Abstract

The fracture of complete dentures fabricated using Polymethyl methacrylate resin constitutes a challenge to the clinician and remains an unresolved problem. To determine whether gradual increase in load or different posterior teeth positions in maxillary denture would influence the pattern of stress. Two groups of maxillary dentures were fabricated with different posterior teeth positions (Group I with teeth on the crest of the ridge; Group II with buccal to the crest of the ridge.) using casts prepared from prefabricated edentulous molds, with 5 dentures in each group. Two strain gauges were cemented on to the midline of each denture, one on the anterior palatal area and other on the posterior palatal area. The dentures were loaded from 0 to 110 N in steps of 10 N, and the strains induced were measured. Differences of the stress magnitudes between the 2 groups were statistically analyzed using Mann–Whitney U test. The anterior palatal area of the maxillary denture was dominated by a tensile stress, which was greater in the group II than in group I. The posterior palatal area was dominated by compressive stress but the outer placement of the maxillary teeth caused a significant decrease in the compressive stress. The high anterior tensile stress with compressive stress in the posterior palatal area during loading may be responsible for denture base fractures that initiate from the anterior palatal area. The buccal placement of posterior teeth may play a role in the fatigue fracture of the maxillary denture.

Keywords: Strain gauges, Functional stress analysis, Digital strain indicator

Introduction

The loss of teeth is a matter of great concern and their replacement by artificial substitute like complete denture prosthesis is vital to the continuance of normal life for esthetic and functional requirements. The complete denture prosthesis is generally fabricated using polymethyl methacrylate resin and this has a tendency to fracture under cyclic loading [1].

Complete maxillary dentures are subjected to significant variations in stress during function intra orally. The stress patterns within complete maxillary denture differs in each patient and depends on many factors like base thickness, material used, muscular power of the test subject, nature of the underlying soft tissues, stability of denture base, form and position of teeth.

Complete dentures typically fracture along the midline due to crack initiation and propagation from stressed areas. Many methods of experimental stress analysis such as Brittle Coatings, Strain Gauges, Photoelastic Models, Holography, Scanning Electron Microscope Replica Technique and simulations such as Finite Element Analysis [2] have been used to examine the deformation of complete maxillary dentures.

Clinical experience has revealed a paradox in complete maxillary dentures. Although load acts on the posterior area of the denture, fracture often begins from the anterior area where no teeth are in contact [3]. Moreover, crack propagation does not always result in separation of its direction away from the midline.

The purpose of this study was to characterize the midline stress field in complete maxillary denture in terms of type and magnitude and to determine whether gradual increase in load or different posterior teeth positions would influence the pattern of stress.

Subjects and Methods

A comparative in vitro study to evaluate functional stresses in maxillary complete dentures with two different posterior teeth positions at a gradual increase in load was undertaken.

Fabrication of Prototype Denture

Two prefabricated edentulous molds (Edentulous mold No 402) one of the maxillary jaw and one of the mandibular jaw were selected for the fabrication of the prototype complete dentures for each group. Edentulous casts of maxillary and mandibular jaw were made in the molds using Dental stone type III (Kalastone cl III, kalabhai, Mumbai).

For group I two guidelines were drawn on prototype maxillary cast to coincide with the longitudinal axis of the ridge crest (Fig. 1). A 2.5 mm thick thermoplastic sheet (ERKOPRESS) was vacuum pressed on the maxillary cast to obtain trial acrylic base of uniform thickness. The lines were transferred onto the trial acrylic bases to indicate the crest of the ridges. Then the maxillary and mandibular casts with occlusal rims were mounted on a semi adjustable articulator (Girbach Artex) in a class I anterior posterior relation. Care was taken to arrange the maxillary posterior teeth in wax so that central grooves of their occlusal surfaces coincided with the two lines transferred from the prototype maxillary cast (Fig. 2). In the same centric occlusion mandibular posterior teeth were arranged with their buccal cusps occluding to the central fossa of the maxillary posterior teeth (Fig. 3).

Fig. 1.

Guide lines on the maxillary cast

Fig. 2.

Group I prototype denture with teeth on the crest of the ridge

Fig. 3.

Waxed up denture for group I

The prototype denture of Group II was produced by changing the teeth position such that lingual cusps of the maxillary posterior teeth coincided with the guide lines on the maxillary cast (Fig. 4). In the same centric occlusion mandibular posterior teeth were arranged with their buccal cusps occluding to the central fossa of the maxillary posterior teeth (Fig. 5).

Fig. 4.

Group II prototype denture with teeth buccal to the crest of the ridge

Fig. 5.

Waxed up denture for group II

Duplication of the Prototype Denture

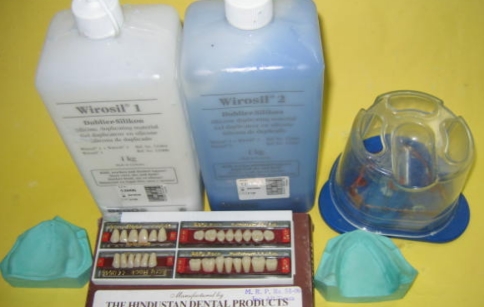

Five identical dentures were produced for each of the two groups by duplicating the prototype denture with silicone duplicating material (Wirosil: Bego, Germany) in duplicating flask (Combi Duplicating Flask; Bego, Germany) (Fig. 6).

Fig. 6.

Silicone duplicating material with duplicating flask and acrylic teeth

Processing of Denture Specimens

The waxed dentures are cured with heat cure denture base material (DPI Mumbai) using standard curing cycles according to manufacturer’s recommendations (Figs. 7, 8).

Fig. 7.

Group I denture specimens

Fig. 8.

Group II denture specimens

Functional Stress Analysis of Denture Specimens

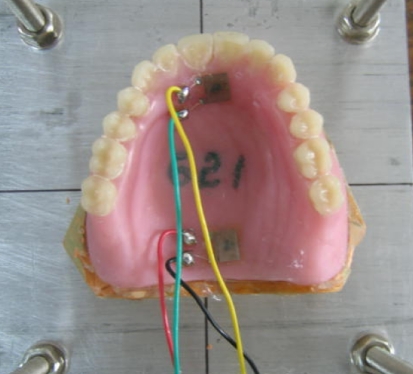

Two strain gauges (foil type 350 Ω; Industrial Engineering Equipments, Bangalore India) were cemented onto each denture specimen with cyanoacrylate cement (EP-160; Industrial Engineering Equipments) (Fig. 9).

Fig. 9.

Maxillary denture with strain gauges

One of the strain gauge was cemented on to the mid-line of the intaglio surface of the denture 6 mm from the contact point of central incisors. The other strain gauge was cemented onto the mid-line of the same surface 4 mm from the posterior border of the denture [4]. Two identical strain gauges were also cemented on an acrylic plate made from the same material with the same procedures as for the complete denture specimens. These gauges were used as references (dummy gauges) in Wheatstone bridge circuit. Each of the denture strain gauge was an active gauge and was connected to each element of the plate strain gauge that formed the dummy gauge of the same half-bridge circuit. This arrangement resulted in 2 pairs of strain gauges connected to a 2-position digital strain-gauge indicator (2-channel strain indicator; Industrial Engineering Equipments, Bangalore India).

Each maxillary and the mandibular denture specimens were mounted on the die stone casts produced by high strength type IV dental stone (Kalrock, die stone class IV, Kalabhai Karson Pvt. Ltd. India). Before the denture specimens were placed on the load casts, their inner surfaces were painted with medium–viscosity silicone (Coltex Medium, Coltene) to simulate the oral mucosa. According to in vivo measurements, the thickness of the masticatory mucosa ranges from 1.92 to 2.38 mm at the maxillary edentulous ridge and from 1.45 to 1.58 mm at the mandibular edentulous ridge [5]. Therefore, to ensure that the thickness of the masticatory mucosa in vivo, 2 and 1.5 mm thickness of die stone were removed from the residual ridges of the maxillary cast and Mandibular cast, respectively, before the placement of painted specimens (Fig. 10).

Fig. 10.

Silicone lined maxillary and mandibular casts

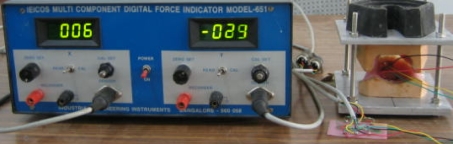

The maxillary and mandibular dentures were positioned in the centric occlusion, and their mounted casts were placed between the plates of a loading instrument (Fig. 11). The dentures were loaded from 0 to 110 N in steps of 10 N. The associated strains were measured at each strain gauge, which were then substituted into the standard equations to calculate the principle stresses at every load level.

Fig. 11.

Digital strain gauge indicator and loading instrument

Modulus of elasticity for heat cure denture base resin (PMMA) is 2350 MPa.

Results

Stresses were calculated at anterior and posterior palate in the midline for each denture specimen in both the groups. A Mann–Whitney U test was used to evaluate the statistical significance of the differences in the stress magnitudes between the two groups. The anterior palatal area of the maxillary denture was dominated by a principal tensile stress, irrespective of the posterior teeth positions and load levels but the tensile stress of the anterior palate was greater in the group II (+6.88 MPa at 110 N load) than in group I (+2.99 MPa at 110 N load). The posterior palatal area was dominated by compressive stresses but the outer placement of the maxillary teeth caused a significant decrease in the compressive stresses in group II.

Discussion

The fracture of complete dentures is an unresolved problem in Removable Prosthodontics despite numerous attempts to determine its causes. Despite the high frequency of denture fracture, there is surprisingly little discussion of the subject in the literature.

Complete maxillary dentures are subjected to significant variation in stress during function intra orally. The stress patterns within maxillary complete denture differs in each patient and depends on many factors like base thickness, material used, muscular power of the test object, nature of the underlying soft tissues, stability of the denture base, form and position of teeth. These stress patterns also influence the flexural fatigue in the denture. Maxillary denture bases deform during functional and para functional activities such as chewing, biting, swallowing and clenching. It deforms in a direction away from the palatal tissues causing internal stresses. Therefore, fatigue stress is a significant factor in fracture.

Detailed photo stress analysis indicated that compressive stresses occurred toward the tissue surface, with greater values beneath the teeth and on the ridge than those toward the palate [6].

Many techniques have been used to examine the stresses and strains in a complete maxillary denture like Brittle coatings, Strain gauges, Photoelastic models, Holography scanning electron microscopy replica technique, and simulations such as finite element analysis.

The use of stain gauges represents a simple and accurate method for measuring stresses developed for plane state of stress or surface stresses. The application of strain gauges in vitro can provide data that are more useful than data from in vivo measurement, as the inadequate sealing of the gauges may produce short circuits that could introduce measurement errors [7, 8].

Sharry [9] proposed in his palatographic study that a thin well-adapted denture base (about 1.5 mm) does not significantly impair speech. However, raising the denture base thickness (to about 2.5 mm) showed marked deficiency in speech clarity and comfort. On the other hand, Farmer [10] stated that denture bases less than 2 mm in thickness were more prone to fracture.

Using this aforementioned information, in the present study it was decided to standardize the denture base thickness for all the denture specimens at 2 mm using a 2 mm thick thermoplastic sheet which was vacuum pressed on the maxillary cast to obtain trial acrylic base of uniform thickness.

Gibbs et al. [11] showed that the average closing force during mastication of complete denture wearers is only 11.7 lb, which is considerably below the weakest closing force of subjects with natural teeth. Prombonas and Vlissidis [12] showed that the force exerted by the edentulous patients at the vertical dimensional of occlusion ranges from 30 to 110 N.

Using this aforementioned information, in the present study it was decided to use an optimum load of 0 to 110 N to analyze the functional stress in the maxillary complete denture. In the present study the stress patterns in the anterior palatal area of all denture specimens were predominantly tensile in nature, irrespective of position of the teeth in relation to the crest of the ridge and load levels. The magnitude of tensile stress increased as the load increased from 0 to 110 N in both the groups. The tensile stress of the anterior palate was greater in the group II with outer placement of maxillary posterior teeth (mean maximum stress of 6.88 Mpa at 110 N) (Table 1) than in group I with teeth on the crest of the ridge (mean maximum stress of 2.99 Mpa at 110 N) (Table 1), and difference was statistically significant (P < 0.05) (Table 3).

Table 1.

Calculated mean stress magnitudes of anterior palatal area for group I and group II

| Load (N) | n | Mean (MPa) | Mean (MPa) |

|---|---|---|---|

| 10 | 5 | +0.2060 | +0.5580 |

| 20 | 5 | +0.6380 | +1.1760 |

| 30 | 5 | +1.1340 | +2.0120 |

| 40 | 5 | +1.4440 | +2.9200 |

| 50 | 5 | +1.7120 | +3.6800 |

| 60 | 5 | +1.9300 | +4.2720 |

| 70 | 5 | +2.1380 | +4.7860 |

| 80 | 5 | +2.3140 | +5.3420 |

| 90 | 5 | +2.5620 | +5.9920 |

| 100 | 5 | +2.7920 | +6.5320 |

| 110 | 5 | +2.9940 | +6.8880 |

Positive values indicates tensile stress

N Newtons; n number of specimens; MPa mega pascal

Table 3.

Shows statistical comparison of stress magnitudes of anterior and posterior palatal area between group I and II

| Load (N) | n | Z1 | P1 | Z2 | P2 |

|---|---|---|---|---|---|

| 10 | 5 | −2.643 | 0.008 hs | −1.576 | 0.115 ns |

| 20 | 5 | −2.611 | 0.009 hs | −1.362 | 0.0173 ns |

| 30 | 5 | −2.611 | 0.009 hs | −2.095 | 0.036 sig |

| 40 | 5 | −2.611 | 0.009 hs | −2.193 | 0.028 sig |

| 50 | 5 | −2.619 | 0.009 hs | −2.402 | 0.016 sig |

| 60 | 5 | −2.619 | 0.009 hs | −2.611 | 0.009 hs |

| 70 | 5 | −2.611 | 0.009 hs | −2.611 | 0.009 hs |

| 80 | 5 | −2.611 | 0.009 hs | −2.611 | 0.009 hs |

| 90 | 5 | −2.619 | 0.009 hs | −2.611 | 0.009 hs |

| 100 | 5 | −2.611 | 0.009 hs | −2.611 | 0.009 hs |

| 110 | 5 | −2.610 | 0.009 hs | −2.610 | 0.009 hs |

Z Mann–Whitney U Test, hs highly significant, sig significant, P probability, ns no significance

The patterns of stresses in the posterior palate in all denture specimens in both the groups were predominantly compressive in nature. The outer placement of the posterior teeth resulted in an unexpected decrease in the compressive stresses in the group II (maximum stress of 2.22 Mpa at 110 N) (Table 2) when compared to group I (maximum stress of 4.00 Mpa at 110 N) (Table 2) and the difference was statistically significant (P < 0.05) (Table 3).

Table 2.

Calculated mean stress magnitudes of posterior palatal area for group I and group II

| Load(n) | n | Mean (MPa) | Mean (MPa) |

|---|---|---|---|

| 10 | 5 | −0.1520 | −0.2360 |

| 20 | 5 | −0.6580 | −0.4640 |

| 30 | 5 | −1.2720 | −0.7300 |

| 40 | 5 | −1.6720 | −0.9200 |

| 50 | 5 | −2.0620 | −1.1000 |

| 60 | 5 | −2.4440 | −1.2700 |

| 70 | 5 | −2.8120 | −1.4840 |

| 80 | 5 | −3.1720 | −1.6520 |

| 90 | 5 | −3.4780 | −1.7680 |

| 100 | 5 | −3.7180 | −1.9680 |

| 110 | 5 | −4.0000 | −2.2260 |

Negative values indicates compressive stress

By reviewing the results of this study, critical questions concerning complete maxillary denture fractures may now be answered. When the posterior teeth are set over the buccal slope of the ridge, there is rotation of the denture base around the crest of the ridge which causes increased tensile stress in the anterior palatal area. The maximum tensile stress in the anterior palatal area was always perpendicular to the mid-line, irrespective of the teeth position or load levels. Because of the brittle nature of denture base materials (PMMA) which are much stronger in compression than in tension the cracks always, begin in anterior palatal area which showed high tensile stresses. In contrast to the anterior palatal area, the pattern of stresses in the posterior palatal area of the complete maxillary denture exhibited a high compressive stress. The compressive nature of the posterior palatal area, as exhibited in this study, may explain why the crack never started from the posterior palatal area. However, in situations in which the crack crossed the posterior palatal area and met a compressive stress lower than the tensile stress that was perpendicular to the mid line, the denture base fractured into two pieces.

By reviewing the results of this study it can be stated that the buccal placement of posterior teeth in relation to crest of the ridge may play a significant role in the fatigue fracture of the complete maxillary denture.

The results of the present study agree with those of Ates et al. [13] who stated that shifting the occlusal contacts to a more buccal localization resulted in an increase of the calculated stresses towards midline (tensile) of the palate in complete maxillary denture. They concluded that the buccal placement of occlusal contacts may play a role in fatigue fracture of the complete maxillary denture.

The results of the present study agree with those of Stafford and Griffiths [14] who used a rosette strain gauge to measure the principal stresses in the posterior palatal area of a complete maxillary denture. They measured principal stresses that ranged from 0.001 to 3.97 MPa.

Conclusions

Within the limitations of this study, the following conclusions were drawn:

The outer placement of the posterior teeth in Group II resulted in increased principal stresses (tensile) of the anterior palatal area and an unexpected decrease of the principal stresses in the posterior palatal area.

The combined pattern of the stress fields in anterior and posterior palatal area may be the main reason that fractures start from the anterior palatal area and may stop or change direction during propagation to the posterior area due to compressive nature of the stresses in this area.

The buccal placement of posterior teeth in relation to crest of the ridge may play a role in the fatigue fracture of the complete maxillary denture.

Conflict of interest

None.

Footnotes

Key Messages The anterior palatal area showed higher tensile stresses than in the posterior palatal area. Therefore any effort to reinforce the maxillary denture should be concentrated on the anterior palatal area. The buccal placement of the posterior teeth resulted in higher stresses in the anterior palate, therefore the placement of the posterior teeth in maxillary complete denture should be as much on the on the crest of the ridge as possible as functionally and esthetically permits.

References

- 1.Prombonas AE, Vlissidis DS. Comparison of the midline stress fields in maxillary and mandibular dentures: a pilot study. J Prosthet Dent. 2006;95:63–70. doi: 10.1016/j.prosdent.2005.11.009. [DOI] [PubMed] [Google Scholar]

- 2.Rees JS, Hugget R, Harrison A. Finite element analysis of the stress concentrating effect of frenal notches in complete dentures. Int J Prosthodont. 1990;3:238–240. [PubMed] [Google Scholar]

- 3.Valittu PK. Fracture surface characteristics of damaged acrylic resin based dentures as analyzed by SEM-replica technique. J Oral Rehabil. 1996;23:524–529. doi: 10.1111/j.1365-2842.1996.tb00890.x. [DOI] [PubMed] [Google Scholar]

- 4.Prombonas AE, Vlissidis DS. Effects of the position of artificial teeth and load levels on stress in the complete maxillary denture. J Prosthet Dent. 2002;88:415–422. doi: 10.1067/mpr.2002.128174. [DOI] [PubMed] [Google Scholar]

- 5.Uchida H, Kobayashi K, Nagao M. Measurement in vivo masticatory thickness with 20 MHz B-mode ultrasonic diagnostic equipment. J Dent Rec. 1989;68:95–100. doi: 10.1177/00220345890680021501. [DOI] [PubMed] [Google Scholar]

- 6.Klotzer VW. Spannungsoptiche Festigkeitsuntersuchungen einiger Prosthesentypen. Dtsch Zahnaertztl Z. 1964;19:375. [Google Scholar]

- 7.Darbar UR, Huggett R, Harrison A. Stress analysis techniques in complete dentures. J Dent. 1994;22:259–264. doi: 10.1016/0300-5712(94)90054-X. [DOI] [PubMed] [Google Scholar]

- 8.el-Ghazali S, Nilner K, Wallenius K. The functional deformation of maxillary complete denture in patients with flabby ridges. Part II after surgery. Swed Dent J. 1991;15:63–70. [PubMed] [Google Scholar]

- 9.Sharry JJ. Complete denture prosthodontics. 3. New York, USA: Blakiston Division, McGraw Hill Inc.; 1974. p. 139. [Google Scholar]

- 10.Farmer JB. Preventive prosthodontics: maxillary dental fracture. J Prosthet Dent. 1983;50(2):172–175. doi: 10.1016/0022-3913(83)90006-9. [DOI] [PubMed] [Google Scholar]

- 11.Gibbs CH, Mahan PE, Lundeen HC. Occlusal forces during chewing-influences of biting strength and food consistency. J Prosthet Dent. 1981;46:561–567. doi: 10.1016/0022-3913(81)90247-X. [DOI] [PubMed] [Google Scholar]

- 12.Prombonas A, Vlissidis D, Molyvdas P. The effect of altering the vertical dimension of occlusion on biting force. J Prosthet Dent. 1994;71:139–143. doi: 10.1016/0022-3913(94)90021-3. [DOI] [PubMed] [Google Scholar]

- 13.Ates M, Cilingir A, Sulun T, Sunbuloglu E, Bozdag E. The effect of occlusal contact localization on the stress distribution in complete maxillary denture. J Oral Rehabil. 2006;33:509–513. doi: 10.1111/j.1365-2842.2006.01603.x. [DOI] [PubMed] [Google Scholar]

- 14.Stafford GD, Griffiths DW. Investigation of the strain produced in maxillary complete denture in fuction. J Oral Rehabil. 1979;6:241–256. doi: 10.1111/j.1365-2842.1979.tb01502.x. [DOI] [PubMed] [Google Scholar]