Abstract

The National Food and Nutrient Analysis Program (NFNAP) was implemented in 1997 to update and improve the quality of food composition data maintained by the United States Department of Agriculture (USDA). NFNAP was designed to sample and analyze frequently consumed foods in the U.S. food supply using statistically rigorous sampling plans, established sample handling procedures, and qualified analytical laboratories. Methods for careful handling of food samples from acquisition to analysis were developed to ensure the integrity of the samples and subsequent generation of accurate nutrient values. The infrastructure of NFNAP, under which over 1500 foods have been sampled, mandates tested sample handling protocols for a wide variety of foods. The majority of these foods were categorized into several major areas: 1) frozen foods; 2) fresh produce and/or highly perishable foods requiring refrigeration; 3) fast foods and prepared foods; 4) shelf-stable foods; 5) specialized study and non-retail (point of production) foods; and 6) foods from remote areas (e.g. American Indian reservations). This paper describes the sample handling approaches, from the collection and receipt of the food items to the preparation of the analytical samples, with emphasis on the strategies developed for those foods. It provides a foundation for developing sample handling protocols of foods to be analyzed under NFNAP and for other researchers working on similar projects.

Keywords: NFNAP, Sample handling, FALCC, Food sample procurement, Food composition database, Sampling strategy, Data management and compilation, Quality assessment, Food analysis, Food composition

1 Introduction

The National Food and Nutrient Analysis Program (NFNAP) was implemented in 1997 by the Nutrient Data Laboratory (NDL), U.S. Department of Agriculture, in cooperation with the National Institutes of Health, National Heart Lung and Blood Institute, in order to update and improve the quality of food composition data maintained in the USDA National Nutrient Database for Standard Reference (SR; NDL, 2008). This ongoing program is designed to sample and analyze frequently consumed foods in the U.S. food supply in order to obtain robust and nationally representative estimates of their mean nutrient content, with the intent of updating and expanding the quantity and quality of food composition data in USDA’s databases (Haytowitz et al., 2008). Over the last 12 years, NFNAP has received support from nine to seventeen Institutes and Offices of the National Institutes of Health to generate nationally representative analytical data for key dietary contributors in both retail and fast-food markets. The National Cancer Institute currently coordinates the National Institutes of Health collaboration in this program.

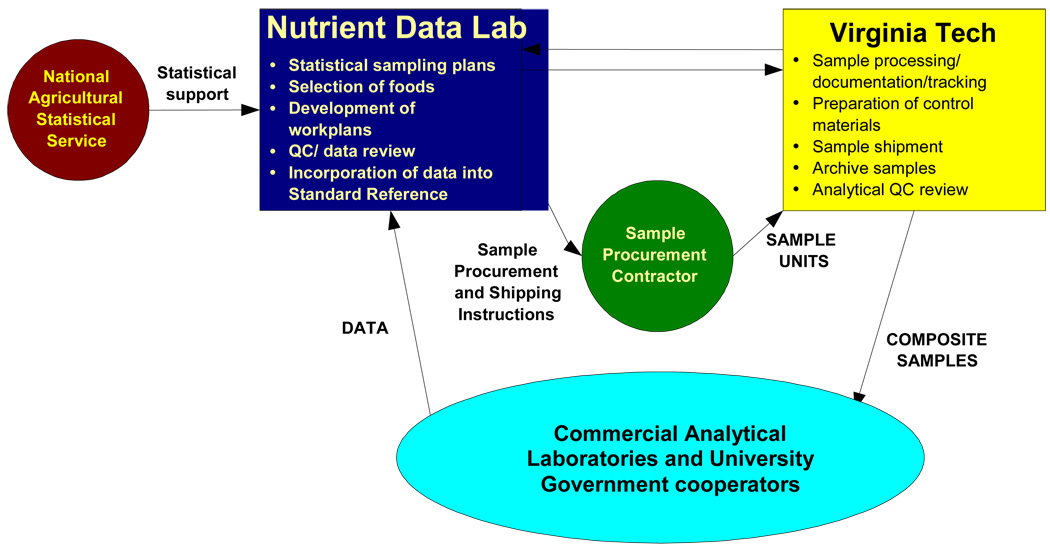

The NFNAP, a multi-site coordinated process (Fig. 1), includes the development of statistically-based sampling plans at NDL, food sampling, food compositing and sub-sampling, and ultimately nutrient analysis and data review, compilation, and dissemination (Haytowitz et al., 2008; Phillips et al., 2006). Because of extensive experience in these areas, the Food Analysis Laboratory Control Center (FALCC) at Virginia Polytechnic Institute and State University (VPI) in Blacksburg, Virginia has been responsible for sample preparation, distribution, and analytical quality control. This lab serves as the centralized coordinating center and processing facility for the NFNAP and is responsible for receiving, storing, homogenizing, inventorying, and then dispensing laboratories.

Figure 1.

NFNAP infrastructure.

Careful handling of food samples from the time of acquisition to the time of analysis is critical to ensuring the integrity of the samples and subsequent generation of accurate nutrient values. No single university/research facility currently can meet the analytical demands for all components and foods for the entire project. Therefore, NDL has qualified a number of commercial food analysis laboratories and identified government and university laboratories for analysis of specific nutrients where specialized expertise is required. Once the analytical results are received by NDL from the labs, they are reviewed by NDL’s Quality Control panel, migrated into the Nutrient Databank System and released in annual updates of the USDA National Nutrient Database for SR on NDL’s Web Site (www.ars.usda.gov/nutrientdata).

Since 1997, as the NFNAP infrastructure evolved, a systematic approach was developed for collecting and handling a wide range of foods to optimize the stability of nutrients in various types of products, such that the levels would not deteriorate beyond what they would be at the point of purchase/consumption. The expense of purchasing and shipping food samples throughout the United States under a nationally representative sampling plan is not inconsequential, and therefore it is imperative that sample integrity is maintained at all levels.

To date, the published literature is limited documenting proper protocols for large-scale food sample collection and shipment from retail outlets in order to preserve product integrity and minimize vitamin and other nutrient deterioration. The Total Diet Study, conducted by the U.S. Food and Drug Administration (FDA), is an ongoing program to analyze nutrients and contaminants in selected foods consumed by the U.S. population (FDA, 2010). Similar to NFNAP, foods in the Total Diet Study are analyzed as consumed (table-ready). The Total Diet Study foods are sampled in several large cities across the U.S.; NFNAP sampling, however, has a greater breadth of geographical dispersion, with at least 12 sampling locations selected according to a probability-proportional-to-size plan, brand selection reflective of current market share data, and specific sample handling procedures. This paper summarizes the NFNAP sample handling approaches, from the collection and receipt of the food items from statistically rigorous, nationally representative sampling plans, to the preparation and dissemination of the analytical samples, that have been developed for different foods, including perishable products, fast-foods, shelf-stable retail items, and industrial ingredients.

2 Program Overview

2.1 Selection and Ranking of Foods

Foods to be analyzed are identified by NDL scientists using the USDA Key Foods approach (Haytowitz et al., 2000, 2002), which utilizes food composition and food consumption data to set priorities for foods and nutrients for analysis. Different sources of market share data are used to identify specific brands and/or menu items within the various classes of foods. For high consumption retail foods, A.C. Nielsen (The Nielsen Company) and Information Resources, Inc. (IRI) data are considered. Market data for retail foods are analyzed based on grams consumed rather than dollar volume sales. For other foods, company and trade association data are utilized. An alternative approach has been applied to fast foods. Rankings from Restaurants and Institutions™, a trade journal which covers quick-service and limited-service chains, have been used to select nationally representative fast-food chains for each specific food category (e.g. fast-food fried chicken) based on total dollar sales. Based on industry data and market information provided by the company’s corporate offices, the top consumed items within these chains were sampled.

2.2 Development of Sampling Plans

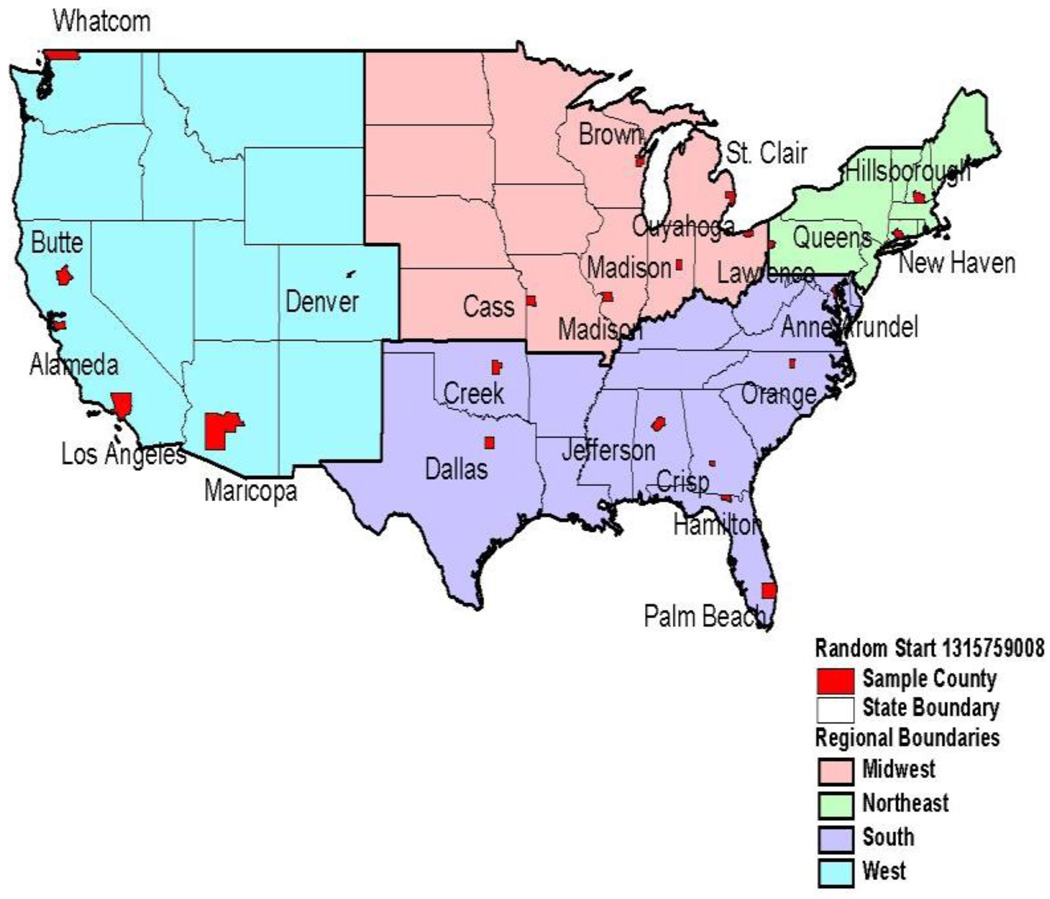

A probability-proportional-to-size food sampling plan has been developed by NDL staff in collaboration with statisticians from the National Agricultural Statistics Service, USDA (Pehrsson et al., 2000). The original NFNAP sampling design was stratified in three stages and incorporated adjusted 1990 census data for four geographic regions (nearly equal in population size) across the 48 conterminous states. A revised sampling design was developed using 2000 census data (Perry et al., 2003); it was also based on a stratified three-stage design using 2001 Census Bureau-projected state population sizes and census regions (U.S. Census Bureau, 2002; Fig. 2). To establish specific retail stores in 24 locations within statistically selected counties, sales volume data were purchased from TradeDimensions (Westport, CT) for supermarkets which had over $2 million dollars in annual sales. Pick-ups of sample units (e.g. bottles, packages, boxes) have been performed in 24 locations, though more typically taken from a random and geographically dispersed subset of 12 locations. A modified NFNAP sampling frame was used for sampling fast foods. For each fast-food chain, food samples were picked up at 12 different locations across the U.S. With few exceptions, fast-food restaurants were located within a 25 mile radius of the retail grocery outlet selected by the original NFNAP sampling plan. Actual retail and fast food sampling sites have been modified throughout the course of the project to incorporate updated census data to maintain a nationally representative, population-based sampling plan. Typically, only one retail store or one fast food restaurant was used to obtain the food samples in each city. In some cases, foods had to be purchased at alternate stores or restaurants in certain locations.

Figure 2.

Current sampling plan for the NFNAP.

2.3 Procurement of Foods

To purchase actual food sample units, NDL contracted with a company which specializes and has extensive experience in procuring and shipping items on a nationwide basis. The contractor was selected under USDA’s contract award process where proposals from offerors were evaluated and the best qualified company was selected. Selection criteria included the company’s ability to pick up food samples simultaneously from multiple cities and ship them to designated processing facilities according to NDL specifications. Food samples were purchased at major grocery supermarkets, convenience stores, fast-food chains, or restaurants according to the designed sampling plans. Agents, trained to carefully follow detailed instructions and familiar with the stores in the specified city, purchased all samples. In the event the sample arrives at the processing facility in poor condition or if the wrong item was purchased, replacement samples are obtained by the contractor at their expense.

Primary and alternate locations where retail or restaurant food items are to be purchased were chosen by NDL and are provided to the pick-up contractor. Primary outlets are designated as those stores where agents should first attempt to purchase all food items. If items are not available at the primary outlet, agents are instructed whether or not to proceed to the alternate store to look for missing items, depending upon the importance of the food. On certain occasions, agents are asked to go to more than one alternate outlet in search of a missing item.

Detailed instructions specifically tailored for the types of foods to be purchased have been developed by NDL for each sample pick-up. These instructions include guidelines for the selection of products (including brand information where relevant), labeling requirements, storage, and handling of products prior to shipping, as well as packaging and shipping specifications. Many factors are taken into consideration in developing specific guidelines for each sample pick-up, including balancing the number and types of foods purchased at one time. Since perishable foods have to be processed within a short time interval, individual sample pick-ups have been designed to include a mix of shelf-stable and perishable foods, corresponding to practical limits on storing and processing foods during a given time frame. For example, an overabundance of refrigerated or frozen foods becomes logistically difficult to handle due to the number of coolers and amount of dry ice and/or freezer packs required. The procurement of perishable foods requires agents to have coolers containing either freezer packs (e.g. blue ice packs) for refrigerated foods or dry ice (for frozen foods) on hand at the time of purchase in order to maintain proper handling temperatures.

To reduce the number of incorrect or unacceptable products received, a large quantity of descriptive information is included in the instruction packets provided to the agents. Market checks and background investigation into the products prior to the pick-ups, such as contacting food manufacturers to determine distribution areas, are performed by NDL staff in order to eliminate error on the part of the purchasing agent. Detailed sample information, such as precise brand and full product name, package size, UPC code, and desired quantity have been provided by NDL when food samples are purchased from retail supermarkets. Since expiration or sell-by dates are associated with many types of food samples, instructions to avoid expired products and to select foods with the longest expiration dates are also provided in the guidelines for each pick-up. If foods are sold under more than one name, i.e. hazelnuts and filberts, broccoli rabe and rapini, chick peas and garbanzo beans, all possible names are provided. Determination of the proper amount to purchase is critical in assuring the processing facility has adequate sample volume. When multiple units of a particular item are to be purchased at each location, specific instructions as to whether each unit is required to have the same lot number or production code are given. Substitutions (e.g. substitution of brand or package size) are permitted, and guidelines regarding what to do if a product is not found are also critical parts of each agent’s instruction packet. If samples are obtained from another venue, such as a fast food or carry-out type restaurant, exact menu item and size descriptions, as well as store hours, are provided. If large quantities are to be sampled, such as fried chicken from leading fast-food chains, agents are instructed to place orders several days in advance of the pick-up.

All necessary supplies are provided by the contractor and shipped to the agents approximately one week before the scheduled pick-up date. Supplies typically include styrofoam coolers or cardboard boxes, zippered plastic bags, bubble wrap, blue ice packs, labels, permanent markers, and the instruction packet. Labels are printed by the contractor and filled out by the agents. Each sample unit, excluding fresh produce, is required to have a label stating the product name, name and address of store where purchased, and date of purchase. The contractor typically allows the agents a one-to two-day window in which to purchase and ship food samples. The majority of foods are wrapped according to standard protocol and shipped to FALCC at VPI. Given that so many of the foods sampled under NFNAP are perishable, coordination and shipping methods that insure foods arrive at the processing facility the day after purchase are critical. Timing issues, such as different time zones and length of time necessary for foods to arrive from distant locations, are taken into consideration. A small percentage of food samples, such as unprocessed fresh meats and some fast food meat items, are sent to other processing facilities where personnel have expertise in handling certain types of foods, unique processing equipment (e.g. institutional cooking equipment), or specialize in analysis of specific nutrients. Fresh and fast-food chicken items were sent to Texas Tech University and fresh pork and ground beef were sent to the University of Wisconsin. The designated processing facility receives and logs in all samples. Sample units are composited and homogenized according to NDL specifications. In some cases, samples are prepared as individual units to form a single homogeneous composite for analysis, while others are combined with sample units from other locations to form the composite. Aliquots of homogenized samples are sent to contract labs for analysis. Archive samples are processed and stored in accordance with NDL guidelines.

2.4 Sample Receipt and Quality Assurance

Since the majority of food samples are received and processed at FALCC, specific sample handling protocols have been developed for NFNAP foods. On the day of receipt, samples are inspected for integrity, including ascertaining that the packaging provided by the manufacturer, retailer, and/or pick-up agent is intact and that the product is in good condition. The temperature of frozen samples is evaluated as they arrive; dry ice is expected to be remaining in the cooler, with no apparent signs of sample thawing; for refrigerated samples, both the products and refrigerator packs are expected to be cold. Sample identities and product labeling are verified against the product descriptions provided to the contracting agents and to FALCC by NDL, and deviations are reported to NDL. The date of purchase, store name, and store address recorded by the agent on the required label are also verified. NDL has designated whether any damaged, incorrectly sampled, or expired products are to be omitted, re-shopped, or replaced by a local sample(s). Food products are stored in the appropriate location (e.g. frozen (−20°C)), refrigerated, or at ambient temperature according to their perishability, until composited and sub-sampled. Expiration dates are tracked to ensure that perishable products are prepared for analysis prior to the expiration date.

A custom-developed database is used to maintain descriptive information about samples received and documentation of all handling, processing, and distribution of the composite sub-samples for analysis. It is designed to track each sample from arrival at the processing facility to the point of data receipt by the analytical laboratories. Each sample unit received is assigned, when logged in, a unique alpha-numeric identification number. All log-in information and subsequent composites and sub-samples of composites are linked to that number. Sample parameters (brand, size/weight, store/city/state of purchase, purchase date, receipt date at FALCC, expiration or sell-by date, packaging, lot number, and UPC code) are entered. Additionally, information from the “Nutrition Facts” panel on each package is itemized in an electronic spreadsheet. Product labels are saved and sent to NDL for inspection and archiving or storage. Digital photographs are taken of samples that were not packaged/labeled (e.g. produce, fast food). A sample identification card showing the sample number, sample description, outlet, and date the picture was taken is included in each photograph.

Quality assurance measures are followed to ensure the accuracy of information stored and of sample handling. At the time samples are to be processed, the quality control officer verifies that the information in each database field has been entered correctly upon log-in, and makes any necessary changes. Each sample unit received is assigned to a composite(s) in the sample tracking database based on the sampling plans developed by NDL. These links are double-checked at the time that the compositing worksheets are reviewed to verify that the correct sample numbers are recorded on the compositing worksheets and that the correct sample numbers are assigned to the composites in the database. Freezer, refrigerator, and room temperature of the sample and subsample storage locations are monitored and logged daily as further quality assurance measures.

Since the origin of the NFNAP project, over 1500 food items representing a wide variety of foods have been sampled. The majority of these foods can be categorized into several major types: 1) frozen foods; 2) fresh produce and/or highly perishable foods requiring refrigeration; 3) fast foods and prepared foods; 4) shelf-stable foods; 5) specialized-study and non-retail (point of production) foods; and 6) foods from remote areas (e.g. American Indian reservations). Food sample handling and shipping strategies have been developed to account for the unique challenges of each category. Through this process, many valuable insights have been gained.

2.4.1 Frozen Foods

Maintaining food samples at frozen temperatures for the entire duration of shipping requires adequate levels of dry ice and sturdy, well-constructed coolers (e.g. styrofoam). The availability and quantity of dry ice needed must be determined by considering the original temperature of the food, the pounds of food to be cooled, the external temperature, and the amount of time for delivery/shipping. Although it depends on the size and shape of the food sample, a one-to-one ratio for weight of dry ice per weight of product has been used as a general guideline in determining the quantity of dry ice needed. Pre-ordering dry ice is essential to insure availability on the day of purchase and shipping. If samples are purchased in rural or remote areas, obtaining dry ice may prove challenging. In addition, the manner in which the cooler was packed has a significant effect on the quality of product received at the processing facility. Products to be shipped are pre-frozen before being placed in the cooler. Careful layering of product between insulating paper and three separate layers of dry ice (bottom, middle, and top) was found to be the optimal method of packing. Product is evenly distributed throughout the layers. No items are placed on the bottom of the cooler under the first layer of dry ice. Dry ice in pellet form is preferable to larger chunks. If dry ice is available only in block form, large blocks have to be broken into small pieces before use.

For optimal frozen storage, it was found that placing solidly frozen items into a cooler packed with dry ice helps to maintain a more uniform temperature among food items throughout the duration of shipping. In this manner, the supply of dry ice is not being used to actually freeze the foods, but rather to maintain the foods at a frozen temperature. If a pick-up involves hot foods, such as from a fast-food or other restaurant, the best method for avoiding spoilage and preserving the condition of the food as it was purchased is to freeze the food items for 18–24 hours prior to shipping so that all units were shipped to the designated location in a frozen state rather than the original state of purchase. Some of these foods require re-wrapping or bagging in re-sealable plastic bags and/or containers prior to freezing. Agents for the pick-up service either have home-size freezers large enough to accommodate the number of food samples purchased for a given pick-up, or freeze the product in the styrofoam coolers themselves. If no home freezer is available, agents monitor temperature of foods while freezing and replace the supply of dry ice prior to shipment. All coolers containing frozen foods are shipped via priority overnight service.

In order to maintain frozen foods at the proper temperature, it is imperative that purchasing agents bring coolers filled with dry ice to the store where food samples are to be purchased. All frozen foods should be purchased at one time and immediately taken to the vehicle and placed in coolers filled with dry ice. The amount of time frozen foods are in the shopping cart should be minimized. The condition of all frozen items should be checked upon receipt. Package size can be critical to allow products to remain in a frozen state, particularly for items that have been purchased as prepared or refrigerated but which will be shipped as frozen items. Smaller package sizes freeze more quickly, are easier to keep frozen during shipping, and should be purchased whenever possible. For example, if sampling six pounds of ground beef from each supermarket, six one-pound packages are preferable to two three-pound packages, if that decision is compatible with the critical elements of the sampling plan.

2.4.2 Highly Perishable and/or Refrigerated Foods

Fresh Produce

Fresh fruits and vegetables can be extremely perishable and often prove difficult to ship. Due to the short shelf-life of most produce, immediate handling at the processing facility is usually required. Before spending large amounts of money obtaining produce samples on a nationwide basis, a pilot study was necessary in order to determine optimal packing materials and shipping methods. As part of the NFNAP project, small-scale pilot studies were performed on bananas, raspberries, strawberries, and blackberries. Samples were purchased in Illinois by the pick-up service and shipped to VPI in Blacksburg, Virginia. Bananas at various stages of ripeness were selected in order to compare how overnight shipping would affect the final color and texture upon arrival at VPI. The extremely fragile nature and short shelf life of fresh berries necessitated a trial run to determine if it was possible for them to arrive in acceptable condition (Fig. 3). After the pilot study, containers for blueberries, raspberries, blackberries, and strawberries are secured with rubber bands and all sides taped in both directions to prevent produce from spilling out into the cooler during shipping. To prevent juice from one type of berry from contaminating other produce or food items, each variety of berry is shipped in separate coolers and any extra space in the coolers filled with large amounts of packing material.

Figure 3.

Open and leaking package of strawberries arrives at FALCC.

Based on the number of sampling locations for NFNAP samples, it is necessary to stagger the pick-up dates so that half the samples for a given item are received one week and the remainder received the following week to avoid the simultaneous delivery of too many perishable items at once. For example, produce samples were purchased at 12 retail stores across the United States. Since the analytical work plan called for four composites for selected nutrients, the country was divided into four geographic regions and samples were received from three separate stores within each region. VPI received produce samples from two regions during the first week of a pick-up and the remaining two regions the following week. The number of different fresh fruits or vegetables received in each pick-up was limited to the number of items that could be composited and processed in one week.

Fresh fruits and vegetables are sampled from all areas of the produce bin, including the top, middle and bottom. Purchasing agents are provided with instructions on how to sample from the bin and how to select individual pieces of fruit and vegetables. These statistically based procedures are designed to prevent agents from choosing only first-rate pieces of fruit and/or vegetables from the top of the bin. Produce with obvious signs of spoilage or intrinsic damage, i.e. mold, skin split open, overripe, wilted, or rotted items are to be excluded. Fruit and vegetables that are not in perfect condition can be selected as long as they do not have any damage that would result in complete spoilage upon arrival at VPI. Procedures have been developed to optimize the likelihood that fresh produce arrives at VPI in the best condition possible. Some coolers (e.g. styrofoam boxes) are perforated with 10 1" diameter holes drilled 2–3" from top of cooler to allow for air to circulate. Holes have been strategically placed in each side of the cooler to allow for optimal air flow. The bottom of each cooler is packed with approximately 4.5 pounds of freezer packs or blue ice. Although weights vary depending on the type of fruit or vegetable being sampled, each cooler typically contains approximately ten to fifteen pounds of produce. The number of freezer packs placed in each cooler is targeted to keep fruit cold but not frozen. Levels of blue ice are adjusted if produce is shipped during extremely hot weather. Layers of clean newsprint or other insulating material are used as cushioning and prevent the produce from coming in direct contact with the blue ice.

Individual pieces of produce, such as apples, nectarines, plums, etc. are placed in a plastic shell trimmed to fit snugly inside the styrofoam cooler (Fig. 4). A second plastic shell is fitted upside down over the produce. Plastic shells are the same type used to ship fruit from farms to distributors or supermarkets. Additional layers of newsprint or other barrier material are placed on top of the sandwiched shells to add cushioning and fill the remaining void. Fragile items, such as lettuce, greens, and asparagus, are wrapped in damp paper towels and placed in unsealed plastic bags prior to shipping. Whole watermelons are placed in individual coolers and shipped separately.

Figure 4.

Plastic shell used in shipping some produce items.

A survey form is completed by the pick-up agent at each store. Information indicating where fruit was grown (country and/or state of origin), how it was stored in the produce section of the store (chilled or at room temperature), whether it received misting, and the condition of fruit at time of purchase is collected.

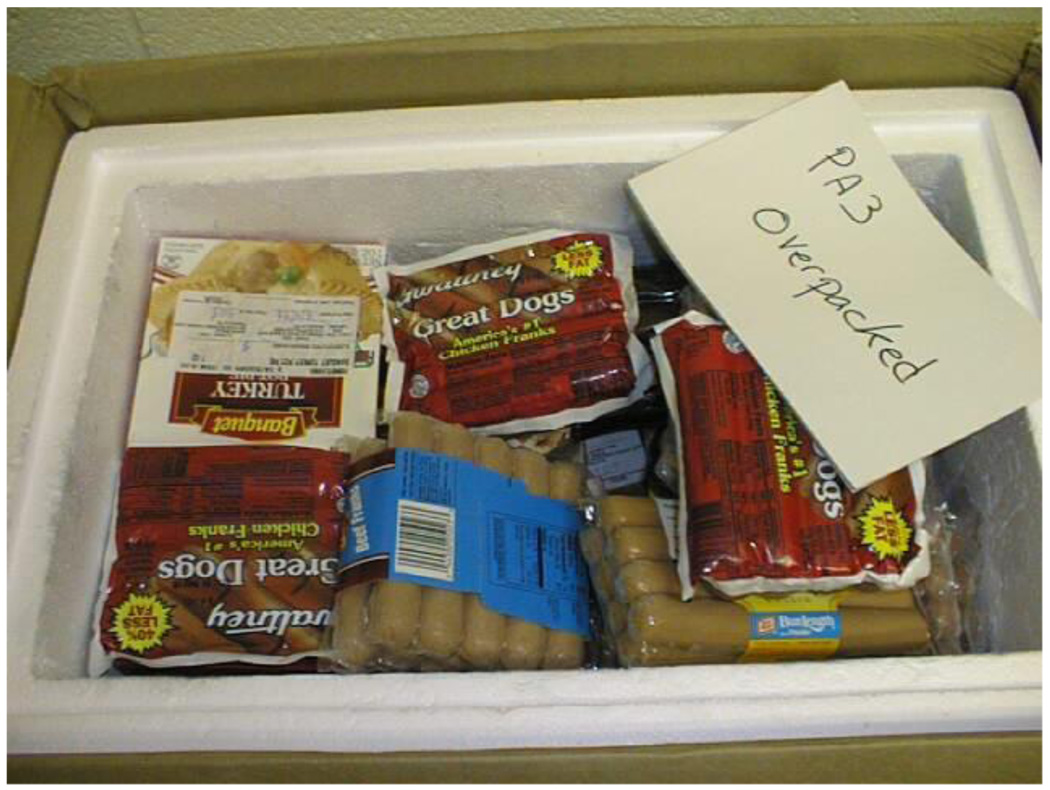

Refrigerated Foods

Over the course of the NFNAP project, a wide array of refrigerated foods have been purchased in retail grocery stores and shipped to VPI. Pre-frozen freezer packs are used as the cooling medium for shipping and handling. Most refrigerated items are handled in a similar manner to frozen foods. Purchasing agents bring coolers filled with freezer packs to the store where refrigerated items are purchased in order to maintain samples at the proper temperatures during transport. For shipment to the processing facility, product is layered between pre-frozen freezer packs and insulating paper, with product evenly distributed throughout two to three layers in each cooler. In some cases, items are frozen prior to shipping and shipped as frozen samples rather than refrigerated foods. Care must be taken not to overcrowd the cooler (Fig. 5a) so that contents remain at appropriate temperatures.

Figure 5.

a: Example of an improperly packed cooler.

b: Biscuits damaged during shipping.

c: Glass bottles damaged during transport.

Although some foods may be packaged in relatively sturdy containers, it is still necessary to use some type of insulation between individual items placed in the cooler in order to avoid damage and/or breakage during shipping (Fig. 5b). In the case of fresh eggs, outer cartons are wrapped in several layers of bubble wrap and thick layers of newspaper are placed between each carton. Styrofoam peanuts are added as additional protection. Due to the extremely fragile nature of some products, extra product is purchased to account for inevitable loss due to inadvertent rough handling during shipping.

2.4.3 Shelf-Stable Foods

Most shelf-stable items purchased and analyzed under the NFNAP project have not required specialized shipping and handling methods such as those used for refrigerated and frozen foods. Items are packed in cardboard boxes rather than styrofoam coolers and are generally shipped to VPI via truck service. Dividers are used in the boxes in order to separate fragile items wherever appropriate. Items packaged in glass bottles or flimsy plastic containers are wrapped in bubble wrap or newspaper to offer cushioning during transport. Fig. 5c shows the necessity of providing adequate protection to guard against rough handling during transport. Although packages were marked “fragile” or “this end up” when appropriate (e.g. eggs), it cannot be assumed that those boxes will be treated according to label information once in the hands of the shipping company. To alleviate problems with packages breaking open inside the boxes, shelf-stable items, such as bags of rice, beans, flour, etc., are placed in individual plastic bags. This prevents contamination of other items if damage to the outer packaging causes product to spill out. The use of plastic bags results in samples that can be salvaged when deterioration of the outer food packaging occurs, thus preventing the need for a re-shop of that product.

2.4.4 Fast-food

Menu items from the leading hamburger, chicken, Mexican, and pizza fast-food chains have been sampled under NFNAP. All establishments sampled have national representation; however a few of the chains had no restaurants in several of the statistically selected counties of the sampling plan. Specific procedures for shipping and handling are similar for the hamburger, chicken, and Mexican food outlets, as described below. Pizza and chicken require specialized instructions for handling and packaging and will be discussed in greater depth below.

Ideally, foods should be sampled immediately following preparation. To avoid selecting foods which have been held under warming lights for an undetermined length of time, menu items are purchased during the peak hours of breakfast, lunch, or dinner. Higher demand produces a quicker turnover during these times, requiring items to be replenished by the restaurant on a more frequent basis. When large numbers of foods are collected during a single shopping visit, menu items are grouped and purchased on two or more trips through the ordering line. Subdividing the order allows agents to properly handle all foods immediately upon receipt of product.

When handling fast food menu items, agents are instructed not to remove the outer wrapper or carton whenever possible. Items are labeled as soon as they are purchased and placed in individual zipper-type freezer bags. To help minimize moisture condensation as the foods cool, bags are not sealed until ten to fifteen minutes from time of purchase in order to allow foods to cool slightly. Beverages, such as sodas and coffee, are transferred to specially cleaned or prepared plastic bottles with leak-proof screw-type lids. Containers are selected to be appropriate for both hot and cold beverages. The bottles are prepared in advance of the purchase of beverages by marking a line in permanent ink on the outside of each bottle and containers were filled no higher than the line. If the entire contents of the beverage do not fit in one container, a second container is used for the remaining liquid. Bottles are further secured by attaching tape to the lid, then completely circling the container with tape from top to bottom at least two times. Each secured plastic container is placed in an individual zippered freezer bag. Bags containing plastic bottles are placed in padded mailing envelopes for shipping. Milkshakes are transferred from original cups to individual zippered freezer bags rather than plastic bottles for ease of freezing and shipping.

All fast-food menu items, excluding soda, coffee, and coleslaw (i.e. cold cabbage salad), are frozen for 18–24 hours and shipped on dry ice to VPI. Items such as nachos, which consist of one or more individually packaged parts, are kept intact. The lids of small plastic cups of cheese sauce or salsa are secured with tape and rubber bands, the cups placed in separate zippered freezer bags, and then frozen. Tortilla chips are shipped in separate zippered freezer bags. Coolers are packed with frozen fast-food items in the same manner as for retail frozen-food items.

Pizza

Specialized protocols have been developed to handle and ship carry-out menu items from the top four major pizza chains. To eliminate any mishandling during transport from the retail outlets, pizzas are not obtained via home delivery. Several different varieties of pizza are ordered by the purchasing agents 15–30 minutes prior to arriving at the specified location. Each pizza is sliced by store personnel into eight individual slices of uniform size. Each box contains a small plastic separator to prevent the cardboard box from coming in contact with the pizza. During transport, a maximum of two boxes are stacked on top of one another to prevent crushing. Plastic non-powdered food service gloves are worn by agents at all times when handling pizza and changed each time a different pizza is handled. Each pizza is divided along the center line with a clean pizza cutter and separated into two halves containing four slices each. Toppings that fall along the center line are sliced through and divided between the two adjoining slices. Once samples reach room temperature, each pizza half is placed in a separate extra-large zippered freezer bag for freezing and shipping. Halves are left intact and slices are not separated or stacked. Proper labeling of bags is mandatory to insure pizzas are composited correctly at VPI. All pizza samples are frozen for 18–24 hours and then shipped on dry ice to VPI.

Fried Chicken

Due to the large number of individual fried chicken pieces procured at one time (24 breasts, 24 thighs, 40 drumsticks, and 56 wings), orders are placed at each outlet two to three days prior to purchase. Specific pick-up times are arranged with the store to minimize potential problems on the designated pick-up day. To reduce the cost of the total order, multiple serving packages sold by the restaurant are purchased and subdivided. The remainder of the chicken is purchased as individual pieces. A pre-determined number of units is needed to provide ample product volume, requiring that purchasing agents open each container before leaving the premises to confirm piece counts. For shipping and handling, fried chicken pieces, as well as any breading left in the bottom of the original container, are transferred from store containers and placed in zippered freezer bags. Plastic non-powdered food service gloves are worn at all times and gloves are changed each time a different type of chicken is handled. The integrity of each package is maintained through careful handling and labeling, allowing the receiving facility to identify which chicken pieces/breading remnants are from each package. All chicken is frozen for 18–24 hours then shipped on dry ice to Texas Tech University.

Rotisserie Chicken

Rotisserie-baked whole chickens have been sampled in conjunction with the fast foods study due to their popularity and convenience as take-home meals. Chickens are roasted in retail grocery stores and are sampled from the warming case or shelf. Package weights vary due to individual differences in weight of birds. Ten to twelve chickens per store are pre-ordered two days before shopping. Due to the large number of birds purchased at one time, it is necessary to coordinate the preparation and time of pick-up with store deli departments. All stores use a hard plastic dome-shaped container with a separate bottom and interlocking top cover. Chickens are kept in the original packaging. An upright position is maintained at all times to prevent loss of juices and drippings from leakage. Rubber bands and string are used to secure lids on containers. Plastic shells containing the rotisserie chickens are double wrapped in plastic bags and samples frozen for 18–24 hours before they are shipped. Rotisserie chickens are shipped on dry ice to Texas Tech University for dissection and processing.

2.4.5 Specialized Non-retail Sampling Studies

Fluoride

The NFNAP model was expanded to include a much larger pool of locations for fluoride in drinking water (Pehrsson et al., 2006). Fluoride can be added voluntarily to municipal water supplies at the 1 ppm level. The number of samples contributing to the estimate of the mean is proportionally larger depending on the importance of the nutrient and food and the expected variability of the nutrient. In the case of fluoride in drinking water, a much larger set of locations was warranted because of the variability of fluoride. The coordination of agents and supplies was of the utmost importance in studies for which a more extensive and time-sensitive sampling is planned. NDL coordinated the collection of residential tap water samples from 144 selected homes in which the homeowners had agreed to provide samples of drinking water from their faucets. These homes were located in 71 different counties (one county was selected twice) across the United States. NDL provided the pick-up service with the name, address, phone number, and an appointment schedule for each homeowner. Specific instructions were provided on the exact manner in which tap water samples were to be collected from the home. Actual water samples were collected using specially designed kits and a water survey was orally administered and completed by the pick-up service representative. Two 250-ml plastic sample bottles were filled, labeled with pre-printed labels, placed in individual zippered plastic bags, and packaged for shipping in special pre-paid padded mailing envelopes. Packages were hand carried to the post office and mailed from inside the postal facility to prevent the possibility of water freezing and bottles bursting. Water sampling was repeated at the same location approximately four to six weeks later.

Industrial Food Ingredients

The prevalence of commercially prepared foods in the U.S. food supply warrants extensive and reliable sampling and analysis of industrial ingredients at the manufacturing facility. This enables NDL scientists to generate, through mathematical regression programs, complete nutrient profiles for commercially prepared multi-ingredient foods. These data are used to estimate the nutrient content of commercial formulations since it is not cost effective to analyze all the different foods available on the market. As an example, bread, cake, and all-purpose flour have been sampled in retail grocery stores and analyzed through NFNAP. However, it is also important to obtain representative nutrient profiles for wheat flours which typically are not sold in retail stores at protein levels used by manufacturers of bakery goods. To obtain samples of wheat flour at the desired protein levels, a sampling plan was developed using a list of the largest U.S. wheat, durum, and rye mills obtained from the Grain and Milling Annual 1999 report. Total daily milling capacity was used as a measure to divide the list of flour mills into 4 strata, with the sums of the daily capacities for mills within each stratum being approximately equal. A random sample of two primary mills, along with a probability-proportional-to-size substitution list, was drawn for each stratum. NDL personnel contacted the companies to inquire whether they would be willing to participate in the study. If willing, they were asked to provide samples of all flour they produced that fit in each of the protein categories. If any of the required protein levels were missing, companies on the substitution list were contacted to fill in the missing protein level. Each participant was sent an instruction letter, forms, and shipping materials. Specific details were provided for labeling and sample size requirements. Two-pound samples double-bagged in heavy duty zippered plastic bags were requested for each type of flour. Since samples had no identifiable outer packaging, precise labels were required in order for VPI to determine the type of flour and corresponding protein level sent by the manufacturing facility. Pre-printed labels with space to fill in all critical information were prepared by NDL and included along with the supplies.

Shipments From Remote Areas (American Indian and Alaska Native Reservations and Tribal Villages)

Sampling of foods for the American Indian and Alaska Native Foods Database requires the identification of 1) stratified regions across the 48 states based on geographical proximity and self-reported tribal enrollment data from the Bureau of Indian Affairs; and 2) harvest regions in Alaska. For tribes located in the conterminous 48 states, options for the sampling frame included five group sizes (six, 12, 24, 35, or 48 strata or regions). Identification of highly consumed foods was obtained through several approaches: 1) festivals or markets; 2) tribal member interviews on hunting and gathering practices and traditional food preparation methods; 3) senior centers and other food parties; 4) informal interviews at health clinics; and 5) other published scientific or government documents.

Hunted animals and harvested-from-wild plants require even more attention than retail products. Examples of foods consumed by the American Indian and Alaska Native populations were classified according to scope of availability and consumption: 1) common (deer, berries); 2) regional (e.g. Southwest mutton and corn); and 3) tribe-specific (ceremonial dishes). Before deciding on specific foods, special exemptions/approvals for American Indians and Alaska Natives to hunt endangered land or marine animal species may require a pre-approved application by researchers to handle sample material of these animals. Sampling efforts must respect the actual food value (cost) to the tribe; minimizing waste is important so securing the weight of the foods at the site must be planned. Seasonal (narrow windows of availability) considerations and extreme perishability of wild plants must be considered in the timing of the sampling and the packing equipment (See Fresh Produce).

Foods were identified and prioritized through interviews with tribal members, focus groups, publications, and ongoing research, both government and academic. Traditional native foods were selected for sampling if consumed in high amounts across tribes (e.g. deer, fish, and berries) or if consumed widely within a region of the U.S. (e.g. frybread). Samples were either purchased by NDL researchers or donated by tribal members.

In general, sampling in remote areas is even more challenging because of the lack the equipment and facilities immediately available in retail food locations and importance of tribal communication and proprietary tribal information. For example, the securing of foods takes place only after the tribal approval process has occurred. Usually, the designated pick-up location is a considerable distance from a shipping facility and dry-ice distributor. Samples secured at remote sites must be packed with more cooling or freezing agents to survive the transport to a shipping facility. Above all, knowledge of the foods likely to be available depending on the type of market, village store, etc., is crucial to minimize inconvenience to the tribe, maximize the number of foods to be sampled, and to be prepared for properly storing and shipping the foods.

3 Results and Discussion

Although many of the types of foods described above have different handling and shipping considerations, one important element common to all is the coordination of product arrival at the processing facility. The manner in which samples are to be composited was the primary consideration when sampling from multiple sites. If individual perishable samples arriving from multiple locations are to be combined and analyzed together as one aliquot, all foods going into the composite have to arrive at the processing facility within one to two days of one another. In addition, the facility has to be able to complete all composites within the first several days of receipt. In most cases, highly perishable foods cannot be held over a weekend without significant deterioration of the product. There is more flexibility built into the receipt and processing of foods which may be held under appropriate conditions and processed at a later date, such as shelf-stable and frozen foods. In order to avoid potential problems and delays, NDL requires all highly perishable foods to arrive at FALCC no later than Wednesday of a designated pick-up week. All other foods arrive no later than Thursday. Establishing a policy of prohibiting shipments from arriving on Fridays helped to prevent loss of perishable food samples due to unforeseeable problems, such as flights grounded by severe weather conditions and misplacement or loss of coolers by the delivery service.

Multiple factors must be taken into account in the design and implementation of a successful sample pick-up. The need to balance the type of foods purchased at one time and to stagger pickups from multiple locations so that the volume of product arriving at the final destination is manageable emerged as key factors in reducing problems associated with a pick-up. Scheduling also needs to avoid major holidays and other events. It is essential to determine how many boxes and/or coolers can be delivered by the shipping company on one truck and how many boxes can be proficiently logged in by the processing facility and placed under appropriate storage in one day. If larger amounts from many locations are to be sampled, some type of staggered pick-up has proven to be easier to manage. In addition, appropriate forms and proper labeling help reduce problems and expedite the log in process upon receipt of product at the designated location. A packing list or inventory sheet provides the recipient with an itemized list of all products in each box. To facilitate quicker sorting of boxes or coolers, the outside of each box is clearly labeled as to the contents of each container. Similar items are grouped and packaged together.

Extensive sampling of foods through NFNAP has enabled NDL to develop handling procedures that minimize shipping problems. The need for pre-determined tested protocols is critical to ensure samples arrive in good condition. The number of samples arriving in poor condition declined dramatically as NDL gained expertise with foods inherently difficult to transport. Previously, NDL had to re-shop many more samples. During the first two years of the project, approximately 10% of all samples received arrived in unacceptable condition. Overall, produce has proven to be more troublesome than shelf-stable and frozen foods and requires the most re-shops of any category of foods procured under NFNAP. Adjustments have been made to procedures based on the condition of the products upon arrival. These improvements have resulted in approximately 98% of food samples now arriving at FALCC undamaged and in good condition. This has provided a valuable reduction in the time it takes for samples to be processed and sent out for analysis. Since FALCC does not have unlimited storage space, the ability to composite and homogenize foods in a timely manner provides cost savings as well as the opportunity and room for more foods to be purchased and shipped.

The fact that each food and pick-up site poses unique considerations mandates that careful thought be given to the logistics of all sample collections. The types of foods to be purchased, as well as the location and climate of the sampling site, all play an important role in determining the most successful shipping and handling strategies. By having a centralized sample handling and processing facility, NDL has assured that sample identity and quality is maintained from sub-sample to sub-sample. Archiving of samples at FALCC provides the added benefit of allowing for sub-samples from the same composite to be sent to multiple labs for analysis of many different nutrients and components.

4 Conclusion

Over the span of the NFNAP project, the experience of purchasing and shipping over 1500 foods has provided NDL with a wide knowledge base and valuable insight into appropriate sample handling strategies. Sample integrity, from retail pick-up to receipt at the processing lab (FALCC), has improved from 90% to nearly 100% during the NFNAP lifetime. This is in large part because NDL has applied the knowledge gained from each pick-up and implemented pilot studies when necessary in order to effectively reduce the number of samples that had to be replaced or re-shopped due to shipping and handling inadequacies. Overall, the number of items arriving at the processing facility in unacceptable condition has drastically decreased. These results show that NDL has been successful at ensuring sample integrity from the time of purchase to the time of receipt in food sampling on a national scale. Therefore, the strategies can be used by other researchers working on similar projects to develop food sample handling protocols.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- Haytowitz DB, Pehrsson PR, Holden JM. Setting priorities for nutrient analysis in diverse populations. Journal of Food Composition and Analysis. 2000;13:425–433. [Google Scholar]

- Haytowitz DB, Pehrsson PR, Holden JM. The identification of key foods for food composition research. Journal of Food Composition and Analysis. 2002;15:183–194. [Google Scholar]

- Haytowitz DB, Pehrsson PR, Holden JM. The national food and nutrient analysis program: a decade of progress. Journal of Food Composition and Analysis. 2008;21:S94–S102. doi: 10.1016/j.jfca.2007.07.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nutrient Data Laboratory (NDL), Agricultural Research Service (ARS), U.S. Department of Agriculture (USDA) National Nutrient Database for Standard Reference, Release 21. [Retrieved 2008-09-03];2008 from: < http://www.ars.usda.gov/nutrientdata>.

- Pehrsson PR, Haytowitz DB, Holden JM, Perry CR, Beckler DG. USDA’s national food and nutrient analysis program: food sampling. Journal of Food Composition and Analysis. 2000;12:379–389. [Google Scholar]

- Pehrsson PR, Perry CR, Cutrufelli RL, Patterson KY, Wilger J, Haytowitz DB, Holden JM, Day CD, Himes JH, Harnack L, Levy S, Wefel J, Heilman J, Phillips K, Rasor A. Sampling and initial findings for a national study of fluoride in drinking water. Journal of Food Composition and Analysis. 2006;19:S45–S52. [Google Scholar]

- Perry CR, Pehrsson PR, Holden J. A revised sampling plan for obtaining food products for nutrient analysis for the USDA national nutrient database. [Retrieved 2008-08-25];2003 Proceedings of the American Statistical Association (CD-ROM) 2003 from: http://www.amstat.org/ASAStore/BOoks_Proceedings_CDs_C4.cfm. [Google Scholar]

- Phillips KM, Patterson KY, Rasor AS, Exler J, Haytowitz DB, Holden JM, Pehrsson PR. Quality control materials in the USDA national food and nutrient analysis program (NFNAP) Analytical and Bioanalytical Chemistry. 2006;384(6):1341–1355. doi: 10.1007/s00216-005-0294-0. [DOI] [PubMed] [Google Scholar]

- U.S. Census Bureau. U.S. Census Bureau Population Estimates 2001. [Retrieved 2007-07-02];2002 from < http://www.censusus.gov/popest/archives/2000s/vintage_2001/#state>.

- U.S. Food and Drug Administration (FDA), Center for Food Safety and Applied Nutrition. Total Diet Study. [Retrieved 2010-25-01]; from: < http://www.fda.gov/Food/FoodSafety/FoodContaminantsAdulteration/TotalDietStudy/default.htm>.