Abstract

Nanostructures, with their very large surface to volume ratio and their non-planar geometry, present an important challenge to surface scientists. New issues arise as to surface characterization, quantification and interface formation. This review summarizes the current state of the art in the synthesis, composition, surface and interface control of CdSe nanocrystal systems, one of the most studied and useful nanostructures.

Keywords: Cadmium, Selenium, Selenide, CdSe, nanocrystal, quantum dot, nanoparticle, surface, synthesis, electron microscopy, Z-STEM, RBS, alloy, core/shell, fluorescence, quantum yield, growth mechanism, expitaxy, spectroscopy

1.0 Introduction

1.1 Background

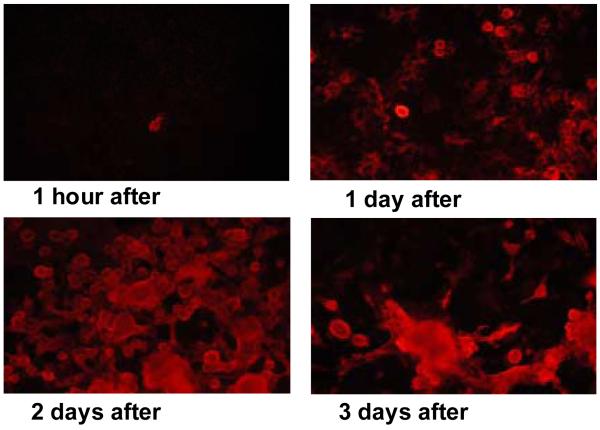

We are currently witnessing an explosion of research in nanoscale science, engineering, and biotechnology. As the nano-revolution proceeds, basic research is leading to the development of true nanotechnologies which have the potential to impact fields from health care and opto-electronics to energy and the environment. One particular type of nanostructure, semiconductor nanocrystals (also known as quantum dots), may ultimately be employed in technologies in each of these fields. For example, antibody-conjugated CdSe/ZnS core-shell nanocrystals have been used to detect respiratory syncytial virus.1 The high brightness of the quantum dots enables the virus to be detected in a matter of minutes, whereas the previous assay required 4 days. The ramification of this new technology is that anti-viral drugs can be given early in the infection when they are most effective, reducing hospitalizations and deaths. In the field of opto-electronics CdSe nanocrystals have been incorporated in light emitting diodes2-6 and it has been demonstrated that they can serve as the gain media in a laser.7, 8 Nanocrystals are also poised to play a role in solar energy conversion.9-14 A specific example is a device in which elongated CdSe nanocrystals (nanorods) are mixed with a conducting polymer and sandwiched between aluminum and indium tin oxide electrodes to create a device with a power conversion efficiency of 1.7 %.12 Nanocrystals may also have a positive impact on the environment, as it has been shown that they can be used to sequester CO2.15

The spark that ignited two decades of intense research in nanocrystal synthesis, properties, and applications was Louis Brus’ demonstration that quantum confinement of the photocreated electron-hole pair leads to the observed size dependent optical properties of CdSe nanocrystals.16, 17 While there have been studies on II-VI, III-V, and IV-VI nanocrystals, as well as metal oxide nanocrystals and others, CdSe remains the most thoroughly studied nanocrystal system. An early breakthrough came in 1993 when Murray, Norris and Bawendi developed the synthesis of CdS, CdSe, and CdTe nanocrystals by the high temperature pyrolysis of organometallic precursors.18 This afforded precise control of nanocrystal size and subsequent assignment of the electronic structure both experimentally and theoretically.19-23 Improvements in the synthesis followed which yielded monodisperse samples and eliminated the need for size selected separation for most applications.24 Near field scanning optical microscopy studies have determined the intrinsic nanocrystal linewidth and explained the phenomenon of single nanocrystal luminescence blinking.25 Structural studies have examined the hysterisis in the phase transition of wurtzite CdSe to rock salt CdSe nanocrystals.26 The ultrafast electronic dephasing,27 intraband transitions,28 and carrier dynamics29-33 have been determined by femtosecond spectroscopy. The molecular symmetry of CdSe nanocrystals have been determined and related to their Raman spectrum. Electron transport in thin films of CdSe nanocrystals has been studied.34 Numerous other studies have characterized the properties and explored the applications of CdSe nanocrystals. For further review see Alivisatos in the Journal of Physical Chemistry (1996) and others.35-38

1.2 Motivation

Nanocrystals present a quintessential problem for surface and interface science. Given that a nanocrystal is virtually all surface; its properties vary considerably as the crystal grows in size. By precisely controlling a nanocrystal’s size and surface its properties can be engineered. The most studied nanocrystal system and the focus of this report is CdSe. CdSe nanocrystals vary in size from ~1-11 nm and contain ten to ten thousand atoms. Through quantum confinement of the photocreated electron hole pair, the optical properties of the nanocrystal can be tuned by size.16 For example, a 1.2 nm nanocrystal will have 88% of its atoms on the surface and absorb light at 420 nm while an 8.5 nm nanocrystals consists of 20% surface atoms and absorbs light at 650 nm. Further, nanocrystals are chemically synthesized in an organic surfactant that not only passivates the surface, but also can control the growth rate of the nanocrystal, its size and shape.39 The surfactant/nanocrystal interface also controls the ultrafast carrier dynamics in the nanocrystal and the fluorescence quantum yield.29, 32, 40 Alternatively, the surface of the CdSe nanocrystal can be passivated with a second inorganic material, such as CdS, ZnS, or ZnSe to create a core-shell nanocrystal. When wrapped in a wider band gap material, the electron-hole pair is further confined and surface states are eliminated. If the interface between the two inorganics is perfect, a near unity quantum yield material may result.41 Here again characterization of the interface is crucial in order to engineer a quantum dot with desired properties.

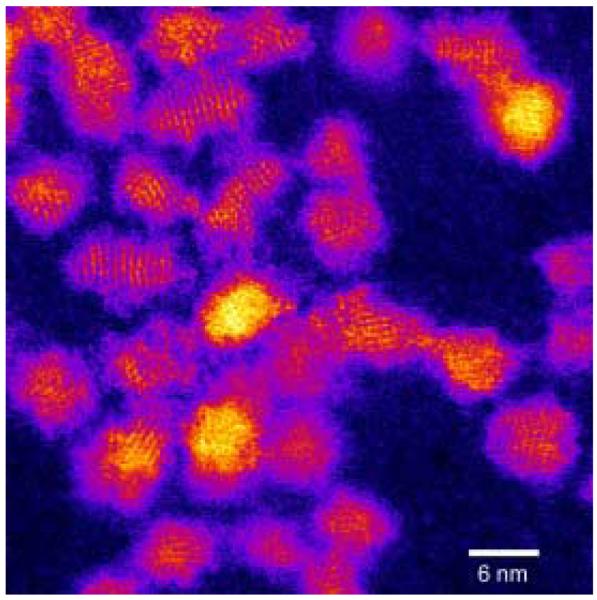

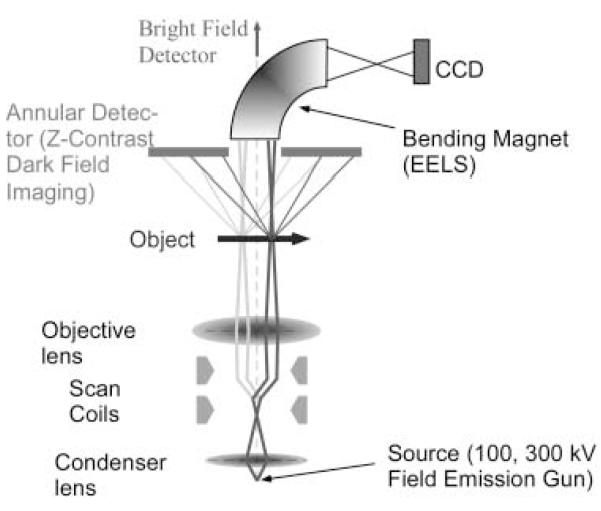

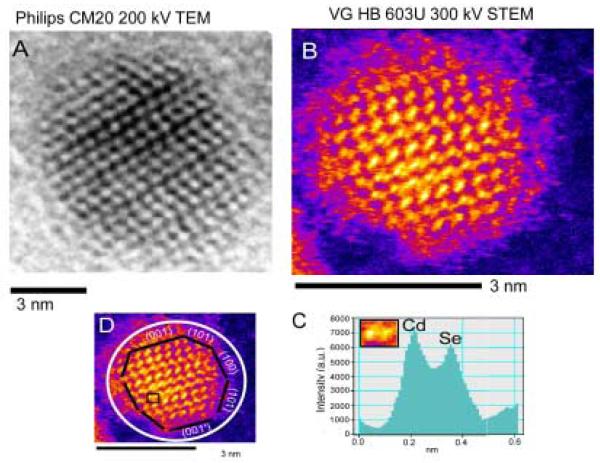

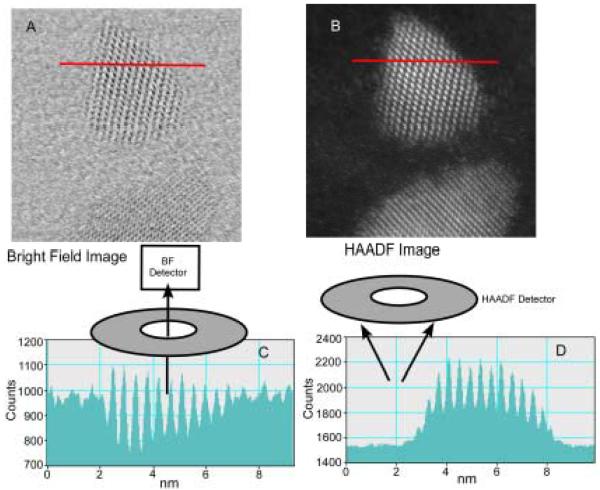

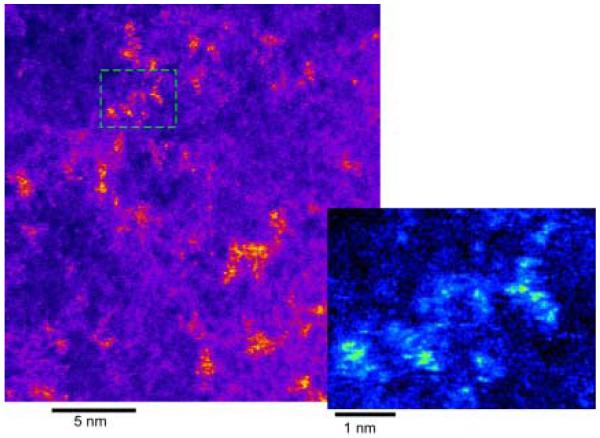

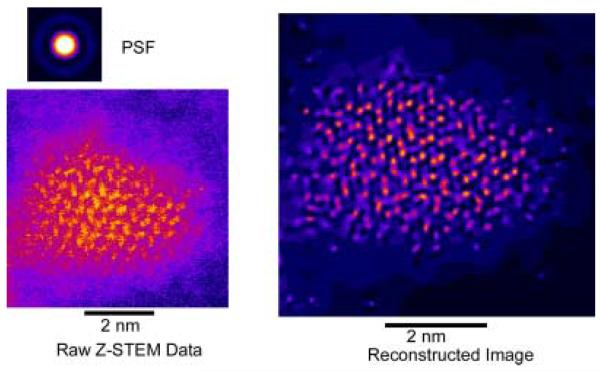

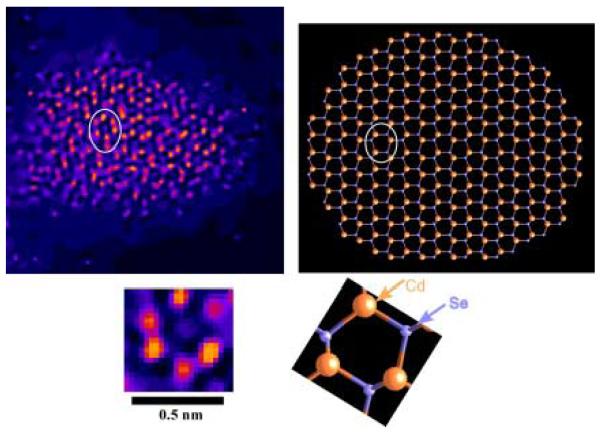

Given their large surface to volume ratio and their non-planar geometry, nanocrystals present an important challenge to surface scientists. We have pioneered the application of two techniques that together are uniquely suited to study nanocrystals, nanocrystal surfaces and interfaces. These techniques are Rutherford backscattering spectroscopy (RBS) and atomic number-contrast scanning transmission electron microscopy (Z-STEM). RBS is a well known tool in surface science while Z-STEM has yielded unprecedented structural detail of solids, defects, and interfaces.42-46 When combined these techniques give information on nanocrystal composition, surface composition, surface ligand coverage, and nanocrystal structure, including interior, interfaces, and surfaces.

1.3 Objectives

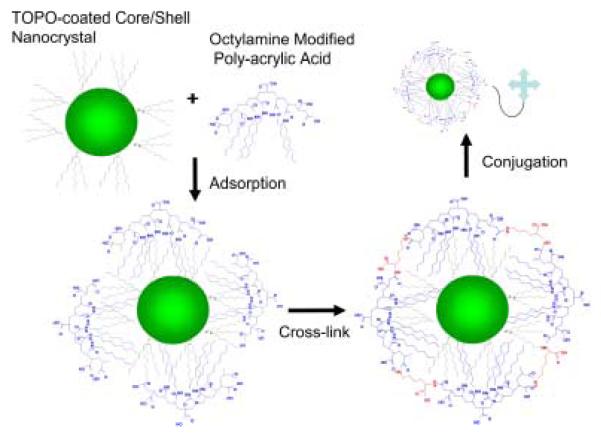

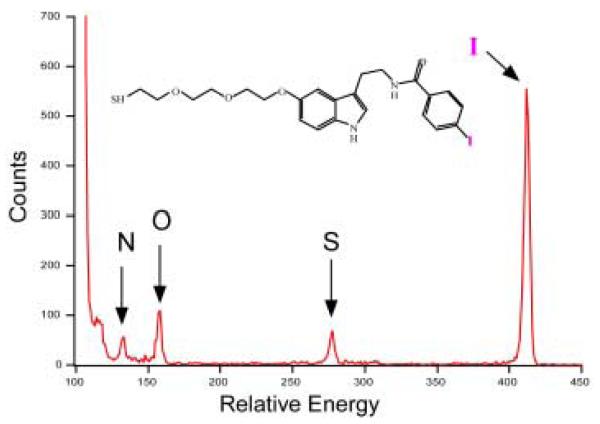

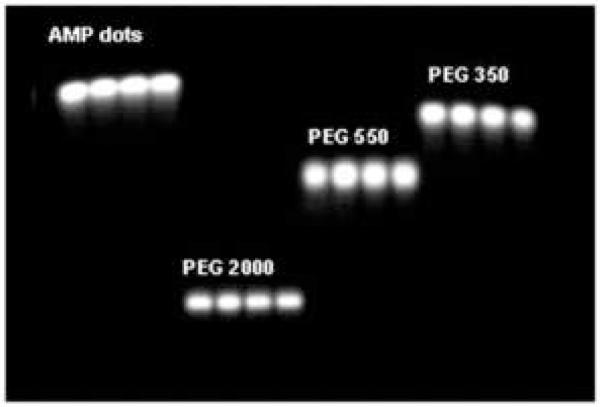

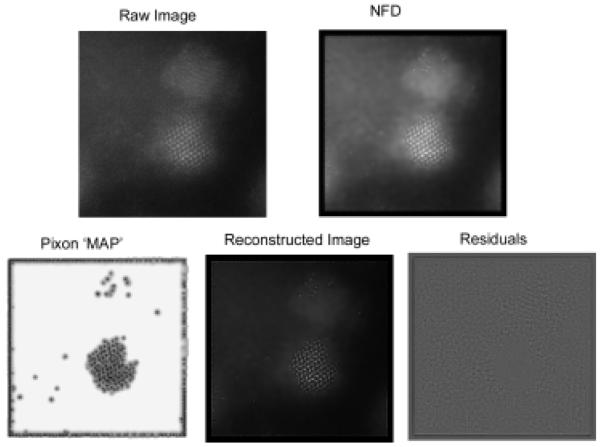

There are several objectives for this report. In Section 2, Preparation of CdSe Nanocrystals and CdSe/ZnS Core/Shell Nanocrystals, the goal is to familiarize the reader with the various methods used to create CdSe nanocrystal structures and illustrate how the synthesis determines surface termination and nanocrystal shape. Section 3, Review of Surface Studies of CdSe Nanocrystals, provides a review of the literature concerning how CdSe surfaces have been previously characterized. In Section 4, Rutherford Backscattering Spectroscopy of CdSe and CdSe/ZnS Nanocrystals, we introduce the reader to RBS and illustrate how RBS can be used to explore the surface composition and coverage of surface passivating ligands. Section 5, Atomic Number-contrast Scanning Transmission Electron Microscopy (Z-STEM) of CdSe and CdSe/ZnS nanocrystals, introduces the reader to Z-STEM, illustrates how Z-STEM can be used for nanocrystal characterization for CdSe and CdSe/ZnS nanocrystals, and shows how Z-STEM allows the analysis of surface structure and even composition. Finally, in Section 6, Engineering a Biologically Active Nanocrystal, we focus on the biological applications of core/shell nanocrystals, the role the surface plays in determining biological activity, and how the surface can be characterized when engineering a biologically active nanocrystal.

2. Preparation of CdSe Nanocrystals and CdSe/ZnS Core/Shell Nanocrystals

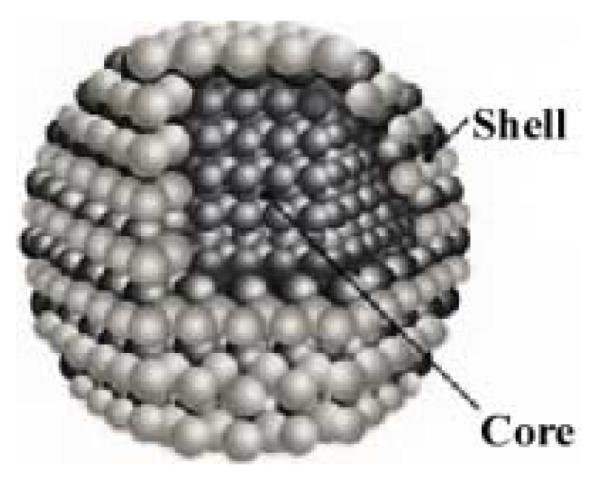

The synthesis of CdSe nanocrystals has now been nearly perfected. Growing flawless nanocrystals is relatively easy because their length scale is so small there is simply not enough time during the growth process to introduce defects. This same tiny length scale, however, makes controlling the size and surface of nanocrystals a tremendous challenge. With current methods it is now possible to synthesize gram quantities of nanocrystals with exquisite control of size (± 2 Å). The procedures for fabricating nanocrystals have evolved over the past 25 years. Originally the synthesis of nanoparticles relied on salts as precursors and micellular methods to attempt to control size.47-49 These methods yielded poor samples as indicated by a lack of sharp absorption features. The emission spectra lacked any band-edge emission feature and consisted of a broad, intense, red-shifted “deep trap” emission originating from radiative recombination at defect sites and surface sites. A quantum leap in the quality and size control of CdSe nanocrystals came from Murray et al. with the development of high temperature pyrolysis of organometallic precursors in the surfactant trioctylphosphine oxide (TOPO).18 These methods are discussed below in Section 2.1.1. One of the reagents in these methods, dimethylcadmium ((CH3)2Cd), is air sensitive, pyrophoric and toxic. As a result, “greener” methodologies were explored and a methodology replacing dimethylcadmium with cadmium oxide (CdO) was developed.50 As an alternative to CdO, cadmium acetate Cd(CH3CO2)2 is also used.51, 52 These greener methods are discussed in section 2.2. Well made CdSe nanocrystals have very low quantum yields. For many applications, such as light emitting diodes and fluorescent labels in biology, bright nanocrystals are a highly desired commodity. Hines and Guyot-Sionnest were the first to synthesize core/shell nanocrystals: a CdSe nanocrystal wrapped in a ZnS shell (Figure 1). The ZnS shell passivates surface states eliminating traps and is a wider band-gap material further confining the electron-hole pair and resulting in efficient radiative recombination. Core/shell synthesis will be discussed in Section 2.3. Finally, Alivisatos and coworkers discovered how to make nanocrystals with different shapes: rods, tear drops, arrow heads, and tetrapods.39 These synthetic methods and a discussion of the role of individual surfaces in determining the shape of the crystal are discussed below in Section 2.4

Figure 1. Schematic of core and core/shell nanocrystal.

The core nanocrystal is coated with a wider band gap semiconductor to passivate the core surface in order to increase radiative recombination processes. Any uncoated surface could provide possible trap sites that result in non radiative recombination and a reduction in fluorescence quantum yield.

2.1 Pyrolysis of Organometallic Precursors

The first method to prepare highly monodisperse CdSe nanocrystals was presented by Murray, Norris, and Bawendi in 1993.18 (Section 2.1.1, the East Coast Method) The synthesis is based on the pyrolysis of organometallic reagents by injection into a hot coordinating solvent. The key to monodispersity is the separation of the nucleation and growth steps. The synthesis begins with the rapid injection of organometallic reagents into a hot coordinating solvent to produce a temporally discrete homogeneous nucleation. Slow growth and annealing in the coordinating solvent results in uniform surface derivatization and regularity in the core structure. Size selective precipitation provides powders of nearly monodisperse nanocrystals which can be dispersed in a variety of solvents. Improvements to this synthesis were made on the West Coast in the Alivisatos group which led to an improvement in the size distribution of the crystals.24 Another improvement came in 1998 when it was discovered that adding additional reagents as the synthesis progressed helped to “focus the size distribution” and enabled larger, more monodisperse CdSe nanocrystals to be grown (Section 2.1.3).53 Finally, the peculiarities of the coordinating solvent, trioctylphosphine oxide (TOPO) and its effect on the synthetic methodology are discussed in Section 2.1.4

2.1.1 The East Coast Method: TOP/TOPO

A typical experimental set up for nanocrystal synthesis is displayed in Figure 2. The solvent in this reaction is TOPO which is placed in the reaction vessel and heated to 300 °C. The TOPO is purchased from Alfa and usually purified by distillation prior to use. The cadmium precursor is dimethylcadmium, (CH3)2Cd, which is handled with standard airless techniques. The dimethyl cadmium is mixed with trioctylphosphine (TOP) as is selenium shot. These two solutions are combined and loaded into a syringe. The heat is removed from the reaction vessel and the reagent:TOP mixture is rapidly injected into the hot TOPO undergoing rapid stirring. Both organometallic reagents thermally degrade to reactive species in the hot solvent. The injection of the room temperature reagent solution causes a sudden decrease in temperature to 180 °C. Heating is resumed and the temperature is gradually raised to 230-260 °C. Aliquots of the reaction solution are removed from the reaction vessel at intervals of 5-10 minutes and absorption spectra are recorded to monitor the growth of the nanocrystals. The best quality samples are prepared over a period of a few hours in response to changes in the size distribution as determined by the width in the absorption features. The growth temperature is lowered in response to a spreading of the size distribution and increased when the growth stops. The nanocrystals are isolated by the addition of methanol which results in the flocculation of the nanocrystals. The flocculent is then separated from the supernatant by centrifugation, dispersed in 1-butanol and further centrifuged again to yield a solution of nanocrystals and a precipitate containing by products. Addition of methanol to the clear solution once again produces a flocculent which when rinsed in methanol and vacuum dried yields 300 mg of TOP/TOPO capped nanocrystals for 13.35 mmol of Cd.18 The characterization of the surface coverage will be discussed in Section 3. The fact that the surface is covered in an organic molecule means that the nanocrystals can be dispersed in organic solvents. As produced TOP/TOPO nanocrystals can be dissolved in non-polar solvents. Ligand exchange reactions can be performed to put polar groups on the surface of the nanocrystals and enable their dispersion in polar solvents.54, 55 As will be discussed in Section 6 surface modification with polar organic molecules is critical for nanocrystal applications in biological systems which are always in aqueous buffer solutions.

Figure 2. Typical experimental set up for the synthesis of nanocrystals.

A three neck flask is placed in a heating mantle and fitted with a thermocouple, a condenser, and a septum by which reagents are injected from a syringe. Argon or nitrogen can be purged from the top bump trap, through the three neck flask and out a needle placed through the septum.

2.1.2 The West Coast method: TBP/TOPO

In 1994, a year after the report of Murray et al. describing a powerful new method for synthesizing crystalline, monodisperse, size tunable CdSe nanocrystals, Bowen-Katari, Colvin and Alivisatos reported an improvement in the procedure which eliminated the need for size-selected precipitation, which is a time consuming, wasteful, and tedious procedure.24 The principal difference is the temperature of the injection, which affects the time evolution of the nanocrystal growth as well as the crystallinity and shape of the nanocrystals. A second difference is the use of tributylphosphine (TBP) to coordinate to Se instead of the use of TOP. The use of TBP instead of TOP results in a low coverage of Se surface atoms, as TBP is more labile at 350 °C. In this preparation, 99% TOPO and TBP were used as received from Aldrich. Se (60 mesh powder) was dissolved in TBP and followed by the addition of dimethylcadmium. The solution is then diluted 4:1 with TBP and the reaction vessel TOPO was heated to ~350 °C. It is found that differences in temperature of less than 1 °C can change both the average size and the quality of the size distribution. When the temperature had stabilized, the reagent solution was rapidly injected. The solution was removed from heat and allowed to cool under argon, which prevents any oxidation of the nanocrystal surface. To recover nanocrystals from the solid, room temperature TOPO mixture, methanol was added to dissolve the TOPO and precipitate the nanocrystals which were then recovered by filtration. To make nanocrystals with an absorption maximum larger than 580 nm, the reaction was cooled from 350 °C to 320 °C and the nanocrystals were allowed to grow (here again the size was monitored by drawing aliquots from solution and monitoring the absorption spectra). Using this growth method the initial tight control of size distribution was lost. This can be overcome by the addition of additional reagent solution to “focus” the size distribution, which is discussed below in section 2.1.3.

2.1.3 Size-Focusing

In 1998 Peng, Wickham and Alivisatos published a kinetic study of nanocrystal growth and demonstrated how the nanocrystal size can be “focused” through the addition of monomer reagents (the initial reagent solution) during the course of the reaction.53 The strategy was designed to overcome Ostwald ripening, or “defocusing” of the size distribution. Ostwald ripening occurs when smaller nanocrystals in the distribution dissolve and become smaller and the monomers released allow the larger nanocrystals in the solution to grow further, subsequently broadening the size distribution.

The “focusing” argument is as follows: at a given concentration of monomer in the reaction solution and assuming diffusion is the rate limiting step for growth, the size dependent growth rate can be obtained by considering the Gibbs-Thompson equation:56

| (2.1) |

Sr and Sb are the solubility of the nanocrystal and the corresponding bulk solid, σ is the specific surface energy, r is the radius of the nanocrystal, Vm is the molar volume of the materials, R is the gas constant and T is the temperature. If 2σVm/rRT << 1 then the diffusion controlled rate of growth of the nanocrystal of a size r is:

| (2.2) |

In the above equation K is a constant proportional to the diffusion constant of the monomer. δ is the thickness of the diffusion layer. At a fixed concentration, r* is the critical radius for which the solubility of the nanocrystal is exactly equal to the concentration of monomer reagent in solution (zero growth rate). At any monomer concentration there is a critical size which is at equilibrium. Nanocrystals smaller than r* dissolve while larger nanocrystals grow at rates strongly dependent on size. When the nanocrystals in solution are slightly larger than the critical radius the size distribution “focuses”. For these conditions, small nanocrystals grow faster than large ones. When the monomer reagent is used up the critical size becomes larger than the average size and Ostwald ripening occurs. The nanocrystal size distribution can be partially recovered by adding more monomer at this time. By varying the initial monomer concentration the focusing time as well as the focused size varies. Focusing times and sizes are determined by experiment. Peng, Wickham and Alivisatos note that in an actual experiment the concentration of the monomer changes continuously so that r* and the relative growth rates of the various sizes are also changing. Peng et al. suggest the optimum way to synthesize narrow size distributions for all desired sizes is to continuously monitor and adjust the monomer reagent concentrations. To our knowledge automation of this procedure has not yet been implemented. Nevertheless, this size focusing methodology provides highly monodisperse size distributions even at larger nanocrystal sizes, which were previously problematic.

2.1.4 The TOPO Story

The choice of trioctylphosphine oxide (TOPO) as the coordinating solvent allows the reaction to take place above the nucleation temperature (since TOPO has a high boiling point) and, as we will discuss extensively below, passivates the surface of the nanocrystal such that nanocrystals do not agglomerate. Further, the TOPO on the surface allows the nanocrystals to be soluble in organic solvents or dispersed in a polymer film. Clearly, Murray’s choice of TOPO was one key to revolutionizing the synthesis. However, it was discovered early on that there were peculiarities in the TOPO. As an example 90 % TOPO (technical grade) from Aldrich produced nanocrystals with sharp absorption features whereas 99 % TOPO yielded nanocrystals with a broad absorption onset and no sharp features. It became apparent that there was an impurity in the TOPO that was affecting the synthesis in a positive way. Peng et al. first postulated that the important impurity was a phosphonic acid.39 The impurity was also variable, leading to fluctuations in the synthesis from one batch of TOPO to the next. This ultimately triggered an evolution in the synthetic methodology used in our laboratory.57 When we found a batch of TOPO that yielded high quality nanocrystals we would buy the entire lot number (several kilos of TOPO). This strategy ultimately failed when all the current batches of TOPO from all suppliers failed to yield high quality nanocrystals. At this point we continued using technical grade TOPO, but added co-solvents that improved yield and quality of the nanocrystals synthesized.58 The first co-solvent was dodecylphosphonic acid (DPA) which supplements the unknown impurity and slows the nucleation process so that the size distribution is not as distorted as the system rapidly cools to the growth temperature. Using DPA helps not only with the quality of the nanocrystals produced but also with the quantity. Large batches of nanocrystals with a narrow dispersity are produced since larger volumes of reagents can be nucleated while maintaining a sharp UV-Vis absorption spectrum.

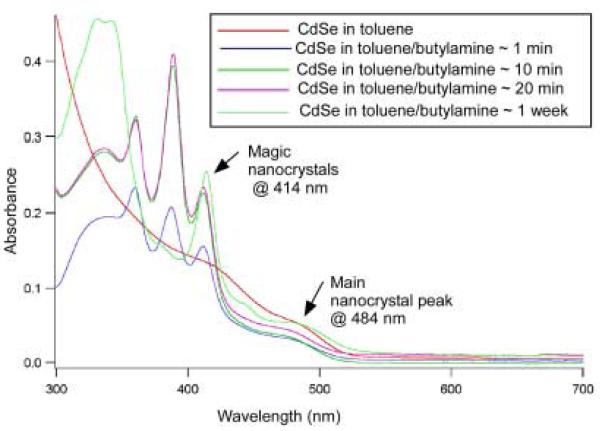

The second co-solvent, hexadecylamine (HDA), provides resistance to Ostwald ripening.59, 60 Nanocrystals grown in TOPO/DPA/HDA maintain a narrow dispersity for many hours (~7 hr) at growth temperatures. The use of only TOPO and DPA yields major broadening of the band edge absorption, and hence a large polydispersity, in less than an hour. The surface-bound HDA must provide a lower overall energy for the nanocrystal than does a larger surface face. Equivalently, if the larger surface face were more stable than a smaller face with HDA, then Ostwald ripening would be observed. The mechanism of Ostwald ripening is noticeably inhibited, since the band edge absorption does not broaden even for extended periods at the growth temperature (Figure 3).61

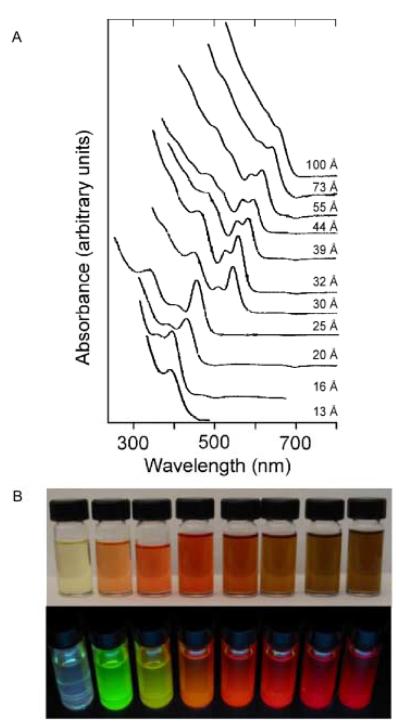

Figure 3. Series of CdSe nanocrystals synthesized in TOPO/HDA/DPA.

The typical CdSe absorption spectrum exhibits a sharp absorption onset followed by multiple electronic states that are visible in the spectra, as shown in Figure 3A. The absorption continuum allows for several sizes of nanocrystals to be optically excited by a single wavelength. Figure 3B is an image of a representative sample of CdSe cores under room lights (TOP) and under UV illumination (BOTTOM).62

It is further observed that a balance between TOPO and HDA is required. Truly unique is the almost complete separation of the activity of both co-solvents, considering that not only is a single reaction being modified, but a single reagent is being targeted. This would seem to lend support to the supposition that the DPA truly influences the cadmium precursor, while the HDA affects the cadmium once incorporated onto the nanocrystal surface. Comparison of TBP:TOPO and TOPO/DPA/HDA nanocrystals by Z-STEM (Atomic Number Contrast Scannin g Transmission Electron Microscopy) is presented below in Section 5.

2.2 “Greener” Methods for CdSe Nanocrystal Synthesis

The cadmium precursor for all of the synthesis described above is dimethylcadmium, (CH3)2Cd. This reagent is pyrophoric and therefore requires standard airless techniques (Schlenk lines and glove boxes). This is fine for a research setting, but difficult for the standard undergraduate laboratory, where fabrication and characterization of CdSe nanocrystals provides a beautiful, “real world” application of the quantum mechanical concept of the particle in a box.62 Further, (CH3)2Cd is expensive and is toxic. Many initially believe dimethylcadmium to have a similar toxicity (LD50 or Lethal Dose, 50%) to dimethylmercury, which in at least one instance has caused a laboratory fatality. Fortunately, for two reasons, dimethylcadmium is actually much less toxic. First, cadmium is bound by the scavenging enzyme, metallothionein. The bound cadmium is then stored in the liver until cell death, then is transported to the kidney for the life of the individual. This explains the low time weighted average (TWA) for cadmium compounds in the MSDS. Even though (CH3)2Cd may cross the blood brain barrier it is bioactive; therefore the mechanisms already in place within the body for dealing with heavy metals are effective. This is unlike alkyl mercury compounds, which have no removal mechanism and do damage in the brain. As with any heavy metal there will be illness and possible morbidity from a large acute dose. Concentrations over 200 μg per kg body mass lead to toxic effects. At these concentrations, cadmium begins to replace copper and zinc in various metallozymes rendering them inactive (e.g. cytochrome P60 and DNA binding proteins). The second reason was an oversight in early testing which over predicted cadmium toxicity. In testing cadmium as an alternative for the anticorrosive tin in “tin cans”, cadmium was found to have a very low LD50. Later work, however, showed the chicken embryos used for testing overproduced metallothionein, which lead to a copper deficiency and fetal death. So although dimethylcadmium is not as toxic as dimethylmercury, it is advisable to use a handling program in accordance with exposure, as should be practiced when handling any heavy metal (e.g. meticulous glove use and require yearly screenings for heavy users). Finally, an inhalation hazard exists. The fine CdO particles from the rapid degradation of Cd(CH3)2 in air in large doses can cause respiratory distress or failure as any fine particulate. Inhalation symptoms usually appear within 1-8 hours of exposure.62

Of course developing new synthetic methodologies which employ a different precursor can eliminate the fire hazard (Cd(CH3)2 is pyrophoric) and some of the health hazard. In large part, the nanocrystal community has headed in this direction. A seminal paper in this regard is from Peng & Peng who put forward a synthetic methodology which uses CdO as the cadmium precursor.50 In this one pot approach, CdO, TOPO and either hexylphosphonic acid (HPA) or tetradecylphosphonic acid (TDPA) were loaded into a three neck flask. At temperatures above 270 °C, the phosphonic acid complexes with the CdO forming a clear and colorless solution. After the formation of the colorless cadmium phosphonate complex, TBP:Se was then injected which initiates the formation of nanocrystals. The authors found that not only can high quality CdSe nanocrystals be produced by this method but when the Se was replaced by Te or S high quality CdTe and CdS nanocrystals can also be produced. Peng et al. postulate that CdO works well as a precursor due to its low stability relative to the phosphonates in comparison to other precursor candidates such as CdCl2.63

CdO is not the only alternative to dimethylcadmium being employed in nanocrystal synthesis. Weller and co-workers developed a synthetic methodology using cadmium acetate Cd(CH3CO2)2 as the precursor.51 In this method a stock selenium solution of TOP:Se is added to a mixture of TOPO:HDA:TDPA at 120°C This is then heated to 300°C to which a stock solution of cadmium acetate in TOP is rapidly injected. Both the cadmium and selenium stock solutions are stored inside a glove box under nitrogen atmosphere. While some air free techniques are still required, these “greener” methods are certainly more favorable for classroom and large scale industrial settings. Indeed, a recent method for synthesizing CdS and CdSe is so “green” it uses vegetable oil (oleic acid) to complex Cd from CdO.64 In this method, TOPO is replaced with the noncoordinating solvent octadecene.

2.3 Core/Shell Nanocrystals

The methodologies described above indicate that CdSe nanocrystals can be prepared that are nearly monodisperse, can be grown to a desired size over a large range, have good crystallinity and desired surface properties. For several applications though, it is desired that the nanocrystals have a high luminescence quantum yield. For the CdSe nanocrystal methodologies described above the quantum yields range between 1-15 %. Indeed, well made large CdSe nanocrystals register no fluorescence. The simplest explanation of this is because of the rapid trapping of carriers to surface sites.29

In 1996 Hines and Guyot-Sionnest made the important discovery that the luminescence from CdSe nanocrystals can be substantially improved by growing heteroepitaxally an inorganic shell of a wide band gap semiconductor, in this case ZnS, around the nanocrystal.65 This work opened the path that led directly to two key publications in Science exploiting the properties of CdSe/ZnS nanocrystals for biological application and initiated that field.55, 66 This will be discussed further in Section 6. Other groups soon followed in developing methods for the synthesis of core/shell nanocrystals.52, 60, 67-72 Indeed, it is now possible to synthesize nearly unity quantum yield materials.41 In this report we will show how a synergistic combination of synthesis, RBS, and Z-STEM has led to these materials. In this section we review a few of the different methods for fabricating core/shell nanocrystals.

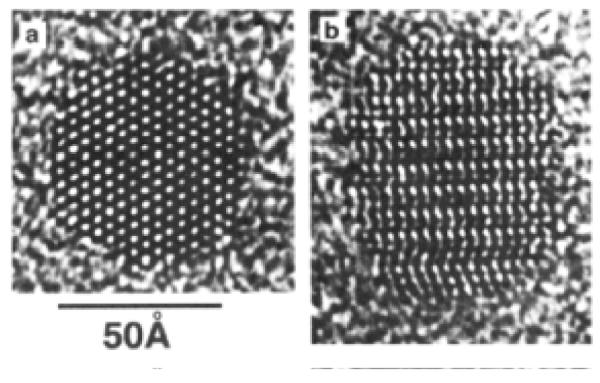

The first method for fabrication ZnS –capped CdSe nanocrystals presented by Hines and Guyot-Sionnest used all organometallic reagents and was a one pot synthesis. Initially CdSe nanocrystals were made by the addition of a TOP:Se and Cd solution to 350 °C TOPO. The reaction mixture was allowed to cool and when it reached 300 °C the Zn/S/TOP reagent solution was added. The Zn/S/TOP stock solution was prepared using (TMS)2S (bis(trimethylsilyl)sulfide) and (CH3)2Cd as the cadmium and sulfur precursors. The Zn/S/TOP reagent solution was injected in five half milliliter proportions at intervals of 20 seconds. The Zn/S/TOP solution was added at lower temperature and in steps in order to avoid nucleation of ZnS nanocrystals. The mole ratio of injected reagents was 1:4 CdSe:ZnS. The reaction mixture was cooled to 100 °C and stirred for 1 hour. The nanocrystals were purified by precipitation with anhydrous methanol, collected by centrifugation and washed three times with anhydrous methanol. Transmission electron microscopy (TEM) and X-Ray photoelectron spectroscopy (XPS) studies indicated that this method produces CdSe/ZnS nanocrystals. The fluorescent quantum yield of these particles was 50% and the broad surface-trapping emission feature was eliminated from the fluorescence spectrum. Fluorescence lifetime measurements determined by the phase method showed a four component lifetime as follows: 8.5%, 160 ns, 53%, 26 ns 37%, 12 ns, and 1.5% 1.5 ns. Hines and Guyot-Sionnest used TEM to characterize the particles. We will see below in Section 5 how Z-STEM can reveal additional information on core/shell structures and how that relates to the fluorescence quantum yield of the material.

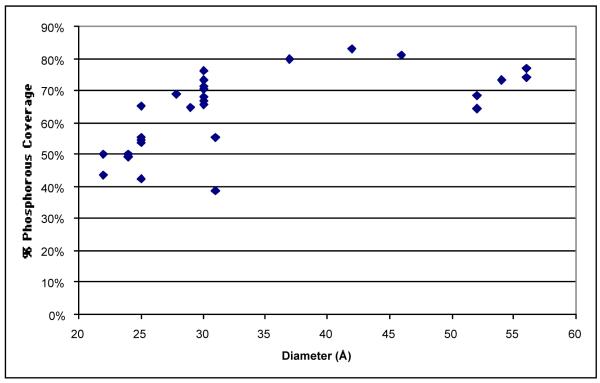

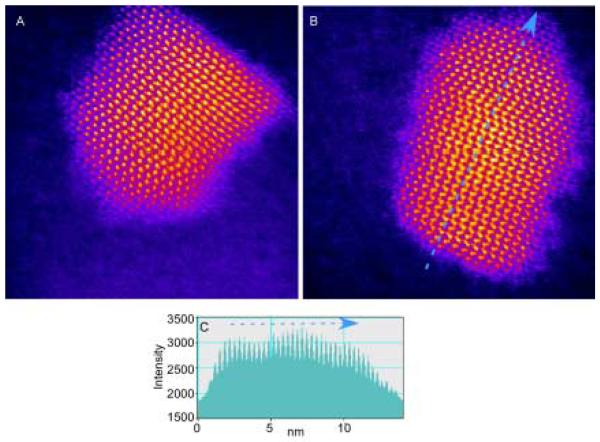

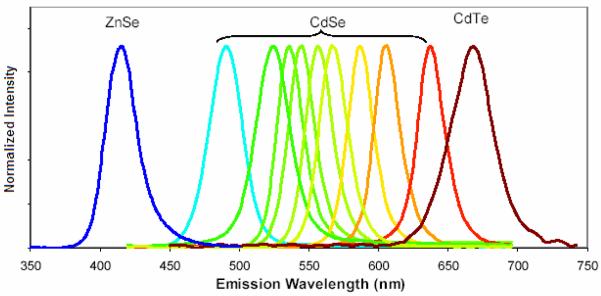

Shortly following the paper of Hines and Guyot-Sionnest, Dabbousi et al. presented their work on the synthesis and characterization of a series of CdSe/ZnS core/shell nanocrystals in which the core size varied from 23 to 55 Å.67 The quantum yields of their materials ranged from 30-50%. The wide spectral range of the emission in these materials is shown below in Figure 4. The synthetic methodology of Dabbousi et al. was a two-pot synthesis.67 The CdSe nanocrystals were first synthesized by the East Coast TOP/TOPO method as described above in Section 2.1.1.18 These nanocrystals were isolated as powders and then redispersed in hexanes. These dots were added to a TOP/TOPO solution at 60 °C via syringe and the hexane solvent was evaporated. The Zn and S precursors were diethylzinc (ZnEt2) and (TMS)2S, respectively. The amount of precursors needed to grow a shell of desired thickness was calculated based on the ratio of the shell volume to the core assuming a spherical CdSe nanocrystal. Equimolar amounts of the Zn and S precursors were dissolved in TOP inside a glove box, loaded into a syringe, and transferred to an addition funnel attached to the reaction flask. The reaction flask containing the CdSe nanocrystals, TOP, and TOPO was heated and the Zn and S precursors were added dropwise to a vigorously stirring reaction mixture over a period of 5-10 min. The temperature of the addition varied depending on the size of the core CdSe. For 23 Å cores the reaction mixture was held at 140 °C whereas for 55 Å cores the reaction mixture was heated to 220 °C. After addition, the mixture was cooled to 90 °C and continued stirring for several hours. Butanol was added to keep the TOPO from solidifying. The ZnS coated CdSe particles were stored in TOPO to ensure surface passivation. They were recovered as powders by precipitation in methanol. Dabbousi et al. characterized their core/shells by wavelength dispersive X-ray spectroscopy (WDS), XPS, TEM, small-angle X-ray scattering (SAXS) and wide-angle X-ray scattering (WAXS) as well as standard optical characterization by absorbance and fluorescence.67 TEM, SAXS, and WDS demonstrated an increase in the size of the core/shells with increasing Zn:Cd ratios as well as an increase in the size distribution and aspect ratio. WAXS probed the internal structure and indicates that at very high coverage the ZnS shell retains its bulk lattice parameter. At low coverage the ZnS shell appears to be epitaxial but Dabbousi et al. concluded that at high coverage the shell is partially epitaxial but probably contains defects to accommodate the 12% lattice mismatch between ZnS and CdSe.67

Figure 4. Series of highly fluorescent CdSe/ZnS core/shell nanocrystals (Bawendi).

The emission can be tuned from blue through red depending upon the size of the core CdSe nanocrystal.

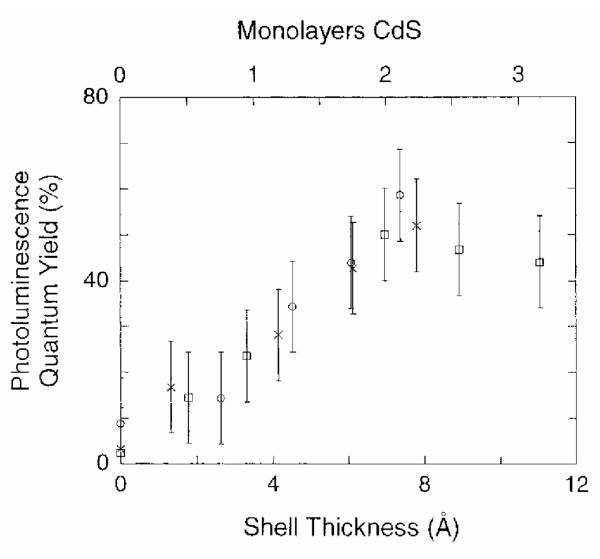

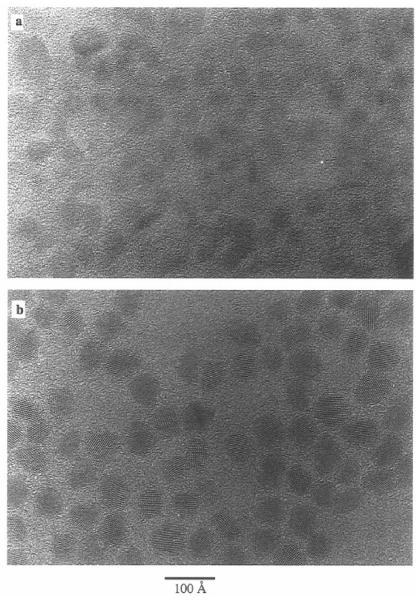

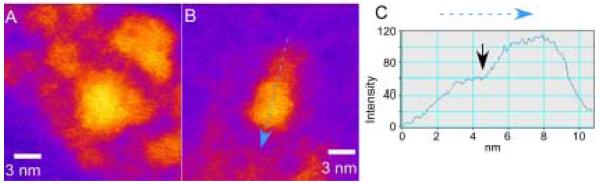

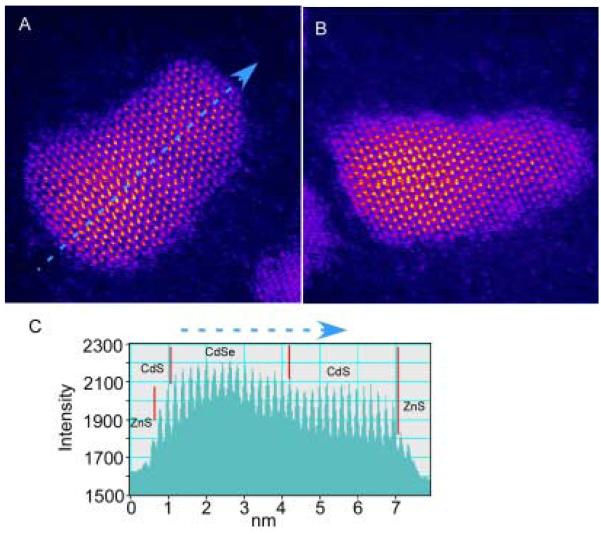

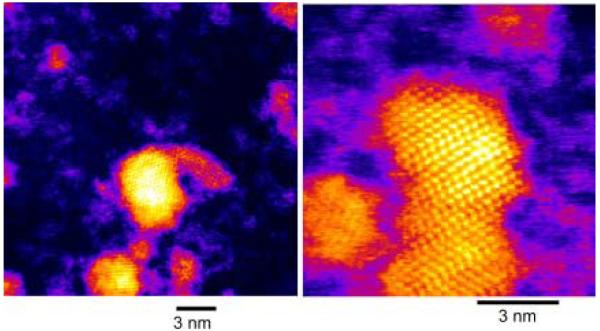

Peng et al. also published the fabrication and characterization of core/shell nanocrystals in 1997 but their system was CdSe capped by CdS.71 They fabricated core/shells from three different sizes of CdSe cores: 23 Å, 34 Å and 39 Å. Their method is also a two pot synthesis. The synthesis of the cores follows the procedure outlined above in Section 2.1.2. The stock solution for shell growth uses (CH 3)2Cd for the cadmium precursor and (TMS)2S for the sulfur precursor. These are dissolved in TBP with an ultimate Cd:S ratio of 1.0:2.1. To grow core/shells CdSe nanocrystals are placed in a three neck reaction flask to which pyridine is added. The nanocrystals readily dissolve in the pyridine which is then refluxed over night. The solution was heated to 100 °C and the shell solution added dropwise at a rate of approximately 1 drop per second. Stopping the CdS addition and removing the heating completed the growth. Dodecylamine was added to the reaction solution at room temperature until the nanocrystals precipitated. The absorption spectra indicated a red shift for the core/shells as compared to the cores. The photoluminescence quantum yield increased with increasing shell thickness, peaking at 50% for all samples at ~7 Å shell thickness, (Figure 5). These core/shells were further analyzed by XPS, TEM, and XRD to demonstrate that a shell is indeed grown as opposed to forming a CdSxSe1-x alloy. A comparison of the 34 Å cores and the core/shells with a shell thickness of 9 Å is shown in Figure 6. It is clear from this comparison that the core/shells are bigger than the cores. However in traditional high-resolution TEM (HRTEM) the shell cannot be distinguished from the shell, therefore the uniformity of the shell coverage cannot be assessed. As we will see below in Section 5 Z-STEM allows for just such an analysis.

Figure 5. Increasing fluorescence quantum yield as a function of shell thickness for CdSe/CdS core shell nanocrystals.

The fluorescent quantum yield peaks for a shell thickness of 7Å. The degradation of the fluorescent quantum yield is likely the result of the formation of CdS nanocrystal which will absorb light but not contribute to the desired luminescence.71

Figure 6. Transmission electron microscopy image comparing 34 Å cores to core/shells with a shell thickness of 9Å.

While a difference in size is clearly observable, details concerning the uniformity of shell coverage cannot be determined by HRTEM.71

Just as “greener” methods were devised for the synthesis of CdSe nanocrystals, Weller and coworkers applied the same principles to the growth of CdSe/CdS nanocrystals in a one-pot approach.52 The procedure begins with the synthesis of CdSe nanocrystals from Cd(CH3CO2)2 and TOP:Se precursors as described above in section 2.2. To make the core/shells a reaction flask containing a freshly prepared crude solution of CdSe nanocrystals was heated to 140 °C. H2S gas was injected above the solution and not bubbled through the reaction solution. The reaction mixture absorbed the H2S during stirring for a half an hour. The temperature of the reaction mixture was then decreased to 100 °C and stirred an additional hour. The mixture was cooled to 50 °C at which point chloroform was added to the solution to prevent solidification of the TOPO and HDA when the mixture was cooled to room temperature. The nanocrystal solution was injected through a 0.2 μm syringe filter followed by isolation of the nanocrystals by precipitation with methanol. The CdSe/CdS core shells produced by this method have narrow photoluminescence spectra (FWHM ~27-35 nm) with quantum yields as high as 50-85%. However, Weller and co-workers do not rule out that a CdSxSe1-x alloy or gradient composition is formed. Below in Section 5 we will see how this dilemma can be addressed with Z-STEM.

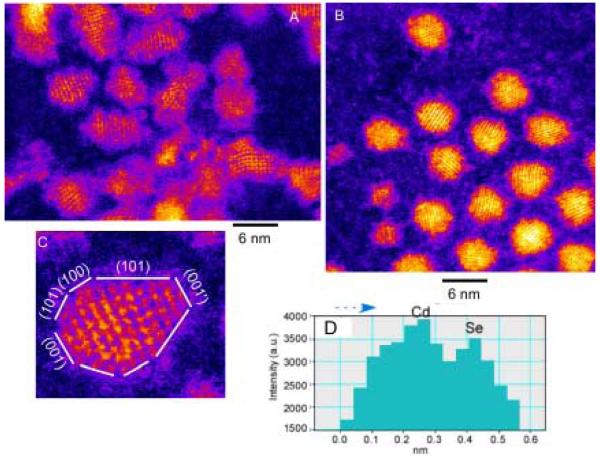

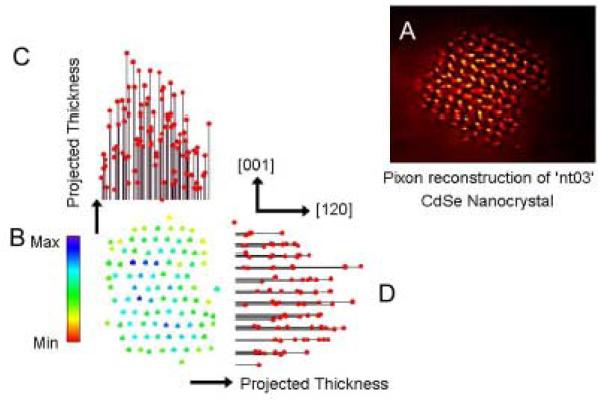

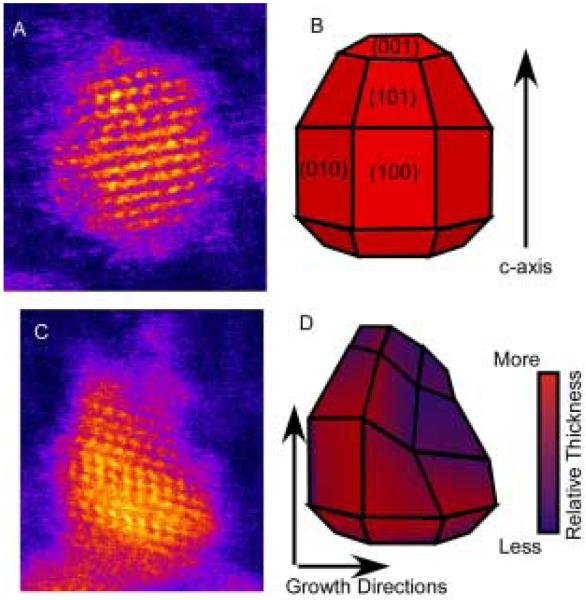

2.4 Unique Shapes

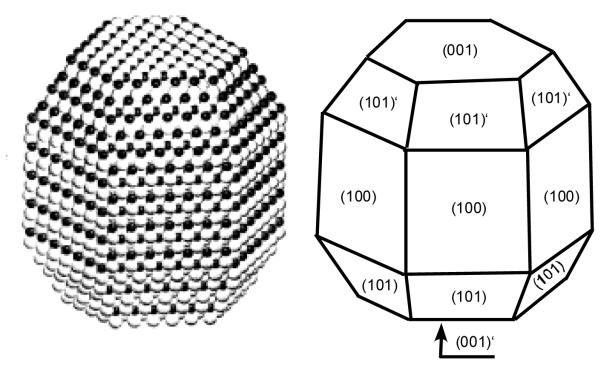

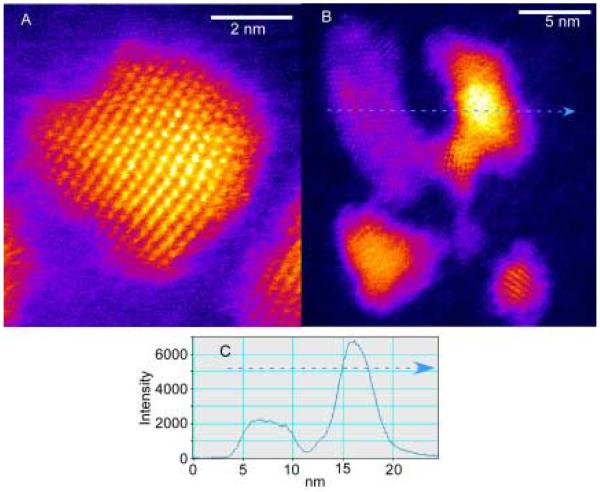

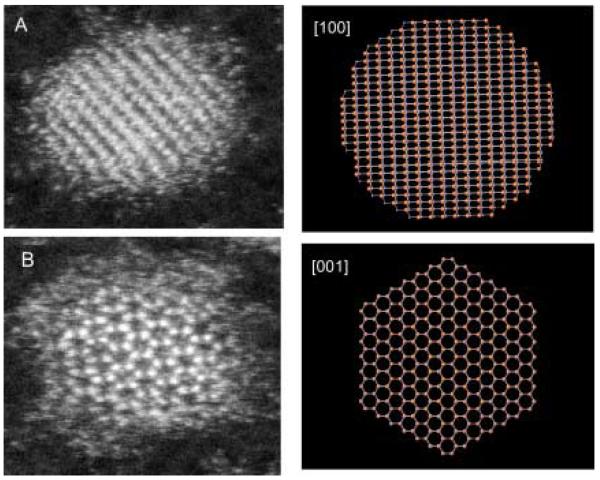

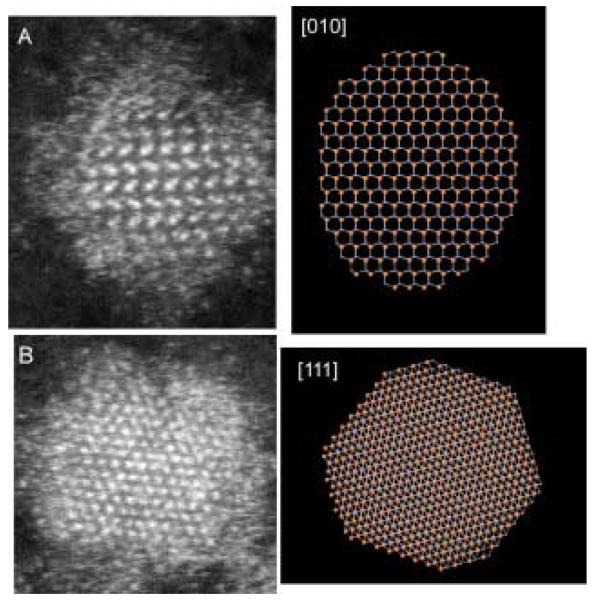

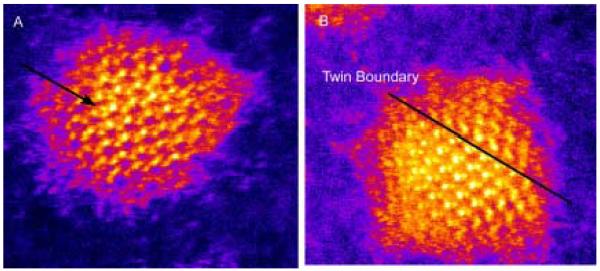

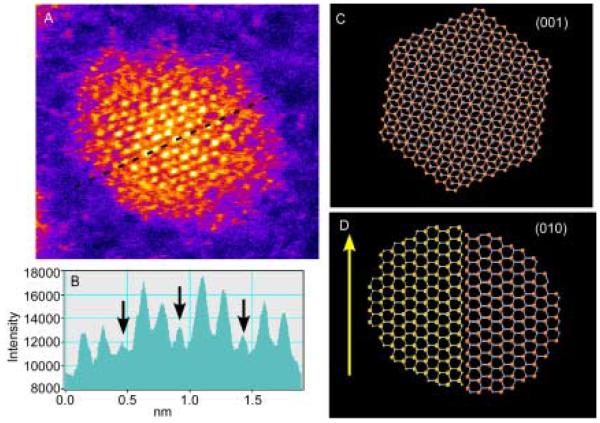

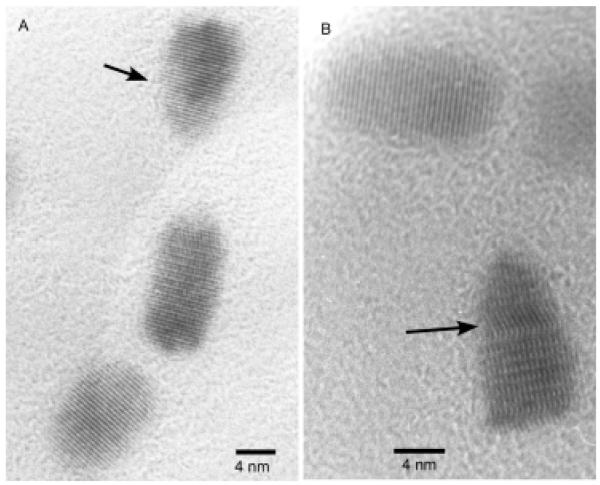

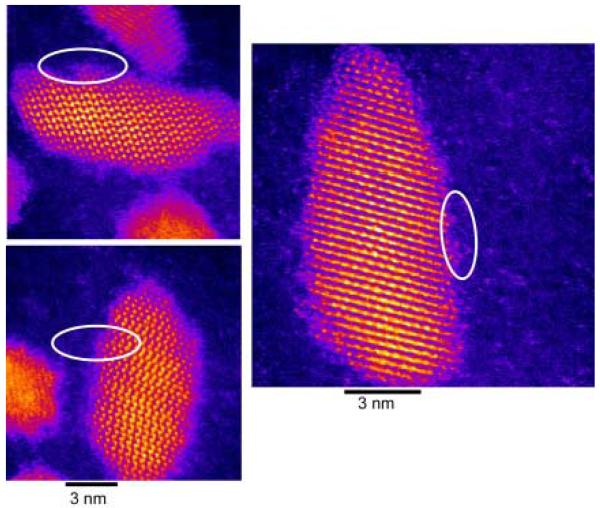

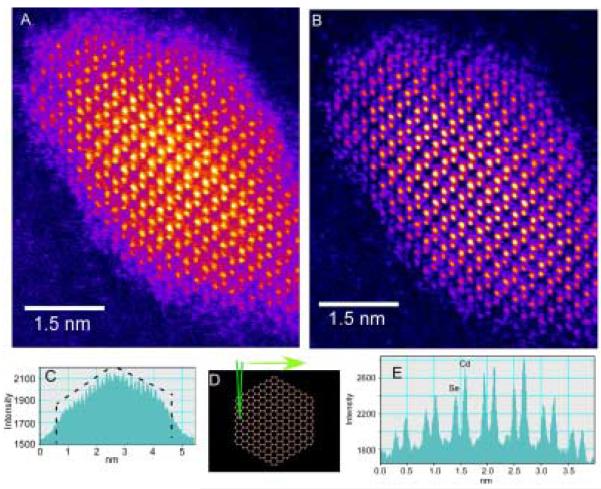

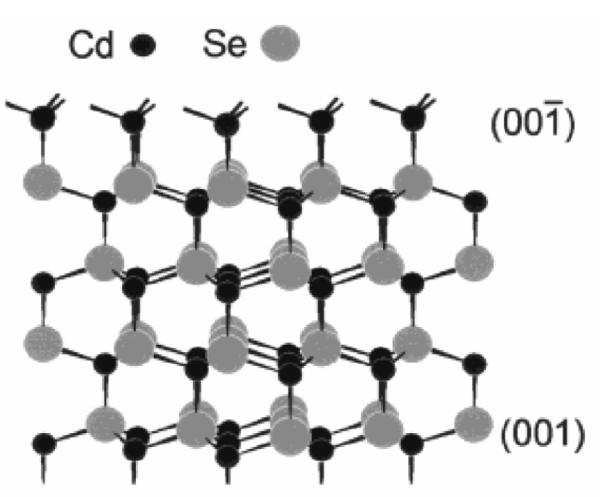

Before describing unique nanocrystal shapes, it is imperative to present the standard shape of CdSe nanocrystals prepared by the synthetic methods presented above in Section 2.1. The defining work on the determination of CdSe nanocrystal shape and symmetry was presented by Shiang et al.73 The shape of the nanocrystal is revealed in the impressive HRTEM images obtained by Kadavanich (Figure 7) which clearly show that the nanocrystals are facetted and slightly elongated in the direction of the C3v symmetry axis. The shape of the nanocrystal can be described as a hexagonal prism capped by two frustrums (Figure 8).74 Indeed Raman depolarization studies confirmed the assignment of CdSe nanocrystals to the C3v point group. The elongation of the nanocrystals varies with size: small nanocrystals have an aspect ratio of ~1.1:1 while larger nanocrystals have a ratio of ~1.4:1.75 The model presented in Figure 8 is for a 1:1 Cd:Se stoichiometric nanocrystal. Implicit in this description of the shape of the nanocrystal is that the terminating top and bottom planes consist solely of Se (001′) and Cd (001). This shape dictates an intrinsic dipole moment which was ultimately observed by Guyot-Sionnest.76 We will see in Section 4 that RBS analysis shows these nanocrystals are indeed not stoichiometric.

Figure 7. HRTEM images of 60 Å CdSe nanocrystals parallel and perpendicular to the C3 axis.

Faceting and elongation along the C3 axis a clearly visible (Figure 7a). Additionally, zinc blende stacking faults are visible running perpendicular to the C3 axis (Figure 7b).

Figure 8. Three dimensional shape of CdSe nanocrystals determined from HRTEM images.

Certain facets are rich in either Cd or Se which results in varied reactivity for certain surfaces.

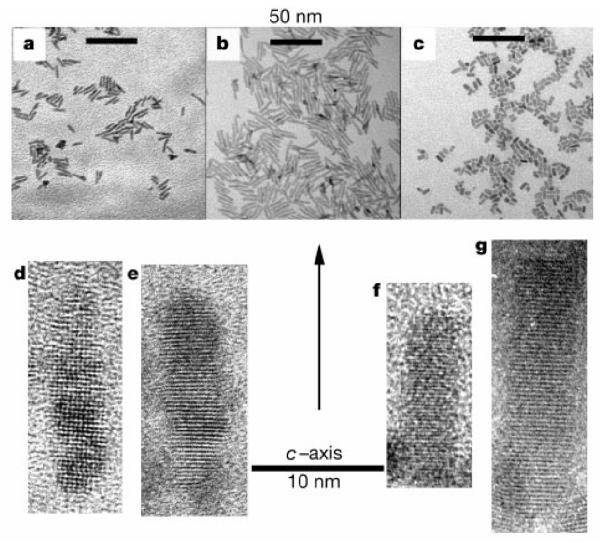

Control of CdSe nanocrystal shape was first demonstrated in CdSe nanorods that could be grown with different aspect ratios (Figure 9).39 It is possible to control the shape of CdSe nanocrystals because of the anisotropic growth of the wurtzite structure. When the system is kinetically driven at extremely high monomer concentrations, the C axis of the wurtzite structure is the preferred growth direction. However, if pure TOPO is used as the surfactant in combination with extremely high monomer concentrations the growth is too fast resulting in insoluble and unprocessable rods. Technical grade TOPO contains impurities which slow the growth.77 The impurities present that are likely to slow the growth by binding strongly to cadmium atoms are alkyl phosphonic and phosphinic acids. Peng et al. discovered that by adding a molecule that bound more tightly to Cd than TOPO, they could control the growth kinetics and produce nanorods.39 Hexylphosphonic acid (HPA) was chosen to simulate the impurities found in technical grade TOPO. The synthesis generally follows the TOPO/TBP scheme outlined above. With small amounts of HPA added to the TOPO (1.5 % and 3 % by weight) spherical nanocrystals result. At higher amounts of HPA (5 %, 10 %, and 15 %) nanorods result. The aspect ratio, size, and growth rate of the nanorods can be systematically controlled by varying the reaction time, the injection and growth temperatures, and the number of injections.

Figure 9. CdSe Nanorods.

HRTEM images of CdSe grown with different aspect ratios, demonstrating the ability to control the growth along the C3 axis.39

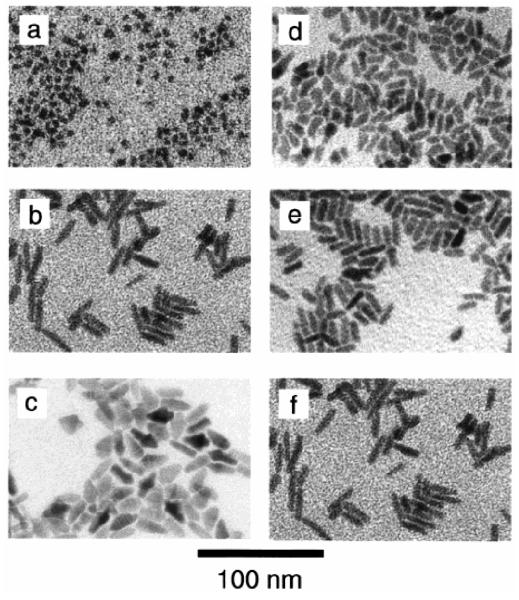

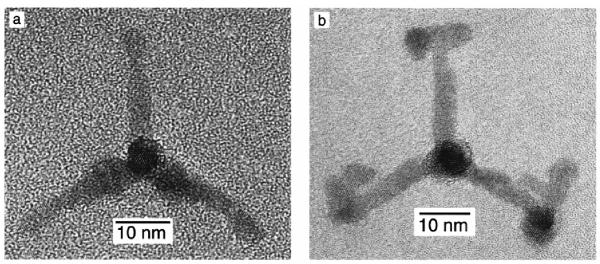

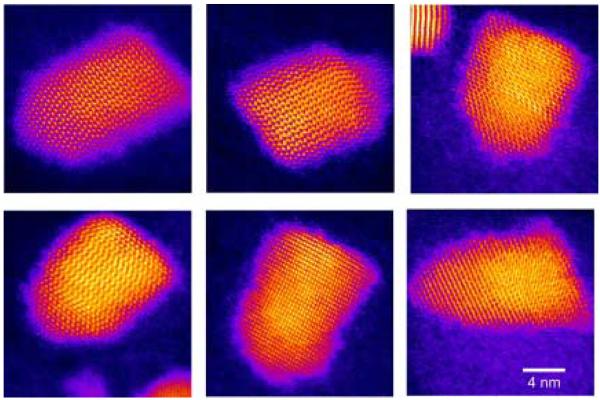

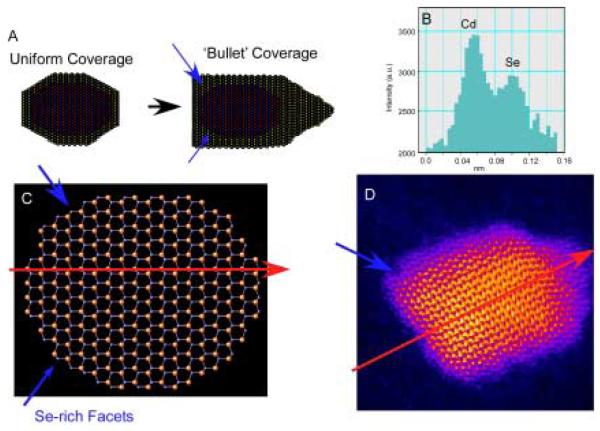

Manna et al. extended the methodology of doping pure TOPO with HPA to create a variety of nanocrystal shapes.78 By controlling the ratio of the surfactants, the injection volumes, and the time-dependent monomer concentrations they produced arrows, teardrops, tetrapods and extremely large aspect ratio (30:1) nanorods. The argument for the origin of shape control is generally as follows: during the growth of the nanocrystals, the surfactants dynamically adsorb to the growing crystallites, allowing atoms to add and subtract for high crystallinity. The surfactant enables the growing crystallite to anneal, resulting in good crystallinity while at the same time preventing aggregation. The growth kinetics can be controlled by varying the time-dependent monomer concentration through the initial injection volume and additional injections, and by the addition of a phosphonic acid, which allows the (001′) surface to grow faster relative to the other surfaces. An example of this principle is shown in Figure 10.

Figure 10. HRTEM images of CdSe nanocrystals demonstrating shape control.

By controlling the ratio of the surfactants, the injection volume, and the time-dependent monomer concentration different shapes and sizes can be obtained. Figures a-c demonstrate the effect of surfactant. The surfactant ratio was increased for (a) 8 to (b) 20 to (c) 60% HPA in TOPO. Figures d-f illustrate the effect of injection volume. The injection volumes used were (d) 1.0, (e) 1.5, and (f) 2.0 ml.78

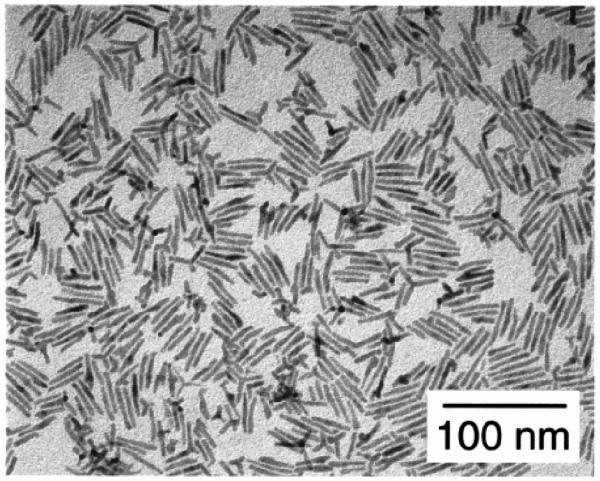

At concentrations of HPA less than 10% a roughly spherical shape results. At a concentration of HPA of 20 % high aspect ratio rods are formed (Figure 10b). With a HPA concentration of 60% arrows are formed (Figure 10c). Figures d-f illustrate the effect of injection volume. For a fixed HPA concentration of 20% larger aspect ratio rods are obtained by increasing the injection volume. Nanorods with an aspect ratio of 10:1 can be obtained by additional injections during the growth phase (Figure 11).

Figure 11. TEM images of nanorods.

The extended rods are obtained by adding additional reagent during the growth. The arms are believed to extend from a zinc blend core.78

Teardrops (tadpoles) result with a slow initial injection rate and additional slow injections during the course of the reaction. The crystals that were pure wurtzite grew significantly more on the (001′) face, forming the teardrop shape. Finally, all of the synthesis that form nanorods contained some percentage of tetrapods (Figure 12) which can be isolated by size-selected precipitation. The tetrapods are crystalline both in the center and the arms.

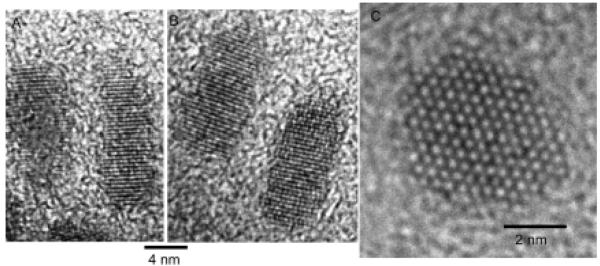

Figure 12. HRTEM images of tetrapods.

The tetrapods are formed as a by product in the synthesis of nanorods and separated by size-selected precipitation. The asymmetric structure of the nanocrystal can be used to form self assembled ordered structures for device application.78

The variation of nanocrystal shapes is an intriguing manifestation of surface science. As discussed above, wurtzite CdSe nanocrystals have differing top and bottom faces i.e. the (001′) is anion rich. If we examine a model from Manna et al. (Figure 13), it can be seen that Cd atoms on the (001) face have one dangling bond while the Cd atoms on the (001′) face have three dangling bonds.78 In the presence of HPA the relative growth rate of the (001′) face is much greater than the other faces. The formation of arrows at large HPA concentration unequivocally points to unidirectional growth. The important role of HPA was confirmed by Peng and Peng who claim that its role is to enable the high monomer concentration necessary for growth of nanorods.63

Figure 13. Schematic of dangling bonds.

Demonstration of the types of dangling bonds available for reaction for the different growth faces of wurtzite CdSe. On the (001) face, Cd atoms have only one dangling bond, while on the (001′) face Cd atoms have three dangling bonds.78

2.5 Practical Guide for the Synthesis of CdSe Nanocrystals

The following reagents and methods are used for the synthesis of CdSe nanocrystals in our laboratory. Tri-n-octylphosphine oxide (TOPO, 90% tech. grade), hexadecylamine (HDA, 90% tech. grade) are purchased from Aldrich and used as received. CdO (99.999% Puratrem), tri-n-butylphosphine (TBP, 97%) and selenium powder (200 mesh) are purchased from Strem and used as received. Dodecylphosphonic acid (DPA) is synthesized via the Abruzov reaction from triethylphosphite and 1-dodecylbromide followed by acidification with concentrated HCl and recrystallization from cold ethyl acetate. All other solvents were HPLC grade and purchased from Fisher Scientific unless otherwise noted.

A 1.0 M stock solution of selenium in TBP is produced by dissolving 7.896 g of selenium powder in 100 ml of TBP and is kept in a glovebox under nitrogen. 30 ml of this solution is mixed with 120 ml of TBP to produce a 0.2 M working solution which is stored in a sealed bottle with a Teflon-lined rubber septum outside the glovebox. 0.128 g of CdO, 0.496 g of DPA, 6g of HDA and 4 g of TOPO are placed in a 100 ml three-neck flask with a Teflon-coated magnetic stir bar. A rubber septum is placed over one of the flask openings to allow the injection of precursors. A rotovap bump-trap fitted with a gas adapter is placed in the middle opening while a temperature probe fitted with an adapter is placed on the remaining opening. Argon is then purged through the flask from the bump-trap out through a needle placed in the rubber septum while the solution is heated to 150 °C. At 150 °C, the purge needle is removed and the solution is allowed to heat to 320 °C. The CdO converts to cadmium phosphonate, yielding a clear reaction solution. 5 ml of the 0.2 M Se:TBP solution is drawn up in a syringe and fitted with a 12 gauge needle. Immediately prior to the Se:TBP injection, the reaction temperature controller is set to 270 °C and the heating mantle is lowered from the reaction flask. The Se:TBP is quickly and forcefully injected into the reaction solution at 315 °C which will drop the reaction temperature to about 270 °C. The heating mantle is raised back under the reaction flask and the reaction is allowed to proceed until the desired size of nanocrystal is achieved. This can be monitored by UV-Vis spectroscopy by pulling aliquots using a glass syringe. The reaction can be stopped by lowering the heating mantle and using compressed air to drop the reaction temperature below 100 °C. A careful injection of 10 – 20 ml of butanol can also be used to stop the reaction quickly.

The nanocrystals are cleaned in three steps. The first step is by precipitation in methanol which serves to remove excess TBP and TOPO. The second step involves the addition of just enough octanol to cover the pellet from the previous step and is mixed into a cloudy suspension. This suspension is again centrifuged until the supernatant is clear. The pellet on the bottom is a mixture of HDA and unreacted cadmium phosphonate. The supernatant is then carefully decanted into a new via. The nanocrystals are then precipitated with methanol and a few drops of ethyl acetate followed by centrifugation.

3. Review of Surface Studies of CdSe Nanocrystals

Studies of surface bonding, surface chemistry, and surface reconstruction have dominated the field of surface science for the past 50 years. Experimental techniques have been designed for, and evolved around, planar structures. Indeed, the electronic properties of the surface 2D electron gas was the first low dimensional problem studied, illustrating changes in properties determined by lower dimensionality. Nevertheless, surface science experimental tools are not well suited for the studies of nanocrystals; hence there is a limited amount of literature concerning the application of surface science tools to chemically synthesized quantum dots. Of course this is a most significant omission since nanostructures are solids in which the surface is more dominant than in any other structure. Here we review the experimental studies which have analyzed CdSe nanocrystal surfaces.

3.1 X-Ray Photoelectron Spectroscopy

X-ray photoelectron spectroscopy (XPS) is a critical tool in the analysis of surfaces. XPS was developed in the mid 1960’s by K. Siegbahn and his research group and was awarded the Nobel Prize for Physics in 1981 for his work in XPS. The phenomenon is based on the photoelectric effect outlined by Einstein in 1905 where impinging photons cause the ejection of electrons from a surface. For XPS, Al Kα (1486.6 eV) or Mg Kα (1253.6 eV) are often the photon energies of choice. Other X-ray lines can also be chosen such as Ti Kα (2040 eV). The XPS technique is highly surface specific due to the short range of the photoelectrons that are excited from the solid. The energy of the photoelectrons leaving the sample is determined using a high resolution electron analyzer and gives a spectrum with a series of photoelectron peaks. The binding energy of the peaks is characteristic of each element. The peak areas can be used (with appropriate sensitivity factors) to determine the composition of the material’s surface. The shape of each peak and the binding energy can be slightly altered by the chemical state of the emitting atom. Hence XPS can provide chemical bonding information as well. XPS is not sensitive to hydrogen or helium, but can detect all other elements.

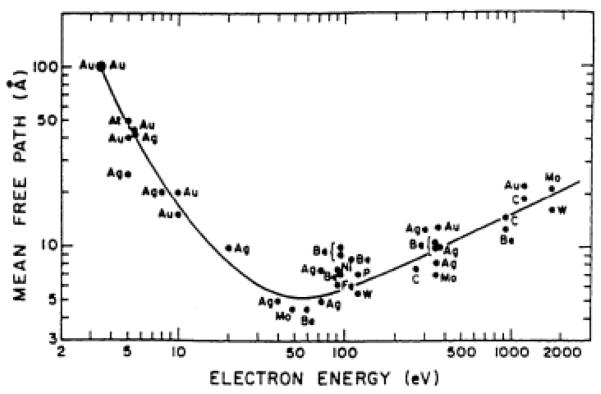

XPS is traditionally carried out in UHV conditions to maintain a pristine surface. The surface sensitivity is governed by the electron escape curve shown below in Figure 14.79 The escape depth of the electrons corresponds to the depth sampled. In XPS of quantum dots, the escape depth can be comparable to the size of the nanocrystal, which can complicate data analysis. In the simplest approximation, the final energy of the electron is given by:

| (3.1) |

where the binding energy corresponds to a specific atom and contains information on the chemical binding. The “escape curve” and this simple equation also illustrate the growing use of synchrotrons as x-ray sources. These variable energy sources allow variation of the incident energy to control the depth sampled.

Figure 14. Electron escape curve.

Graph of the mean free path in Å verses electron energy for surface sensitivity in XPS.79

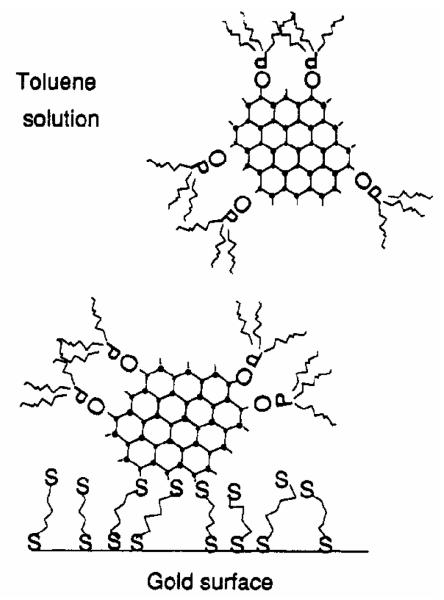

One of the earliest and most extensive studies of the nature of the CdSe nanocrystal surfaces was an XPS study by Katari, Colvin, and Alivisatos.24 This is also one of the few examples of a traditional surface science technique applied to CdSe nanocrystals. In this work, the TBP/TOPO method (Section 2.1.2) was used to fabricate the nanocrystals. In order to perform an XPS experiment, the nanocrystals must be attached to a conducting surface so they do not charge during the experiment. The nanocrystals must also be attached at a uniform distance which must be small. Further, the nanocrystals must be in a single layer without bunching or stacking. Finally the samples must be robust. To meet these requirements the authors employed the method of Colvin et al. in which the nanocrystals are covalently attached to a gold surface using hexanedithiol (Figure 15).80

Figure 15. Sample geometry for performing XPS on CdSe nanocrystals.

The nanocrystals are tied off to a gold surface using hexane dithiol as a “molecular glue”.

In this method, hexanedithiol is self-assembled on ion-etched gold evaporated onto glass slides. The slides are then soaked in a solution of TOPO coated nanocrystals which covalently bind to the sulfur atom of the hexanedithiol. Empirically it was determined that hexanedithiol has the optimal chain length. Longer alkanethiols have the potential to loop, leaving no site for nanocrystal attachment, while shorter chains do not bind strongly enough to the gold to bind nanocrystals to the surface. In addition to attaching nanocrystals to gold surfaces Bowen-Katari et al. also attached CdSe nanocrystals to doped silicon surfaces. Acid cleaned Si (111) wafers were placed in a boiling solution of 10 g of distilled water and 10 g of (3-mercaptopropyl)trimethoxysilane in 400 g of 2-propanol. This process was repeated three times and then the wafers sat in a nanocrystal solution overnight. In the case of both the gold and silicon substrates, the samples were stored under nitrogen to avoid oxidation of the nanocrystal surfaces. FTIR on these samples showed the presence of TOPO on the nanocrystals and Raman spectroscopy confirmed the presence of nanocrystals on the surfaces. RBS on these samples indicated roughly one-sixth a monolayer of coverage. The above methodologies for creating monolayers of nanocrystals attached to surfaces lend themselves to other “traditional” surface science experiments.

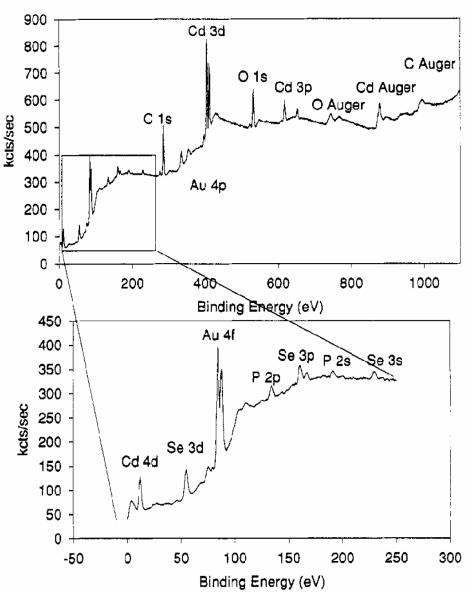

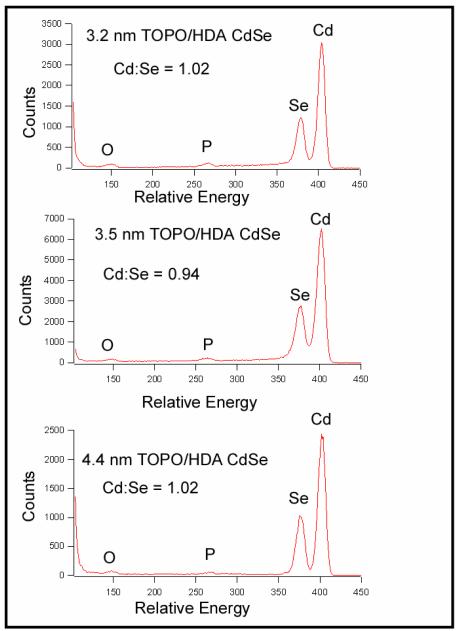

A typical low resolution XPS spectrum from the Bowen-Katari study is depicted in Figure 16. After taking into account the nanocrystal geometry in order to determine composition from the photoelectron spectra, several aspects of the CdSe nanocrystals prepared in TBP/TOPO were analyzed. First, peak areas of the Cd and Se cores were measured to determine Cd:Se ratios. However the resulting ratios are only good to ~10% because of the uncertainty in the shape of the background beneath the peaks. The calculated Cd:Se ratio was determined to be 1.02 ± 0.14 and does not vary systematically with size. We will find below that RBS, which has a higher accuracy in this regard than XPS, shows that these nanocrystals are indeed not stoichiometric as suggested by the XPS study. The binding energy measured from the XPS spectra can be analyzed to determine what species are on the surface of the nanocrystals. Bowen-Katari et al. found by analyzing the P region of the spectra that the P was not bound directly to Cd.24 This means that the tributylphosphine used in the TBP/TOPO preparation acts to deliver precursors but does not remain on the nanocrystal surface, and the P observed in the spectrum originates from TOPO bound to surface Cd atoms. Therefore, we see directly how nanocrystal preparation affects the nature of the surface of the nanocrystal.

Figure 16. Low resolution XPS spectrum of CdSe nanocrystals.

The electronic transitions for specific elements can be readily identified, indicating the surface coverage.

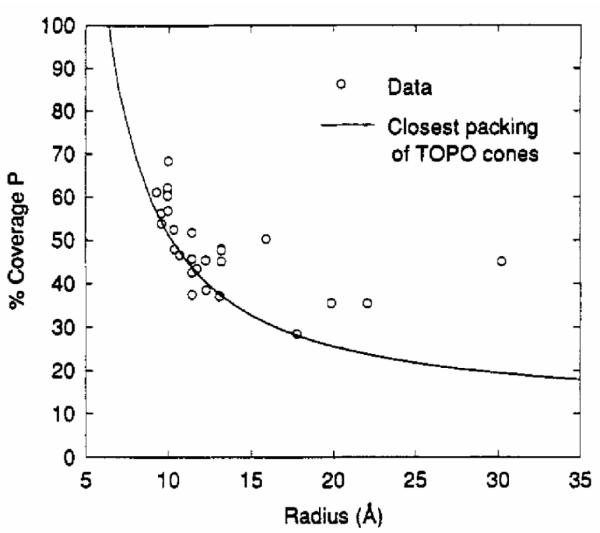

Cd:P ratios can be determined from the XPS spectra, however the analysis is complicated by the fact that P atoms on the surface of the nanocrystal facing the analyzer contribute more to the signal than P atoms facing away from the analyzer. The Cd:P ratios best fit a 1/r curve, indicating the ligands are on the surface. The extrapolated percentage of ligand coverage is shown in Figure 17.24 This result is again different than what was determined by RBS (Section 4.3), thus the analysis technique bears some detailed explanation. First, the number of CdSe units in a nanocrystal for a given radius is calculated using the bulk density, which does not change significantly with size as confirmed from the XRD analysis.81 Then, the number of CdSe units in a nanocrystal of a given radius minus the CdSe bond length of 2.63 Å was calculated, and this number was subtracted from the previous number, giving the number of Cd and Se units on the surface. The percent coverage is obtained by taking the P:Cd ratio and multiplying it by the total number of Cd atoms on the surface of the nanocrystals and dividing this number by the total number of Cd and Se surface atoms per nanocrystal. Thus assuming a uniform distribution of Cd and Se on the nanocrystal surface, coverage of 50% means that every Cd atom is bound to one TOPO molecule on average, with nothing bound to the surface Se atoms. The percentage coverage is larger for smaller size nanocrystals and varies from 60% to 30%. The coverage is lower than that determined by RBS and originates in the details for determining the number of surface atoms.74

Figure 17. Percentage of TOPO ligand coverage on the nanocrystal as a function of nanocrystal size as determined by XPS.

The fit indicates that as the nanocrystal radius increases the amount of TOPO coverage decreases, which is counterintuitive.24

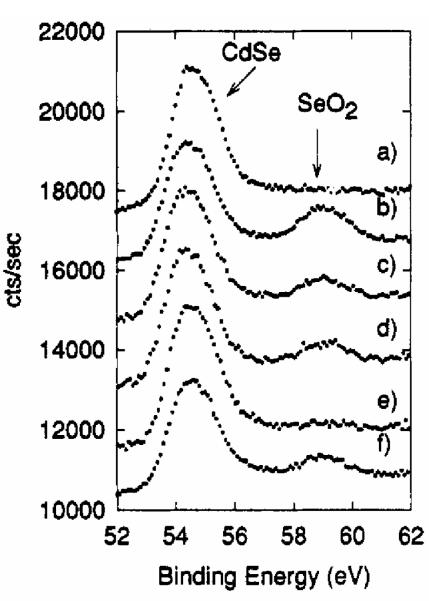

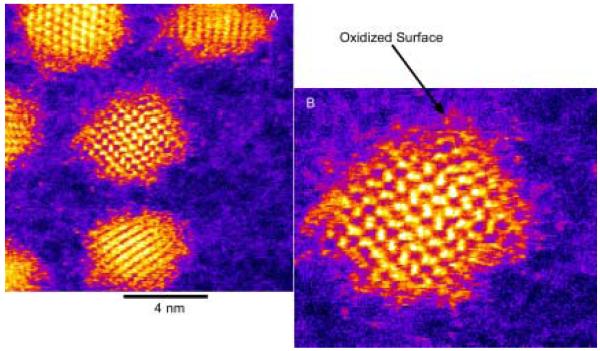

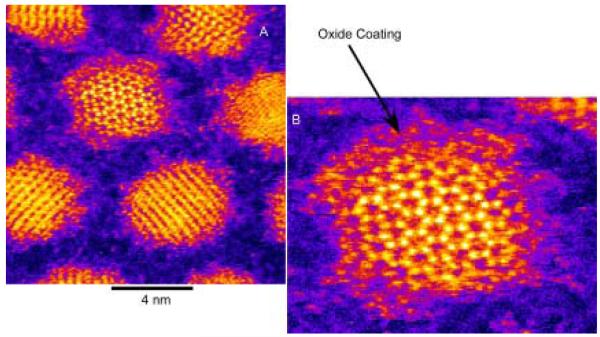

In their study Katari et al. also used XPS to follow the surface oxidation of the nanocrystals. They monitored the Cd and Se peaks as the monolayers were left out in air.24 All samples developed an oxidized Se peak after 24 hours in air while there was no observation of a Cd oxidation peak. The P remained unchanged as well. The Se oxide peak grows in, then decays, and then grows in again (Figure 18). The Cd:Se ratio rises simultaneously with the oxide peak decay, indicating that Se is lost from the nanocrystal. As the surface Cd atoms are bound to TOPO, Bowen Katari et al.24 concluded that the formation of a compound oxide is unlikely and that the oxide formed is SeO2. Finally, XPS spectra for nanocrystals deposited from pyridine solution show a lack of both a phosphorus and a nitrogen peak, indicating that the pyridine displaces the phosphorus and then is pumped off while under vacuum at room temperature, leaving a bare nanocrystal surface.

Figure 18. Dynamics of the growth of a surface oxide on the nanocrystal as monitored by XPS.

This plot indicates the formation of volatile SeO2 which leaves the surface and allows the generation of more SeO2.24

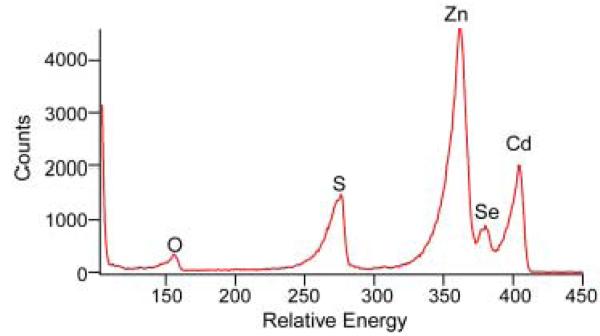

XPS has also been used to verify shelling when making core/shell nanocrystals. Hines et al. observed Zn in the XPS spectrum of CdSe/ZnS core shells.65 Their results indicate three times as much Zn than Cd, to which they attributed the short (50 Å) probe depth. Daboussi et al. took the application of XPS to the studies of core/shells further by studying the degree of passivation of the CdSe surface with ZnS by exposing the nanocrystal surface to air and studying the evolution of the Se peak.67 Their results show that at ~1.3 monolayers of ZnS the oxide peak does not appear, even at long exposure times, suggesting this is sufficient to create a continuous shell of ZnS around the CdSe core. Further, for core/shells with more than 1.3 monolayer coverage, no change in the Cd:Se ratio was observed, even after 80 hours in air, indicating Se did not desorb as an oxide and the shell was complete. Another method to probe the spatial location of the ZnS relative to the CdSe core used by Daboussi et al., was to compare the ratios of the XPS and Auger intensities of the Cd photoelectrons for bare and overcoated samples.67 This analysis confirmed the growth of ZnS on the surface of CdSe cores. Another example of the use of XPS to analyze core/shells is the work of Peng et al., in which CdSe/CdS cores were compared to CdS films.71 These results, combined with the concept of the escape length, were used to analyze the structure of the core/shell. Recognizing that the intensity of the core Se is limited in escape by the shell, according to I/Io=exp(−z/λ), with λ as the escape length, the authors were able to demonstrate that the structure was indeed a core/shell and not an alloy. Such results are critical to understanding the photoemission properties of the semiconductor structure with respect to band-gap and quantum confinement.

The thorough study of Katari et al. demonstrates that it is possible to apply traditional, high vacuum, surface science techniques to the study of nanocrystals.24 The methodology for using hexane dithiol to tether nanocrystals to a gold surface could be extended to other techniques. Nanocrystal composition, surface ligand coverage, surface shell coverage, and surface oxidation have been examined by XPS. A different methodology will be needed to determine surface structure and reconstruction at the atomic level. As we will see below, one technique which might fully achieve this is high resolution Z-STEM.

3. 2 Nuclear Magnetic Resonance Studies of Ligand Surface Coverage

Nuclear magnetic resonance (NMR) can reveal information about crystallite surfaces due to its ability to probe local chemical environments. Becerra et al. applied magic angle spinning, solid state, 31P NMR to the study 37 Å diameter CdSe nanocrystals prepared in TOP/TOPO in order to investigate surface morphology.82 Both TOPO and TOP (bound to Se) were identified in the NMR spectrum with 55% coverage of all surface atoms; 70% of the ligands are TOPO and 30% are TOP:Se. The TOP:Se capping species can be removed by preparing the nanocrystals in 4:1 TOPO:TOP and exchanging the surface TOP with warm TOPO. An average P-P distance of 8 to 10 Å was determined by spin echo experiments, consistent with capping of alternate atomic sites on the surface. The picture that arises from the NMR study is that the two capping species, TOPO and TOP:Se form a close packed shell which physically stabilizes the nanocrystal and electronically passivates the surface. Unlike the XPS study, it was concluded that all Cd sites are passivated while Se sites are bare. Thermal gravimetric analysis, in conjunction with quantitative 1H NMR, indicated these same 37 Å nanocrystals have only 30% of the surface Cd atoms passivated with either TOPO or TOP bonded to Se.83 One might conclude that while NMR can identify the presence of surface species, it may not be the best tool for quantifying surface species.

3.3 Positron Spectroscopy

One of the more novel surface probes applied to nanocrystals involves the use of positron annihilation.84 In this technique, low energy positrons (~3 KeV) are implanted into a solid, lose their energy, thermalize coming to near rest, and eventually annihilate with electrons of the solid into two ~511 KeV gamma rays. High resolution measurements of the energy distribution of the gammas and their angular correlation, measured in coincidence with two detectors, give information on the momentum distribution of the annihilating electrons. (For a general review of the positron technique see Refs 11, 12, 17 of Eijt et al.)84 These momenta may then be correlated with the band structure and/or used to identify core levels of the annihilating electrons.

In the Eijt et al. experiments, relatively thick films of CdSe nanocrystals were used (~2 μm).84 The shape of the energy distribution sharpens relative to bulk CdSe, indicating annihilation with low momenta electrons. Generally such a sharpening is attributed to positron annihilation with vacancy type defects or at surfaces/interfaces, where the positron is far from the high momenta core. In this case the authors conclude that the positron annihilation is primarily at the surface, as the vacancy concentration would be unreasonably high. Interestingly, the annihilation appears to be independent of the nature of the passivating ligand; the positron wave function is strongest at the interface of the inorganic nanocrystal and the organic ligand.

Finally, the complete analysis suggests that this interface is Se rich, in apparent contradiction with RBS results described here. However the authors point out that “positrons are strongly attracted to the relaxed outer shell of Se”, which gives rise to a preferential sensitivity and may explain the difference. This use of positrons is an additional example of the use of novel probes to address the surface interface problem for nanocrystals. Clearly more systematic studies are required. Nevertheless, it is an interesting example of exploring surfaces in non-planar structures, making use of the fact that the positron seeks the surface site.

3.4 Perspective on Surface Analysis and Surface Analysis Probes of Nanocrystals

The discussion of surface analysis of quantum dot nanostructures demonstrates the challenges in clear and unambiguous analysis of the surface and interface chemistry and structure. Planar surfaces have been the focus of the surface science community for decades and the probes, both chemical and structural, have need designed for the planar geometry. Standard techniques such as Auger spectroscopy, x-ray photoelectron spectroscopy, surface sensitive ion scattering all possess characteristics that do not lend themselves straightforwardly to the quantum dot geometry. For example, the fact that the escape length in conventional XPS is comparable to the size of the nanocrystals makes definitive surface analysis difficult. It is clear that more atomic level probes need to be applied to the problem. The clearest example would be the use of scanning tunneling microscopy investigations, although interfacial chemistry will still be problematic. While advances have been made in the surface analysis of nanocrystals, this pursuit remains the most challenging aspect in quantum dot characterization.

4 Rutherford Backscattering of CdSe and CdSe/ZnS Nanocrystals

Rutherford backscattering is a well known tool in surface science.42 With its high sensitivity of detection and ability to provide extremely accurate elemental composition it is an ideal tool for determining the composition of core and core/shell nanocrystals. We have made extensive use of RBS to analyze the composition of nanocrystals. In this section we begin with a discussion of the theory of RBS.41, 58, 74, 85 This is followed by a description of how RBS analysis of nanocrystals is performed. Finally, the results of different RBS experiments performed on nanocrystals are presented in section 4.3.

4.1 Theory of Rutherford Backscattering

Rutherford Backscattering Spectroscopy (RBS) can be used to quantify the chemical composition of a sample to an accuracy of better than a picomol.86 RBS consists of a high energy ion beam that is directed at a sample. The basic signal is the ions that are scattered back through large angles, close to 180°. The intensity of backscattered ions is related to the atomic number (Z) of the detected element and the sample thickness. The energy distribution of backscattered ions is used to form a spectrum with the position of the signal along the x-axis dependent on the energy of the backscattered ion while the area of each peak is related to the abundance of the element being detected. With the use of a standard, such as bismuth-implanted Si, the areal density Nt (atoms/cm2) of any element in the sample can be determined.42

| (4.1) |

In Equation 4.1, Yx is the area of the peak for element x. The integrated charge, Qx, is the amount of current collected during sample acquisition. σx is the non-Rutherford correction factor and is determined by Equation 4.2, where Z1 is the atomic number of the detected element and Z2 is the atomic number of the gas used to create the ion beam divided by Elab, the beam energy in KeV.

| (4.2) |

The absolute accuracy in determining the number of atoms per cm2 using the Bi standard is ~ 5 %.

4.2 Performing RBS experiments on nanocrystals

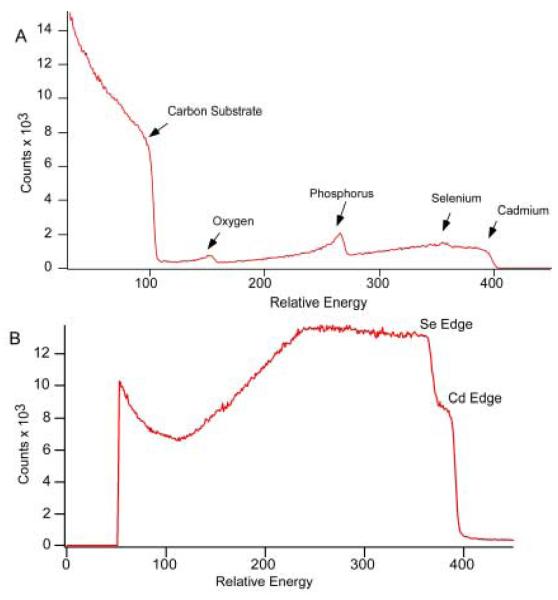

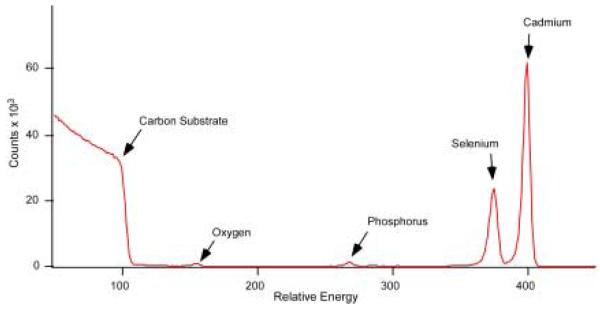

RBS samples were prepared by washing the nanocrystals to remove excess surfactants and organometallic precursors. Excess surfactants can leave an insulating coating on the graphite substrate that causes peak broadening, while excess starting materials cause the experimentally determined atomic ratios to be non-representative of the nanocrystals in the sample. Once the samples were washed, a solution of nanocrystals with an optical density greater than 0.3 was made using a volatile solvent such as toluene or chloroform. Next, one or two drops were placed onto a piece of pyrolytic graphite (Carbone of America) that had been cut to roughly 1 cm2 in size. Once the entire piece of graphite was coated, the solvent was then wicked off by touching the corner of the graphite with a Kimwipe™. This action drew the solvent off the graphite, leaving a uniform coating of nanocrystals without the formation of drying marks. Pieces of a silicon wafer were also used in the same fashion if a smoother surface was required and information for elements lighter than the silicon edge was not needed. If there were excess starting materials, or the sample was too thick, the spectrum could be difficult to decipher (Figure 19).87

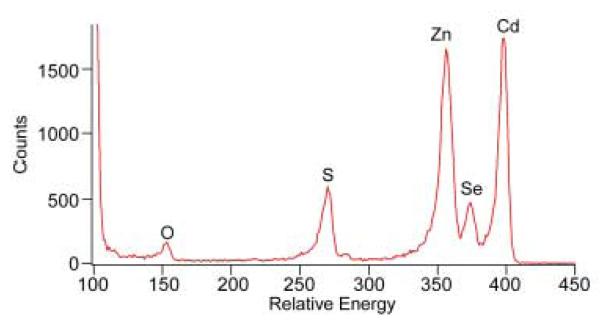

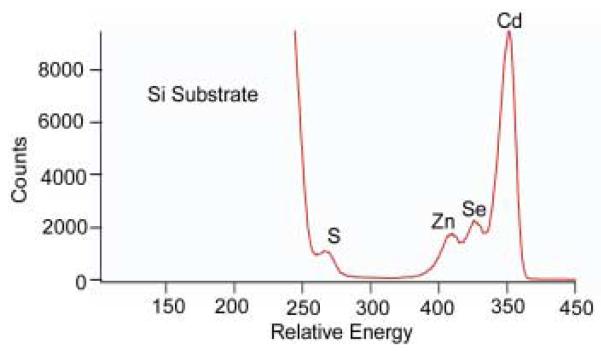

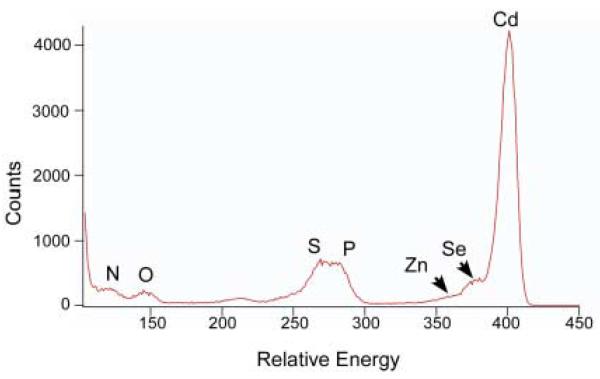

Figure 19. Poor RBS spectra.

The spectrum in Figure 19A is the result of large amounts of insulating organic reagents and rough surfaces leading to peak broadening. The spectrum in Figure 19B is the result of the sample being too thick as the clear onset of the substrate is obscured by the sample. Both spectra illustrate the necessity of clean nanocrystals and good sample preparation to obtain information from RBS.87

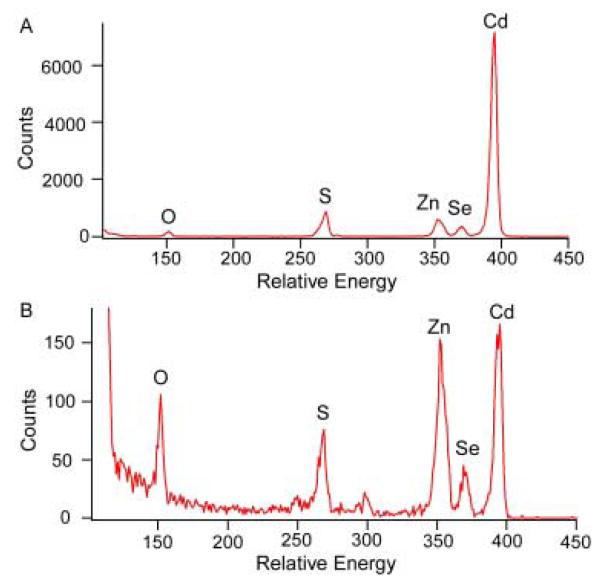

The Van de Graaf generator was typically set to run at 1.8 MeV with He as the ion source and a 1 mm aperture in-line with the beam. The samples were attached to a multi-sample holder using either a small piece of conductive carbon tape or by using copper clips. Each day, a spectrum of a bismuth standard with a known areal density of 4.77 × 1015 atoms/cm2 was acquired before data collection to ensure that the detector was functioning properly and to facilitate normalization for quantitative studies. Currents of around 10 nA on the Faraday cup, which measures the current carried by the ion beam, were adequate for characterization of thin films or nanocrystal samples. Using too high a current would lead to increased dead time. The detector was run under a 50 V bias and all data was collected through a program written in Igor Pro.88 An example of a good RBS spectrum of CdSe is shown in Figure 20.

Figure 20. RBS spectrum of CdSe nanocrystals.

This is a typical RBS spectrum of a CdSe nanocrystal sample on a graphite substrate. The peaks appear in order of atomic number with the lighter elements appearing at lower channel numbers. The substrate appears as an ‘edge’ due to its thickness.

An RBS spectrum is a plot of the number of counts per channel number. The heavy Cd and Se atoms appear at the highest energy in the spectrum, while lighter elements such as oxygen appear at lower energy (channel numbers). The substrate appears as a step edge followed by a sloping continuum of counts. This is because of the loss of scattering energy and increased cross-section as the beam penetrates deeper into the substrate. Individual peaks were assigned to specific elements by fitting the channel numbers to a line equation using tabulated kinematic factors. Once the elements are identified, the areal densities in atoms/cm2 for each element are calculated. Although traditional elemental analysis can also provide similar results, the availability of the accelerator facility on site and the increased accuracy makes RBS the better choice for nanocrystal studies.

4.3 RBS Results for Different Nanocrystal Systems

RBS data not only provides elemental composition of nanocrystals but also lends insight in to the structure of the nanocrystal. In this section we provide four examples of the use of RBS to provide insight into the nature of CdSe nanocrystals

4.3.1 RBS determination of non-stoichiometric TOPO capped CdSe nanocrystals

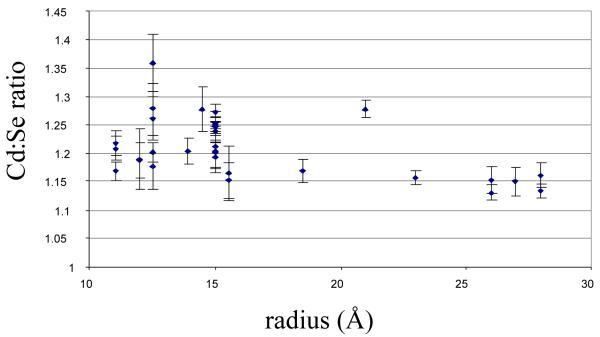

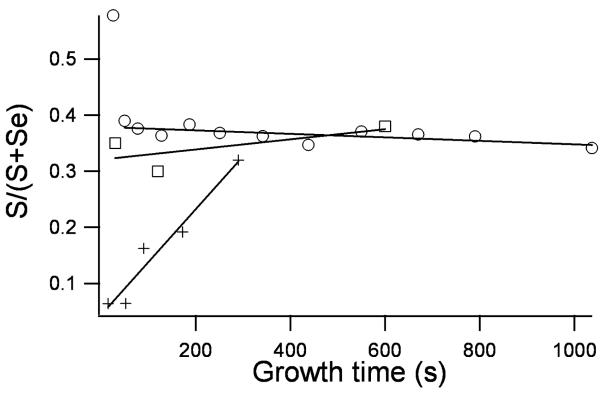

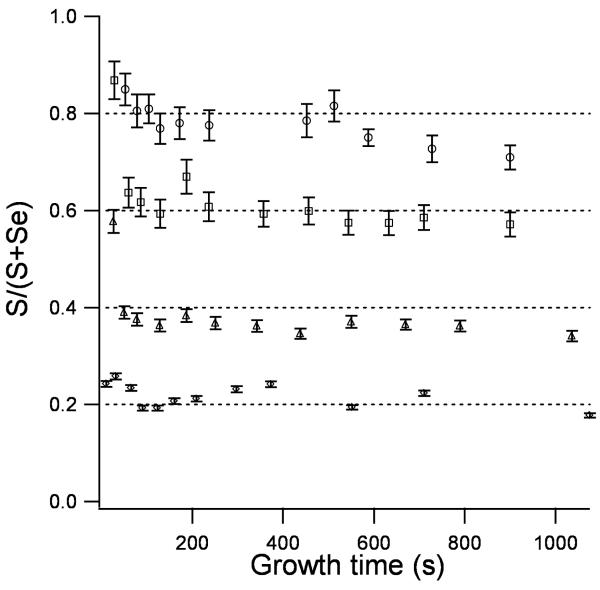

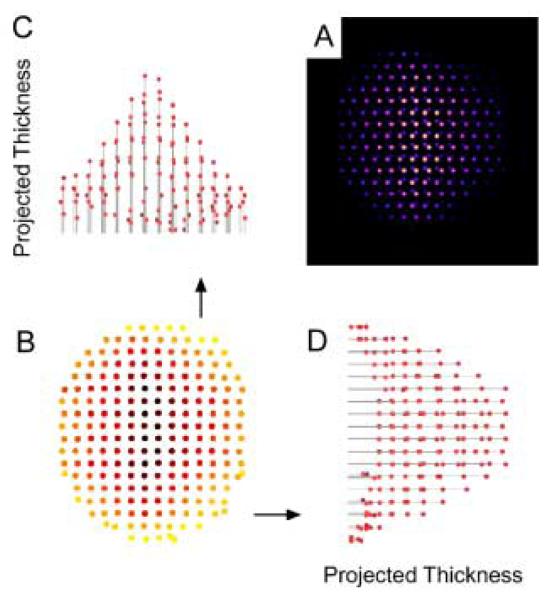

As described above in Section 2, for many years the most popular method for synthesizing nanocrystals was the TOPO only method, without addition of co-surfactants. Our initial exploration into implementing RBS to investigate nanocrystal composition was performed on these TOPO only prepared nanocrystals.74 Not only did it immediately become apparent that RBS was a powerful tool for determining nanocrystal stoichiometry, but information on surface ligand coverage and insight into nanocrystal structure could also be obtained. We determined that these nanocrystals are non-stiochiometric, with a Cd:Se ratio of 1.2:1 ± 0.1, that all surface Cd atoms are passivated by TOPO, and that the ideal location of the excess Cd was at the Se-rich (010′) facets (Figure 8). We did not observe channeling of the He ions through the nanocrystal due to the random orientation of the nanocrystals on the substrate.

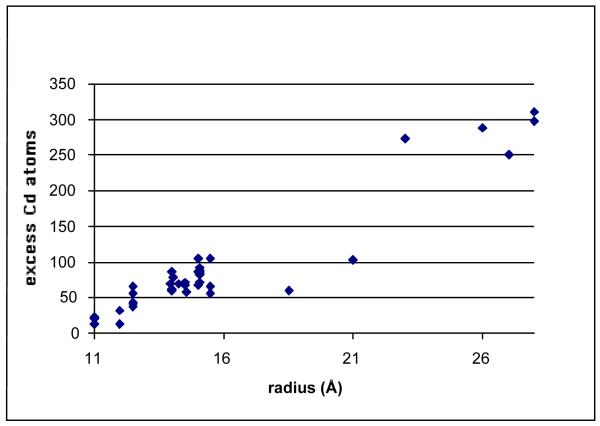

The absolute Cd:Se ratios determined for nanocrystals ranging from 22 Å to 56 Å in mean diameter are summarized in Figure 21. In all cases we found the nanocrystals are Cd rich. The Cd:Se stoichiometry decreases from 1.2 at 22 Å to 1.15 at 56 Å. To convert the Cd:Se ratios in Figure 21 to a number of excess Cd atoms (Figure 22) it is only necessary to know the total number of atoms in a nanocrystal of a given mean diameter, which is the atomic density of CdSe multiplied by the volume of the nanocrystal. Using the experimentally determined shape and size dependent aspect ratio (long/short axis, Section 2.4 above), we determined the volume of a hexagonal prism capped with two frustums to obtain the volume of the nanocrystals and thus the number of Cd atoms.

Figure 21. Stoiciometry of TOPO-prepared CdSe nanocrystals determined by RBS.

The average Cd:Se ratio of all samples is 1.2:1 ± 0.1, indicating that the nanocrystals are Cd rich.74

Figure 22. Number of excess Cd atoms on TOPO prepared CdSe nanocrystals as a function of size.

The change in the stoichiometry due to size is likely the result of asymmetric growth as the nanocrystal becomes larger.74

The size dependence of the excess Cd atoms depicted in Figure 22 does not follow a simple r2 dependence. Given the non-spherical shape of the nanocrystal and the non-uniform surface sites for excess Cd, discussed below, this is to be expected. The characterization of these nanocrystals by X-ray diffraction indicates the core is stoichiometric wurtzite. The luminescence is dominated by the band edge fluorescence, indicating the absence of vacancy defects which would have to be present if the excess Cd were distributed throughout the crystal. We therefore conclude the excess Cd is on the surface of the crystal.

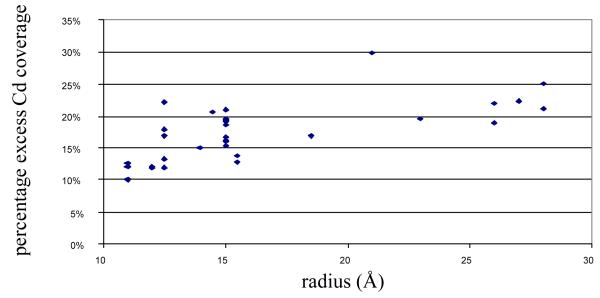

In Figure 23 the excess Cd is displayed as a fraction of the total surface atoms. The total number of surface atoms is obtained by calculating the total surface area and multiplying by the atomic surface density. Values of the excess Cd coverage are in the range of 15-20%, consistent with a substantial surface enrichment. These values indicate that approximately 1 in every 5-6 surface atoms is an excess Cd atom. The absolute P:Cd ratios determined by RBS are extremely similar to those determined by XPS.24 The percentage of phosphorous atoms covering the surface atoms as determined by RBS is presented in Figure 24.

Figure 23.

Excess Cd atoms in TOPO-prepared CdSe as a function of size given as a percentage of total atoms.74

Figure 24. Surface coverage of TOPO on CdSe nanocrystals as a function of nanocrystals size as determined by RBS.

This data contradicts the XPS results, instead suggesting slight increase of coverage as the nanocrystal size increases. This is likely due to the steric bulk of the TOPO ligands limiting the maximum amount of coverage of small nanocrystals.74

As XPS analysis indicated that there was no tributylphosphine coordinated to the nanocrystals, each phosphorous atom represents one TOPO molecule. From this data we obtain an average TOPO surface coverage of 70 %. This TOPO surface coverage is larger than that reported by XPS. This difference originates from considering the atomic surface density of a hexagonal prism capped with two frustums and counting only those atoms which are not fully four-fold coordinated as surface atoms.

The RBS analysis reveals intriguing insight in to the structure of these TOPO only nanocrystals. The presence of excess Cd is not due to contamination from unreacted starting material as RBS analysis of the supernatants used in the washing procedure verified that unreacted Cd and Se are completely removed with the third methanol wash. The excess Cd is either a result of the initial excess Cd used in the synthetic reaction mixture or is a result of the surface passivating ability of the TOPO ligand. We found the stoichiometry to be independent of the initial amount of Cd in the reaction mixture, therefore the excess Cd must be due to the stabilization of Cd dangling bonds by the passivating TOPO.

Dangling bonds from unpassivated Cd and Se surface atoms lead to higher energy surfaces. As described above in Section 3, XPS indicates surface Se atoms are bare while surface Cd atoms are coordinated to TOPO. It is therefore consistent that excess Cd would passivate surface Se atoms. However, not all surface Se atoms are equivalent. For example, Se atoms on the (101) facets (see Figure 8) are ideal sites for excess Cd, as one Cd atom can tie up two Se dangling bonds without the addition of strain energy or requiring surface reconstruction. The Se atoms on the top surface Se (001′) and equatorial CdSe (100) planes, however, have only one dangling bond. If excess Cd atoms passivated these Se surface atoms, one dangling Se bond would be passivated but two Cd dangling bonds would be created, so this is a less favorable site for excess Cd. Preferential passivation of the Se facets is also consistent with the observation that CdSe nanocrystals prepared in TOPO have a permanent dipole moment,76 as the Se (001′) terminating plane retains its partial negative charge. Location of excess Cd atoms at the Se facets would lead to an egg shape of the nanocrystals. This shape can be seen in some Z-STEM images of large nanocrystals (below in Section 5, Figure 45). The passivation of Se atoms with two dangling bonds also explains why the midgap absorption features predicted by Leung and Whaley are not observed experimentally.23, 89 Thus, the RBS results not only provide insight into nanocrystal structure but helps explain other experimental and theoretical observations.

Figure 45. Z-STEM of TOPO CdSe.

This is one of the first aberration corrected Z-STEM images of a CdSe sample. The shapes of the nanocrystals seem irregular with some exhibiting an elongation along the c-axis.