Abstract

In this paper, 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 (PMN-PT) single crystal/epoxy 1–3 composite was used as the active material of the endoscopic ultrasonic radial array transducer, because this composite exhibited ultrahigh electromechanical coupling coefficient (kt = 0.81%), very low mechanical quality factor (Qm = 11) and relatively low acoustic impedance (Zt = 12 MRayls). A 6.91 MHz PMN-PT/epoxy 1–3 composite radial array transducer with 64 elements was tested in a pulse-echo response measurement. The −6-dB bandwidth of the composite array transducer was 102%, which was ~30% larger than that of traditional lead zirconate titanate array transducer. The two-way insertion loss was found to be −32.3 dB. The obtained results show that this broadband array transducer is promising for acquiring high-resolution endoscopic ultrasonic images in many clinical applications.

I. Introduction

Endoscopic ultrasound (EUS) combines endoscopy and ultrasound to obtain images and information about the digestive tract or respiratory system. Endoscopy used in the digestive tract refers to the procedure of inserting an endoscope via the mouth or the rectum to visualize the surrounding organs or tissues, while an ultrasound transducer installed on the tip of the endoscope is producing images for those organs and tissues inside the body such as lungs, liver, gallbladder, pancreas, aorta, etc. [1]–[4]. The obtained images are more accurate and detailed than those acquired by a traditional transducer being placed directly on the skin overlaying the target organ(s). Numerous studies have been performed showing that this methodology is very effective, safe, well-tolerated, and minimally-invasive [5]–[7].

Most EUS systems are based on single-element transducers, which are mechanically driven by a motor to rotate inside the endoscope to form an image by 360° scanning. The fabrication of this type of transducer is relatively easy, but the requirement of mechanical scanning often limits the frame rate of the imaging system [8]. Radial array transducers have solved this problem by electrically scanning for imaging. However, the difficulties in the fabrication of radial array transducer have restricted the wide application of this solution.

The active material used for most existing endoscopic ultrasound transducers is the piezoelectric ceramic Pb(Zr1−xTix)O3 (PZT), but other piezoelectric materials may have better piezoelectric properties [9], [10]. The challenges for building the radial array transducer are that the array elements have to be extremely small in size and are subject to considerable bending force as they are rolled into the shape of a ring, so this fragile ceramic certainly has a great chance to be broken during the rolling process. Although piezopolymers such as polyvinylidene fluoride (PVDF) have good acoustic impedance matching with human tissues and high flexibility, it is also not recommended for use as the material to fabricate radial array elements with extremely small size because of its low dielectric permittivity and low piezoelectric response [11]–[13]. Compared with those single-phase materials, a 1–3 composite of piezoelectric rods embedded in a passive epoxy matrix a better choice for the active material because of its high electromechanical coefficient, high flexibility, and the acoustic impedance of this composite is comparable to that of human tissues [14]–[16].

Relaxor-based ferroelectric single crystals (1−x) Pb(Mg1/3Nb2/3)O3-xPbTiO3 (PMN-PT) with compositions near the morphotropic phase boundary (MPB) exhibit large piezoelectric coefficients (d33 > 2000 pC/N), high electromechanical coupling factors (k33 ~ 94%) and high E-field induced strain (1.7%) [17]–[20]. By utilizing the excellent longitudinal vibration performance of PMN-PT single crystal, the 1–3 composite can have ultrahigh electromechanical coupling factor (kt ~ 90%), low mechanical quality factor (Qm ~ 10), and low acoustic impedance (Z < 20 MRayls) [21]. With these improved parameters, the pulse-echo response and bandwidth of the fabricated ultrasound transducer will be greatly enhanced. The plane transducers fabricated with PMN-PT single crystal and its 1–3 composite for NDE and medical applications have already been reported [22], [23]. In this paper, an endoscopic ultrasound radial array transducer with PMN-PT single crystal/epoxy 1–3 composites as the active elements was designed, fabricated, and tested.

II. Fabrication and Characterization of PMN-PT/Epoxy 1–3 Composites

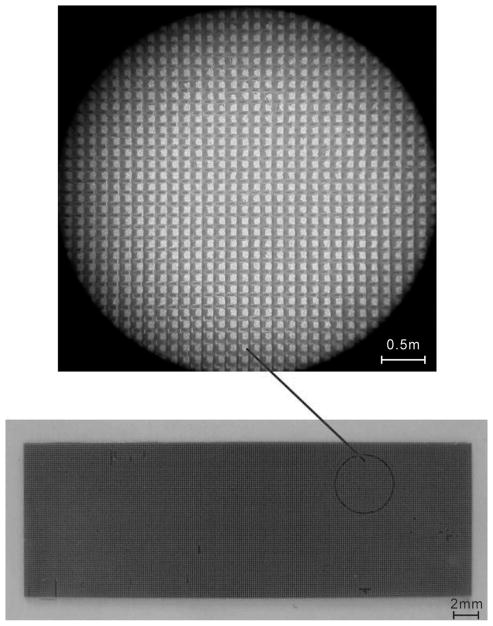

Large-size and high-quality rhombohedral PMN-PT single crystals with PT composition of 30%, which is close to MPB [21], [22], were grown by a modified Bridgman method [24], [25]. The as-grown single crystals were oriented along [001] direction as examined by an X-ray diffractometer, and diced to a large plate with dimension of 35 × 12 × 0.4 mm. The 1–3 piezocomposites were fabricated from this single crystal plate by using the dice-and-fill method [26]. A 50-μm-thick dicing nickel/diamond blade and a DAD 321 dicing saw (Disco Corp., Tokyo, Japan) was used to cut the PMN-PT single crystal, but kerf width was measured to be 57 μm. The element pitch was 73 μm. The dicing pitch and depth were set as 130 and 300 μm, respectively. The volume fraction of PMN-PT pillars in the composite was calculated to be 32%. The dicing process was performed under a low cutting speed of 0.46 mm/s to avoid breakage of the fragile PMN-PT single crystal. Fig. 1 shows the photograph of the diced PMN-PT single crystal and an enlarged image of a randomly selected area on the diced plate. The kerfs were filled by low-viscosity epoxy (Epo-Tek 301, Epoxy Technology, Billerica, MA). The epoxy matrix was placed under vacuum before solidification to remove the trapped bubbles. After the epoxy was cured, the bottom and the top side of the composite were ground to remove the bulk PMN-PT single crystal layer and the excess epoxy layer, respectively. The final thickness of the composite was 165 μm. Chromium/gold (Cr/Au) electrodes with thickness of ~500 nm were sputtered on both sides of the composite. The composite was poled under an electric field of 1.5 kV/mm at room temperature for 15 min. Finally, a composite with a smaller area of 30.08 × 11 mm was cut from the original plate for fabricating the radial array transducer. A testing sample with an area of 0.47 × 11 mm was also cut from the original plate for electrical characterization of the array elements.

Fig. 1.

(Bottom) Photograph of the diced PMN-PT single crystal and (top) an enlarged image of a randomly selected area on the diced plate.

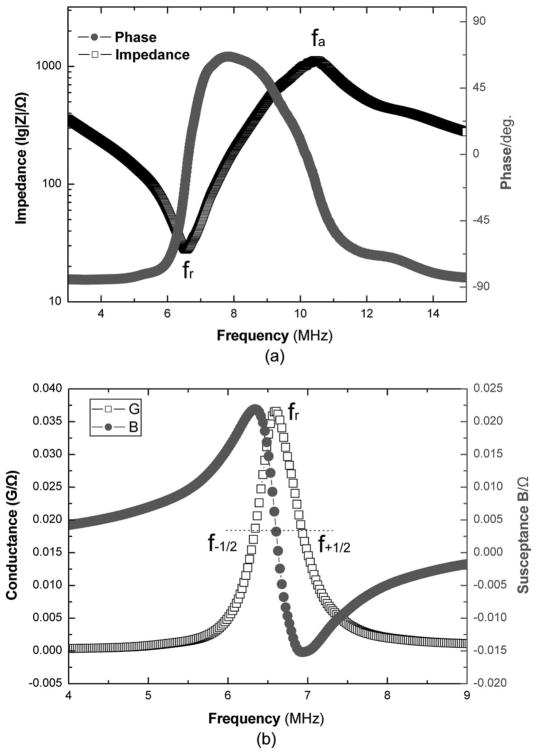

According to the IEEE standards on piezoelectricity [27], the following parameters were derived from the measured spectrum of the composite sample as shown in Fig. 2 using an impedance analyzer (4294A, HP/Agilent Technologies, Santa Clara, CA) at room temperature:

Fig. 2.

(a) The impedance and phase angle, and (b) conductance and susceptance spectra for the PMN-PT/epoxy 1–3 composite testing sample.

resonance frequency (fr) and anti-resonance frequency (fa) from the impedance spectrum in Fig. 2(a);

- electromechanical coupling coefficient (kt)

(1) -

frequency constant (Nt)

(2) where t is the thickness of the sample;

- sound velocity (c)

(3) -

acoustic impedance (Zt)

(4) where ρ represents the density of the sample.

-

clamped dielectric constant ( )

(5) where C is the capacitance measured at a high frequency of 40 MHz, S is the sample area, and ε0 is the dielectric constant in vacuum.

- lower and upper −6-dB frequency (f−1/2 and f+1/2) from the conductance spectrum in Fig. 2(b)

(6) (7) - mechanical quality factor (Qm)

(8)

The measured properties of the testing sample of the PMN-PT/epoxy 1–3 composite and those of other common piezoelectric materials are shown in Table I. The fabricated composite possesses very low acoustic impedance and mechanical quality factor, moderate dielectric constant, and ultrahigh electromechanical coupling factor. These advantages suggest that it is possible to make broadband high-resolution ultrasound transducers with this PMN-PT/epoxy 1–3 composite.

TABLE I.

Measured Properties of PMN-PT/Epoxy 1–3 Composites in Comparison With Common Piezoelectric Materials.

| Property | PMN-PT/epoxy 1–3 composites | PZT-5H ceramic [9], [10] | PVDF [11]–[13] | PMN-PT single crystal [18] |

|---|---|---|---|---|

| Dielectric constant | 170 | 1500 | 5 | 1000 |

| Coupling coefficient kt | 0.81 | 0.51 | 0.15 | 0.63 |

| Longitudinal velocity c (m/s) | 3600 | 3900 | 2200 | 4600 |

| Acoustic impedance Zt (MRayls) | 12 | 34 | 3.9 | 37 |

| Mechanical quality factor Qm | 11 | 65 | 13 | 50 |

III. Design Consideration of the Radial Array Transducer

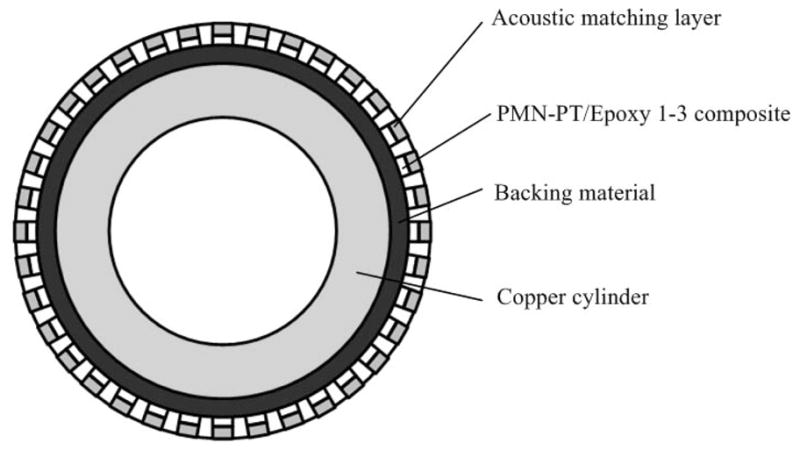

The as-prepared PMN-PT/epoxy 1–3 composite with the dimensions of 30.08 mm (length) × 11 mm (width) × 0.165 mm (thickness) was then used to fabricate the radial array transducer. Fig. 3 shows the schematic cross section of the radial array transducer. The designated resonance frequency of a single element of the array was 6.5 MHz. The backing layer was made by mixing polyether-modified epoxy resin (LER-0350, Liyi, Shanghai, China) with tungsten powder and micro-bubbles. This layer possesses high acoustic attenuation so that it can eliminate the back-wall reflections and reduce the ring-down time of the transducer. The backing layer is also highly flexible so that it can be easily wrapped onto the copper cylinder. To further enhance the bandwidth and sensitivity of the transducer, a front-face matching layer was employed. The thickness of matching layer was set to be λ/4, where λ is the wavelength of the acoustic wave emitted by a single array element when it is activated at its resonance frequency. The designated acoustic impedance of the single matching layer (Z1 = 3 MRayls) was calculated as follows [28]:

| (9) |

where Z0 (12 MRayls) is the impedance of the PMN-PT/epoxy 1–3 composite and ZL (~1.5 MRayls) is the impedance of load medium (i.e., body tissue and water). In this work, the matching layer was made by mixing low-viscosity epoxy (Epo-Tek 301) with alumina powder of ~5 μm in diameter. The measured impedance of the fabricated matching layer is 3.9 MRayls which is close to the designated value. The transmitting and receiving properties of the matching layer are optimal for this thickness. The material properties of the backing and matching layers are listed in Table II.

Fig. 3.

Schematic cross section of a PMN-PT/epoxy 1–3 composite based radial array transducer.

TABLE II.

Properties of the Fabricated Passive Materials Used in the Radial Array Transducer.

| Material | Use | c (m/s) | ρ (kg/m3) | Z (MRayls) | Loss at 5 MHz (dB/mm) |

|---|---|---|---|---|---|

| 5 μm alumina particles/EPO-TEK 301 | Matching layer | 2650 | 1500 | 3.9 | 2.1 |

| 2 μm tungsten particles/microbubbles/LER-0350 | Backing layer | 1650 | 4850 | 8.0 | 15.0 |

IV. Fabrication and Characterization of Radial Array Transducer

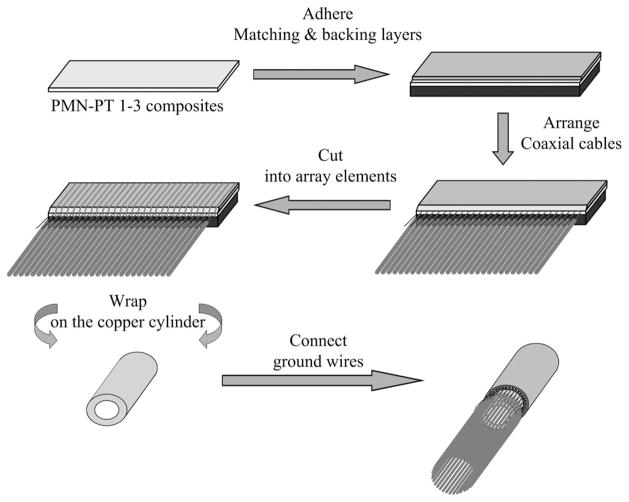

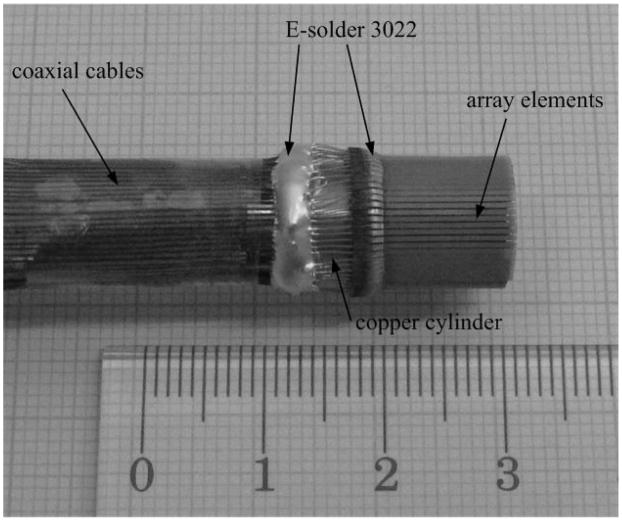

Fig. 4 shows the fabrication procedures of the radial array transducer. The backing layer with thickness of 330 μm and the matching layer with thickness of 100 μm were cured at room temperature for 24 h. The fabricated backing and matching layer were adhered to the lower and upper surface of the prepared PMN-PT/epoxy 1–3 composite by using low-viscosity epoxy (Epo-Tek 301). Because margins of 1 mm were required at both ends of the width of the composite for wire connection, the areas of backing and matching layer were 30.08 mm (length) × 10 mm (width). An external stress was imposed on the three-layer laminate to ensure thin bonding layers (<5 μm). A slender epoxy rod consisting of 64 equally distributed grids with distance between two consecutive troughs equal to 470 μm was made. This rod was used to arrange 64 coaxial cables regularly on the top electrode where the matching layer was attached. Actually, only the core wires of the coaxial cables were bonded on the top electrode using an electrically conductive adhesive (E-Solder 3022, Von Roll Isola USA Inc., Schenectady, NY) cured at room temperature for 24 h. Then, the three-layer laminate was vertically cut into 64 elements along the width direction with thorough separation on matching and piezoelectric layer and partial separation on the backing layer (the ~200-μm-thick backing layer remained uncut). The center-to-center distance between two consecutive array elements was 470 μm. Because the cut width was measured to be 57 μm, the actual width of a single array element was 470 – 57 = 413 μm. The three-layer laminate with 64 array elements was then wrapped on a copper tube to form the radial array transducer. This transducer has an outer diameter of 10 mm and an inner diameter of 6 mm. The copper tube was electrically connected to the bottom electrodes of the array elements and the ground wires of the coaxial cables by using electrically conductive adhesive (E-Solder 3022). After that, a thin layer of parylene C (supplied by Specialist Coating Systems, Indianapolis, IN) with 1 μm thickness was deposited onto the arrays as a waterproof coating. Fig. 5 is a photo of the radial array transducer.

Fig. 4.

Fabrication procedures for a PMN-PT/epoxy 1–3 composite radial array transducer.

Fig. 5.

Photograph of a fabricated PMN-PT/epoxy 1–3 composite radial array transducer.

The performance of the radial array transducer was measured by using a conventional pulse-echo response measurement method [29]. The center frequency (fc), −6-dB bandwidth (BW), and two-way insertion loss (two-way IL) of the transducer were obtained from the measurement. The radial array transducer was mounted on a holder and immersed in a water tank with a stainless steel target placed inside. By connecting to an ultrasonic pulser-receiver (Panametrics 5900PR, Olympus, Tokyo, Japan), each of the array elements was excited individually by a 1-uJ electrical impulse with 1 kHz repetition rate and 50 Ω damping factor. The echo responses were captured by the receiving circuit of the pulser-receiver and displayed on an oscilloscope (Infinium 54810A, HP/Agilent). The built-in fast Fourier transform (FFT) feature of the oscilloscope was used to compute the frequency spectrum of the pulse-echo response. The fc and BW of the transducer were determined from the measured FFT spectrum [29]:

| (10) |

| (11) |

where f1 and f2 represent the lower and upper −6-dB frequencies, respectively; that is, the two frequencies at which the magnitude of the amplitude in the spectrum is 50% (−6 dB) of the maximum.

The two-way IL or the relative pulse-echo sensitivity is the ratio of the transducer output power Po to the input power Pi delivered to the transducer from a driving source. If the output resistance Ro is assumed to be equal to the input resistance Ri, the two-way IL can be simplified as the ratio of the echo voltage Vo to the excitation voltage Vi,

| (12) |

The radial array transducer was connected to a function generator (8116A, HP/Agilent) which was used to generate a tone burst of 20-cycle sine wave with amplitude equal to Vi and frequency equal to fc. In response to this excitation signal, the radial array transducer would receive an echo signal with amplitude Vo, as measured by the oscilloscope with 1 MΩ coupling. The amplitude of the driving signal was then measured with 50 Ω coupling.

V. Performance of the Fabricated Radial Array Transducer

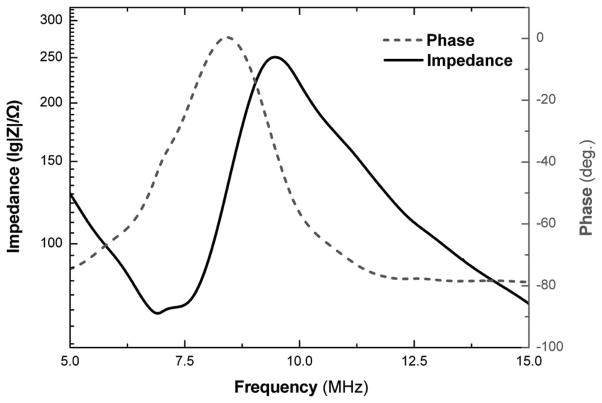

Fig. 6 shows the impedance and phase spectrum of a single array element of the PMN-PT/epoxy 1–3 composite radial array transducer. These spectra were measured by an impedance analyzer (HP 4294A) at room temperature. The resonance frequency and anti-resonance frequency for the thickness vibration mode of an array element are found to be 6.96 and 9.60 MHz, respectively. The corresponding effective electromechanical coupling coefficient is calculated to be 0.69.

Fig. 6.

The impedance and phase spectra of a single array element of the PMN-PT/epoxy 1–3 composite radial array transducer.

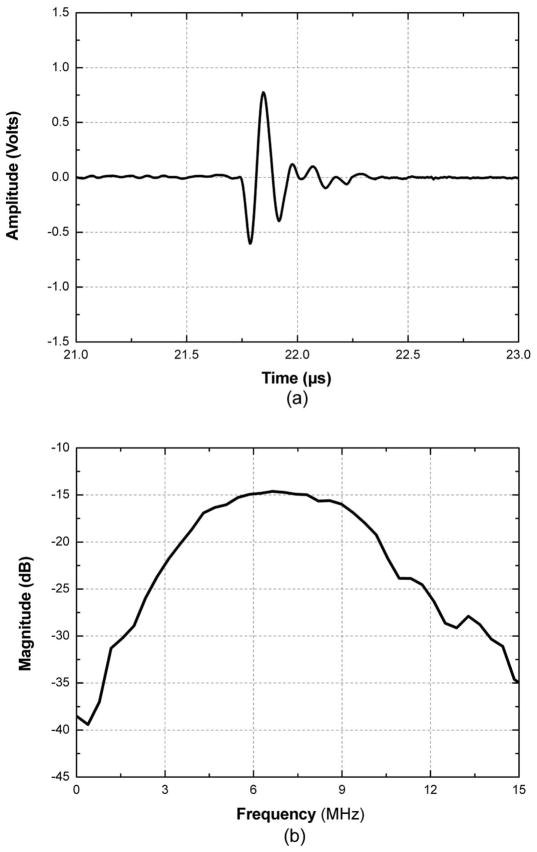

The pulse echo response of the radial array transducer was measured by receiving the reflected vibration from the surface of a stainless steel target placed in a water bath. Ten array elements were randomly chosen for the measurement. Fig. 7 shows the pulse-echo response and FFT spectrum of a single array element. By using (10), the average center frequency of the chosen elements was found to be 6.91 MHz, which is very close to the resonance frequency. The average −6-dB bandwidth was calculated to be 102% by using (11). The −6-dB bandwidth of our radial array transducer (~100%) is much higher than that of the common commercial PZT array transducers (~70%). The average two-way insertion loss at center frequency of the chosen elements was calculated to be −32.3 dB using (12).

Fig. 7.

(a) Pulse-echo waveform and (b) frequency spectra of a single array element of the PMN-PT/epoxy 1–3 composite radial array transducer.

VI. Conclusion

A 6.91 MHz PMN-PT/epoxy 1–3 composite radial array transducer with 64 elements has been fabricated and characterized. PMN-PT single crystal/epoxy 1–3 composite was fabricated and proved to have ultrahigh electromechanical coupling factor (kt = 0.81), very low mechanical quality factor (Qm = 11), and relatively low acoustic impedance (Zt = 12 MRayls) compared with other traditional piezoelectric materials. The result suggests that 1–3 composite is more suitable for use as the active material in radial array transducers. The −6-dB bandwidth of the fabricated transducer was 102%, which is much higher than common commercial PZT array transducers (~70%). The fabricated transducer also exhibits a low two-way insertion loss of −32.3 dB. Therefore, this research work has indicated the promising potential of the PMN-PT/epoxy 1–3 composite radial array transducer for applications in the endoscopic imaging field.

Acknowledgments

The authors would like to thank R. Chen for help with pulse-echo response measurement.

This work was supported by the Hong Kong Innovative Technology Council (Project No. ZP-1H), the Department of Applied Physics of the Hong Kong Polytechnic University and NIH Grant #P41-EB2182.

Biographies

Dan Zhou was born in June 1982 in Jiangsu Province, China. He received his B.S. degree from Fudan University, Shanghai, China, 2004, and Ph.D. degree from the Shanghai Institute of Ceramics, Chinese Academy of Sciences (SICCAS), Shanghai, China, 2009. Currently, he is working as a research associate in the Dept. of Applied Physics, Hong Kong Polytechnic University, Hong Kong, China. His research interests are ferroelectric, piezoelectric materials and ultrasonic transducer devices.

Kowk Fung Cheung was born in Hong Kong, China, on October 22, 1984. He received the B. Eng. degree in mechanical engineering from the Hong Kong University of Science and Technology in 2006, and the M.Phil. degree in applied physics from the Hong Kong Polytechnic University in 2009. He is presently a Research Assistant responsible for the fabrication of endoscopic ultrasound imaging system for medical diagnostics in the Department of Applied Physics at the Hong Kong Polytechnic University. His research interests include modeling of ultrasound transducers for high-power application and radial arrays for medical imaging.

Yan Chen was born in Hebei Province, China. She obtained B.E. and M.Phil. degrees in 2006 and 2009, respectively, both from the Jingdezhen Ceramic Institute, Jingdezhen, China. Now she is a Ph.D. candidate in the Dept. of Applied Physics, Hong Kong Polytechnic University, Hong Kong, China. Her research interests are piezoelectric materials and ultrasound transducers.

Sien Ting Lau received the B.Sc., M.Phil., and Ph.D. degrees in 1998, 2001, and 2004, respectively, all from the Hong Kong Polytechnic University. From 2004 to 2009, she was with the Department of Applied Physics at the Hong Kong Polytechnic University, first as a Postdoctoral Fellow, then as a Research Associate working on ferroelectric materials characterizations and ultrasonic transducer and array fabrication. Currently, she is a Research Associate at the NIH Resource Center for Medical Ultrasonic Transducer Technology and the Department of Biomedical Engineering at the University of Southern California, Los Angeles, CA. Her current research interests include development of ferroelectric polymers, ceramics and composites, MEMS technology, and design and fabrication of high-frequency ultrasonic transducers for medical applications. She has published more than 60 papers in these areas.

Qifa Zhou received his Ph.D. degree from the Department of Electronic Materials and Engineering at Xi’an Jiaotong University, China, in 1993. He is currently a Research Associate Professor at the NIH Resource on Medical Ultrasonic Transducer Technology and the Department of Biomedical Engineering at University of Southern California, Los Angeles, CA. Before joining USC in 2002, he worked in the Department of Physics at Zhongshan University of China, the Department of Applied Physics at Hong Kong Polytechnic University, and the Materials Research Laboratory at Pennsylvania State University. His current research interests include the development of ferroelectric thin films, MEMS technology, nano-composites, modeling and fabrication of high-frequency ultrasound transducers/arrays, and photoacoustics/OCT for medical imaging applications. He has published more than 100 papers in this area. He is an Associate Editor and committee member of the IEEE UFFC Society.

K. Kirk Shung obtained a B.S. degree in electrical engineering from Cheng-Kung University in Taiwan in 1968, an M.S. degree in electrical engineering from the University of Missouri, Columbia, MO, in 1970 and a Ph.D. degree in electrical engineering from the University of Washington, Seattle, WA, in 1975. He did postdoctoral research at Providence Medical Center in Seattle, WA, for one year before being appointed a research bioengineer holding a joint appointment at the Institute of Applied Physiology and medicine. He became an assistant professor at the Bioengineering Program, Pennsylvania State University, University Park, PA, in 1979 and was promoted to professor in 1989. He was a Distinguished Professor of Bioengineering at Penn State until September 1, 2002, when he joined the Department of Biomedical Engineering, University of Southern California, Los Angeles, CA, as a professor. He has been the director of the NIH Resource on Medical Ultrasonic Transducer Technology since 1997.

Dr. Shung is a fellow of the IEEE, the Acoustical Society of America, and the American Institute of Ultrasound in Medicine. He is a founding fellow of the American Institute of Medical and Biological Engineering. He has served for two terms as a member of the NIH Diagnostic Radiology Study Section. He received the IEEE Engineering in Medicine and Biology Society early career award in 1985 and coauthored a best paper published in the IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control in 2000. He is the distinguished lecturer for the IEEE UFFC society for 2002–2003. He was elected an outstanding alumnus of Cheng-Kung University in 2001.

Dr. Shung has published more than 160 papers and book chapters. He is the author of a textbook, Principles of Medical Imaging, published by Academic Press in 1992. He co-edited a book, Ultrasonic Scattering by Biological Tissues, published by CRC Press in 1993. Dr. Shung’s research interest is in ultrasonic transducers, high-frequency ultrasonic imaging, and ultrasonic scattering in tissues.

Haosu Luo received his B.S. degree from Nanjing Normal University, Nanjing, China, 1982, and his Ph.D. degree from the Shanghai Institute of Ceramics, Chinese Academy of Sciences (SIC-CAS), Shanghai, China, 1992. He became as a professor at SICCAS in 1997.

His research interests include the growth, characterization, and practical applications of ferroelectric single crystals. Current researches involve the growth of high-Tc relaxor-based single crystals, lead-free piezoelectric single crystals, and device applications of these single crystals in ultrasonic transducers, high-strain actuators, infrared detectors, ultrasonic motors, and various sensors. He is involved in more than 200 publications.

Jiyan Dai received his B.Sc. degree in physics from Fudan University in 1988, his M.S. degree in electrical engineering from Tsinghua University in 1991, and his Ph.D. degree in materials physics from the Chinese Academy of Sciences in 1994. He has worked at Northwestern University as a Research Associate for three years, and after one year working in the Institute of Materials Research and Engineering Singapore, he joined Chartered Semiconductor Manufacturing Ltd. in Singapore in failure analysis. His research interest is materials science and medical ultrasound transducers. He joined the Department of Applied Physics at the Polytechnic University in 2001 as lecturer and currently is Associate Professor. He has been working on a few projects in fabricating endoscopic and high-frequency ultrasound transducers and imaging systems.

Helen Lai Wa Chan received the B.Sc. and M. Phil. degrees in physics from the Chinese University of Hong Kong in 1970 and 1974, respectively, and the Ph.D. degree in physics from Macquarie University, Australia, in 1987. She worked as a research scientist in the National Measurement Laboratory of the CSIRO Division of Applied Physics, Sydney, Australia, from 1987 to 1991, where she was responsible for setting up the Australian standards for medical ultrasound transducer calibration. She then worked as a senior acoustic engineer at GEC-Marconi Pty., Australia, for a year on hydrophone arrays for underwater acoustics before she returned to Hong Kong in 1992. Prof. Chan is currently the chair professor and head of applied physics at The Hong Kong Polytechnic University. She is a senior member of IEEE.

Contributor Information

Dan Zhou, Department of Applied Physics and Materials Research Centre, The Hong Kong Polytechnic University, Hong Kong, China.

Kwok Fung Cheung, Department of Applied Physics and Materials Research Centre, The Hong Kong Polytechnic University, Hong Kong, China.

Yan Chen, Department of Applied Physics and Materials Research Centre, The Hong Kong Polytechnic University, Hong Kong, China.

Sien Ting Lau, Department of Biomedical Engineering and NIH Transducer Resource Center, University of Southern California, Los Angeles, CA.

Qifa Zhou, Department of Biomedical Engineering and NIH Transducer Resource Center, University of Southern California, Los Angeles, CA.

K. Kirk Shung, Department of Applied Physics and Materials Research Centre, The Hong Kong Polytechnic University, Hong Kong, China. Department of Biomedical Engineering and NIH Transducer Resource Center, University of Southern California, Los Angeles, CA.

Hao Su Luo, Information Materials and Devices Research Center, Shanghai Institute of Ceramics, Chinese Academy of Science, Shanghai, China.

Jiyan Dai, Email: apdaijy@inet.polyu.edu.hk, Department of Applied Physics and Materials Research Centre, The Hong Kong Polytechnic University, Hong Kong, China.

Helen Lai Wa Chan, Department of Applied Physics and Materials Research Centre, The Hong Kong Polytechnic University, Hong Kong, China.

References

- 1.Annema JT, Veselic M, Rabe KF. EUS-guided FNA of centrally located lung tumours following a non-diagnostic bronchoscopy. Lung Cancer. 2005 Nov;48:357–361. doi: 10.1016/j.lungcan.2004.11.017. [DOI] [PubMed] [Google Scholar]

- 2.Prasad P, Schmulewitz N, Patel A, Varadarajulu S, Wildi SM, Roberts S, Tutuian R, King P, Hawes RH, Hoffman BJ, Wallace MB. Detection of occult liver metastases during EUS for staging of malignancies. Gastrointest Endosc. 2004;59(1):49–53. doi: 10.1016/s0016-5107(03)02378-2. [DOI] [PubMed] [Google Scholar]

- 3.Lachter J, Zelikovsky S. EUS changes diagnosis from pancreatic to gallbladder carcinoma. Int J Gastrointest Cancer. 2002;32(2–3):161–164. doi: 10.1385/IJGC:32:2-3:161. [DOI] [PubMed] [Google Scholar]

- 4.Tran QNH, Urayama S, Meyers FJ. Endoscopic ultrasound-guided celiac plexus neurolysis for pancreatic cancer pain: A single-institution experience and review of the literature. J Support Oncol. 2006 Feb;4:460–464. [PubMed] [Google Scholar]

- 5.Stigt JA, Oostdijk AH, Timmer PR, Shahin GM, Boers JE, Groen HJM. Comparison of EUS guided fine needle aspiration and integrated PET-CT in restaging after treatment for locally advanced non-small cell lung cancer. Lung Cancer. 2009 Jan;66(2):198–204. doi: 10.1016/j.lungcan.2009.01.013. [DOI] [PubMed] [Google Scholar]

- 6.Hünerbein M, Totkas S, Balanou P, Handke T, Schlag PM. EUS-guided fine needle biopsy: Minimally invasive access to meta-static recurrent cancer. Eur J Ultrasound. 1999;10(2–3):151–157. doi: 10.1016/s0929-8266(99)00060-9. [DOI] [PubMed] [Google Scholar]

- 7.Annema JT, Hoekstra OS, Smit EF, Veselic M, Versteegh MIM, Rabe KF. Towards a minimally invasive staging strategy in NSCLC: Analysis of PET positive mediastinal lesions by EUS-FNA. Lung Cancer. 2004 Oct;44:53–60. doi: 10.1016/j.lungcan.2003.10.013. [DOI] [PubMed] [Google Scholar]

- 8.Bow CR, McDicken WN, Anderson T, Scorgie RE, Muir AL. A rotating transducer real-time scanner for ultrasonic examination of the heart and abdomen. Br J Radiol. 1979 Jan;52:29–33. doi: 10.1259/0007-1285-52-613-29. [DOI] [PubMed] [Google Scholar]

- 9.Kino GS. Acoustic Waves: Devices, Imaging, and Analog Signal Processing. Englewood Cliffs, NJ: Prentice Hall; 1987. [Google Scholar]

- 10.Zipparo MJ, Shung KK, Shrout TR. Piezoceramics for high frequency (20–100 MHz) single-element imaging transducers. IEEE Trans Ultrason Ferroelectr Freq Control. 1997;44(5):1038–1048. [Google Scholar]

- 11.Brown LF. Design considerations for piezoelectric polymer ultrasound transducers. IEEE Trans Ultrason Ferroelectr Freq Control. 2000;47(6):1377–1396. doi: 10.1109/58.883527. [DOI] [PubMed] [Google Scholar]

- 12.Brown LF, Mason JL, Klinkenborg ML, Scheinbeim JI, Newman BA. Ferroelectric nylon materials and their feasibility for ultrasound transducers. IEEE Trans Ultrason Ferroelectr Freq Control. 1997 Sep;44(5):1049–1059. [Google Scholar]

- 13.Chung CH, Lee YC. Broadband poly(vinylidene fluoride-trifluoroethylene) ultrasound focusing transducers for determining elastic constants of coating materials. J Nondestr Eval. 2009 Jul;28:101–110. [Google Scholar]

- 14.Safari A, Janas VF, Bandyopadhyay A. Development of fine-scale piezoelectric composites for transducers. AlChE J. 2004 Jun;43(suppl 11A):2849–2856. [Google Scholar]

- 15.Smith WA. The role of piezocomposites in ultrasonic transducers. IEEE Proc Ultrason Symp. 1989:755–766. [Google Scholar]

- 16.Gururaja TR. Piezoelectrics for medical ultrasonic imaging. Am Ceram Soc Bull. 1994;73(5):50–55. [Google Scholar]

- 17.Saitoh S, Takeuchi T, Kobayashi T, Harada K, Shimanuki S, Yamashita Y. A 3.7 MHz phased array probe using 0.91Pb(Zn1/3Nb2/3)O3-0.09PbTiO3. IEEE Trans Ultrason Ferroelectr Freq Control. 1999 Mar;46:414–421. doi: 10.1109/58.753031. [DOI] [PubMed] [Google Scholar]

- 18.Zhou D, Wang F, Luo L, Chen J, Ge W, Zhao X, Luo H. Characterization of complete electromechanical constants of rhombohedral 0.72Pb(Mg1/3Nb2/3)-0.28PbTiO3 single crystals. J Phys D Appl Phys. 2008 Aug;41 art. no. 185402. [Google Scholar]

- 19.Service RF. Materials science: Shape-changing crystals get shiftier. Science. 1997 Mar;275(5308):1878. [Google Scholar]

- 20.Park SE, Shrout TR. Ultrahigh strain and piezoelectric behavior in relaxor-based ferroelectric single crystals. J Appl Phys. 1997;82(4):1804–1811. [Google Scholar]

- 21.Zhou D, Luo L, Wang F, Jia Y, Zhao X, Luo H. Research on the performance of 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 single crystal/polymer 1-3 piezoelectric composite material. Acta Phys Sin. 2008;57(7):4552–4557. [Google Scholar]

- 22.Cheng KC, Chan HLW, Choy CL, Yin Q, Luo H, Yin Z. Single crystals PMN-0.33PT/epoxy 1-3 composites for ultrasonic transducer applications. IEEE Trans Ultrason Ferroelectr Freq Control. 2003;50(9):1177–1183. doi: 10.1109/tuffc.2003.1235328. [DOI] [PubMed] [Google Scholar]

- 23.Kim KB, Hsu DK, Ahn B, Kim YG, Barnard DJ. Fabrication and comparison of PMN-PT single crystal, PZT and PZT-based 1-3 composite ultrasonic transducers for NDE applications. Ultrasonics. 2010;50(8):790–797. doi: 10.1016/j.ultras.2010.04.001. [DOI] [PubMed] [Google Scholar]

- 24.Luo H, Shen G, Wang P, Le X, Yin Z. Study of new piezoelectric material—Relaxor ferroelectric single crystals. J Inorg Mater. 1997;12(5):768. [Google Scholar]

- 25.Luo H, Xu G, Wang P, Xu H, Yin Z. Compositional homogeneity and electrical properties of lead magnesium niobate titanate single crystals grown by a modified Bridgman technique. Jpn J Appl Phys. 2000 Jun;39(9B):5581–5585. [Google Scholar]

- 26.Savakus HP, Klicker KA, Newnham RE. PZT-epoxy piezoelectric transducers: A simplified fabrication procedure. Mater Res Bull. 1981;16(6):677–680. [Google Scholar]

- 27.IEEE Standard on Piezoelectricity, ANSI/IEEE Std. 176, 1987.

- 28.Desilets CS, Fraser JD, Kino GS. The design of efficient broad-band piezoelectric transducers. IEEE Trans Son Ultrason. 1978 May;SU-25(3):115–125. [Google Scholar]

- 29.Erikson KR, Banjavic RA, Carson PL. Standard methods for testing single-element pulse-echo ultrasonic transducers—AIUM interim standard. J Ultrasound Med. 1981;1(suppl S):1–18. [Google Scholar]