyclic aromatics starting from bromo-tropones via this strategy.87,88

Scheme 11.

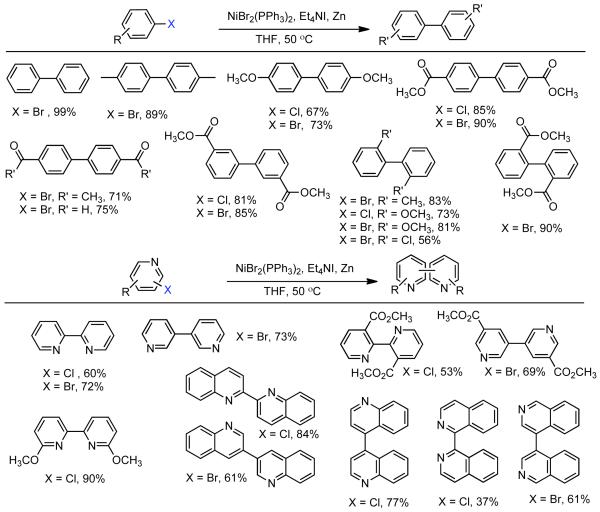

Iyoda’s work on Et4NI promoted Ni0-catalyzed homocoupling culminated in a detailed investigation of the homocoupling of aryl and pyridyl halides.70 This methodology had several innate advantages that contributed to its widespread adoption. First, like the method developed by Colon it proceeded efficiently with less expensive and more readily available aryl chlorides. Additionally, it did not require significant excess ligand. But most importantly, Iyoda’s method was compatible in THF as solvent as opposed to less easily removed DMF or DMAc. In the course of the optimization the homocoupling technique for aryl bromides, Iyoda observed that only 10 mol% Et4NI was needed for the homocoupling of bromobenzene, methyl 4-bromobenzoate, or 4-bromoanisole, yet 100 mol% was needed to maximize the homocoupling yield of methyl 2-bromobenzoate. Interestingly, no Et4NI was needed when aryl iodides were employed, suggesting the sufficient iodide is generated in situ to form stabilized nickelate complexes or alternatively to accelerate electron transfer. Using this knowledge of appropriate Et4NI loading level, several para/meta and ortho-bis(substituted biphenyls) were prepared using 10 mol% Et4NI and 100 mol% Et4NI respectively. For para/meta-substituted aryl halides only 10 mol% Ni was required, while the ortho-substituted aryl halides required higher catalyst loading levels of 20-50 mol% (Scheme 12, top). Yields were only marginally better for aryl bromides than aryl chloride after similar reaction time under identical reaction conditions. Furthermore, an attempt to perform the homocoupling of para-chlorobromobenzene gave only polymer and yielded no isolable 4,4′-dichlorobiphenyl. Together these results indicate that under these homocoupling conditions the rates of chloro- and bromoarene homocoupling are comparable. Overall, the rate of homocoupling appeared to be I>>Br>Cl, which parallels the results of Semmelhack, but contradicts those of Colon. The contradiction of both Semmelhack and Iyoda’s rate observations with the observations of Colon, could simply stem from the fact that the former two ignore the role of autocatalysis and are measuring uncorrected rates. Aware that some N-heterocyclic arylbromides had been successfully homocoupled in the past using Ni0,62,89 Iyoda sought to provide a more general approach to the homocoupling of halo pyridine derivatives. Under similar conditions, the homocoupling of a variety of substituted bromo- and chloropyridines to produce bipyridines also proceeded smoothly (Scheme 12, bottom). Due to the propensity of bipyridines especially 2,2′-bipyridines to serve as ligand of Ni0/II, higher loading levels of catalyst were employed (30 mol%). Identical conditions were also able to furnish biquinolines from haloquinolines and biisoquinolines from haloisoquinolines (Scheme 12, bottom). At the time, biisoquinolines were a particularly challenging target using the state-of-the art Ullmann coupling techniques available at that time.

Scheme 12.

2.1.2. Homocoupling of Aryl Sulfonates to Produce Biaryls

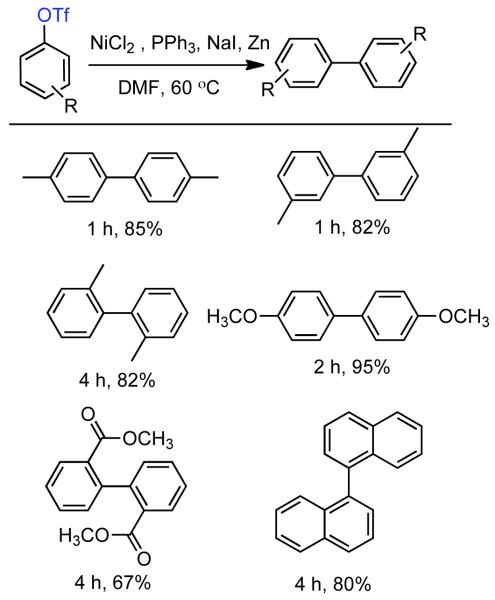

The ability to homocouple aryl halides under mild reaction conditions with relatively inexpensive Ni-based catalytic systems is of great practical utility. Nevertheless, phenol derived arenes are typically less expensive and provide access to a variety of substitution patterns that may be difficult to access for aryl halides. Phenols can be readily converted to activated and nonactivated sulfonate leaving groups, such as triflates, tosylates, and mesylates by treatment with the corresponding sulfonyl halide or anhydride. The first efforts to expand Ni0-catalyzed homocoupling from aryl halides to activated aryl sulfonates were reported by Yamashita in 198690 and 1987.91 To homocouple aryl triflates, Yamashita employed the general conditions established by Colon,73,74 specifically NiIICl2 as the progenitor salt in the presence of PPh3 ligand, NaI additive, and excess Zn0 as reducing agent (Scheme 13). The rate of the reaction was increased up to two-fold through the use of ultrasonication in DMF at 60 °C. In general, a molar ratio of [Ar-OTf]o:[Zn0]o:[NiIICl2]o:[NaI]o:[PPh3]o = 1.0 : 1.5 : 0.08 : 0.6 : 0.6 was employed. Decreasing the excess of NaI and PPh3 relative to NiIICl2 progenitor salt, severely diminished the rate and yield of the reaction.

Scheme 13.

While triflates are the most reactive of conventional sulfonate leaving groups, they are expensive and the precursors are more difficult to handle. A method to homocouple the least expensive, most-atom efficient, yet nonactivated aryl mesylates is therefore preferred. The homocoupling of less reactive aryl sulfonates such as aryl tosylates and mesylates was suggested to proceed at a much lower rate,90 and later demonstrated for one example with low yield.91

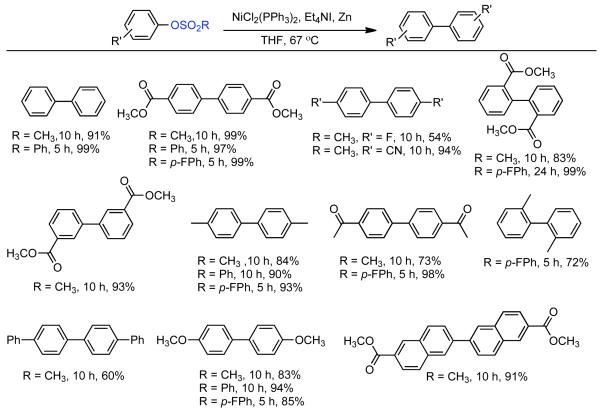

Concurrent with his development of analogous methods to produce poly(p-phenylenes) via Ni-catalyzed polycondensation (See section 2.2.3.), Percec undertook a comprehensive investigation of the scope and reactivity of Ni0 catalyzed homocoupling of non-activated aryl sulfonates.92 Starting from methyl 4-hydroxybenzoate, six activated and nonactivated arylsulfonates were prepared: -OSO2CF3, -OSO2CH3, -OSO2Ph, -OSO2-p-PhCH3, -OSO2-p-PhF, and -OSO2-p-PhCl. All six substrates were subjected to homocoupling conditions using Ni0 generated in situ from NiIICl2(PPh3)2 in the presence of Zn0 and Et4NI in refluxing THF as solvent. Nearly quantitative GC yields were obtained for all substrates except for methyl 4-(((4-chlorophenyl)sulfonyl)oxy)benzoate, which suffered from diminished yield due to competitive cross-coupling with the aryl chloride on the sulfonate leaving group. The triflate, the phenylsulfonate, and the p-fluorophenylsulfonate exhibited similar reactivity achieving complete conversion in <5 h while the mesylate and the tosylate were somewhat slower achieving complete conversion in <10 h. Broad substrate scope was demonstrated for both aryl phenylsulfonates and more promisingly from aryl mesylates (Scheme 14). Electron withdrawing esters, ketones, and cyano groups were tolerated as well as electron donating, methyl, and methoxy groups. Polyaromatic mesylates such as methyl 6-((methylsulfonyl)oxy)-2-naphthoate were also effectively homocoupled. Lower yields were noted for p-fluorophenyl methanesulfonate, suggesting a competition between inductive and resonance effects. The order of reactivity was shown to be para > meta > ortho. Para- and meta-substituted aryl mesylates achieved high conversion in 10 h, while ortho-substitution required extended reaction times for maximum conversion. Neither pentafluorophenyl nor p-nitrophenyl methanesulfoante participated in the homocoupling pathway. Interestingly, under these reaction conditions, pentafluorophenyl methanesulfonate underwent complete demesylation to form the free-phenol. The fate of the p-nitrophenyl methanesulfonate was less certain, but competitive electron transfer reactions such as reduction of the aryl-nitro group or formation of nitro-Ni0 complexes93 are possible. The incompatibility of nitro groups with Ni0 mediated homocoupling had been well documented for aryl halides.

Scheme 14.

In 1986, Colon proposed a mechanism for the homocoupling of arylchlorides in polar aprotic solvents using Ni0-generated in situ in the presence of excess Zn0 (Scheme 8).74 While this mechanism was postulated for aryl chlorides, it can be envisioned for both aryl halide and aryl sulfonate leaving groups. Experimental observations for the homocoupling of aryl mesylates were more consistent with Colon’s mechanism than with other alternatives. As with the homocoupling of aryl chlorides reported by Colon, the homocoupling of aryl mesylates almost always resulted in minute quantities of monosubstituted biphenyl adducts resulting from an aryl exchange mechanism. In this subprocess the aryl-halide was cross-coupled with a PPh3 derived phenyl unit. Even if no aryl mesylate was provided, small levels of biphenyl were generated from NiIICl2(PPh3)2 alone. In some cases the reduction of the aryl mesylate was also observed. Reduction could occur either through nickel hydride formation or through radical hydrogenolysis.68,69 Percec, provided evidence that the prevalence of reduction is not determined only by the reductive potential of the mesylate, but also by the availability of abstractable proton sources such as adventitious moisture, thereby providing evidence for a radical pathway. For example, the homocoupling of 4-acetylphenyl-methansulfonate was plagued by 20% reductive side-product while sulfonates with lower reduction potential such as aryl p-fluorobenzenesulfonates under similar conditions did not exhibit such extensive levels of reduction. In the former case, the presence of an abstractable proton from the enolizable ketone could explain the higher levels of byproduct.

Optimization of reaction conditions indicated that the dipolar aprotic solvents typically employed for the homocoupling of aryl-halides were not as effective as less polar THF for the homocoupling of aryl-mesylates as they seemed to produce colloidal Ni-black and mediate a greater degree of reduction. This side-product could be diminished through the use of a greater excess of PPh3, but such efforts resulted in more sluggish reactions and lower overall yields. While, almost all reports of Ni0 catalyzed homocoupling have indicated that the presence of even adventitious moisture can retard the reaction or mediate reduction of halide, in the homocoupling of aryl mesylates catalyzed by Ni0 generated in situ from NiIICl2(PPh3)2 in the presence of Zn0 and 20% excess PPh3, high yield (90%) could be achieved using reagent grade THF without drying. The robustness of this homocoupling reaction was demonstrated by the fact that the addition of a further 5 mol% H2O relative to aryl mesylate reduced the yield by a meager 7%. If on the other hand, no excess PPh3 ligand was provided 5 mol% H2O will shut down the reaction completely. Of course, the rate of Ni0-catalyzed homocoupling is also affected by the catalyst loading level. High conversion required 10 mol% of Ni0, while 1-5 mol % loading level showed high residual aryl mesylate.

The optimization studies also provided some insight into the mechanism of Ni0-catalyzed homocoupling. Relatively high catalyst loading levels (1.5 equivalents of catalyst relative to the aryl) of Et4NI were required for efficient coupling, as yield increased with increasing loading level. It was apparent, that addition of Et4NI on its own was able to improve the stability of Ni0 complexes, while Et4NBr was shown to be far less effective. Perhaps as discussed by Colon, iodide stabilizes Ni0 through the formation of penta-coordinate nickelate intermediates. In the present case, even less PPh3 is used than with Colon’s systems and therefore, even higher levels of iodide may be required. The increased demand for Et4NI in the presence of lower ligand levels provides further support for the role of the halide as stabilizer for nickel to prevent decomposition, rather than as a reagent that promotes electron transfer.

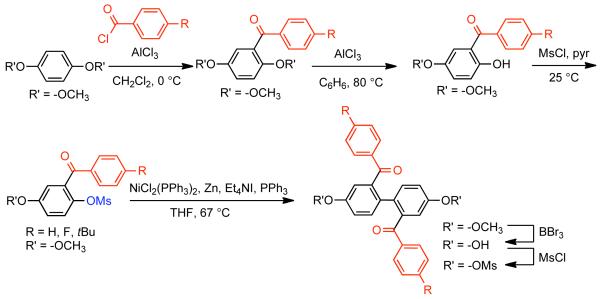

In a later report, Percec used the Ni0-catalyzed homocoupling strategy to outline a general strategy for the synthesis of 2,2′-diaroyl-4,4′-dihydroxybiphenyls (Scheme 15).94 Here, 5-methoxy-2-[(methylsulfonyl)oxy]benzophenones were efficiently homo-coupled with using Ni0 generate in situ from NiIICl2(PPh3)2 in the presence of Zn0, Et4NI. Due to the retarding effects of the ortho-substituents, extra PPh3 (40%) was required to stabilize the Ni0 from premature decomposition. The resulting 2,2′-diaroyl-4,4′-dimethoxybiphenyls could be deprotected in the presence of BBr3 to reveal free phenols. The phenolic sites allow for further mesylation to prepare a bifunctional monomer for the synthesis of soluble poly(p-phenylenes) (See section 2.2.3). The yields for the Ni0-catalyzed homocoupling were lower than normal (45-65%) on account of the bulky ortho-aryl substituents. Nevertheless, the ability to generate coupling fragments efficiently from a phenolic precursor using inexpensive methanesulfonyl chloride imparts a distinct advantage to this route. A subsequent report, detailed the synthesis of a bismesylate monomer via the same route, starting from the phenol-derived precursor, 2-benzoyl-4-ethoxyphenyl methanesulfonate.95 Here, in the absence of additional PPh3 ligand, very low conversion was achieved using THF as solvent, and significant starting material was recovered. Previous work demonstrated that low conversion in the presence of ortho-substituents could be alleviated by the addition of excess ligand.94 Here, an alternative solution was provided which greatly improved the yield (56%) when the reaction was performed at higher temperature (100 °C) in dioxane. Higher yield was ultimately restricted by the competitive formation of demesylated, C-O bond cleavage, and phenyl transfer byproducts. Similar findings were noted, when 3-benzoyl-4-((methylsulfonyl)oxy)phenyl acetate was used as an alternative homocoupling electrophile.96

Scheme 15.

2.1.3. Ni-Catalyzed Homocoupling of Aryl Halides to Produce Poly(phenylenes) and other Polymers

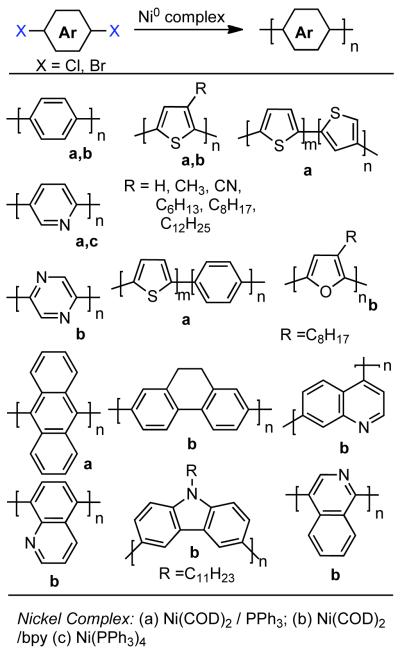

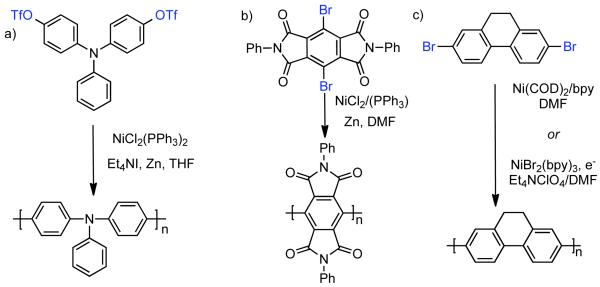

The first poly(arylenes) prepared via homocoupling mediated by Ni0 were the poly(2,5-pyridinediyl)s reported by T. Yamamoto in 1988.97 In this early example, zero-valent nickel complexes previously explored by Semmelhack for the homocoupling of haloarenes such as Ni0(COD)2 in the presence of PPh3 ligand or Ni0(PPh3)4 were employed in stoichiometric or superstoichiometric quantities. The synthetic application of Ni0(COD)2 and Ni0(PPh3)4 were developed extensively by A. Yamamoto, and as a consequence their use in the polycondensation of aryl halides, heteroaryl halides, and related monomers is often dubbed “Yamamoto Coupling.” A variety of conjugated polymers have been prepared through this approach including poly(2,5-pyridinediyl)s,97,98 poly(2,2′-bipyridine-5,5′-diyl)s,98,99 poly(pyrazine)s,100 poly(p-phenylene)s,101,102 poly(thiophene)s,101,102,103,104 poly(furan)s,105 poly(2,7-[9H,10H]dihydrophenanthrenene)s,102 poly(9,10-anthracene)s, 102 poly(quinoline)s,106 poly(isoquinoline)s,106, high molecular weight poly(carbazole)s,107 copolymers,102 and many others (For selected examples see Scheme 16).108,109

Scheme 16.

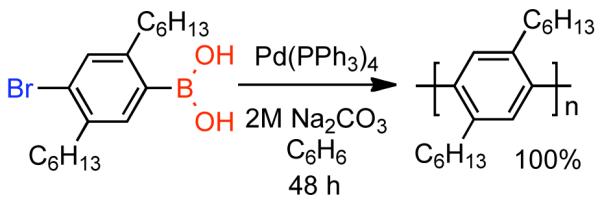

In the 1980s and 90s, the synthesis of poly(p-phenylene) (PPP) and related polymers represented a significant challenge.110,-115 Academic research groups were interested in PPP as an aromatic analogue of linear poly(ethylene) for fundamental studies into their conformation, crystallization, material properties and polymer physics, while industrial laboratories sought approaches to soluble PPPs with accessible synthesis, processing and device fabrication. Ultimately, interest in transition metal catalysis using designed aromatic monomers emerged as a possible solution. In 1989,116 Wegner, Feast and Schlüter reported the synthesis of soluble poly(para-2,5-di-n-hexylphenylene) via Pd0(PPh3)4 catalyzed Suzuki polycondensation117 (Scheme 17). Through this heterophase synthesis employing an AB para-bromophenylboronic acid monomer, soluble PPP with DP~28 was prepared.

Scheme 17.

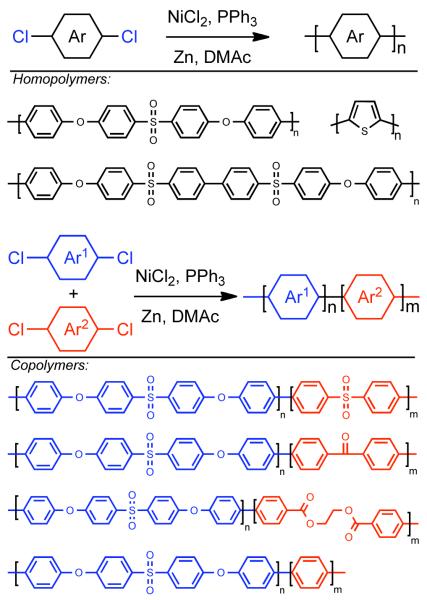

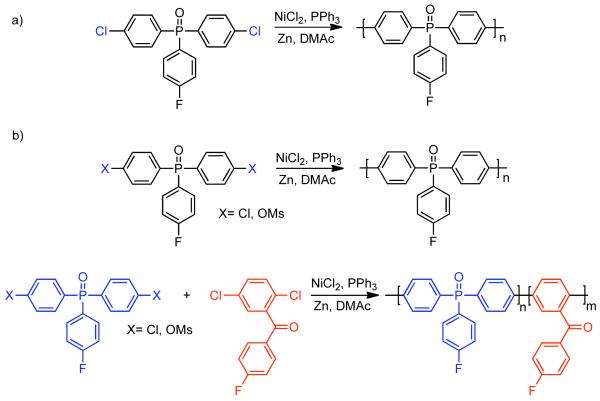

In 1990, Colon and Kwiatkowski were the first to utilize NiIICl2 catalysis that they developed earlier for biaryl synthesis73,74 to the synthesis of poly(aryls) and poly(heteroaryls) (Scheme 18).118 This methodology can be distinguished from the method developed by T. Yamamoto, in that it is catalytic in nickel. Ni0 catalyst generated in situ from Zn0 reduction of NiIICl2 in the presence of PPh3 as ligand and DMAc as solvent provided high molecular weight poly(arylethersulfone) homopolymers, poly(arylethersulfone) copolymers, and poly(thiophene). Polymerization of 1-chloro-4-((4-(4-chlorophenoxy)phenyl)sulfonyl)benzene, the 1:1 adduct of p-chlorophenol and 4,4′-dichlorodiphenylsulfone, elucidated the regiochemistry of the polymerization. Sulfone activates the aryl chloride toward coupling while aryl ethers are deactivating. Therefore, the resulting polymer is composed largely of symmetrical biaryl subunits. Investigation into the robustness of the reaction revealed that complete removal of adventitious moisture is necessary to prevent Ni0/H2O mediated reduction119 of aryl halide reactants and intermediates. While the use of PPh3 ligand provides some tolerance toward O2, a significant excess of O2 will deactivate the catalyst. It was also found that Zn0 purity, particularly the complete exclusion of ZnIIO, is necessary for the reductant to mediate continuous catalyst renewal and for the polymerization to achieve high molecular weight polymers. Chain-end analysis revealed that without further modification, polymers produced via this method are almost exclusively aryl-Ni terminated. In most applications, the aryl-nickel end-groups are typically consumed via addition of chlorobenzene after complete consumption of the monomer. Related studies, demonstrated that the polymers could be end-capped with other functional aryl chlorides or propargyl chloride to produce chain-end functionalized polymers that can be cured at high temperature to form cross-linked coatings.120

Scheme 18.

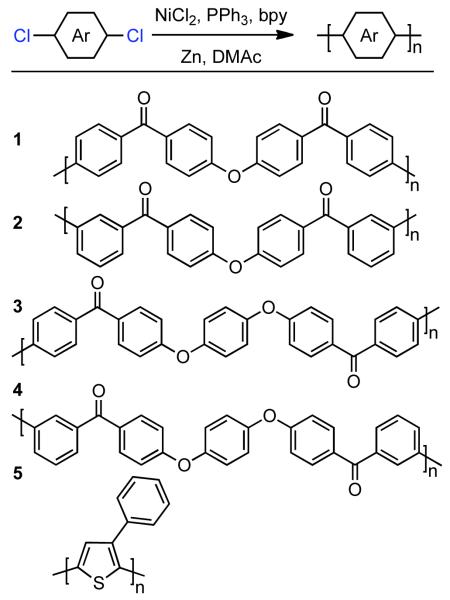

Shortly after, Ueda employed a similar approach to prepare four high molecular weight poly(ether ketones) (polymers 1-4, Scheme 19).121 A similar catalytic system was employed, though bipyridine (bpy) was added as a coligand to suppress the Ni0/PPh3-catalyzed reduction of phenyl group transfer to aryl chlorides. For all monomers employed, quantitative conversion was achieved, though with unoptimized conditions molecular weights were low. Only polymer 4 (Scheme 19), was soluble throughout the course of the polymerization, and was therefore selected for optimization. A 1:1:2 ratio of bpy to NiIICl2 to PPh3 was typically employed, to form a Ni0(bpy)/(PPh3) complex in situ through reduction with superstoichiometric Zn0. Excess bpy was shown to limit MW by forming an overly stable Ni0(bpy)2 complex. Maximum molecular weight was achieved at 90 °C in DMAc as solvent, though DMF, NMP, HMPA, and DMSO as solvents also provided quantitative conversion. Under optimized conditions polymer 4 (Scheme 19) could be prepared with Mn = 28,000. Relatively high DP(n) ~ 236 was calculated for this polymer, based on chlorine analysis of the chain-ends. However, this DP(n) does not match well with the molecular weight, and as suggested by Colon and Kwiatkowski,118 most chains may be Ar-Ni terminated. If the Ar-Ni chain-ends are not accounted for the DP will be overestimated. Later, Ueda expanded this approach to the synthesis of poly(3-phenyl-2,5-thiophene) from the corresponding 2,5-dichlorothiophene.122 Ueda favored a mechanism involving slow metathesis of ArNiIL3. This approach was devoid of 2,4-coupling and branching side-reactions common to electrochemical polymerizations of thiophenes, with the main side-reaction being aryl-transfer from phosphine, which in the case of polycondensation, has the effect of terminating growing chains. This chain-termination via aryl transfer could be suppressed, just as it could in homocoupling to form biaryls, by the use of bpy as co-ligand and/or higher phosphine loading levels. 13C NMR studies confirmed an equal distribution of head-to-tail and head-to-head addition triads, indicating random regiochemistry in the polymerization.

Scheme 19.

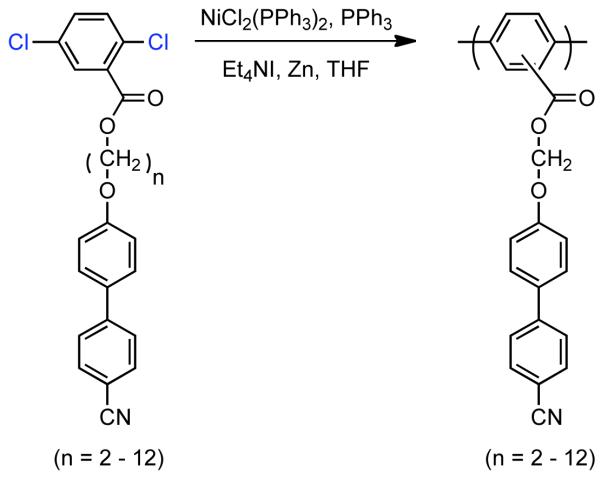

In 1999, Percec utilized Ni0-catalysis to prepare side-chain liquid crystalline polymers (SCLCP)s based on a PPP backbone.123 SCLCPs were prepared from n-[(4-cyano-4′-biphenyl)oxy]alkyl-2,5-dichlorobenzoate using Ni0 prepared via the in situ reduction of NiIICl2(PPh3)2 with Zn0 (Scheme 20). PPPs with DP between 3 and 62 were obtained in good yield, with regioirregular orientation of the side-chains. For all alkyl chain lengths investigated (n = 2-12), NII LC phases where observed in between the glassy and isotropic domains, exhibiting clear even-odd effects in N-I phase transition temperature and enthalpy.

Scheme 20.

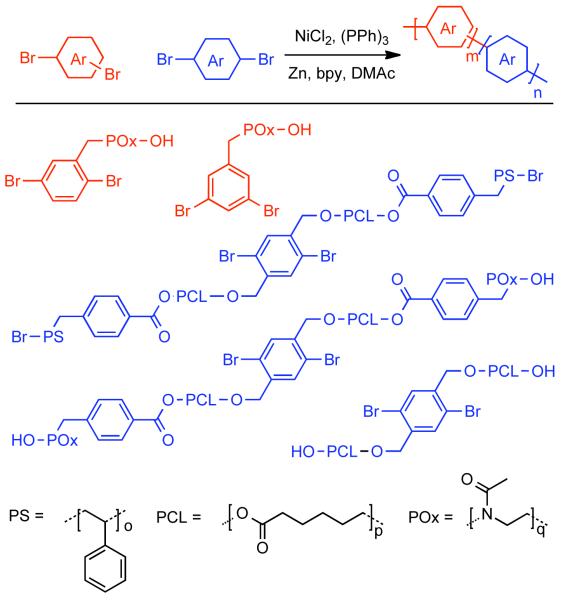

While the development of new methods for Ni0-catalyzed homocoupling of aryl halides has seemed to subside, new applications continue to surface. In 2004, Yagci reported the preparation of a dibromo macromonomer via the controlled ring-opening polymerization of poly(ε-caprolactone) (PCL) initiated by 2,5-dibromo-1,4-(dihydroxymethyl)benzene.124 The PCL functionalized dibromide was utilized in Pd0(PPh3)4 catalyzed polycondensation with 2,5-dihexylbenzene-1,4-boronic acid to form an alternating copolymer or NiIICl2(PPh3)2/Zn0/bpy catalyzed homopolymerization. Later, in an attempt to discern the effect of side-chain architecture on the structure morphology of PPPs, Dimerel prepared a diverse array of PPP oligomers with pendant grafted polymers via macromonomer approach.125 Para- and meta-dibromo arenes bearing poly(oxazoline) (POx) side-chains were prepared via the controlled ring-opening polymerization of methyl 2-oxazoline in acetonitrile using 1,4-dibromo-2-(bromomethyl)benzene or 1,3-dibromo-5-(bromomethyl)benzene as initiators. The POx bearing dibromides were used in tandem with the graft-PCL, PCL-b-PS, or PCL-b-POx dibromobenzenes of Yagci as co-monomers in NiIICl2/PPh3/bpy/Zn0 catalyzed polycondensation (Scheme 21). The various copolymers (DP ranging 17-25) exhibited phase separated morphologies that were visualized with AFM and supported WAXS studies.

Scheme 21.

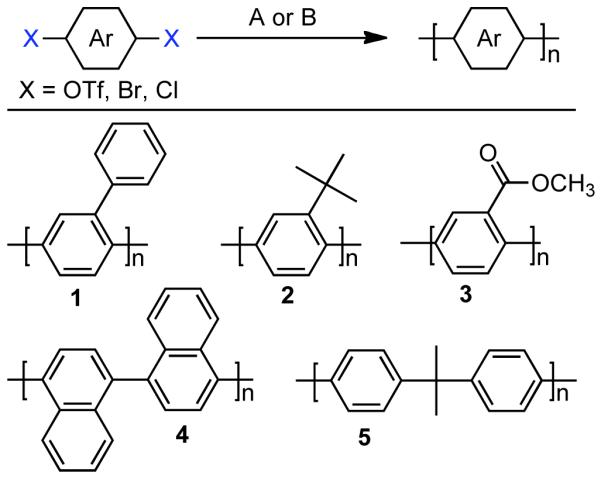

2.1.4. Ni-Catalyzed Homocoupling of Aryl Sulfonates to Produce Poly(phenylenes) and other Polymers

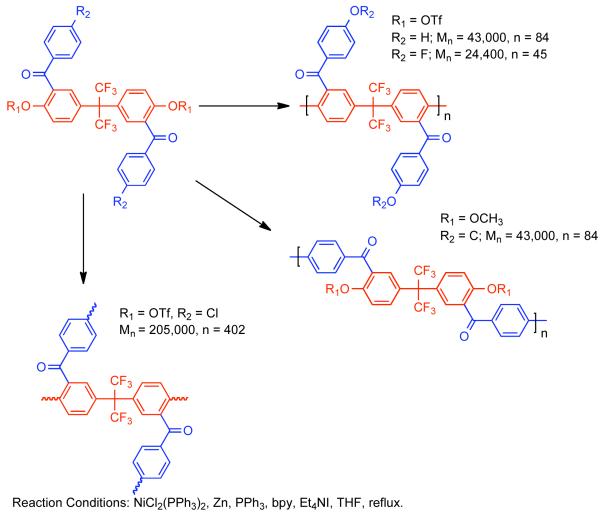

In a preliminary report in 1991, Percec reported the Ni-catalyzed polymerization of bisaryltriflates to prepare poly(phenylene)s (Polymers 1, 2, 4, 5, Scheme 22).126 In a subsequent report, these approaches were detailed as convenient approaches to soluble poly(p-phenylenes).127 This approach greatly expanded the scope and feasibility of PPP synthesis as it could utilize hydroquinone derived monomers, as well as bishalides. Two methods for generating Ni0 in situ were investigated: (A) the NiIICl2/PPh3/bpy/Zn0 system reported by Colon and Kwiatkowski for poly(ether sulfones)118,121,122 and (B) the NiIICl2(PPh3)2/Zn/Et4NI/THF system originally developed by Iyoda for the homocoupling of aryl halides.70 Both methods were effective at mediating the polymerization of substituted 2,5-dibromo-, 2,5-dichloro-, and 2,5-bis(trifluoromethyl)sulfonylarenes to produce unbranched poly(p-phenylenes) (Polymers 1-3, Scheme 22.). It is important to note that in addition to using a precomplexed NiIICl2(PPh3)2 as the pre-catalyst, method (B) employs Et4NI as an additive. Et4NI as a source of iodide is thought to promote electron-transfer by bridging Ni and Zn species,70,54 but may also stabilize the active catalyst through formation of penta-coordinate nickelates. In polymerization experiments where excess Zn0 reductant is present, it was evident that the rate determining step was the reduction of ArNiII(PPh3)2X to ArNiI(PPh3)X, and therefore, potential electron-transfer accelerants such Et4NI greatly improve the overall rate and efficiency of the reaction.

Scheme 22.

The efficacy of the two methods was judged by their ability to produce high molecular weight polymers. It was apparent for method A in DMF that the molecular weight of the polymer increased according to leaving group -Cl>-Br>-OTf, while for method B in THF the order was reversed with triflates being the most effective. The observations of opposite reactivity trends in the two methods were not definitively explained. However, these trends suggest that in DMF the rate of oxidative addition to Ni0 is controlled by the electronegativity of the leaving group, while in THF the bond strength plays a more crucial role. The highest molecular weights ~6300 (DP ~ 47) was achieved using method B with methyl 2,5-bis[[(trifluoromethyl)sulfonyl]oxy]benzoate as monomer. The application of method B to the polycondensation of 2,5-bis[[(trifluoromethyl)sulfonyl]oxy]biphenyl and 2-tert-butyl-1,4-bis[[(trifluoromethyl)sulfonyl]oxy]benzene produced polymer of lower molecular weight, thereby suggesting that the steric effects of the ortho-substituent on the reactivity of the leaving group can be dramatic. In all cases the distribution of regioisomers and high degree of conformational isomerism present in the laterally substituted poly(p-phenylenes) provided solubility in most polar organic solvents (Scheme 23).

Scheme 23.

Following the disclosure by Percec that soluble poly(2-methoxycarbonylphenylene-1,4-dyl) could be prepared through the Ni0-catalyzed homocoupling of methyl 2,5-dichlorobenzoate,127 Kaeriyama devised an approach to convert the resulting polymer into poly(p-phenylene).128 Saponification of the methyl ester with NaOH provided poly(2-carboxyphenylene-1,4-diyl), which could be converted in nearly quantitative yield to poly(p-phenylene) by decarboxylation upon treatment CuIIO in refluxing quinoline.

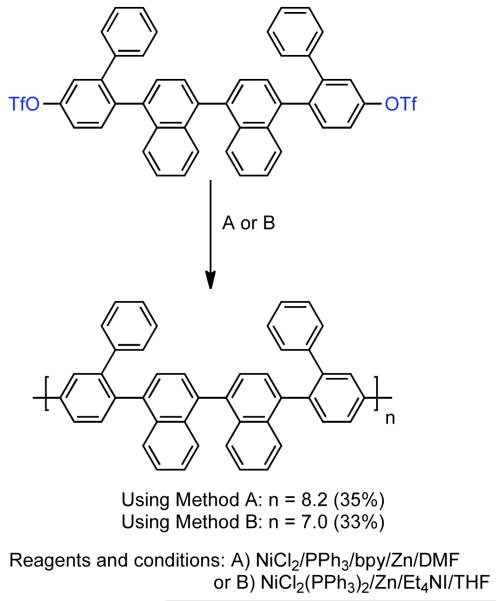

Later, Percec reported the synthesis of other soluble PPPs containing alternating 4,4′-(1,1′-binaphthyl) and 4,4′-(3,3′-diphenyl)biphenyl moieties along the main chain (Scheme 24).129 The alternating sequence was achieved through the homopolymerization 4,4′-bis[5-trifluoromethanesulfonyloxy)-2-biphenylyl]-1,3′-binaphthyl, a bistriflate monomer containing an interior binaphthyl group and periphery biphenyl groups. Both of the aforementioned methods for the in situ generation of Ni0 catalyst were employed and provide similar conversions ~35% and degrees of polymerization DP = 8-9. Since each monomer repeat unit contains four main-chain phenyl units the resulting polymers are comparable to PPPs with DP = 32-36.

Scheme 24.

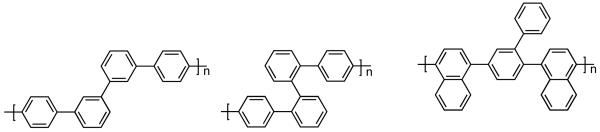

Using identical conditions to those developed for polymerization of bismesylates, low molecular weight oligomers of 4,4′′′-dichloro-l,1′:2′,1′′′-quaterphenyl and 4,4′′′-dichloro-l,1′:3 ′,1′′: 3′′,1′′′-quaterphenyl were prepared through Ni0-catalyzed homocoupling (Scheme 25, left and middle).130 The low molecular weight achieved for these meta- and ortho- kinked poly(p-phenylenes) were largely due to general insolubility. In the case of the meta-quaterphenyl, low molecular weight may also be partially attributable to the formation of cyclic trimers. More soluble polyaromatic PPPs were prepared via the Ni0-catalyzed polymerization of 2,5-bis(4-chloro-1-naphthyl)biphenyl (Scheme 25, right).131 In this case, higher molecular weight polymers Mn = 2700 due to the improved solubility of the polymer. Ultimately, efforts to make higher DP polymers from 2,5-bis(4-chloro-1-naphthyl)biphenyl seemed to be hampered by steric hindrance imposed by the naphthyl rings, which act as a pseudo-ortho substituent. Nevertheless, the white color of these polymers demonstrated an absence of secondary cyclization reactions which plague analogous cation-radical polymerizations and produce discoloring perylene and triphenylene units in the main-chain.132

Scheme 25.

In subsequent work, Percec expanded the Ni-catalyzed homocoupling procedure he developed for bismesylates92,94 to the polymerization to bismesylate monomers.133 In contrast to previous systems, the bismesylate monomers were readily prepared in high yield from the substituted hydroquinones by treatment with inexpensive methanesulfonyl chloride in the presence of pyridine as base. Initial selection of the most appropriate catalytic system was performed using methyl 2,5-bis[(methylsulfonyl)oxy]benzoate as the monomer (Scheme 26). The NiIICl2(PPh3)2/Zn/Et4NI/THF system reported previously bistriflates and bishalides126,127 achieved high yield and molecular weight, while the NiIICl2/PPh3/bpy/DMAc was less effective.118,121,122 Even higher yields and molecular weights could be achieved by switching to dioxane as solvent and increasing the reaction temperature. Other ligands besides PPh3 were explored such AsPh3, P(o-tolyl)3, and PCy3, but only oligomeric products were formed due to rapid decomposition of the catalyst. It was thought that improved molecular weight could be achieved by employing monomers with a larger branched substituent with greater configurational entropy, such as 2-ethylhexyl 2,5-bis[(methylsulfonyl)oxy]benzoate (Scheme 26). Unfortunately, the steric bulk of the larger substituent had a retarding effect on the polymerization, which could only be overcome by increasing the Zn0 loading level from 3.1 equivalents to 7.0 equivalents. Nevertheless, studies with the 2-ethylhexyl ester substituent revealed the universality of the catalyst system for dibromides, dichlorides, bis mesylates, bistriflates and bis(p-fluorobenzenesulfonates).

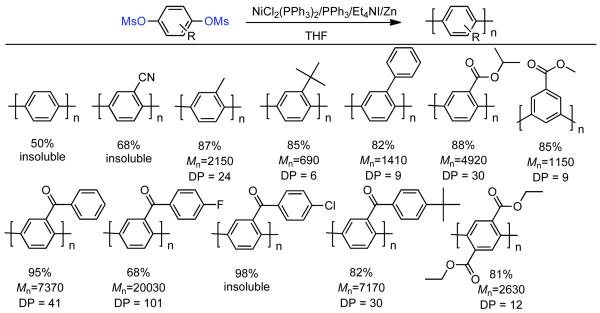

Scheme 26.

Homopolymers of methyl 2,5-bis[(methylsulfonyl)oxy]benzoate were limited to DP~30, due to premature precipitation during the polymerization caused by the diminished solubility of the higher molecular weight polymer. Copolymerization with 5-50% 2-ethylhexyl 2,5-bis[(methylsulfonyl)oxy]benzoate, isopropyl 2,5-bis[(methylsulfonyl)oxy]benzoate, or methyl 3,5-bis[(methylsulfonyl)oxy]benzoate increased solubility of the polymer allowing for higher DP (Scheme 26). The highest DP was achieved with a monomer feed ratio of 75% methyl 2,5-bis[(methylsulfonyl)oxy]benzoate and 25% 2-ethylhexyl 2,5-bis[(methylsulfonyl)oxy]benzoate. Similar, liquid crystalline poly(alkoxycarbonyl-m-phenylene)s and poly(alkoxycarbonyl-p-phenylene)s were prepared through similar Ni0-catalyzed polycondensation of alkoxy 2,5- and 3,5-dichlorobenzoates.134 The Ni0-catalyzed polycondensation was tolerant of a broad array of bismesylate monomers (Scheme 27). With the exception of poly(p-phenylene) and the poly(p-phenylene) bearing cyano or p-chlorobenzoyl substituents at the ortho-position, all of the resulting polymers were soluble. The highest molecular weight was achieved for the polymerization of 4′-fluoro-2,5-bis[(methylsulfonyl)oxy]benzophenone (DP~101). It is apparent that the homocoupling polymerization is influenced by the nature of the substituent ortho to the mesylate and that bulky groups such as tert-butyl are inhibitory. By reducing the rate of homocoupling, the bulky ligands amplify reduction and phenylation side reactions, leading to premature chain-termination. Side-reactions leading to triphenylphosphine incorporation into the main-chain were not detected.135,136-137

Scheme 27.

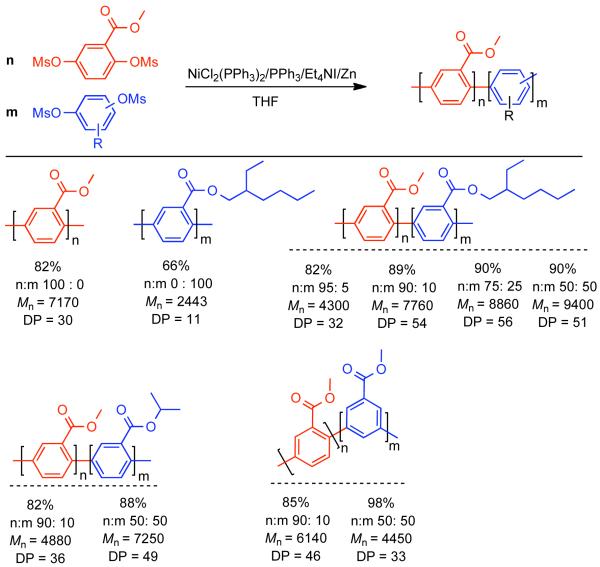

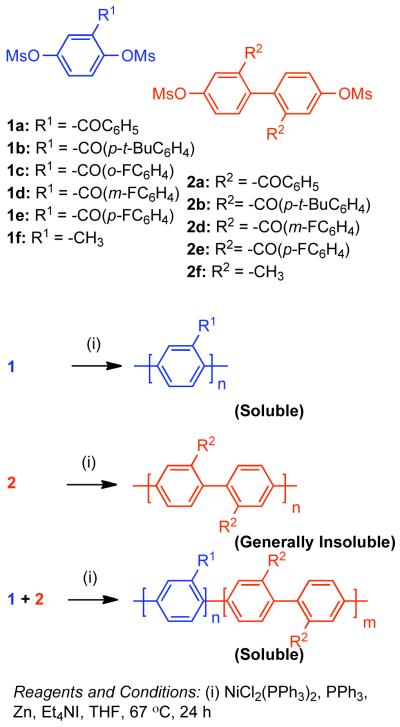

The solubility of PPPs is greatly enhanced by the configurational entropy that results from conformational and regioisomerism inherent to mono-functional bismesylate monomers. However, the ortho-substituent to the mesylates can reduce the rate of polymerization and ultimately limit conversion. Elimination of ortho-substituents to the mesylate, while maintaining some degree of configurational entropy was conceived as a potential method to enhance the reactivity while maintaining sufficient solubility to achieve high MW PPPs.138 Regioirregular PPPs derived from aryl bismesylates (1a-1f, Scheme 28) are generally soluble, whereas regioregular PPPs derived from 2,2′-disubstituted 4,4′-bis[(methylsulfonyl)oxy]biphenyls possessed less configurational entropy and were generally insoluble (2a-2f, Scheme 28). Copolymerization of the two classes of monomers provided a somewhat regioirregular structure with fewer ortho-substituents to the mesylates providing enhanced reactivity (Scheme 28). Through this compromise, the highest molecular weights PPPs (Mn = 34,790, DP= 176) were produced through the polymerization of –CO(p-FC6H4) substituted 1e and 2e.

Scheme 28.

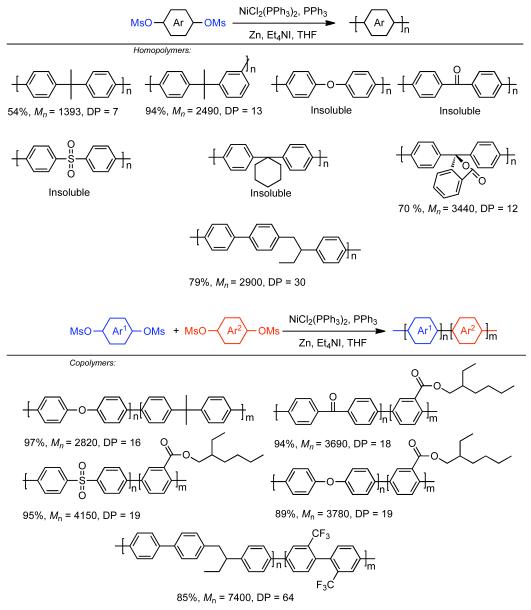

The solubility, and resulting molecular weight of regioregular PPPs derived from 2,2′-disubstituted 4,4′-bis[(methylsulfonyl)oxy]biphenyls or 2,2′-disubstituted 4,4′-bis[(trifluoromethylsulfonyl)oxy]biphenyls monomers could be improved by selection of substituent groups, such as trifluoromethyl and trifluoromethoxy, that themselves possessed greater configurational entropy.139 While high molecular weight (Mn = 35,200, DP = 220) could be achieved for the homopolymerization of the aryl bistriflate, 2-(trifluoromethoxy)-1,4-bis[[trifluoromethyl)sulfonyl]oxy]benzene, similar 2,2′-disubstituted 4,4′-bis[(methylsulfonyl)oxy]biphenyls or 2,2′-disubstituted 4,4′-bis[(trifluoromethylsulfonyl)oxy]biphenyls were even more effective. The homopolymerization of 2,2′-bis(trifluoromethoxy)-4,4′-bis[[(trifluoromethyl)sulfonyl]oxy]biphenyl or the copolymerization of 2,2′-bis(trifluoromethoxy)-4,4′-bis[[(methylsulfonyl]oxy]biphenyl and 2,2′-bis(trifluoromethoxy)-4,4′-bis[[(methylsulfonyl]oxy]-biphenyl provided polymers with molecular weight Mn = 54,500 (DP = 340) and Mn = 55,200 (DP= 363), respectively. Expansion of the Ni0-catalyzed polymerization of bismesylates to the synthesis of other poly(arylenes)s derived from more symmetric monomers resulted in larger insoluble homopolymers (Scheme 29).140 Exceptions included the homopolymers derived from 2,2-bis(methylsulfonyloxyphenyl)propane, 2-(3-methylsulfonyloxyphenyl)-2-(4′methylsulfonyloxyphenyl)propane, and bulky phenolphthalein derivative (3,3-bis(4-methylsulfonyloxyphenyl)-1-[3H]-isobenzofuranone). These monomers provided relatively soluble polymers, but with low DPs of 7, 13, and 12, respectively. Alternatively the introduction of asymmetry through a 1-(ethyl)-ethyl linker group in 1-(4-methylsulfonyloxyphenyl)-2-(4-methylsulfonyloxy-4′-biphenylyl)butane) provided greatly enhanced solubility and polymer with significantly higher molecular weight. Copolymerization of these symmetric poly(arylenes) monomers with each other or with a branched arylbismesylate, 2-(ethylhexyl)-2,5-bis(methylsulfonyloxy)benzoate, also improved solubility and permitted access to higher molecular weight polymers.

Scheme 29.

Main-chain phosphorous-containing polymers are often used as thermally stable resins for fire-retardency applications. In 1997, McGrath prepared amorphous poly(arylene phosphine oxide)s (PAPO)s via the NiIICl2/PPh3/Zn0 mediated homocoupling of bis(4-chlorophenyl)phenylphosphine oxide (Scheme 30a).141 Interestingly, higher molecular weight polymer (Mn = 15,300) was produced when the bisdichloro was added to a mixture of preactivated Ni0-catalyst, whereas lower molecular weights (Mn = 9,280) were achieved when the monomer was mixed with NiIICl2, PPh3, Zn0 in DMAc and then elevated to the reaction temperature of 70 °C. The resulting PAPOs could be partially reduced to poly(arylene phosphine) via treatment with phenylsilane. In 2001, Sheares prepared poly(4′-fluoro-2,5-diphenyl sulfone) via the method described previously by Colon where Ni0 was produced in situ from the NiIICl2 in the presence of Zn0, PPh3 and bpy.142 A series of novel poly(p-phenylene)s were prepared via post-polymerization functionalization of aryl-fluoride via SNAr substitution. In a later work, Sheares used the same methods to prepare poly(4′-fluorophenyl-bis(4-phenyl)phosphine oxide) and related copolymers (Scheme 30b).143 Both dichloro and dimesylate monomers were compatible with Ni0-catalyzed homocoupling polymerization, but somewhat higher molecular weights were achieved for the dichloride monomer. The presence of the para-fluoro substituent on the arylphosphineoxide monomer or on the benzophenone comonomer allowed for the same facile post-polymerization functionalization via SNAr substitution with alkoxy, phenoxy, or amino nucleophiles. The substituted PAPOs and PAPO-co-PPPs were demonstrably more soluble in organic solvents.

Scheme 30.

Zengin prepared similar main-chain nitrogen-containing polymer from bis-(4-trifluoromethane-sulfonyloxyphenyl)phenylamine monomer. Using Ni0 generated in situ from NiIICl2(PPh3)2 in the presence of Zn0 and Et4NI, poly(bis(4-phenyl)phenylamine) with Mn = 23,714 (Scheme 31, a) was achieved.144 The resulting polymer was doped with HCl to produce conducting/photo-luminescent polymers. Other conducting and PL polymers have been prepared via Ni0-catalyzed homocoupling of functional aryldihalides, such as poly(N,N’-phenyl-3,6-pyromellitic-dianhydride) (Scheme 31, b)145 and poly(9,10-dihydrophenanthrene-2,7-diyl) (Scheme 31, c).146 The former was prepared through Colon’s NiIICl2/PPh3/Zn0/DMF conditions, starting from a dibromo monomer, while the latter either through Semmelhack’s Ni0/(COD)2 method (Yamamoto Coupling) or through electrochemical generation of Ni0 in situ from NiIIBr2(bpy)3.

Scheme 31.

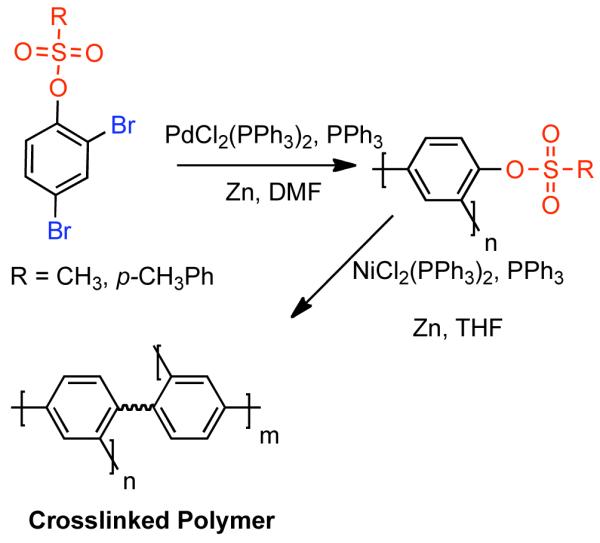

The homocoupling of mesylates has also been used in the post-polymerization functionalization of poly(arylenes). Bae prepared poly(2,4-phenyl sulfonates) via Pd0-catalyzed homocoupling of AB2-type dihaloaryl sulfonate monomers (Scheme 32).147 Subsequent treatment of the sulfonate-bearing poly(meta-phenylene) provided a crosslinked polymer network.

Scheme 32.

More recently, Sheares148 developed monomers were prepared that combined the structural elements of 2,2-bis(((trifluoromethanesulfonyl)oxy)phenyl) hexafluoropropane and p-chlorobenzophenone. In this fashion depending upon their periphery functionality, they could be polymerized using Ni0-catalyzed conditions of Percec, either through the bis(triflate), the p-chlorobenzophenone, or both to prepare isomeric hexafluoroisopropylidene-linked benzophenone-containing polymers (Scheme 33). The use of the tetrafunctional monomer provided tough-crosslinked films that could not previously be achieved with typical benzophenone-based polymers.

Scheme 33.

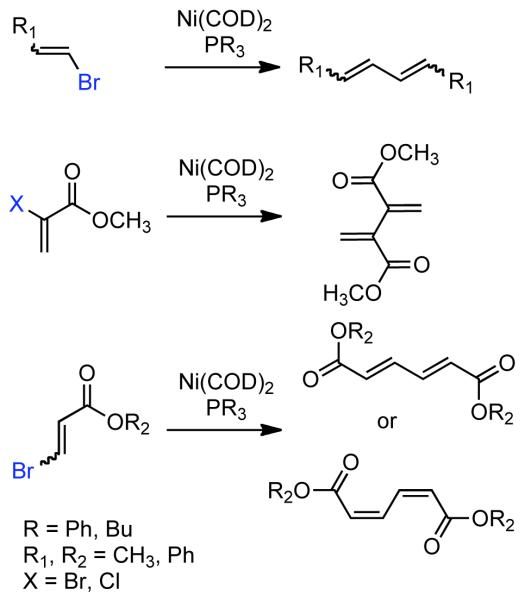

2.1.5 Homocoupling of Vinyl Halides and Sulfonates

Subsequent to his disclosure of aryl halide homocoupling,42 in 1972 Semmelhack reported that Ni0(COD)2 was also an effective catalyst for the homocoupling of vinyl bromides or 2-, and 3-haloacrylates to form symmetric 1,3-dienes (Scheme 34).149 Alkyl bromides and 2-bromostyrenes reacted rather sluggishly providing only fair yield, while electron-deficient 2-, and 3-haloacrylates provided nearly quantitative conversion and high yield.

Scheme 34.

The system developed by Kende for the generation of Ni0 in situ from the Zn0 mediated reduction of NiIICl2(PPh3)2 was a more versatile reagent used to mediate the homocoupling of aryl halides as well as the vinyl halides and allyl halides.47 β-bromostyrene and cinnamyl chloride were successfully homocoupled under these conditions to furnish trans-1,4-diphenylbutadiene (43% yield) and biscinnamyl (50% yield), respectively. Likewise, Takagi’s high-temperature Ni0(PEt3)n catalyst derived from the Zn0-mediated reduction of NiIICl2(PEt3)2 also effectively homocoupled vinyl halides such as 2-bromo-1,1-diphenylethene (97%), β-bromostyrene (85%), and 1-bromo-2-methylpropene (83%).81

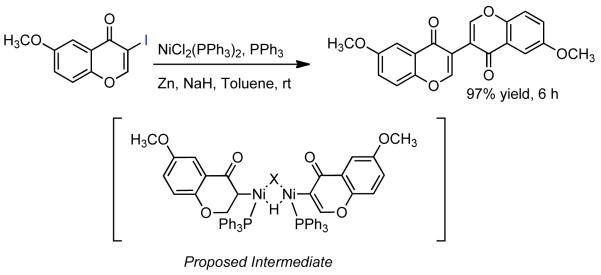

During efforts directed toward the synthesis of natural product bibenzopyran-4-ol, Lin discovered a modified catalytic system capable of mediating the homocoupling of various vinyl iodides and bromides.150 The synthesis called for the homocoupling of 3-iodo-6-methoxybenzopyran-4-one (Scheme 35), using Cu-mediated Ullmann strategies or with Ni0 generated in situ from NiIICl2(PPh3)2 in the presence of Zn0. Using DMF as solvent with excess PPh3 ligand as additive, it was found that the use of K2CO3 as a base improved the yield and limited the degree of dehalogenation. Nevertheless, yields were still relatively low. It was surmised that protonation of neutral arylnickel intermediates was occurring and that K2CO3 deprotonated the resulting cationic byproduct providing re-entry to the catalytic cycle. To improve the yield further more powerful bases were examined. Ultimately, it was determined that NaH provided remarkable acceleration of the reaction and improved product selectivity. Both rate, yield, and selectivity could be further enhanced by switching the solvent from DMF to non-polar toluene. From the distribution of byproducts, a variant of Ullmann-type reactions was proposed and a bridged dinuclear organo-Ni intermediate was invoked, though the mechanism for its formation was not elucidated or supported (Scheme 35). It is surprising that NaH provided dramatic improvements to yield, rate, and selectivity, even if Zn0 was omitted. This may suggest that the role of NaH is at least in part similar to that of Zn0, a reductant, and that they reinforce each other. This is supported by Caubère’s work on NiCRA56-63 (See Section 2.2.1), where NaH mediated hydridic reduction of NiII species was shown to be a contributing reaction. Regardless of the mechanism of this transformation, a variety of α-iodo-α, β-unsaturated ketones, as well as 2-bromopyridine, α-bromostyrene, and β-bromostyrene were compatible with this catalytic system.

Scheme 35.

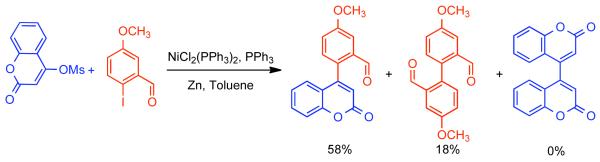

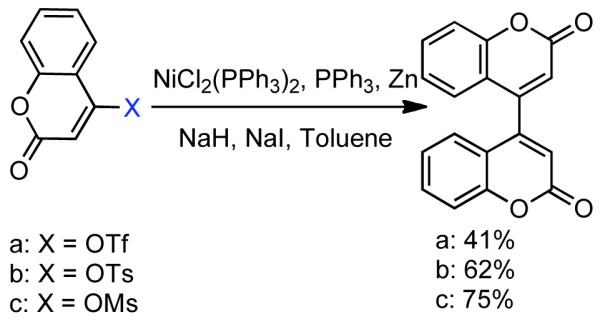

In a later report, Lin demonstrated the application of the NiIICl2(PPh3)2/PPh3/Zn0/NaH/toluene catalytic system for the homocoupling of 4-tosylcoumarins en route to biologically active biscoumarins.151 Kappe later explored a similar strategy for the synthesis of aza-analogues of biscoumarins.152,153 The compatibility of this catalytic system with tosylates, brings into question the involvement of halide-bridged intermediate (Scheme 35), though it is technically possible that the use of NaI as additive may facilitate the formation of this intermediate through displacement chemistry. Subsequently, Lin showed that the aforementioned catalytic system can efficiently homocouple 4-methanesulfonyl, 4-toluenesulfonyl, and 4-trifluoromethylsulfonyl coumarins (Scheme 36).154 The best yields and highest rates were achieved for the mesylates, while the triflates provided the lowest yields, and tosylates the most sluggish reactivity. In the case of the triflates, significant reduction byproduct was observed.

Scheme 36.

Given the convenience of generating 4-mesylcoumarin electrophiles, Lin also investigated the potential of using these intermediates directly in a modified cross-coupling reaction with aryl halides (Scheme 37).154 This cross-coupling is perhaps more appropriately described as an asymmetric homocoupling reaction, as it lacks the transmetallation step common to most Ni-catalyzed cross-coupling reactions. Lin determined that by adding the aryl halide, for instance 2-iodo-5-methoxybenzaldehyde, to a 4-mesylcoumarin such as 2-oxo-2H-chromen-4-yl methanesulfonate, and by eliminating iodide containing additives and NaH, the cross-coupled adduct could be enhanced while the two respective homo-coupling products minimized (Scheme 37). The methodology for cross-coupling was shown to be quite robust for a diversity of mesylcoumarins and arylbromides/iodides, providing an array of 4-aryl coumarins in 52-90% yield. Neither the substitution pattern of the 4-mesylcoumarin nor of the aryl halide had a pronounced effect on yield or product distribution, indicating unusual limited steric and electronic effects on reactivity. If however, instead of PPh3, dppe was used as a ligand, homocoupling of the aryl iodide dominated.

Scheme 37.

2.2. Cross-Coupling of Aryl and Vinyl Mesylates and Tosylates

In the previous chapter (Section 2.2), reactions involving Ni0 catalyzed homocoupling of sulfonates were surveyed. Typically, these reactions were used to produce symmetric biaryls or related polymers, though there were selected examples where cross-coupling was achieved through control of reagent feed and reaction conditions. Nevertheless, the synthesis of asymmetric molecules is typically more efficient when the cross-coupling reaction employs chemically dissimilar fragments. A number of Ni0 catalyzed techniques have emerged from the cross-coupling of aryl, vinyl, and alkyl sulfonates, including less reactive but often more desirable mesylates and tosylates.

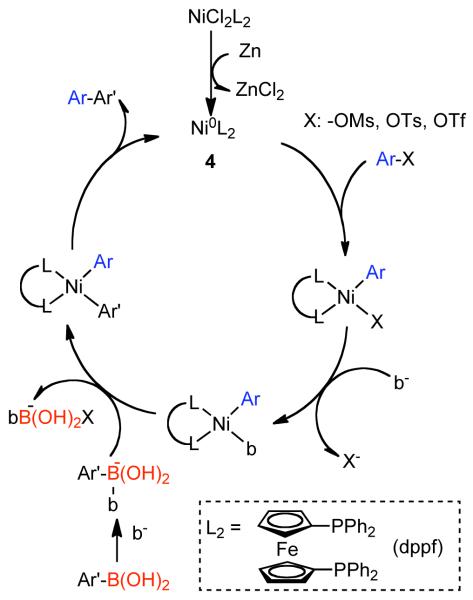

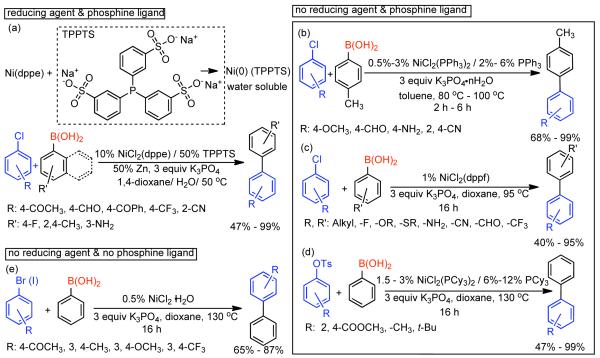

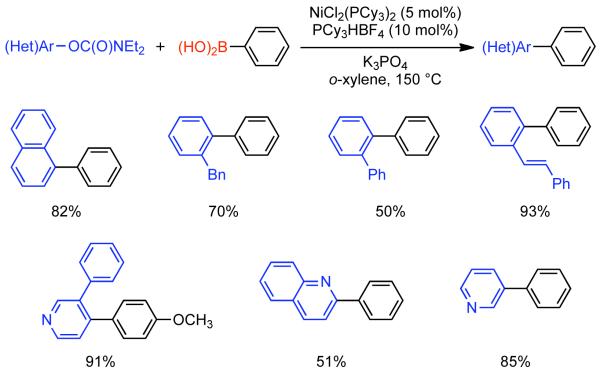

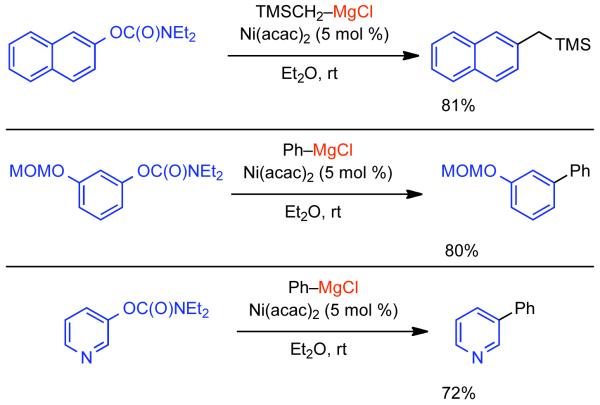

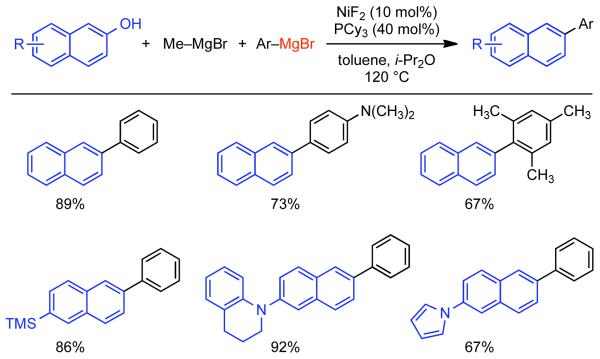

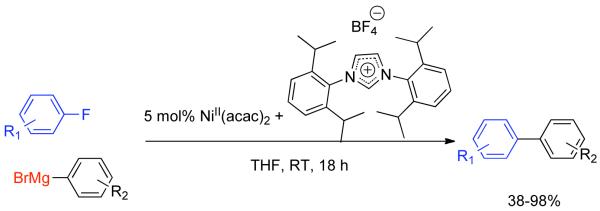

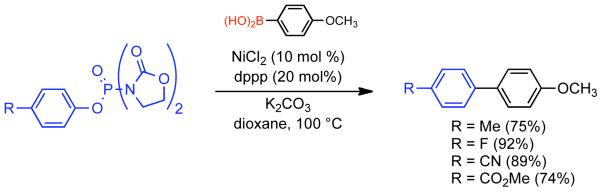

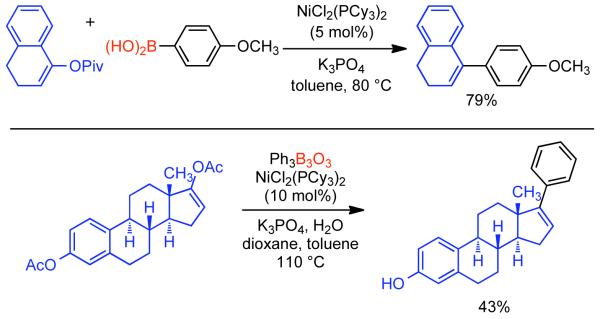

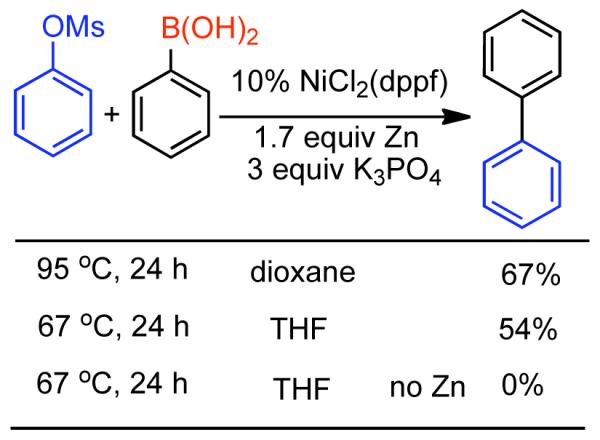

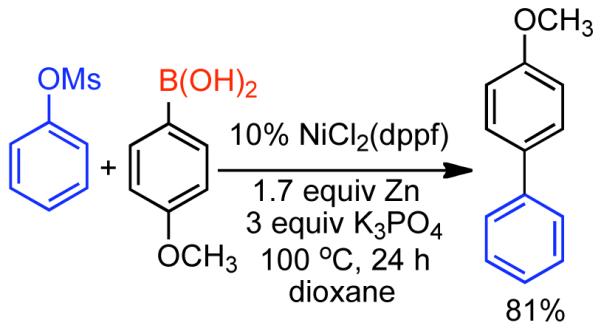

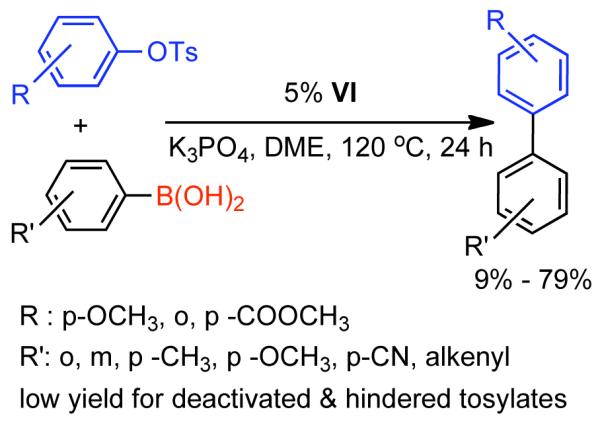

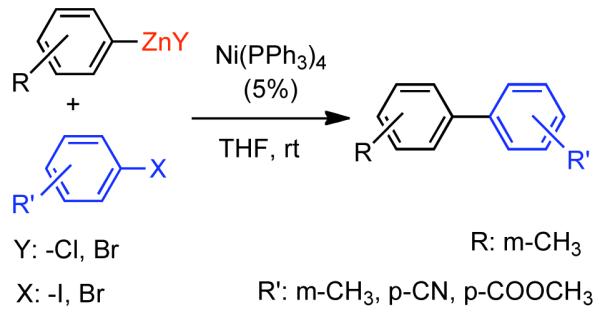

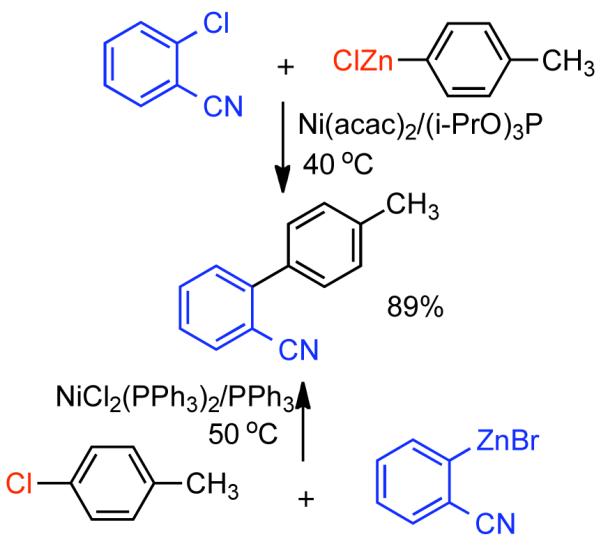

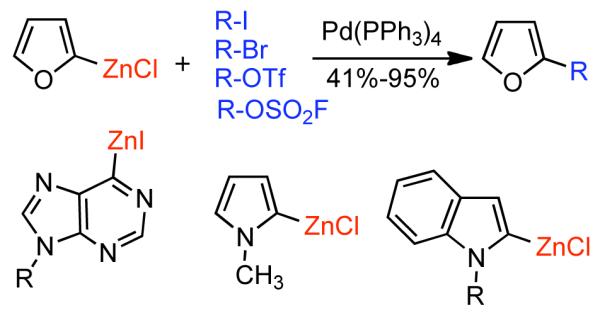

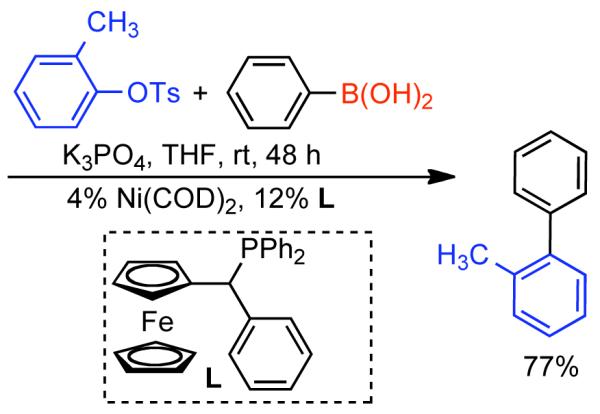

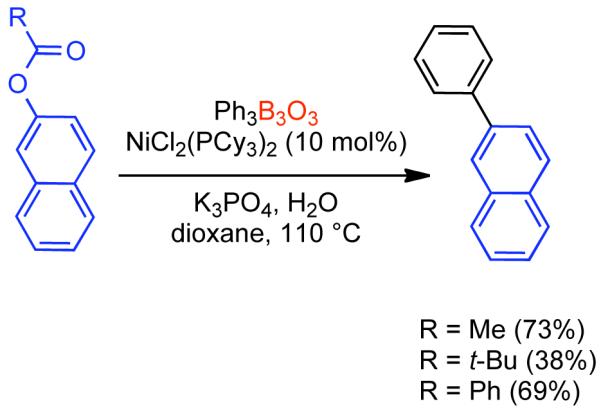

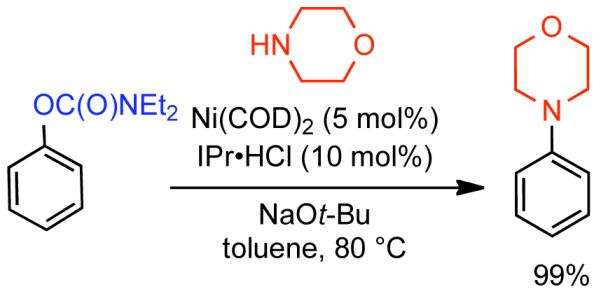

2.2.1 Suzuki-Miyaura Cross-Coupling

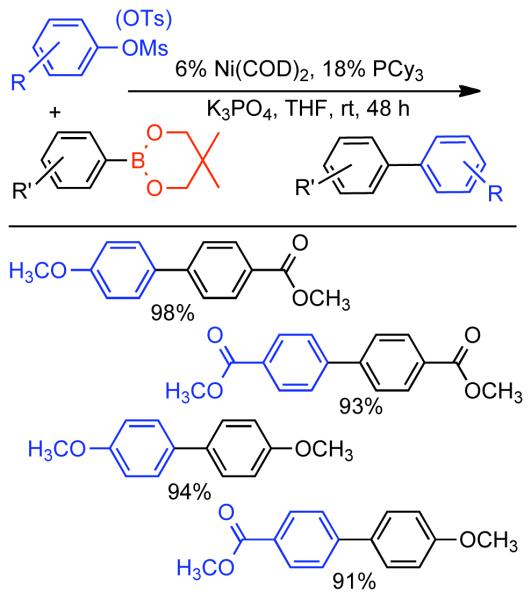

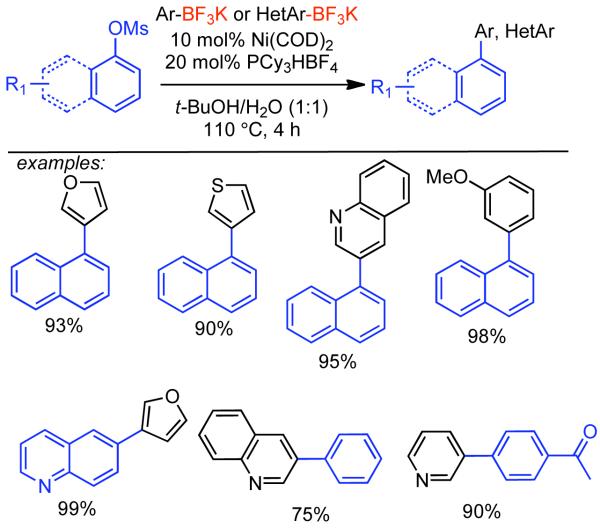

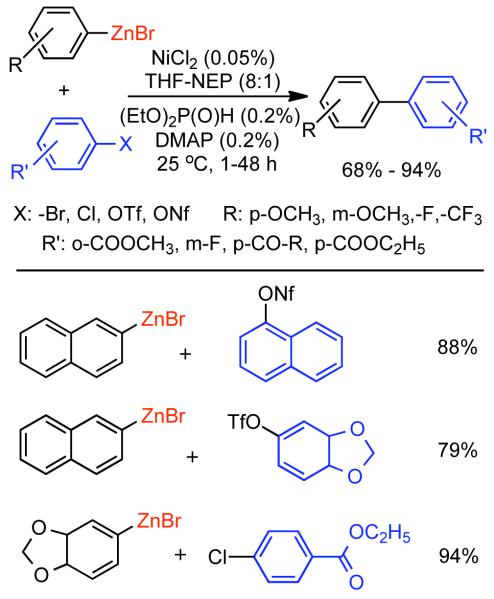

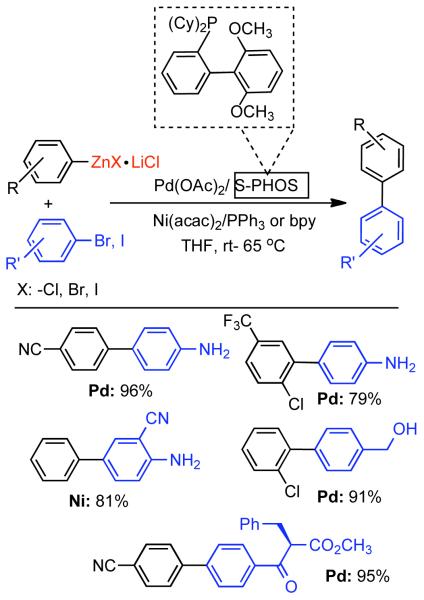

Discovered in 1979,155 the Suzuki-Miyaura cross-coupling reaction has become a standard for the synthesis of asymmetric biaryls via Csp2-Csp2 cross-coupling, due in large part to mild reaction conditions and high functional groups tolerance as well as the stability, ease of handling, and low toxicity of the organoboron coupling partners. Suzuki-Miyaura cross-coupling was born as Pd – triarylphosphine chemistry for the cross-coupling of aryl halides and triflates.22,10,36,156,157 However, as the field matured, exploration of new ligands as well as less expensive but more reactive Ni-catalysts have led to the expansion of the scope into the realm of less active aryl tosylates and mesylates. While it will not be comprehensively covered in this review, it should be noted that the development of advanced Pd-catalysts have also recently allowed for Pd-catalyzed Suzuki-Miyaura coupling of aryl tosylates and mesylates with aryl boronic acids,158,159 boronate esters,159 and trifluoroborate salts.160,161,162,163

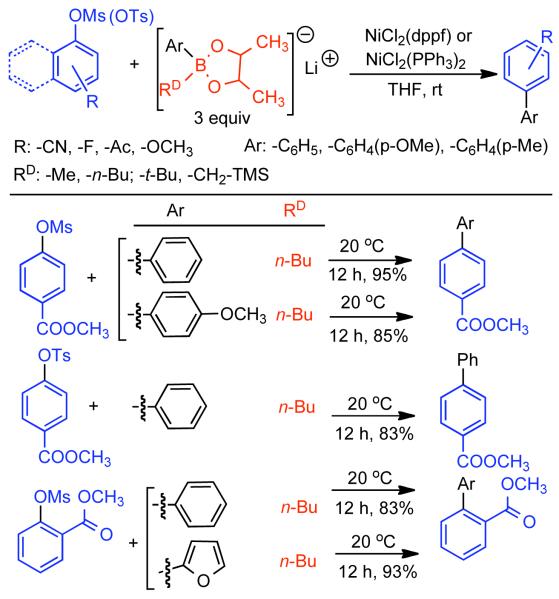

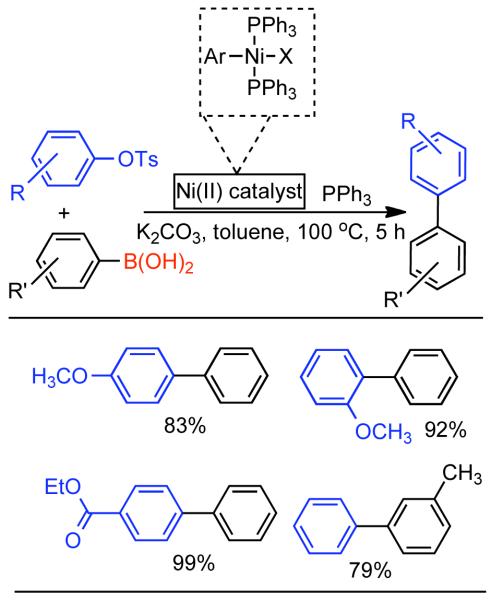

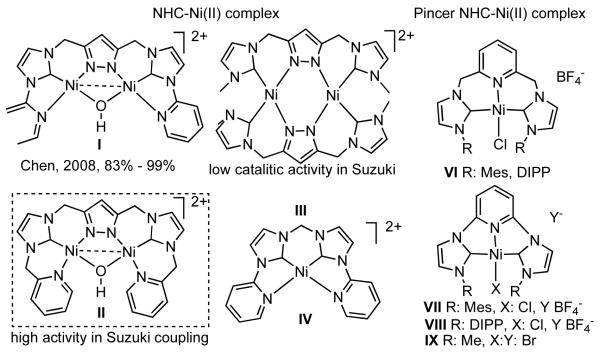

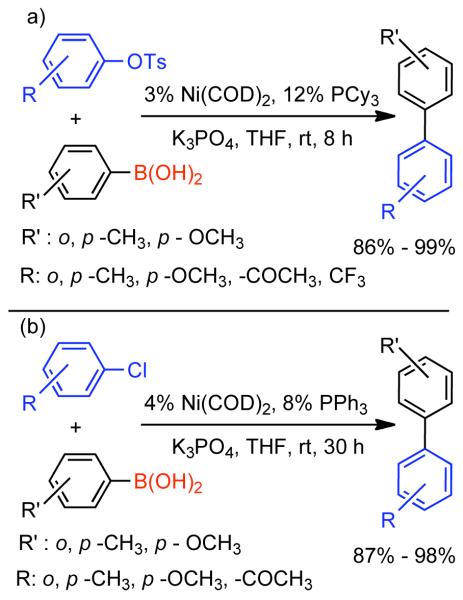

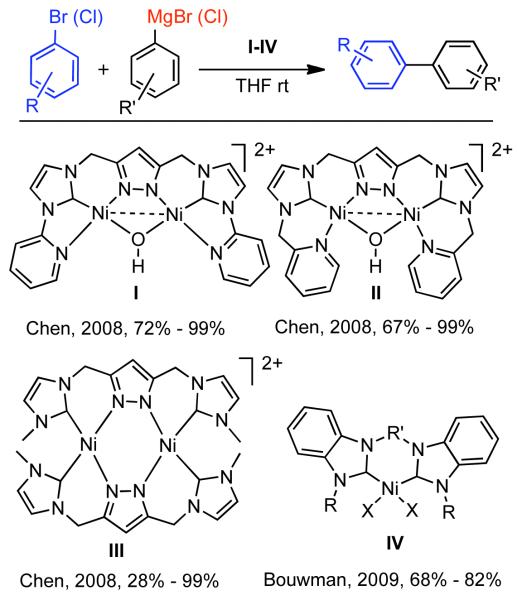

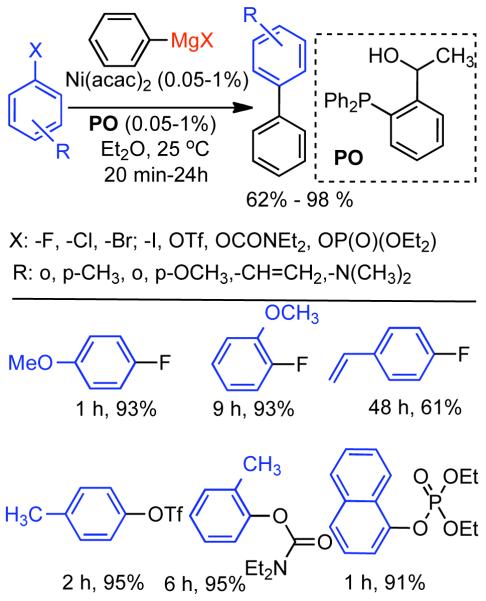

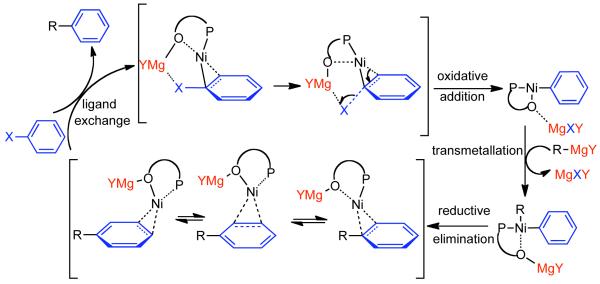

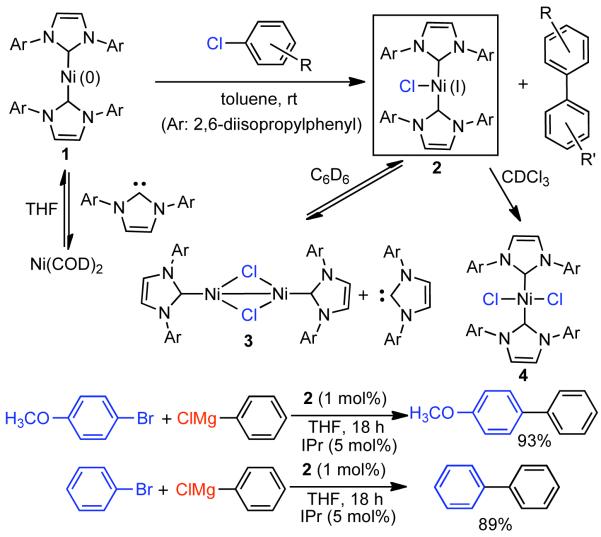

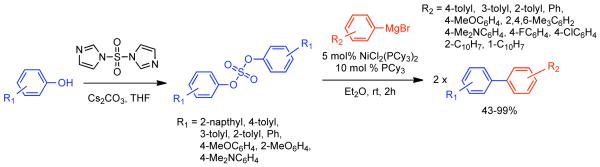

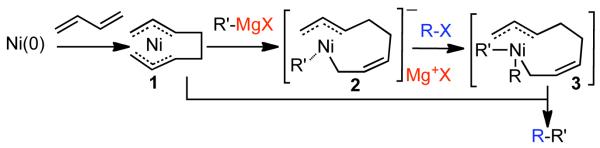

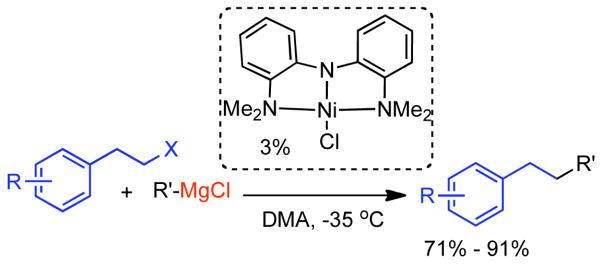

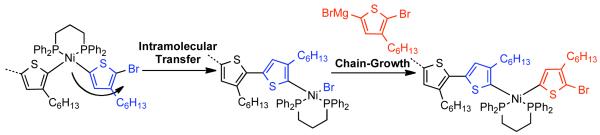

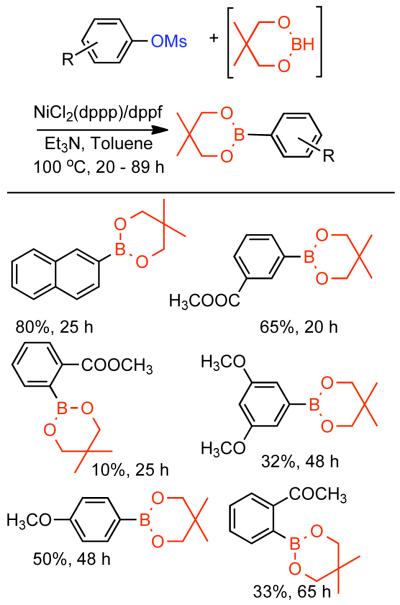

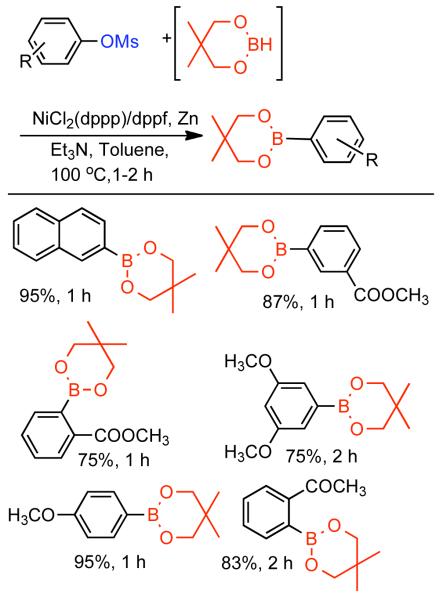

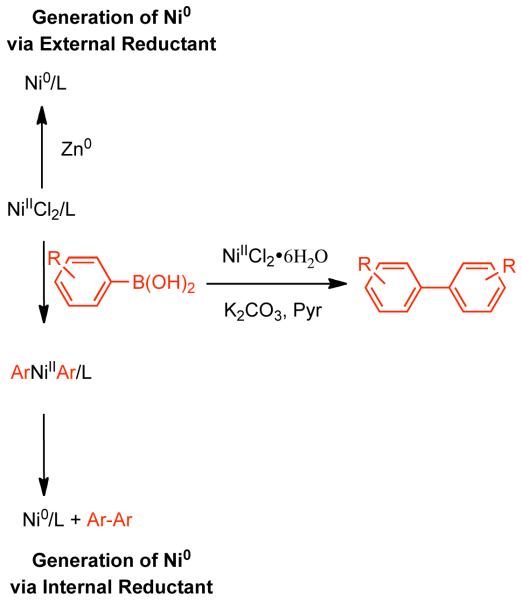

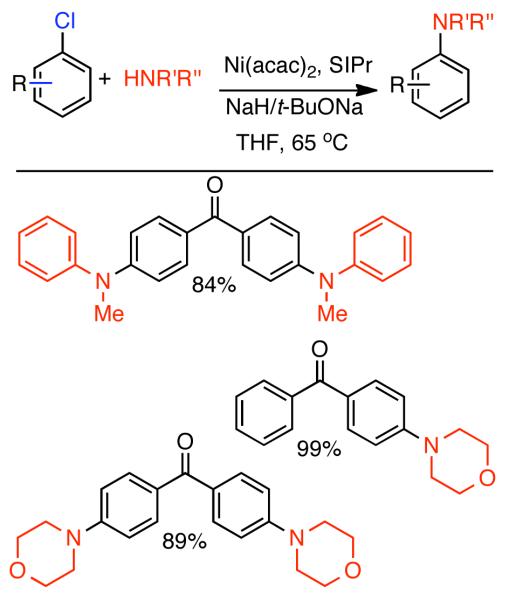

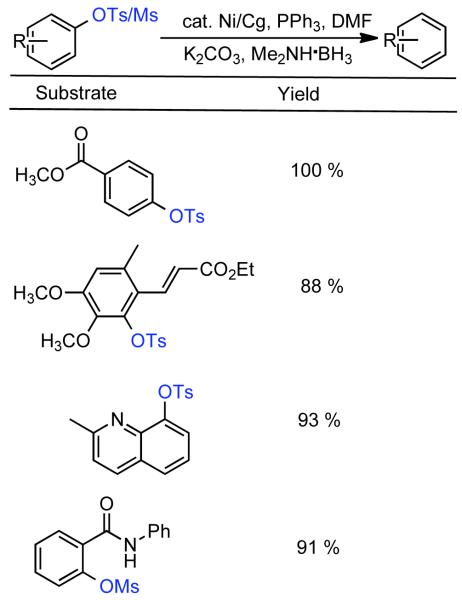

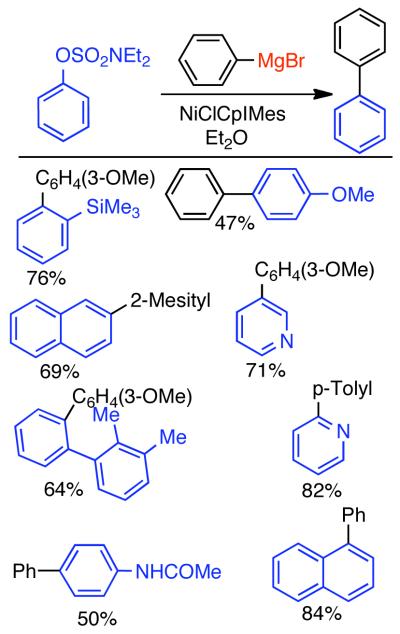

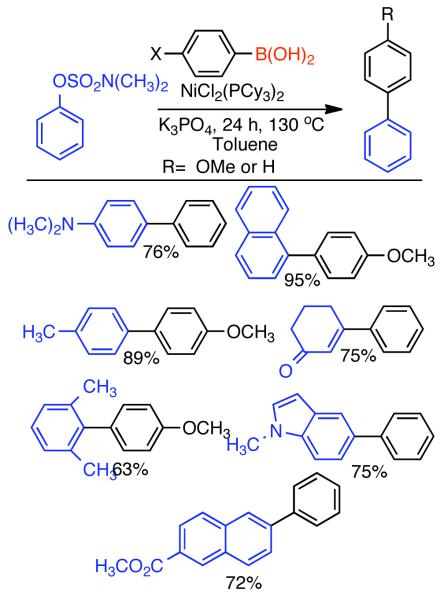

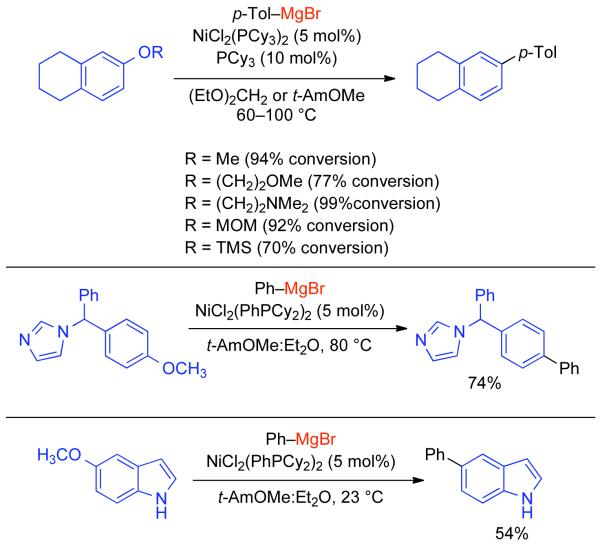

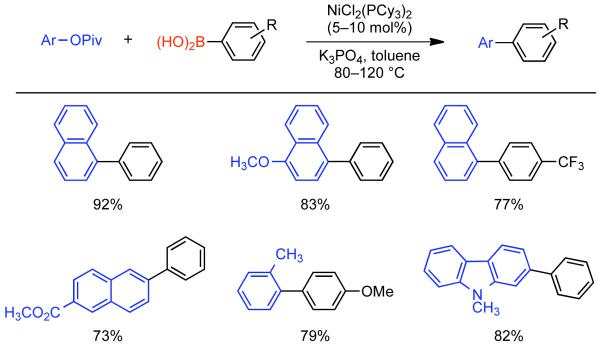

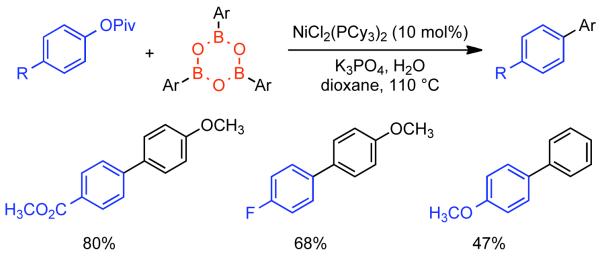

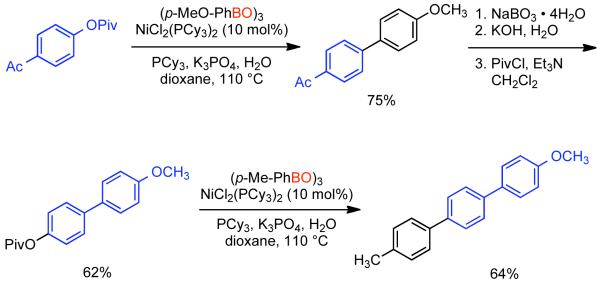

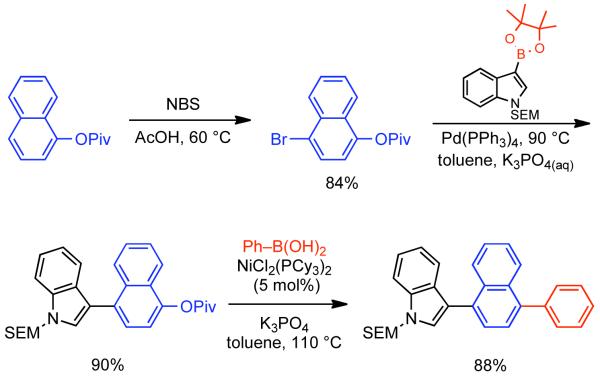

2.2.1.1. NiII phosphine catalysts to Ni0 with reducing agents