Abstract

Three types of novel coiled column configurations, i.e., a triangular coiled column and elliptical coiled columns I and II, were designed for type-I countercurrent chromatography and their performances were evaluated with two solvent systems each with suitable test samples. Three DNP-amino acids (DNP-DL-glu, DNP-β-ala and DNP-L-ala) were separated with a moderately hydrophobic two-phase solvent system composed of hexane-ethyl acetate-metanol-0.1M hydrochloric acid (1:1:1:1, v/v), while two dipeptides (tryptophyl tyrosine and valyl-tyrosine) were separated with a polar solvent system composed of 1-butanol-acetic acid-water (4.75:0.25:5, v/v). The overall results indicated that the performance of compact type-I counter-current chromatography was improved by elliptical coiled column II which was mounted with its maximum coil diameter perpendicular to the surface of the column holder. Hydrodynamic effects involved in these separations were discussed.

Keywords: Compact type-I counter-current chromatography, coiled column configuration, retention of the stationary phase, resolution, dipeptide, DNP-amino acid

1. Introduction

Type-I coil planet centrifuge performs highly efficient separation in counter-current chromatography [1, 2]. Recently, the design of the type-I coil planet centrifuge was improved with a shorter revolution radius and a decreased column holder height which enormously widened the application ranges of the original design [3–5].

In the past, many factors, such as instrument design [6], column configurations [7, 8], tubing geometries [9], flow rate [10, 11] and rotational speed [12, 13], have been improved to yield an efficient mixing of the two phases in such a way that about 50 000 partition steps per hour of the analytes in the two-phase solvent system can be achieved [14, 15]. The separation column in the traditional or compact type-I counter-current chromatography (type-I CCC) is made by winding a single piece of PTFE tubing onto multiple pieces of nylon pipes in such a way that every other coil unit has opposite handedness [1–3].

In this study, the coiled columns were prepared in three different cores from circular, ellipsoid and triangular pipes to investigate the effect of the core shape. The performances of these columns were evaluated in terms of peak resolution and stationary phase retention using two different two-phase solvent systems each with suitable test samples.

2. Experimental

2.1. Apparatus

The apparatus used in the present study is a type-I coil planet centrifuge fabricated at the NIH Machine Shop, Bethesda, MD, USA [3]. It holds a separation column on one side and a counterweight on the other side of the rotor each at 10 cm from the central axis of the apparatus. The column holder undergoes type-I synchronous planetary motion, i.e., the holder counter-rotates about its own axis once during each revolution around the central axis of the centrifuge. This unique planetary motion is produced by coupling a pair of identical toothed pulleys, one fixed on the bottom of the central axis of the centrifuge (stationary pulley) and the other around the lower end of the column holder shaft (planetary pulley) with a toothed belt. This planetary motion forms a centrifugal force field uniformly circulating around every point on the column holder. The separation column was made by winding a single piece of 0.76 mm I.D. tubing (PTFE SW No. 22, Zeus Industrial Products, Orangeburg, SC, USA) onto 5 cm long plastic cores, i.e, cycloid (round) and elliptical (squashed) nylon pipes (5 mm and 6 × 4 mm OD, respectively, 43 pieces for each column) or PTFE equilateral triangular pipes (6 mm side, 57 pieces) in such a way that every other coil unit has opposite handedness (Fig. 1). The length of the tubing was approximately 20 m with a total capacity of 7.8 ml. Each coiled column was mounted around the holder hub in such a way that all coil units were arranged parallel to the axis of column holder (Figure 1). The rotational speed of the apparatus was regulated from 600 to 1200 rpm with a speed controller (Bodine Electric, Chicago, IL, USA). A metering HPLC pump (Shimadzu LC-10ADVP, Columbia, MD, USA) was used for pumping the solvents, and the effluent was continuously monitored with a UV detector (LKB Instruments, Stockholm, Sweden).

Figure 1.

The coiled column for type-I counter-current chromatography. A) triangular coiled column; B) elliptical coiled columnI; C) elliptical coiled columnII.

2.2. Reagents

1-Butanol, hexane, ethyl acetate and methanol were purchased from Fisher Scientific, Fair Lawn, NJ, USA and other solvents such as acetic acid and hydrochloric acid from Mallinckrodt Chemicals, Phillipsburg, NJ, USA. Dipeptide samples including tryptophyl-tyrosine (Trp-Tyr), valyl-tyrosine (Val-Tyr) and N-2, 4-dinitrophenyl-L-alanine (DNP-L-ala), N-2, 4-dinitrophenyl-β-alanine (DNP-β-ala), N-2, 4-dinitrophenyl-DL-glutamic acid (DNP-DL-glu) were all obtained from Sigma Chemicals (St. Louis, MO, USA).

2.3. Two-phase Solvent Systems and Sample Solutions

In the present study, the solvent systems and their test samples were chosen according to their K values as reported in our previous studies [4, 5]. Two typical two-phase solvent systems composed of 1-butanol-acetic acid-water (4.75:0.25:5, v/v) (BAW) and hexane-ethyl acetate-methanol-0.1 M HCl (1:1:1:1, v/v) (HEMW) were used to separate the dipeptide and DNP-amino acid test samples, respectively. Each solvent mixture was thoroughly equilibrated in a separatory funnel by repeated vigorous shaking and degassing, and the two phases separated shortly before use. Sample solution 1 was prepared by dissolving 25 mg of Trp-Tyr and 100 mg of Val-Tyr in 20 ml of the upper phase of 1-butanol-acetic acid-water., andsample solution 2 was prepared by dissolving 5.7mg of DNP-L-ala, 5.1 mg of DNP-β-ala and 5.3 mg of DNP-DL-glu in 10 ml of the upper phase of hexane-ethyl acetate-methanol-0.1 M HCl (1:1:1:1, v/v).

2.4. Separation Procedure

In each separation, the separation column was entirely filled with the stationary phase, followed by sample injection, and the column was rotated at a given revolution speed while the mobile phase was pumped into the coiled column at a given flow rate. The effluent from the outlet of the coiled column was continuously monitored with a Uvicord IIS (LKB, Stockholm, Sweden) at 280 nm and the elution curve was traced using a strip-chart recorder (Pharmacia, Stockholm, Sweden). After the desired peaks were eluted, the run was stopped and the column contents were collected into a graduated cylinder by pressured air to determine the volume of the stationary phase retained in the column. The retention of the stationary phase was computed by dividing the volume of the retained stationary phase by the total column volume.

2.5. Evaluation of Partition Efficiency

The partition efficiency of separation column was evaluated by computing theoretical plate number (N) for each peak and peak resolution (Rs) between the peaks using the following conventional equations:

| (1) |

| (2) |

where tR and W indicate the retention time and the peak width in Eq. (1) and those for the specified peaks in Eq. (2), respectively.

3. Results and discussion

As mentioned earlier, the separation column for traditional type-I counter-current chromatography was made by winding a single piece of tubing onto nylon cycloid pipes in such a way that every other coil unit has opposite handedness. In the present study, the shape of column cores was changed to elliptical or triangular, which should modify the fluid dynamics that occurs inside the separation column. Three different core configurations for type-I CCC were examined, namely (A) triangular coiled column (PTFE triangular pipes were used, Fig. 1A), (B) elliptical coiled column I (nylon elliptical pipes were used, and the maximum diameter of elliptical cross-section was parallel to the surface of the column holder, Fig. 1B) and (C) elliptical coiled column II (nylon elliptical pipes were used, and the maximum diameter of elliptical cross-section was perpendicular to the surface of the column holder, Fig. 1C). Their performances were investigated and compared with that obtained from the traditional column configuration using the following two-phase solvent systems: a moderately hydrophobic solvent system composed of hexane-ethyl acetate-metanol-0.1M hydrochloric acid (HEMW) for separation of separate three DNP-amino acids (DNP-DL-glu, DNP-β-ala, DNP- L-ala) and a polar solvent system composed of 1-butanol-acetic acid-water (BAW) for separation of two dipeptide samples(Trp-Tyrand Val-Tyr).

3.1. DNP-amino acids separation using the different coiled column configurations

Table 1 shows the comparison of the performance of DNP-amino acids separation using four different geometric coiled columns at various flow rates by compact type-I counter-current chromatography. The test samples of DNP-DL-glu, DNP-β-ala and DNP-L-ala were separated with the HEMW solvent system at 600 rpm and 800 rpm and at flow rates ranging from 0.2 to 0.8 mL/min. Both retention of stationary phase (Sf) and resolution (Rs) were decreased with increased flow rate in all runs, while both Sf and Rs became maximum at the flow rate of 0.2 mL/min,

Table 1.

Comparison of the performance on DNP-amino acids separation using four different coiled columns at various flow rates by type-I countercurrent chromatography

| Revolution speed (rpm) | Flow rate (ml/min) | Triangular coiled column | Elliptical coiled column I | Elliptical coiled column II | Standard coiled column | ||||

|---|---|---|---|---|---|---|---|---|---|

| Sf(%) | Rs | Sf(%) | Rs | Sf(%) | Rs | Sf(%) | Rs | ||

| 800 | 0.2 | 27.0 | 1.93/1.93 | 28.1 | 1.75/1.62 | 32.1 | 2.08/1.85 | 36.8 | 2.37/2.06 |

| 0.4 | 16.2 | 1.01/1.70 | 24.3 | 1.25/1.16 | 16.2 | 1.32/1.25 | 23.7 | 1.52/1.46 | |

| 0.6 | 14.9 | 0.92/0.89 | 14.9 | 1.20/1.11 | 13.5 | 0.87/0.83 | 16.7 | 1.35/0.86 | |

| 0.8 | 10.8 | 0.62/0.86 | 12.2 | 1.19/0.79 | 9.5 | 0.75/0.58 | 9.3 | 0.99/0.73 | |

| 600 | 0.2 | 18.9 | 1.34/1.39 | 26.8 | 1.94/1.65 | 34.2 | 2.5/2.22 | 33.3 | 1.91/1.98 |

| 0.4 | 12.8 | 1.20/1.05 | 24.6 | 1.45/1.31 | 25 | 1.68/1.37 | 24.4 | 1.30/1.29 | |

| 0.6 | 10.6 | 0.81/0.64 | 18.9 | 1.20/1.15 | 16.2 | 1.2/0.96 | 21.8 | 1.26/1.13 | |

| 0.8 | 9.5 | 0.71/0.63 | 9.5 | 1.08/1.13 | 8.1 | 0.76/0.51 | 15.2 | 0.93/0.70 | |

Note: Samples: DNP-DL-glu, DNP-β-ala, DNP-L-ala; Solvent system: HEMW; Mobile phase: Lower phase; Elliptical coiled column I: The longer diameter of nylon core pipe is parallel to the holder surface; Elliptical coiled column II: The longer diameter of nylon core pipe is parallel to perpendicular to the holder surface.

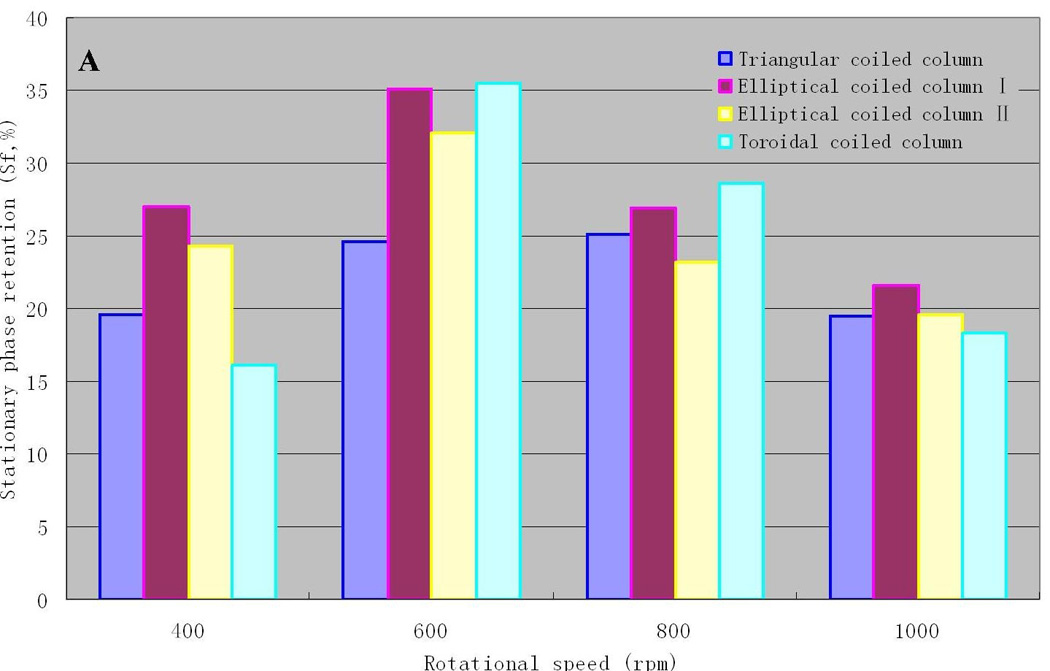

Then, the various rotational speeds were investigated at the flow rate of 0.2 mL/min. The result is shown in Fig. 2. At 800 rpm the standard coiled column showed the best Sf of 36.3% followed by the elliptical coiled column II. At the 600 rpm, however, elliptical coiled column II gave the best Sf at 34.2%, followed by the standard coiled column. The Sf at 600 rpm and 800 rpm was higher than at 400 rpm and 1000 rpm (Fig. 2A).

Figure 2.

Comparison of the performance of DNP-amino acids separation using four geometric coiled column at the various rotational speed by type-I counter-current chromatography. A) Retention of stationary phase; B) Resolution. Sample: DNP-DL-glu, DNP-β-ala and DNP-L-ala; sample size: 40 µl; solvent system: HEMW; flow rate: 0.2 ml/min.

Fig. 2B indicates Rs at various rotational speeds obtained from the different coiled column configurations. At the flow rate of 0.2 mL/min, Rs (Peak1/2=2.5, Peak2/3=2.22) of elliptical coiled column II was the highest followed by Rs (Peak1/2 = 2.37, Peak 2/3= 2.06) of the standard coiled column. The performances of these two columns were much better than the other two columns.

3.2. Dipeptides separation using the different coiled column configurations

Table 2 shows comparison of the performance of four different coiled columns in dipeptide separation at various flow rates by type-I countercurrent chromatography. The test samples of Val-Tyr and Trp-Tyr were separated with the BAW solvent system at 600 rpm and 800 rpm and at the flow rates ranging from 0.2 to 0.8 mL/min. Both retention of stationary phase (Sf) and resolution (Rs) were decreased with increased flow rate in all runs. At the lowest flow rate of 0.2 mL/min produced ant highest Sf and Rs values as in the DNP-amino acid separation. And then, the effects of rotational speeds on the separation were investigated at a flow rate of 0.2 mL/min (Fig. 3). At 600 rpm Sf became maximum in all groups (Fig. 3A), while the best Rs was obtained at 800 rpm (Fig. 3B). Elliptical coiled column II and standard coiled column yielded high Sf and Rs values. Sf of standard coiled column was slightly higher than that of elliptical coiled column II (Fig. 3A).

Table 2.

Comparison of the performance of dipeptide separation using four different coiled columns at various flow rates by type-I countercurrent chromatography

| Revolution speed (rpm) |

Flow rate (ml/min) |

Triangular coiled column | Elliptical coiled column I | Elliptical coiled column II | Standard coiled column | ||||

|---|---|---|---|---|---|---|---|---|---|

| Sf(%) | Rs | Sf(%) | Rs | Sf(%) | Rs | Sf(%) | Rs | ||

| 800 | 0.2 | 25.1 | 1.29 | 26.9 | 1.65 | 23.2 | 1.83 | 28.6 | 1.65 |

| 0.4 | 22.3 | 1.27 | 18.2 | 1.33 | 20.8 | 1.43 | 18.4 | 1.41 | |

| 0.6 | 16.5 | 0.91 | 13.5 | 1.08 | 18.6 | 1.10 | 15.8 | 1.23 | |

| 0.8 | 13.2 | 0.74 | 9.5 | 0.78 | 16.2 | 0.97 | 13.1 | 1.20 | |

| 600 | 0.2 | 24.6 | 1.25 | 35.1 | 1.70 | 32.1 | 2.07 | 35.5 | 1.88 |

| 0.4 | 22.5 | 0.91 | 29.7 | 1.24 | 26.1 | 1.63 | 25.6 | 1.61 | |

| 0.6 | 16.2 | 0.89 | 26.6 | 0.98 | 24.3 | 1.26 | 23.8 | 1.47 | |

| 0.8 | 14.8 | 0.75 | 23.1 | 0.87 | 17.6 | 0.96 | 19.9 | 1.28 | |

Note: Samples: Val-Tyr, Trp-Tyr; Solvent system: BAW; Mobile phase: Lower phase; Elliptical coiled column II: The longer diameter of nylon core pipe is parallel to the holder surface; Elliptical coiled column II: The longer diameter of nylon core pipe is perpendicular to the holder surface.

Figure 3.

Comparison of the performance of dipeptides separation using four geometric coiled column at the various rotational speed by type-I countercurrent chromatography. A) Retention of stationary phase; B) Resolution. Sample: Trp-Tyr, Val-Tyr; sample size: 40 µl; solvent system: BAW; flow rate: 0.2 ml/min.

Fig. 3B shows Rs at various rotational speeds using the four different coiled column configurations at a flow rate of 0.2 ml/min. The elliptical coiled column II yielded the best Rs (2.07) followed by the standard coiled column.

3.3. Speculation on hydrodynamic motion of the two-phase in the coiled column

As in the slowly rotating coiled tube in the unit gravity, the coiled column vertically mounted on the type-I coil planet centrifuge is subjected to uniformly rotating force field. This motion creates an Archimedean screw effect on the two phases in the column where each phase competitively moves toward one end of the coil called the head. Consequently, the mobile phase, either lighter or heavier, introduced at the head of the coil is constantly mixed with the other phase and collected through the tail end leaving a large volume (near 50% of the total column capacity) of the stationary phase in the column. This CCC system can yield high partition efficiency while a long separation column tends to produce high back pressure counteracting against the Archimedean screw force.

In the present studies the triangular coiled column with multiple sharp turns (at 60 degrees each helical turn) interferes with the two phase motion toward the head end of the coil resulting in low retention of the stationary phase and loss of peak resolution, while the rest of the coiled columns with less flow restriction produced much higher Sf and Rs values. As shown in Figs. 2 and 3 revolution speed of the coiled column produces complex effects on both Sf and Rs in all groups. As the revolution speed is increased from 400 to 600 rpm, both Sf and Rs increased in all groups. When the revolution speed is increased from 600 to 800 rpm, Sf continues to increase in the moderately hydrophobic mobile HEMW group while decreasing in the polar BAW group. Further increase in rpm, however, resulted in loss of Sf and Rs values in all groups, apparently due to elevated column pressure which causes expansion and pulsation of the coiled column. This ill effect is more pronounced in the polar viscous BAW solvent system which tends to undergo emulsification by violent mixing. Theoretically speaking, the two elliptic coiled columns mounted in different orientations would yield the identical results since the type-I planetary motion produces uniformly rotating centrifugal force field at every point on the holder. Nevertheless, column II (maximum core diameter mounted perpendicular to the surface of the column holder) produced substantially higher Rs than column I (maximum core diameter mounted parallel to the surface of the column holder) in both two-phase solvent systems. This unexpected result may be explained on the basis of column deformation caused by pressure of the adhesive tape used for mounting the coiled column against the surface of the column holder. When the maximum diameter is mounted parallel to the holder surface, the pressure of the tape causes the column to be squashed resulting in more advanced elliptical shape. In contrast, when the same column is fixed its maximum core diameter perpendicular to the holder surface, the elliptical shape is reduced to become close to the cycloid shape to improve both Sf and Rs. In fact, however, this deformed elliptic column yielded higher Rs in both two-phase solvent systems is not well understood. It may be speculated that two restricted portion of each helical turn reduces ill effect of coil pulsation under high column pressure.

4. Concluding remarks

Overall results indicated that elliptical coiled column II, which was mounted its maximum core diameter perpendicular to the holder surface, produced the best separation in both test samples at relatively lower revolution speed of 600 rpm. The triangular coil showed the lowest Sf and Rs probably due to too restricted motion of the two phases at three sharp turns of each helical unit.

References

- 1.Ito Y, Bowman RL. Science. 1971 173;:420–422. doi: 10.1126/science.173.3995.420. [DOI] [PubMed] [Google Scholar]

- 2.Ito Y, Bowman RL. J. Chromatogr. Sci. 1973;11:284–291. doi: 10.1093/chromsci/11.6.284. [DOI] [PubMed] [Google Scholar]

- 3.Yang Y, Gu D, Liu Y, Aisa HA, Ito Y. J. Chromatogr. A. 2010;1217:1313–1319. doi: 10.1016/j.chroma.2009.12.055. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Yang Y, Gu D, Aisa HA, Ito Y. J. Chromatogr. A. 2010;1217:3167–3170. doi: 10.1016/j.chroma.2010.03.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Yang Y, Gu D, Aisa HA, Ito Y. J. Chromatogr. A. 2010;1217:7612–7615. doi: 10.1016/j.chroma.2010.10.012. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Ito Y. CRC Crit. Rev. Anal. Chem. 1986;17:65–143. [Google Scholar]

- 7.Yang Y, Gu D, Aisa HA, Ito Y. J. Liq. Chromatogr. Rel. Technol. 2010;33:1542–1549. doi: 10.1080/10826076.2010.503780. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Guan YH, Bourton EC, Hewitson P, Sutherland IA, Fisher D. Sep. Purif. Technol. 2009;65:79–85. [Google Scholar]

- 9.Yang Y, Aisa HA, Ito Y. J. Liq. Chromatogr. Rel. Technol. 2010;33:336–348. doi: 10.1080/10826070903524100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Oka H, Ikai Y, Hayakawa J, Harada K, Nagase K, Suzuki M, Nakazawa H, Ito Y. J. Liq. Chromatogr. Rel. Technol. 1992;15:2707–2719. [Google Scholar]

- 11.Du Q, Wu C, Qian G, Wu P, Ito Y. J. chromatogr. A. 1999;835:231–235. [Google Scholar]

- 12.Du Q, Wu P, Ito Y. Anal. Chem. 2000;72:3363–3365. doi: 10.1021/ac991423q. [DOI] [PubMed] [Google Scholar]

- 13.Ito Y, Clary R, Powell J, Knight M, Finn TM. J. Liq. Chromatogr. Rel. Technol. 2008;31:1346–1357. doi: 10.1080/10826070802019913. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Degenhardt A, Schwarz M, Winterhalter P, Ito Y. J. chromatogr. A. 2001;922:355–358. doi: 10.1016/s0021-9673(01)00908-6. [DOI] [PubMed] [Google Scholar]

- 15.Conway WD. Countercurrent Chromatography: Apparatus, Theory, and Application. New York: VCH; 1990. [Google Scholar]