Abstract

Novel, unitized structures with porous Ti6Al4V alloy on one side and compositionally graded, hard CoCrMo alloy surface on the other side have been fabricated using laser engineered net shaping (LENS™) process. Gradient structures with 50%, 70% and 86% CoCrMo alloy on the top surface showed high hardness in the range of 615 and 957 HV. The gradient structures were evaluated for their in vitro wear rate and Co release up to 3000 m of sliding distance. The wear rate of ultrahigh molecular weight polyethylene and 100% CoCrMo alloy substrates found to depend on the hardness and microstructural features of the counter surface rubbing against them. In general, the wear rate of both the substrates increased with a decrease in the CoCrMo alloy concentration on the top surface of gradient pins. However, the wear rate of gradient pins was lower than 100% CoCrMo alloy pins due to their high hardness. Lowest wear rate in the range of 5.07 to 7.99 × 10−8 mm3/Nm was observed for gradient pins having 86% CoCrMo alloy on the top surface. The amount of Co released, in the range of 0.38 and 0.91 ppm, during in vitro wear testing of gradient structures was comparable to that of 100% CoCrMo alloy (0.25 and 0.77 ppm). Present unitized structures with open porosity on one side and hard, wear resistant surface on the other side can minimize the wear-induced osteolysis and aseptic loosening, and eliminate the need for multiple parts with different compositions for load-bearing implants such as total hip prostheses.

Keywords: Functional graded materials, Laser processing, Ti6Al4V alloy, CoCrMo alloy, In vitro wear, Co- ion release

1. Introduction

The high wear rate of ultrahigh molecular weight polyethylene (UHMWPE) liner used in traditional hip replacements is a cause of serious concern due to osteolysis. Osteolysis and aseptic loosening have been identified as major factors limiting the life of hip prostheses. Fine ultra high molecular weight poly-ethylene (UHMWPE) wear debris [1, 2], generated primarily at the interface between the femoral head and the acetabular cup, promotes this degradation. Such wear-particle-induced bone loss is considered one of the key factors affecting the long-term stability of UHMWPE liner-based total hip replacements and other load-bearing implants [3, 4]. Several attempts have been made to minimize the wear-induced osteolysis including the use of design modifications [5], UHMWPE property modification [6] and alternative bearing couples, such as metal-on-metal and ceramic-on-ceramic, eliminating the use of UHMWPE [7, 8]. Among these approaches, metal-on-metal is a popular one. However, current multi-component load bearing metal-on-metal hip implants suffer from low dynamic stability, interlocking mechanism problems, and possible malpositioning of the components during surgery including complicated/lengthy surgical procedures. Despite numerous literature documenting lower dislocation rates in association with enhanced soft-tissue repair techniques and the use of large-diameter femoral heads [9–12], hip instability/dislocation was the primary indication reported for a large percentage (22.5%) of revision total hip arthroplasty procedures [13]. Therefore, improved stability for enhanced longevity is still an important performance criterion in the development of orthopedic prostheses necessitating the development of innovative designs and use of unitized/mono-block implants.

Considering implant design and manufacturing, there is a growing interest in the fabrication of novel structures to mimic multiple tissues and tissue interfaces on the same implant, such as implants with gradients in porosity and pore sizes that will allow on one side of the implant high vascularization and direct osteogenesis, while promoting osteochondral ossification on the other. In this direction, innovative designs such as functionally graded acetabular shells with open porosity on one side in contact with the bone to improve cell–material interactions, and a hard ceramic/alloy coating on the other side in contact with UHMWPE liner to reduce liner wear can significantly improve the implant’s in vivo life. The benefit of using such unitized structures for metal-on-metal configuration is obvious such as the ability to use the larger femoral head diameter for a given acetabular diameter, which not only increases the range of motion and reduces the risk of dislocation, but also optimizes the tribology for decreased wear for this bearing couple [14, 15]. We have successfully fabricated and evaluated in vitro biocompatibility of compositionally and structurally graded CoCrMo-Ti6Al4V [16], TiO2-Ti [17] and ZrO2-Zr-Ti [18] unitized structures using laser engineered net shaping (LENS™) to minimize wear induced osteolysis. Other load bearing implant design concepts that can potentially be implemented via LENS™ processing can be found in [19].

Our earlier work [16] showed that functionally graded, hard CoCrMo alloy coatings on porous Ti6Al4V alloy can significantly increase the surface hardness without deleterious effects on in vitro biocompatibility. During microstructural analysis, notable changes were observed in the morphology and scale of the CoCrMo alloy phase as the concentration of CoCrMo alloy in the top surface of the gradient structures was increased [16]. It is generally accepted that the wear resistance of any alloy is primarily governed by microstructural features, such as the amount, morphology and distribution of hard particles in the matrix. Therefore, in the present investigation, in vitro wear performance and metal ion release rate of CoCrMo-Ti6Al4V gradient structures with different CoCrMo alloy concentrations in the top surface were evaluated. The wear rate and Co metal ion release was determined for these gradient structures rubbing against UHMWPE and 100% CoCrMo to simulate different articulating conditions.

2. Material and Methods

2.1 Gradient Sample Fabrication

Ti6Al4V alloy powder (Advanced Specialty Metals, Inc., Nashua, NH) with particle size between 50 and 150 µm and CoCrMo alloy powder (Stellite Coatings, Goshen, IN) with 50–100 µm particle size was used in this study. Gradient samples of 10 mm diameter were fabricated on a substrate of 3 mm thick rolled, commercially pure Ti plates using LENS™-750 (Optomec Inc. Albuquerque, NM) equipped with a 500W Nd:YAG laser and a double powder feeder system. Samples were fabricated in a glove box containing argon atmosphere with O2 content less than 10 ppm to limit oxidation of alloys during processing. Gradient pins with 50%, 70% and 86% CoCrMo alloy on the top surface were made at 450 W laser power and 22.5 mm/s scan speed. These compositionally graded structures consisted of porous (~ 30% porosity) 100% Ti6Al4V alloy in the first six layers. The composition in the transition region of the gradient structure was varied from 100% Ti6Al4V alloy at the first layer to various concentrations of CoCrMo alloy at the top layer over 5–6 layers. The porous region of first six layers of Ti6Al4V alloy were made at 200 W (to create 30 % porosity) and remaining layers were made at 450 W to achieve fully dense structures in the transition region and top surface of the gradient structures. In the transition zone, the powder feed rate for CoCrMo alloy increased from 0 to 46.5 g/min over the number of transition layers. For Ti6Al4V alloy, it was 17.5 g/min to start with and reduced to 0 g/min over the same number of layers. Complete process details and optimization details are provided in [16]. For comparison, 100% CoCrMo alloy pins ϕ (10 mm, 15 mm height) and 18 mm square blocks with 30 mm height were also made at 450 W laser power, 22.5 mm/s scan speed and 46.5 g/min feed rate. Top surface microstructures of the samples were examined using both optical and scanning electron microscopy (SEM). The average composition of the top surface of gradient structures was measures using a field emission SEM (FEI-SIRION) equipped with a “Genesis EDAX” energy-dispersive spectrometer (EDS). The hardness of gradient pins and laser processed 100% CoCrMo alloy was measured using Vickers microhardness tester (Leco, M-400G3) at 200 g load applied for 15 s.

2.2 In Vitro Wear Testing

In vitro wear testing was performed using 100% CoCrMo alloy pins (here after referred as P100) and gradient pins with 50, 70 and 86% CoCrMo alloy on top surface (here after referred as GP50, GP70 and GP86, respectively) rubbing against 3 mm thick square discs of UHMWPE and 100% CoCrMo alloy (here after referred as S100). The UHMWPE discs had dimensions of 25 mm × 25 mm × 3 mm, and 3 mm thick discs were cut from 18 × 18 mm square block of 100% CoCrMo alloy using a high pressure water jet. The top surface of the pins were machined to a radius of 40 mm and further ground using series of SiC grinding papers with various sizes up to 1200 grit. Samples were then polished on velvet cloth using a series of Al2O3 powder up to 1 µm suspended in distilled water. Similar procedure was used to prepare the surfaces of UHMWPE and 100% CoCrMo alloy discs. Finally, just before wear testing, all the samples were ultrasonically cleaned in an alcohol bath. The surface roughness of each test samples was measured using a surface profilometer (SPN Technology, Goleta, CA).

Linear reciprocating spherical tip pin-on-disc wear testing, according to ASTM G133, was performed using a tribometer (NANOVEA, Microphotonics Inc., CA, USA) with pins having 40 mm radius of curvature rubbing against UHMWPE (metal-on-PE) and 100% CoCrMo alloy discs (metal-on-metal). A linear oscillatory motion 10 mm in length (the full cycle represents 20 mm of travel) with a speed 1000 mm/min was used. Wear tests were carried out in simulated body fluid at 37±1°C to represent the biological environment in the body. The wear tests were performed with a normal load of 5N for sliding distances of 1 and 3 km (equivalent to 150,000 cycles). The width of the wear track was measured using SEM images of worn pins and substrates, and from the known curvature of the pin and linear oscillatory stroke length the wear track volume was estimated. The wear rates of UHMWPE, 100% CoCrMo alloy and gradient sample pins were then calculated in mm3/Nm.

2.3 In Vitro Metal Ion Release

At the conclusion of each wear test run, the remaining SBF was collected analyzed for Co ion concentration. The resulting sample volumes varied from 50 ml to 200 ml. Each sample was treated with 5 ml 1N hydrochloric acid and 1 ml concentrated nitric acid. The liquid volumes were reduced to below 30 ml on a hot plate. Samples were removed after the solution turned yellow or when they were reduced to 15 ml. Then, deionized water was added to the samples to increase the volume to 100 ml. This vigorous digestion process was used to ensure that all the Co was fully ionized prior to analyzing the samples by flame atomic absorption spectrometry (AAS). The concentration of Co in the samples was analyzed on a Shimadzu 6300 flame AAS with a cobalt lamp. Each sample was analyzed twice with an average taken unless they differed by more than 5% than a third aliquot was analyzed and the closest two were averaged. Each measurement was taken for 5 seconds with a 20 sec stabilization period prior to analysis. A linear 5 point standard curve at 0, 0.1, 0.2, 0.5 and 1.0 ppm of cobalt was used. A method spike standard curve was also prepared to ensure the SBF matrix did not cause interference with determination of cobalt concentrations. A blank was also analyzed in AAS for every 10 samples to ensure baseline stability.

3. Results and Discussion

In vitro wear rate or wear coefficient, in mm3/Nm, of pin and substrate materials was calculated from wear track dimensions measured using SEM images of worn pins and substrates. Figure 1 shows the wear coefficient of UHMWPE discs tested against gradient metal pins with varying concentration of CoCrMo alloy on top surface. Under present experimental conditions, average wear coefficient of UHMWPE against metallic pins varied between 1.70 × 10−6 mm3/Nm and 9.35 × 10−6 mm3/Nm. No detectable wear or wear tracks were observed on the metallic pins. However, occasional scratches were found on the pins surface. For all metal-on-PE combinations, the wear coefficient decreased with an increase in the sliding distance. The high wear coefficients during initial 1000 m sliding distance is due to higher initial running-in wear. With an increase in the sliding distance, the system enters in to steady-state wear regime, during this period the wear rate gradually decreases and reaches a constant value. A similar decrease in the wear coefficient with an increase in sliding distance has been reported earlier [20, 21].

Figure 1.

Influence of CoCrMo alloy concentration, in the top surface of metallic pins, on the wear rate of UHMWPE.

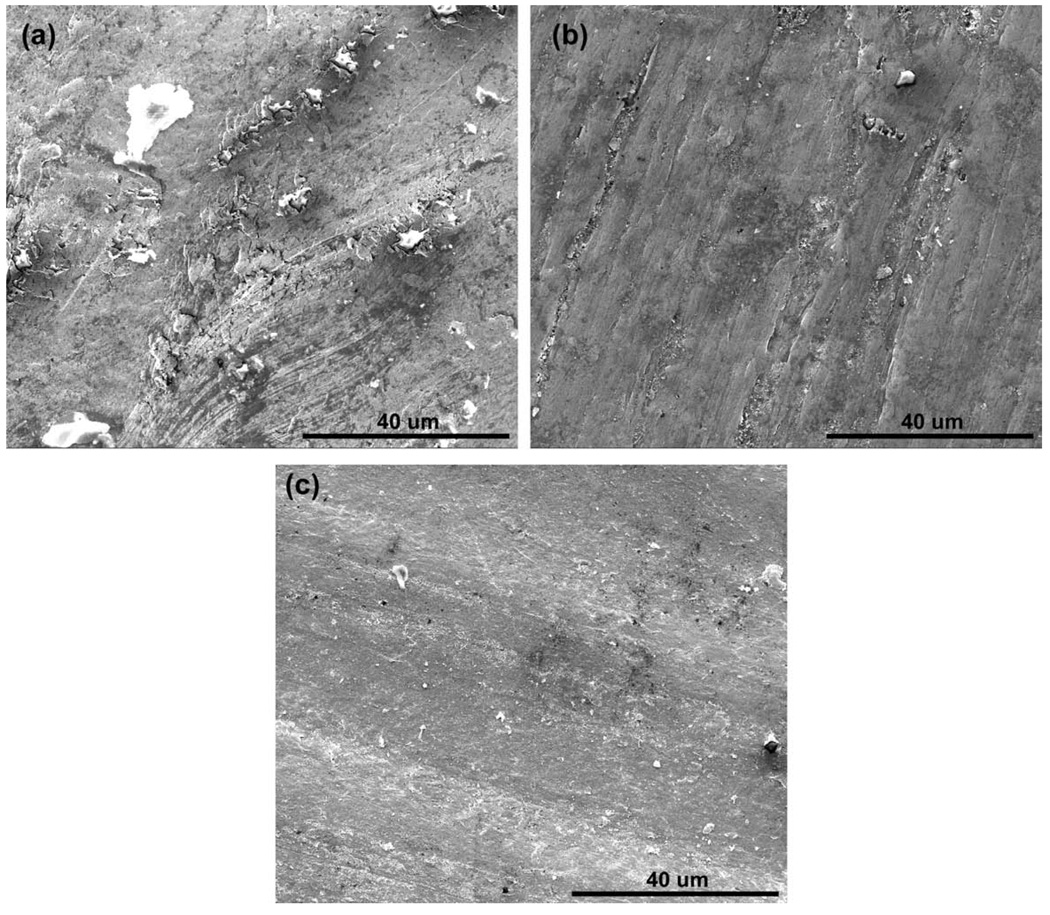

No significant difference in the wear rate of UHMWPE was observed when tested with P100 pin, GP70 and GP86 pins. However, tests with GP50 pins always resulted in higher wear rates of UHMWPE. Since the test conditions are same for all metal-on-PE couples, the observed differences in wear coefficients of UHMWPE can be explained on the basis of microstructural features present in the top surface of different pins. Top surface microstructural variation as a function of CoCrMo alloy concentration in graded pins is shown in Figure 2. As the CoCrMo alloy content increased, the most significant change in the micrographs was the decrease in the volume fraction of the Ti6Al4V alloy phase and the consequent increase in the volume fraction of CoCrMo alloy. Notable change was also observed in the morphology and scale of the CoCrMo alloy phase as the amount was increased. As shown in Figure 2a, the GP50 pins exhibited a bimodal distribution of CoCrMo phase with large chunks of CoCrMo phase and some thin, continuous phase predominantly along Ti6Al4V alloy grain boundaries. With an increase in the concentration of CoCrMo alloy the grain boundary precipitation/phase was completely replaced by a two-phase microstructure. The laser processed 100% CoCrMo alloy (P100 and S100) showed very fine carbide precipitates in the interdendritic regions (Figure 2c). We hypothesize that the microstructure of GP50 pins with large chunks of hard CoCrMo alloy phase acted as isolated abrasive particles leading to local grooving and high wear rate of UHMWPE. Also, the local grooving resulted in large variations in the measured wear rates with GP50. Absence of chunks of isolated CoCrMo alloy phase in the pins with high concentration of CoCrMo eliminated the grooving due to large area of contact between the pin and the discs. These microstructural features decreased the wear rate of UHMWPE with increasing concentration of CoCrMo alloy on the top surface of the gradient pins. Further, the observed microstructural differences between the gradient pins resulted in some variation in the surface roughness of the as-polished gradient pins before wear testing. The average surface roughness of P100/S100 was found to be 5 ± 0.4 µm and the gradient pins showed an average surface roughness of 5.4 ± 0.3 µm, 6.2 ± 0.4 µm and 7 ± 0.9 µm for GP86, GP70 and GP50, respectively. Therefore, the large chunks of hard CoCrMo alloy phase in GP50 pins resulted in high wear rate of UHMWPE due to its high average surface roughness compared to other gradient pins.

Figure 2.

Top surface microstructures of the pins with varying concentrations of CoCrMo alloy in the top layer: (a) GP50, (b) GP86 and (c) P100.

Typical wear track morphologies of UHMWPE discs are shown in Figure 3. It can be seen from Figure 3a that specimens tested with a sliding distance of 1000 m show the presence of heavy wear tracks/grooves on their worn surfaces and at 3000 m the wear tracks were shallow and smoother (Figure 3b) indicating lower wear rates at 3000 m. It is also important to note that the no significant grooving was observed on the worn specimens when tested with P100 or GP86 pins (Figure 3c). The observed results suggest that the wear rate of UHMWPE during articulation against metal primarily depends on microstructural features such as morphology and distribution of hard phase within the matrix, which controls the surface roughness of gradient pins during polishing. Also, the wear rate of UHMWPE does not change significantly, compared to P100 (100% CoCrMo alloy), when tested against the new articulating surfaces developed in the present work, especially with CoCrMo alloy concentrations ≥ 70%.

Figure 3.

Typical morphologies of wear tracks on UHMWPE when tested against (a) GP50 pin, 1000 m (b) GP50 pin, 3000 m, (c) GP86 pin, 3000 m.

Although, the wear performance of present gradient structures, with ≥ 70% CoCrMo on top, against UHMWPE was comparable with that of P100 (100% CoCrMo alloy), the newly developed articulating surfaces might show superior wear characteristics during metal-on-metal articulation. As stated earlier, the real benefits of present gradient/unitized structures comes from its use as metal-on-metal configuration, which include the ability to use larger femoral head diameter to increase the range of motion and reduce the risk of dislocation [14, 15]. To evaluate this hypothesis, the pins with varying concentrations of CoCrMo on top were tested against laser processed S100 (100% CoCrMo alloy) discs. The wear rate of gradient pins and P100 pins under metal-on-metal articulating condition i.e., pins rubbing against laser processed 100% CoCrMo alloy discs, is shown in Figure 4. For both the sliding distances of 1000 m and 3000 m, P100 pins always showed highest wear rate between 6.480 × 10−8 mm3/Nm and 1.68 × 10−7 mm3/Nm. Lowest wear rate in the range of 5.07 to 7.99 × 10−8 mm3/Nm was observed for GP86 pins. The wear rate was found to increase with a decrease in the top surface CoCrMo alloy concentration; however the difference was observed to decrease with an increase in the sliding distance. These results correlate well with the observed top surface hardness of various pins. The average top surface hardness of gradient pins increased from 615 ± 38 HV (GP50) to 739 ± 25 HV (GP70) to 957 ± 32HV (GP86) with increase in the CoCrMo concentration. Therefore, the wear rate decreased with an increase in the CoCrMo alloy concentration of the pin’s surface. Also, the hardness of these gradient pins was significantly higher than the average hardness of laser processed 100% CoCrMo alloy discs/pins (S100 and P100), which was 361±11 HV. Similar hardness of P100 pins with that of S100 disc resulted in its higher wear of P100 pins compared to that of gradients pins with harder top surface. These wear test results show that present laser processed gradient structures have superior wear resistance up to 1000 m and comparable, if not better, wear resistance up to 3000 m than that of 100% CoCrMo alloy. Figure 5 shows the wear rate of S100 discs tested for 3000 m against P100 pins and gradient pins. The wear rate of the substrate was high when tested against gradient pins and the wear rate increased with a decrease in the CoCrMo alloy concentration in the pin’s top surface. This trend is similar to that observed for UHMWPE and can be directly correlated with the microstructural features and consequent surface roughness of the pins. From the experimental data it appears that the wear rate of discs (100% CoCrMo alloy) depends on the hardness and microstructural features of articulating surfaces. With P100 and S100 combination the similar hardness and microstructural features of both the articulating surfaces resulted in lower wear rates of S100. However, the wear rate of S100 discs during articulation against gradient pins found to strongly depend on the microstructural features of gradient pins. Although the hardness of GP50 is less than GP86/GP70 the large chunks of hard CoCrMo alloy phase in GP50 pins resulted in high wear rate of S100 due to its high average surface roughness compared to other gradient pins.

Figure 4.

Wear rate of laser processed P100 and CoCrMo-Ti6Al4V alloy gradient pins.

Figure 5.

Wear rate of laser processed S100 substrate tested for 3000 m against various gradient pins.

Figure 6 shows typical wear track morphologies of CoCrMo-Ti6Al4V alloy gradient pins and S100 discs during metal-on-metal wear testing. The wear tracks of GP50 pins (Figure 6a) showed deep scratches with large chunks of hard CoCrMo alloy phase projecting out of soft Ti6Al4V alloy phase, which was worn during wear testing. However, GP86 pins, due to their relatively uniform microstructural features, showed no deep scratches and the wear track was smoother than observed on GP50 pins. The deeper wear tracks of GP50 pins compared to GP86 pins supports its higher wear rate than that of GP86 pins (Figure 4). The wear track morphologies of S100, shown in Figures 6 c and d, are similar to those observed on UHMWPE - heavy wear tracks/groves when tested with GP50 pins, and no significant grooving when tested with GP86 pins. The metal-on-metal wear morphologies also suggest that the wear rate of counter articulating surface depends on morphology and distribution of hard phase within the matrix.

Figure 6.

Typical morphologies of wear tracks observed during metal-on-metal wear testing (a) on GP50 pin, 1000 m (b) on GP86 pin, 1000 m, (c) on S100 substrate tested with GP50 pin, 3000 m, (d) on S100 substrate tested with GP86 pin, 3000 m.

Table 1 shows the concentration of Co in SBF for metal-on-metal and metal-on-UHMWPE couple after wear testing. As expected the Co release was high during metal-on-metal wear testing compared to that of metal-on-UHMWPE. The Co concentration was found to be in the range of 0.25 and 0.91 ppm for metal-on-metal articulation. After 3000 m of sliding the Co concentration was slightly higher for gradient pins than observed with laser processed 100% CoCrMo alloy pins. This is intuitive, as the wear of S100 discs was high when tested with gradient pins due to their relatively high hardness than the discs. The higher concentration of Co in the SBF for gradients pins with GP50 pins is also attributed to the high wear rate of these pins and respective S100 discs. It is also important to note that the present Co concentrations in SBF were significantly lower than observed during previous study on the pin-on-disc wear testing of CoCrMo alloys [22], where the reported Co concentration was between 2 and 13 ppm. Therefore, the present CoCrMo-Ti6Al4V alloy gradients structures showed enhanced in vitro wear resistance with a decrease in Co ion release.

Table 1.

Co ion concentration (ppm) in the SBF after wear testing.

| S100 substrate (metal-on-metal) | ||||

|---|---|---|---|---|

| Pins → | P100 | GP86 | GP70 | GP50 |

| 1000 m | 0.25 ± 0.12 | 0.46 ± 0.19 | 0.38 ± 0.20 | 0.51 ± 0.17 |

| 3000 m | 0.77 ± 0.27 | 0.87 ± 0.16 | 0.86 ± 0.07 | 0.91 ± 0.04 |

| UHMWPE substrate (Metal-on-UHMWPE) | ||||

| 1000 m | 0.08 ± 0.05 | * | * | * |

| 3000 m | 0.08 ± 0.01 | 0.01 ± 0.05 | * | * |

(* below the detection limit of the instrument)

4. Conclusions

Compositionally graded hard and wear-resistance CoCrMo alloy coatings on porous Ti6Al4V alloy have been prepared using LENS™ process. In vitro wear testing of these gradient structures against UHMWPE discs showed comparable wear rates for both the gradient coatings and 100% CoCrMo alloy. The wear of UHMWPE was found to depend on microstructural features such as CoCrMo alloy phase morphology and distribution at the contact surface. For metal-on-metal articulation, the wear rates of gradient structures were low compared to that of 100% CoCrMo alloy due to their relatively high hardness. The wear rate of 100% CoCrMo alloy discs was found to be a combined effect of surface hardness and microstructural feature present in the top surface of gradient structures. Material combinations that resulted in high amount of total wear also lead to higher Co concentration in SBF after wear testing. These laser-processed gradient structures with CoCrMo alloy concentrations ≥ 70%, having low wear rates of the order of 10−8 mm3/Nm, show their potential to reduce wear induced osteolysis when used in monoblock structures.

Acknowledgements

Authors would like to acknowledge the financial support from the W. M. Keck Foundation to establish a Biomedical Materials Research Lab at WSU. Authors also acknowledge the financial support from the M. J. Murdock Charitable Trust, National Science Foundation NSF (Grant No. CMMI 0728348) and National Institutes of Health (Grant No. NIHR01-EB-007351).

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Cooper RA, McAllister CM, Borden LS, Bauer TW. J Arthroplasty. 1992;7:285. doi: 10.1016/0883-5403(92)90050-z. [DOI] [PubMed] [Google Scholar]

- 2.Howie DW, Rogers SD, Haynes DR, Pearcy MJ. Trans. Orthop. Res. Soc. 1994;19:201. [Google Scholar]

- 3.Schmalzried TT, Kwong LM, Jasry M, Sedlacek RC, Haire TC, Connor DO. Clin. Orthop. Rel. Res. 1992;274:60. [PubMed] [Google Scholar]

- 4.Edidin AA, Rimnac CM, Goldberg VM, Kurtz SM. Wear. 2001;250:152. [Google Scholar]

- 5.Bartel DL, Bicknell VL, Wright TM. J Bone Joint Surg. 1986;68A:1041. [PubMed] [Google Scholar]

- 6.Ries MD, Scott ML, Jani S. J Bone Joint Surg. 2001;83A Suppl. 2:116. doi: 10.2106/00004623-200100022-00009. [DOI] [PubMed] [Google Scholar]

- 7.Rieker C, Kottig P. Hip Int. 2002;12:73. doi: 10.1177/112070000201200202. [DOI] [PubMed] [Google Scholar]

- 8.Douglas N, Christopher PR, Javad P, Daniel JB, Stefan E, Andre B. J Arthroplasty. 2004;19(7) Suppl. 2:35. [Google Scholar]

- 9.Chivas DJ, Smith K, Tanzer M. Clin. Orthop. Relat. Res. 2006;453:147. doi: 10.1097/01.blo.0000238857.61862.34. [DOI] [PubMed] [Google Scholar]

- 10.Lachiewicz PF, Soileau ES. Clin. Orthop. Relat. Res. 2006;453:153. doi: 10.1097/01.blo.0000238851.31368.e7. [DOI] [PubMed] [Google Scholar]

- 11.Sierra RJ, Raposo JM, Trousdale RT, Cabanela ME. Clin. Orthop. Relat. Res. 2005;441:262. doi: 10.1097/01.blo.0000194308.23105.f4. [DOI] [PubMed] [Google Scholar]

- 12.White RE, Jr, Forness TJ, Allman JK, Junick DW. Clin. Orthop. Relat. Res. 2001;393:163. doi: 10.1097/00003086-200112000-00019. [DOI] [PubMed] [Google Scholar]

- 13.Bozic KJ, Kurtz SM, Lau E, Ong K, Vail TP, Berry DJ. J Bone Joint Surg. Am. 2009;91:128. doi: 10.2106/JBJS.H.00155. [DOI] [PubMed] [Google Scholar]

- 14.Cuckler JM, Moore KD, Lombardi AV, Jr, McPherson E, Emerson R. J Arthroplasty. 2004;19(8 suppl 3):41. doi: 10.1016/j.arth.2004.09.006. [DOI] [PubMed] [Google Scholar]

- 15.Cuckler JM. Clin. Orthop. Relat. Res. 2005;441:132. doi: 10.1097/01.blo.0000193809.85587.f8. [DOI] [PubMed] [Google Scholar]

- 16.Krishna BV, Xue W, Bose S, Bandyopadhyay A. Acta Biomater. 2008;4:697. doi: 10.1016/j.actbio.2007.10.005. [DOI] [PubMed] [Google Scholar]

- 17.Balla VK, DeVasConCellos P, Xue W, Bose S, Bandyopadhyay A. Acta Biomater. 2009;5:1831. doi: 10.1016/j.actbio.2009.01.011. [DOI] [PubMed] [Google Scholar]

- 18.Balla VK, Xue W, Bose S, Bandyopadhyay A. Acta Biomater. 2009;5:2800. doi: 10.1016/j.actbio.2009.03.032. [DOI] [PubMed] [Google Scholar]

- 19.España FA, Balla VK, Bose S, Bandyopadhyay A. Mater. Sci. Eng. C. 2010;30:50. [Google Scholar]

- 20.Yang LJ. Wear. 2005;259:1453. [Google Scholar]

- 21.Ramesh CS, Anwar Khan AR, Ravikumar N, Savanprabhu P. Wear. 2005;259:602. [Google Scholar]

- 22.St. John KR, Zardiackas LD, Poggie RA. J Biomed. Mater. Res. Part B: Appl. Biomater. 2004;68B:1. doi: 10.1002/jbm.b.10053. [DOI] [PubMed] [Google Scholar]